Patents

Literature

37results about How to "Uninterrupted delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

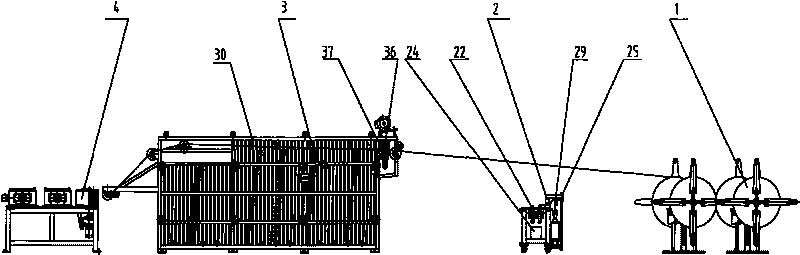

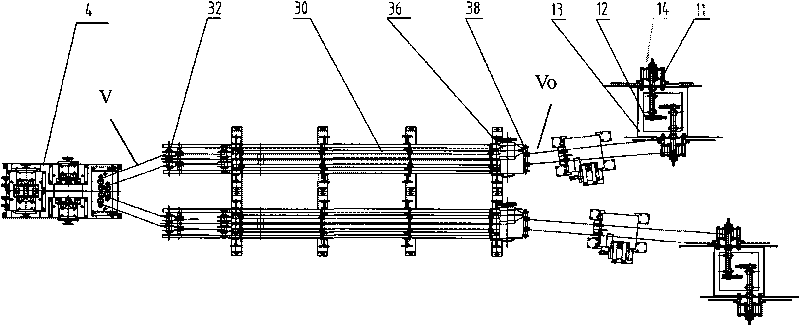

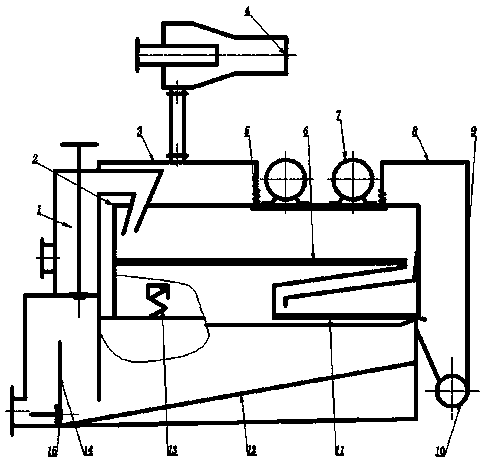

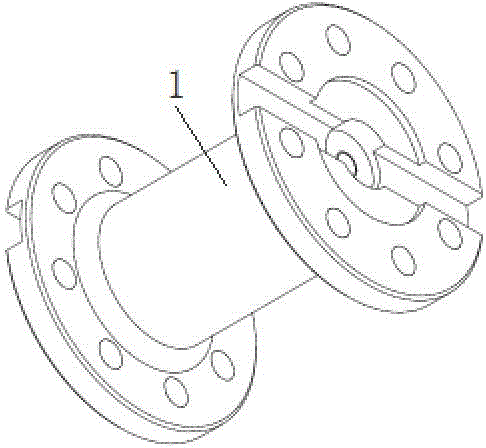

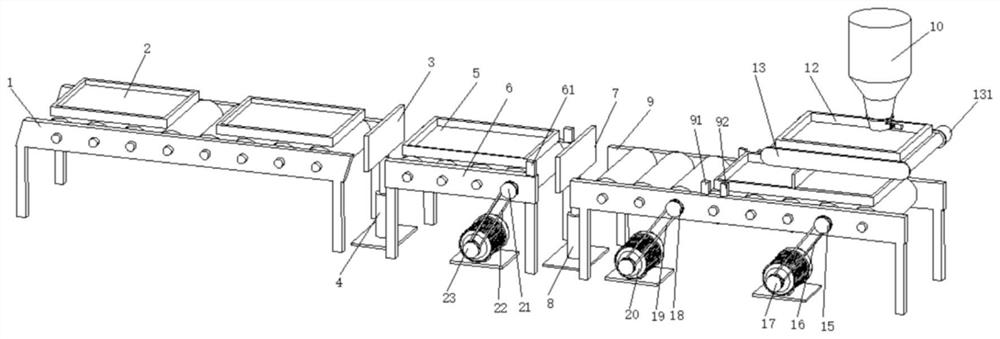

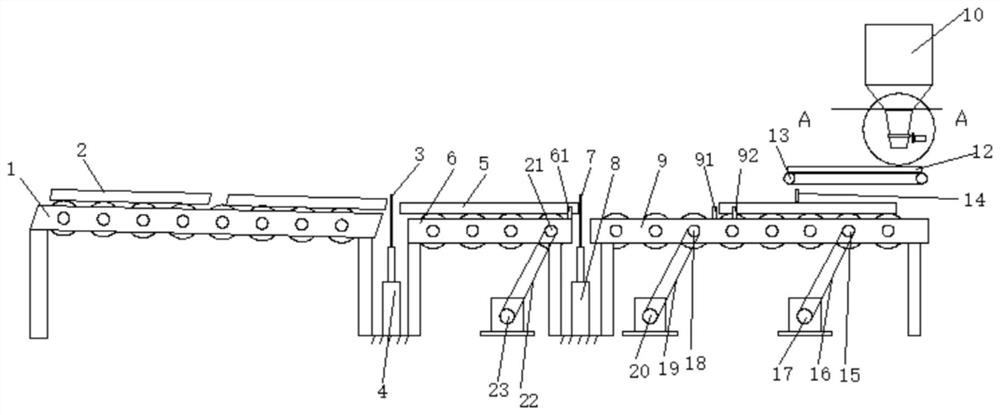

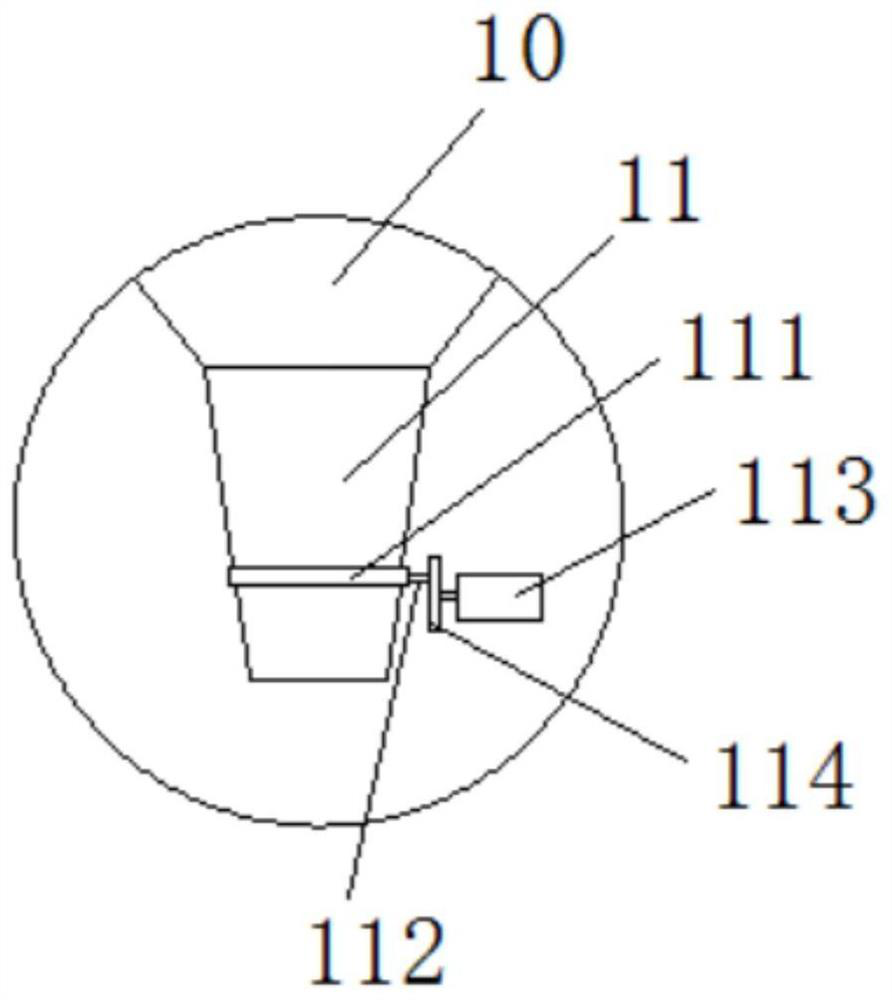

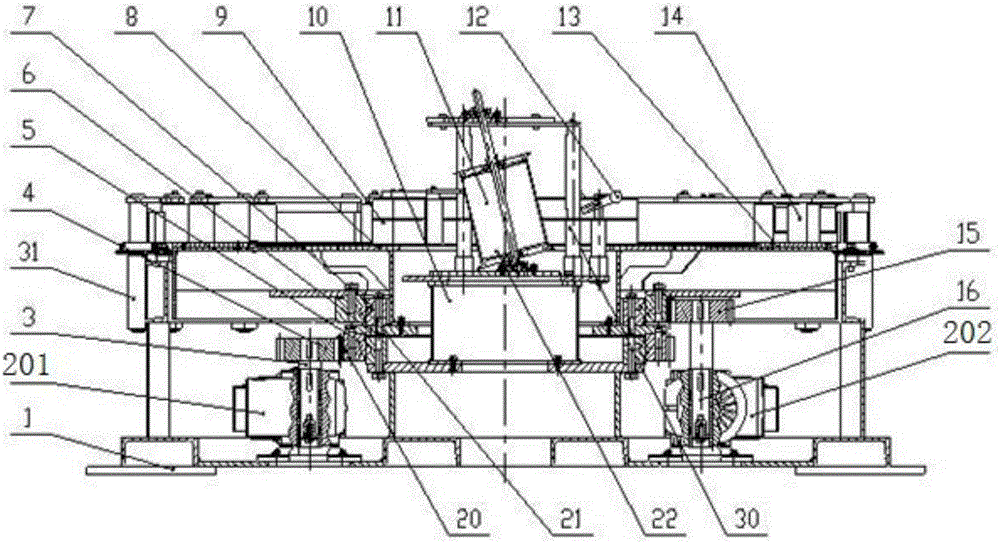

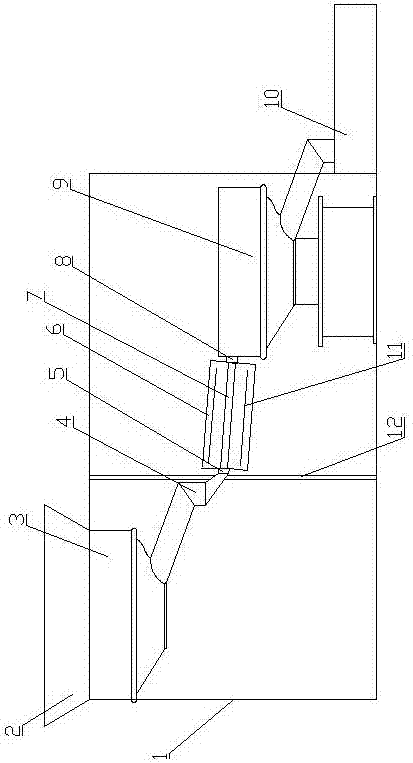

Device and method for continuously feeding strip coils

ActiveCN101734501AUninterrupted deliveryReduce wasteMaterial accumulating devicesWebs handlingContinuous productionEngineering

The invention relates to device and method for continuously feeding strip coils. A strip hanging machine of the device is provided with two or more than two sets of strip disc systems independent to each other, two or more than two sets of strip disc systems are fixed on a worktable capable of rotating at the same level and can be used for respectively hanging a coil of strips for alternate working, and the two sets of strip disc systems connect the strips between different strip disc systems through a splicing machine. The device also comprises a strip storing machine for storing the strips,and the strips outputted by the two or more than two sets of strip disc systems are alternatively inputted to the strip storing machine. The device and method can ensure the continuous production so as to enhance production efficiency and reduce waste.

