Patents

Literature

58results about How to "Easy and fast loading" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Pre-stretched wrapping film roll with entrapped air and method

InactiveUS20060243842A1Easy and fast loadingLayered productsFunction indicatorsLinear low-density polyethyleneAir entrainment

A pre-stretched film roll of a mono orientated linear low density polyethylene (LLDPE) is stretched between 30% and 320% depending on the final product that is required. Stretching is in the machine direction (MD) at a controlled rate in two stages. Differentially rewinding the film entraps air between the layers of the roll and creates soft overlapping edges around the roll to produce a spongy, “soft” roll that prevents and resists drop damage due to its shock absorbent characteristic.

Owner:MARTIN GUILLERMO DURAN ESPINOZA & ANGEL GERARDO SANTILLAN DIAZ DE LEON

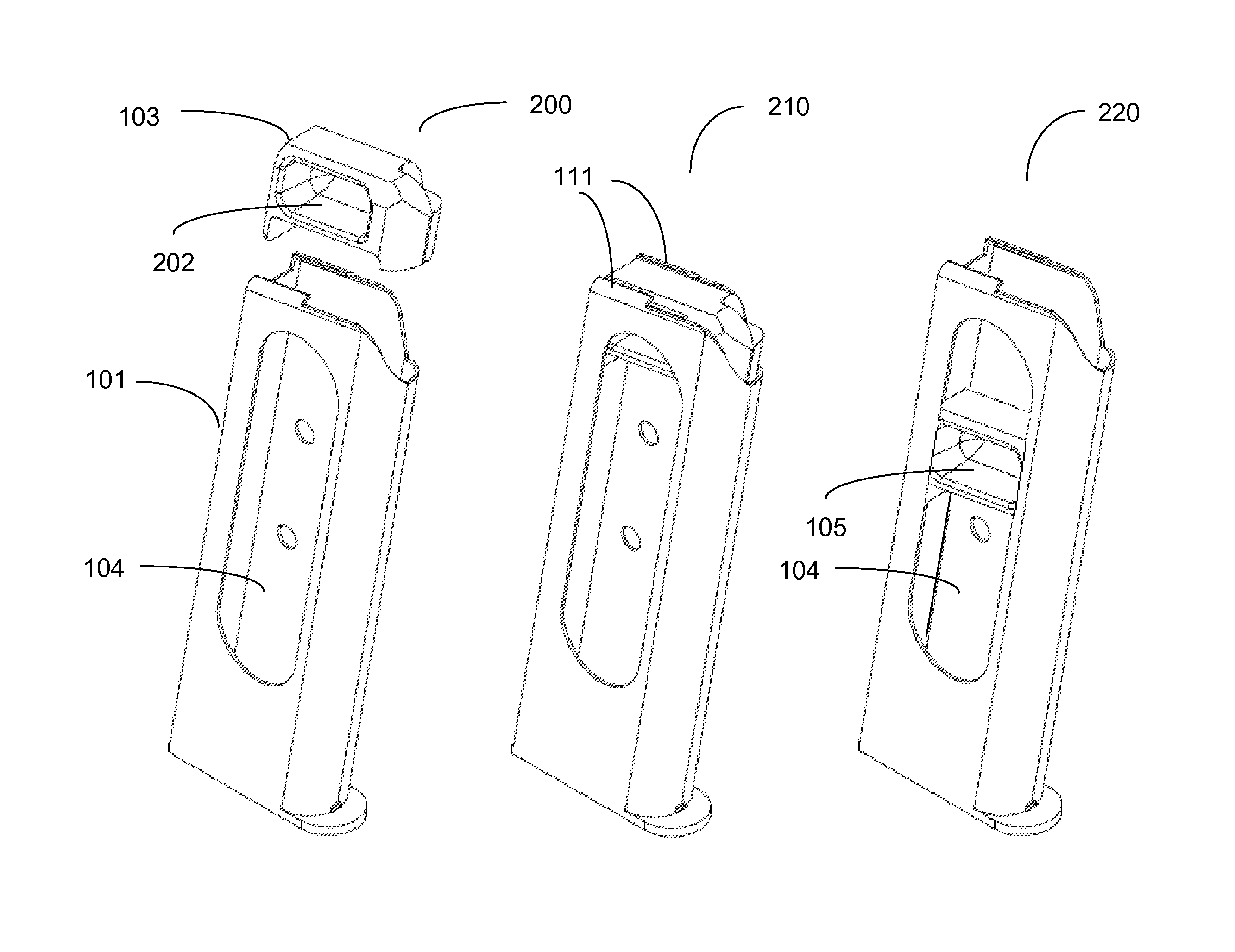

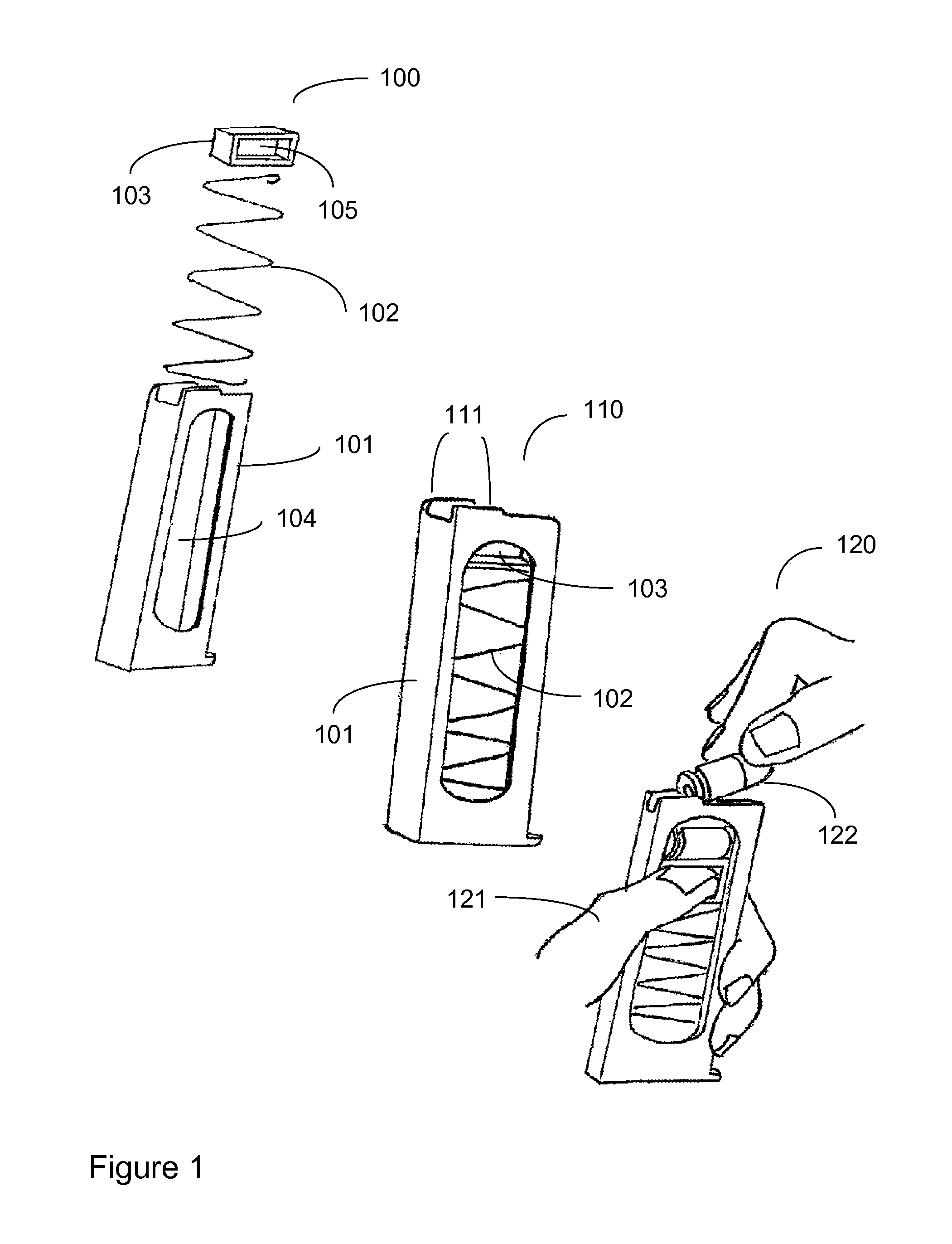

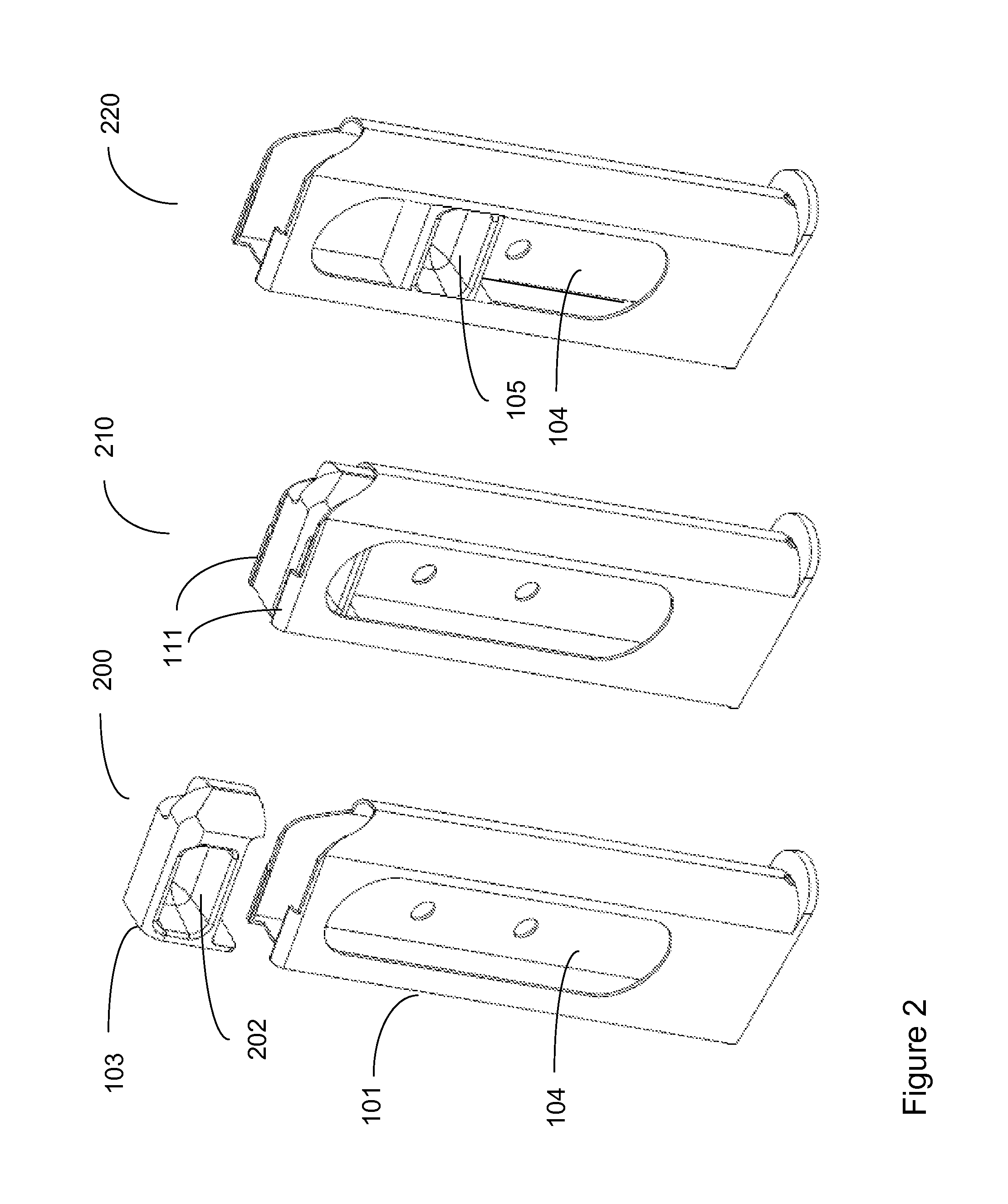

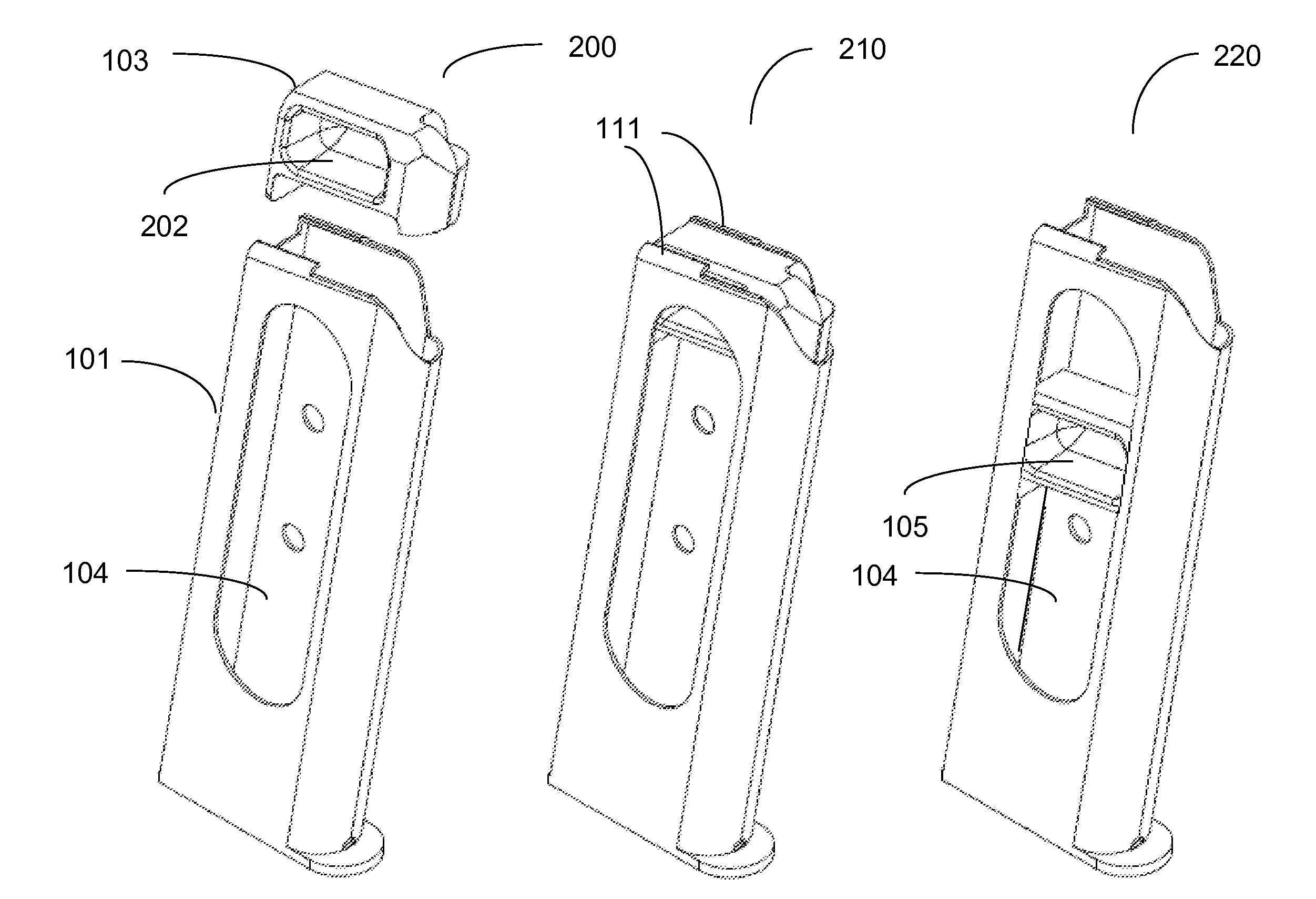

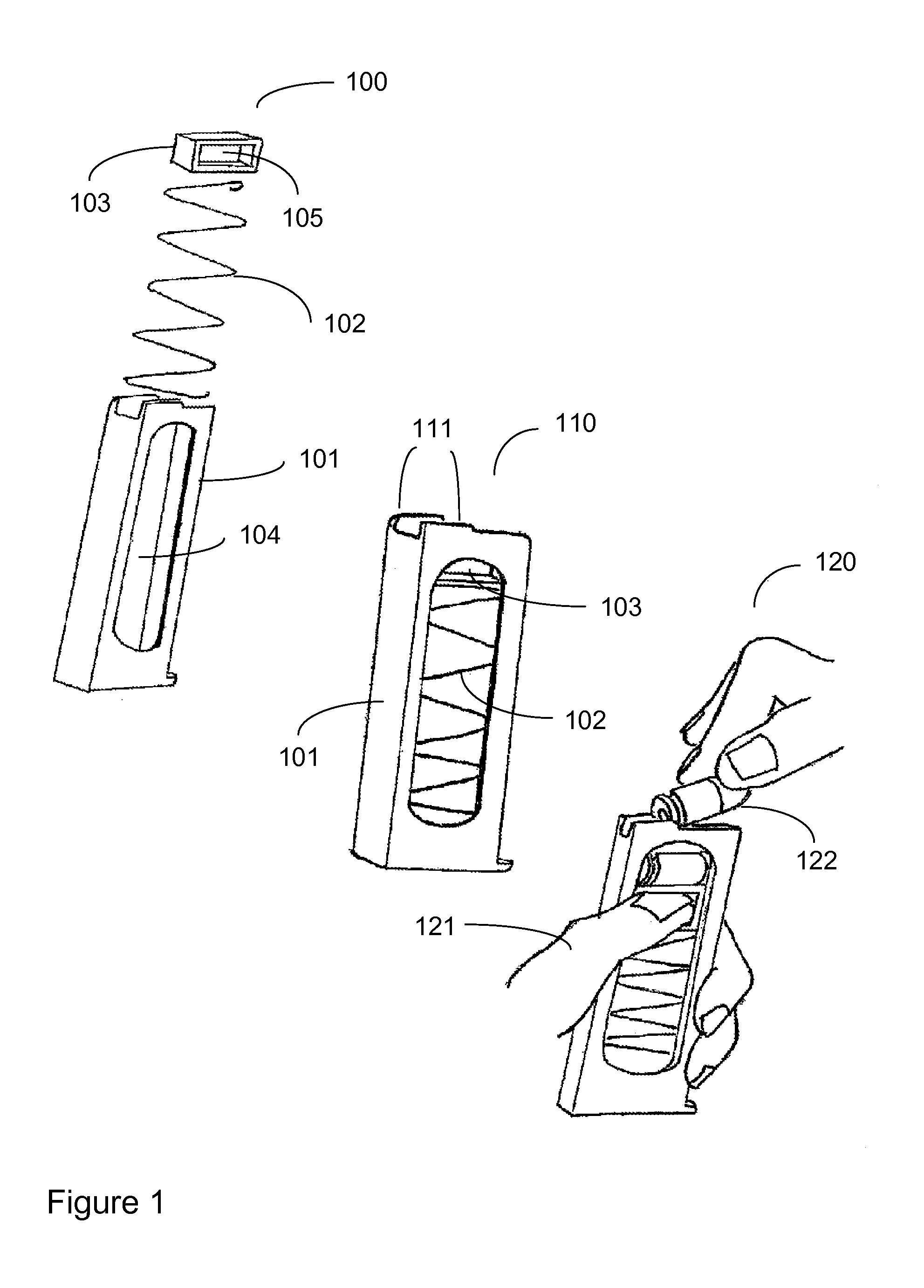

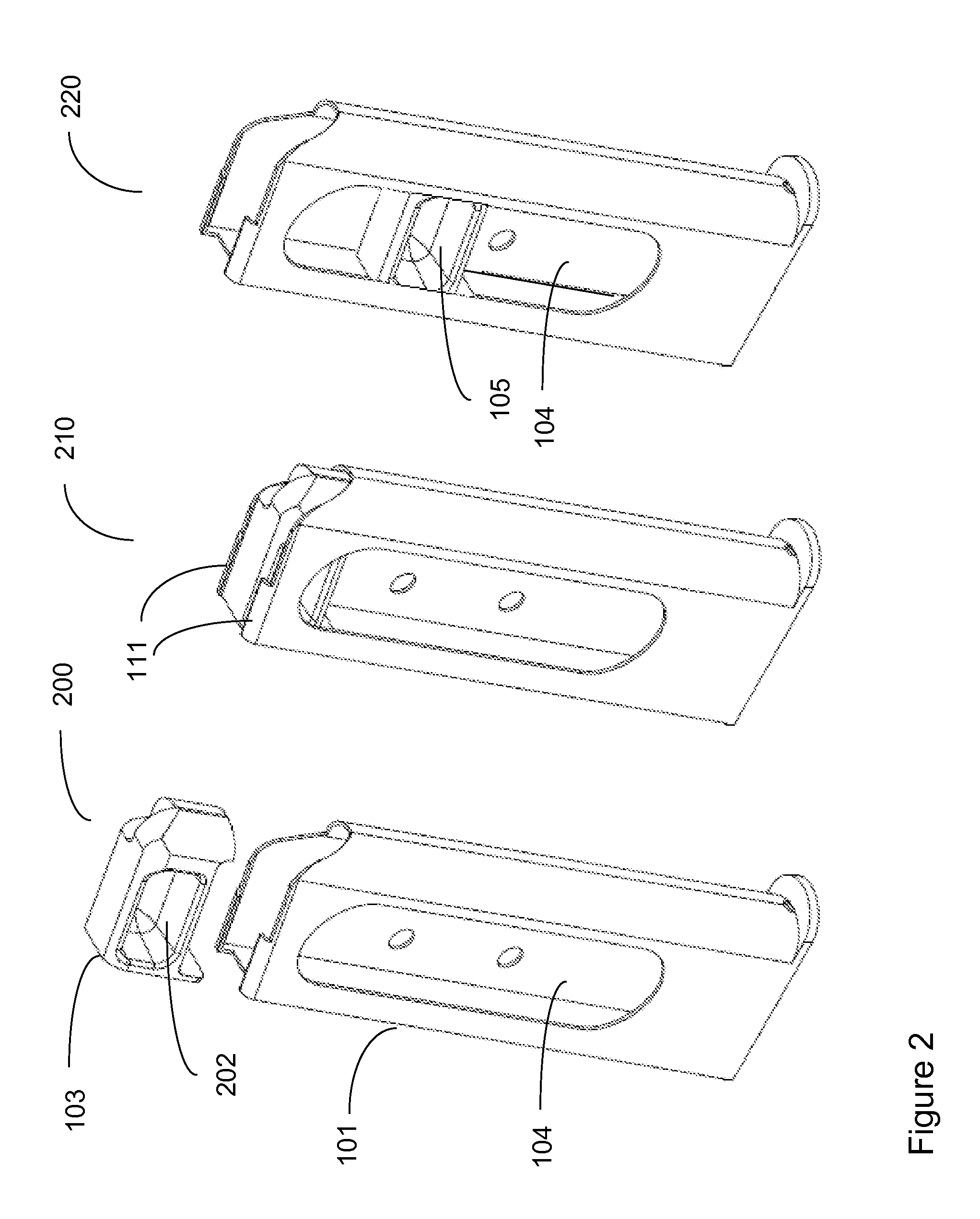

Firearm magazine

A firearm magazine that is designed to make the loading of cartridges easier and faster, while being constructed of fewer parts for higher reliability and with no protruding elements that preclude its use in pre-existing firearms. In one embodiment, a box-type magazine is provided with an internal spring and a follower. The body of the magazine and the follower are specially constructed to facilitate manual loading. The body of the magazine incorporates a slot extending along the path of the follower. The follower is fabricated with a concave opening on a lateral surface that can be manually accessed through the slot in the magazine body, thereby allowing a user to depress the follower against the pressure of the internal spring using a finger or thumb while the cartridges are easily loaded at the top of the magazine body.

Owner:WRIGHT PERRY

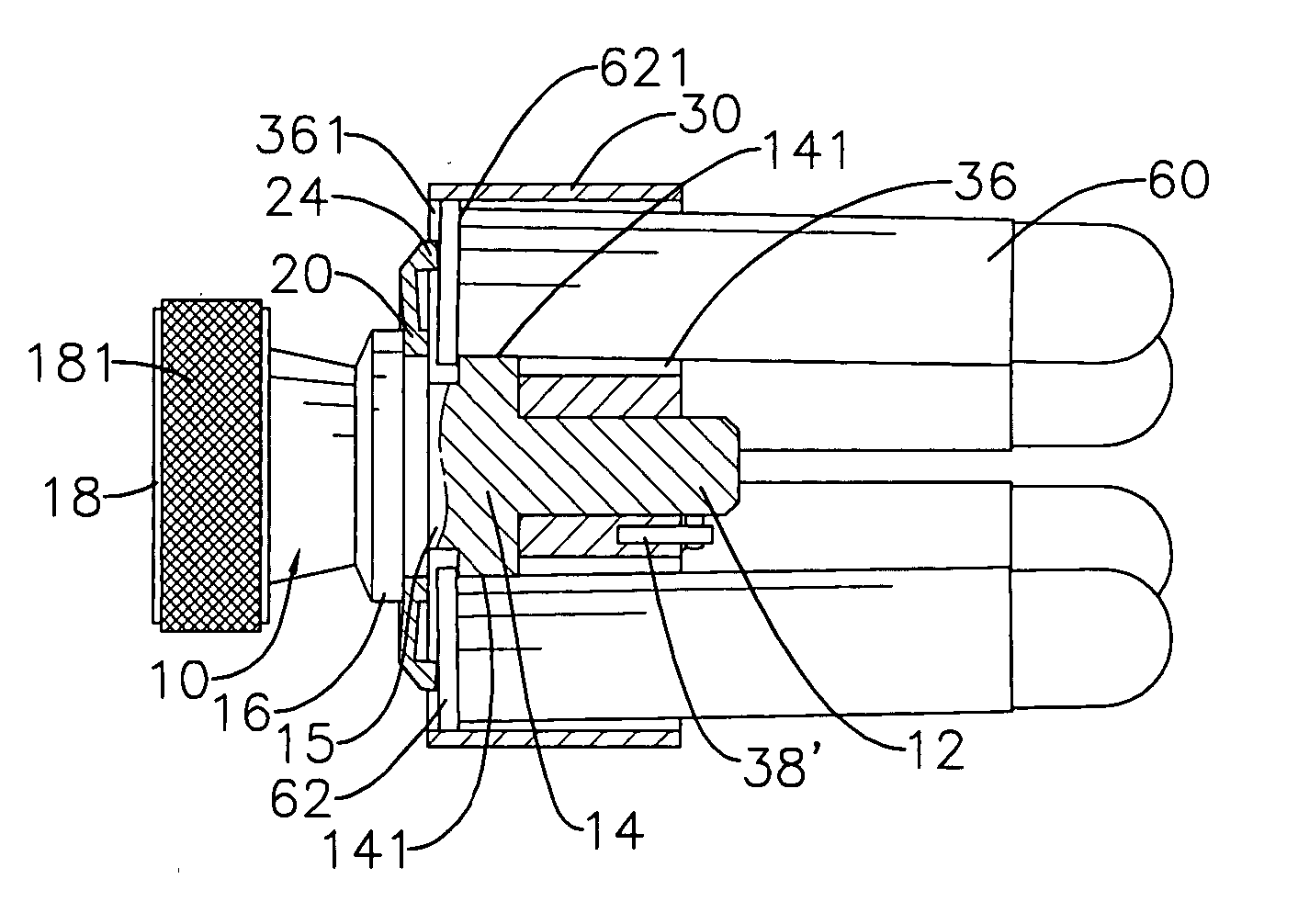

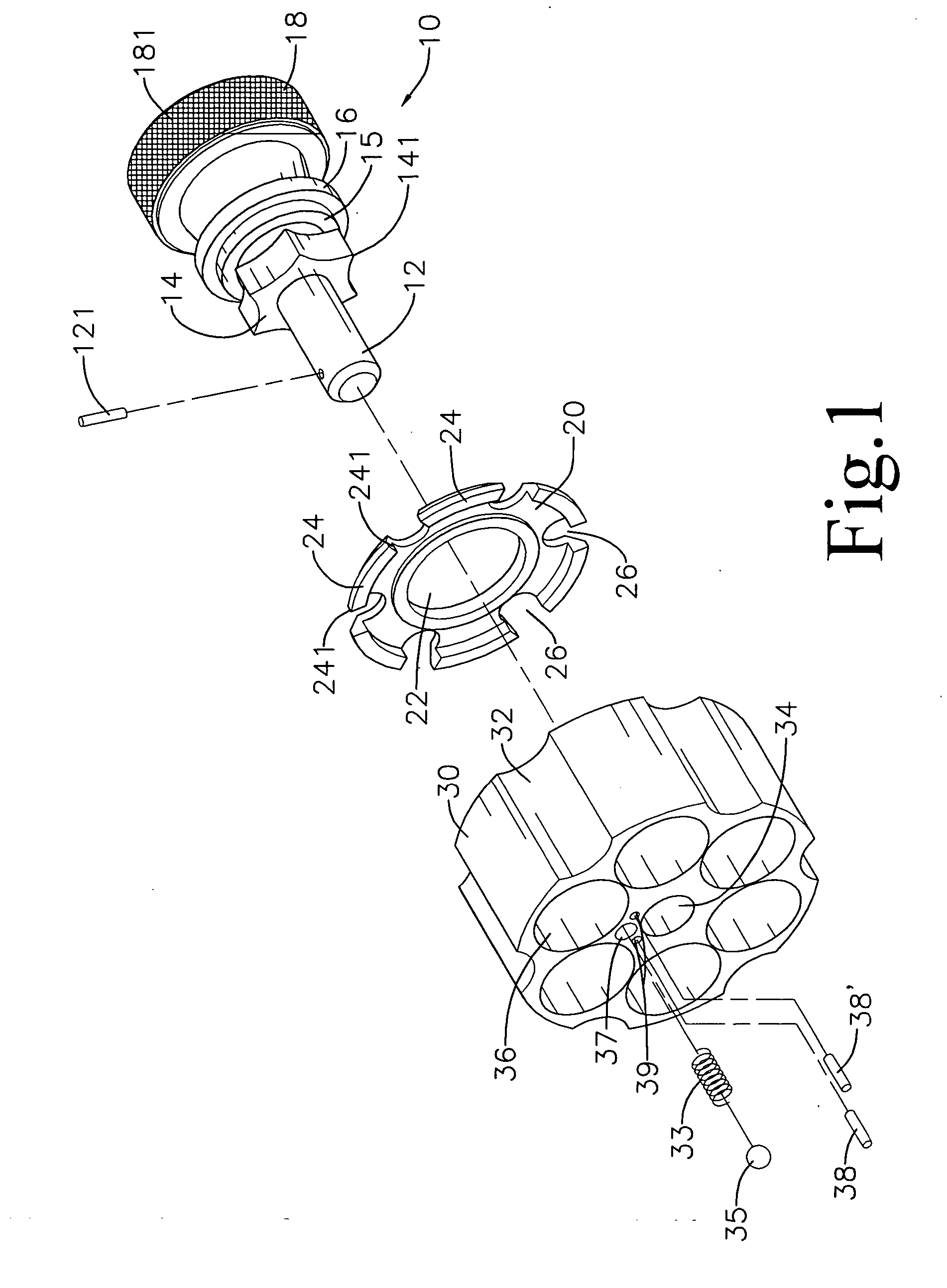

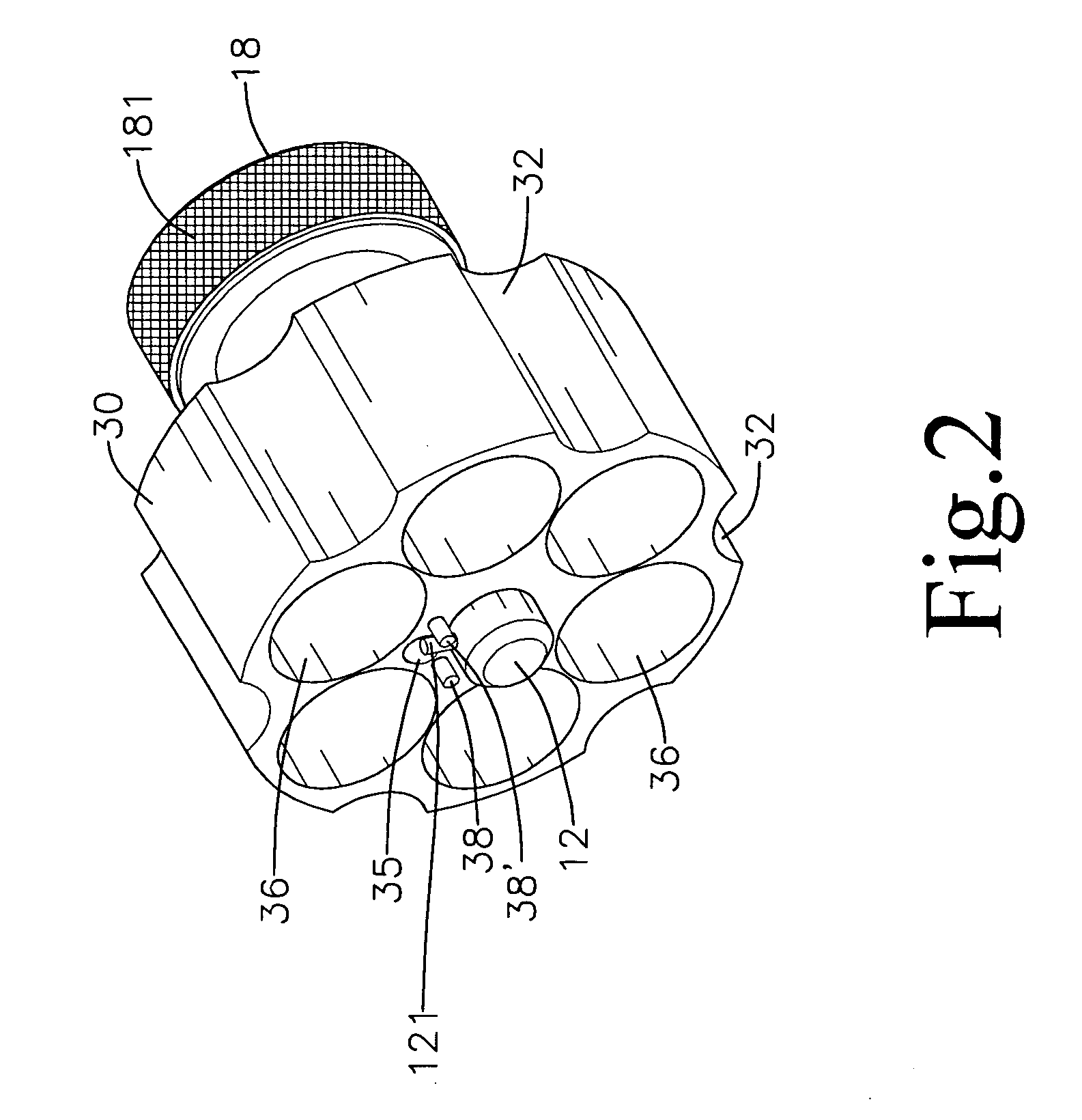

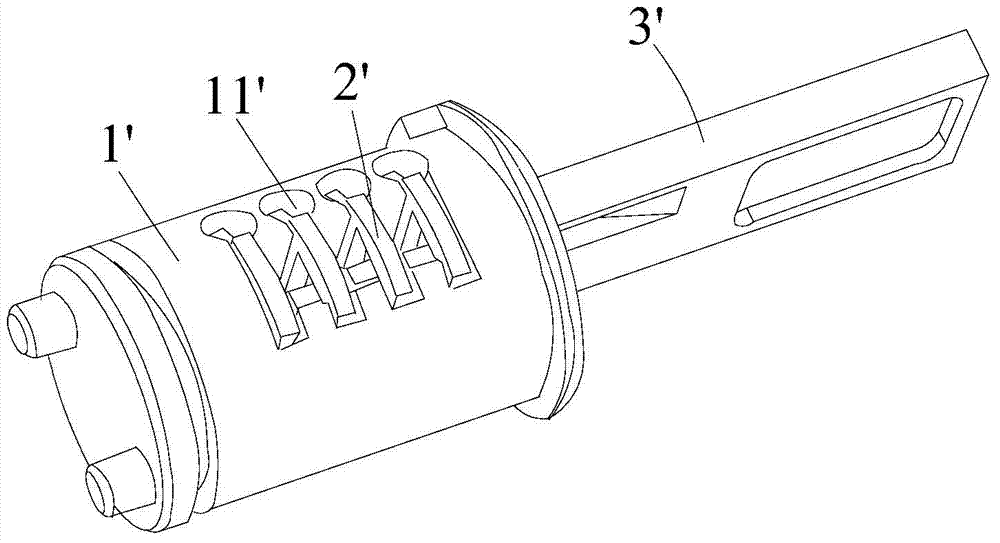

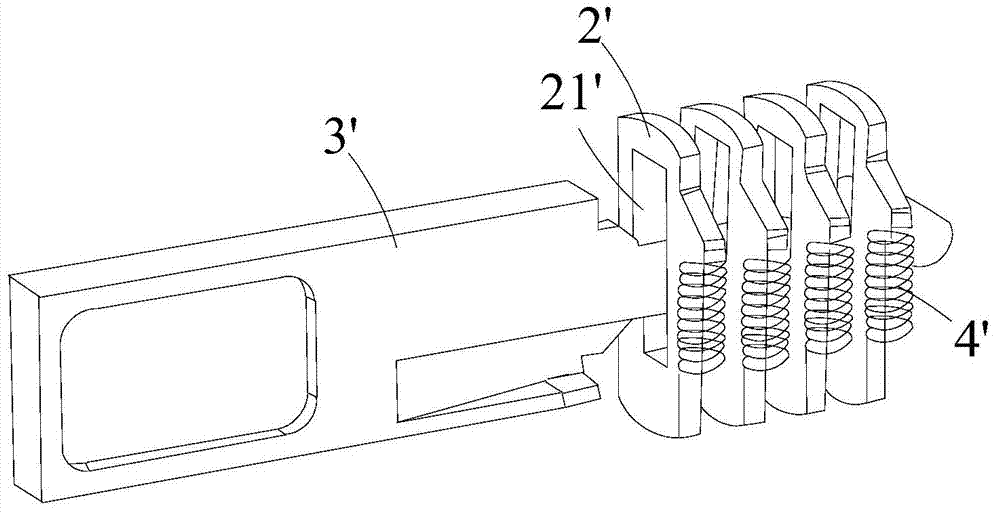

Casing configuration for revolver cartridge loader

A casing configuration for revolver cartridge loader embodying a rotating shaft member; a packing member; a casing, an outer circumferential surface of which is configured with a plurality of successional arc-shaped grooves, and a shaft hole is defined central of the casing, moreover, a plurality of cartridge bores are equicicumferentially configured around the shaft hole. Configured side of the shaft hole is a locating hole, which provides for a spring and a ball bearing to be disposed thereinto, and two locating holes, which provide for two inserting pins to respectively penetrate thereinto and fix position. The shaft member is movably disposed within the shaft hole. The successional arc-shaped grooves thus allow for quickly grasping onto with fingers, thereby enabling rapid and convenient loading of cartridges into a cylinder of a revolver.

