Concrete pouring pumping equipment for geotechnical engineering

A technology of geotechnical engineering and pumping equipment, applied in the field of geotechnical engineering, can solve the problems such as the inability to adjust the gap of the screen plate, the inability to continue the conveying of concrete, and the influence of the continuous construction of the building, so as to ensure smooth flow, avoid blockage, and protect normal use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

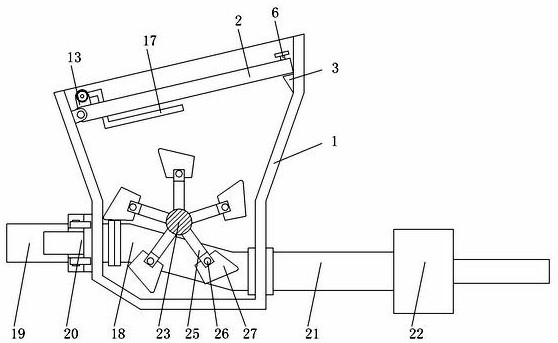

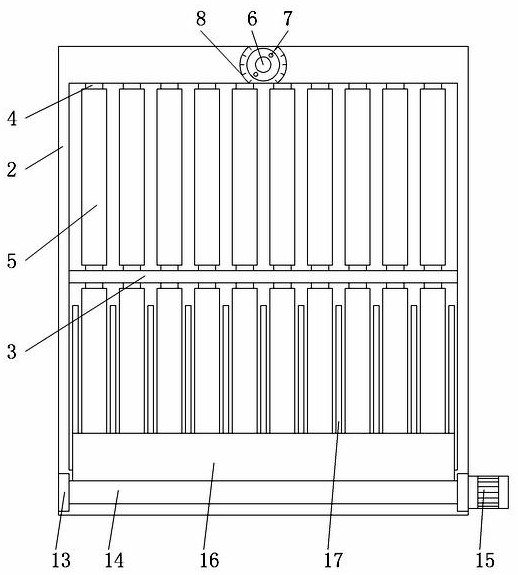

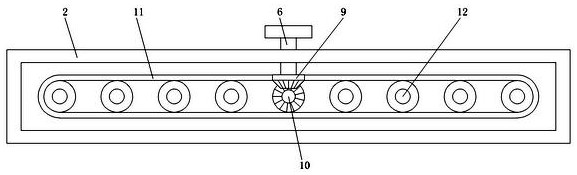

[0022] see Figure 1 to Figure 4 As shown, a concrete pouring pumping equipment for geotechnical engineering includes a body 1, a sieve plate 2 is hinged on the top of the body 1, and a cross bar 3 is arranged at the bottom of the sieve plate 2, and the cross bar 3 is fixedly connected to the right side of the body 1. On the side inner wall, the right side of the top of the sieve plate 2 is provided with an adjustment knob 6, the left side of the top of the sieve plate 2 is fixedly connected with a support plate 13, the inside of the body 1 is provided with an S tube 18, and the left side of the S tube 18 is movably connected with a The discharge pipe 19 is provided with a fixed buckle 20 on the outside of the discharge pipe 19, the right side of the S pipe 18 is movably connected with a delivery cylinder 21, and the right side of the delivery cylinder 21 is fixedly connected with a drive valve 22, and the inside of the body 1 is movably socketed with a center The shaft 23, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com