Owner:HUAHAN SCI & TECH

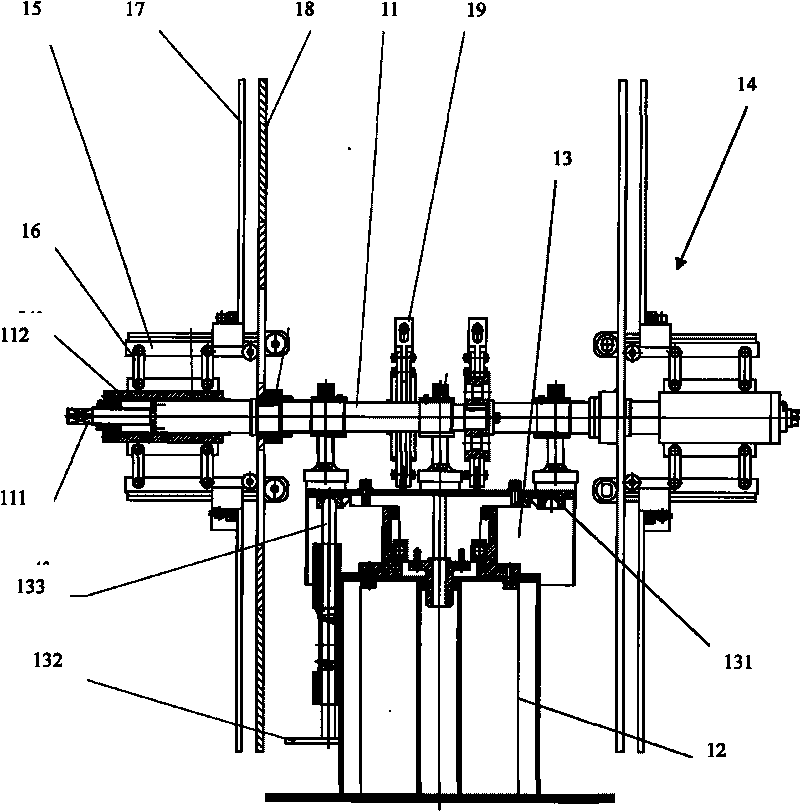

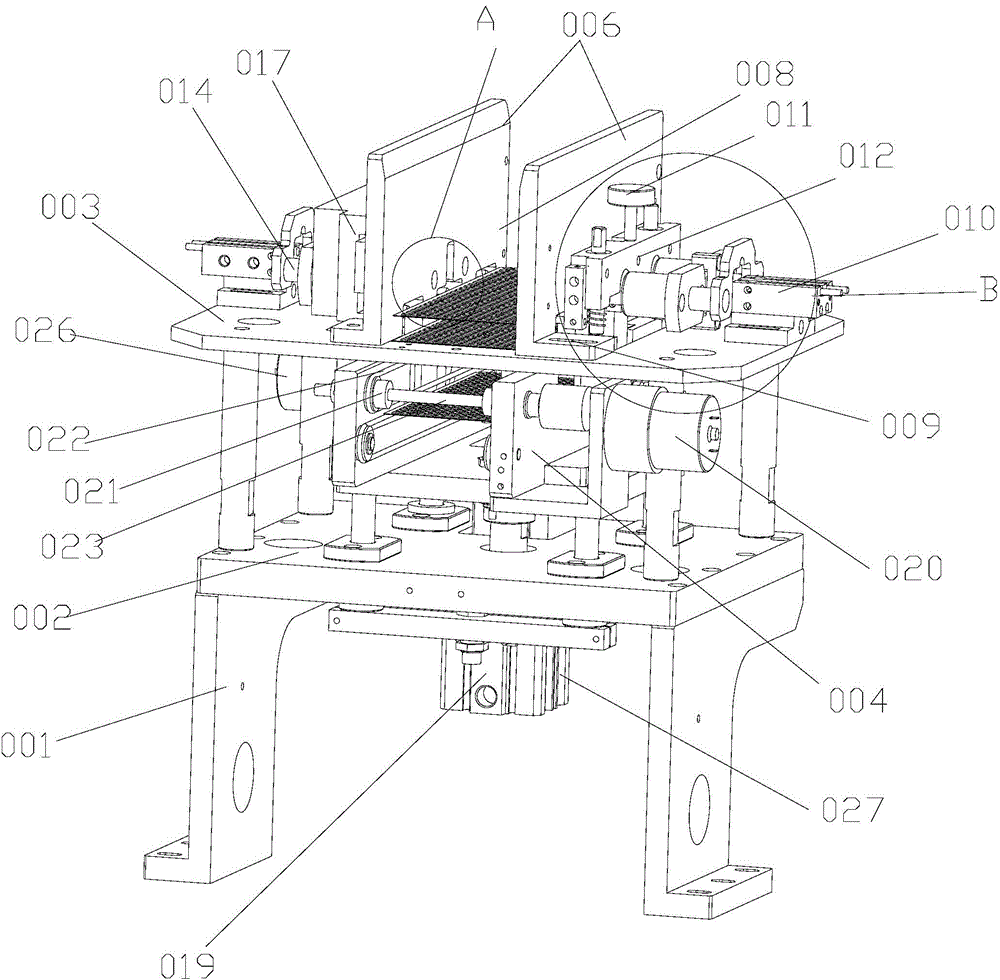

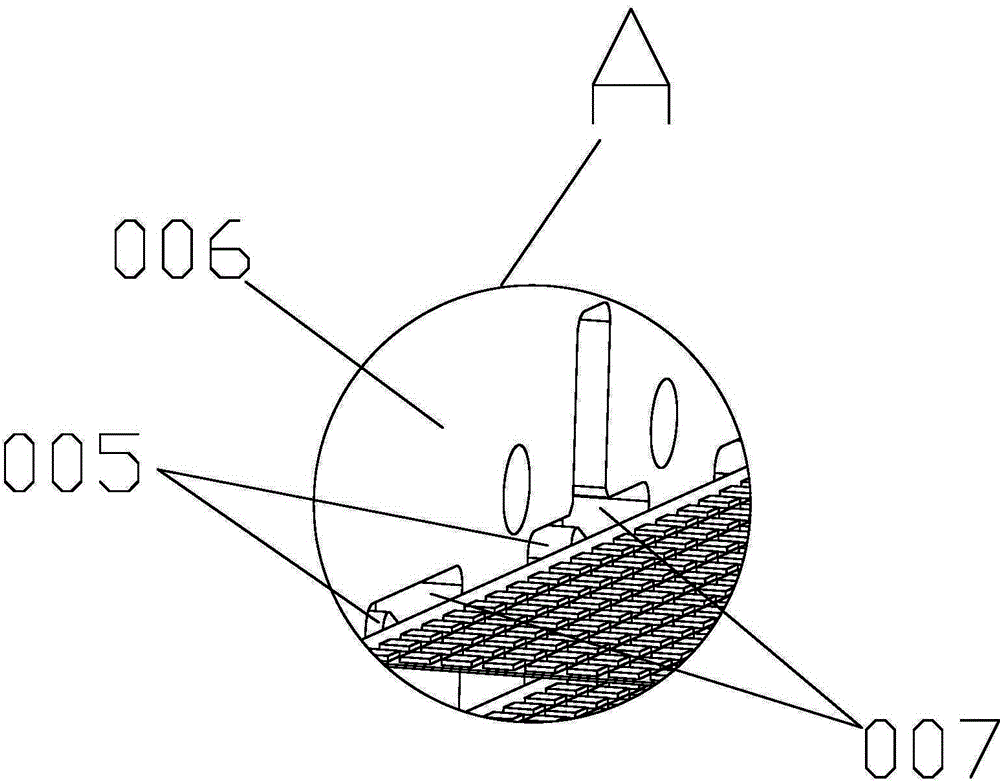

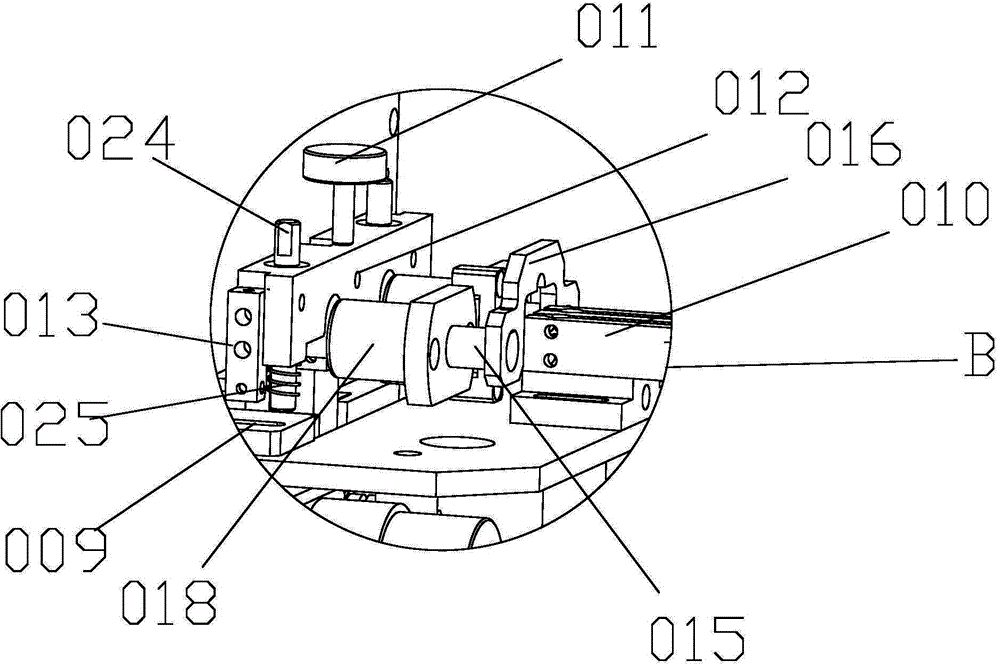

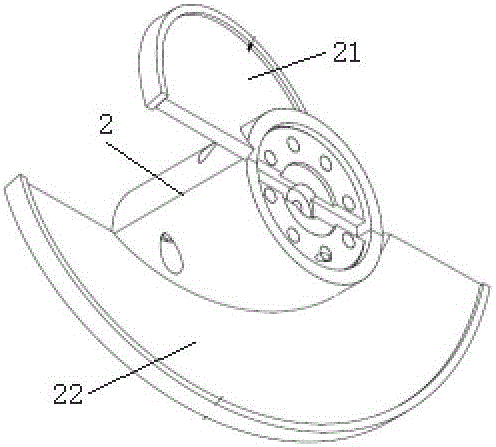

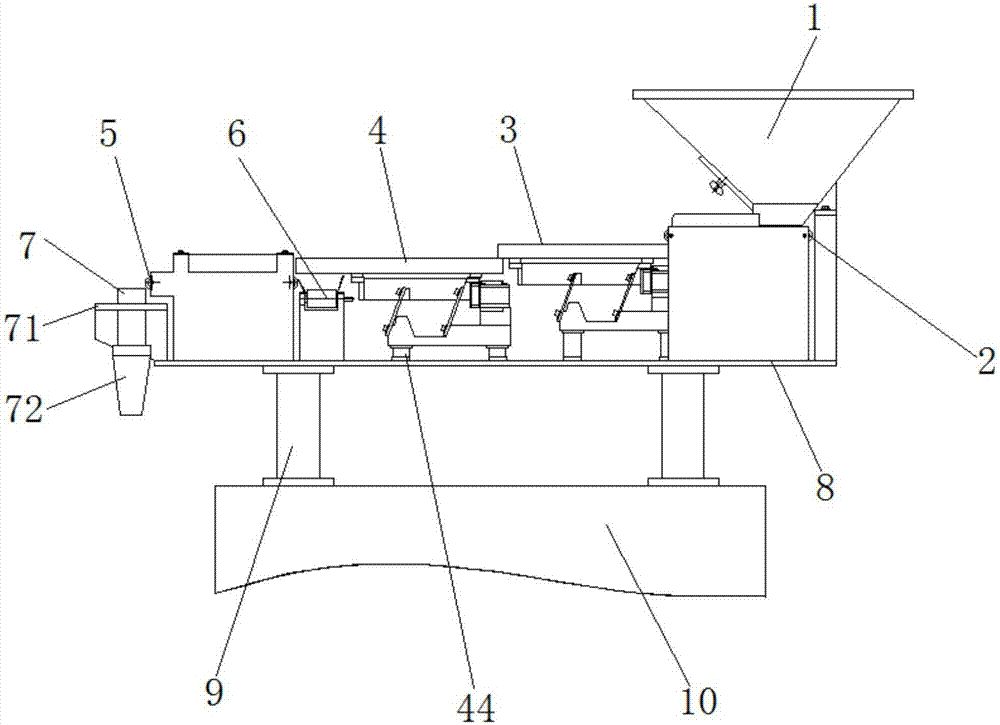

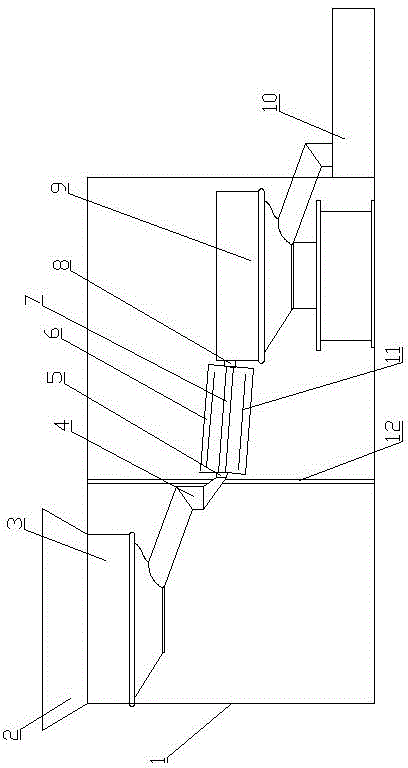

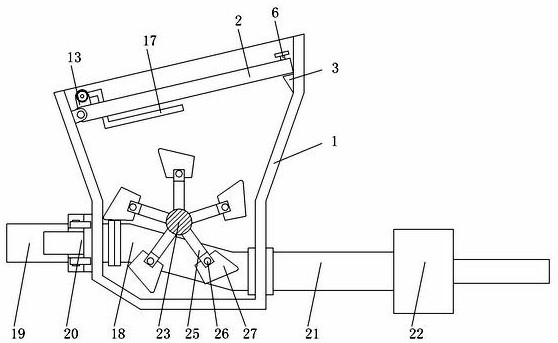

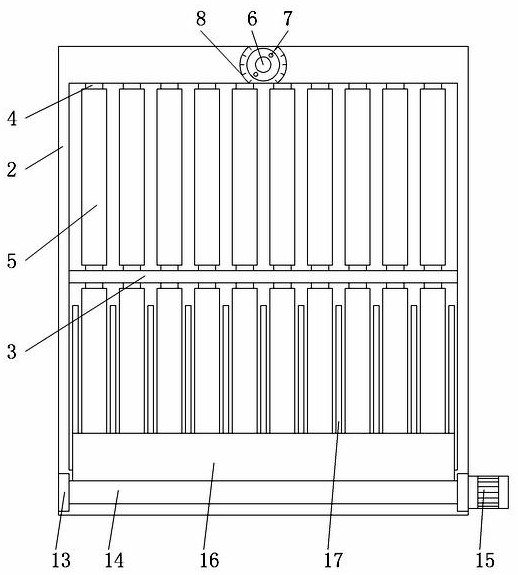

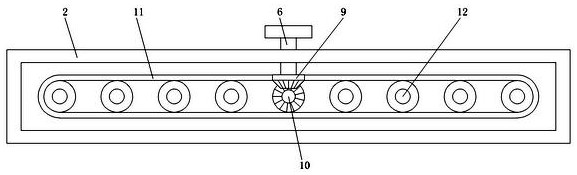

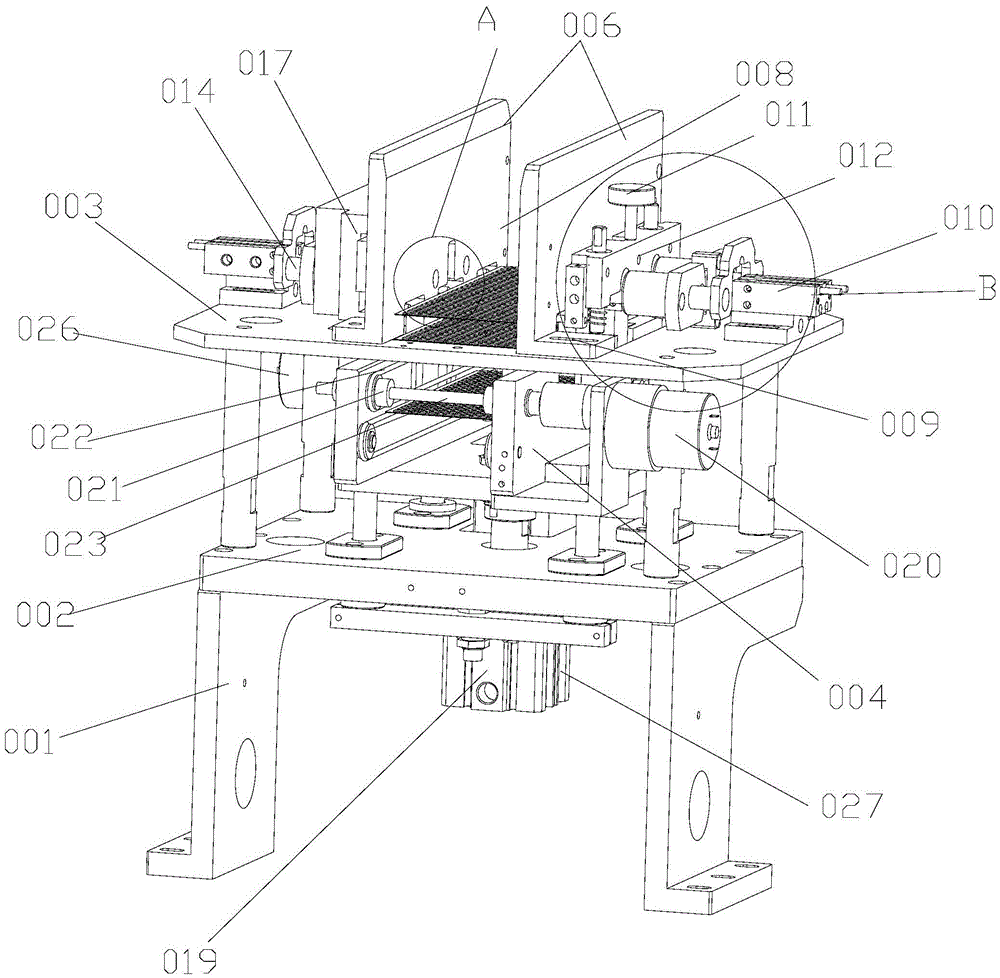

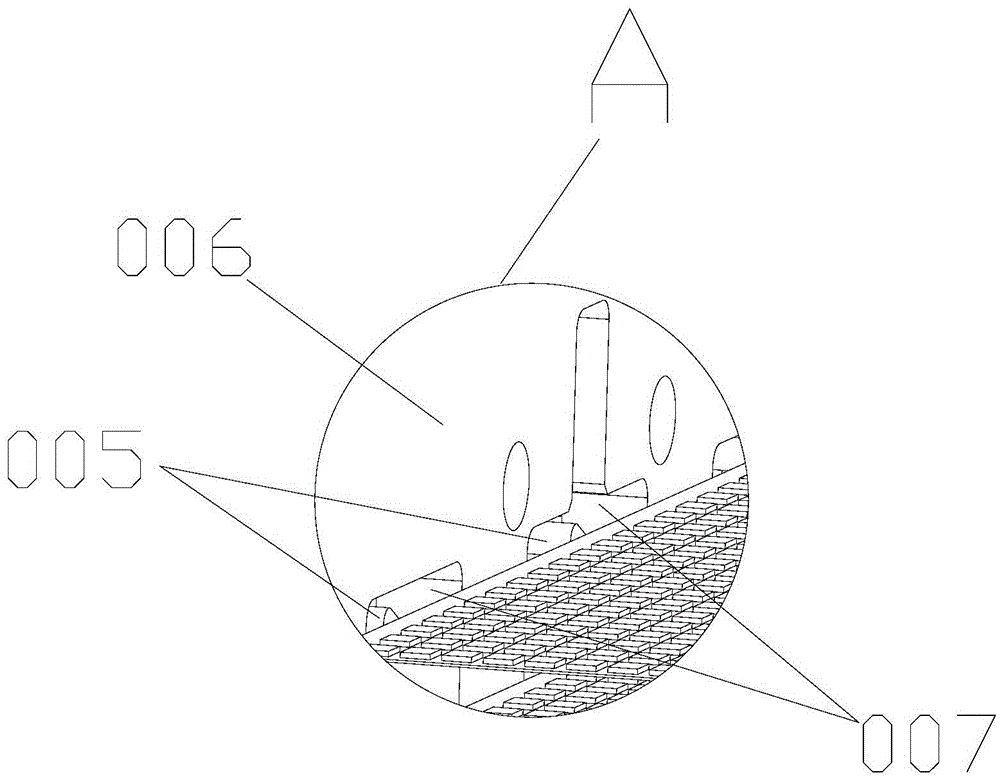

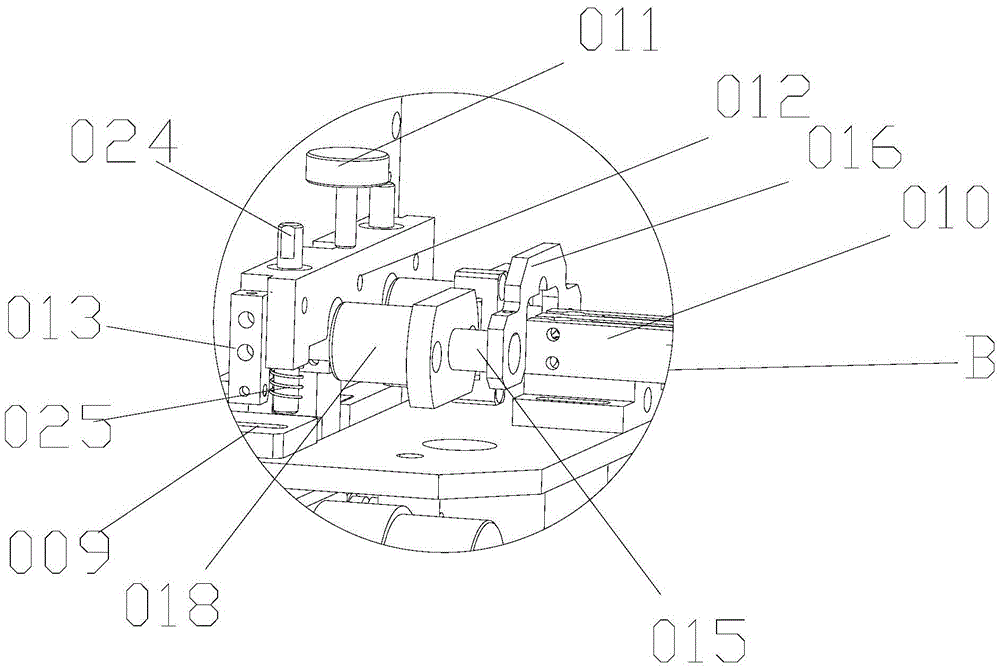

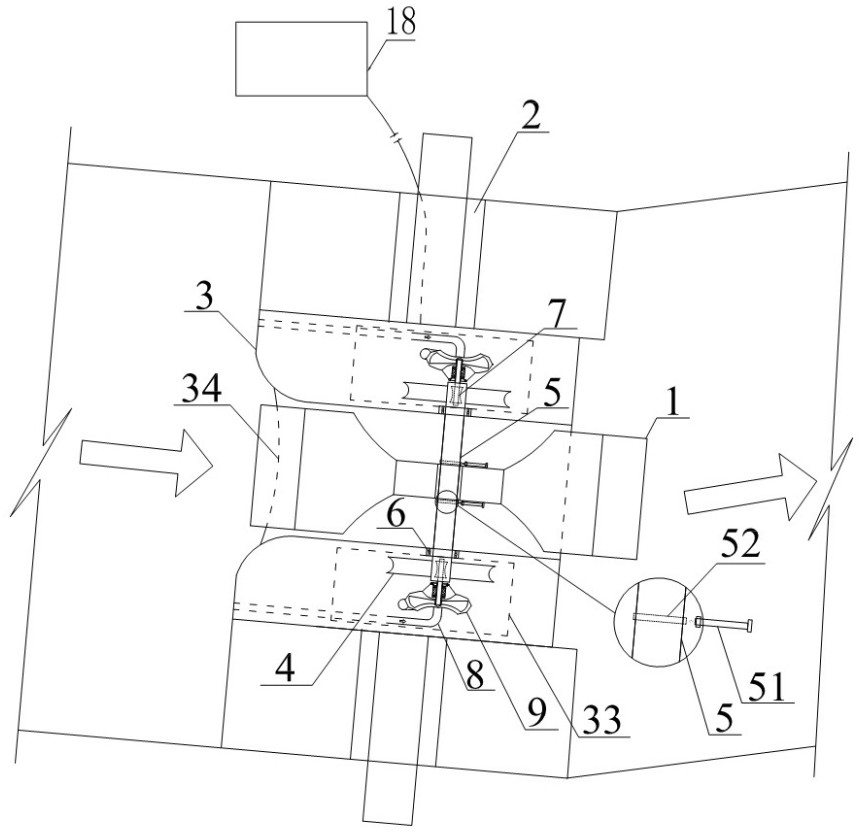

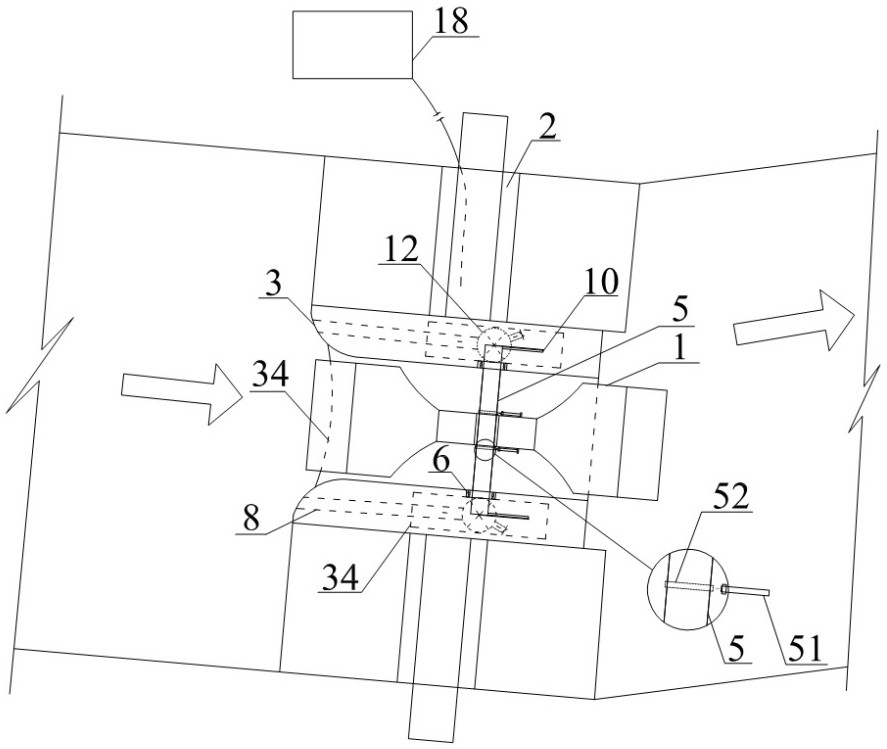

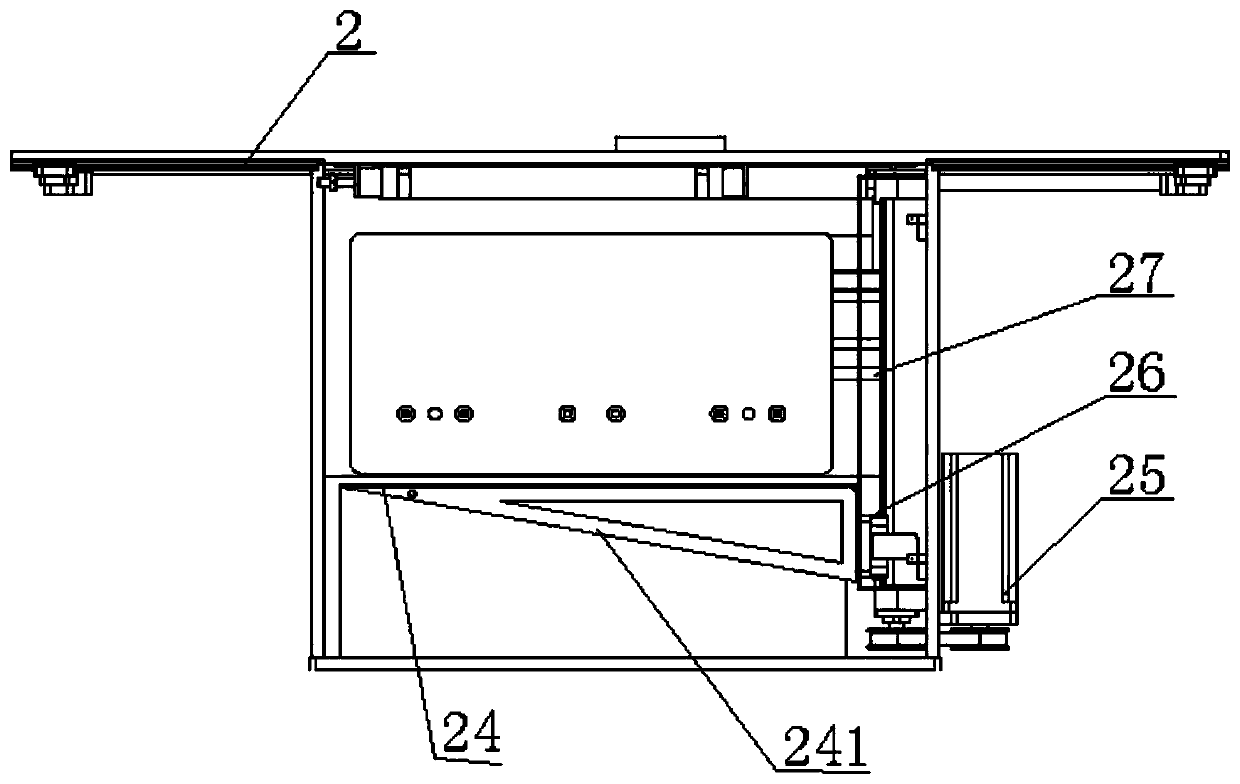

A same-side material loading and blanking method and an automatic material loading and blanking mechanism for realizing the above method

ActiveCN103606592AUninterrupted deliveryImprove work efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingManipulatorEngineering

The invention discloses a same-side material loading and blanking method and an automatic material loading and blanking mechanism for realizing the above method. A rack, a material stacking mechanism and a blanking mechanism are comprised. A falling-off-type material loading mode is realized through the cooperation of a material distributing thimble and related mechanisms, and accordingly following beneficial effects are obtained: 1, the falling-off-type material loading mode is adopted, and material loading steps can be rapidly carried out; and intelligent automation can be realized, and processing materials can be conveyed continuously, so that the working efficiency of a machinery is raised; 2, through novel structures of a material feeding mechanism and the blanking mechanism, a function of same-side material loading and blanking can be realized, so that connection between the material loading and the blanking is more compact, and synchronization of the material loading and the blanking is realized; the efficiency and the automation degree are high; the same-side material loading can be realized, and a lot of machinery disposing space can be saved, so that the utilization rate of places is better improved; and 3, modes of material loading by manipulators are replaced, so that complex control of the manipulators is avoided. The same-side material loading and blanking method and the automatic material loading and blanking mechanism for realizing the above method are simple in structure, convenient to operate, and the same-side material loading and blanking method and the automatic material loading and blanking mechanism for realizing the above method substantially reduce costs.

