Conveying roll with wire separation function

A conveying roller and function technology, which is applied in the field of plastic processing and conveying, can solve the problems of conveying roller failure and the inability of weaving yarn to be cleaned in time, so as to achieve the effect of preventing failure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

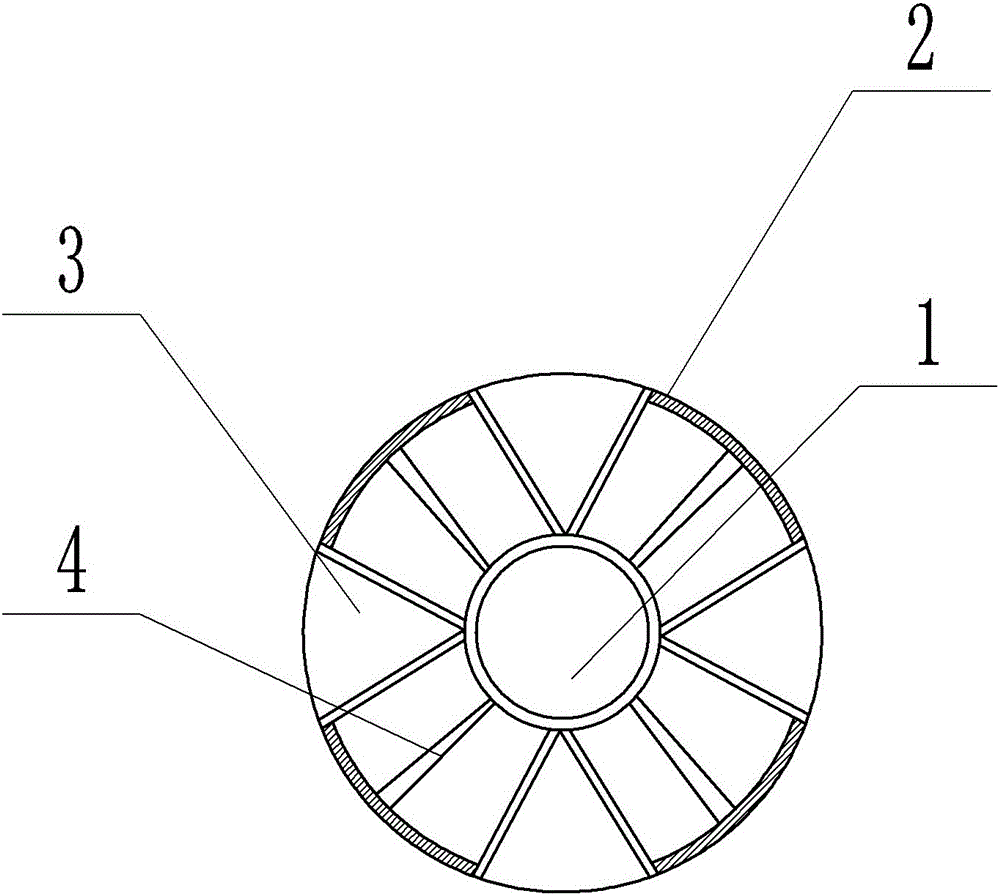

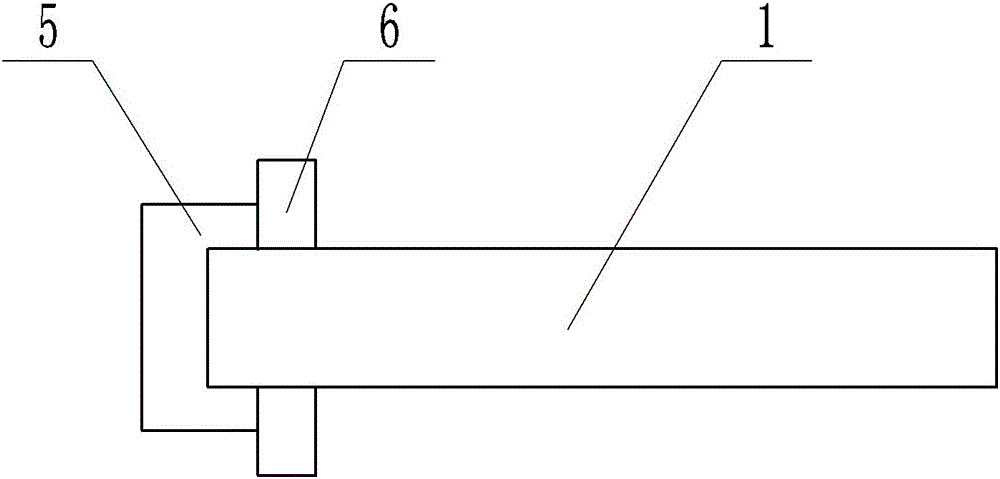

[0019] Example 1 as figure 1 Shown: a conveying roller with defiling function, including a conveying roller body, the conveying roller body includes an inner roller 1 and an outer roller 2, the outer roller 2 is arranged outside the inner roller 1, and a roller is arranged between the outer roller 2 and the inner roller 1 There are support rods 4, the outer roller 2 is provided with a gap, and the gap is provided with a fan-shaped air bag 3, the air bag 3 is installed on the inner roller 1, the arc edge of the air bag 3 is flush with the outer surface of the outer roller 2, and the inner roller 1 shaft There is a groove in the direction, and one end of the groove is connected to the outside, such as figure 2 As shown, the end of the inner roller 1 communicating with the outside is dynamically connected with an air pump 5 , and the inner roller 1 and the air pump 5 are sealed by a rotary dynamic sealing ring 6 .

