Rolled pipe blank winding and scheduling device

A scheduling device and a technology for rolling tube blanks, which are used in manufacturing tools, equipment for accumulating materials, metal processing equipment, etc., which can solve the problems of large diameter, high hardness, and inability to rewind tube blanks, and reduce waiting time. , the overall stability of the effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

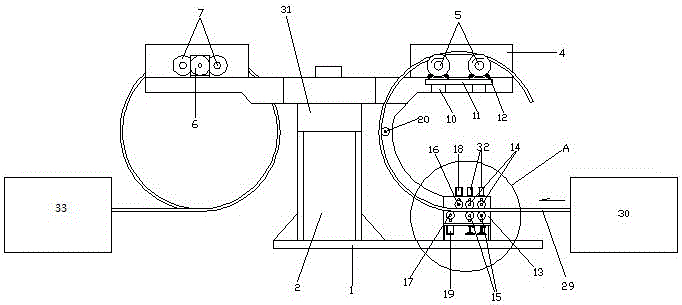

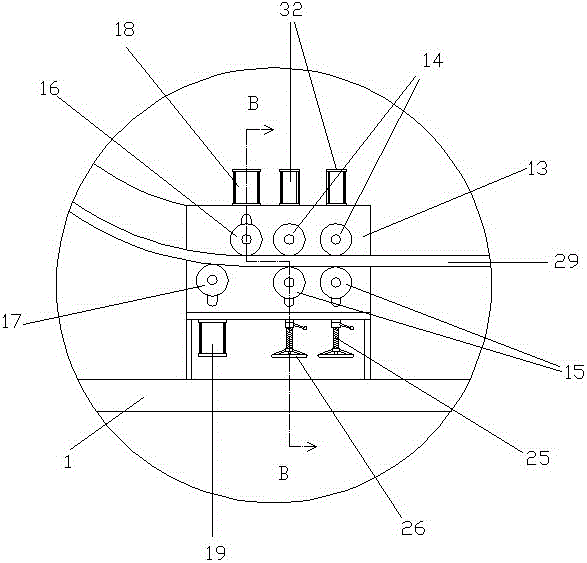

[0020] Such as figure 1 The rolling tube billet coiling dispatching device shown is arranged between the rolling mill 30 and the combined drawing machine 33, and includes a base 1, a support frame 2 located at the left end of the base, a cabinet 13 located at the right end of the base, and the support frame The upper end of the crossbeam is provided with a crossbeam 3, the center of the crossbeam is connected to the top of the support frame in rotation, the top of the support frame 2 is provided with a crossbeam rotation drive mechanism 31, and the sides of the two ends of the crossbeam are provided with a tube billet traction suspension mechanism symmetrical about the crossbeam rotation center;

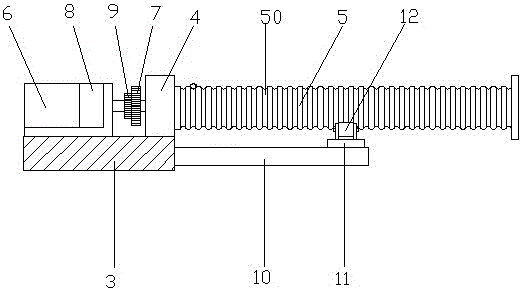

[0021] Such as image 3 As shown, the tube billet traction and suspension mechanism includes a support plate 4, two horizontal drums 5, and a motor 6. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com