Owner:GKG PRECISION MACHINE

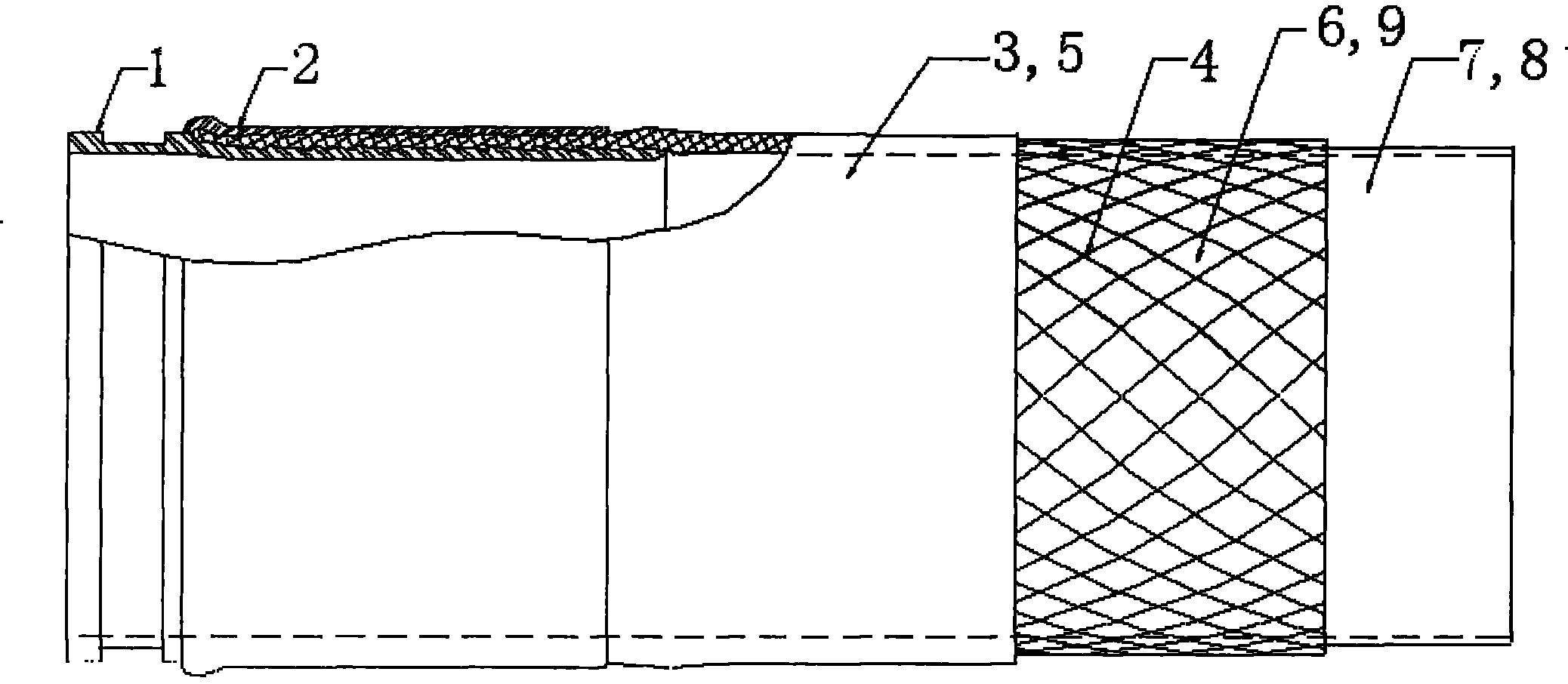

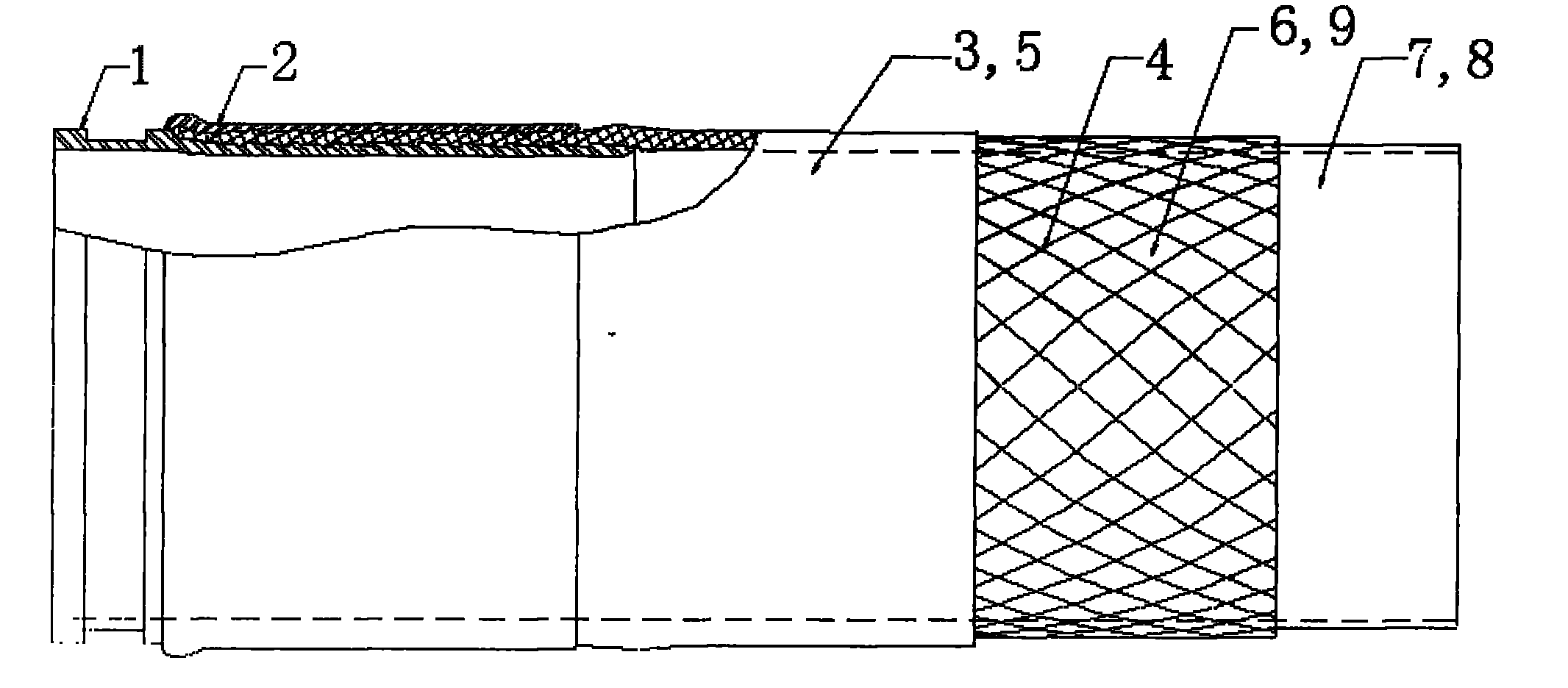

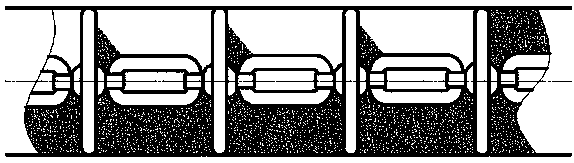

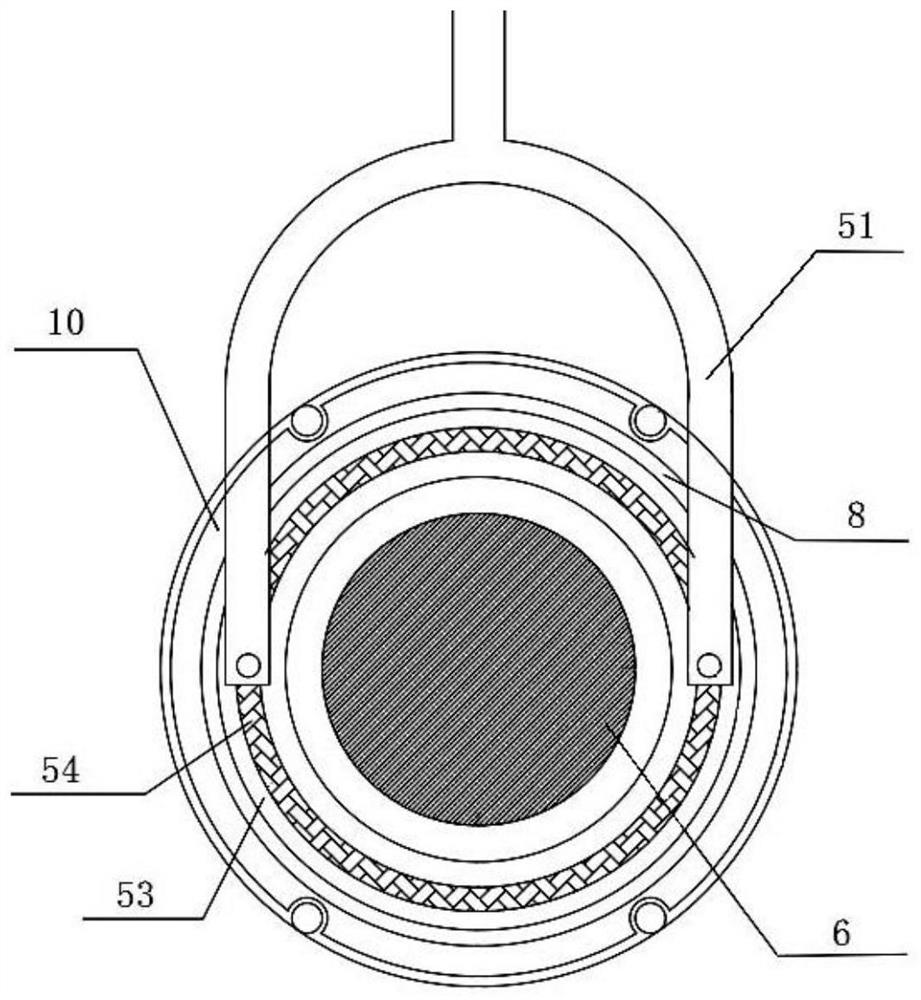

Composite reinforced construction rubber pipe

InactiveCN102128321AHigh compressive strengthImprove securityFlexible pipesRubber layered productsEngineeringUltimate tensile strength

The invention discloses a composite reinforced construction rubber pipe, which comprises a pipe body and joints, wherein the pipe body is a multilayer composite pipe and comprises an outer rubber layer, a middle rubber layer and an inner rubber layer; multilayer wound high-tensile steel wires or steel wire bundles are distributed in the middle rubber layer and are well bonded with the rubber of the middle rubber layer to form a high-tensile composite reinforced layer; the space between the outer rubber layer and the middle rubber layer and the space between the middle rubber layer and the inner rubber layer are provided with a pressure rubber flat chafer fabric layer respectively; the joints are arranged at the two ends of the pipe body; each joint comprises a bushing and a wrap, is made of a high-tensile material and is subjected to electroplating antirust treatment, and heat treatment is performed on the bushing; and a buckling press process is performed between the bushing and the wrap as well as between the bushing and the rubber pipe. By the composite reinforced construction rubber pipe, the compression strength and the safety stock of the rubber pipe are greatly improved, the service life of the rubber pipe is prolonged, concrete delivery quantity of each pipe is increased by more than one time, uninterrupted construction can be realized, and the working efficiency is improved; and the rubber pipe has important value, particularly for the pouring of concrete with high volume.

Owner:郑林波

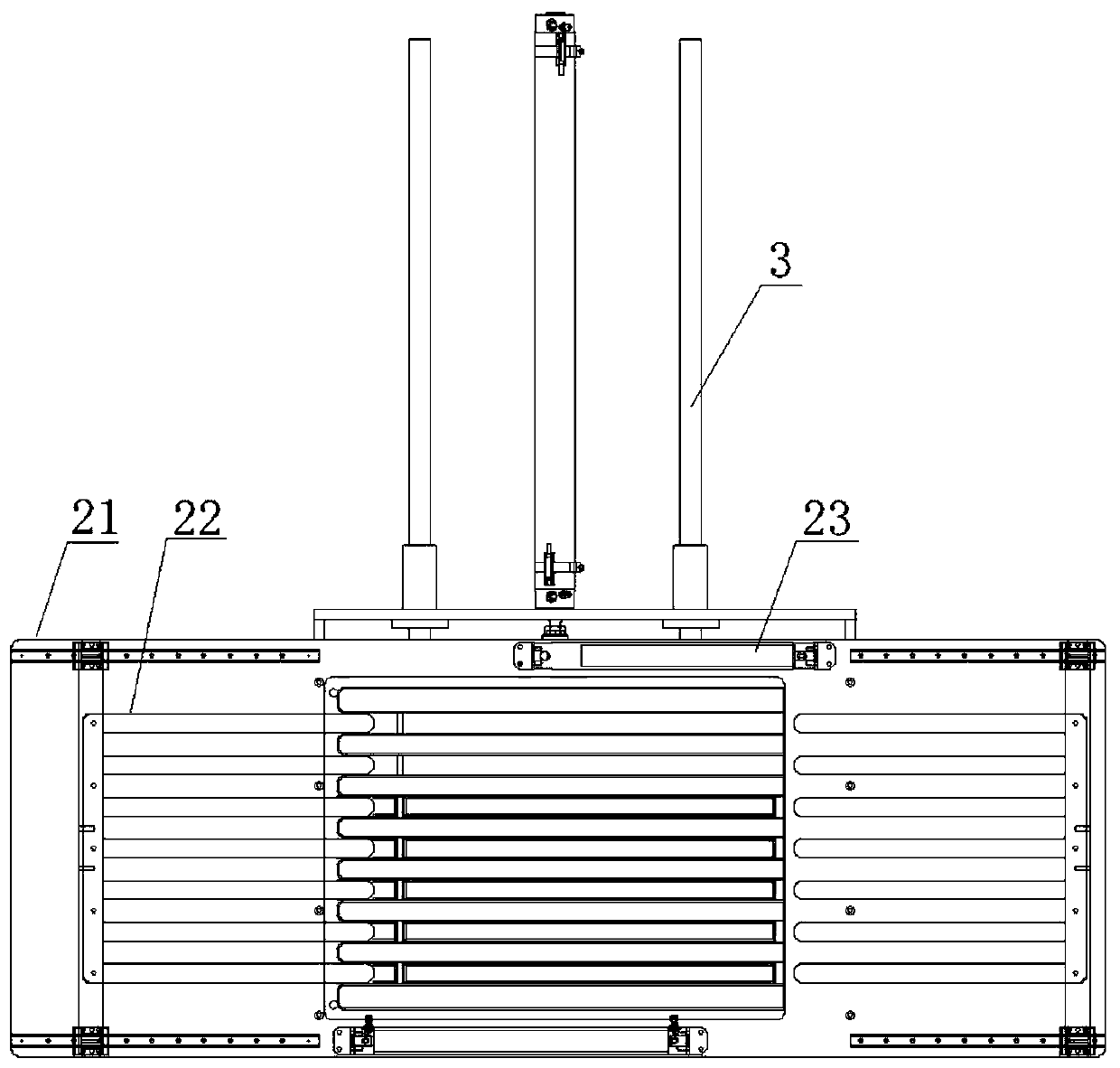

Sealed vibration screen for pipe chain chip removal

PendingCN108729867AEnsure safetySafe and reliable transmission efficiencySievingConstructionsEngineeringHydrogen sulfide

The invention relates to a sealed vibration screen for pipe chain chip removal. The closed vibration screen mainly comprises two parts including a vibration screen body and a sealing device; the vibration screen body is composed of a buffer tank, a screen frame, an upper-layer screen net, vibration excitation motors, a lower-layer screen net, a base and vibration reduction springs; the sealing device is composed of a feeding-end upper sealing cover, a jet pump, an elastic sealing device body, a discharging-end upper sealing cover, an outlet sealing cover, a pipe chain chip removal device, a liquid sealing baffle and an underflow emptying valve; the vibration screen body is arranged in the sealing device, the feeding-end upper sealing cover and the discharging-end upper sealing cover are arranged above the screen frame, and the elastic sealing device body is installed between the screen frame and the feeding-end and discharging-end upper sealing covers; the liquid sealing baffle is arranged at the left side of the base, and an S-shaped pipe formed in the portion, in the base, of the liquid sealing baffle prevents hydrogen sulfide from leaking; the pipe chain chip removal device is installed at the discharging portion of the screen frame and can continuously and efficiently remove rock chip particles, the jet pump is installed on the feeding-end upper sealing cover, and the hydrogen sulfide is recycled through the jet pump. The sealed vibration screen is simple in structure and high in safety, the screening efficiency requirement of the vibration screen can be met, the rock chips are timely removed, the hydrogen sulfide is effectively controlled and recycled, and the effect is obvious.

Owner:SOUTHWEST PETROLEUM UNIV

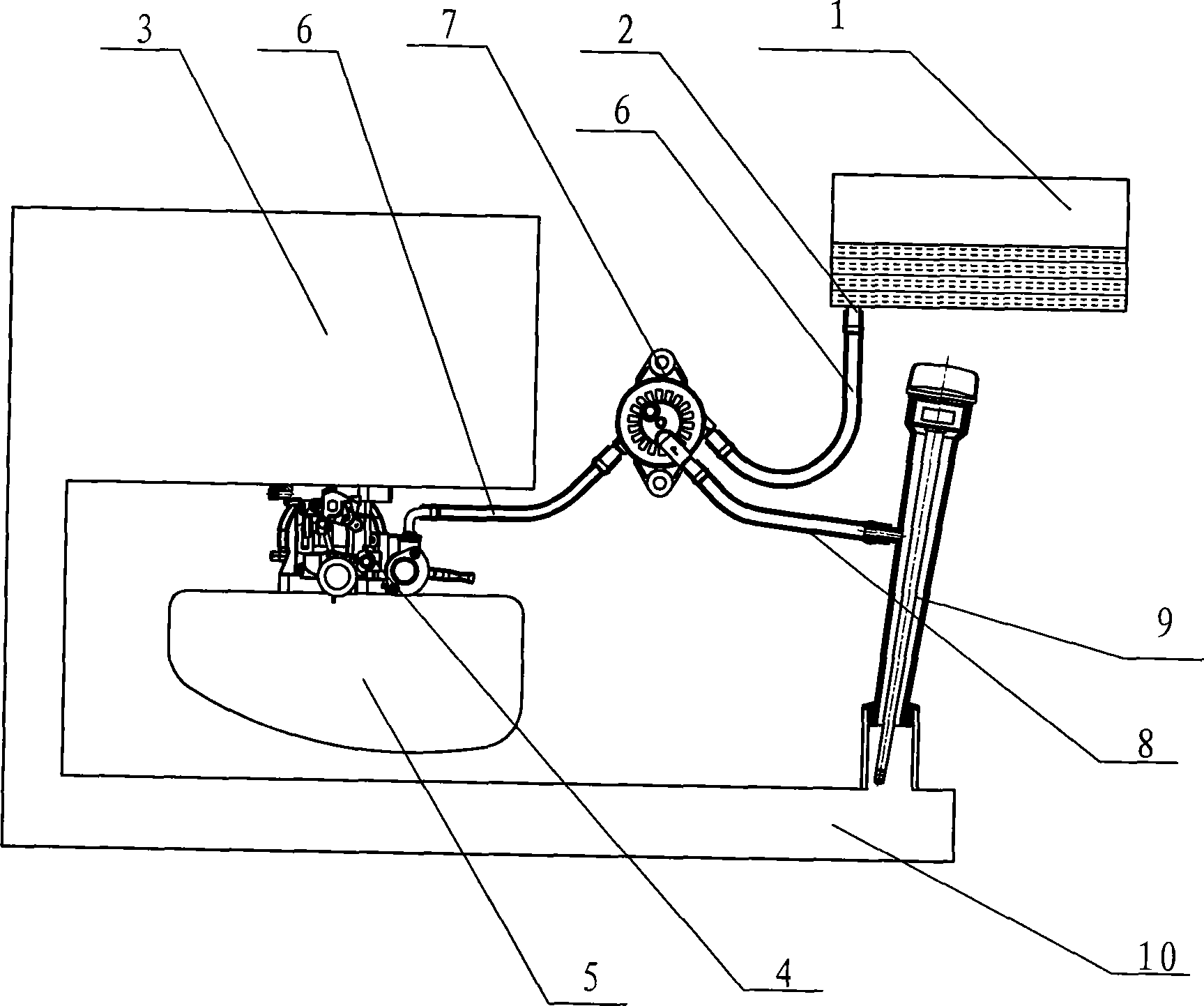

General gasoline-engine negative-pressure drive fuel-oil supplying apparatus

InactiveCN101070801AUninterrupted deliveryStable deliveryMachines/enginesLiquid fuel feedersPressure.driveFuel tank

The invention discloses all-purpose gasoline machine negative pressure-driven fuel supply installations, including oil mouth out with the fuel tank, carburetor, fuel tube and crankshaft box. Its characteristic lies: there are three ports are installed the fuel pump, the two of which are connected with the fuel pipe, one pipe connecting the fuel ports on the other side of the fuel tank and oil connecting the mouth and the other connecting the port at the other end of the fuel pipe connecting with the carburetor; the third port of Fuel Pump is connected with the vacuum sampling tube linked vacuum tube sampling box connectivity with the crankshaft, sampling box crankshaft pressure changes, control fuel pump on - and closed the invention of the fuel supply installations. According to changes of pressure in Engine box, it automatically guarantee uninterrupted fuel, stability transported to carburetor, the protection of traffic safety; simple structure, installation flexibility. Under the package can be installed with the motor vehicle configuration requirements of the different ways and change its installation location.

Owner:LONGXIN IND GROUP

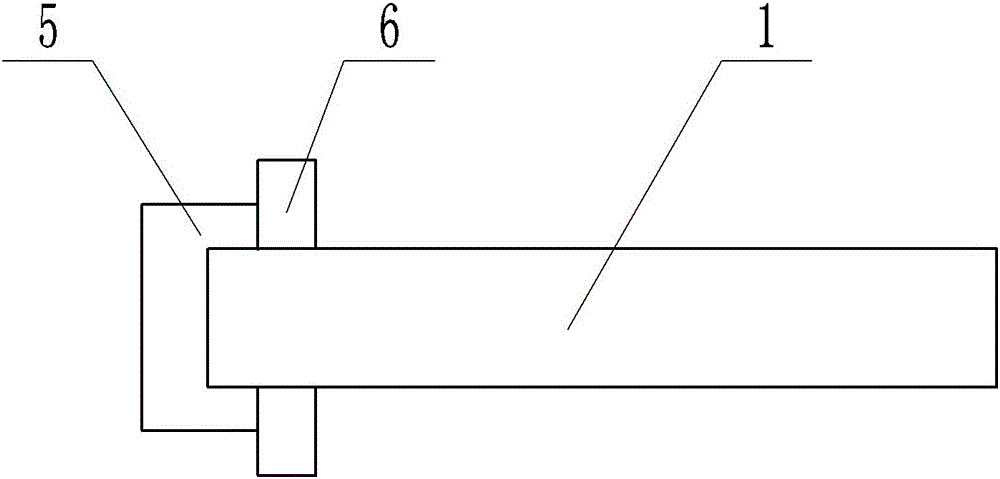

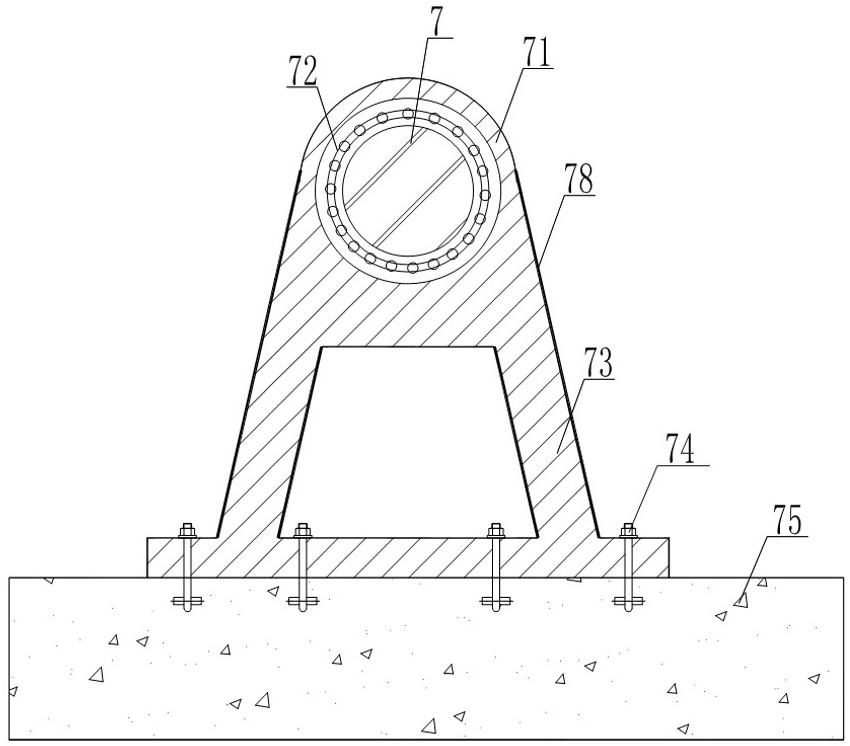

Special Sliding Rotary Support

The invention discloses a special sliding slewing bracket, including shaft coupling and bearing base. On the outside of the shaft coupling there fixed a hough auger retainer, which is made up of no. 1 half hough auger retainer and no. 2 half hough auger retainer, the edges of both are equipped with wear-resisting insert. Bearing outer ring is installed on the outside of the bearing base, and the shaft coupling and Hough auger retainer are located inside bearing base. This invention can effectively guarantee the concentricity of the lay and simplicity of adjustment, efficiently constraining the flexible deformation generated by the packing auger; free of maintenance or any lubricating medium, reducing service cost, simple in structure and easy to operate.