Owner:LIN JENN YUAN

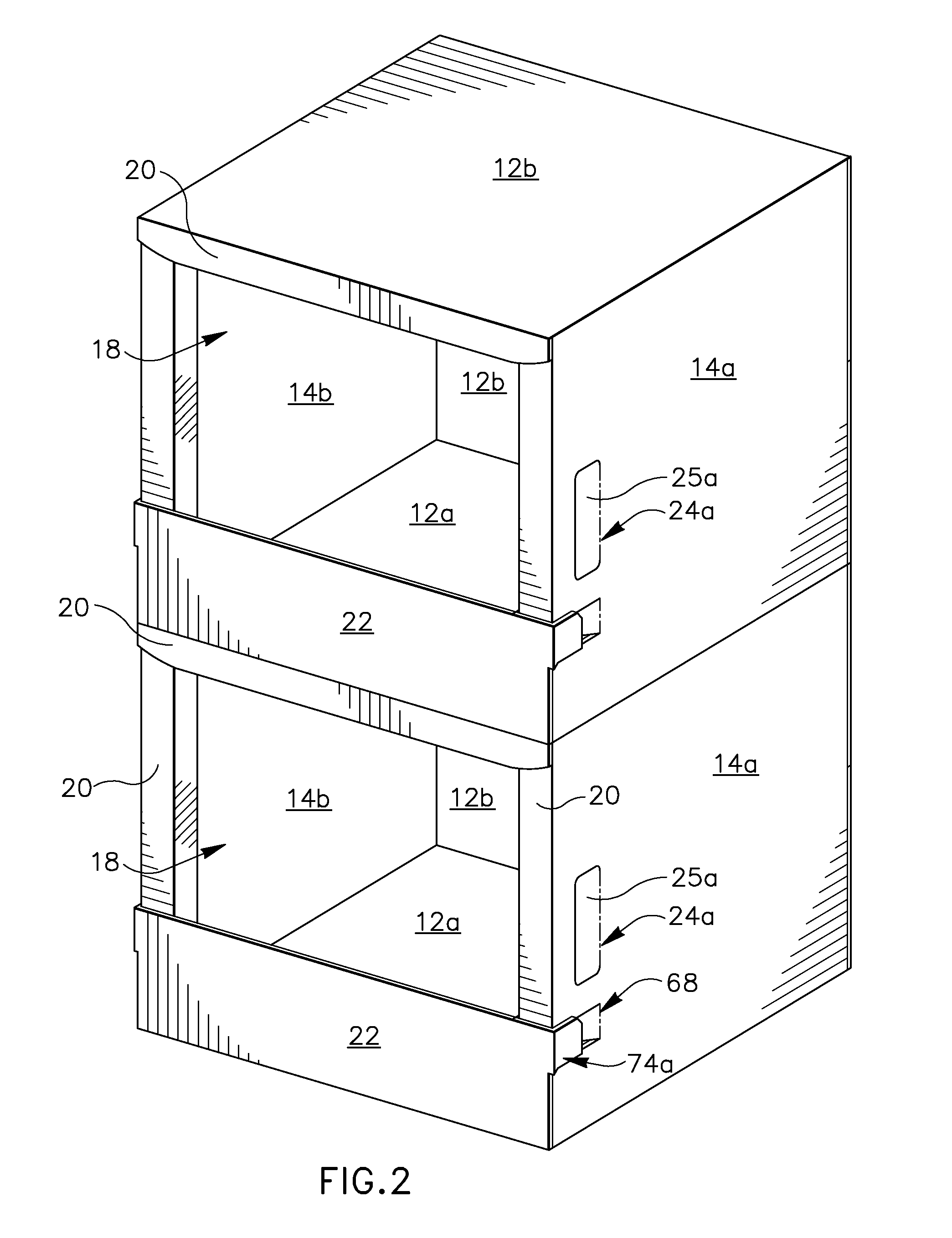

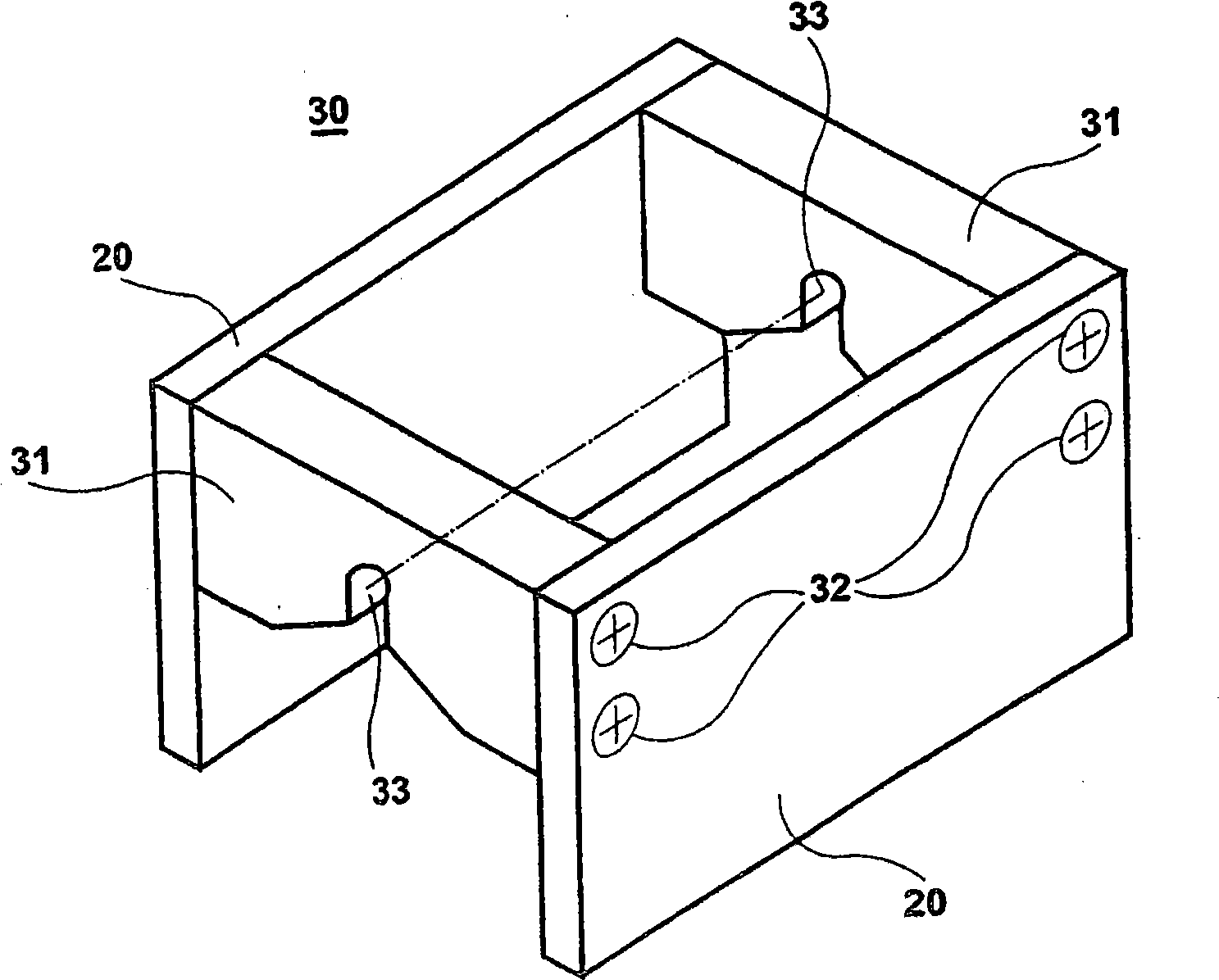

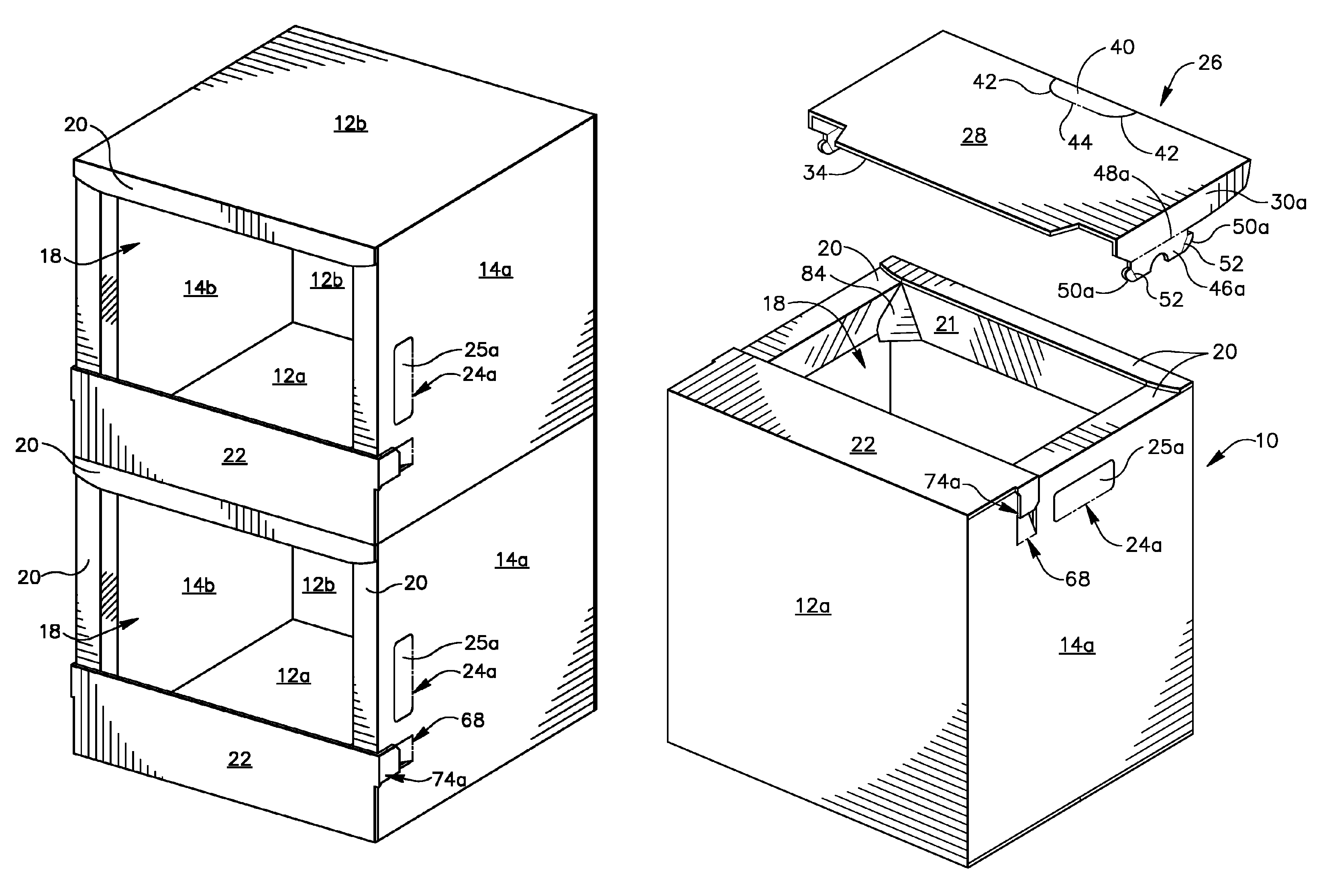

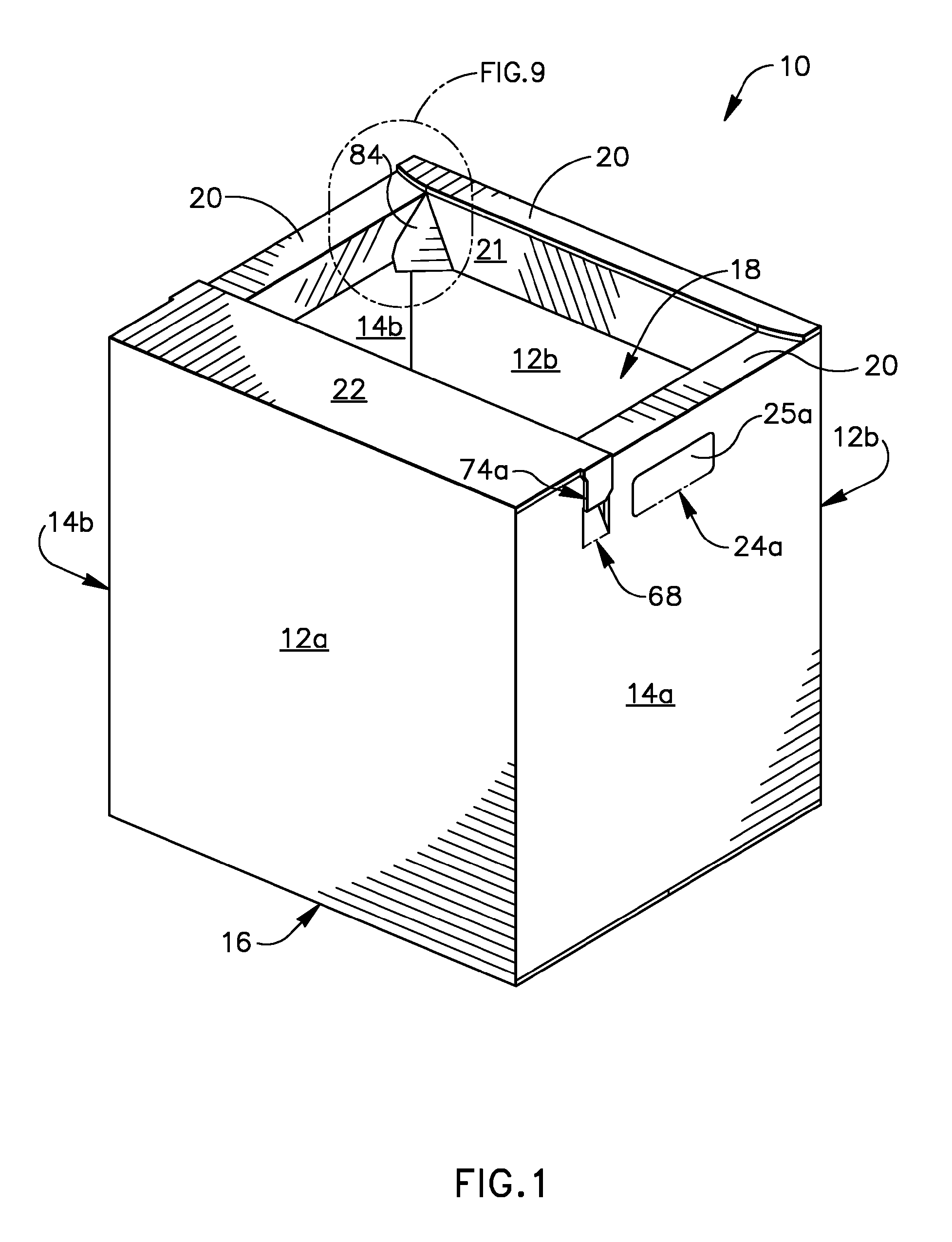

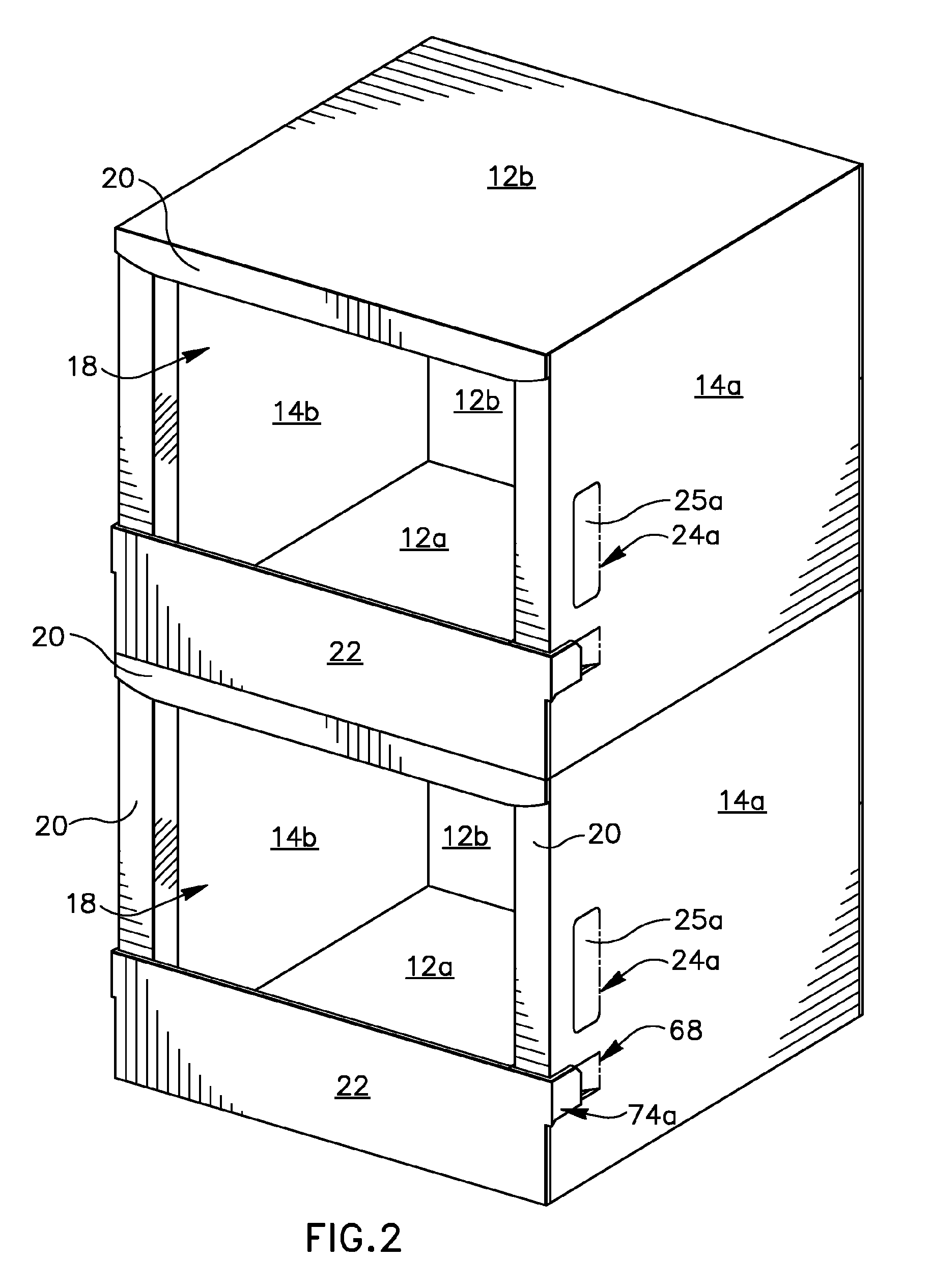

Modified frame face shipping and display container

InactiveUS20150096921A1Good top-to-bottom compressionAugments presentationRigid containersEngineeringMechanical engineering

