Sealed vibration screen for pipe chain chip removal

A vibrating screen and pipe chain technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of poor sealing performance of screw conveyors, large space occupied by the mechanism, easy leakage of hydrogen sulfide gas, etc., and achieve good sealing performance. , to ensure the effect of safe, safe and reliable transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings. The schematic embodiments of the present invention and their descriptions are only used to explain the present invention, and are not intended as an explanation of the present invention. limited.

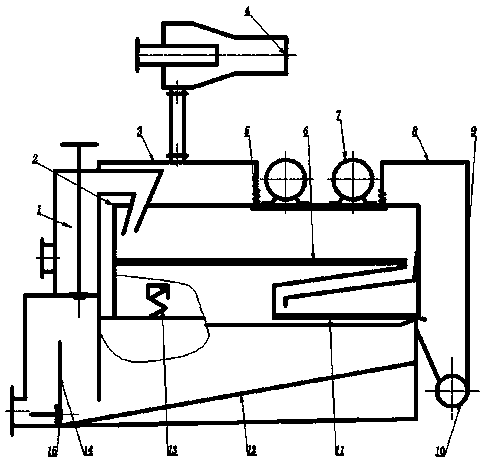

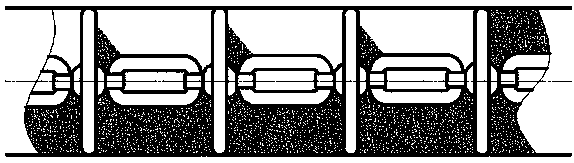

[0020] Such as figure 1 , figure 2 As shown, a closed type vibrating screen for pipe chain chip removal in the present invention mainly includes two parts: a vibrating screen and an airtight device. Net 11, base 12 and damping spring 13; the sealing device consists of a sealing cover 3 on the feed end, a jet pump 4, an elastic sealing device 5, a sealing cover 8 on the discharge end, an outlet sealing cover 9, and a pipe chain chip removal device 10. It consists of a liquid seal baffle 14 and an underflow vent valve 15.

[0021] The buffer tank 1 is located at the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com