Owner:台州恒投工贸有限公司

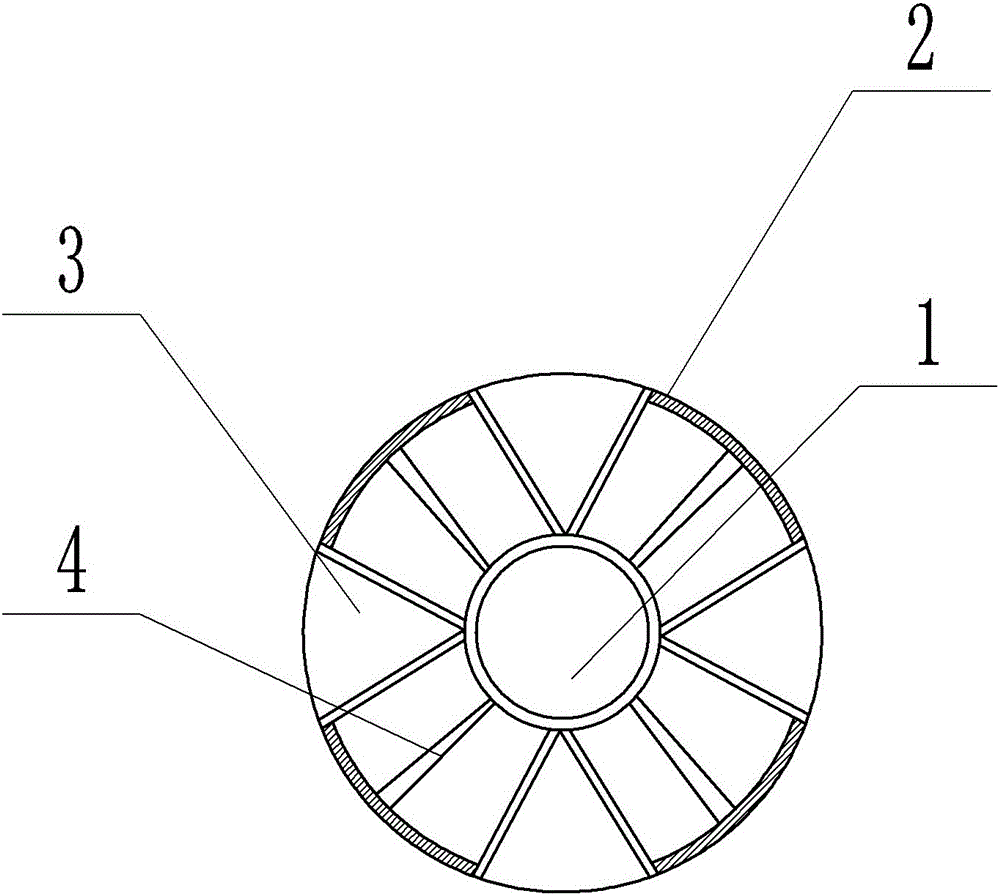

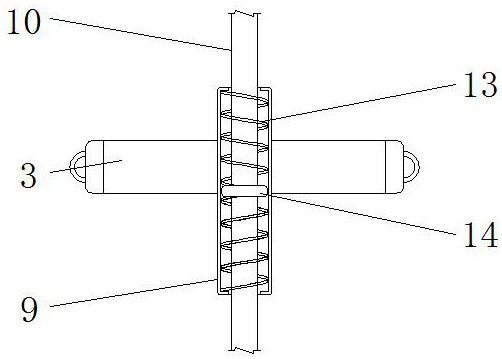

Conveying roll with wire separation function

ActiveCN106698049AAvoid failureAutomatic disengagementWebs handlingEngineeringMechanical engineering

The invention discloses a conveying roll with a wire separation function. The conveying roll comprises a rack, a guide rail and a conveying roll body, wherein the guide rail is vertically arranged in the rack; the conveying roll body is connected on the guide rail in a sliding manner; the conveying roll body comprises an inner roll and an outer roll; the outer roll is arranged at the outer part of the inner roll; the two ends of the outer roll are connected on the guide rail in a sliding manner; supporting rods are arranged between the outer roll and the inner roll; the outer roll is provided with notches; fan-shaped air sacs are arranged at the notches; the air sacs are connected with the inner roll; and arc-shaped surfaces of the air sacs and the outer side surface of the outer roll are flush. Through the adoption of the scheme, a woven wire wound on the outer roll can be automatically separated timely, and the conveying roll is prevented from breaking down.

Owner:CHONGQING STRONG DUDLEY TECH DEV

Corrugated mechanism and distributing equipment

ActiveCN107284742AGood shunt effectEasy follow-upPackaging automatic controlEngineeringMechanical engineering

The invention provides a corrugated mechanism and distributing equipment, and relates to the technical field of food machines. The corrugated mechanism comprises multiple second grooves formed in parallel and used for conveying particle materials; the opening width is larger than the width of the groove bottom of each second groove, and the output end of each second groove comprises a single-particle channel and an opening used for outputting overlapped materials; a guide part used for conveying the particle materials into the single-particle channel is fixedly connected to each second groove and located between the corresponding single-particle channel and the corresponding opening, the guide part gradually inclines to the single-particle channel in the particle material conveying direction, and the technical problems that in the prior art, before quantitative counting packaging of the particle food, as distributing operation is difficult, quantitative count is inaccurate, and production efficiency is low are solved; by adopting a conveying mechanism and the corrugated mechanism for alternating conveying, the distributing equipment has the advantages of being high in conveying speed, good in distributing effect and accurate in quantitative counting.

Owner:南通恒力包装科技股份有限公司

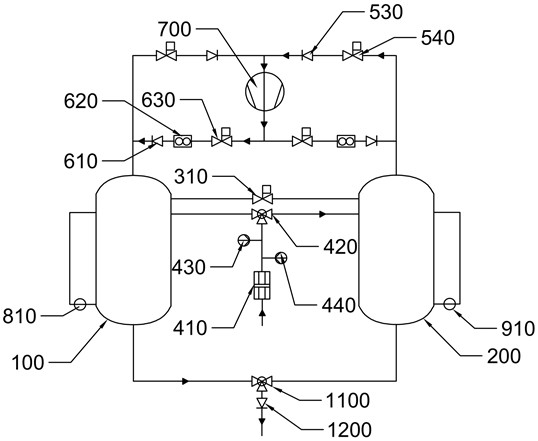

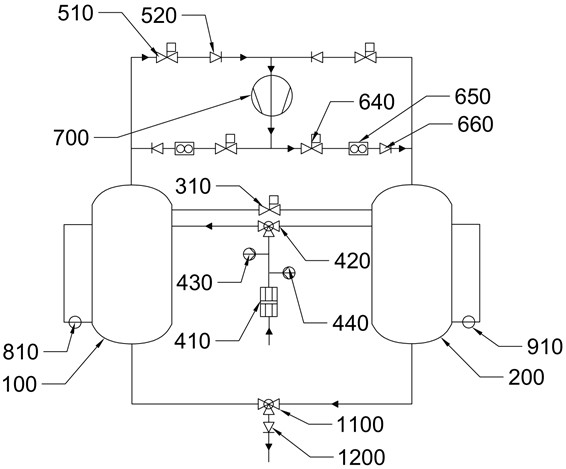

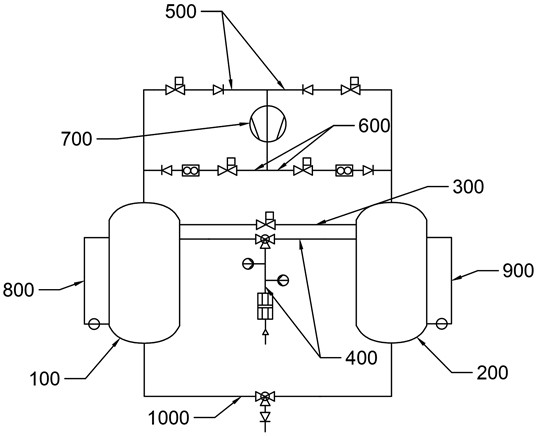

Multiphase metering mixed transportation method and multiphase metering mixed transportation system

ActiveCN113550730ARealize mixed inputRealize online measurementSurveyFluid removalFluid phaseOil field

The invention provides a multiphase metering mixed transportation method and a multiphase metering mixed transportation system, and relates to the technical field of oil well mixed transportation. The multiphase metering mixed transportation method comprises the following steps of obtaining the water content of a to-be-transported multiphase fluid, and sending the to-be-transported multiphase fluid into a first separation tank, so that liquid in the multiphase fluid in the first separation tank is deposited in the first separation tank; converting a gas separated from the first separation tank into the high-pressure gas, feeding the high-pressure gas into a second separation tank, and discharging the high-pressure gas through the second separation tank; obtaining the water content of the to-be-conveyed multiphase fluid, and conveying the to-be-conveyed multiphase fluid into the second separation tank, so that enabling liquid in the multiphase fluid in the second separation tank to be deposited in the second separation tank; and converting gas separated from the second separation tank into the high-pressure gas, and feeding the high-pressure gas into the first separation tank. The technical problem that in the prior art, in the oil and gas exploitation process of an oil field, the metering effect of a gas phase and a liquid phase in a mixed transportation device is not ideal is solved.

Owner:SHENGLI OILFIELD SHENGJI PETROLEUM EQUIP

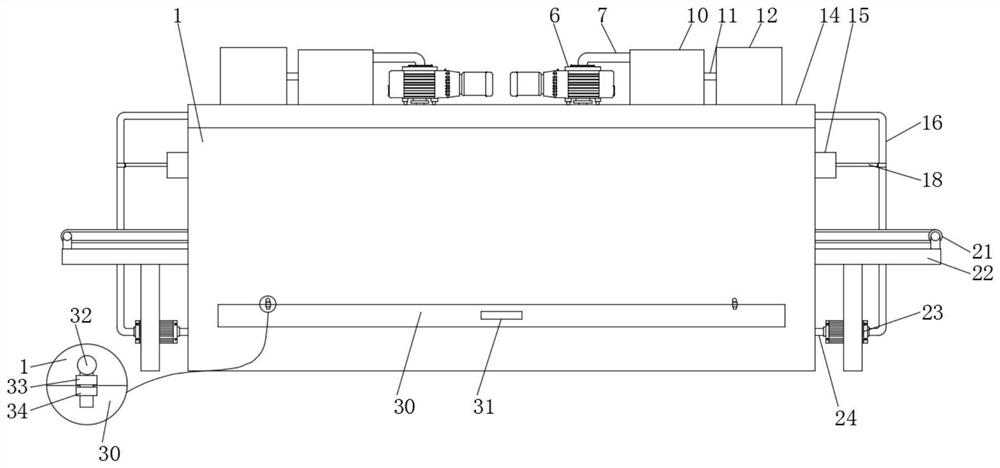

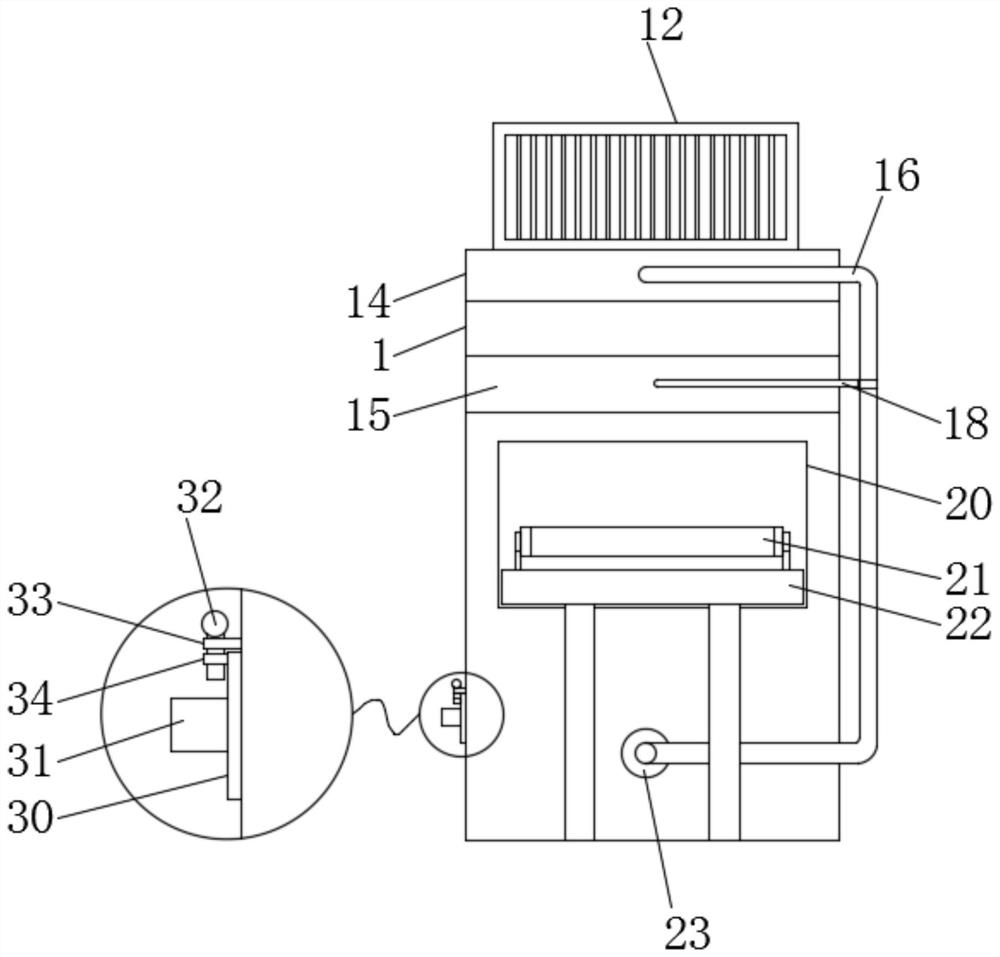

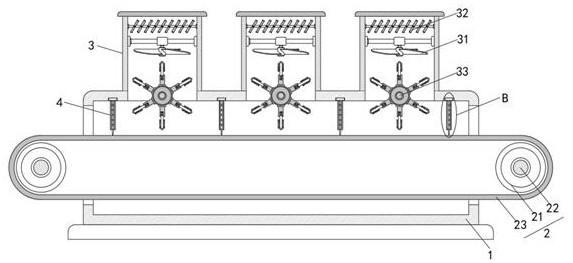

Tray abutting assembly line device

ActiveCN112850000AEasy and fast loadingImprove efficiencyFinal product manufactureControl devices for conveyorsElectric machineryRight lateral position

The invention discloses a tray abutting assembly line device. The device comprises a feeding conveying belt, wherein a waiting conveying belt is arranged on the right side of the feeding conveying belt, a material receiving conveying belt is placed on the right side of the waiting conveying belt, a second driving wheel is fixed to the left side of the material receiving conveying belt, a third driving wheel is fixed to the right side of the material receiving conveying belt, a second bottom plate is arranged on the left side of the lower portion of the material receiving conveying belt, a second motor support is fixed to the upper surface of the second bottom plate, a second motor is fixed to the middle of the upper end of the second motor support, a third bottom plate is fixed to the right side of the lower portion of the material receiving conveying belt, a third motor support is fixed to the upper surface of the third bottom plate, a third motor is fixed to the upper end of the third motor support, the second driving wheel is connected with the second motor through a second belt, and the third driving wheel is connected with the third motor through a third belt. The device has the beneficial effects of continuous material receiving, high efficiency and simple operation.

Owner:阳泉市广凯机械制造有限公司

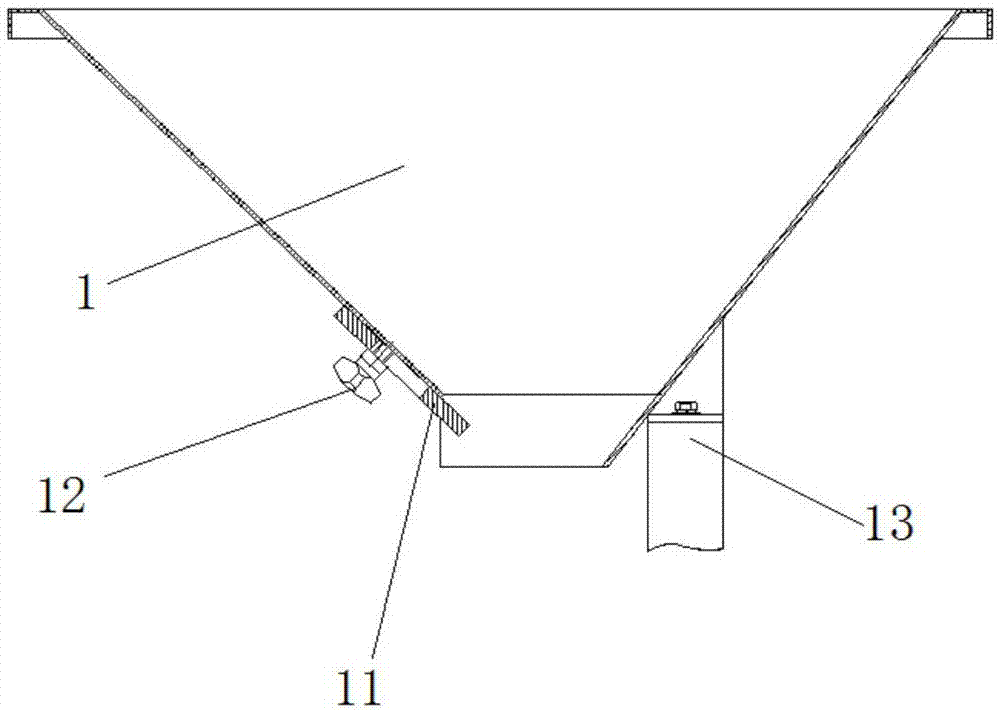

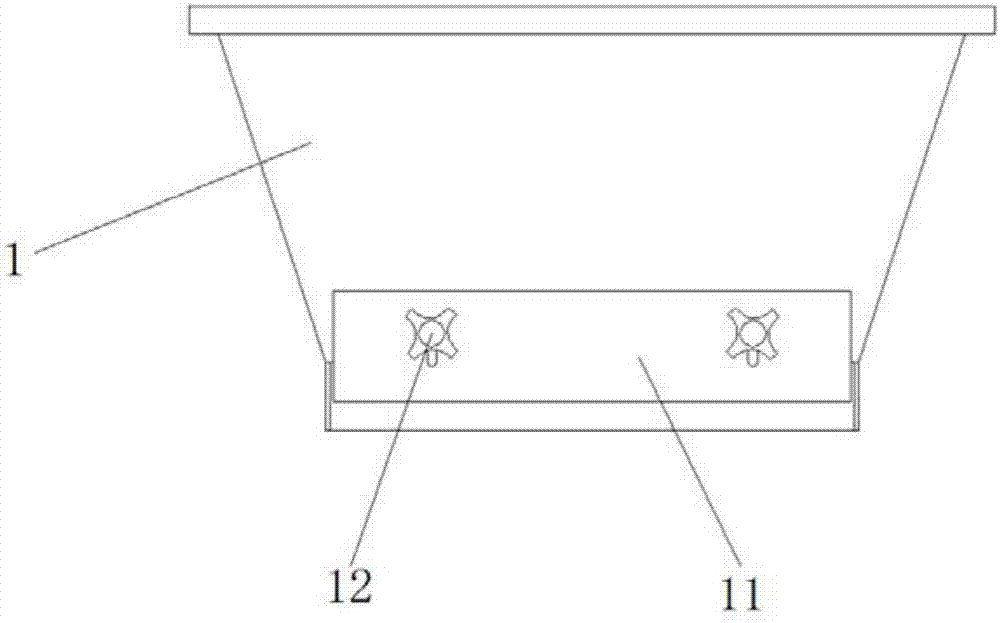

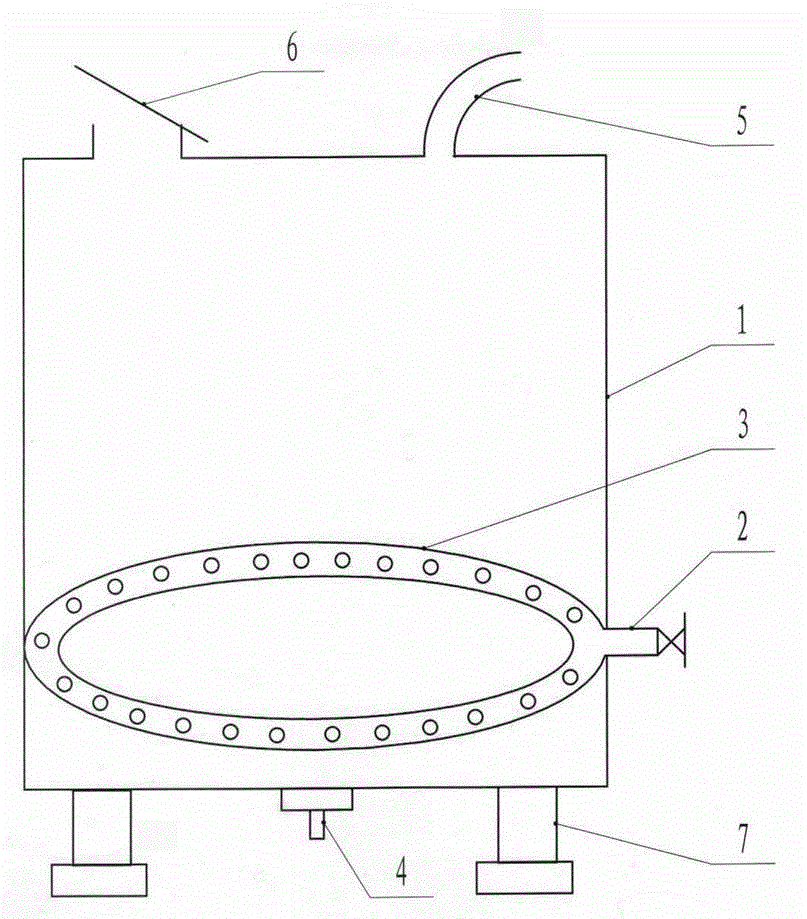

Powder feeder

PendingCN104876032AImprove delivery efficiencyUninterrupted deliveryBulk conveyorsGas compressorEngineering

The invention discloses a powder feeder, and mainly relates to a powder spraying device. The powder feeder comprises a powder tank, an annular air duct, an air inlet, a discharging opening, a charging opening and a pneumatic vibrator, and is characterized in that the air inlet is formed in the bottom of the inner part of a cavity of the powder tank and is connected with the annular air duct mounted on the inner wall of the tank; a plurality of holes are drilled in upper, lower and inner sides of the annular air duct so that the compressed air blows the powder; the discharging opening is formed in the upper part of the tank; the air vibrator is mounted at the bottom of the tank so that the powder stuck on the tank wall drops and is conveyed uniformly. The powder feeder is simple in structure, reasonable in design and convenient to manufacture; the powder feeder can be connected with an air compressor by only one air duct, without any electrical power equipment; compared with the traditional powder feeder, the powder feeder greatly improves the conveying efficiency, avoids equipment maintenance, improves the operational capability of the equipment, and can realize the continuous and uniform conveying of powder.