Owner:INT PAPER CO

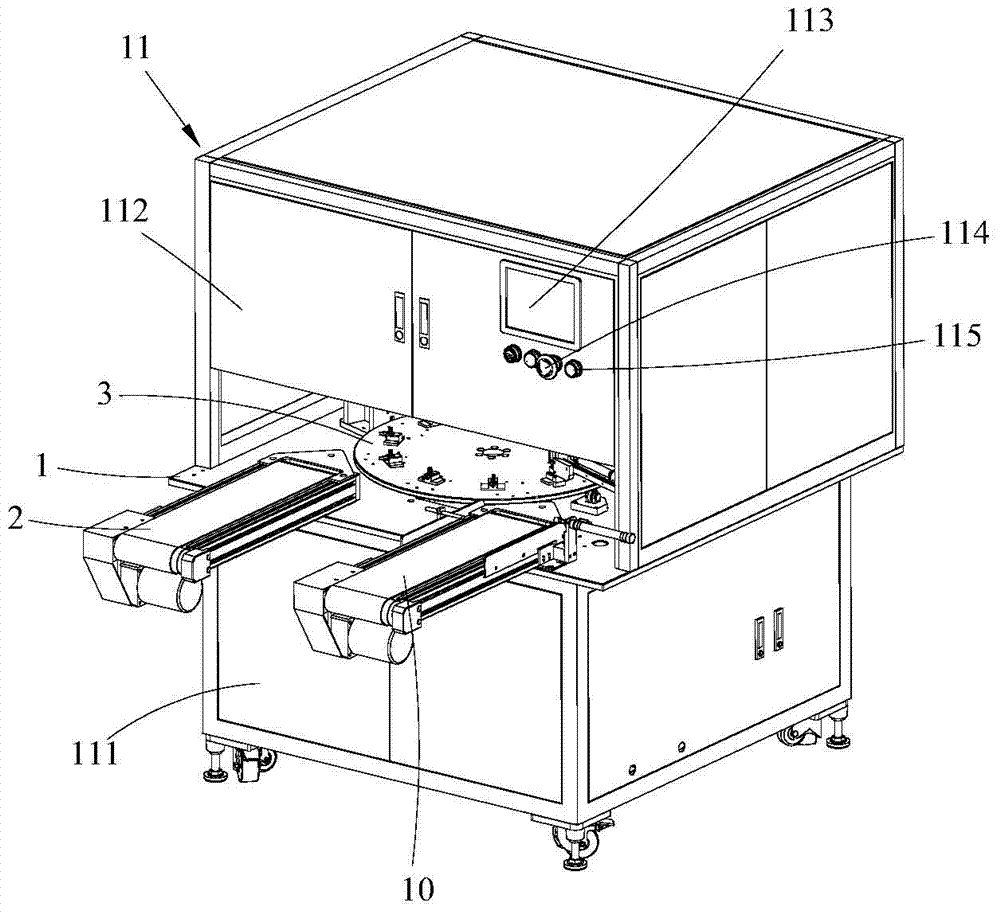

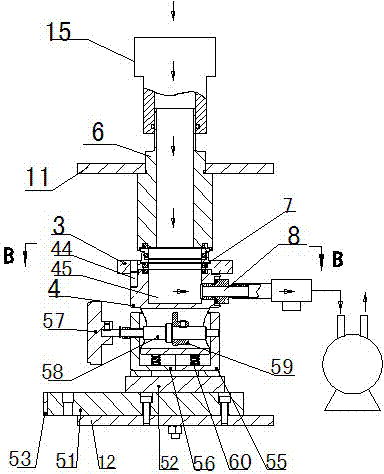

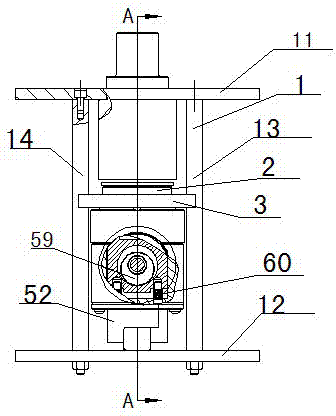

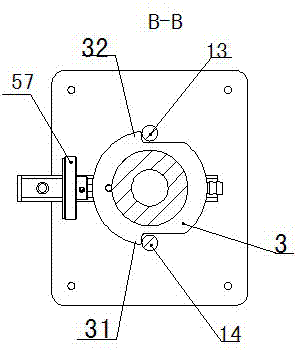

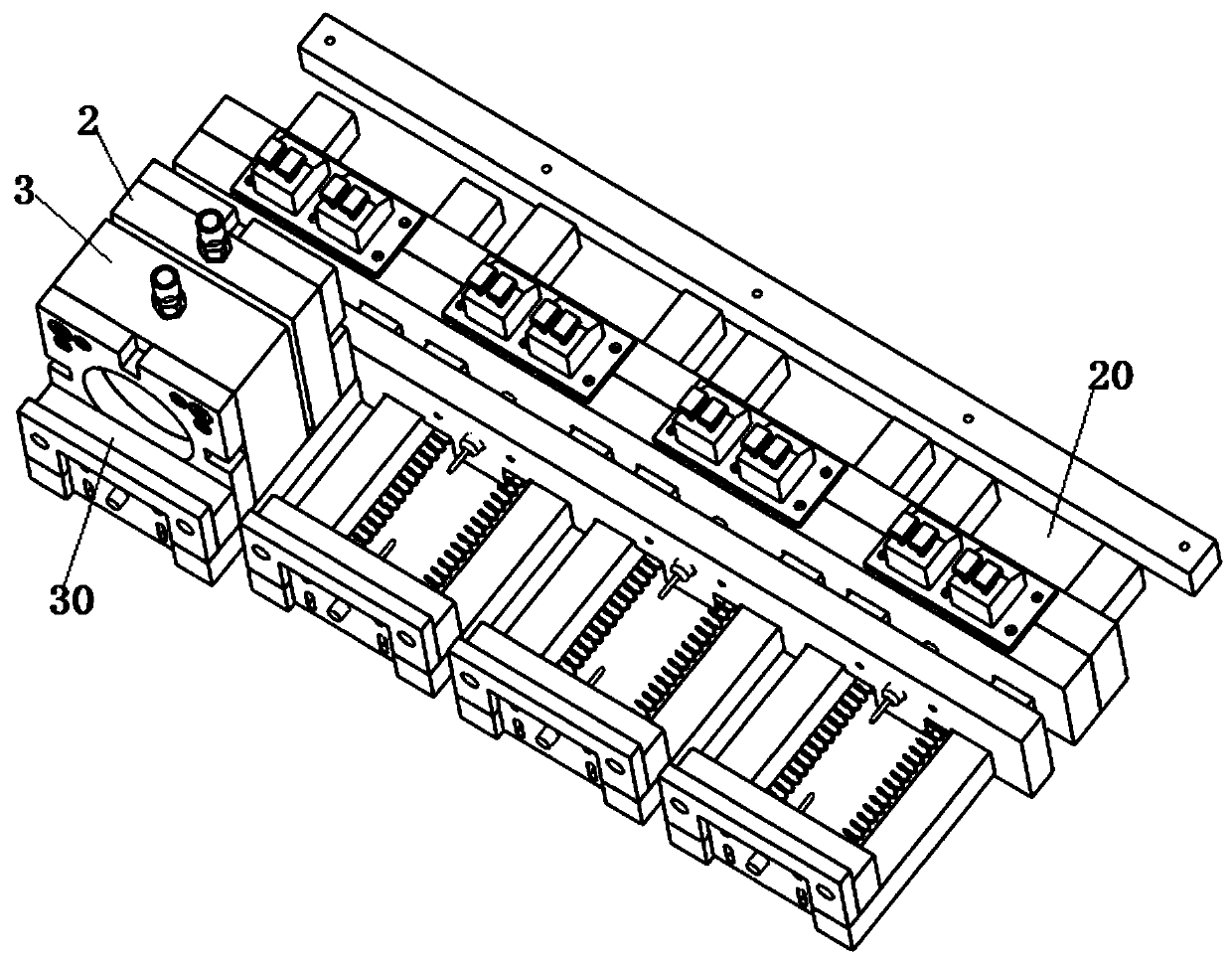

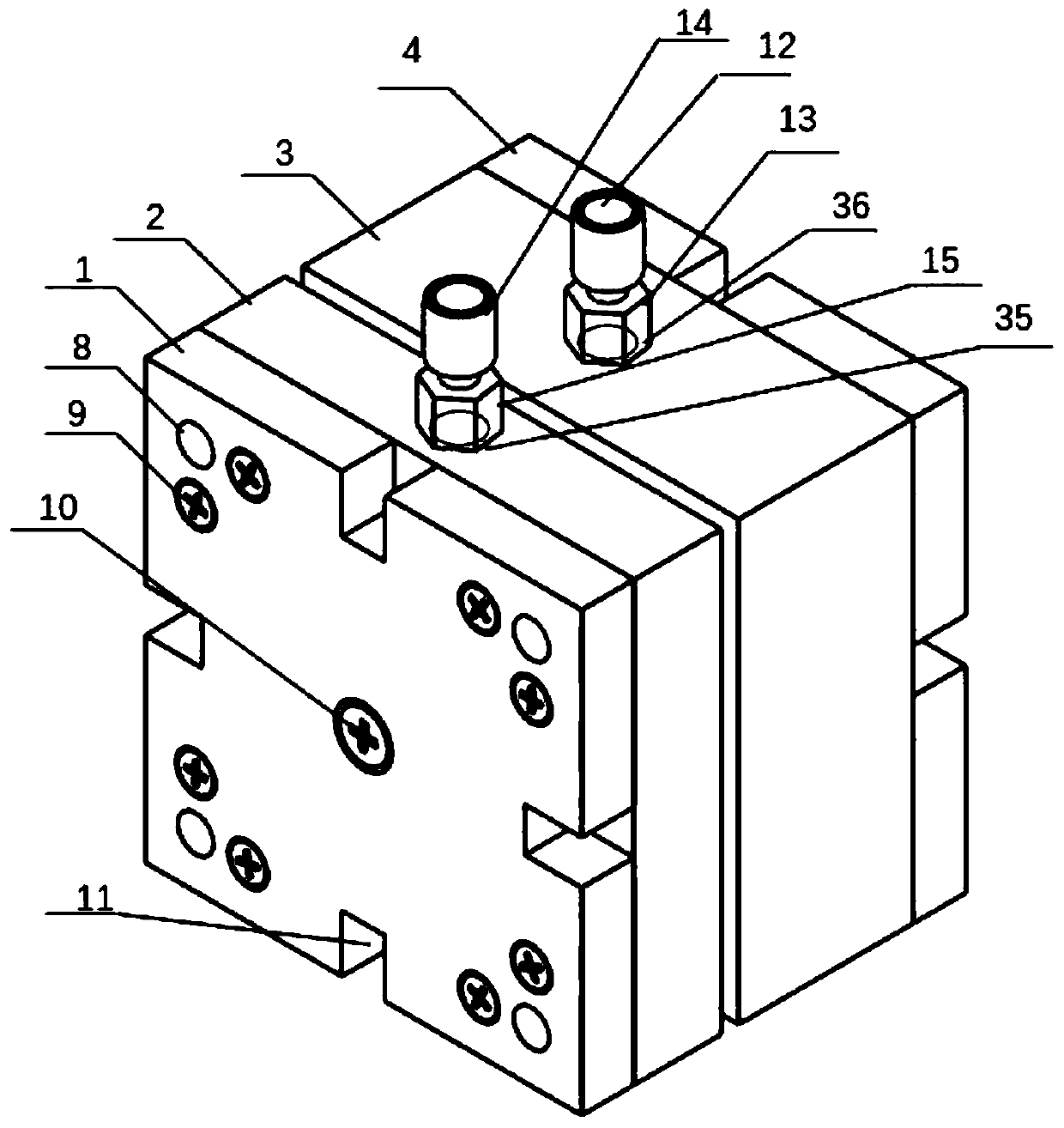

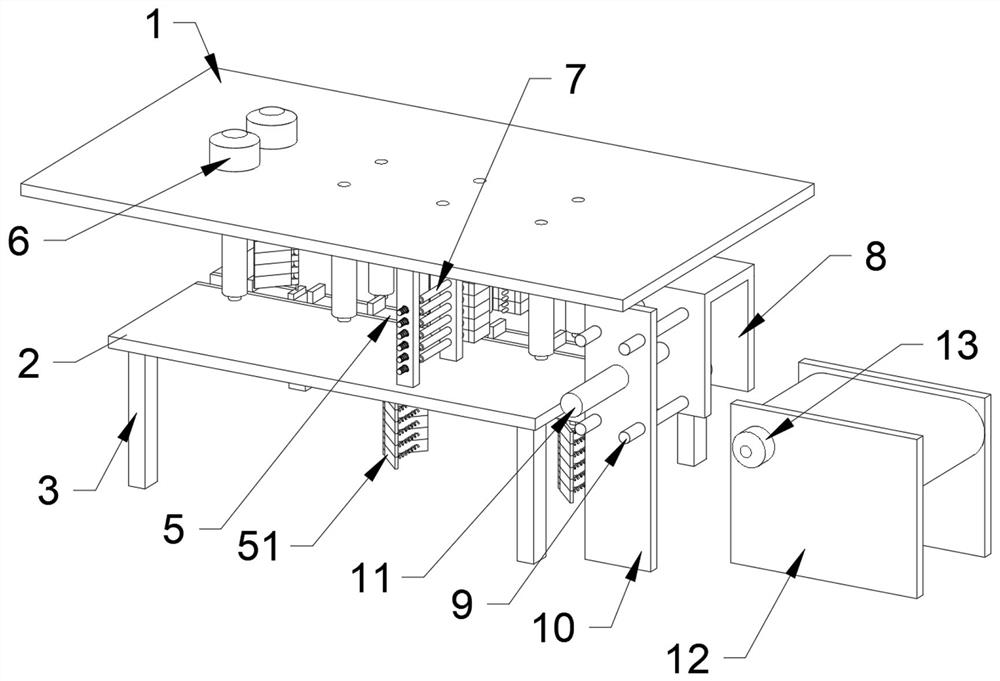

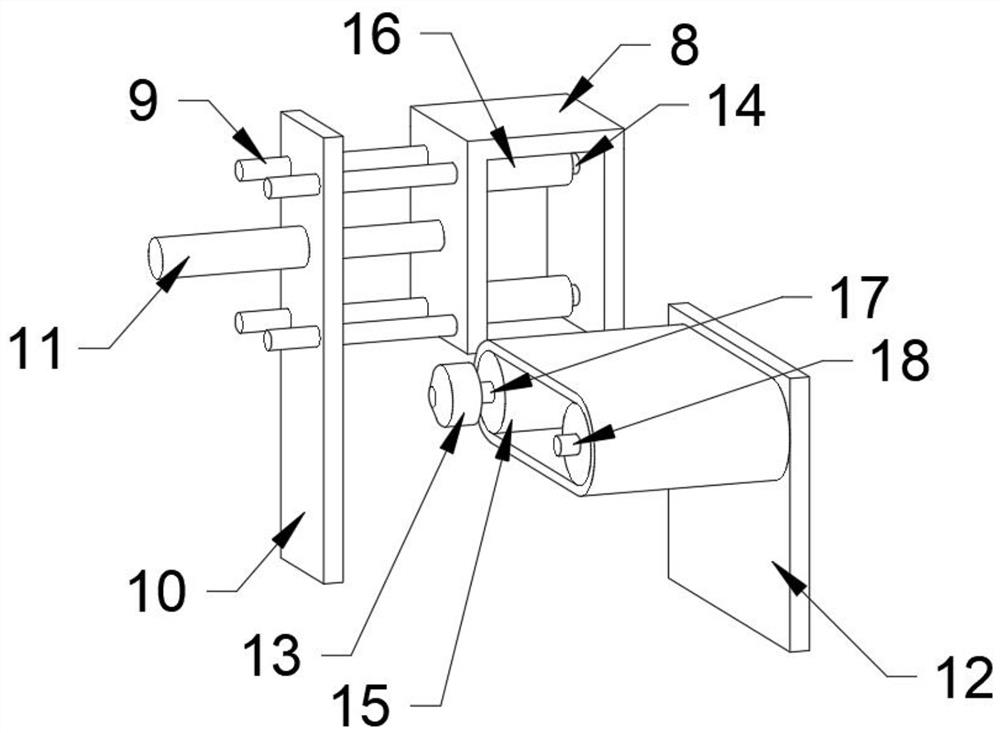

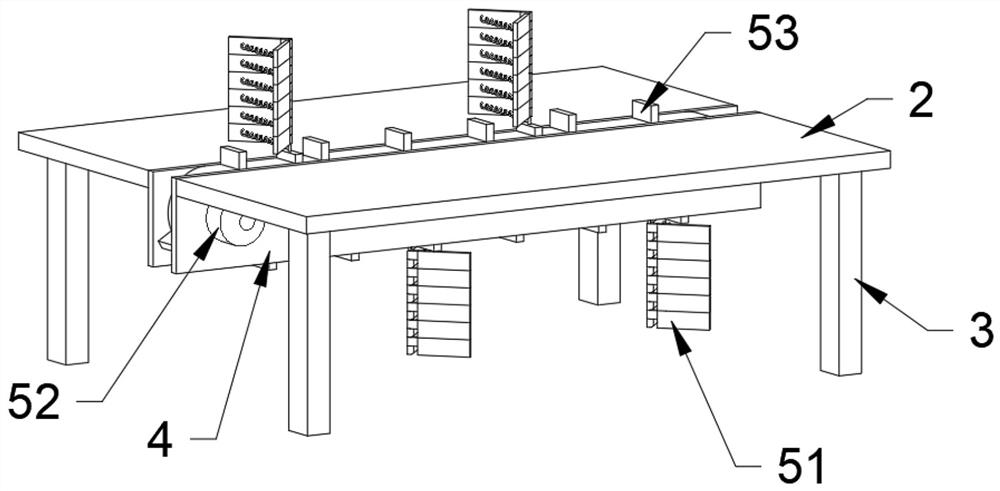

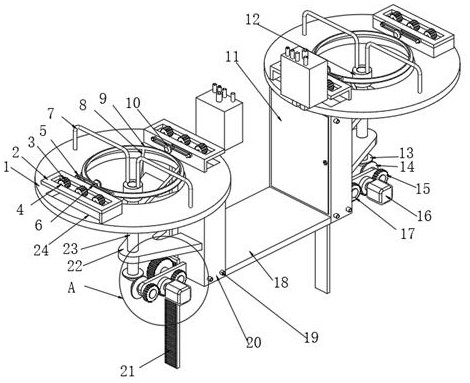

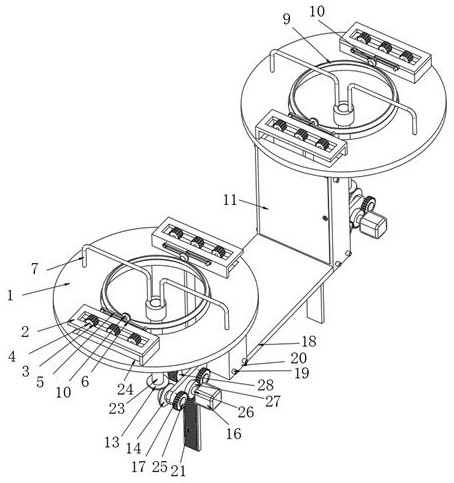

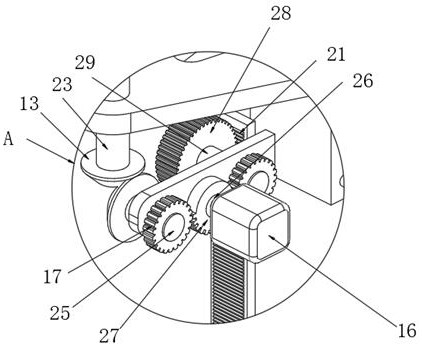

Luggage lock cylinder full-automatic assembling machine

ActiveCN104723101AImprove assembly efficiencyImprove assembly accuracyAssembly machinesAutomatic controlControl system

The invention belongs to the technical field of luggage lock equipment and particularly relates to a luggage lock cylinder full-automatic assembling machine which comprise a machine frame, a feeding device, a rotating divider, a locating component, a spring sorting and screening component, a spring mounting component, a lock row piece classifying and storing-taking component, a lock row piece mounting component, a key inserting component, a discharging device and a control system. Compared with the prior art, the machine at least has the advantages that the automatic assembling machine can achieve full-automatic assembling of various parts of a lock cylinder, the producing mode of worker manual assembling is replaced, and assembling efficiency and accuracy are greatly improved. PLC full-automatic control assembling on different lock cylinders, different lock row pieces and keys with different model numbers is completed in the equipment creatively, and accordingly the requirements of full intelligentizing and flexibility can be met. Assembling of a lock cylinder can be completed every four seconds, compared with current manual assembling, efficiency is improved by at least 10 times, and a large amount of manual cost is saved.

Owner:DONGGUAN JINGYU IND

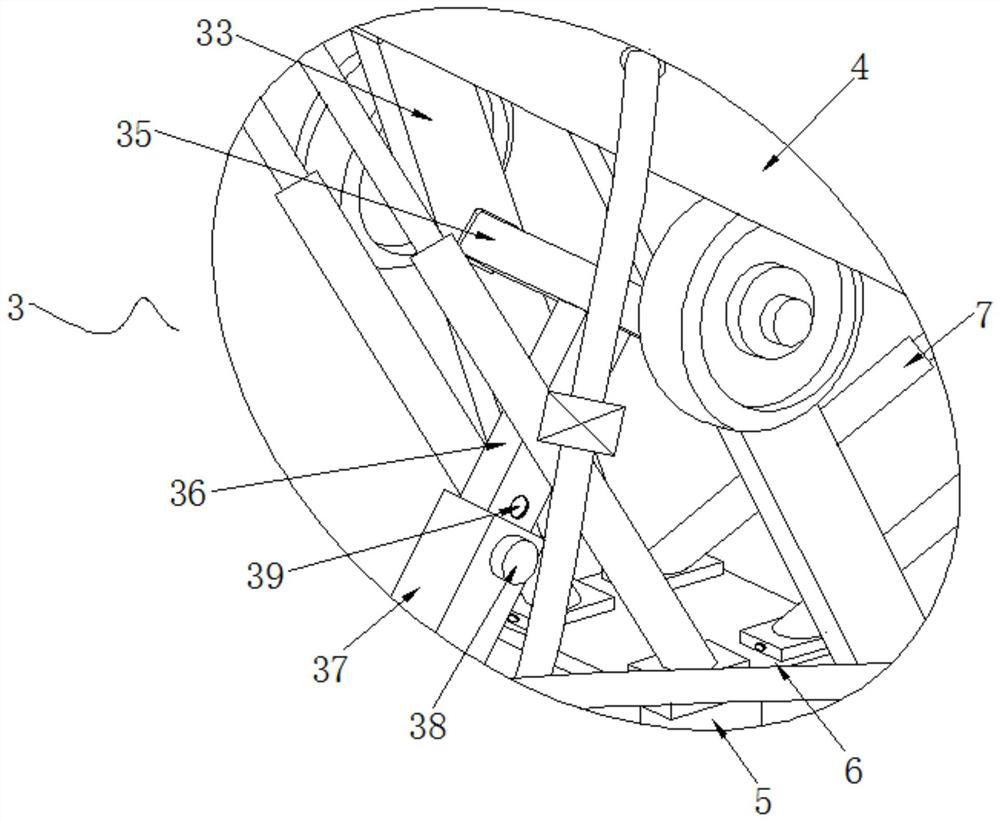

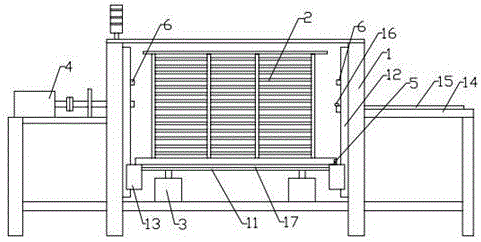

Membrane sampling device capable of lifting to move

ActiveCN103759982AEasy and fast loadingEasy to take outWithdrawing sample devicesLocking mechanismIndustrial engineering

The invention discloses a membrane sampling device capable of lifting to move. The membrane sampling device is characterized by comprising a framework, as well as a cutter joint, a seal ring, a filter membrane clamp, a filter membrane clamp fixed disk, a lifting air chamber and a lifting locking mechanism and an air cock which are arranged in the framework; the lifting locking mechanism is arranged on the lower part of the lifting air chamber. The filter membrane clamp can be put in or taken out conveniently and fast through the membrane sampling device capable of lifting to move, therefore, samples are simply and conveniently put in or taken out, a great deal of filter membrane taking and changing time can be saved, the working efficiency can be improved, and samples are not easily lost.

Owner:QINGDAO HENGYUAN TECH DEV

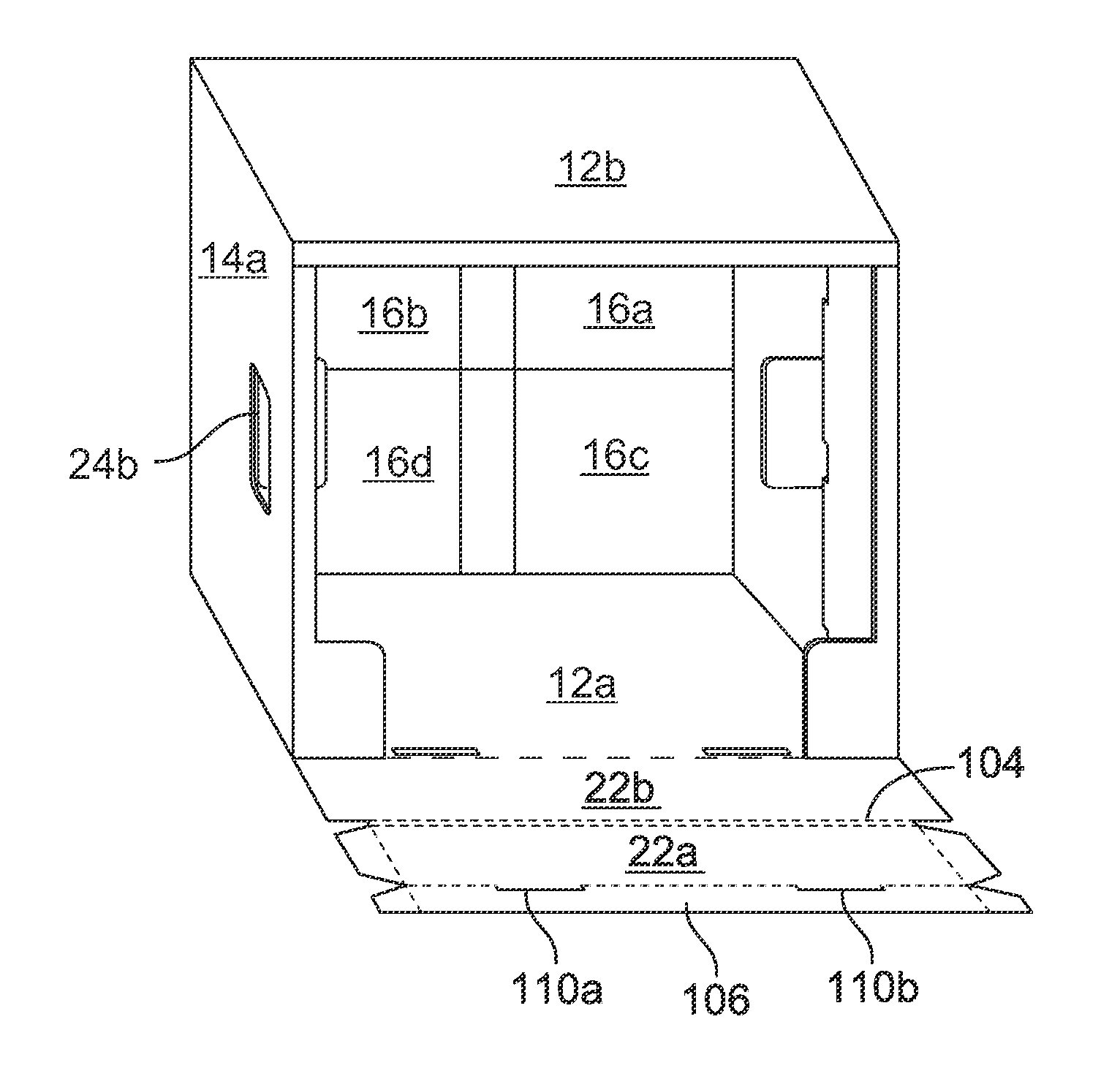

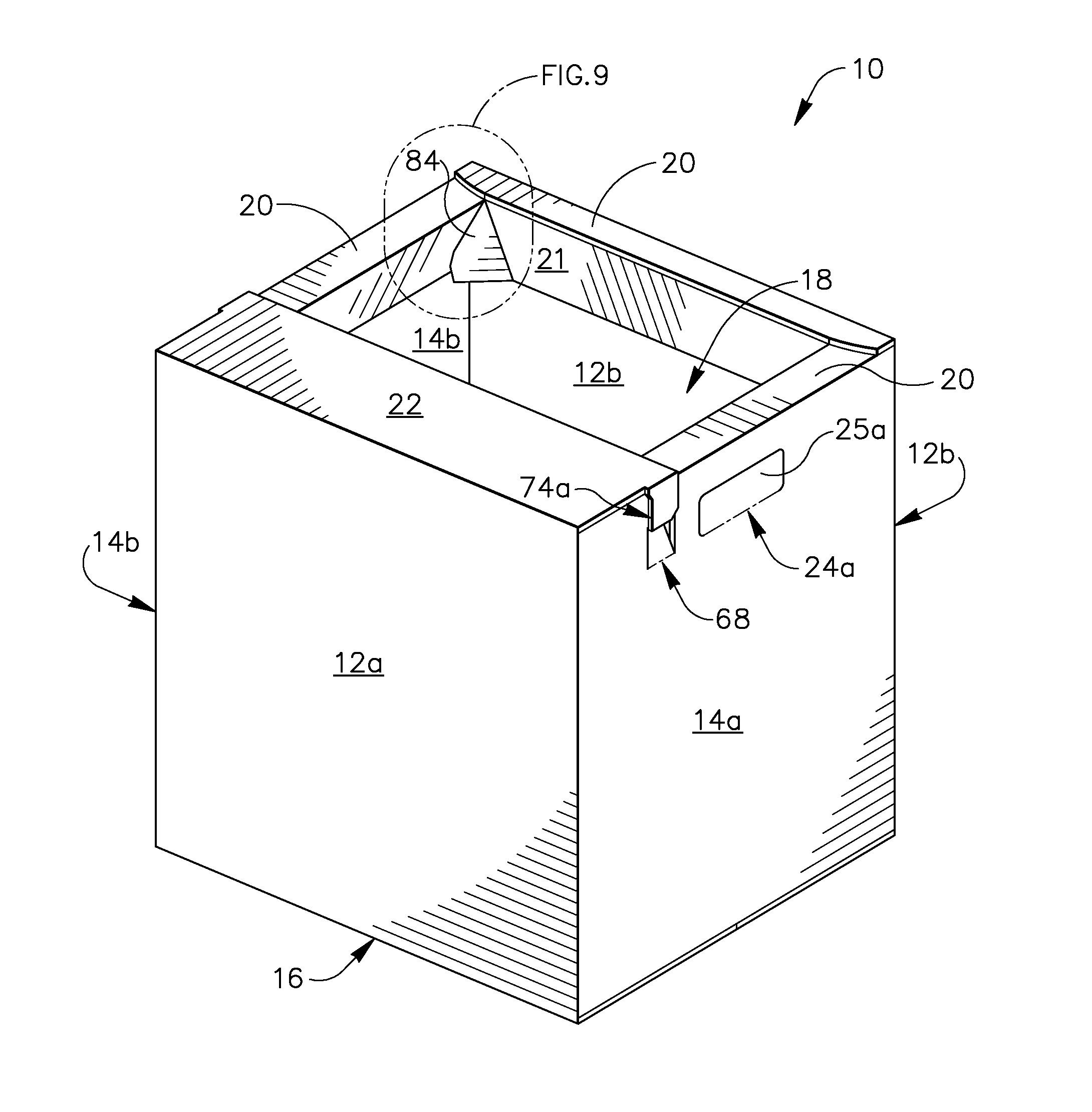

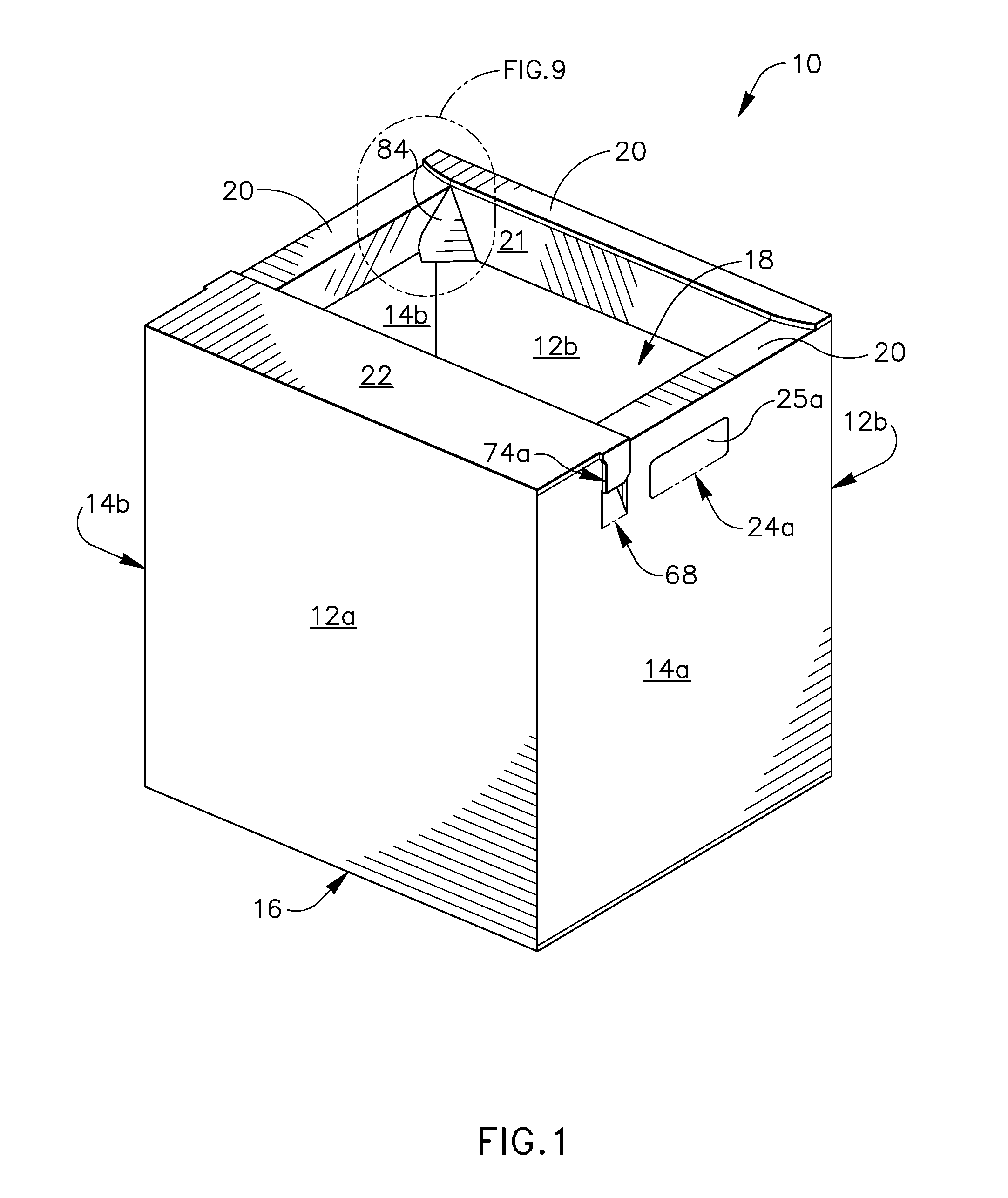

Frame face display and shipping container

ActiveUS20120080426A1Augments presentationEasily damagedRemovable lids/coversContainer/bottle contructionFace sheetFlange

The present invention is directed to an open-top container for shipping and displaying products which comprises a plurality of side walls. Bottom wall flaps are foldably joined to bottom edges of the side walls and are folded inwardly therefrom into overlapping relationship with one another to form a bottom wall closure. A respective plurality of triangularly-shaped beams foldably joined to upper edges of the respective plurality of side walls. Each of the plurality of the triangularly-shaped beams is defined by a shoulder panel and a flange panel foldably joined to one another. A bumper sticker panel is foldably joined to upper edge of one of the plurality of side walls forming a partial top closure when the open-top container is in the shipping position and partially prevents products from falling out when the open-top container is in the displaying position.

Owner:INT PAPER CO

Pre-Stretched Film Roll with Entrapped Air and Method

InactiveUS20090131618A1Easy to useAvoid injuryTextiles and paperWebs handlingLinear low-density polyethyleneAir entrainment

A pre-stretched film roll of a mono orientated linear low density polyethylene (LLDPE) is stretched between 30% and 320% from it's original length depending on the final product that is required. Stretching is in the machine direction (MD) at a controlled rate in two stages. Differentially rewinding the film entraps air between the layers of the roll and creates soft overlapping edges around the roll to produce a spongy, soft roll that prevents and resists drop damage due to its shock absorbent characteristic.

Owner:SANTILLAN DIAZ DE LEON ANGEL GERARDO

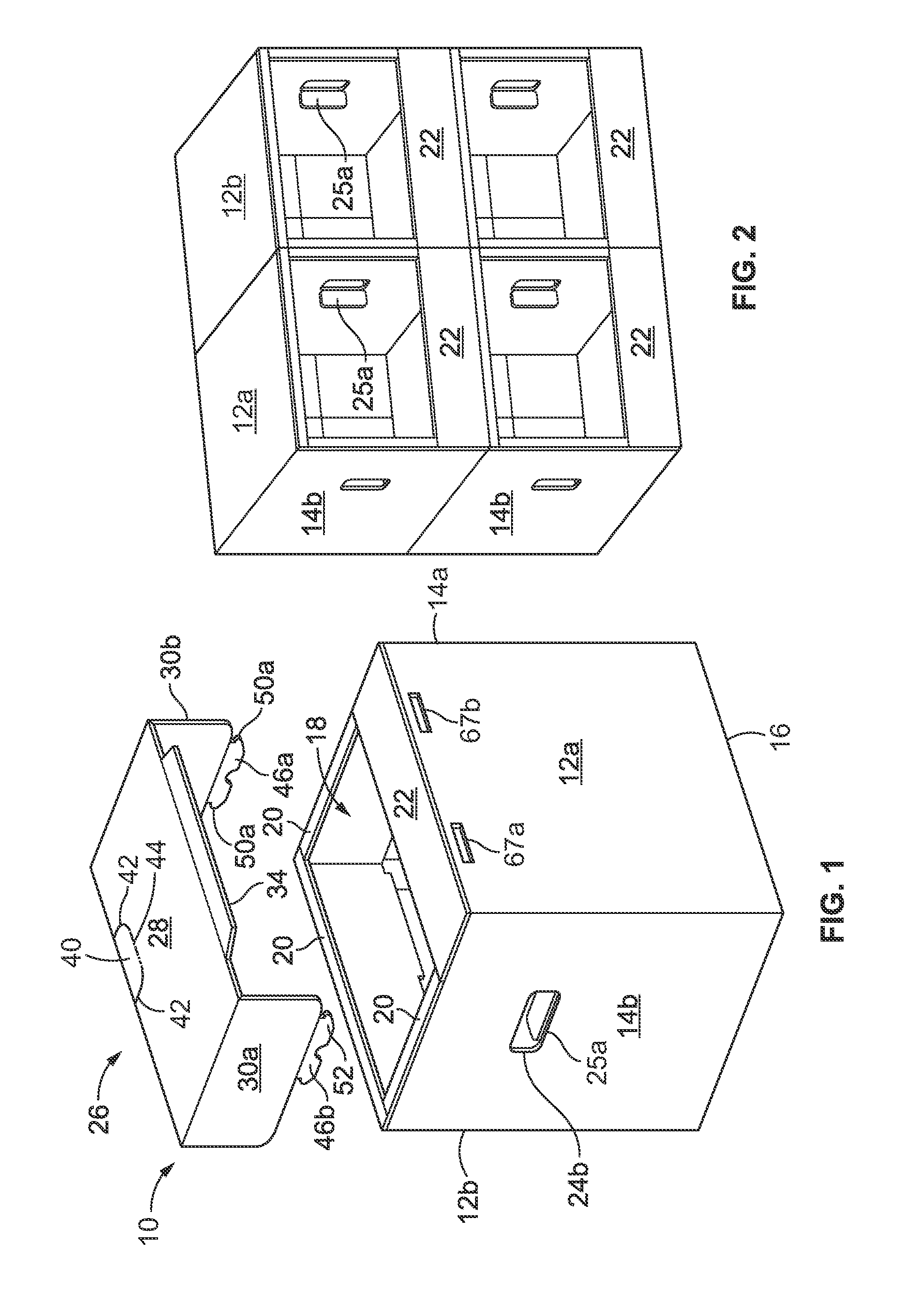

Firearm magazine

ActiveUS20110308128A1Facilitate manual loadingEasy loadingAmmunition loadingEngineeringMechanical engineering

A firearm magazine that is designed to make the loading of cartridges easier and faster, while being constructed of fewer parts for higher reliability and with no protruding elements that preclude its use in pre-existing firearms. In one embodiment, a box-type magazine is provided with an internal spring and a follower. The body of the magazine and the follower are specially constructed to facilitate manual loading. The body of the magazine incorporates a slot extending along the path of the follower. The follower is fabricated with a concave opening on a lateral surface that can be manually accessed through the slot in the magazine body, thereby allowing a user to depress the follower against the pressure of the internal spring using a finger or thumb while the cartridges are easily loaded at the top of the magazine body.

