Lubricating oil automatic adding device of rotor sealing end of internal mixer

A technology of rotor sealing and automatic addition, which is applied in the direction of engine lubrication, lubricating parts, mechanical equipment, etc., to reduce labor intensity, avoid seal ring wear or scrapping, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

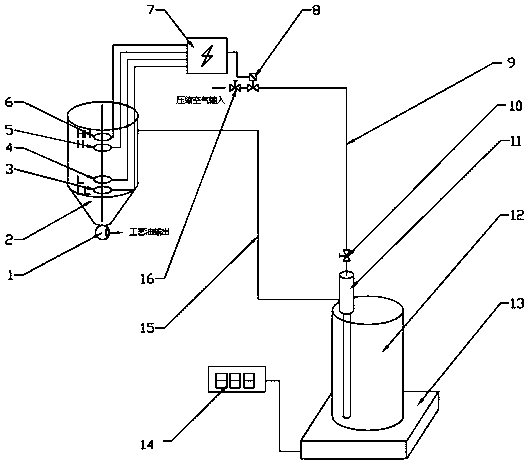

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0015] see figure 1 , the embodiment of the present invention includes:

[0016] A device for automatically adding lubricating oil to the sealed end of the rotor of an internal mixer, comprising: a standard oil barrel 12, a pneumatic pump 11, a process oil reserve tank 2, an output oil pump 1, material level sensors 3-6, a solenoid valve 8 and a PLC controller 7. The air pump 11 is installed on the standard oil drum 12, the air inlet of the air pump 11 is connected to the external compressed air input port through the air control pipeline 9, and the high pressure oil outlet of the air pump 11 is connected through the The oil pipeline 15 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com