Owner:HENAN CHAOBEI ENG EQUIP

Lubricating oil automatic adding device of rotor sealing end of internal mixer

PendingCN108953963AAvoid seal wear or scrapReduce labor intensityLubrication elementsElectromagnetic valveHigh pressure

The invention discloses a lubricating oil automatic adding device of a rotor sealing end of an internal mixer. The device comprises a standard oil barrel, a pneumatic pump, a process oil preparation oil tank, an output oil pump, a material level sensor, an electromagnetic valve and a PLC; the pneumatic pump is mounted on the standard oil barrel; an intake port of the pneumatic pump is connected with external compressed air; a high-pressure oil outlet of the pneumatic pump is connected with an oil inlet of the process oil preparation oil tank; an oil outlet of the process oil preparation oil tank is connected with an oil inlet of the output oil pump; the material level sensor is mounted on the inner side wall of the process oil preparation oil tank; the electromagnetic valve is mounted on an air control pipe; and the material level sensor and the electromagnetic valve are electrically connected to the PLC. Through the mode, the output oil pump can be guaranteed to continuously convey lubricating oil to the rotor sealing end, so that the wear or waste phenomenon of a sealing ring caused by shortage of the oil is prevented, meanwhile, the labor intensity can be reduced, and the production efficiency is improved.

Owner:常熟市海虞橡胶有限公司

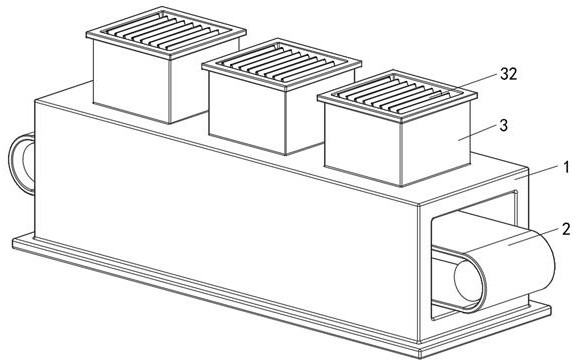

Powder material plasma sterilizer

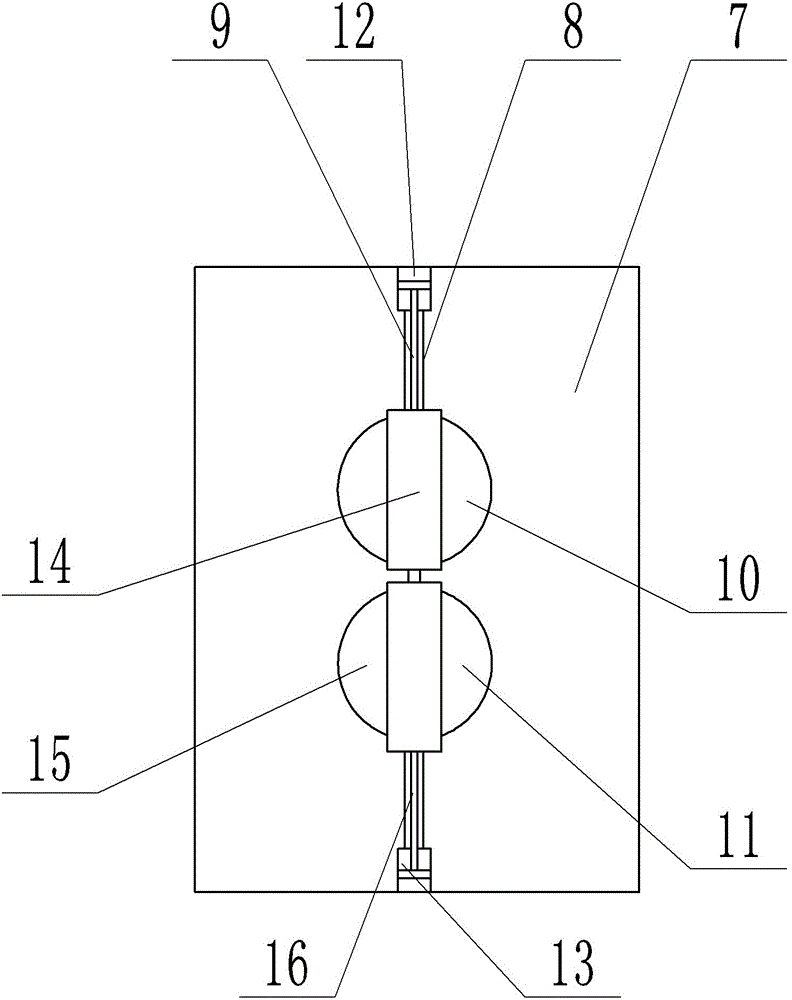

ActiveCN104800870ARealize separation and sterilizationImprove liquidityLavatory sanitoryDisinfectionFlow dividerElectrical and Electronics engineering

A powder material plasma sterilizer comprises a machine case, a feeding vibrating bed and a discharging vibrating bed are arranged in the machine case, a sterilizing cavity is formed between the feeding vibrating bed and the discharging vibrating bed, a plasma generating device is arranged in the sterilizing cavity, the plasma generating device comprises a positive electrode plate and a negative electrode plate which are symmetrically arranged in an up-down mode, a plurality of micro pipes are arranged in the sterilizing cavity between the positive electrode plate and the negative electrode plate, feeding ports of the micro pipes are connected with a discharging port of the feeding vibrating bed through a flow divider, discharging ports of the micro pipes are connected with the discharging vibrating bed, feeding electromagnetic clamping valves are arranged on the micro pipes close to the feeding ports, and discharging electromagnetic clamping valves are arranged on the micro pipes close to the discharging ports. By means of the plasma generating device, normal-temperature sterilization of powder materials is achieved. By means of the micro pipes, separated sterilization is achieved, and good sterilizing effects are guaranteed. Due to the feeding vibrating bed and the discharging vibrating bed, powder materials can flow and be conveyed. Due to the discharging electromagnetic clamping valves, the sealing performance is achieved.

Owner:LIANYUNGANG YOUYUAN MEDICAL EQUIP MFG

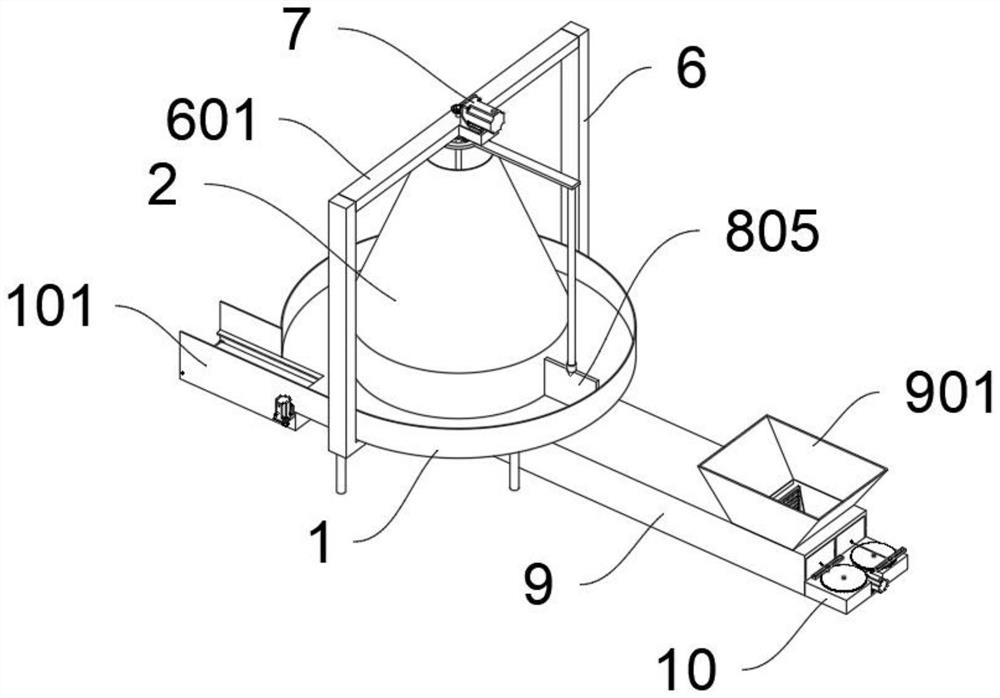

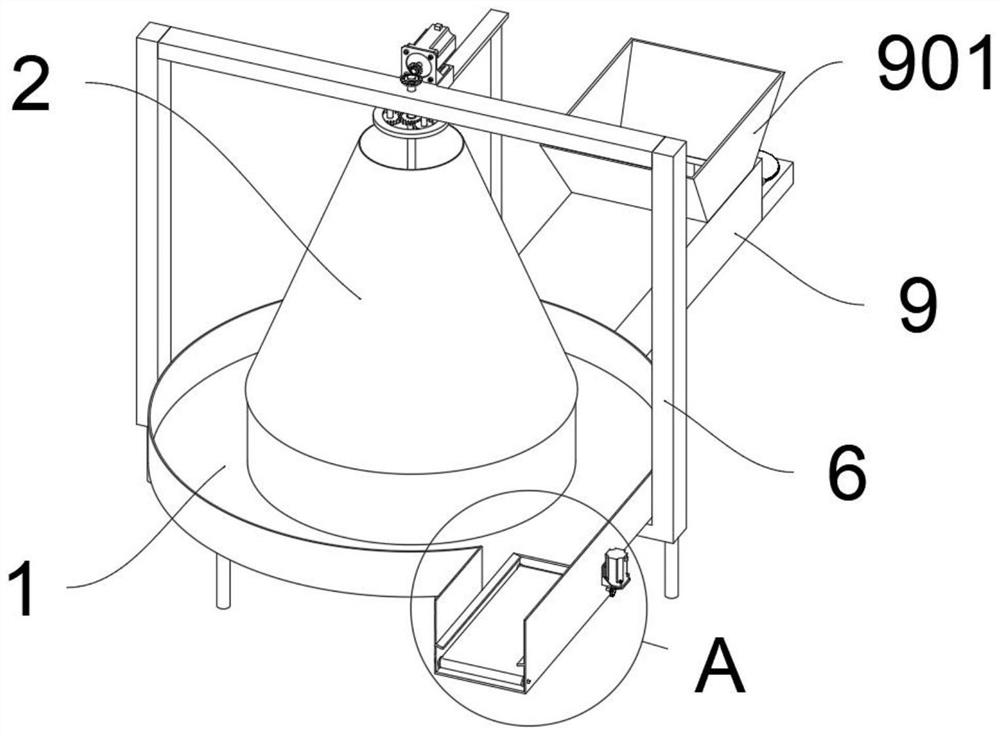

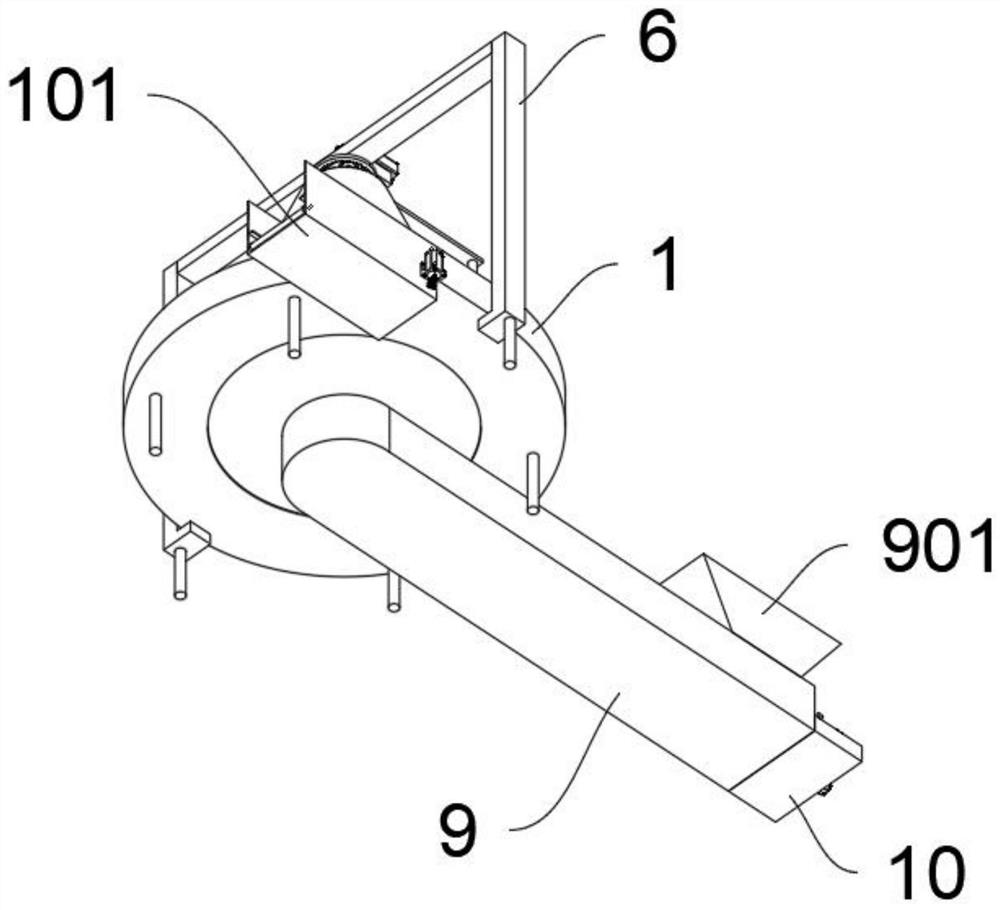

Desilting slurry dewatering and solidifying method

InactiveCN111847831AEfficient dischargeFast evaporationSludge treatment by de-watering/drying/thickeningConveyor partsElectric machineryProcess engineering

The invention discloses a desilting slurry dewatering and solidifying method. According to the method, dewatering and solidifying of desilting slurry are achieved through desilting slurry dewatering and solidifying integrated equipment provided with an annular seat stand, a conical cover, a vacuum heat insulation ring, a graphite heat insulation ring, a motor A, a side frame, a motor B, a liftingshaft, a feeding bin, a rear seat, a motor C and a push shaft. The desilting slurry dewatering and solidifying method successfully solves the problems that the existing dehydration method provided bythe prior art is mainly used for dehydration in a centrifugal force drainage and water absorption mode; the dehydration speed is low, water cannot be continuously, uniformly and quickly discharged andcrystallized, water in desilting slurry cannot be better and thoroughly discharged, and meanwhile, the dehydration is easily hindered by equipment, and quick discharge is not facilitated are solved.

Owner:莱西市寰球新能源技术中心

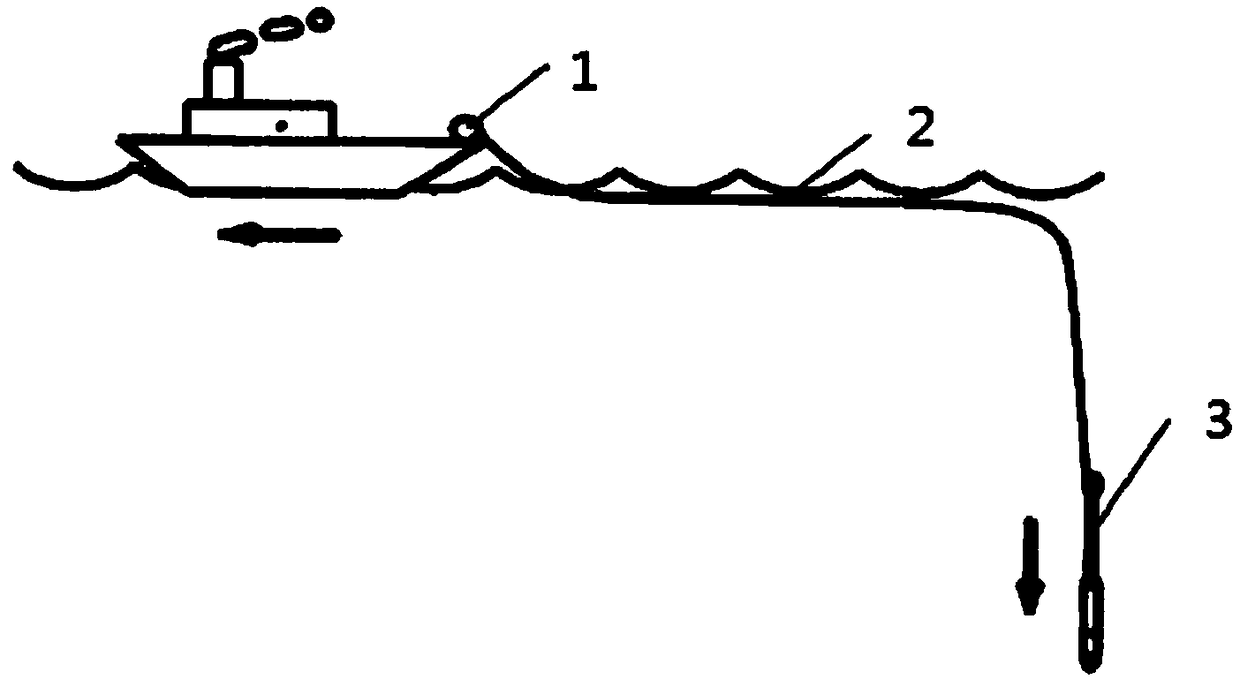

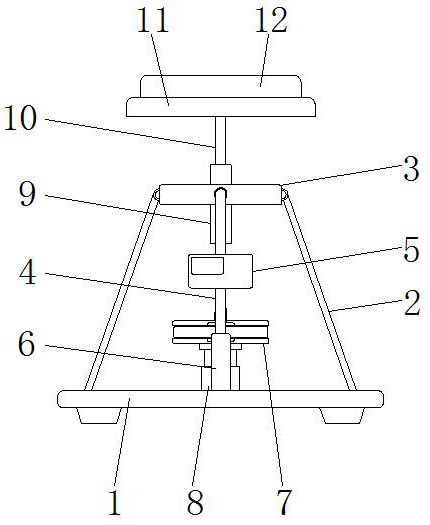

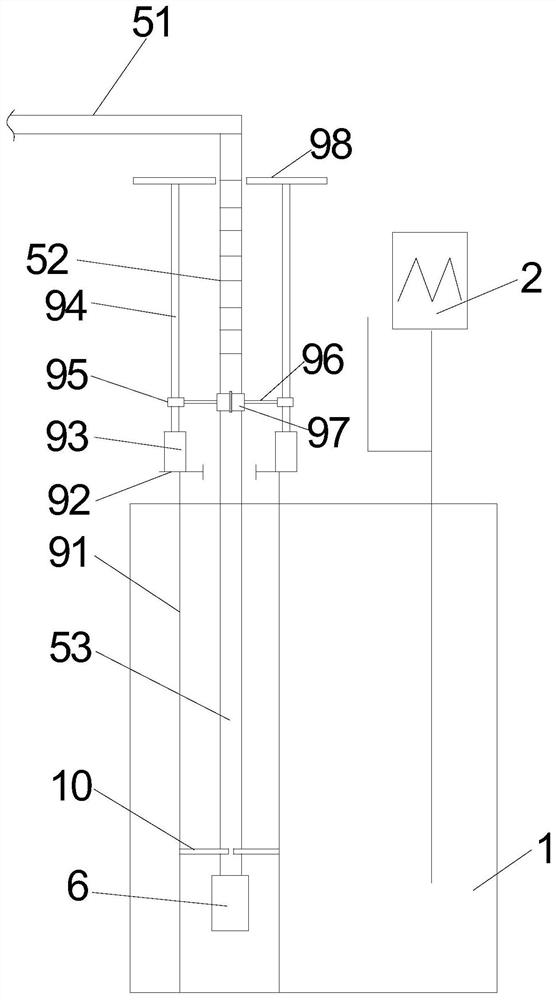

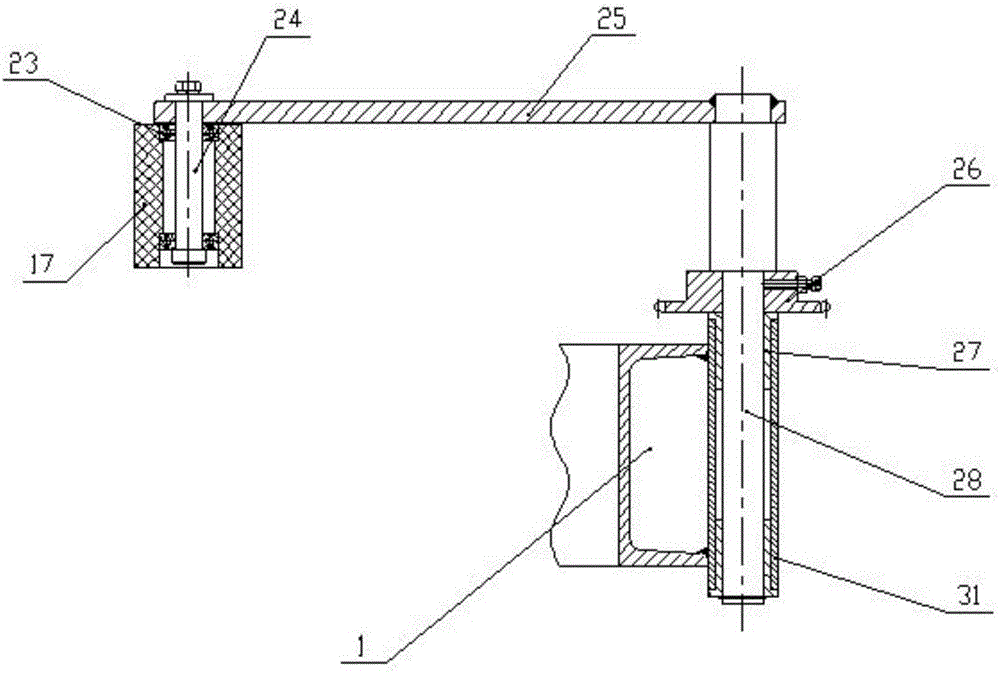

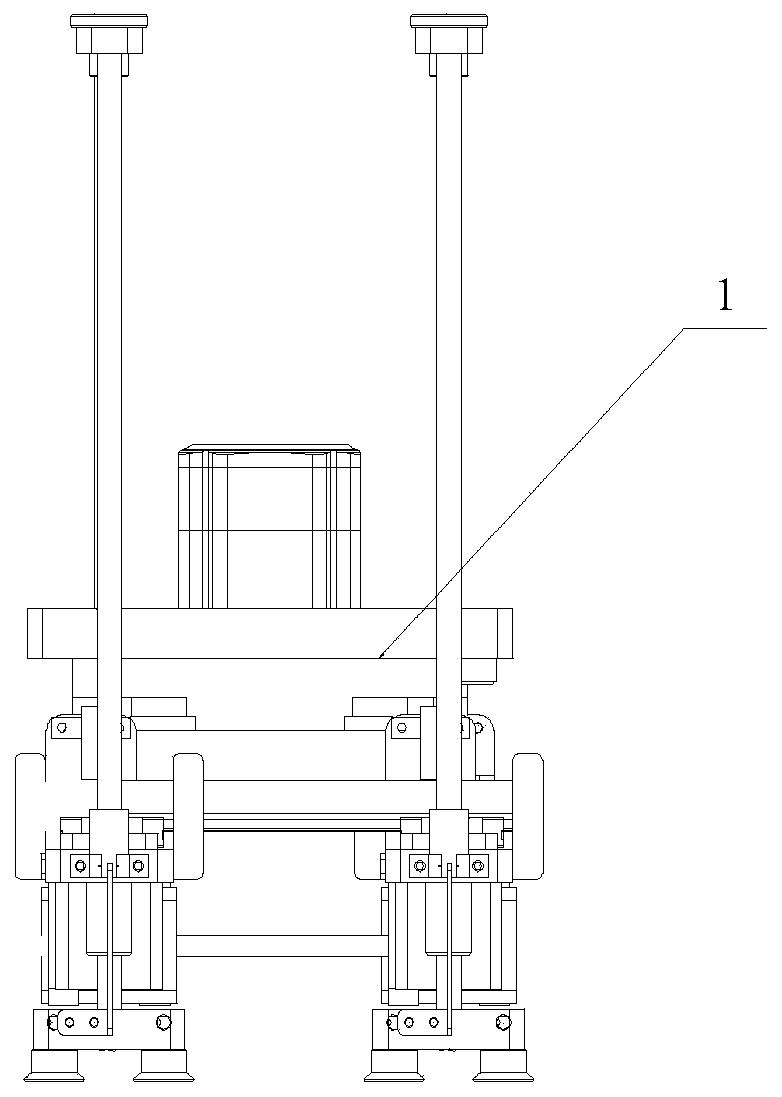

Underway conductivity temperature depth measuring system

PendingCN108116996AImprove reliabilityIncrease the level of automationMeasuring open water movementControl using feedbackWinding machineEngineering

The invention discloses an underway conductivity temperature depth measuring system which comprises a winch, a winding machine, a recovery cotton rope, a UCTD (underway conductivity temperature depth)probe and a deck terminal computer. The winch is used for rapidly placing and recovering the probe, the winding machine is used for rapidly winding on a reel after the probe is recovered, the probe carries a self-contained CTD (conductivity temperature depth) instrument and is used for measuring CTD data of a marine profile, and the terminal computer collects probe data after the probe is recovered to a deck. The requirements of a research vessel for rapid installation, convenience in use, stability and reliability are met, and reliability, environmental adaptability and maintainability of UCTD equipment are improved.