Owner:WRIGHT PERRY

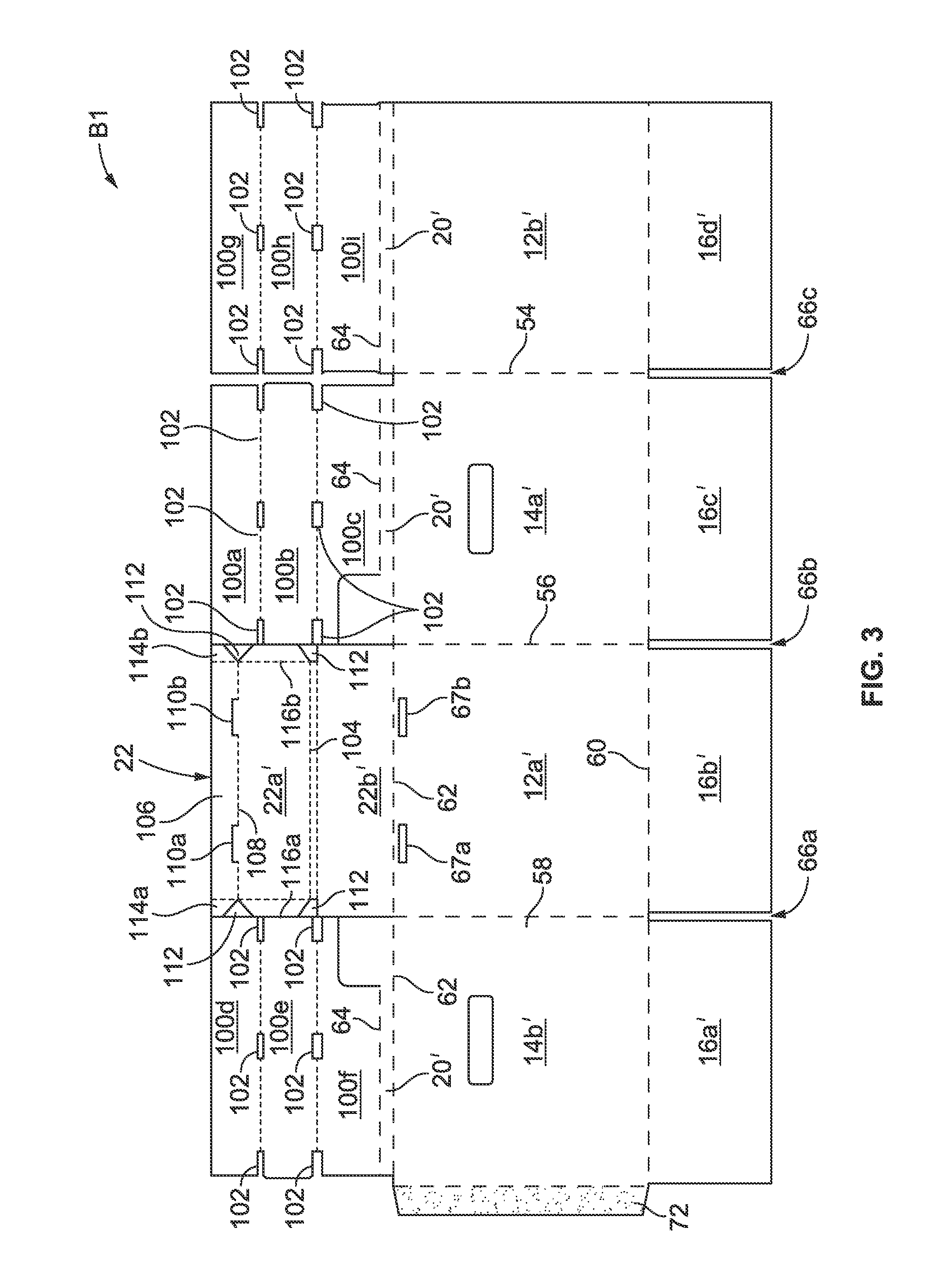

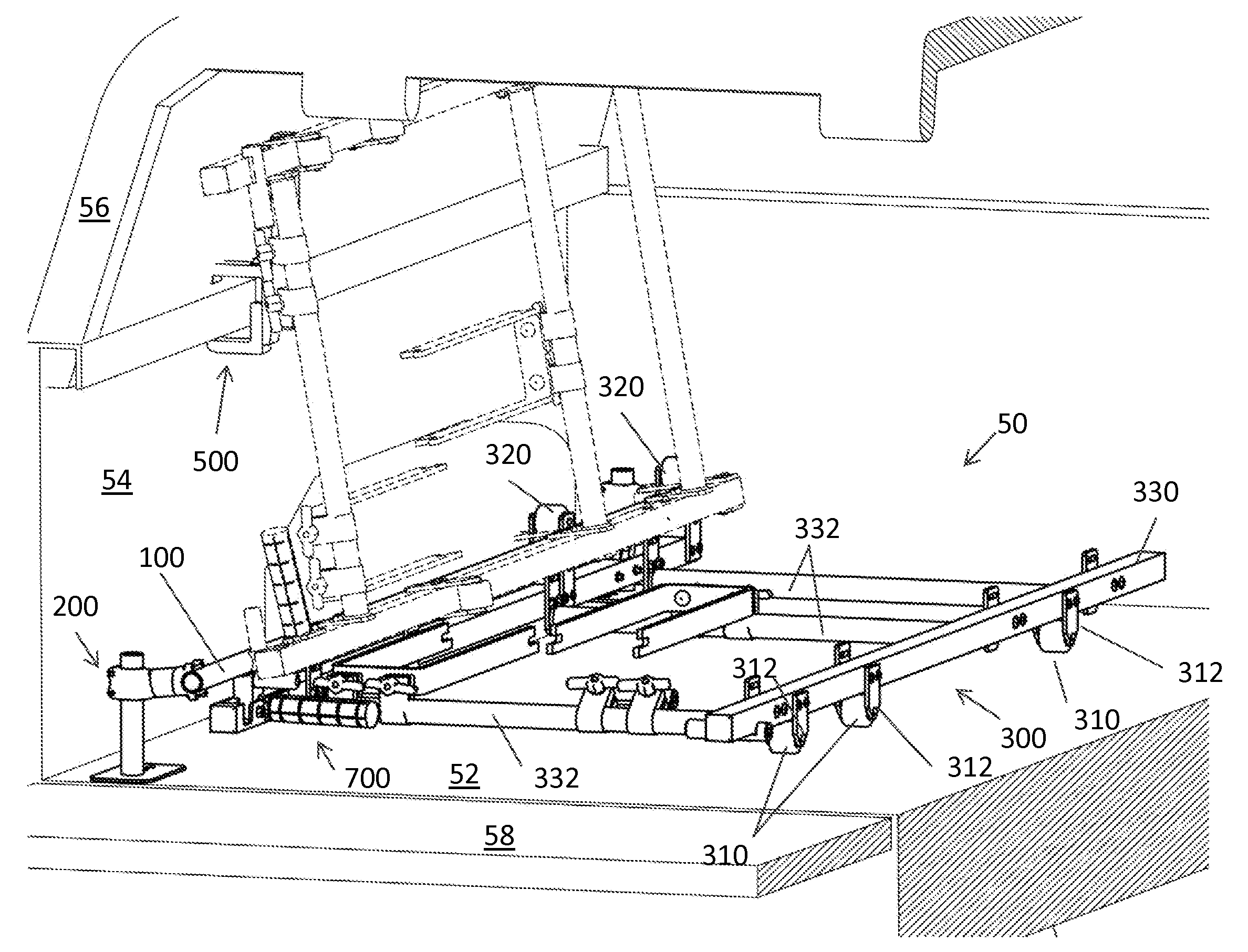

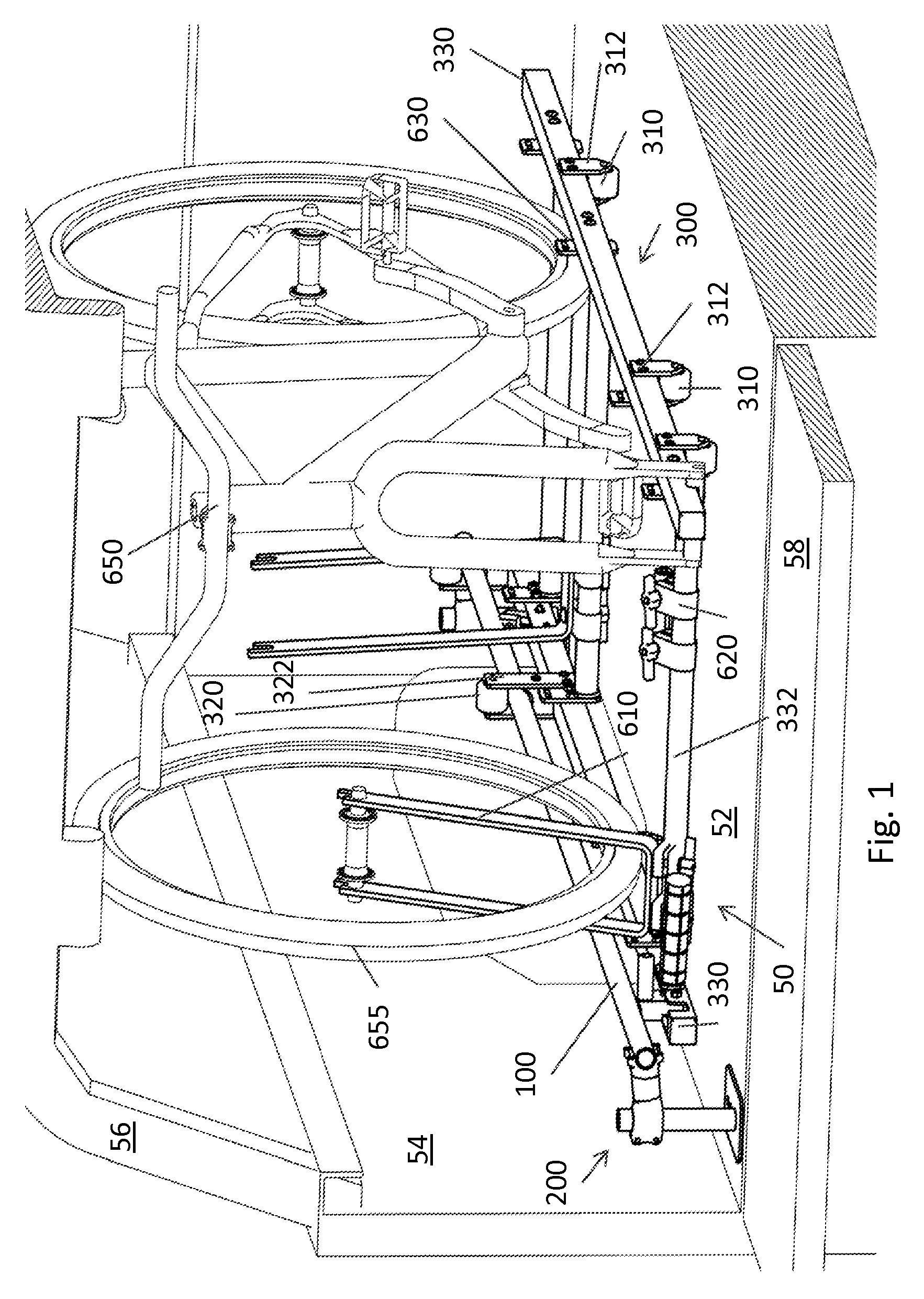

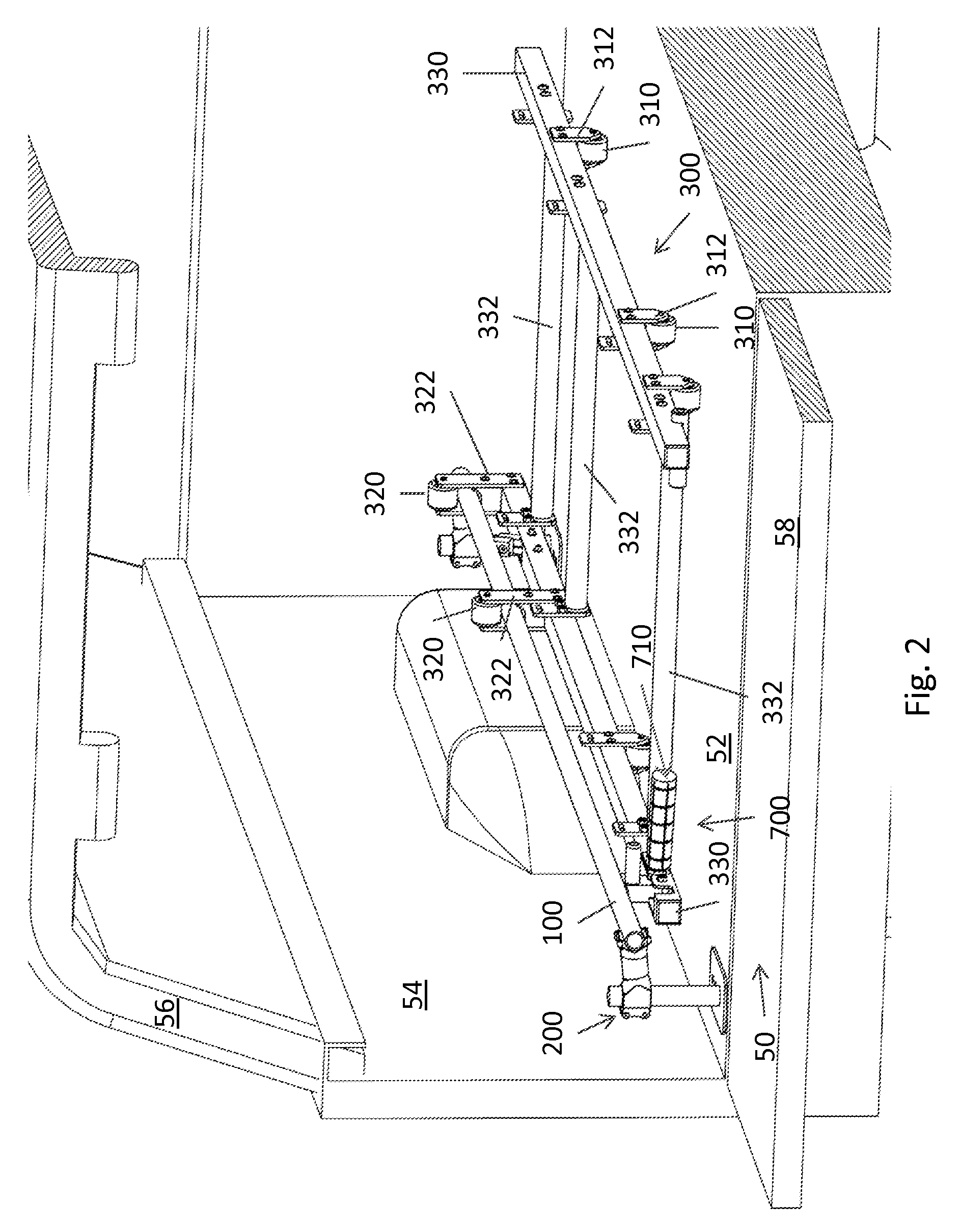

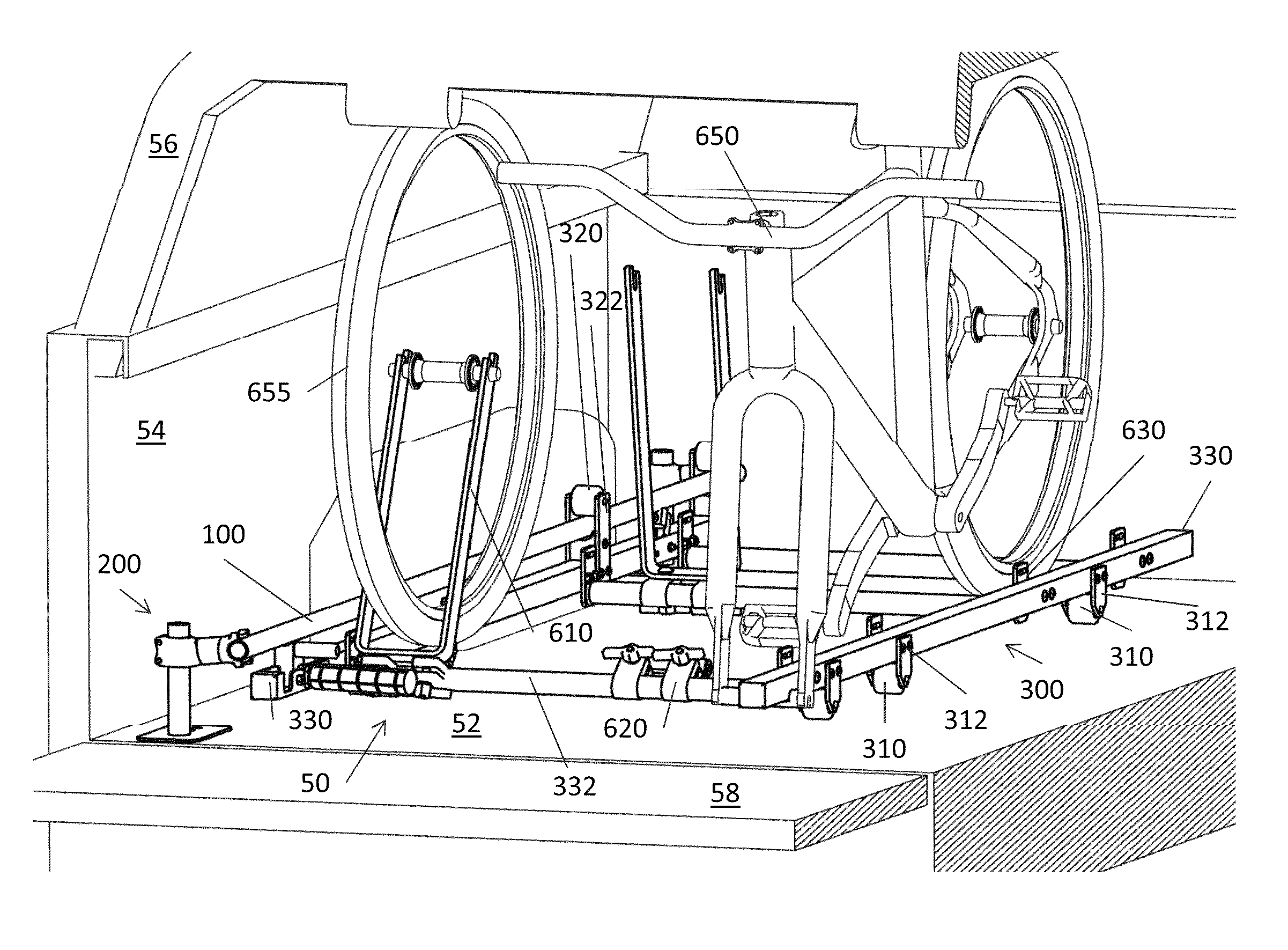

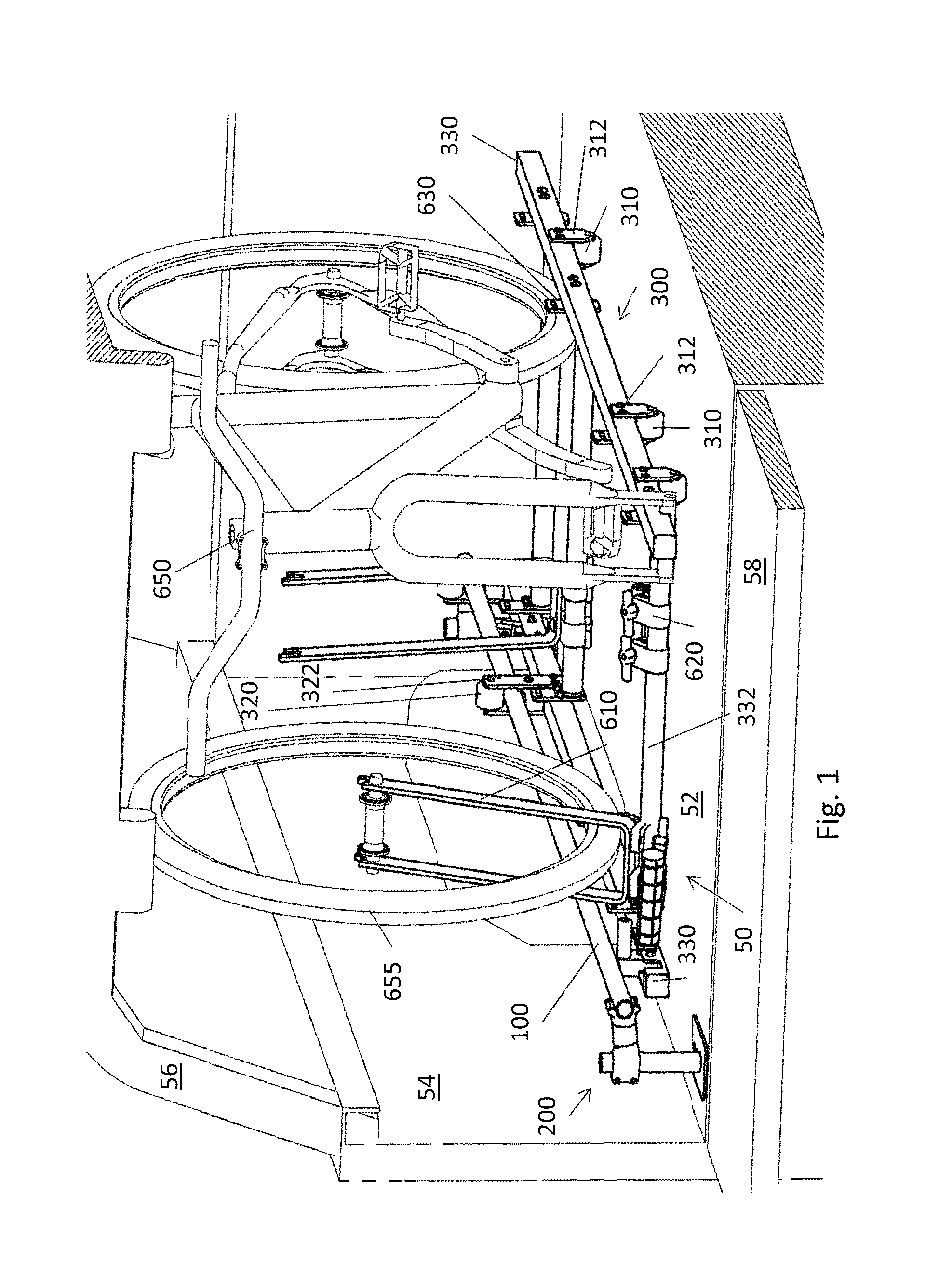

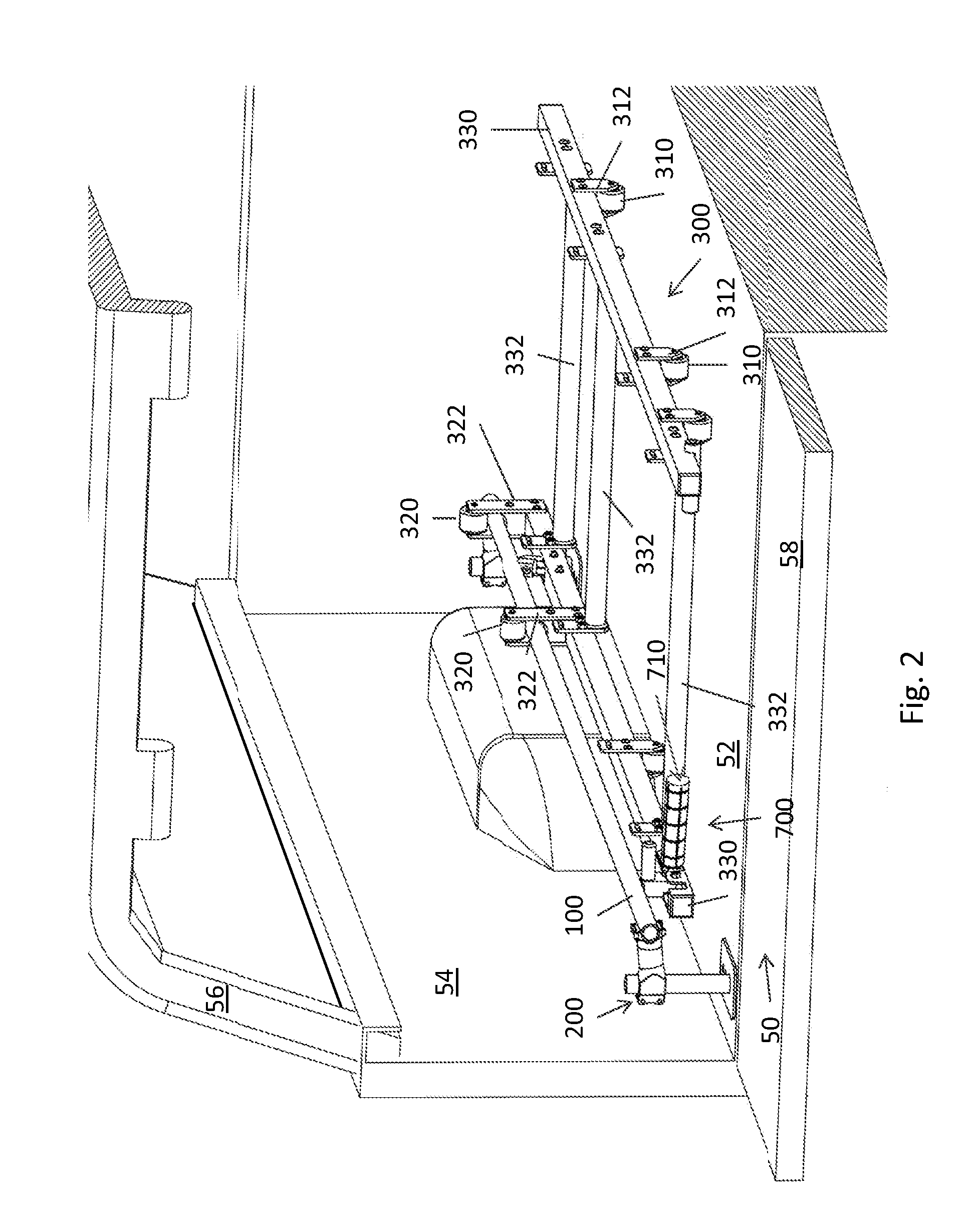

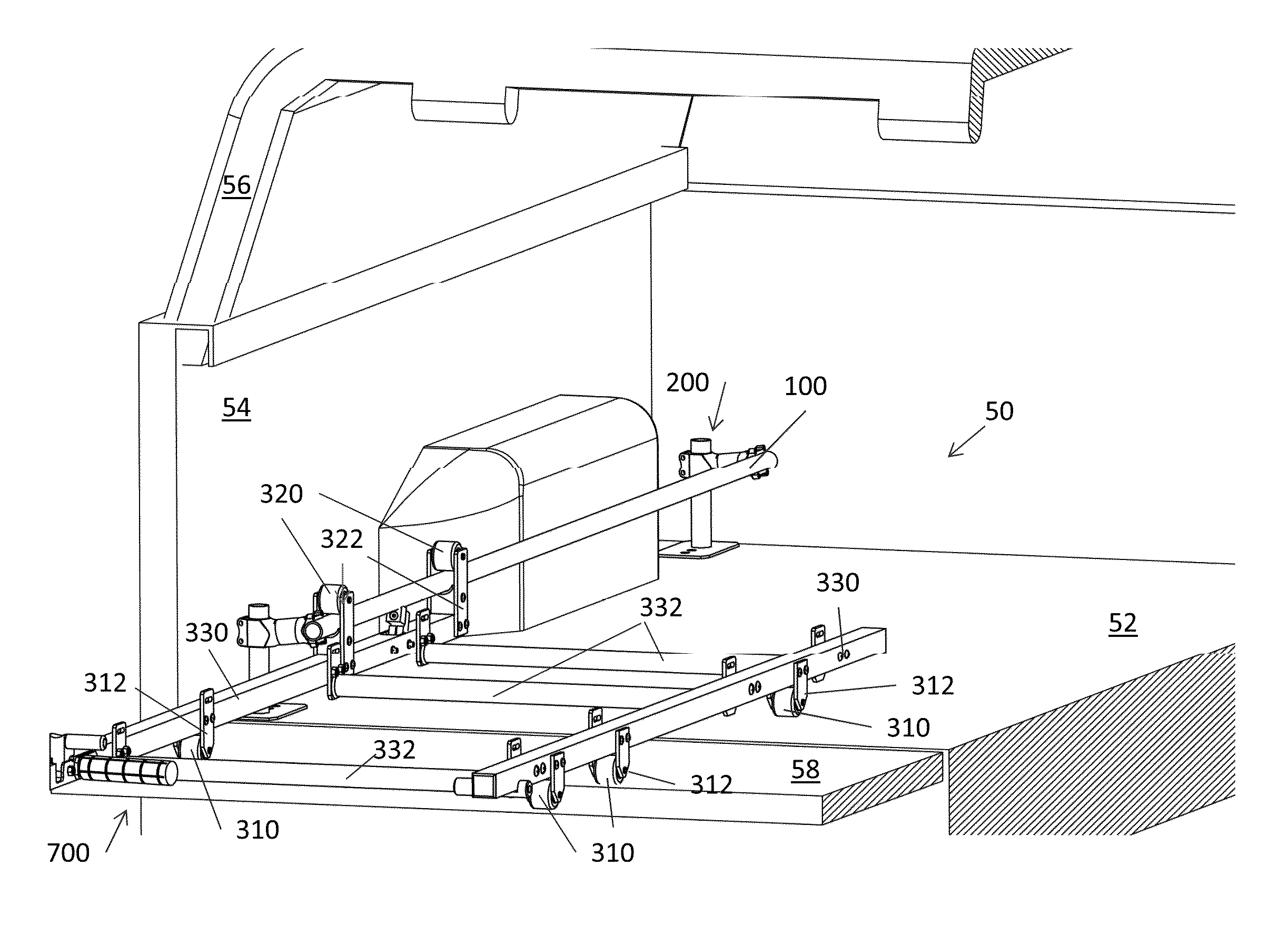

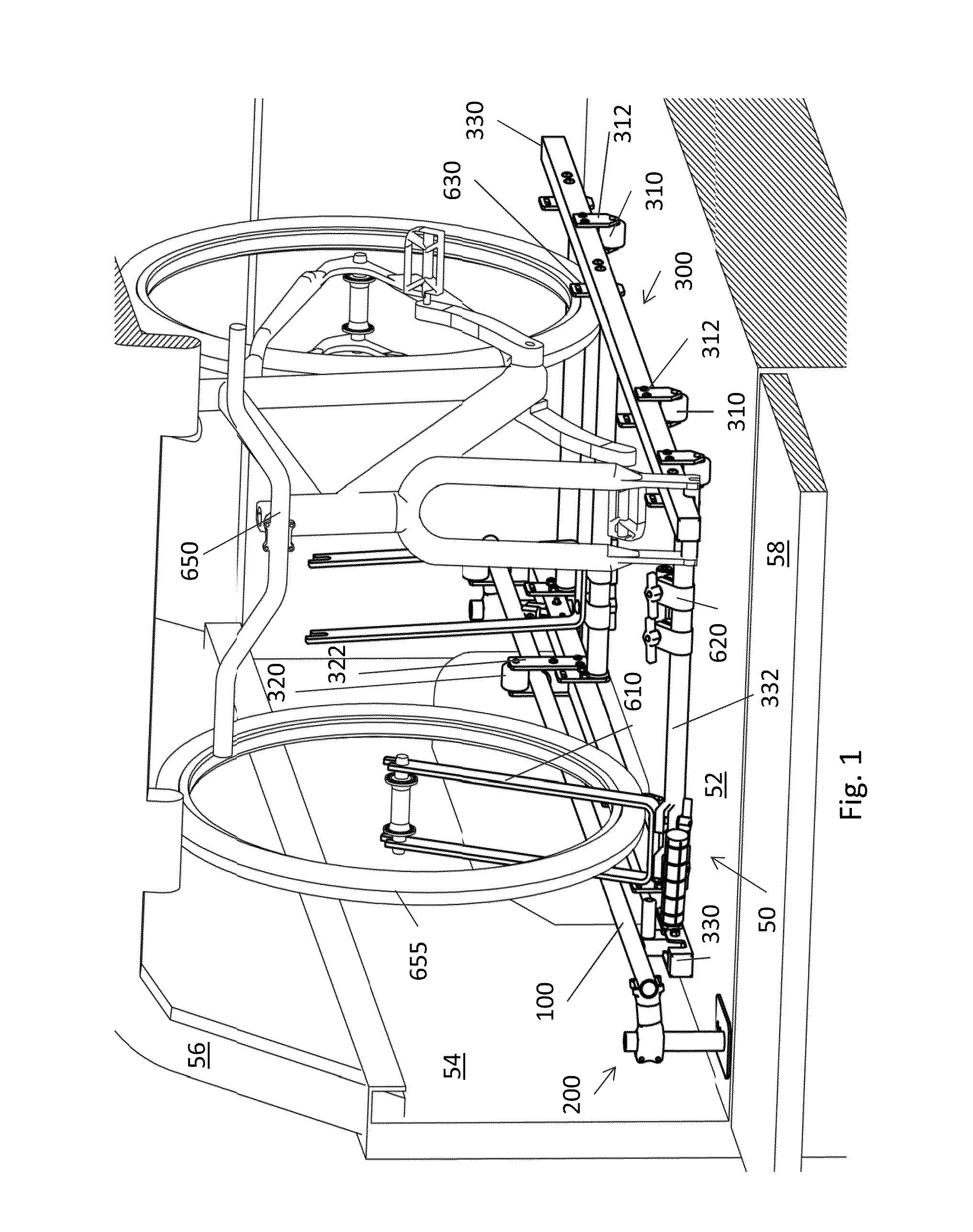

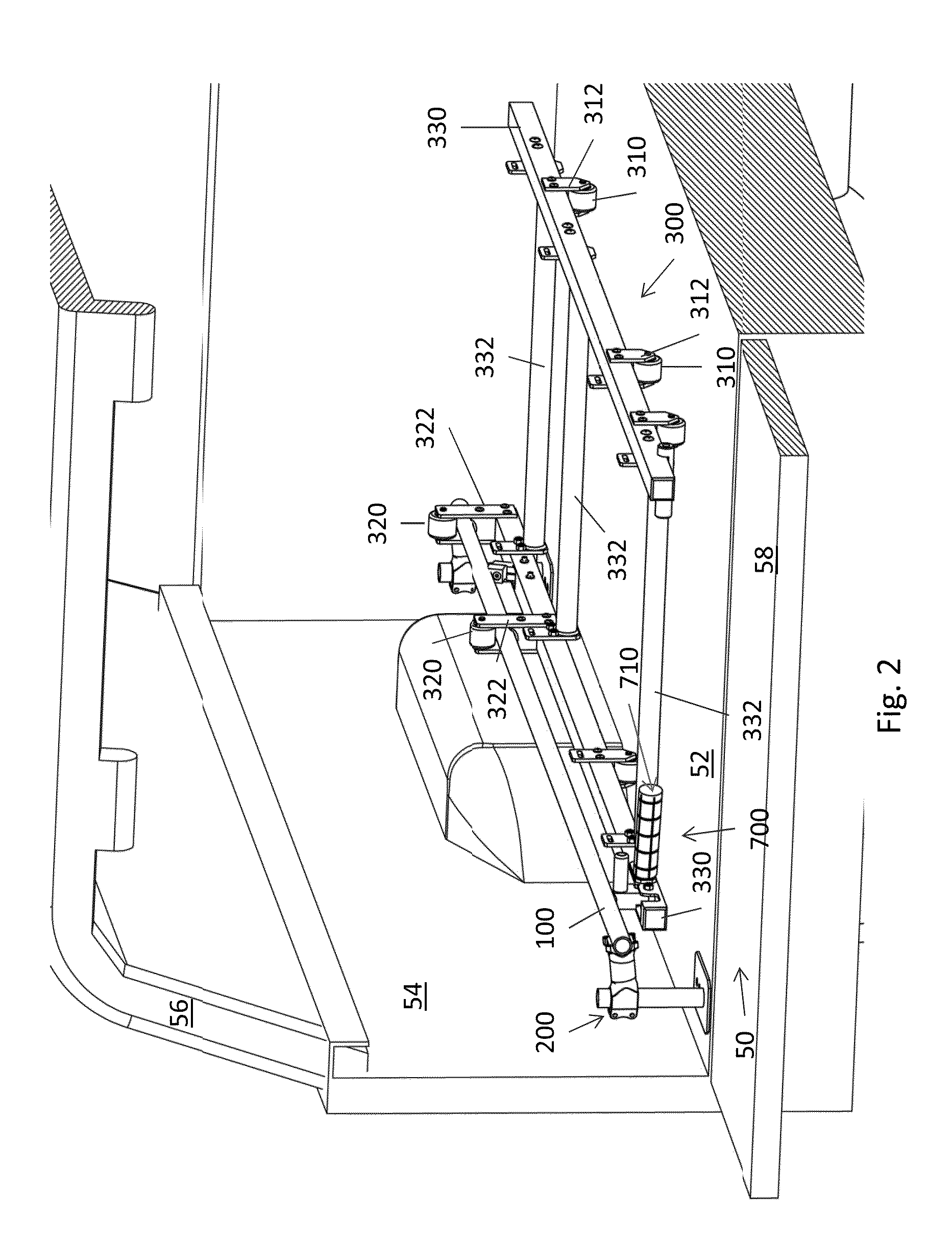

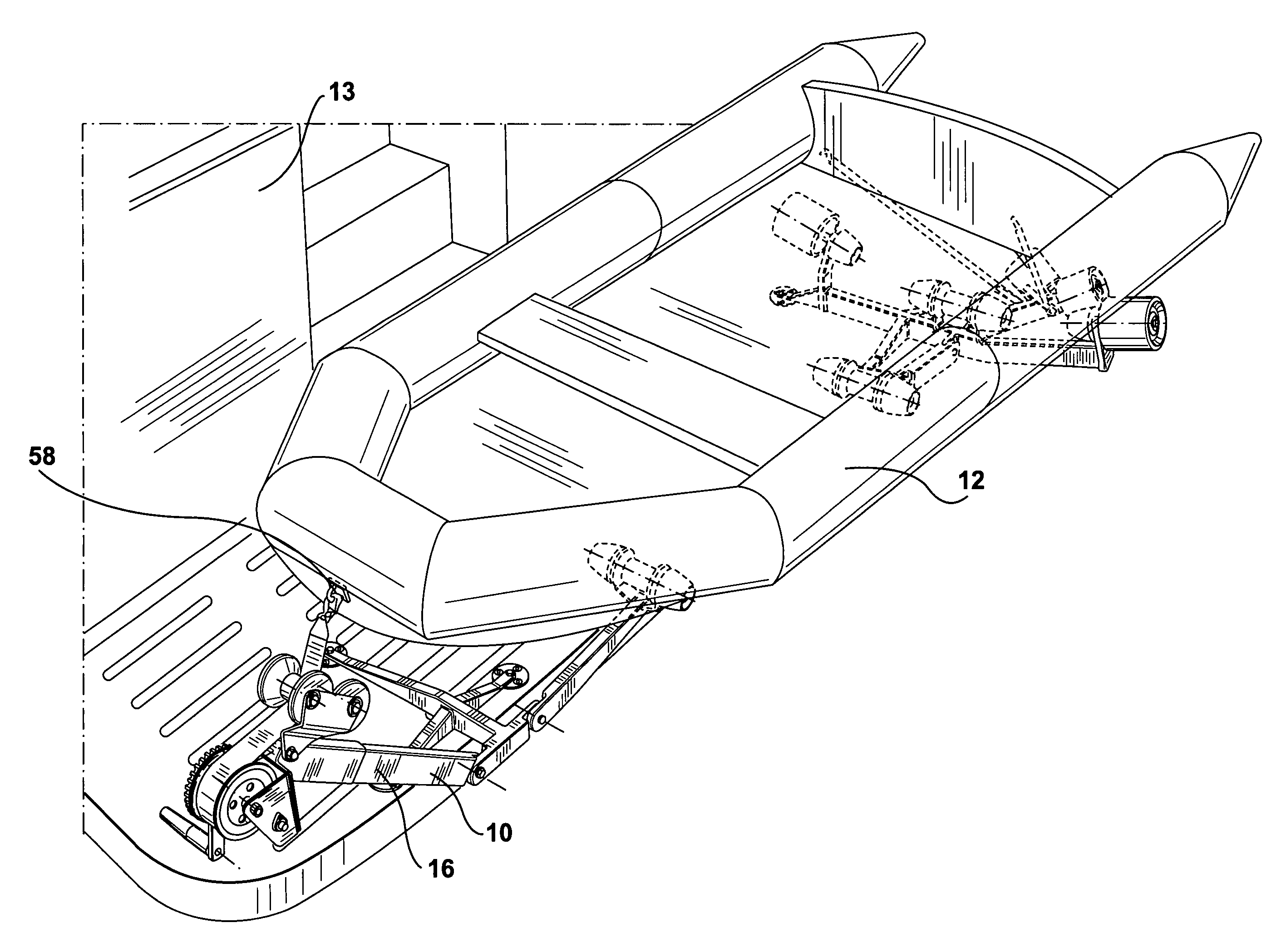

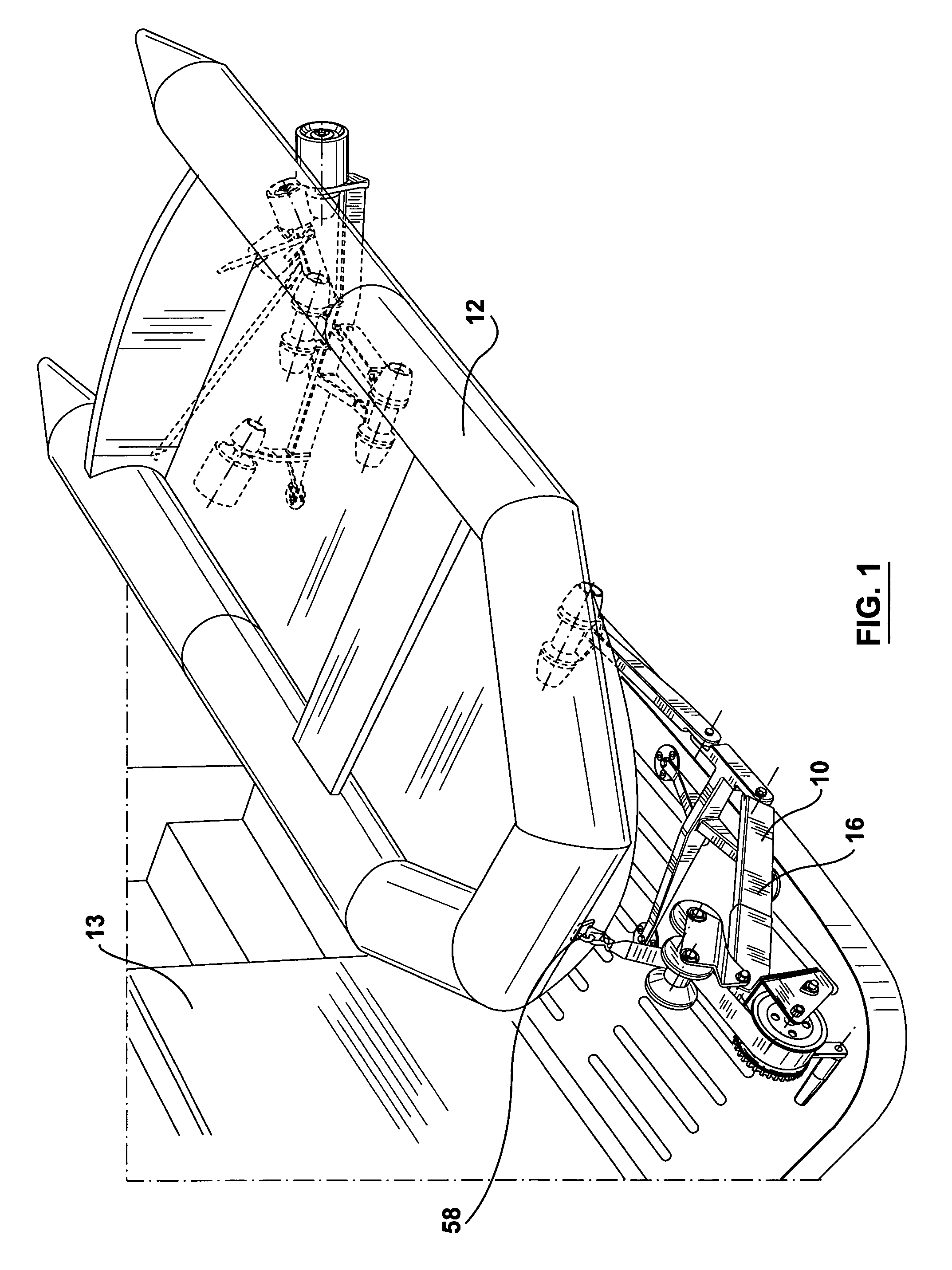

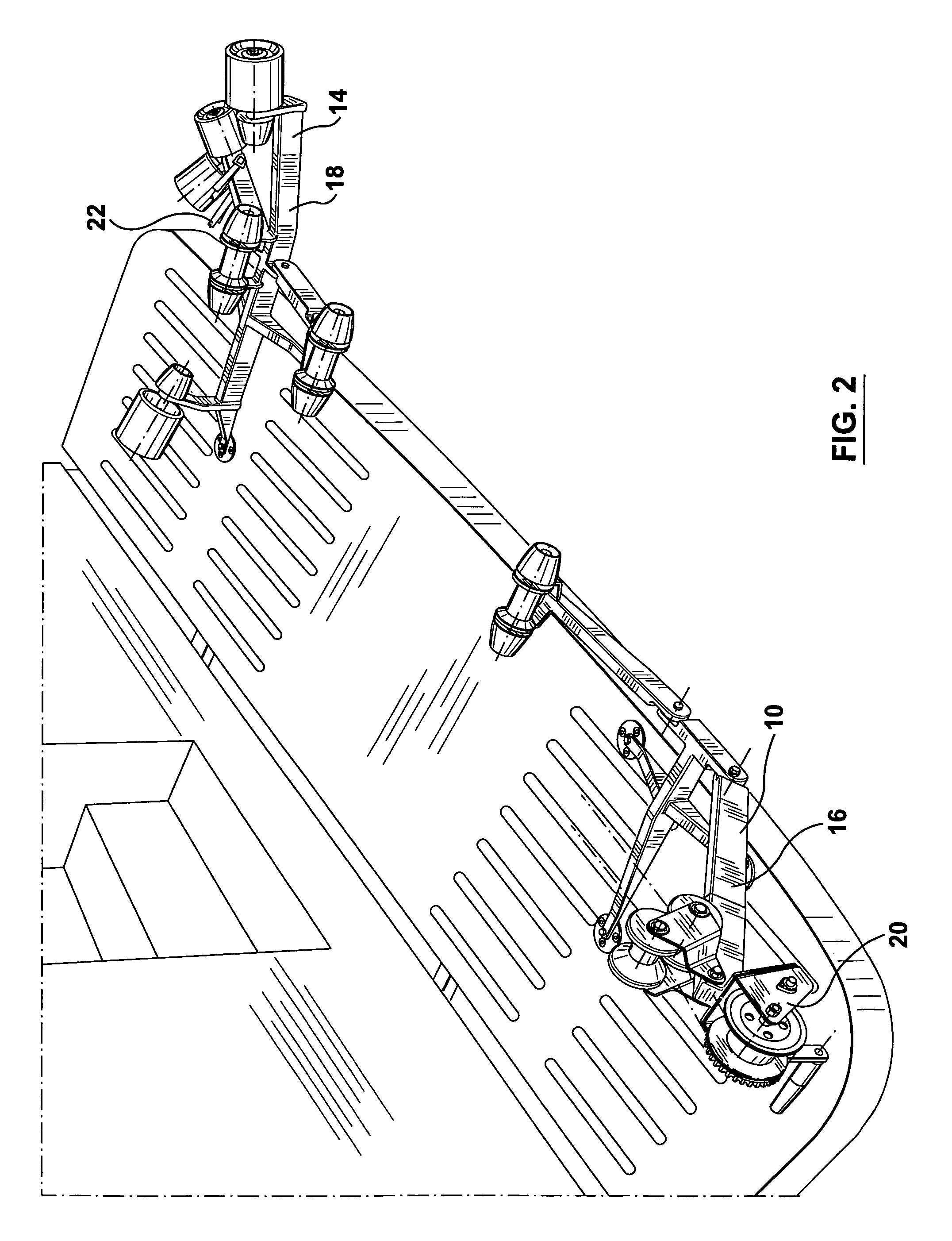

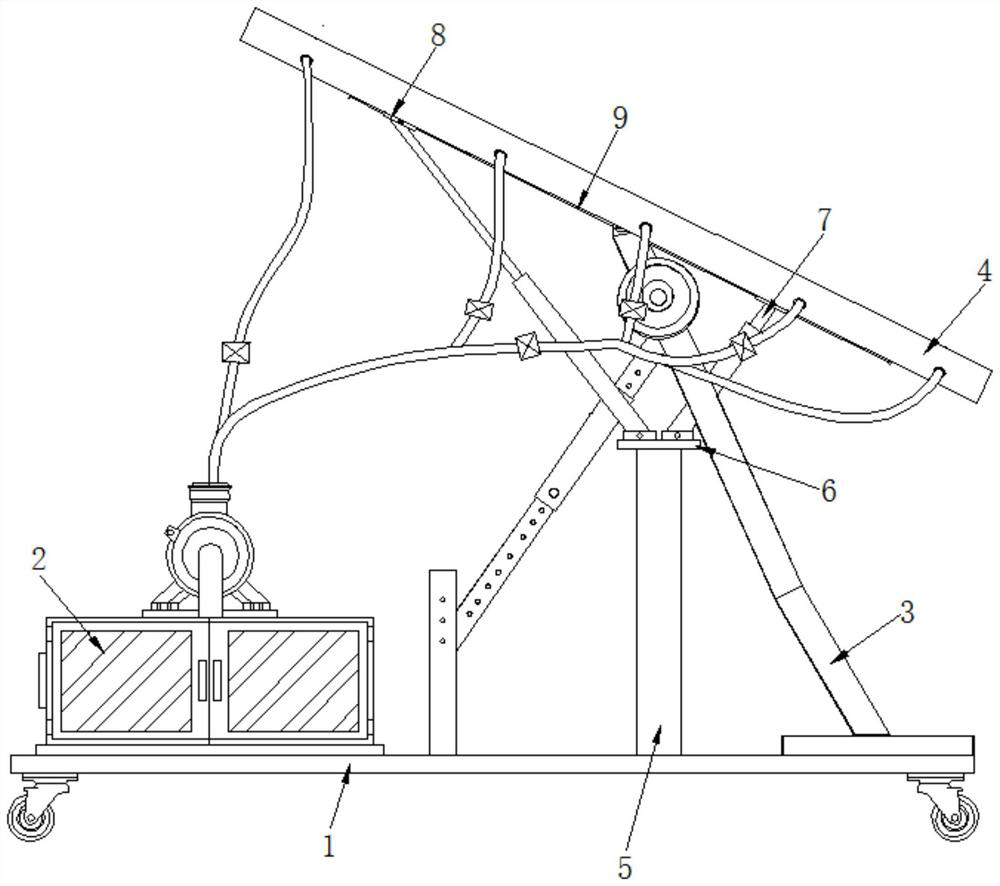

Equipment storage and retrieval system

ActiveUS9254792B2Easy to foldEasy retrievalSupplementary fittingsItem transportation vehiclesPick-up truckEngineering

An equipment storage and retrieval system retrieves equipment from the back of pick-up trucks and other cargo carrying vehicles. A guide rail and a frame with attached rollers and equipment hold-downs, platforms or carts allow for easy access, retrieval, and storage of equipment in the bed of a vehicle. A frame extends out the back of a pickup for access to equipment, and folds into a vertical position for improved use of the pickup bed. A brake system prevents locks the sliding frame in place until the brake is released by a brake lever.