[0020] When the woven bag is transferred from the forming mach...

Embodiment 2

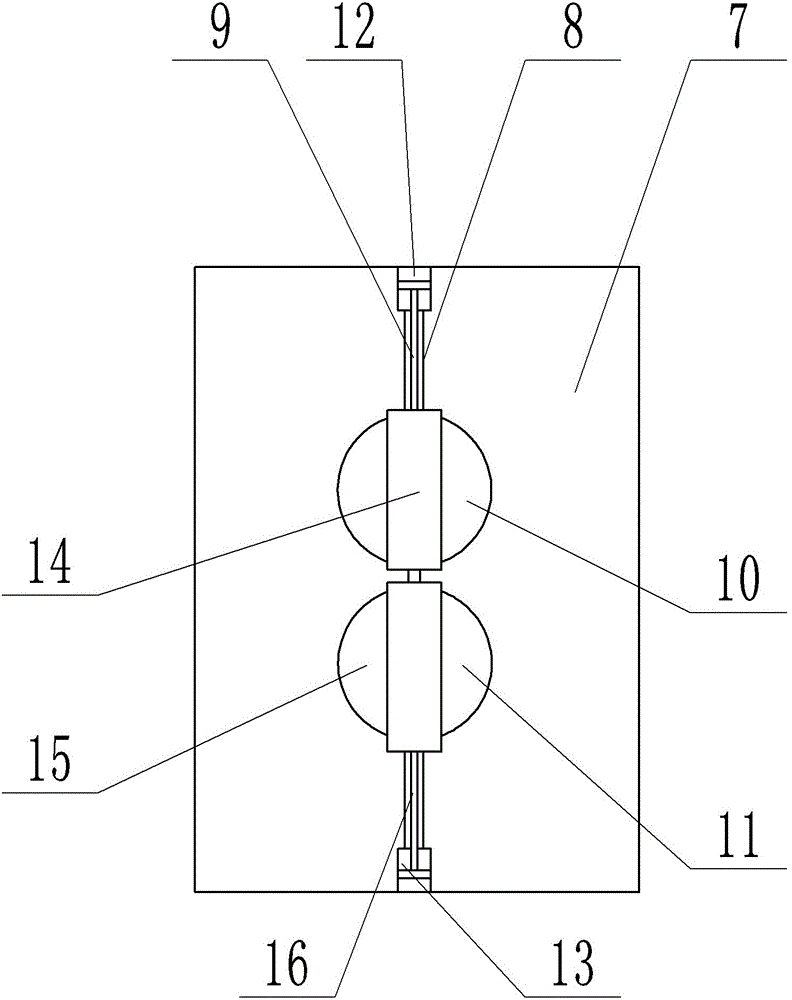

[0022] Such as image 3 As shown, the difference with Embodiment 1 is only that it includes a frame 7, the top of the frame 7 is connected with the first hydraulic cylinder 12 through the first piston rod 9, and the bottom of the frame 7 is connected with the second piston rod 16 through the second piston rod. Two hydraulic cylinders 13, a guide rail 8 is vertically arranged in the middle of the frame 7, a first base 14 and a second base 15 are slidably connected to the guide rail 8, and two conveying rollers are also included, namely an upper pressing roller 10 and a lower pressing roller 11 , the upper pressing roller is fixedly connected to the first base 14 , and the lower pressing roller 11 is fixedly connected to the second base 15 .

[0023] Changing the pressure of the hydraulic cylinder can make the upper pressure roller 10 and the lower pressure roller 11 slide up and down. When cleaning the braided yarn on the upper pressure roller 10, move the lower pressure roller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com