Owner:STATE OCEAN TECH CENT

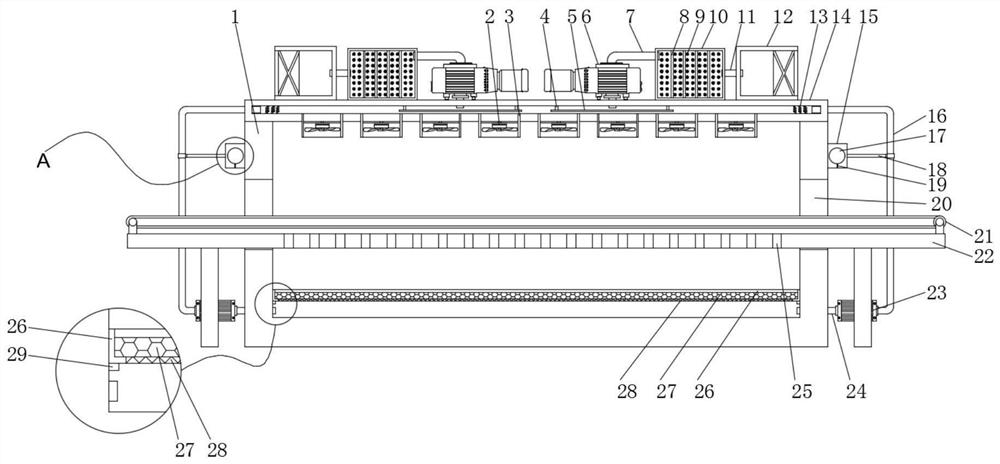

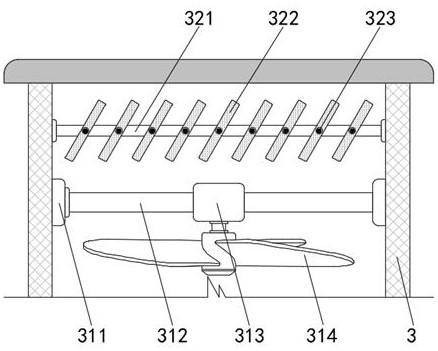

Wind power drying device for food processing production line

InactiveCN112815685AExtended flow pathImprove cleanlinessDrying gas arrangementsDrying machines with progressive movementsIngested foodEnergy conservation

The invention discloses a wind power drying device for a food processing production line. The wind power drying device comprises a drying bin and a mounting table. The wind power drying device for the food processing production line has the beneficial effects that air sucked into a heating box is filtered through a medium efficiency filter, the cleanliness of drying wind power is improved, dust pollution to food in the drying process is reduced, meanwhile, guide plates in the heating box are distributed in a staggered mode, the air flowing path is increased, the contact time of the air and a primary heating wire is prolonged, the air outlet temperature is improved, the heating efficiency is improved, and the drying efficiency is improved; and in addition, dried hot air penetrates through a conveying mesh belt, a mounting table and activated carbon to enter the lower portion of the drying bin, is conveyed back into an air box again by a conveying pump, is heated by a secondary heating wire and then is blown out through an axial flow fan again, the hot air is recycled, waste heat of the hot air is fully utilized, energy waste is reduced, energy consumption is reduced, and more energy conservation and environmental protection are achieved.

Owner:武汉商贸职业学院

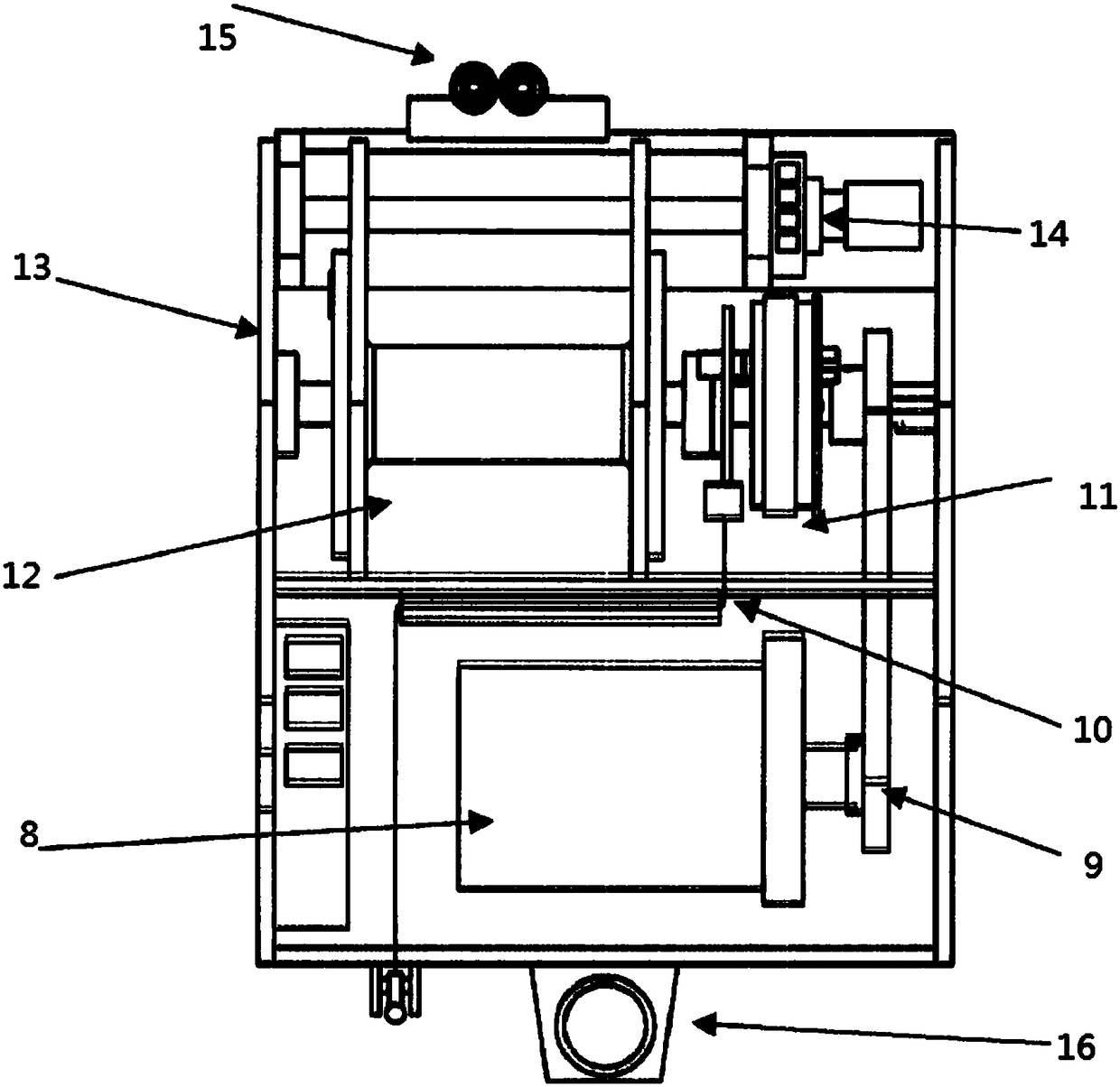

A weighing device for logistics sorting with uninterrupted transportation

ActiveCN111359904BEasy to sortHigh precisionSortingSpecial purpose weighing apparatusLogistics managementStructural engineering

Owner:芜湖同泰智能物流园有限公司

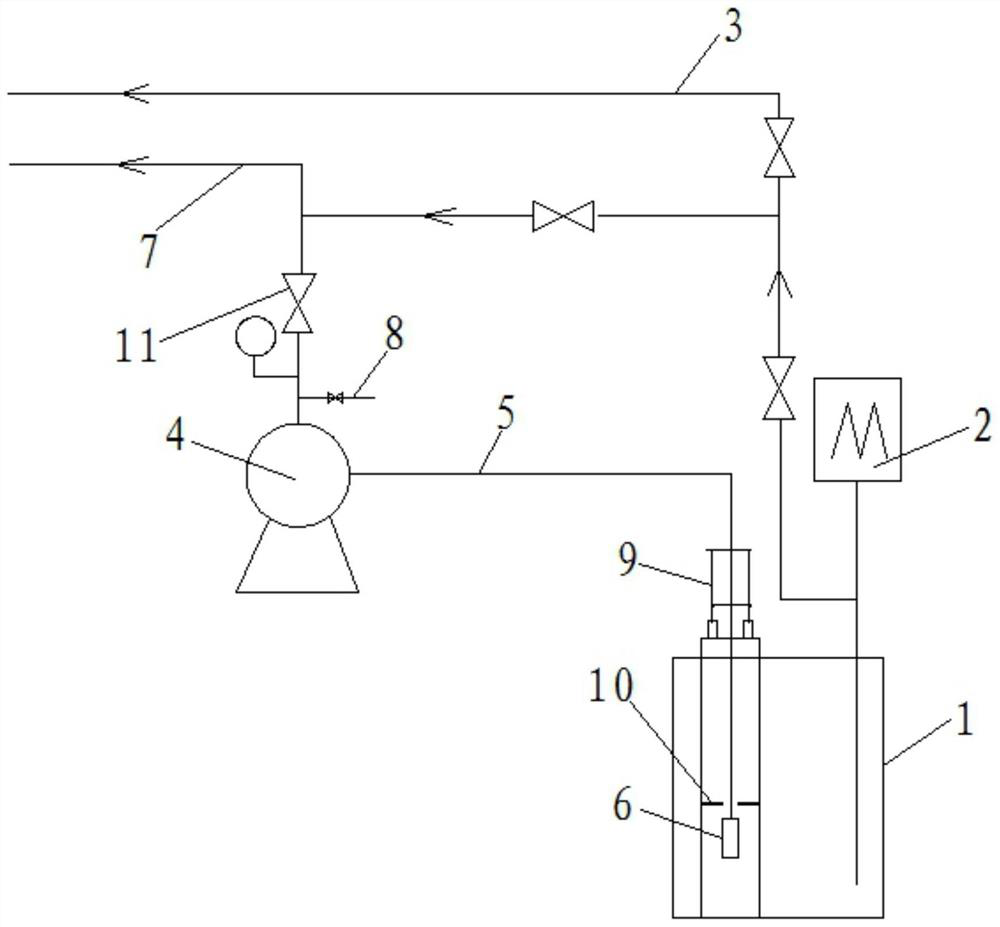

A self-priming device for waste liquid transportation and its realization method

ActiveCN111828334BBurn out preventionReduce maintenance workloadPump componentsPriming pumpExhaust valveEnvironmental engineering

The invention discloses a self-priming device for transporting waste liquid and its realization method, which comprises: a waste liquid collection tank for collecting waste liquid; a submerged pump whose inlet extends into the waste liquid collection tank, and The outlet of the pump is connected with the first infusion pipe; the inlet of the self-priming pump is connected with one end of the liquid inlet pipe, and the other end of the liquid inlet pipe extends vertically downward into the waste liquid collection tank, and the other end of the liquid inlet pipe One end is provided with a liquid suction head; the outlet of the self-priming pump is respectively connected with the second infusion pipe and the outlet of the submerged pump, and the self-priming pump is provided with an exhaust valve; the height adjustment mechanism is arranged in the waste liquid collection tank In the middle, the height adjustment mechanism is connected with the liquid inlet pipe, and is used to adjust the height of the liquid suction head in the waste liquid collection tank; the scrubbing unit is arranged on the height adjustment mechanism, and the scrubbing unit is used to scrub the liquid suction head. The invention reduces the overall maintenance workload and manpower input, and is applicable to the transportation of various waste liquids and different liquid level requirements.

Owner:INNER MONGOLIA HENGKUN CHEM CO LTD

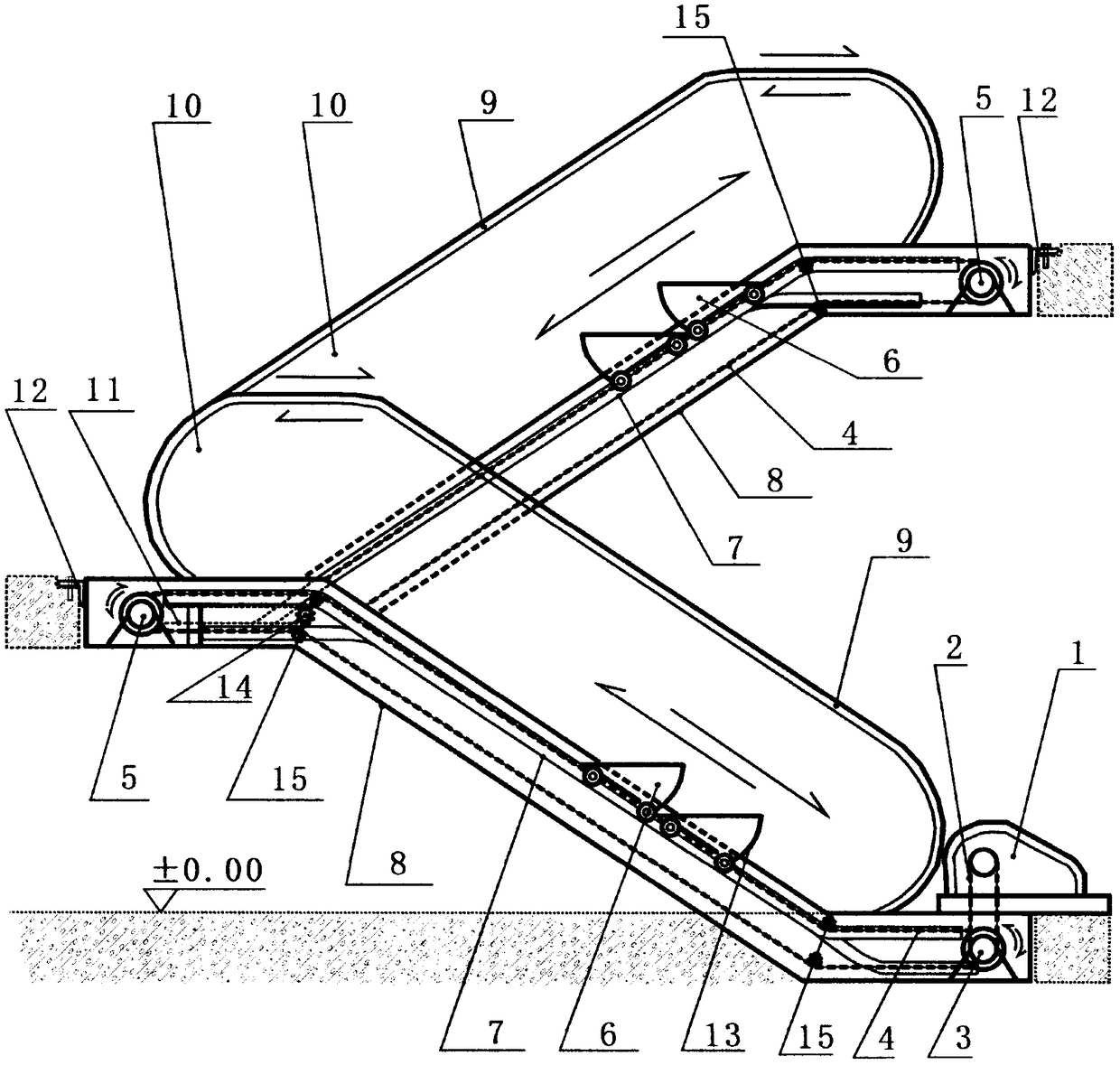

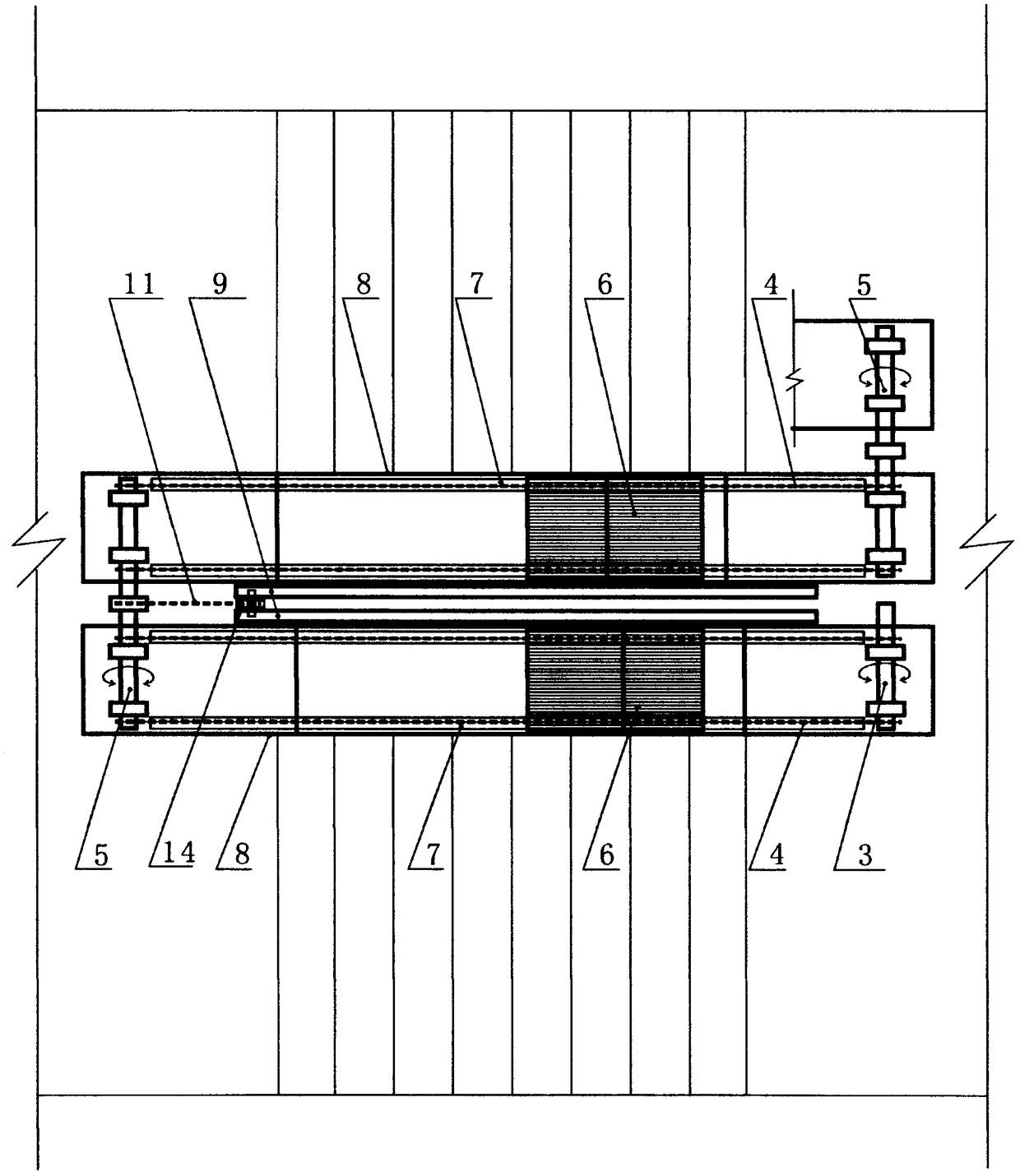

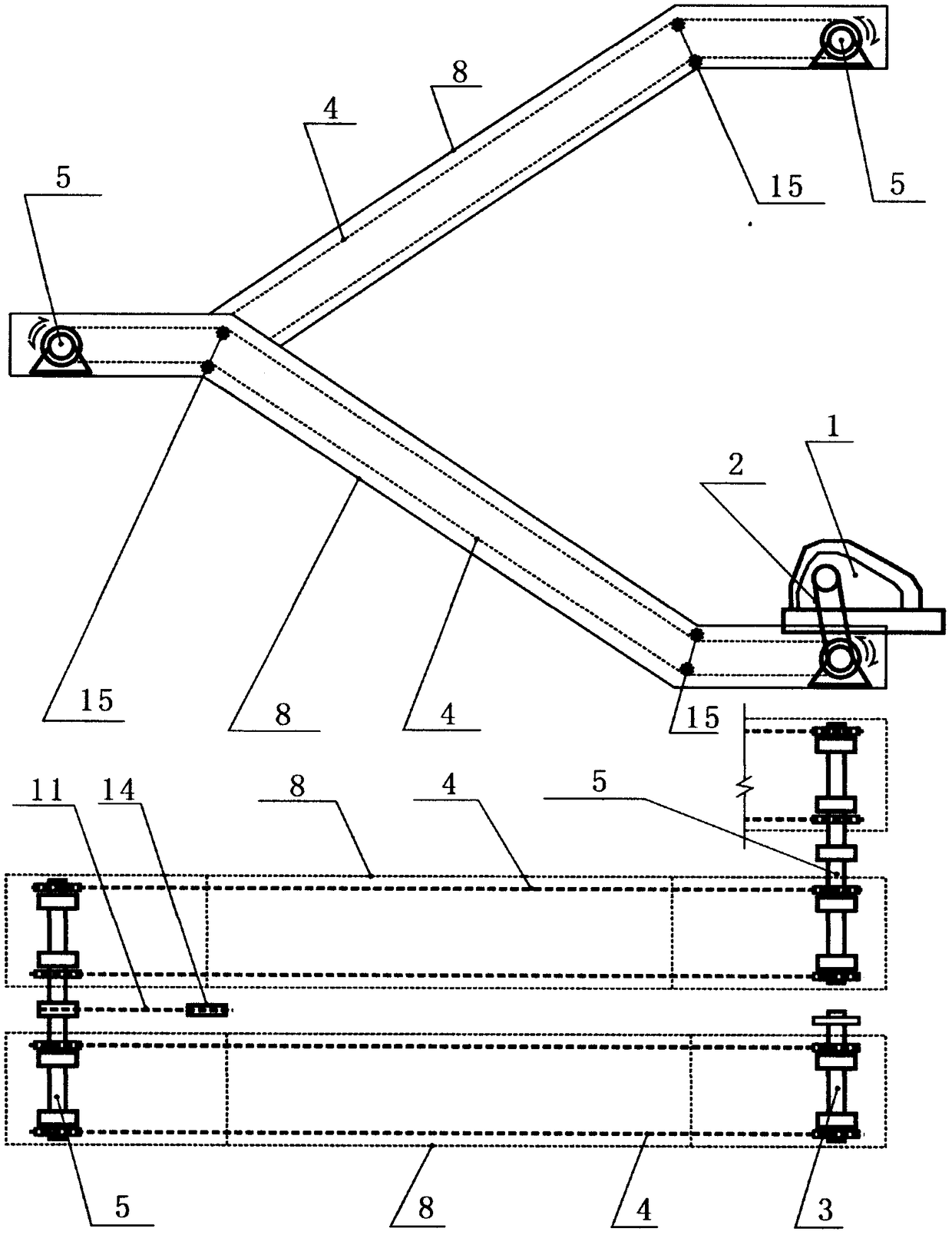

Corridor escalator

The invention discloses a corridor escalator. The corridor escalator comprises a closed truss box erected in a reserved spatial position at the inner side of the corridor, a moveable tread reciprocated upwards and downwards and an external hand strap. A power transmission shaft, a power transmission chain and a travelling trail are installed in the closed truss box. The power transmission shaft isinstalled at the upper and lower horizontal sections of the box. Power is obtained from a driving main machine by the first section of an active force shaft of the first group of the box, and the common transmission shaft in two groups of the neighboring horizontal section boxes in the previous level is driven by the transmission chain. One group of the moveable treads (two or three treads are installed according to the actual use condition) is borne by the travelling rail in each closed box, and the moveable treads are upwards and downwards moved into the horizontal section of the boxes under the traction of the chain, reach the flat layer simultaneously with the neighboring group of the moveable treads, and are moved to an opposite direction, so the purpose of walking up and down stairsby carrying persons is achieved. The corridor escalator is high in operating efficiency, safe and reliable, is directly erected and installed at the inner side of the corridor, and is capable of solving a problem that small high-rise building residents walk up and down the stairs.