Owner:PATTON MARK +1

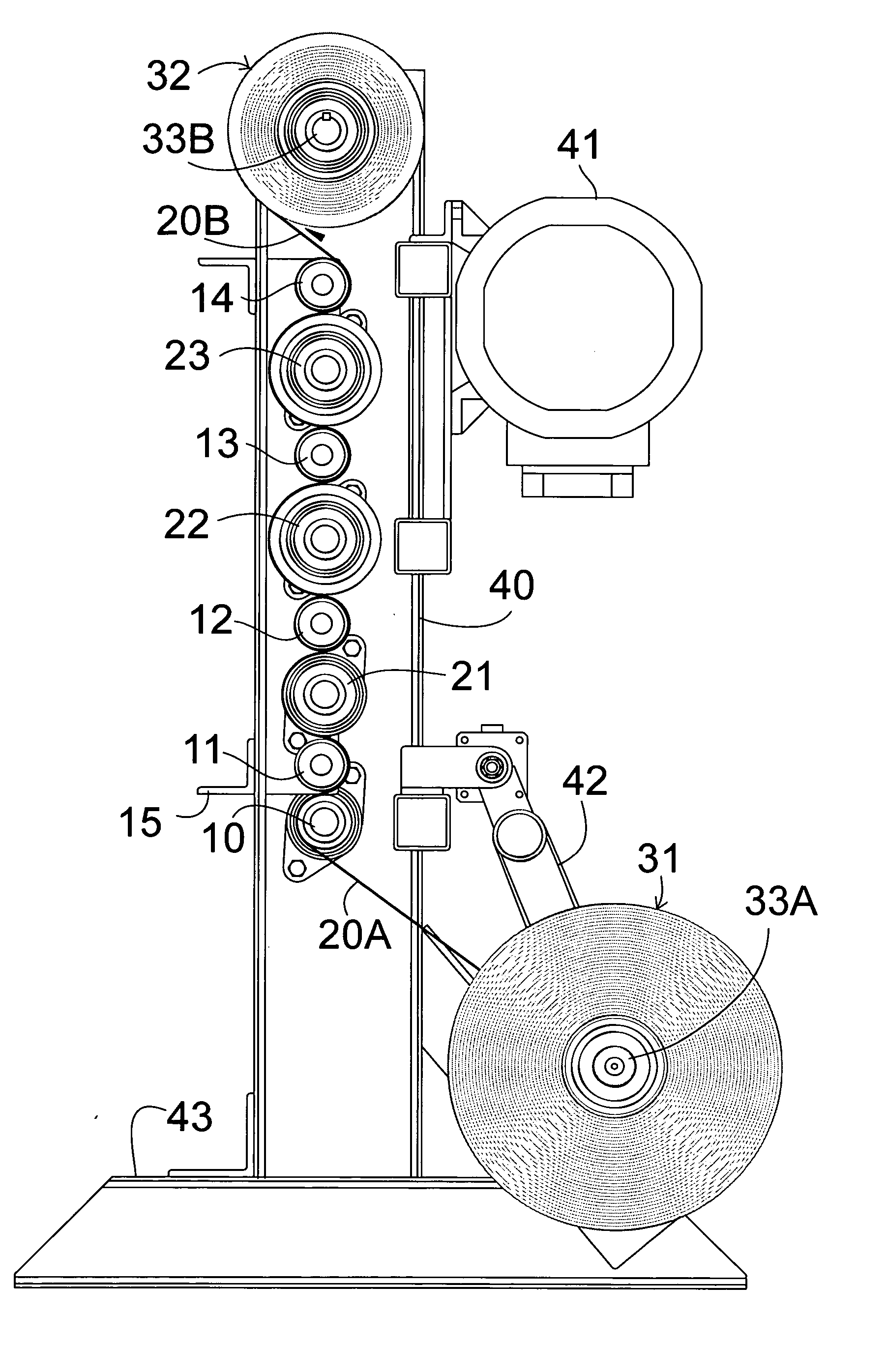

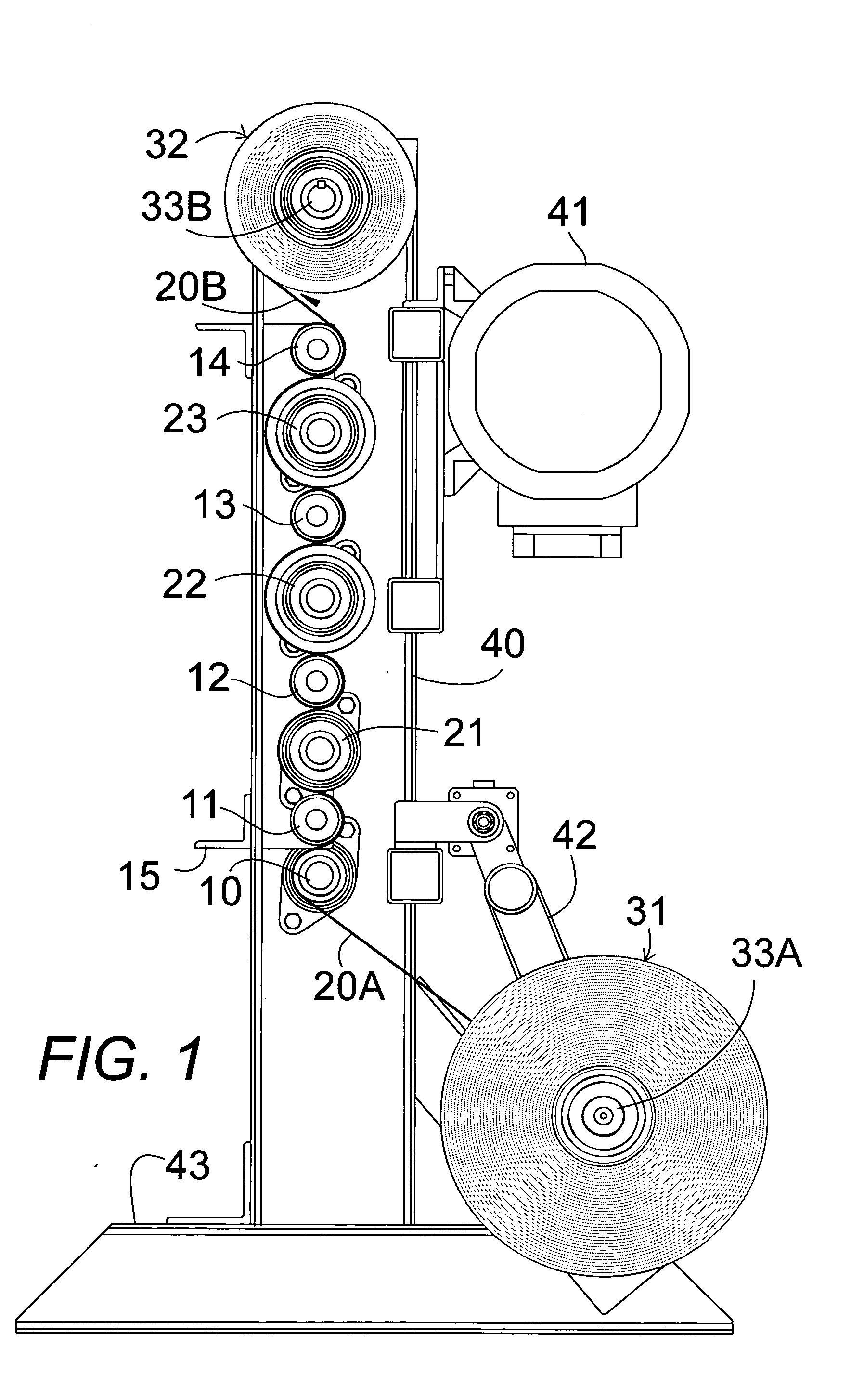

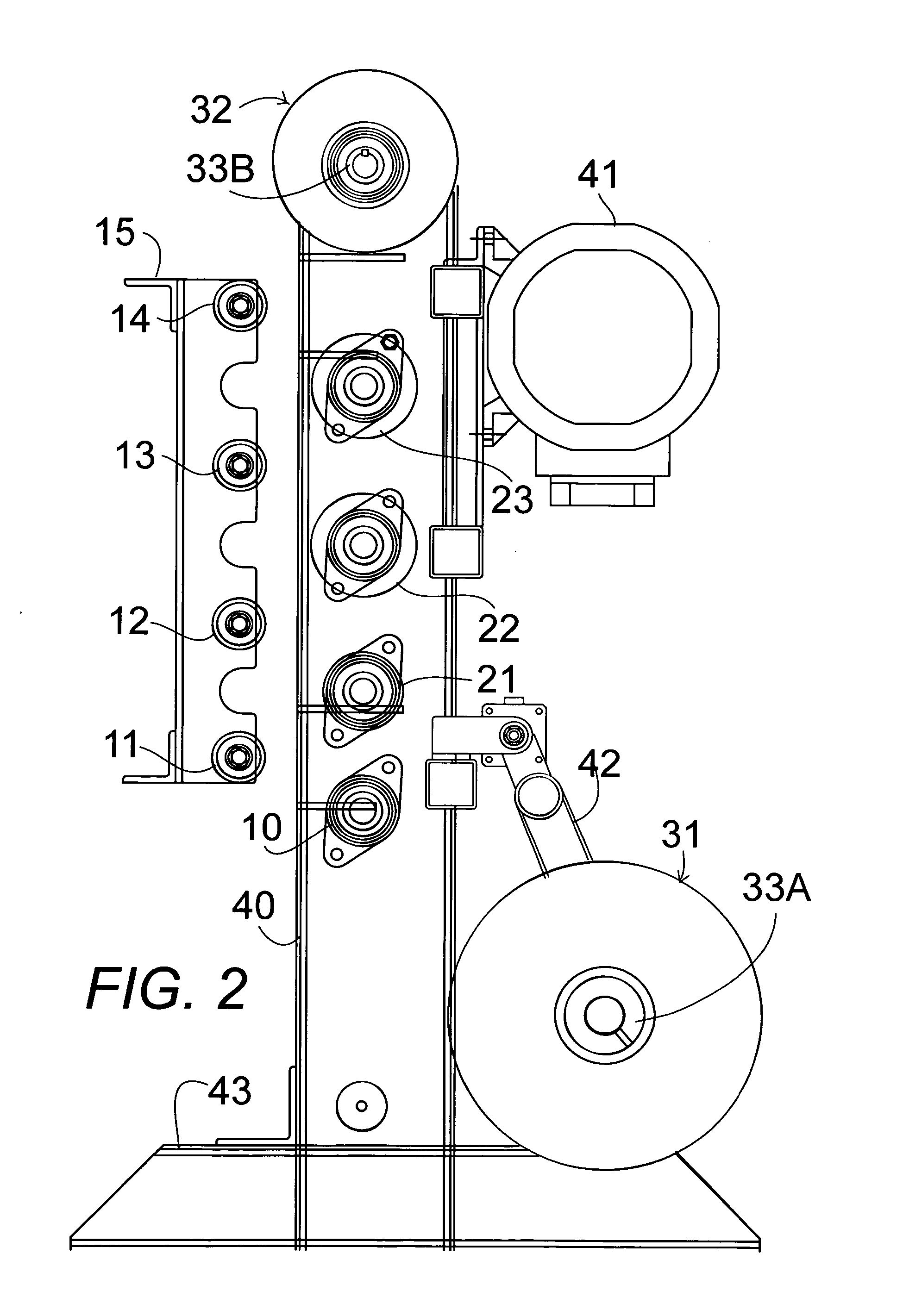

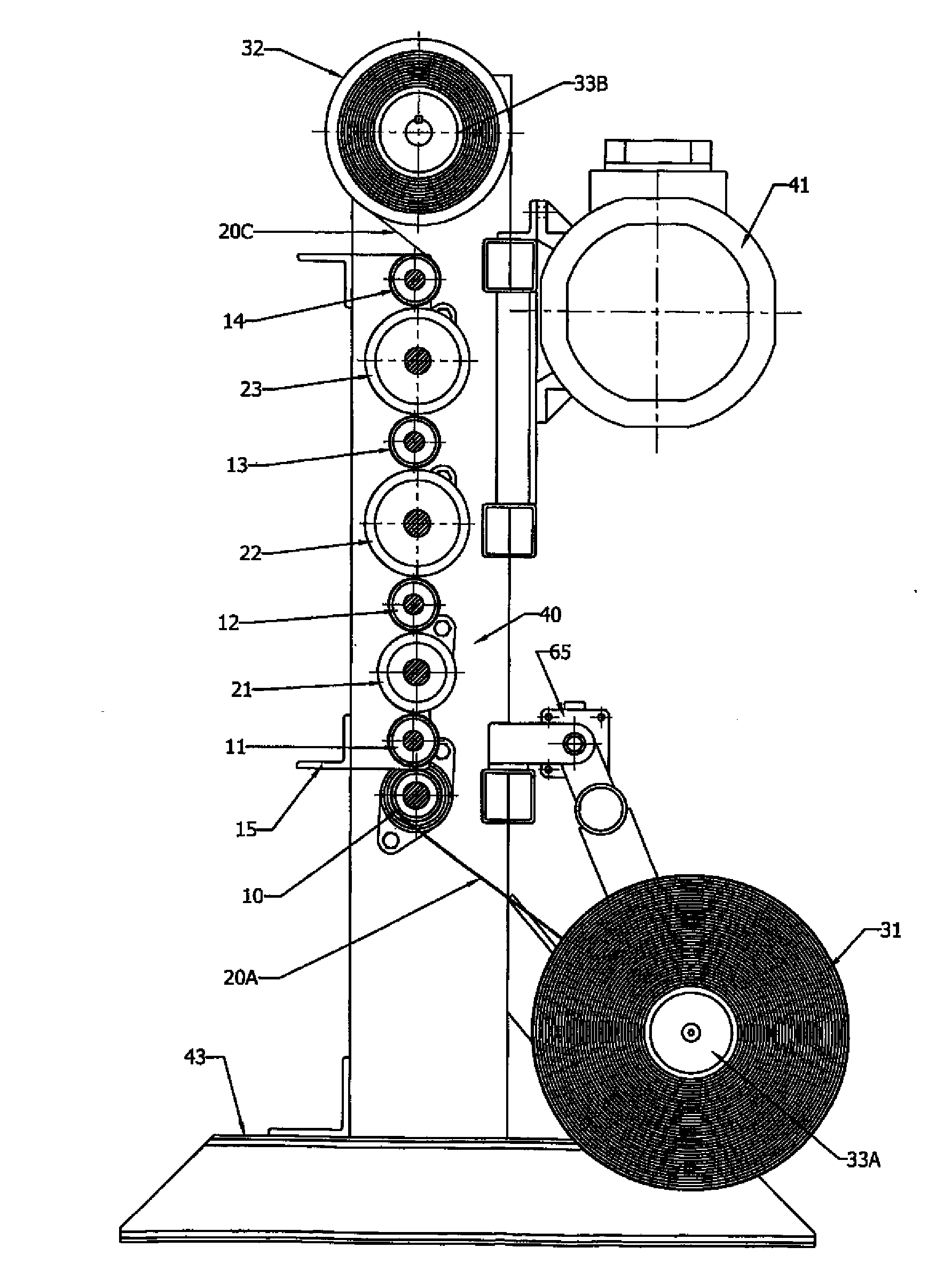

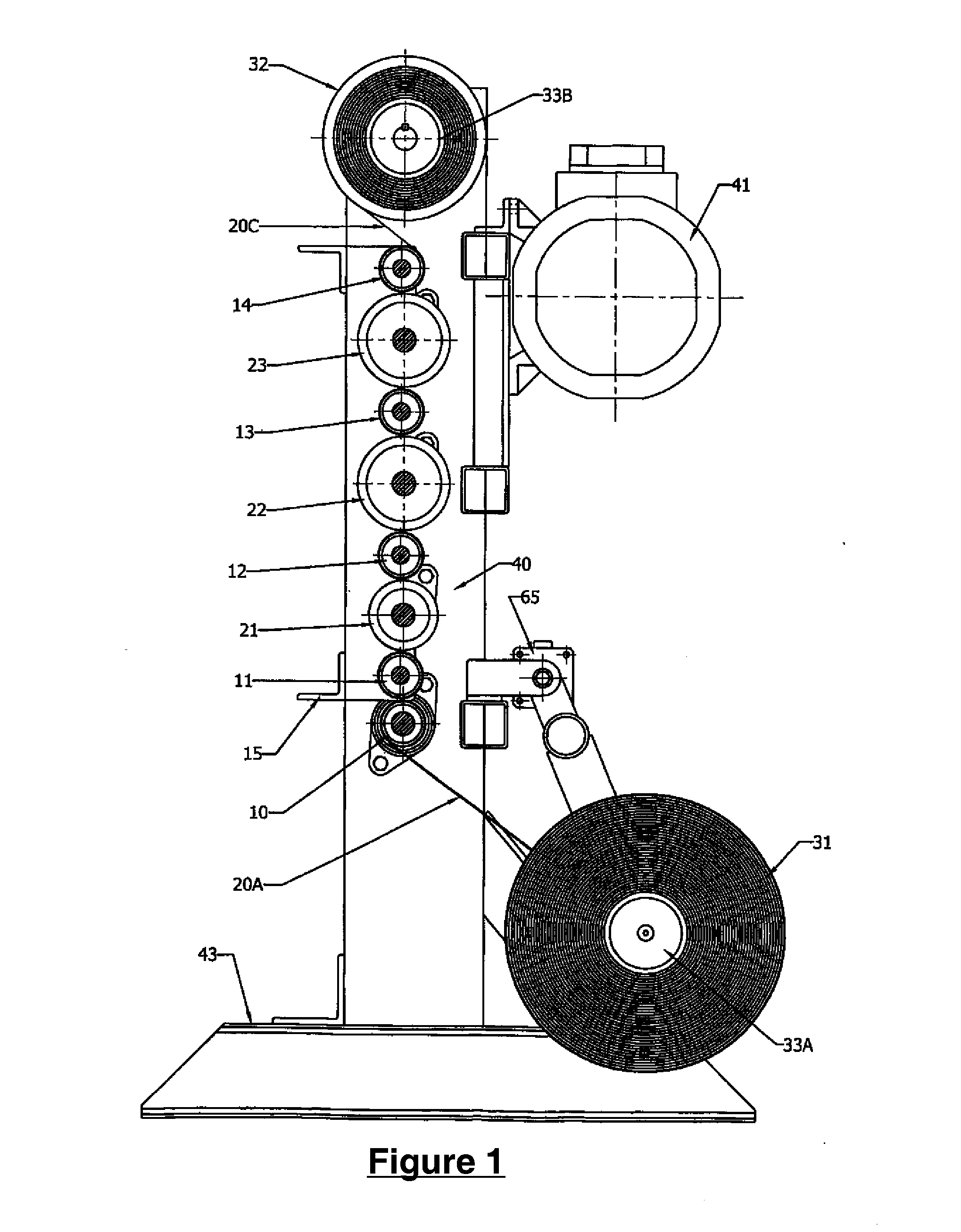

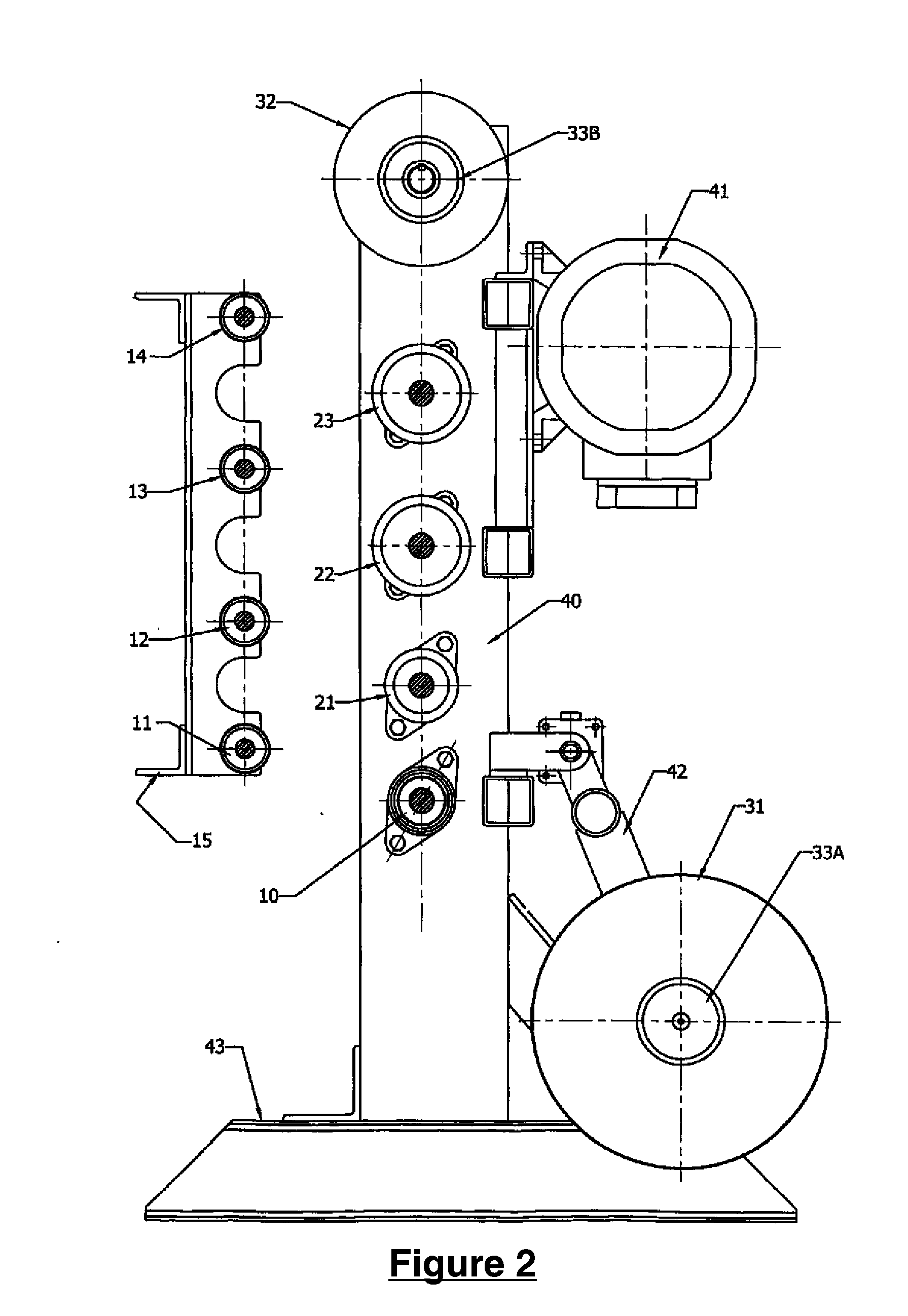

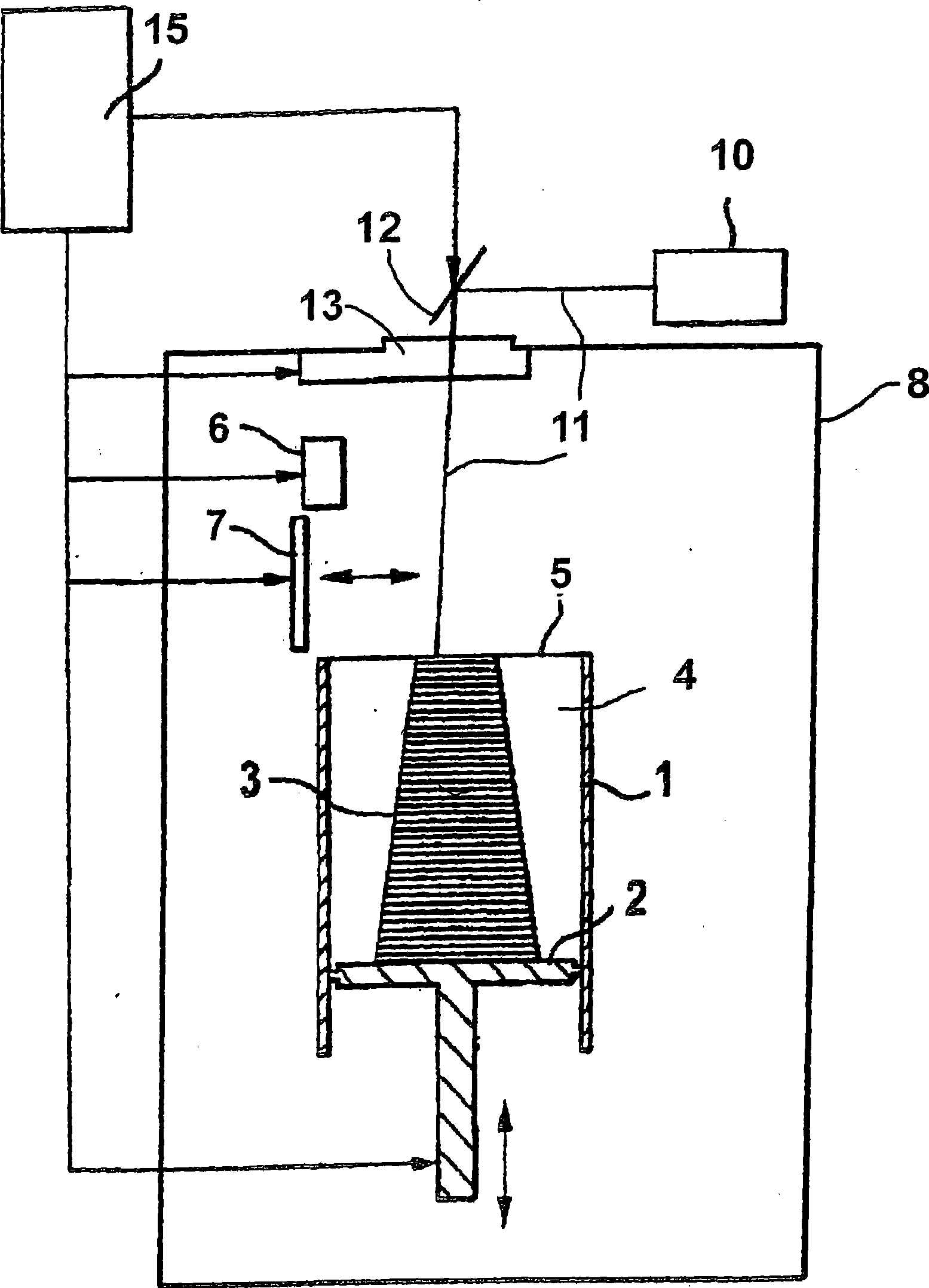

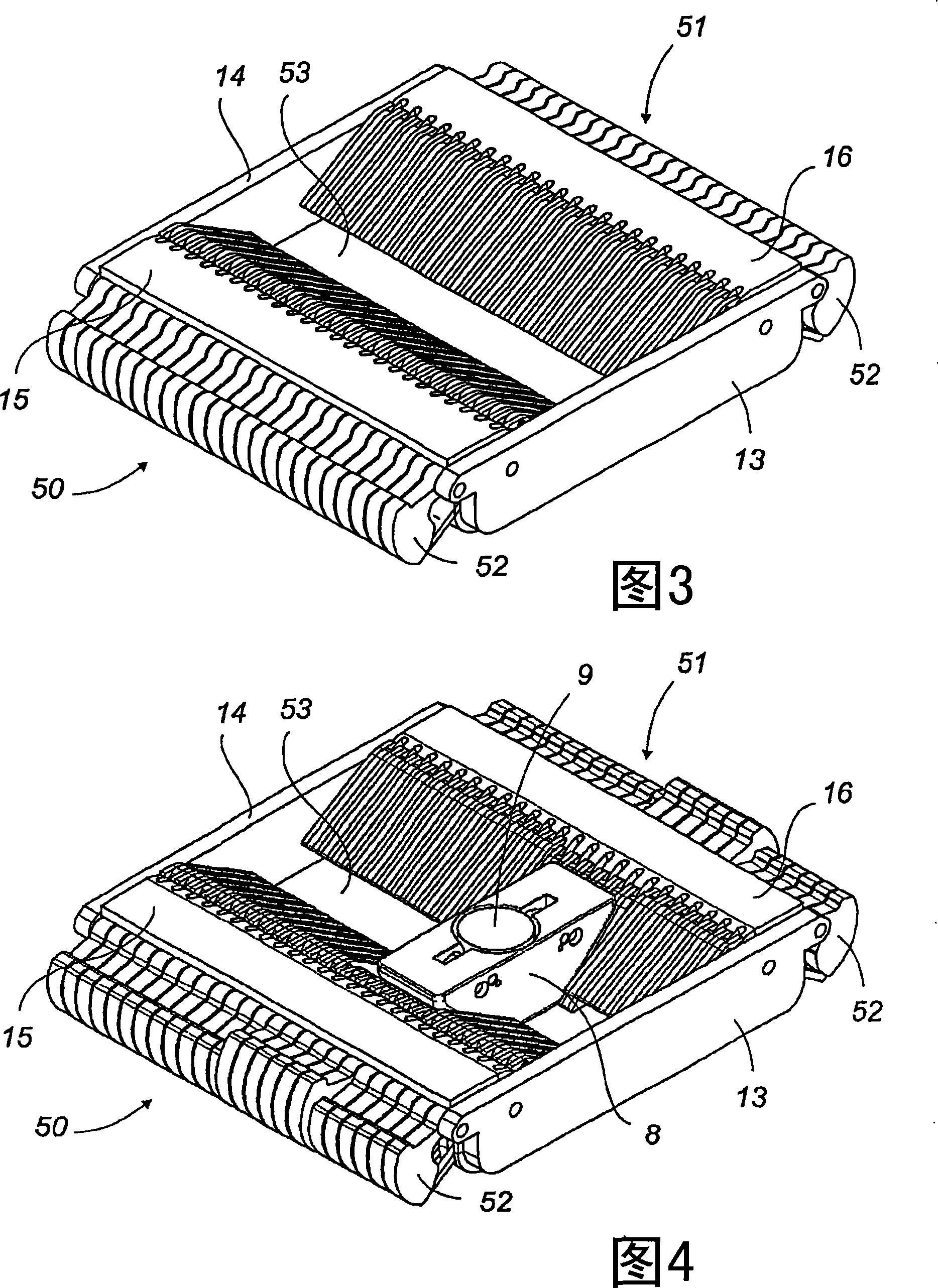

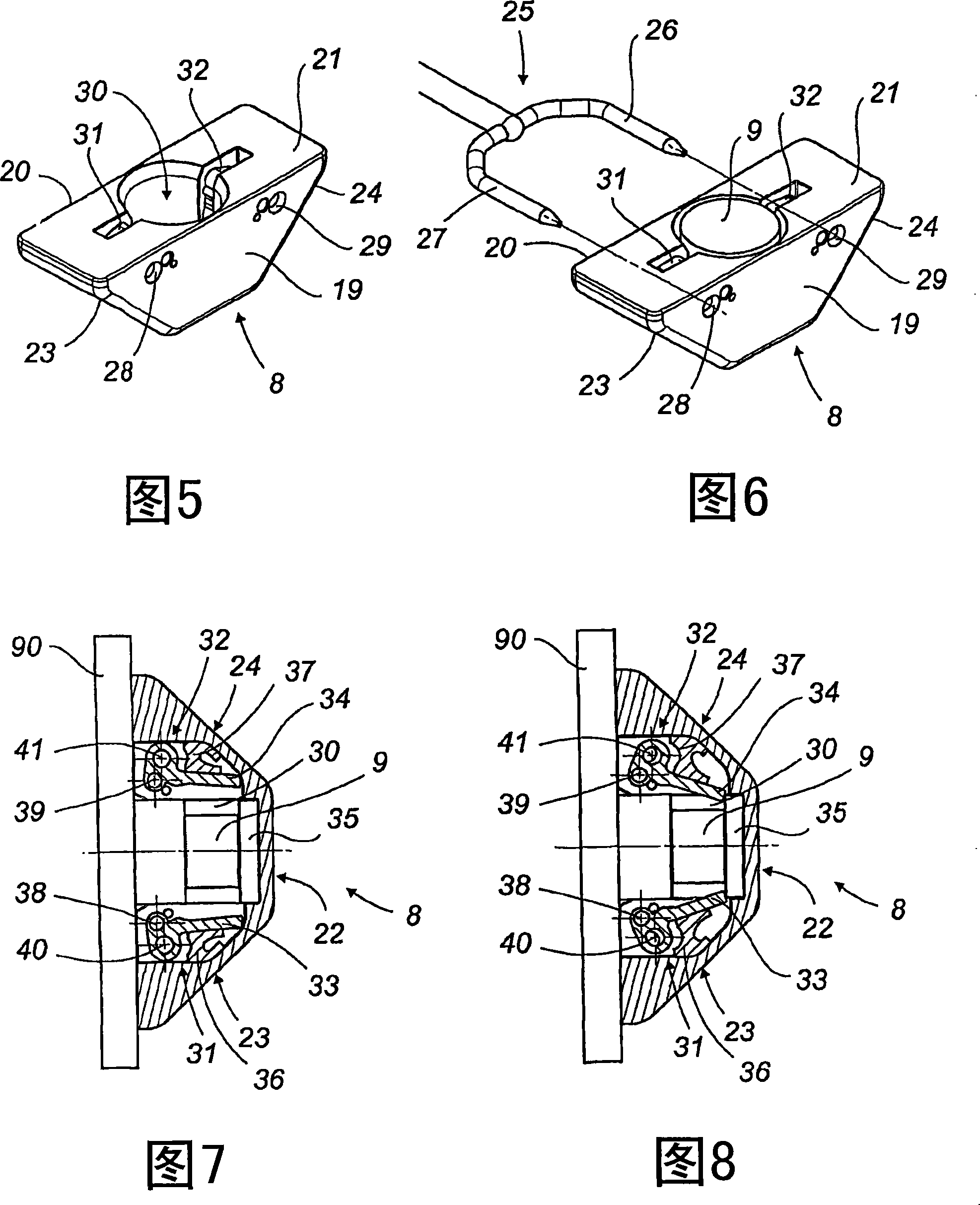

Device for producing a three-dimensional object in layers

ActiveCN101500785AEasy and fast loadingOptimal Layer CoatingAdditive manufacturing apparatusIncreasing energy efficiencyBiomedical engineeringLaser

The invention relates to a device for producing a three-dimensional object (3) by solidifying powdery build-up material on the points corresponding to the cross-section of the object (3) to be produced in the respective layer, under the action of a laser or another energy source. Said device comprises a carrier (2) on which the object (3) is produced, and a coating element (6, 7) for applying a layer of the build-up material to the carrier or a previously at least partially solidified layer. The coating element (6, 7) comprises a receiving device (40) for receiving a coating module such as a blade module (30). The receiving device (40) is embodied in such a way that the coating module (30) can be inserted into the receiving device (40) in a replaceable manner and removed therefrom such that a pre-determined position of the coating module (30) is fixed in the receiving device (40) in a reproducible manner.

Owner:EOS ELECTRO OPTICAL SYST

Equipment storage and retrieval system

ActiveUS9327633B1Easy to foldEasy retrievalSupplementary fittingsItem transportation vehiclesPick-up truckEngineering

