Device and method for continuously feeding strip coils

A strip material and material feeding technology, which is applied in the direction of accumulating material equipment, thin material processing, winding strips, etc., can solve the problem that cutting methods cannot be quickly connected, continuous material feeding cannot be carried out smoothly, and production efficiency of the production line is affected. problems, to achieve the effect of convenient control, accurate and quick belt change, and waste reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

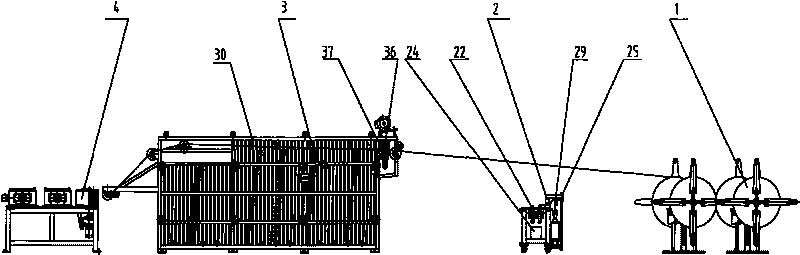

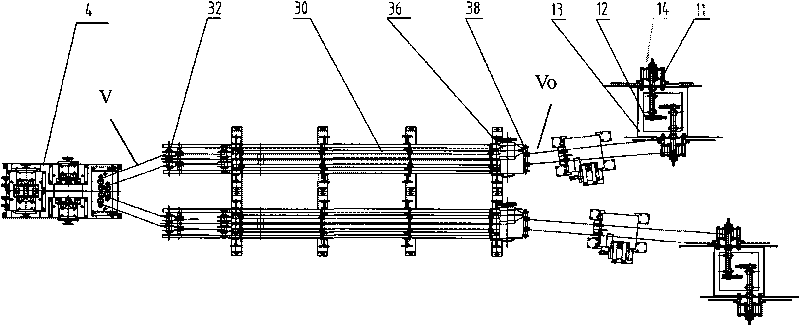

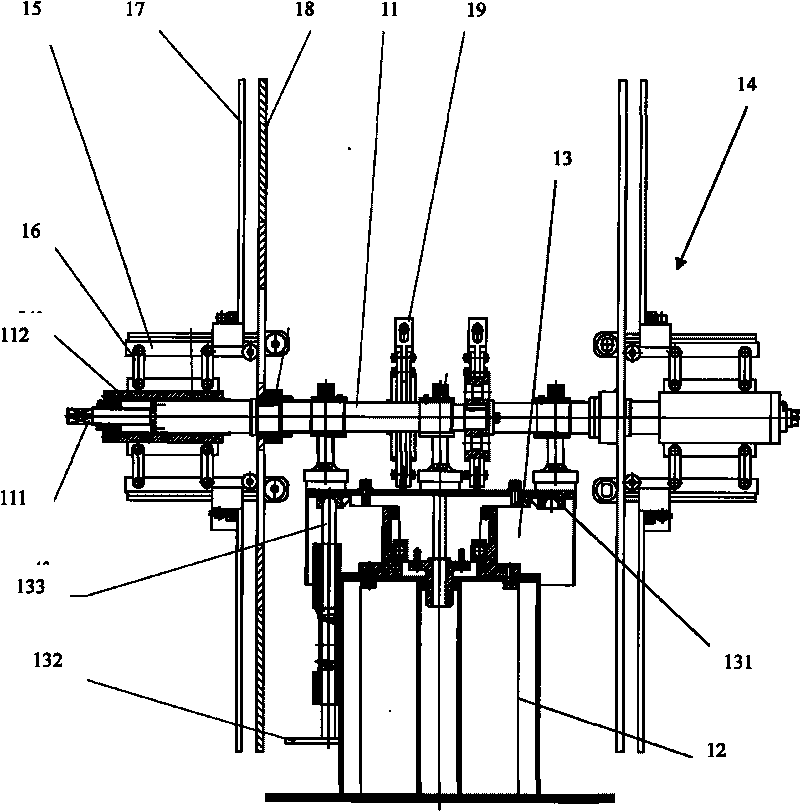

[0038] Such as figure 1 , figure 2 As shown, the device for the continuous feeding of strip rolls in this embodiment mainly includes a strap hanging machine 1, a splicing machine 2 and a tape storage machine 3, and the strap hanging machine 1 outputs the strip material 5 (also known as material tape, Steel band, hereinafter referred to as steel band), and enters belt storage machine 3. Between the belt hanging machine 1 and the belt storage machine 3, a shearing and welding machine 2 is provided as a cutting and welding device for the steel strip. One of the shear welding machines is to cut and weld the tape head and tape tail of the tape-reel system, and the other is to cut off unqualified steel strips in the tape-reel system. It is used to continuously feed the light and weldable steel strip into the straightening machine 4 for subsequent processing; the steel strip welded and polished by the shear welding machine 2 is input into the straightening machine 4 through the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com