Owner:韦连文

Belt type sludge drying machine with active ventilation function

PendingCN114735912AReduce lossExtended service lifeSludge treatment by de-watering/drying/thickeningEnergy based wastewater treatmentElectric machineryDrive motor

The invention provides a belt type sludge drying machine with an active ventilation function, which comprises a main body, a conveying assembly is arranged in the main body, a ventilation device is arranged on the upper side of the main body, and the ventilation device comprises a ventilation assembly, a dustproof assembly and a uniform dispersion device. The ventilation assembly comprises a mounting frame, a mounting rack, a driving motor and a ventilation fan; the outer side wall of the mounting frame is fixedly connected with the inner wall of a ventilation device, and a mounting frame is fixedly mounted on the inner side wall of the mounting frame. According to the belt type sludge drying machine with the active ventilation function, by arranging the uniform dispersion device and a buffer air cushion, pressure borne by a dispersion connecting plate can be effectively avoided and effectively relieved, loss of the dispersion connecting plate is reduced, the service life of the dispersion connecting plate is prolonged, meanwhile, stirring of sludge can be achieved through a uniform dispersion mechanism, and the drying efficiency is improved. Sludge on the conveying belt is more uniformly and quickly ventilated, so that the sludge is quickly dehydrated and air-dried, and the drying efficiency and the energy utilization rate are improved.

Owner:南通爱可普环保设备有限公司

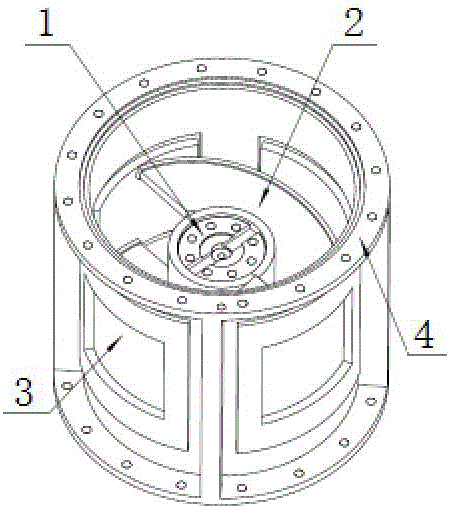

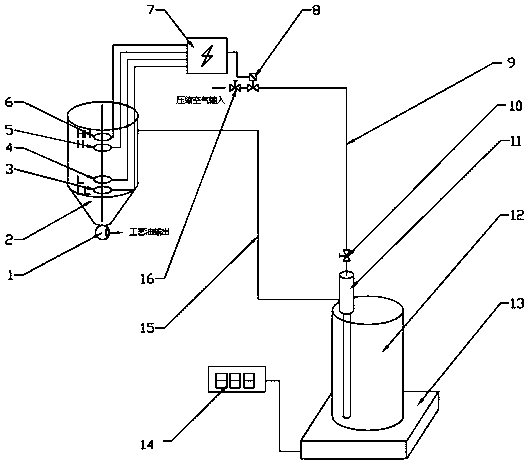

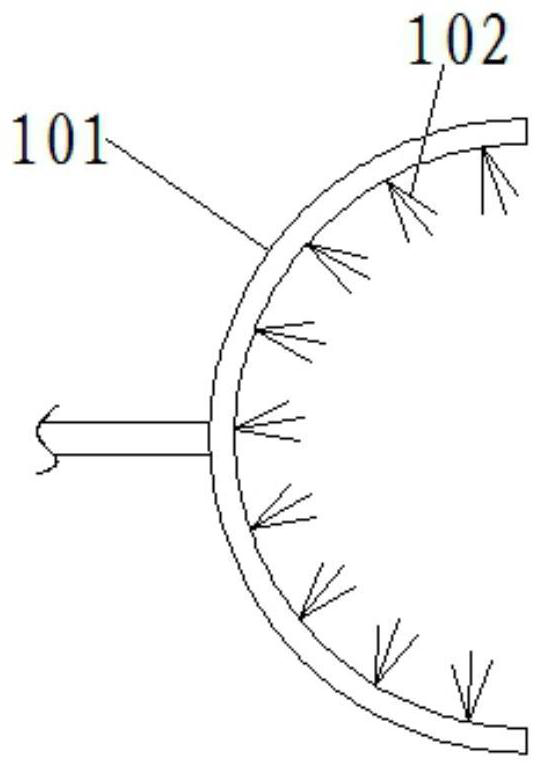

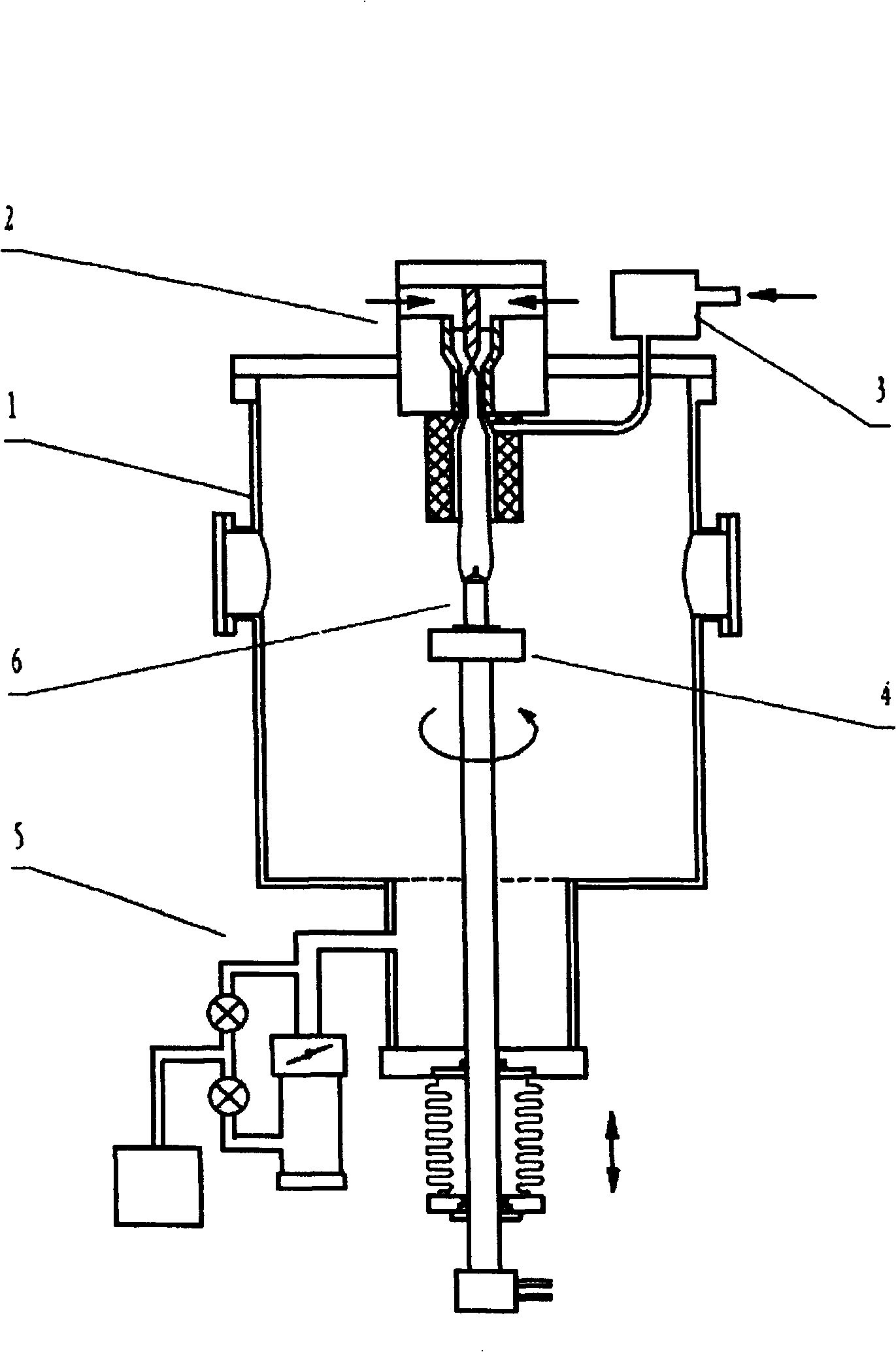

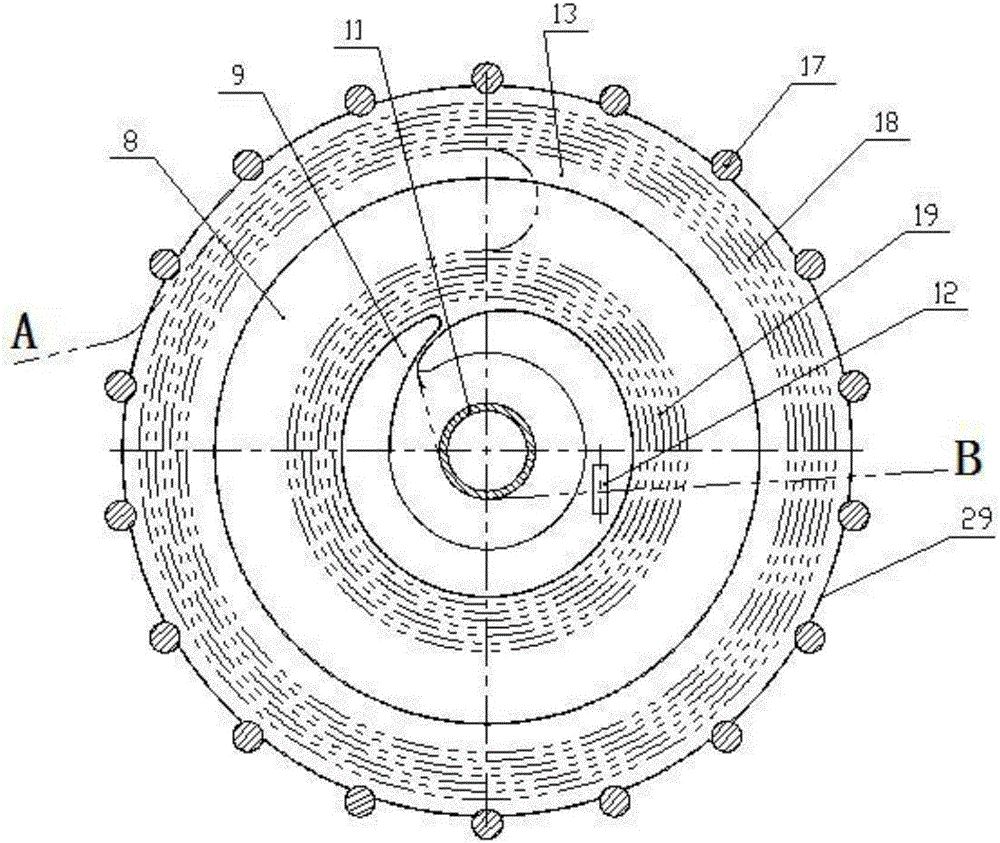

Method for developing aluminum nitride crystal in large size through flow of plasma flame

InactiveCN100434573CControlling the Crystal Growth RateUninterrupted deliveryPolycrystalline material growthFrom chemically reactive gasesNitrogen gasPlasma flow

This invention discloses a method for growing AlN single crystal by heating raw materials with plasma flow. The method comprises: utilizing plasma flow as the heating source, and AlN micropowder or high-purity Al micropowder and N2 as the raw materials, sending the raw materials into plasma flow by using carrier gas, utilizing AlN single crystal as the crystal seed or AlN polycrystal as the matrix material for self-nucleating growth, heating the crystal seed or matrix material by plasma flow or other methods to the temperature need for crystallization, and growing in the growth chamber with N2 as the growth environmental gas. The powder delivery rate is adjustable. The stage for supporting the crystal seed or matrix material can be elevated and rotated with controllable speed. The pressure of N2 is adjustable. This invention also shows the figure for depicting the reaction apparatus for growing AlN single crystal by heating raw materials with plasma flow.

Owner:SHENZHEN UNIV

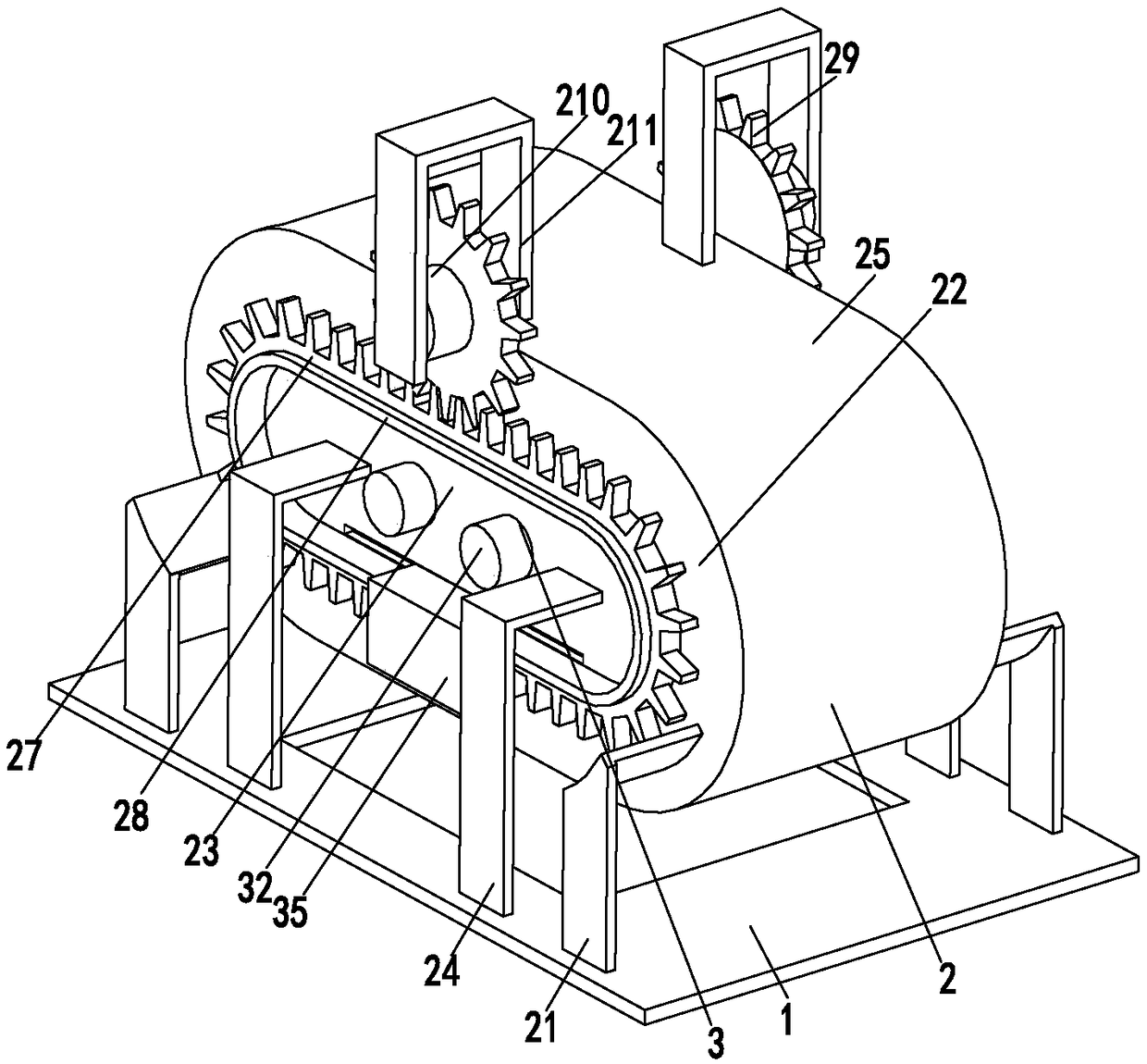

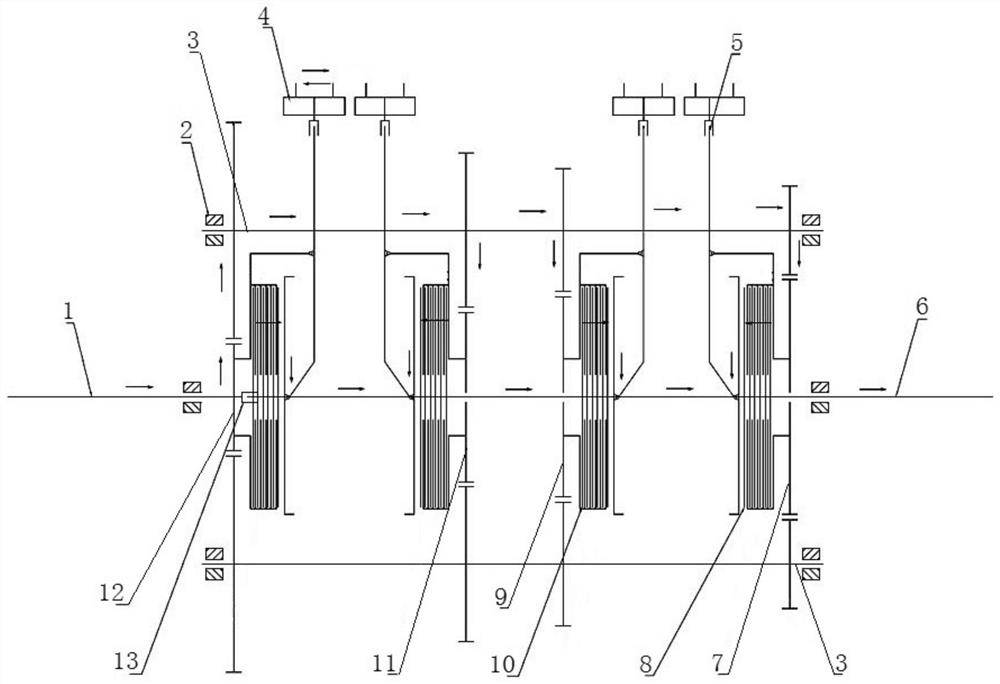

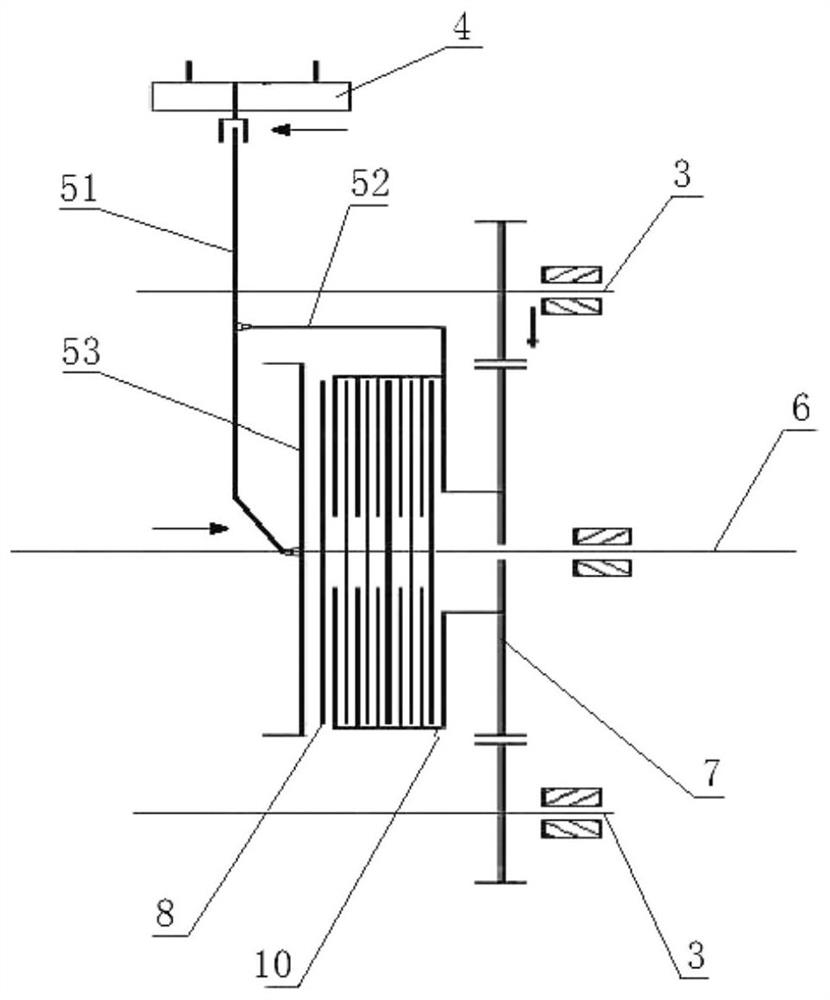

Concrete pouring pumping equipment for geotechnical engineering

ActiveCN110847179BEasy to control the gapEasy to control the size of the gapSievingMixing operation control apparatusDrive shaftGear wheel

The invention discloses a concrete pouring pumping equipment for geotechnical engineering, relates to the technical field of geotechnical engineering, specifically a concrete pouring pumping equipment for geotechnical engineering, comprising a body, the top of which is hinged with a sieve plate, The bottom of the sieve plate is provided with a cross bar, and the cross bar is fixedly connected to the right inner wall of the body, and the right side of the top of the sieve plate is provided with an adjustment knob. The concrete pouring pumping equipment for geotechnical engineering, the bevel gear is driven to rotate by rotating the adjustment knob, and then the bevel gear drives the driving shaft to rotate, and the driving shaft uses the transmission chain to drive the driven shaft to rotate, so that the screen is tilted and the screen is conveniently controlled The size of the gap between them is convenient for screening stones of different diameters, removing large stones in the concrete, preventing larger stones from entering the interior of the concrete pumping equipment and causing blockage of the delivery pipeline, and protecting the device. safety and proper use of the pumping device.