Owner:PATTON MARK +1

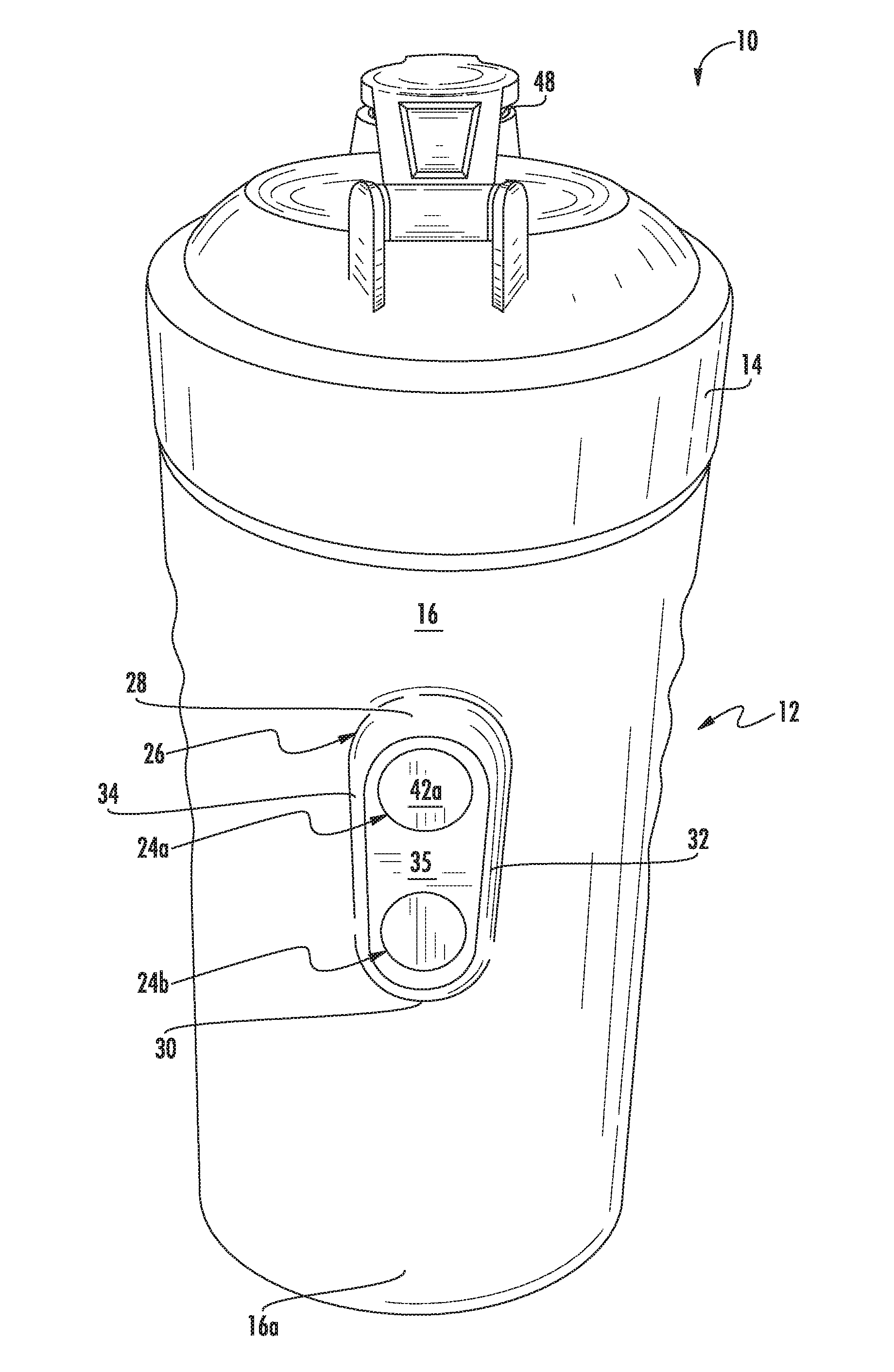

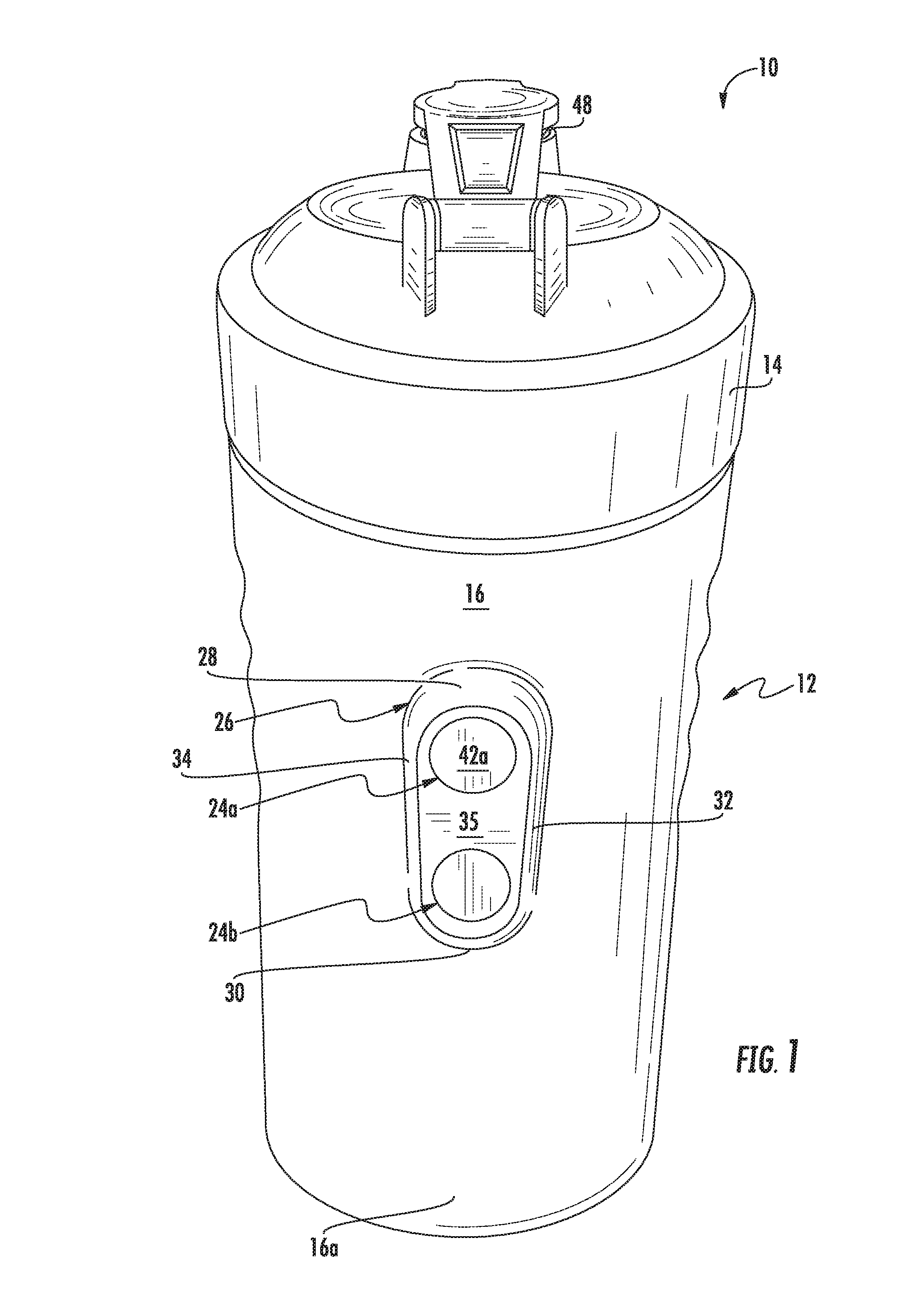

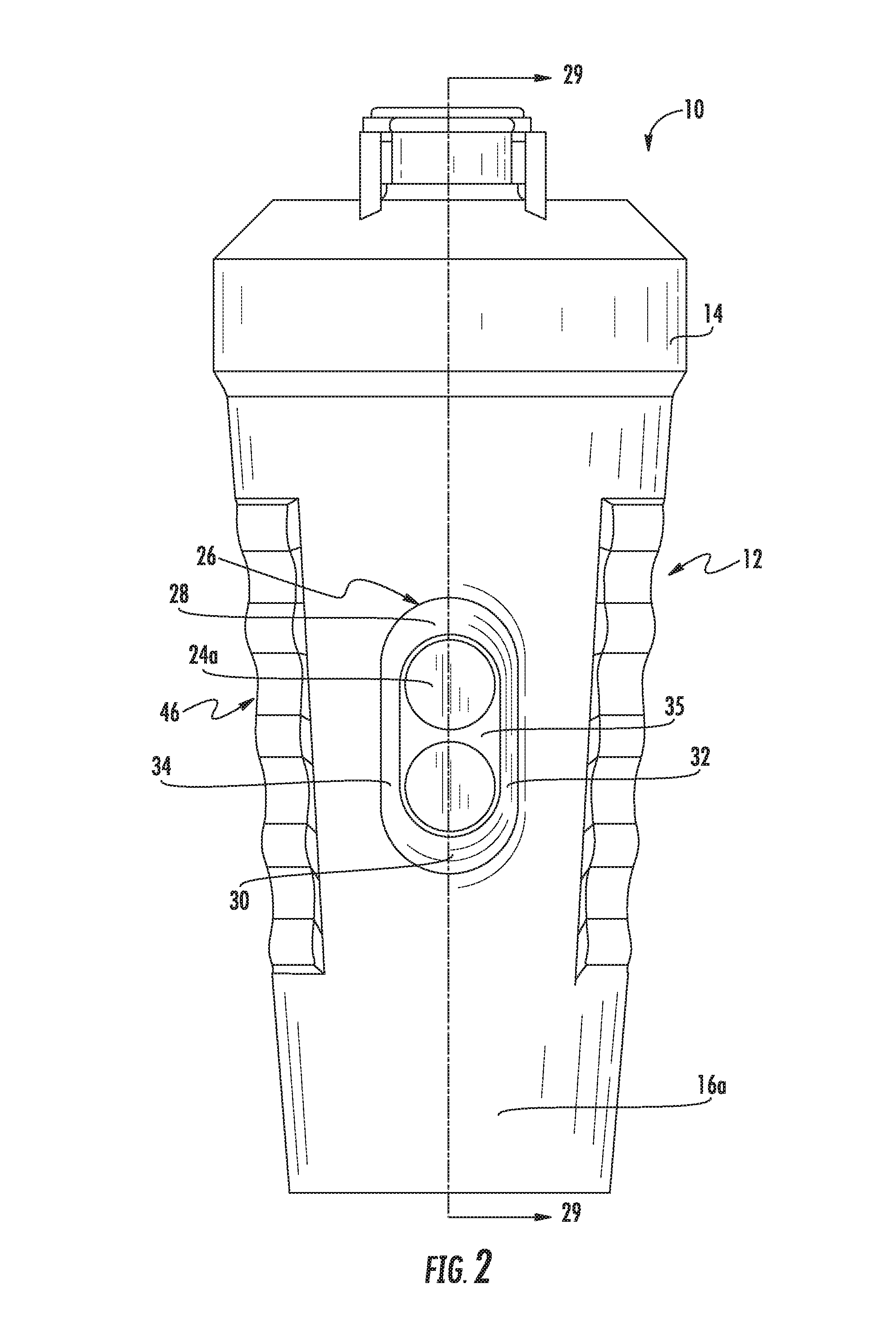

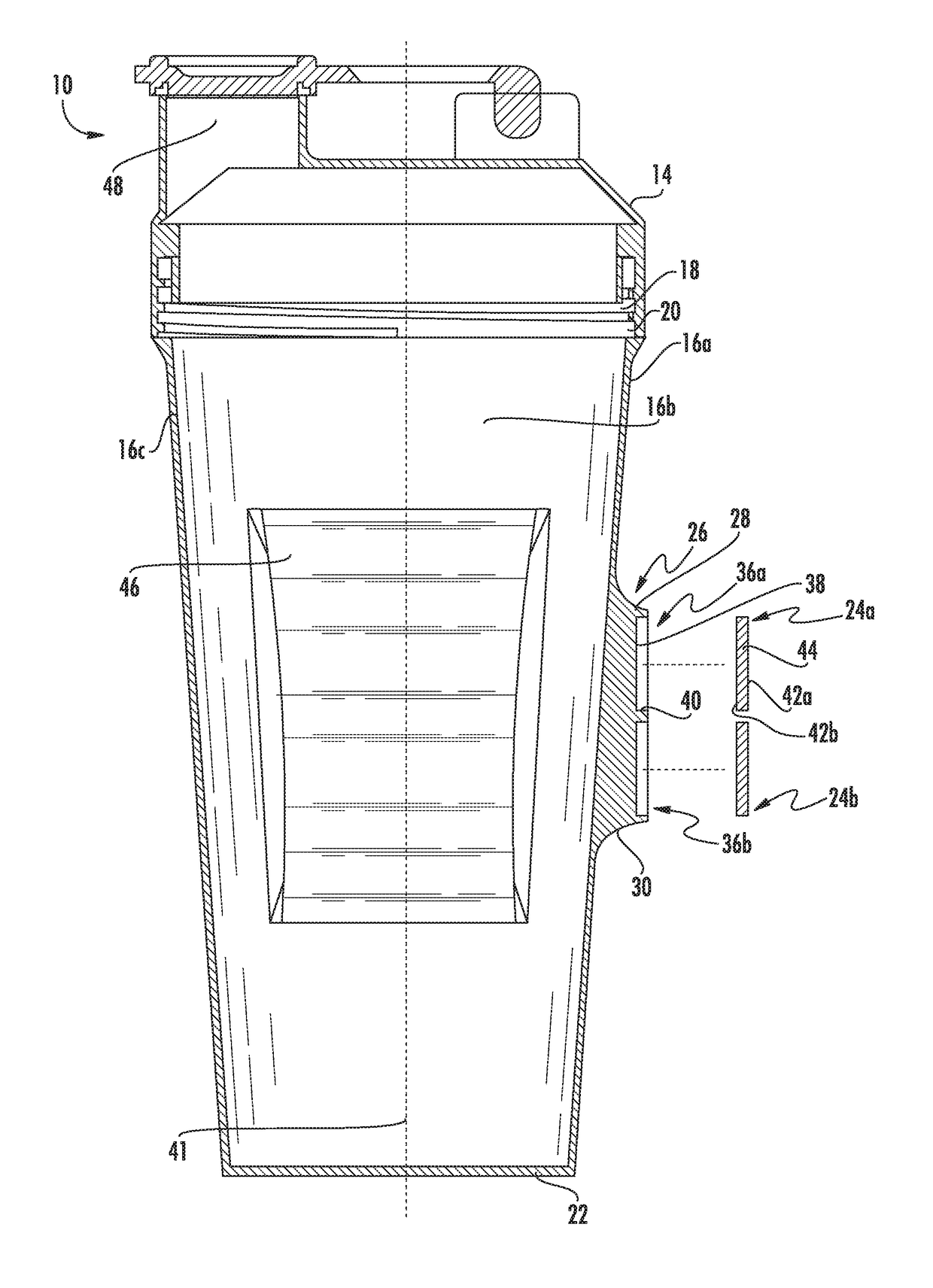

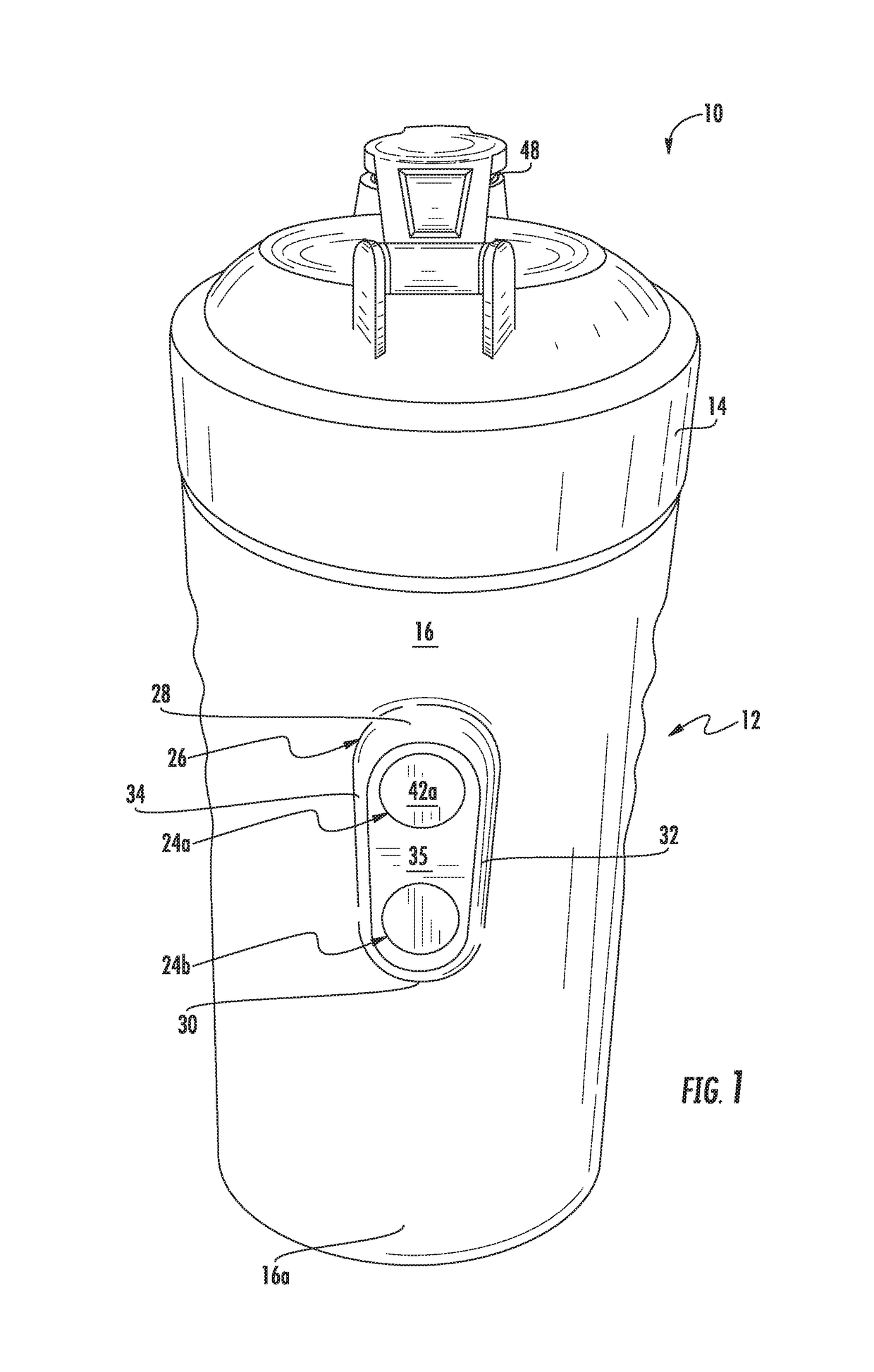

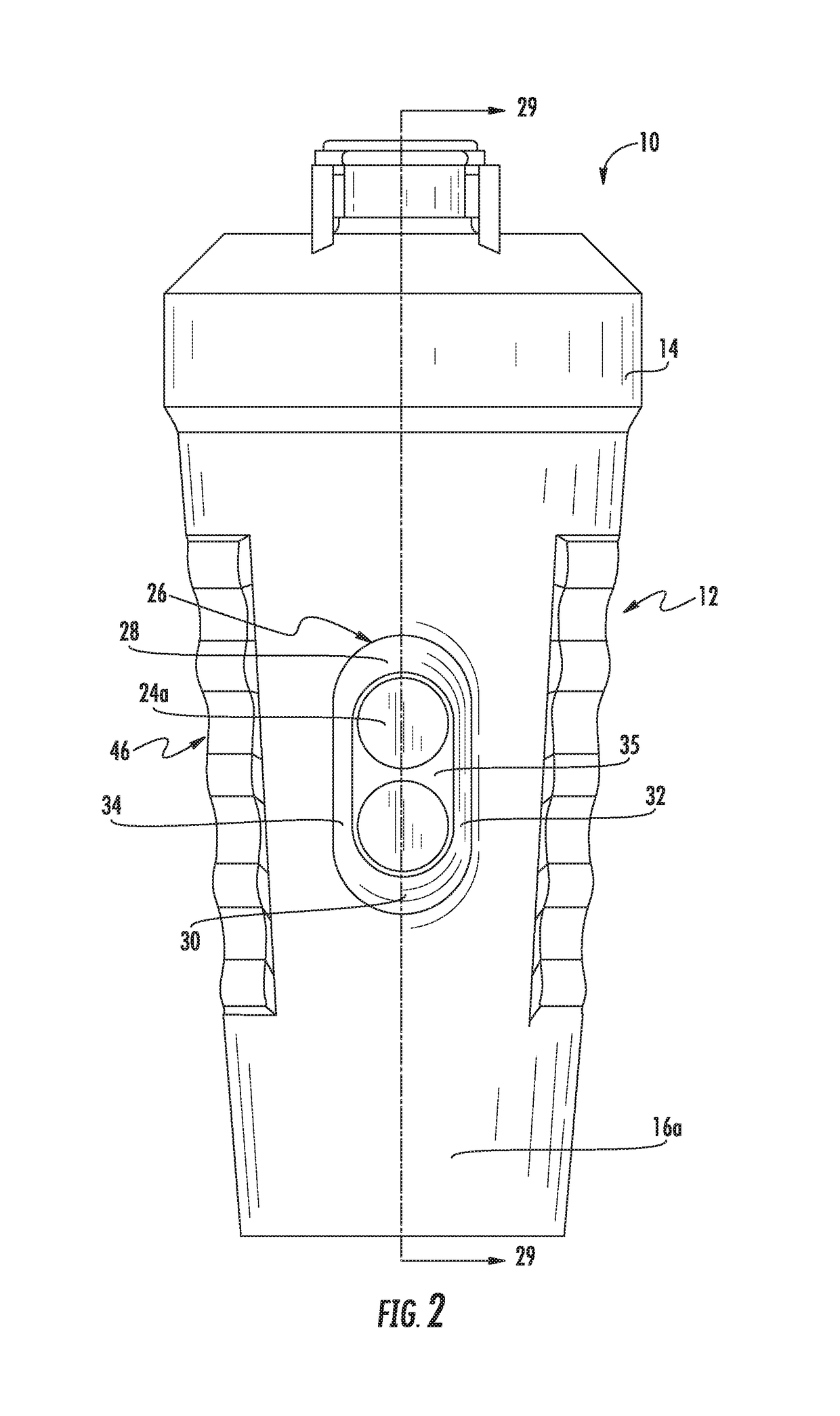

Shaker bottle with magnetic elements for temporary securement to exercise equipment

A protein shaker bottle or similar beverage container that has one or more magnets on its outer surface. The magnets allow for the shaker bottle to magnetically adhere to a metallic or ferrous surface. The inventive bottle allows a user to quickly and temporarily adhere the bottle to a piece of gym equipment on a gym floor.

Owner:YURKOVETSKAYA HANNA +1

Frame face display and shipping container

The present invention is directed to an open-top container for shipping and displaying products which comprises a plurality of side walls. Bottom wall flaps are foldably joined to bottom edges of the side walls and are folded inwardly therefrom into overlapping relationship with one another to form a bottom wall closure. A respective plurality of triangularly-shaped beams foldably joined to upper edges of the respective plurality of side walls. Each of the plurality of the triangularly-shaped beams is defined by a shoulder panel and a flange panel foldably joined to one another. A bumper sticker panel is foldably joined to upper edge of one of the plurality of side walls forming a partial top closure when the open-top container is in the shipping position and partially prevents products from falling out when the open-top container is in the displaying position.