Owner:郑炎昊

A lead belt storage and discharge device

Owner:CECEP ENVIRONMENTAL PROTECTION EQUIP CO LTD

A method for loading and unloading on the same side and an automatic loading and unloading mechanism for realizing the method

ActiveCN103606592BUninterrupted deliveryImprove work efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringManipulator

The invention discloses a same-side material loading and blanking method and an automatic material loading and blanking mechanism for realizing the above method. A rack, a material stacking mechanism and a blanking mechanism are comprised. A falling-off-type material loading mode is realized through the cooperation of a material distributing thimble and related mechanisms, and accordingly following beneficial effects are obtained: 1, the falling-off-type material loading mode is adopted, and material loading steps can be rapidly carried out; and intelligent automation can be realized, and processing materials can be conveyed continuously, so that the working efficiency of a machinery is raised; 2, through novel structures of a material feeding mechanism and the blanking mechanism, a function of same-side material loading and blanking can be realized, so that connection between the material loading and the blanking is more compact, and synchronization of the material loading and the blanking is realized; the efficiency and the automation degree are high; the same-side material loading can be realized, and a lot of machinery disposing space can be saved, so that the utilization rate of places is better improved; and 3, modes of material loading by manipulators are replaced, so that complex control of the manipulators is avoided. The same-side material loading and blanking method and the automatic material loading and blanking mechanism for realizing the above method are simple in structure, convenient to operate, and the same-side material loading and blanking method and the automatic material loading and blanking mechanism for realizing the above method substantially reduce costs.

Owner:GKG PRECISION MACHINE

A hydraulic device for automatically fetching and delivering water and its application method

ActiveCN110686163BRealize continuous conversion functionUninterrupted deliveryWatering devicesPipeline systemsHydraulic pumpMechanical energy

The invention discloses a hydraulic device for automatically fetching and delivering water and a method for using the same. ; or include waterwheels, double-leg dams, dam piers, waterwheel main shafts, embedded bearings, water intake pipes, main shaft struts, movable connecting rods, pistons, piston cylinders, and water delivery pipes. The present invention uses double-legged dams to block the water level in the torrent section, converts the potential energy of the water flow into the mechanical energy of the waterwheel, and the waterwheel drives the hydraulic pump or the piston cylinder to automatically fetch and deliver water. The hydraulic device is detachable and maintainable, practical, economical and convenient. No pollution; this method of use can adjust the water intake flow rate and head height, adapt to different water intake and delivery requirements, can supply water continuously, and can also store the water supply for centralized use.

Owner:江西省水利厅工程建设稽察事务中心

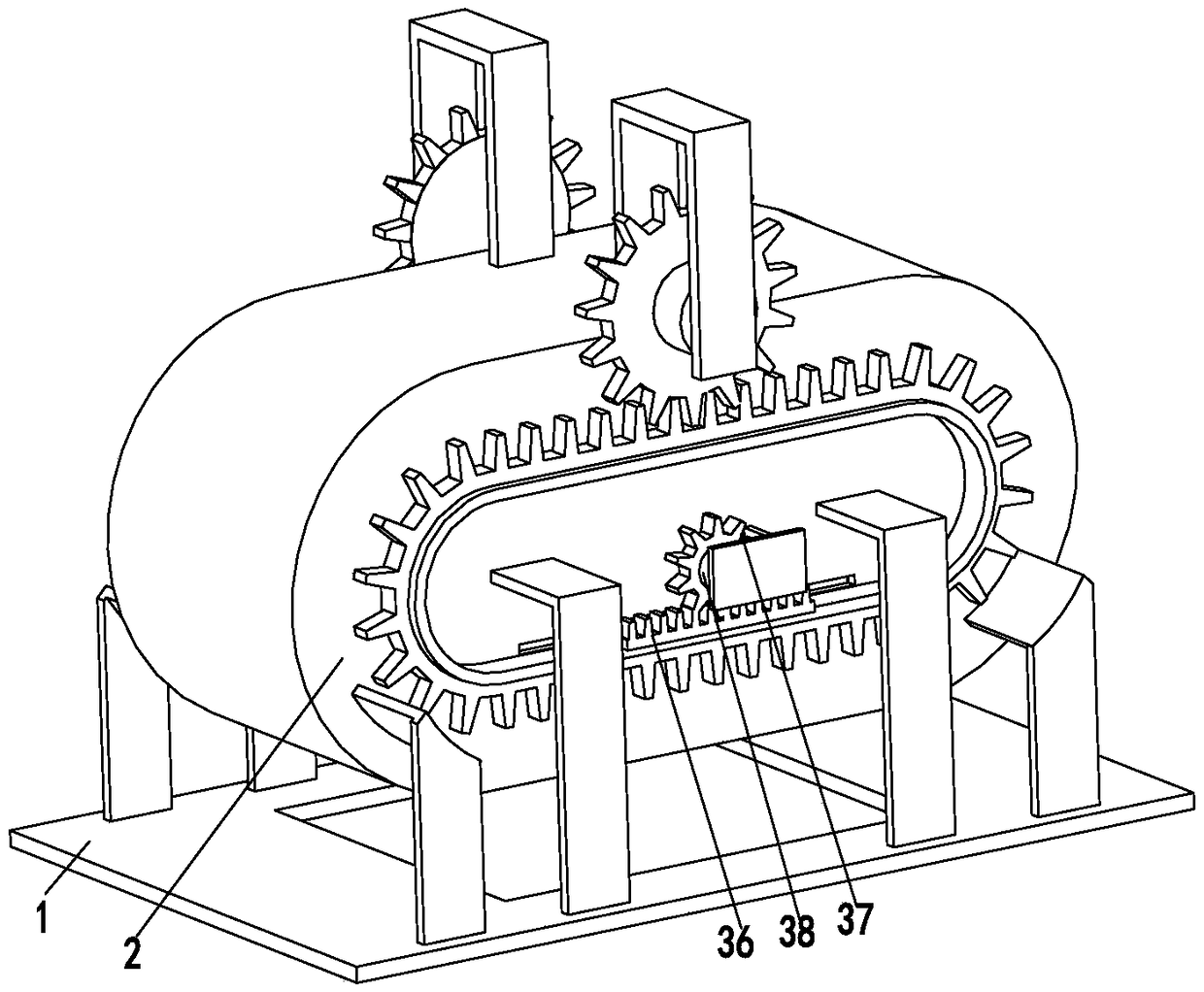

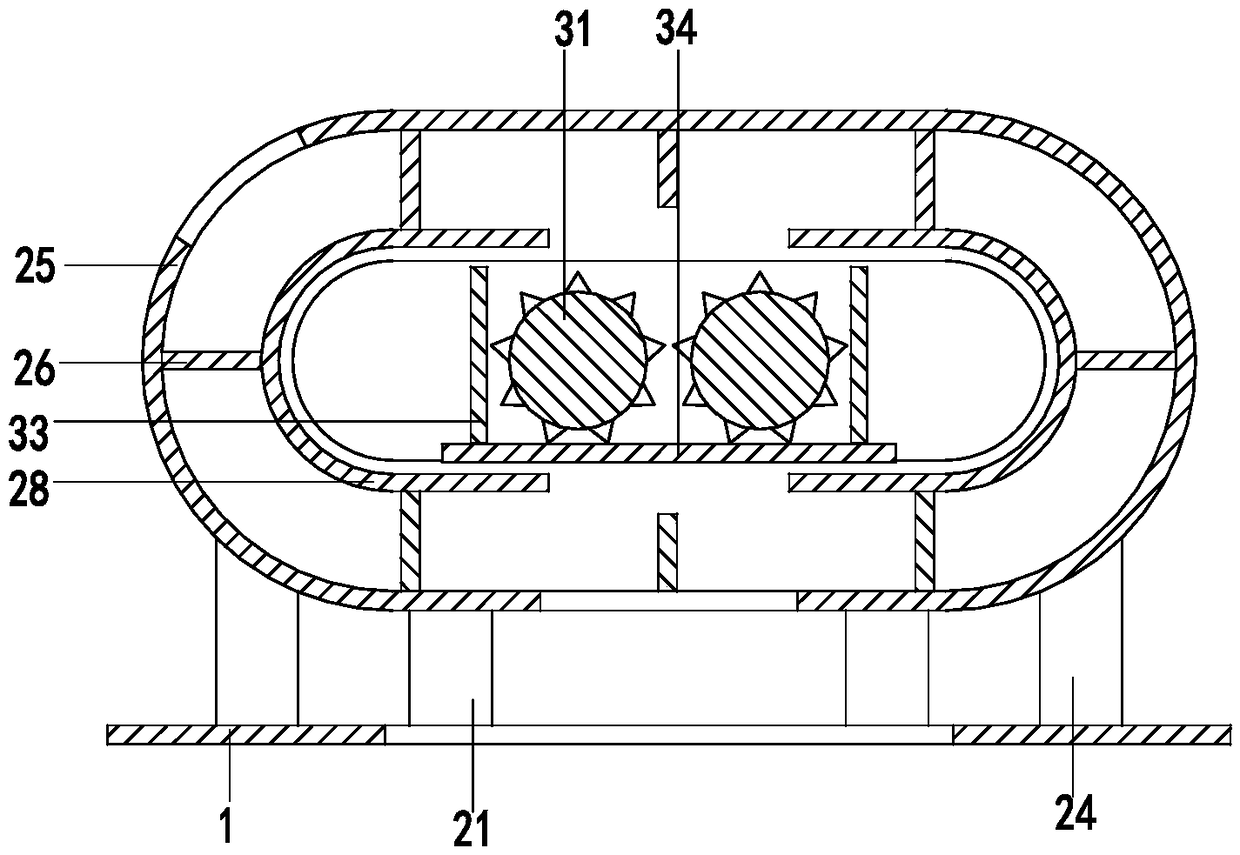

Regenerated rubber production automatic rubber crushing machine

InactiveCN109397577ARealize the function of automatic crushingSmash in timePlastic recyclingMechanical material recoveryFixed frameElectric machinery

The invention relates to a regenerated rubber production automatic rubber crushing machine. The regenerated rubber production automatic rubber crushing machine comprises a bottom plate, a conveying mechanism and a crushing mechanism, wherein the bottom plate is provided with the conveying mechanism, and the crushing mechanism is arranged inside the conveying mechanism; the middle of the bottom plate is provided with a square opening; the conveying mechanism comprises a first fixing frame, a first baffle, a second baffle, a second fixing frame, a connecting rack, a separating plate, a conveyingbelt, a support frame, a conveying gear, a conveying motor and a mounting frame; the crushing mechanism comprises a crushing roller, a crushing motor, a protective plate, a screen plate, a support plate, a rack, a driving gear and a driving motor. The regenerated rubber production automatic rubber crushing machine can solve the problems of incomplete crushing, poor working continuity, material accumulation and waste and the like during regenerated rubber production automatic rubber crushing processes, achieve a rubber automatically crushing function and have the advantages of being thorough in crushing, good in working continuity, less prone to material accumulation and waste and the like.

Owner:西安科技成果转化工程有限公司

Gearbox with uninterrupted shifting torque and shifting method

ActiveCN112096802BGuaranteed continuous outputSmooth shiftingFluid actuated clutchesToothed gearingsGear wheelClassical mechanics

Owner:SHAANXI FAST GEAR CO

A continuous receiving device

ActiveCN107472588BIncreased load-bearing capacityImprove stabilityPackagingMotor driveElectric machine

The invention discloses a continuous undertaking device which comprises a taking and placing mechanism, an undertaking mechanism and a cigarette bar pushing mechanism. The undertaking mechanism comprises a support, temporary storage plates symmetrically installed on the support, an air cylinder located at the bottom of the support and pushing the temporary storage plates to move, a supporting plate arranged between the temporary storage plates, a supporting frame located at the bottom of the supporting plate, a guide rail, a sliding block and a motor, wherein the sliding block is arranged on the side edge of the supporting frame, the guide rail is perpendicularly arranged on the support and located at the bottom of the support, the sliding block is installed in the guide rail, and the motor drives the sliding block to move. The way that cigarette bars are alternately stacked to the temporary storage plates and the supporting plate is adopted, continuous stacking of the cigarette bars is achieved, conveying is uninterrupted, the time period of stacking and conveying cigarette bars into a box sealing unit is greatly shortened, the stacking and box sealing efficiency is effectively improved, and the whole bearing capacity and stability of the undertaking device are greatly improved since the triangular supporting frame is designed at the bottom of the supporting plate.

Owner:TIANHAI OUKANG TECH INFORMATION XIAMEN

Powder material plasma sterilizer

ActiveCN104800870BRealize separation and sterilizationImprove liquidityLavatory sanitoryDisinfectionGuide tubeFlow divider

A powder material plasma sterilizer comprises a machine case, a feeding vibrating bed and a discharging vibrating bed are arranged in the machine case, a sterilizing cavity is formed between the feeding vibrating bed and the discharging vibrating bed, a plasma generating device is arranged in the sterilizing cavity, the plasma generating device comprises a positive electrode plate and a negative electrode plate which are symmetrically arranged in an up-down mode, a plurality of micro pipes are arranged in the sterilizing cavity between the positive electrode plate and the negative electrode plate, feeding ports of the micro pipes are connected with a discharging port of the feeding vibrating bed through a flow divider, discharging ports of the micro pipes are connected with the discharging vibrating bed, feeding electromagnetic clamping valves are arranged on the micro pipes close to the feeding ports, and discharging electromagnetic clamping valves are arranged on the micro pipes close to the discharging ports. By means of the plasma generating device, normal-temperature sterilization of powder materials is achieved. By means of the micro pipes, separated sterilization is achieved, and good sterilizing effects are guaranteed. Due to the feeding vibrating bed and the discharging vibrating bed, powder materials can flow and be conveyed. Due to the discharging electromagnetic clamping valves, the sealing performance is achieved.

Owner:LIANYUNGANG YOUYUAN MEDICAL EQUIP MFG

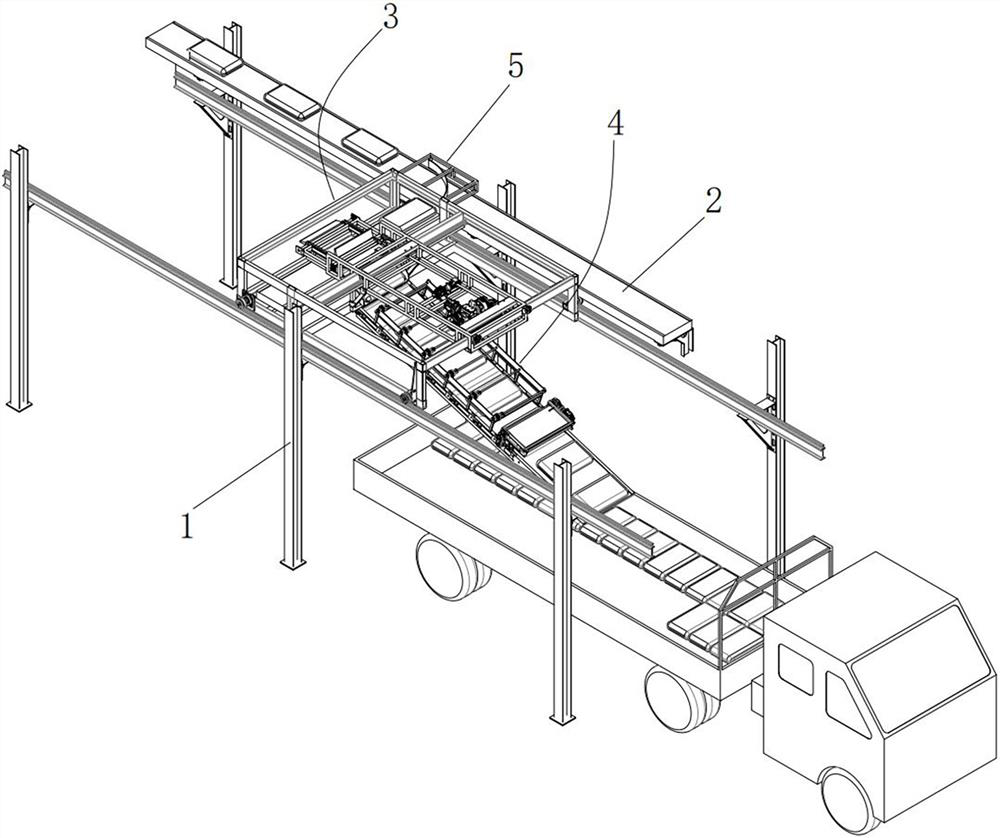

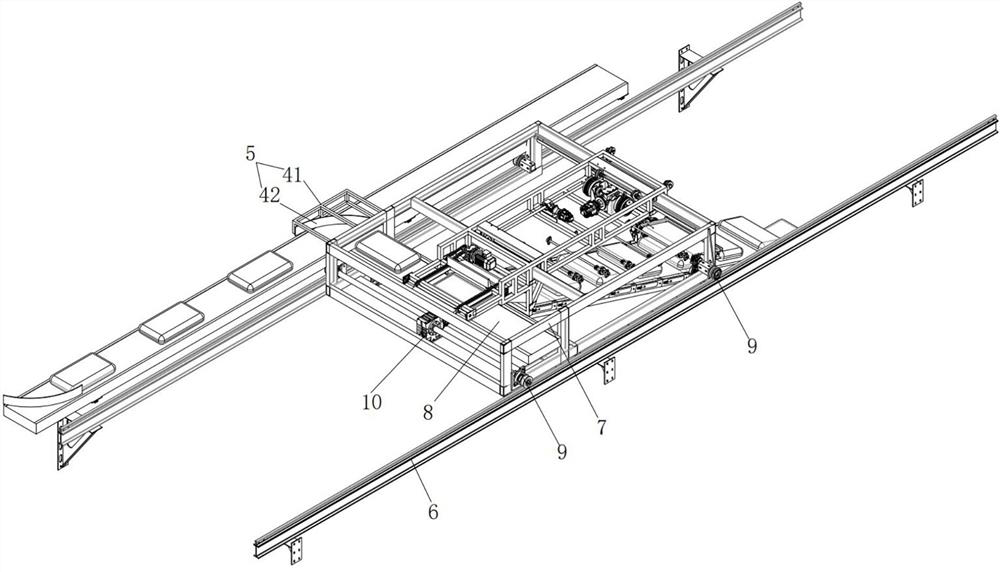

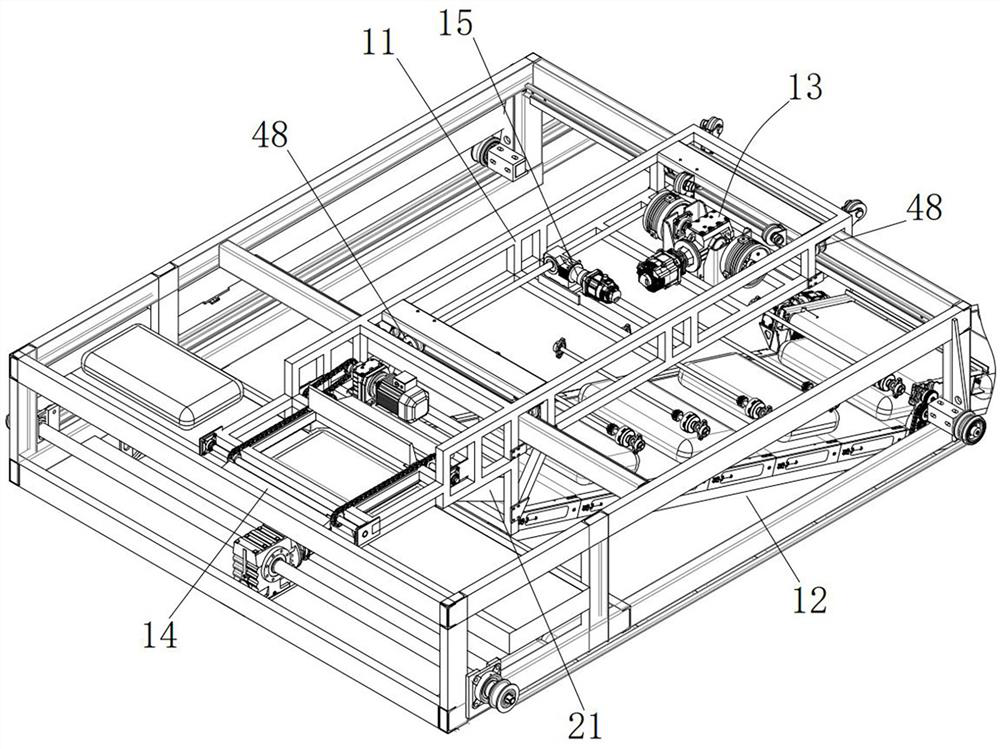

A truss-type unattended five-axis delivery robot

ActiveCN113306988BRealize layer-by-layer stackingScheduled deliveryConveyorsStacking articlesControl engineeringTruck

The invention relates to the technical field of material transportation, and discloses a truss-type unattended five-axis delivery robot, which includes a main frame, a main conveyor installed on one side of the main frame, and a transfer conveyor installed on the main frame. The bottom end of the transfer conveyor is equipped with a code conveyor. The main conveyor is connected to the transfer conveyor through the steering mechanism, and the transfer conveyor is connected to the code conveyor. The code conveyor performs automatic loading and stacking of the materials. , the material on the main conveyor is transferred to the transfer conveyor through the steering mechanism. The invention does not require manual cooperation, saves labor costs, reduces costs, has a high degree of automation, and improves the loading efficiency; the car stops at the main frame for installation Loading can be realized at any position below, with high flexibility and improved practicability; it can accurately send out materials at a time without stopping or other operations, making the transportation uninterrupted, improving the conveying efficiency, and ensuring the loading efficiency.

Owner:山东加法智能科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com