Owner:INT PAPER CO

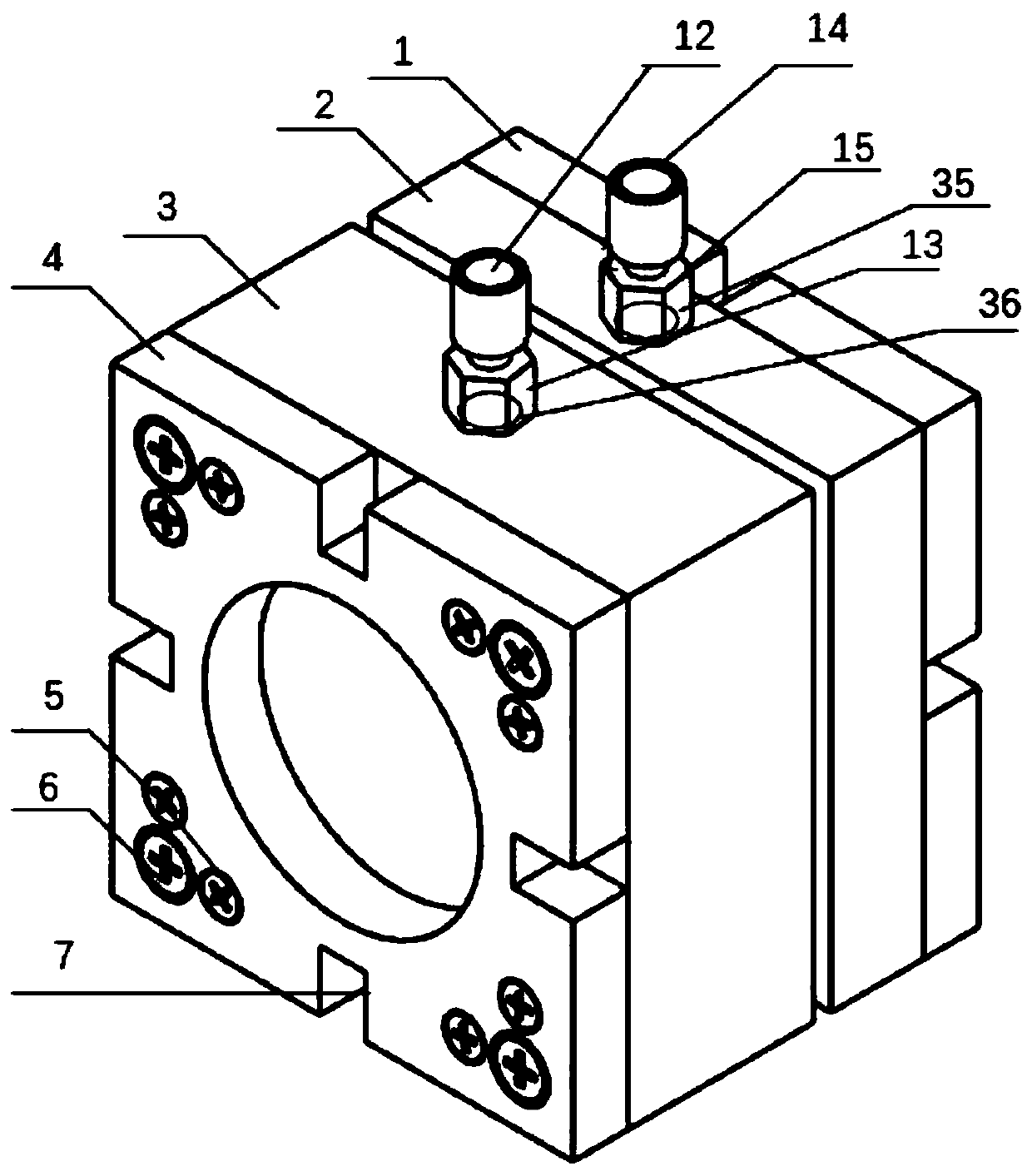

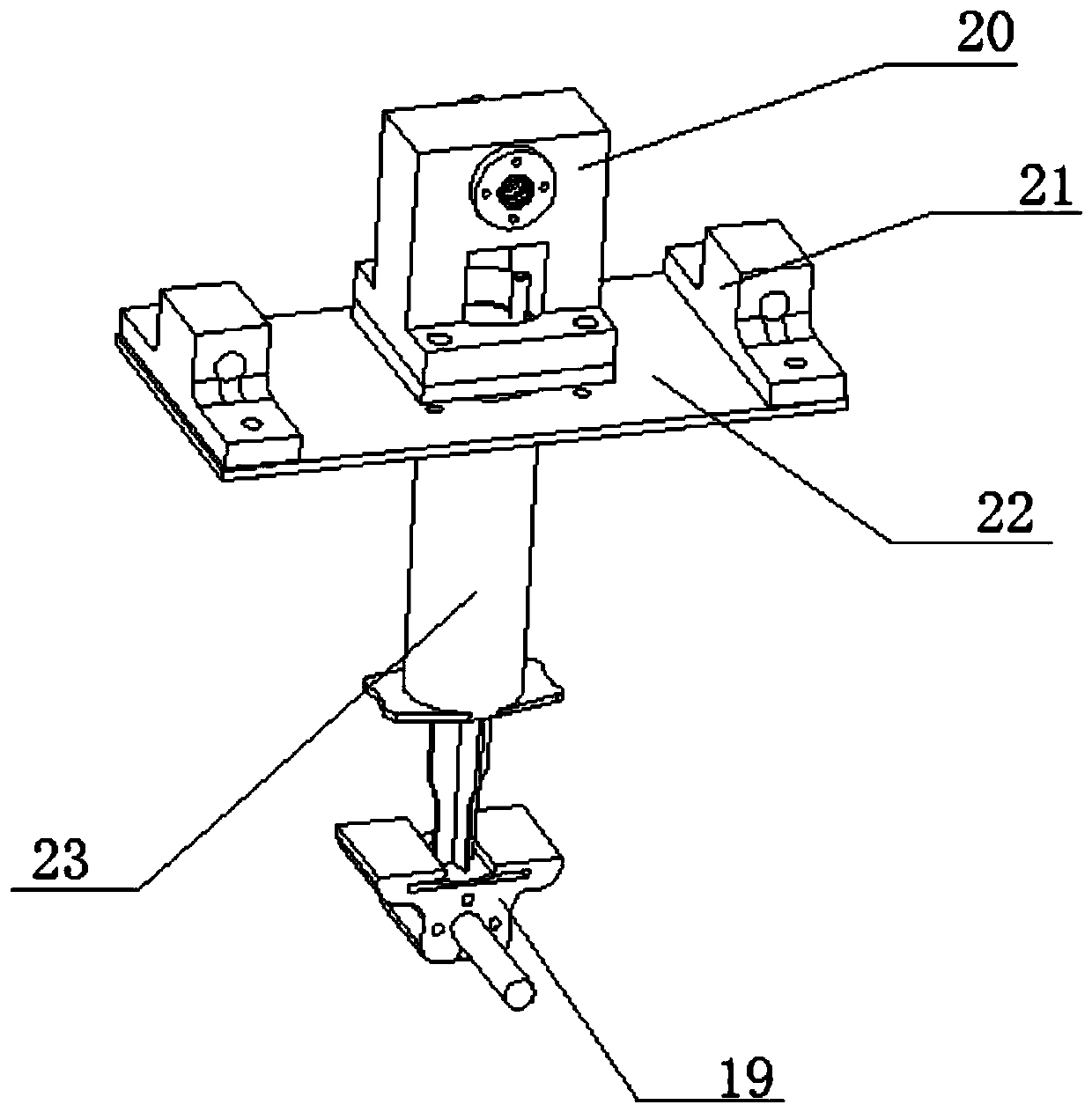

Novel microbial fuel cell generating device and assembling method thereof

PendingCN111224142AEasy and fast loadingEnsure anaerobic environmentTreatment with anaerobic digestion processesBiochemical fuel cellsMicrobial fuel cellFuel cells

The invention belongs to the technical field of sewage treatment, and relates to a novel microbial fuel cell generating device and an assembling method thereof. A cell body sequentially comprises an anode cover plate, anode carbon cloth, an anode chamber, a proton membrane, a cathode chamber, cathode carbon cloth and a cathode cover plate which are fixedly connected, wherein liquid adding ports are formed in the top of the anode chamber and the top of the cathode chamber, and an anode electrode contact piece and a cathode electrode contact piece are fixedly mounted at the bottom of the anode cover plate and the bottom of the cathode cover plate respectively; a cell base comprises a cell bottom plate seat, a wiring seat, a cell clamping plate and a cell movable clamping plate, a conductivespring is hinged between the cell clamping plate and the cell movable clamping plate, a cell wiring terminal and a resistor wiring terminal are arranged on the wiring seat, an anode electrode contactpin and a cathode electrode contact pin which are respectively in contact with the anode electrode contact piece and the cathode electrode contact piece are fixedly arranged on the inner side of the cell clamping plate and the inner side of the cell movable clamping plate, so that the problems of long starting time and low power generation capacity of the fuel cell caused by complicated liquid change assembly of the fuel cell and poor leakproofness of the anode chamber are solved.

Owner:CHONGQING INST OF GREEN & INTELLIGENT TECH CHINESE ACADEMY OF SCI +1

Equipment storage and retrieval system

ActiveUS20160101740A1Easy to foldRetrieving equipmentSupplementary fittingsOther load carrying vehiclesPick-up truckEngineering

An equipment storage and retrieval system retrieves equipment from the back of pick-up trucks and other cargo carrying vehicles. A guide rail and a frame with attached rollers and equipment hold-downs, platforms or carts allow for easy access, retrieval, and storage of equipment in the bed of a vehicle. A frame extends out the back of a pickup for access to equipment, and folds into a vertical position for improved use of the pickup bed. A brake system prevents locks the sliding frame in place until the brake is released by a brake lever.

Owner:PATTON MARK +1

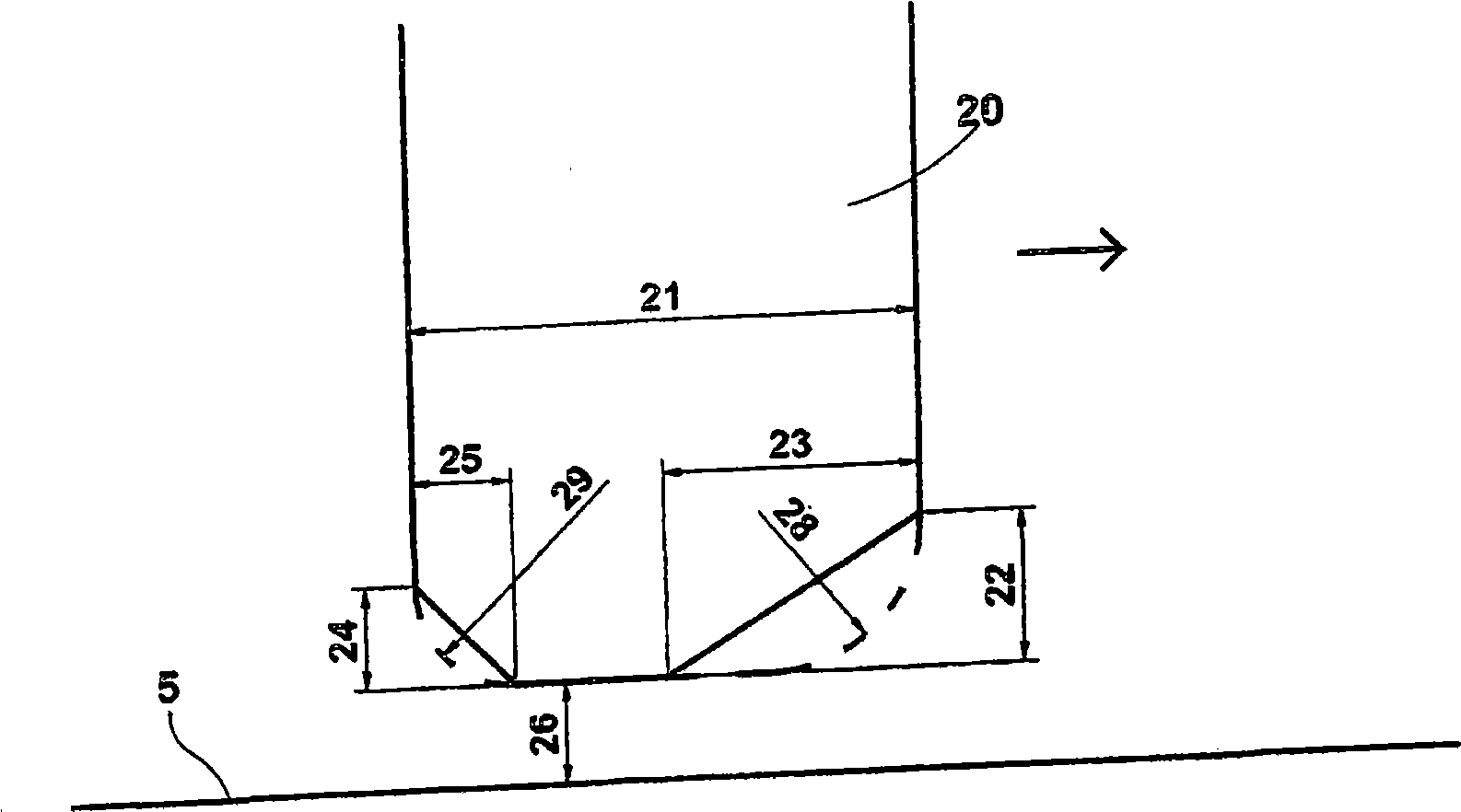

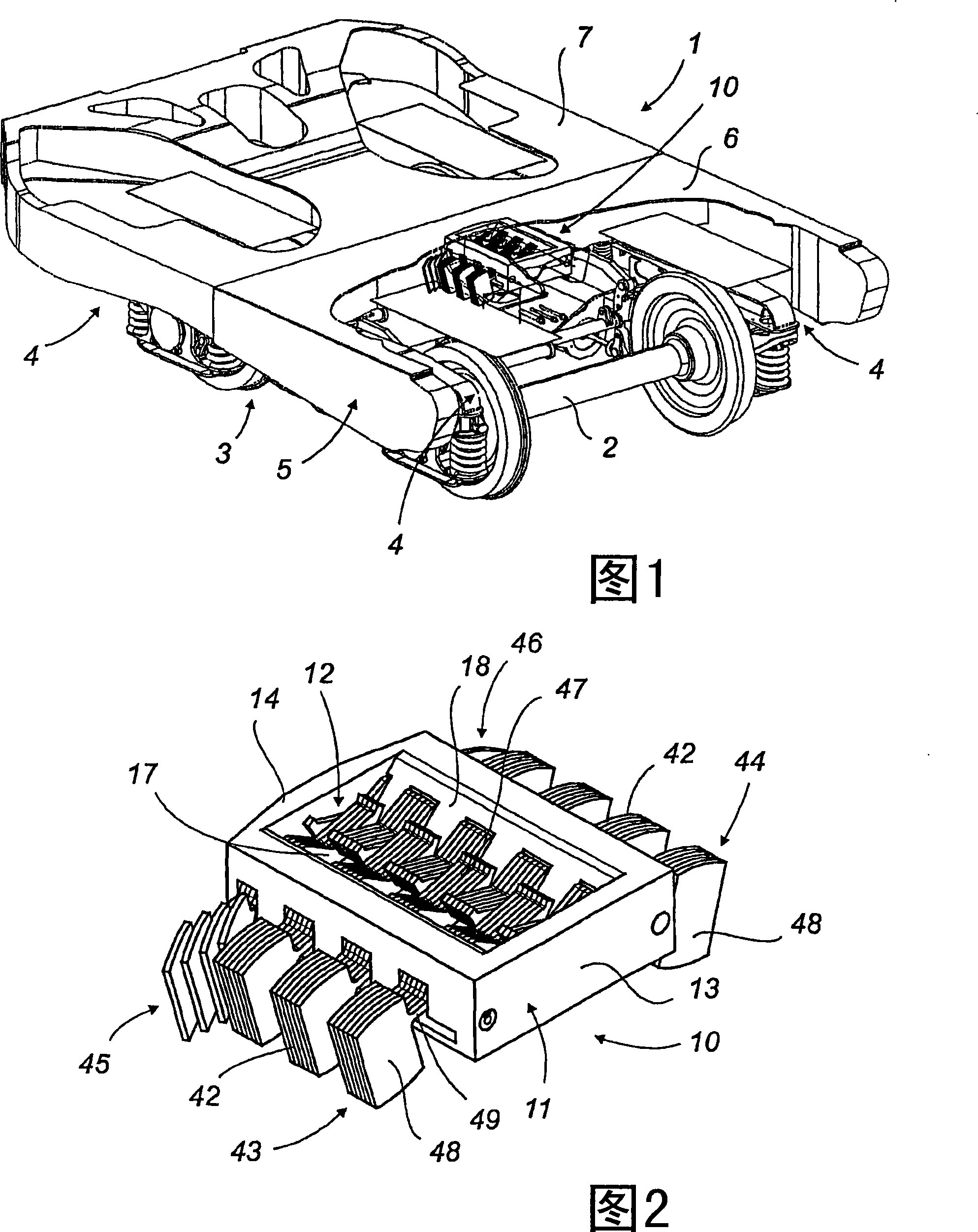

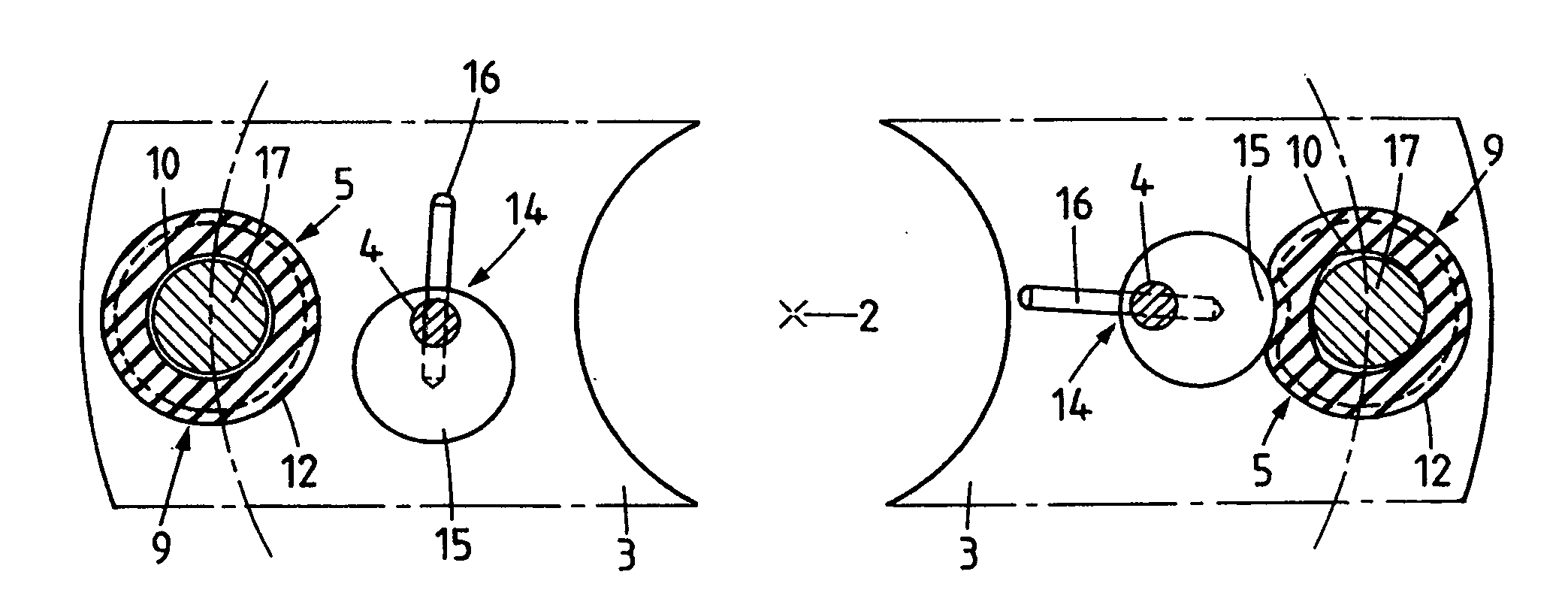

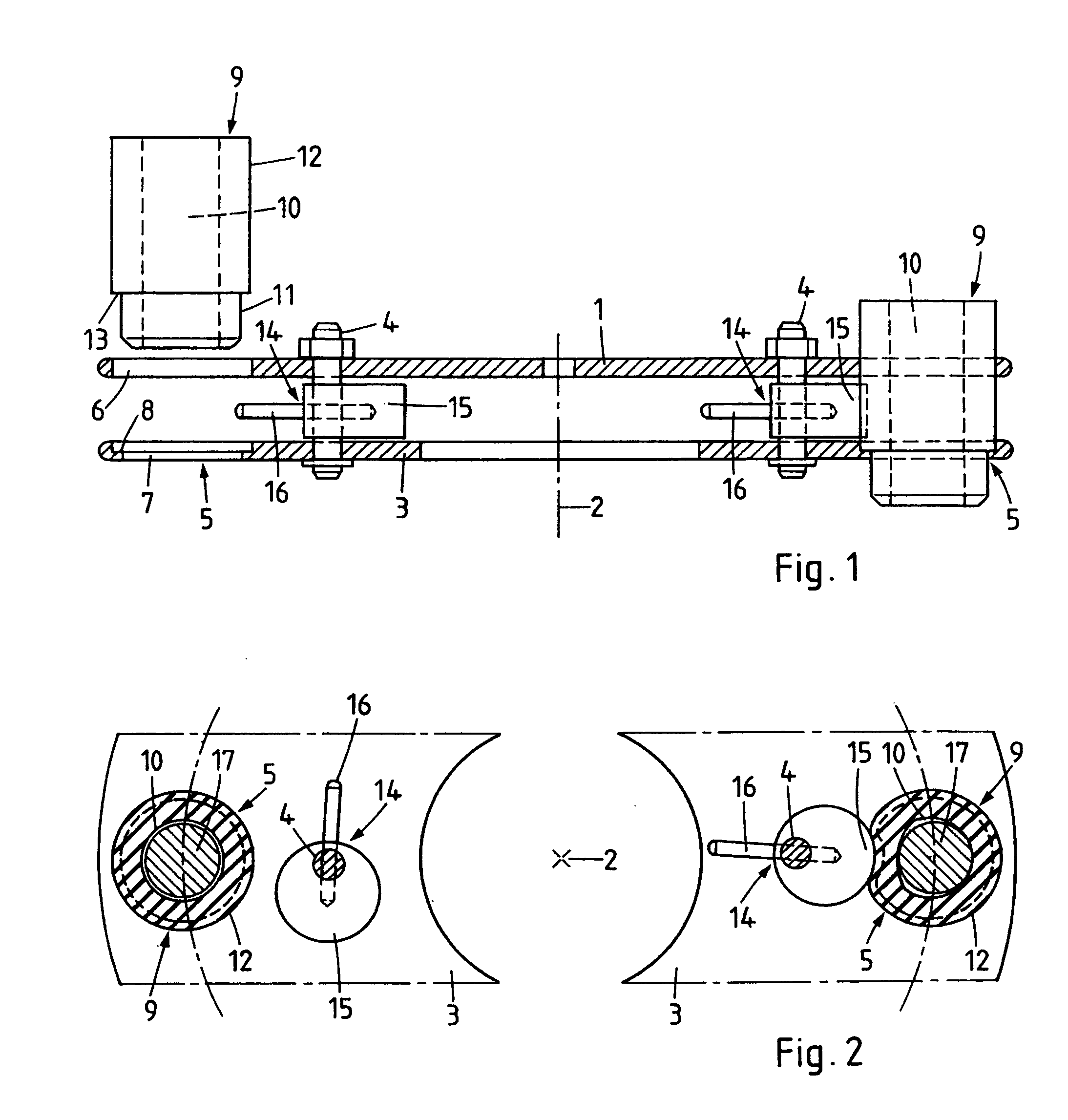

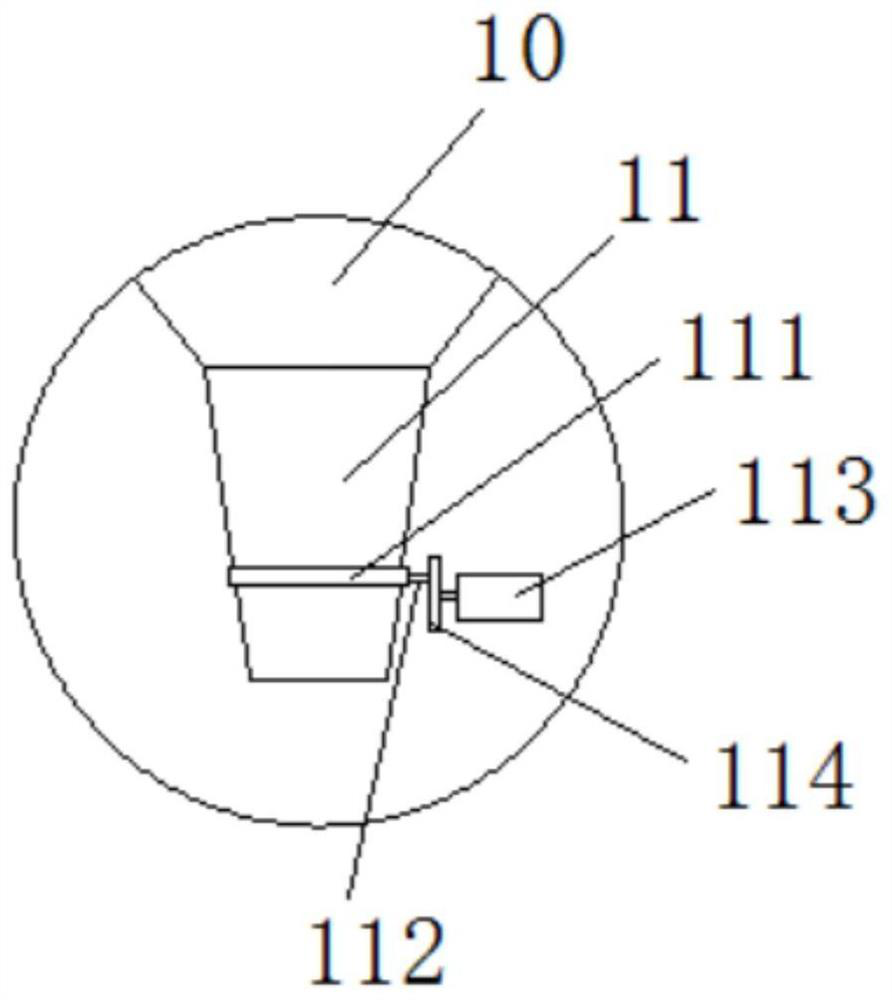

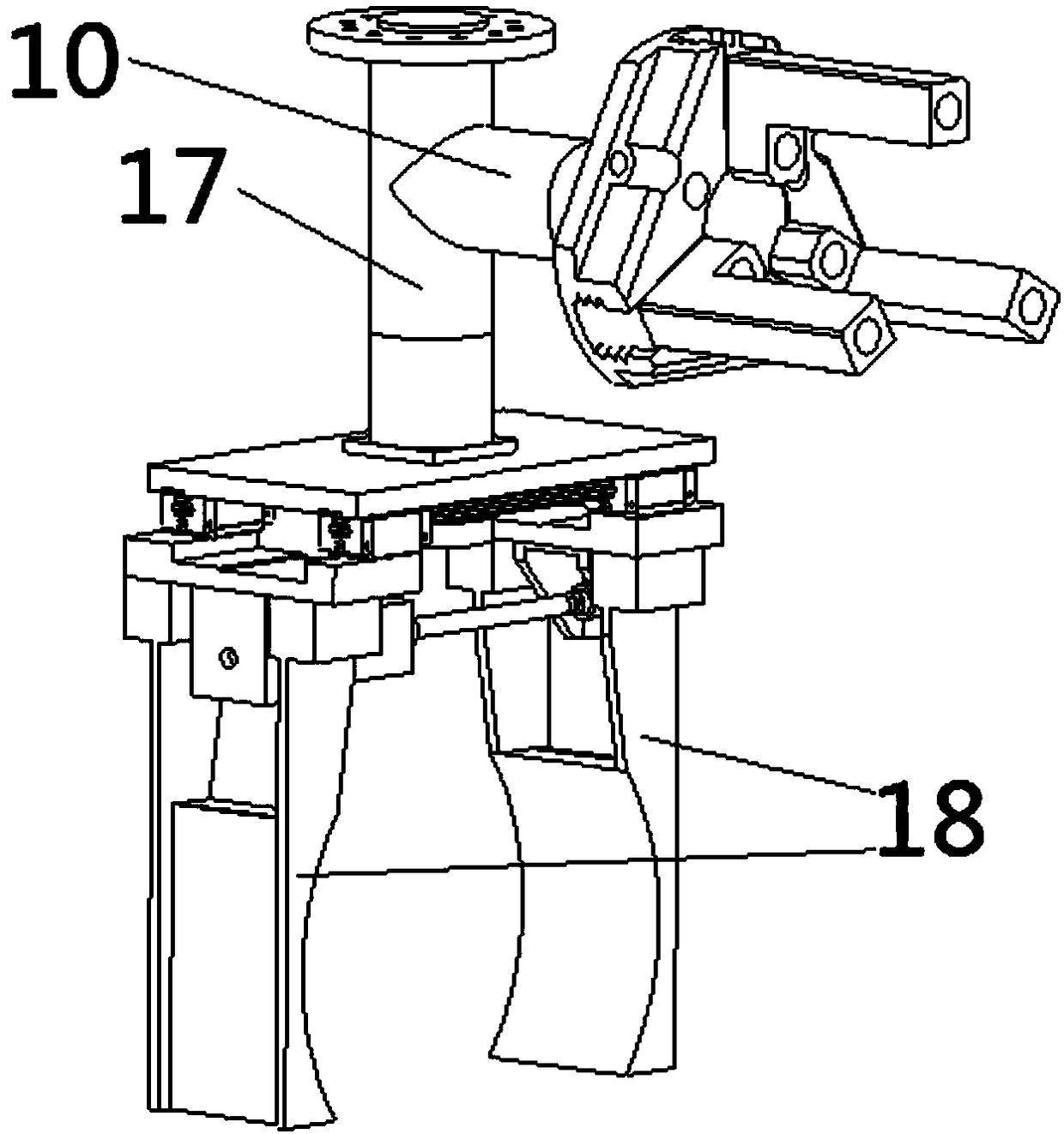

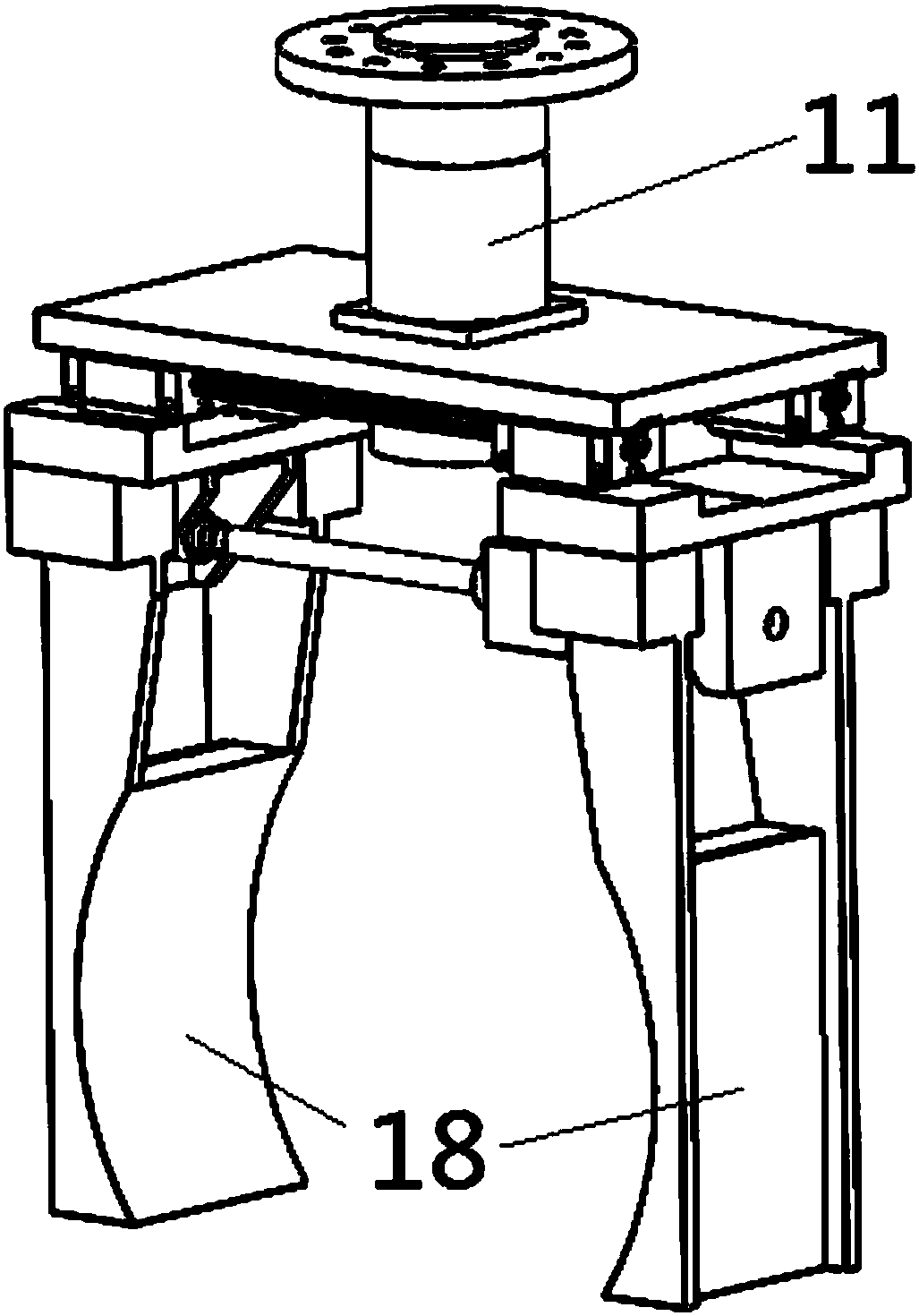

Device for lateral self-centering support and immobilization on a railway structure of a semi-trailer kingpin

InactiveCN101189154AEasy and fast loadingWagons/vansCargo supporting/securing componentsNacelleEngineering

The invention concerns a device for lateral self-centering support and immobilization of a semi-trailer kingpin on a railway structure transporting same characterized in that it comprises a nacelle (10) with a mobile frame (11) and a receiving space (12) actuated in vertical movements through lifting means and mounted stable in rolling and yawing motions and through a cowling part urged to be mounted on the kingpin and whereof the outer lateral surfaces co-operate with pivoting components (42) of the mobile frame (11) so as to obtain a self-centering and immobilizing effect, the pivoting components (42) acting as bilateral visual indicators allowing the operator to determine the end of the self-centering and immobilizing operations on either side of the railway car. The invention is applicable to railway transport of road semi-trailers.

Owner:LOHR IND

Workpiece carrier

InactiveUS20110260386A1Fast and easy and unloadingReliable retentionDrawing boardsChucksEngineeringMechanical engineering

A workpiece carrier comprises a base with an upper part rotatable about a vertical axis and a lower part connected to the upper part at a distance by bolts. Workpiece holders each comprise a sleeve of elastically deformable material like rubber surrounding a duct where the shaft of a workpiece can be inserted, the sleeve being accommodated in a recess on the base. The vertical position of the sleeve which extends through holes in the upper part and lower part of the base, respectively, is fixed by a stop formed between a recessed rim surrounding the hole in the lower part and a downward-facing projecting rim of the sleeve. The shaft can be fixed by swivelling a lever about one of the bolts into an active position where a compressing surface of the same compresses the sleeve such that the shaft is jammed and released by swivelling the lever back into an inactive position where the compressing surface is not in contact with the sleeve.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

Shaker bottle with magnetic elements for temporary securement to exercise equipment

A protein shaker bottle or similar beverage container that has one or more magnets on its outer surface. The magnets allow for the shaker bottle to magnetically adhere to a metallic or ferrous surface. The inventive bottle allows a user to quickly and temporarily adhere the bottle to a piece of gym equipment on a gym floor.

Owner:YURKOVETSKAYA HANNA +1

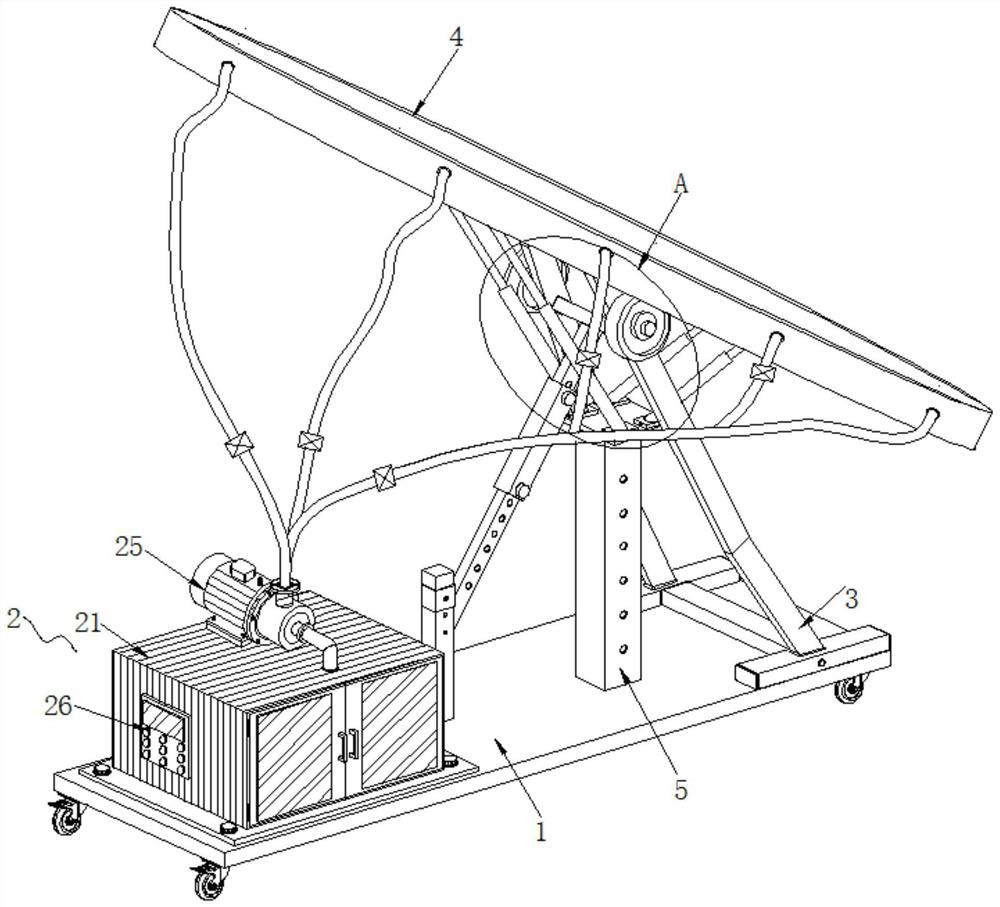

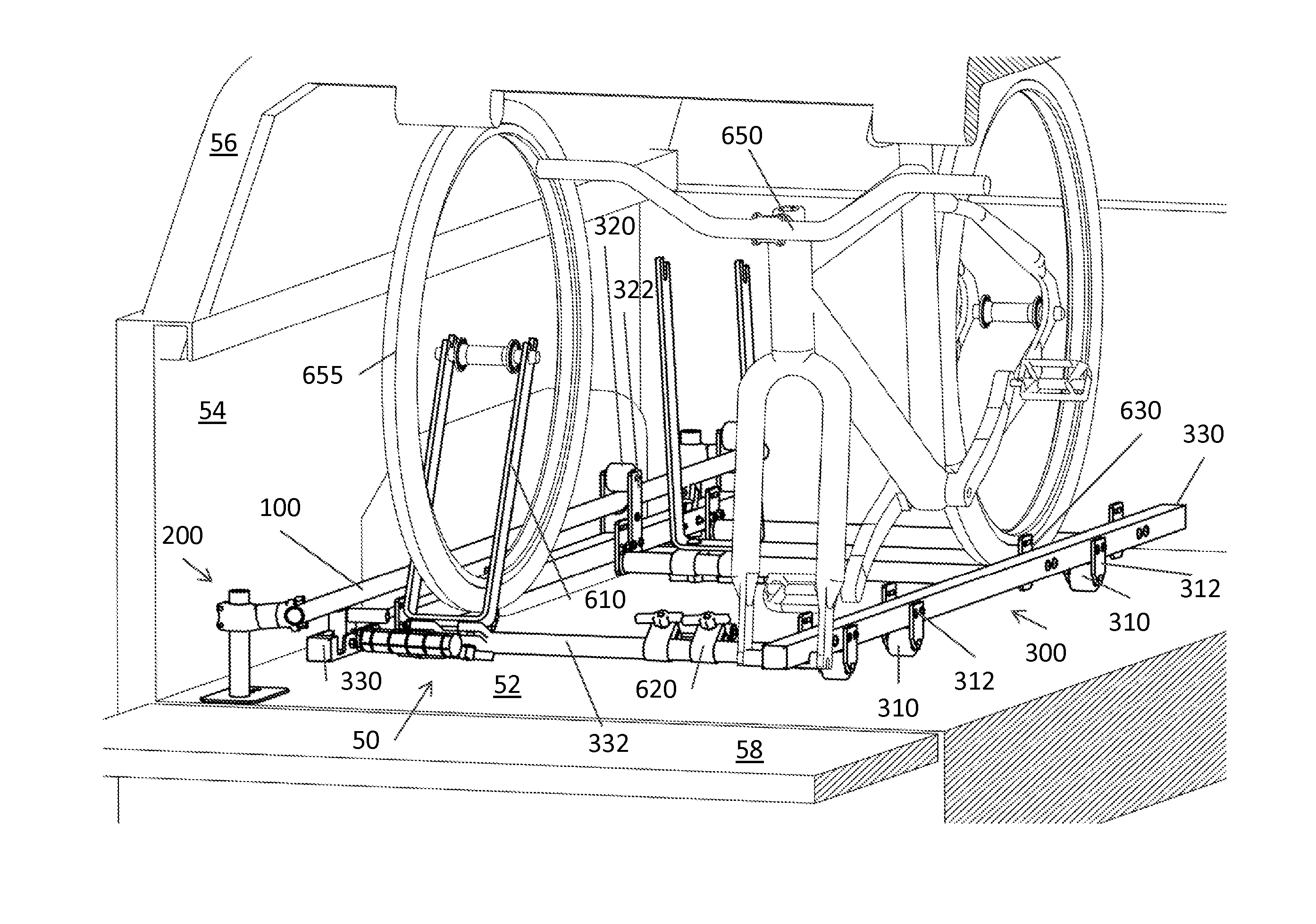

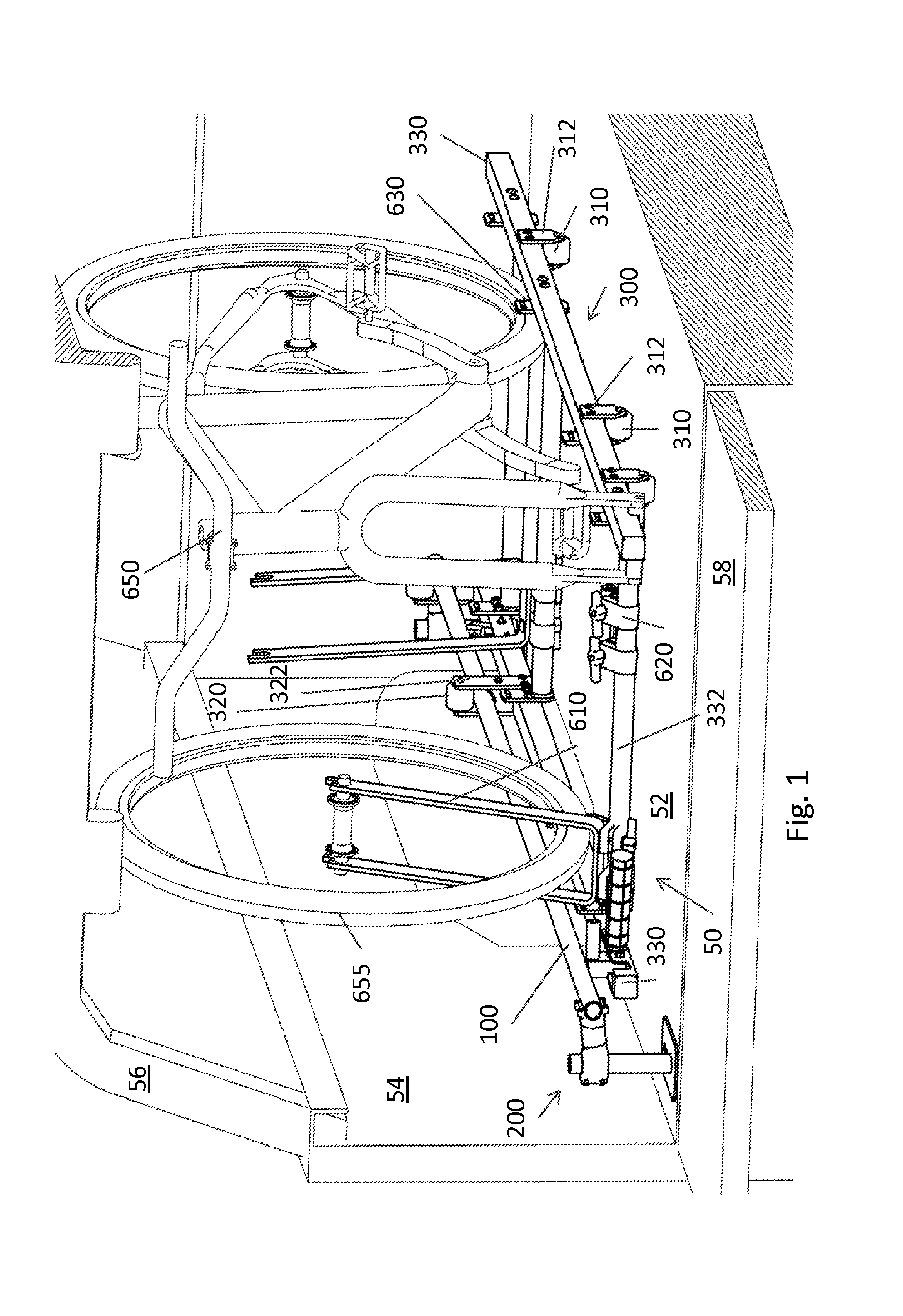

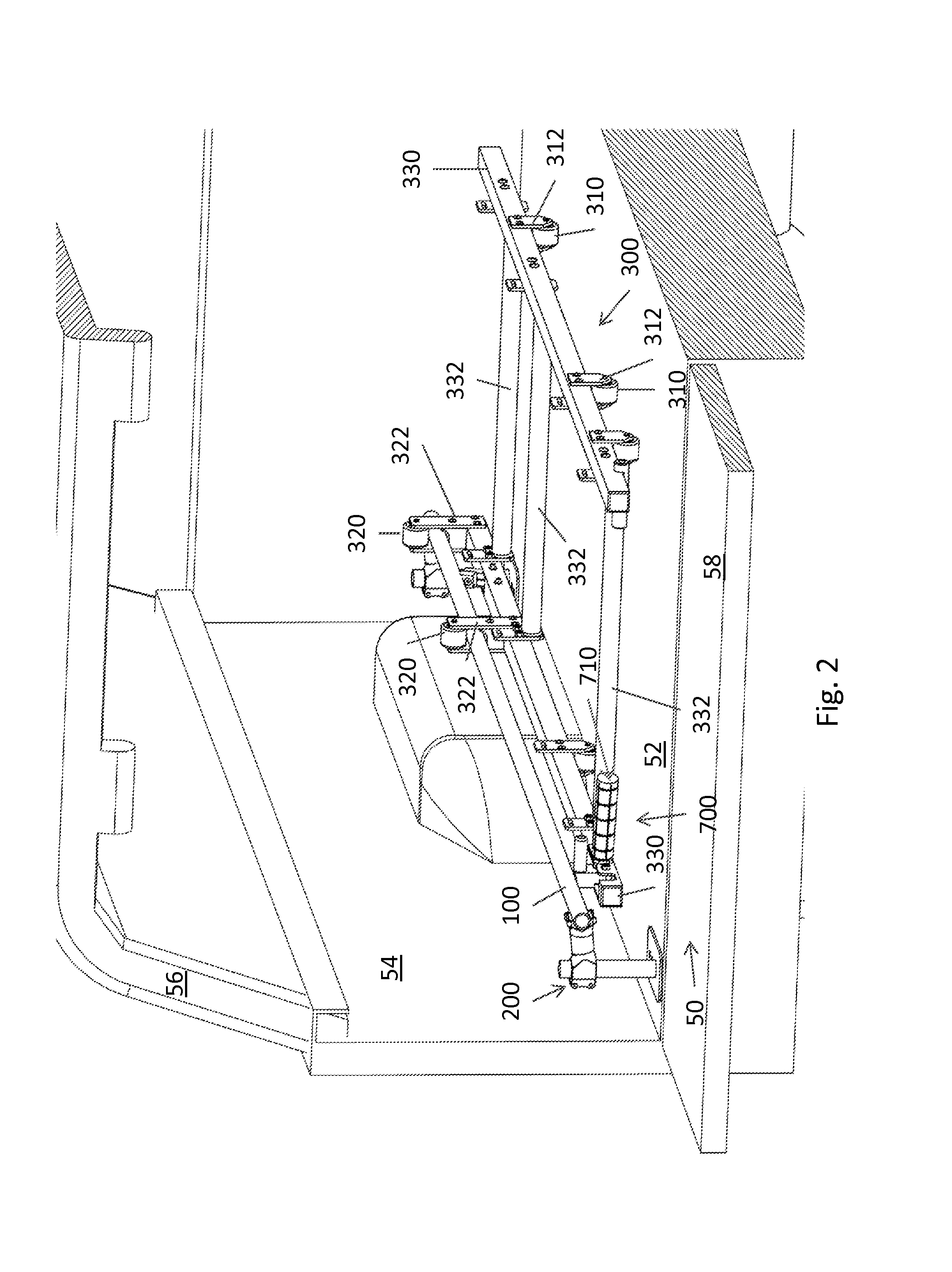

Support assembly for loading and securing a tender

ActiveUS7231882B2Easy and fast loadingEasy loadingBoat guiding devicesBoats storing/fasteningMechanical engineering

A support assembly for loading and securing a tender including first and second subassemblies. The first assembly includes a winch assembly for positioning the tender on the support assembly and the second subassembly includes a releasable securing device. Both subassemblies include a series of pivotal shafts having rollers which help guide and support the tender into position.

Owner:ANCHOR WELDING

Self-material-turning type traditional Chinese medicine airing system capable of producing multiple kinds of medicine materials at same time

InactiveCN114111285AEfficient dryingAvoid insufficient dryingDrying chambers/containersDrying machines with non-progressive movementsMedicinal herbsProcess engineering

The automatic material turning type traditional Chinese medicine airing system comprises a bottom plate and a control mechanism fixedly installed at the top of the bottom plate, and is characterized in that a supporting assembly is fixedly installed at the position, located on one side of the control mechanism, of the top of the bottom plate, and an airing mechanism is arranged at the top of the supporting assembly; the invention relates to the technical field of traditional Chinese medicine processing. According to the self-material-turning type traditional Chinese medicine airing system capable of producing multiple kinds of medicine materials at the same time, different kinds of traditional Chinese medicine materials can be aired at the same time, the use range is wide, the use functions are rich, manual timed material turning is not needed, it can be guaranteed that all the traditional Chinese medicine materials are aired sufficiently, a large amount of manpower and material resources are saved, and the airing efficiency is high; according to the traditional Chinese medicinal material airing device, the automatic material overturning mechanism is arranged in the airing device, so that the airing device can automatically overturn materials, the purpose of quickly and efficiently airing traditional Chinese medicinal materials is well achieved, and great convenience is brought to use of people.

Owner:朱彦伟

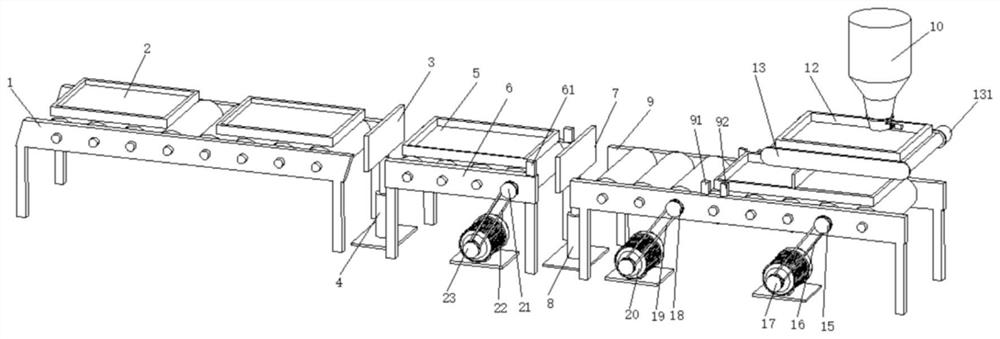

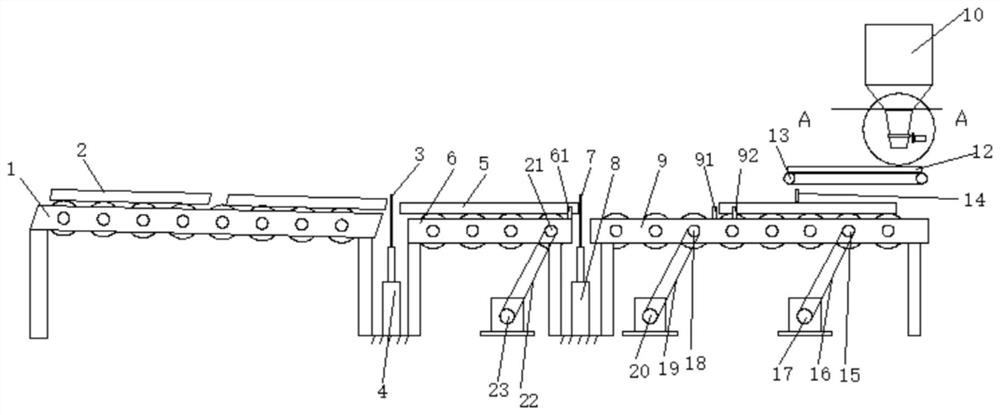

Tray abutting assembly line device

ActiveCN112850000AEasy and fast loadingImprove efficiencyFinal product manufactureControl devices for conveyorsElectric machineryRight lateral position

The invention discloses a tray abutting assembly line device. The device comprises a feeding conveying belt, wherein a waiting conveying belt is arranged on the right side of the feeding conveying belt, a material receiving conveying belt is placed on the right side of the waiting conveying belt, a second driving wheel is fixed to the left side of the material receiving conveying belt, a third driving wheel is fixed to the right side of the material receiving conveying belt, a second bottom plate is arranged on the left side of the lower portion of the material receiving conveying belt, a second motor support is fixed to the upper surface of the second bottom plate, a second motor is fixed to the middle of the upper end of the second motor support, a third bottom plate is fixed to the right side of the lower portion of the material receiving conveying belt, a third motor support is fixed to the upper surface of the third bottom plate, a third motor is fixed to the upper end of the third motor support, the second driving wheel is connected with the second motor through a second belt, and the third driving wheel is connected with the third motor through a third belt. The device has the beneficial effects of continuous material receiving, high efficiency and simple operation.

Owner:阳泉市广凯机械制造有限公司

Equipment storage and retrieval system

ActiveUS20140037410A1Easy to foldRetrieving equipmentSupplementary fittingsItem transportation vehiclesPick-up truckEngineering

An equipment storage and retrieval system retrieves equipment from the back of pick-up trucks and other cargo carrying vehicles. A guide rail and a frame with attached rollers and equipment hold-downs, platforms or carts allow for easy access, retrieval, and storage of equipment in the bed of a vehicle. A frame extends out the back of a pickup for access to equipment, and folds into a vertical position for improved use of the pickup bed. A brake system prevents locks the sliding frame in place until the brake is released by a brake lever.

Owner:PATTON MARK +1

Online continuous monitoring system and method for aluminum profile production

ActiveCN113324512ATimely detectionEasy to detect and monitorMeasurement devicesElectric machineryStructural engineering

The invention provides an aluminum profile production online continuous monitoring system. The system comprises a top plate, bottom plates, supporting rods, side plates, U-shaped plates, limiting rods, a supporting plate, a push rod motor, a square plate, a first motor, a linkage shaft, a transmission roller, a sleeve roller, a first rotating shaft and a second rotating shaft, wherein the bottom plates are symmetrically arranged below the top plate, and the side plates are fixedly connected with sides opposite to the bottom plates; supporting rods are symmetrically and fixedly connected to the bottom of the bottom plate, and a supporting plate is arranged on one side of the top plate. The detection mechanism can monitor and detect surface flatness and whether surface defects exist or not during aluminum profile production, so unqualified aluminum profiles can be detected in time during production, a distance between the detection rods can be adjusted by rotating the threaded rod, the multiple detection rods are matched with one another, aluminum profiles in different shapes can be conveniently monitored and detected, so the aluminum profiles can be continuously monitored and detected during production, unqualified aluminum profiles can be identified, and production efficiency is improved.

Owner:广东新合铝业新兴有限公司

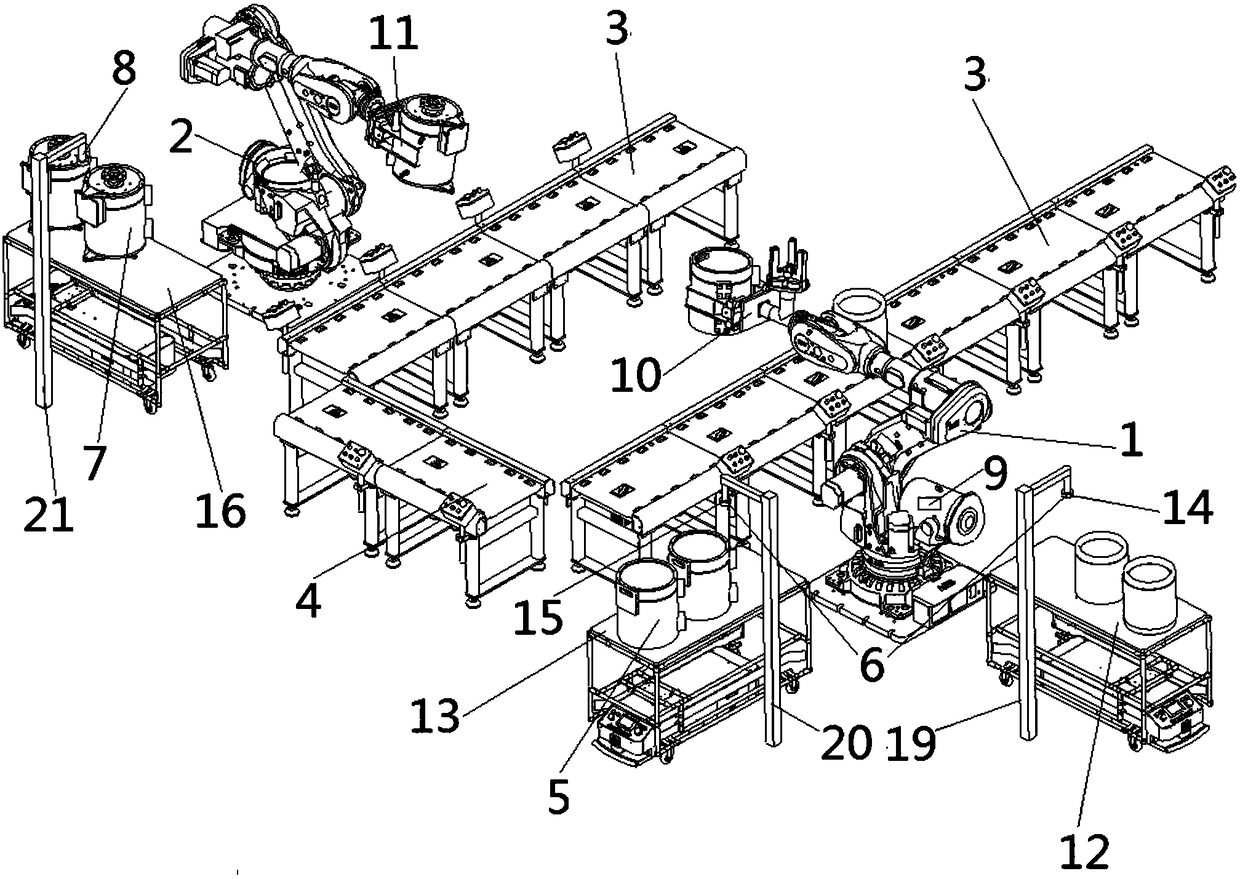

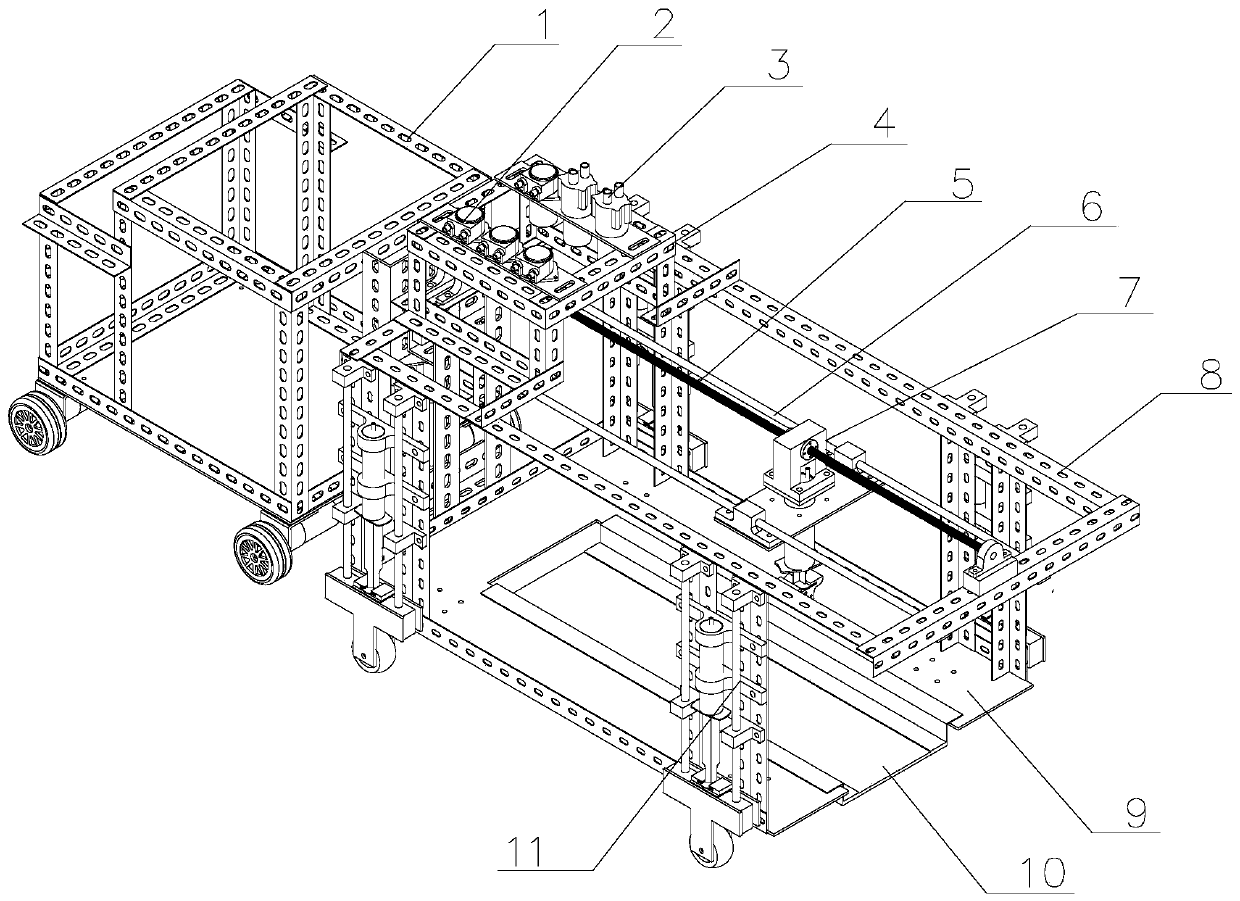

Motor module conveying and loading-unloading system

InactiveCN108161393AConvenient and fast deliveryEasy and fast loadingManufacturing dynamo-electric machinesMetal working apparatusProduction lineLoading unloading

The invention provides a motor module conveying and loading-unloading system and belongs to the technical field of robot motor production lines. A loading robot (1) of the motor module transporting and loading-unloading system is arranged at the start position close to a conveying line (3), an unloading robot (2) is arranged at the stop position close to the conveying line (3), the conveying line(3) is provided with an assembly station (4), first visual scanning sensors (6) are arranged in positions close to the loading robot (1), a second visual scanning sensor (8) is arranged in a positionclose to the unloading robot (2), and the loading robot (1) and the unloading robot (2) are connected with control components (9) correspondingly. The motor module conveying and loading-unloading system is simple in structure, and automatic transporting, loading and unloading of the columnar shape forming process of motor modules can be conveniently and fast achieved; and meanwhile, placing posesof motor workpieces and the motor modules can be automatically recognized, and the robots can perform transporting, loading and unloading precisely and conveniently.

Owner:WUHU HIT ROBOT TECH RES INST

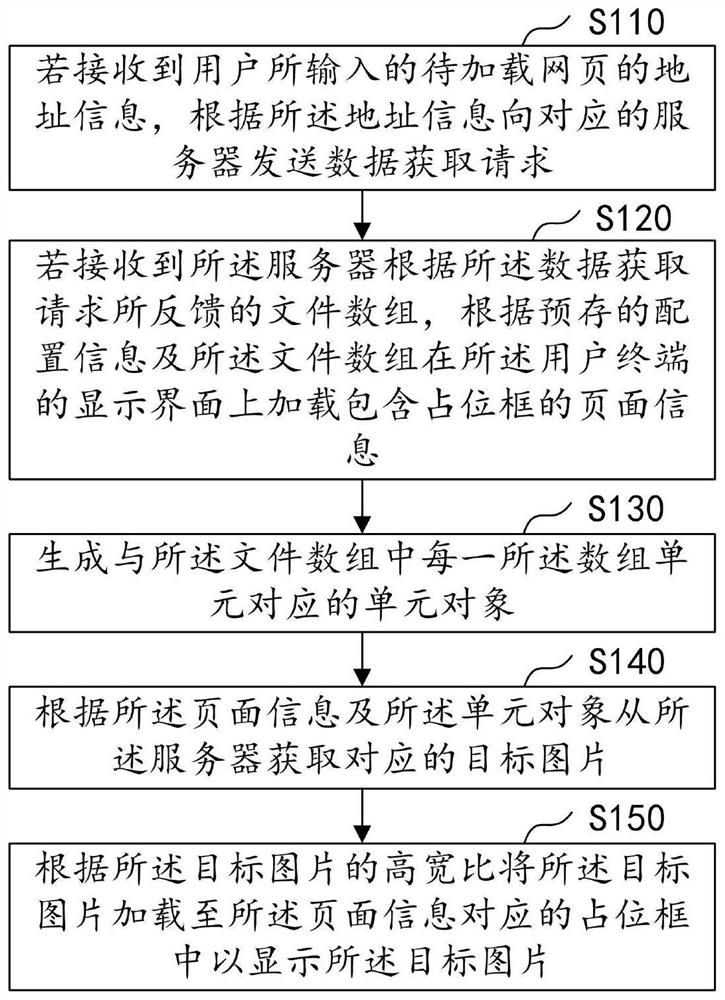

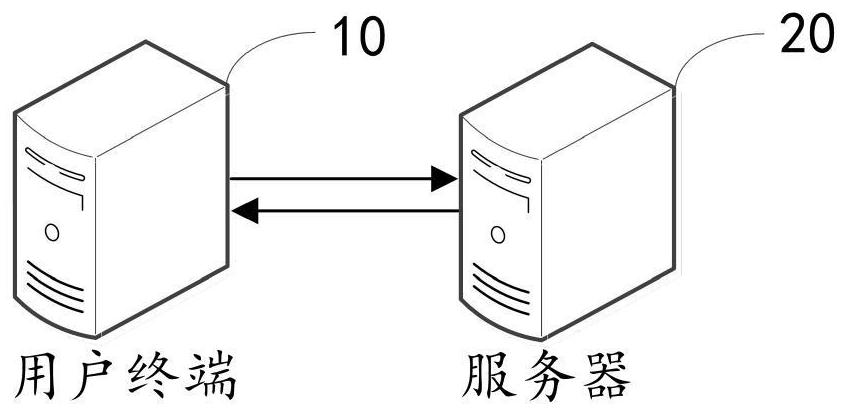

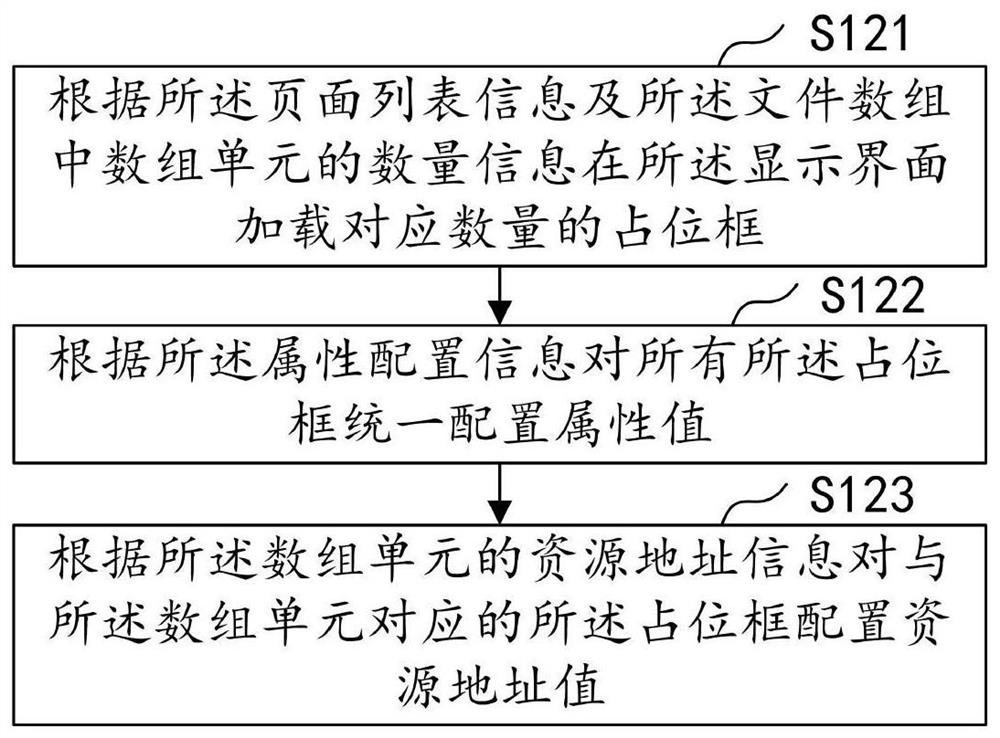

Picture loading method and device, computer equipment and storage medium

ActiveCN111767492AQuality improvementEasy and fast to getWebsite content managementProgram loading/initiatingComputer hardwareMorphing

The invention discloses a picture loading method and device, computer equipment and a storage medium. The method comprises the following steps: sending a data acquisition request to a server accordingto the address information of the to-be-loaded webpage so as to acquire a fed-back file array, and according to the configuration information and the file belonging group loading page information, generating a unit object corresponding to each array unit, obtaining a corresponding target picture from a server, and completing loading of the target picture on a display interface according to the aspect ratio of the target picture. The method is based on a data visualization technology; based on the technical method, the target picture can be acquired and loaded more conveniently and quickly bygenerating the unit object, and the target picture is loaded in the placeholder of the page information, so that distortion and deformation of the target picture in the loading process can be avoided,and the loading quality of the picture in the webpage is greatly improved.

Owner:CHINA PING AN PROPERTY INSURANCE CO LTD

Shell inserting device for full-automatic wire harness double-end shell inserting machine

PendingCN113745938AImprove efficiencyEasy and fast loadingContact member assembly/disassemblyElectronic waste recyclingElectric machineryEngineering

The invention discloses a shell inserting device for a full-automatic wire harness double-head shell inserting machine; the device comprises a rotating disc with notches symmetrically formed in two sides of the top, limiting plates are arranged at the positions, located at the notches, of the top of the rotating disc, pressing gears for pressing terminals are rotatably connected to the limiting plates, and a bevel gear ring fixed relative to the rotating disc is arranged at the top of the rotating disc. One pressing gear is connected with a driven bevel gear meshed with the bevel gear ring through a rotating shaft; an incomplete gear is separated from a second straight gear and is engaged with a first straight gear, so that the rack can be driven to move upwards, the terminal on the pressing plate is driven to move upwards, the terminal is moved to the limiting plate for wiring harness insertion, and after insertion is completed, the motor is started again for the next working cycle; by means of the structure, the terminals can be conveniently and rapidly fed and discharged, so that the wiring harness shell inserting efficiency is improved, and the device is high in overall continuity, convenient to operate and high in production efficiency.

Owner:深圳市源刚自动化设备有限公司

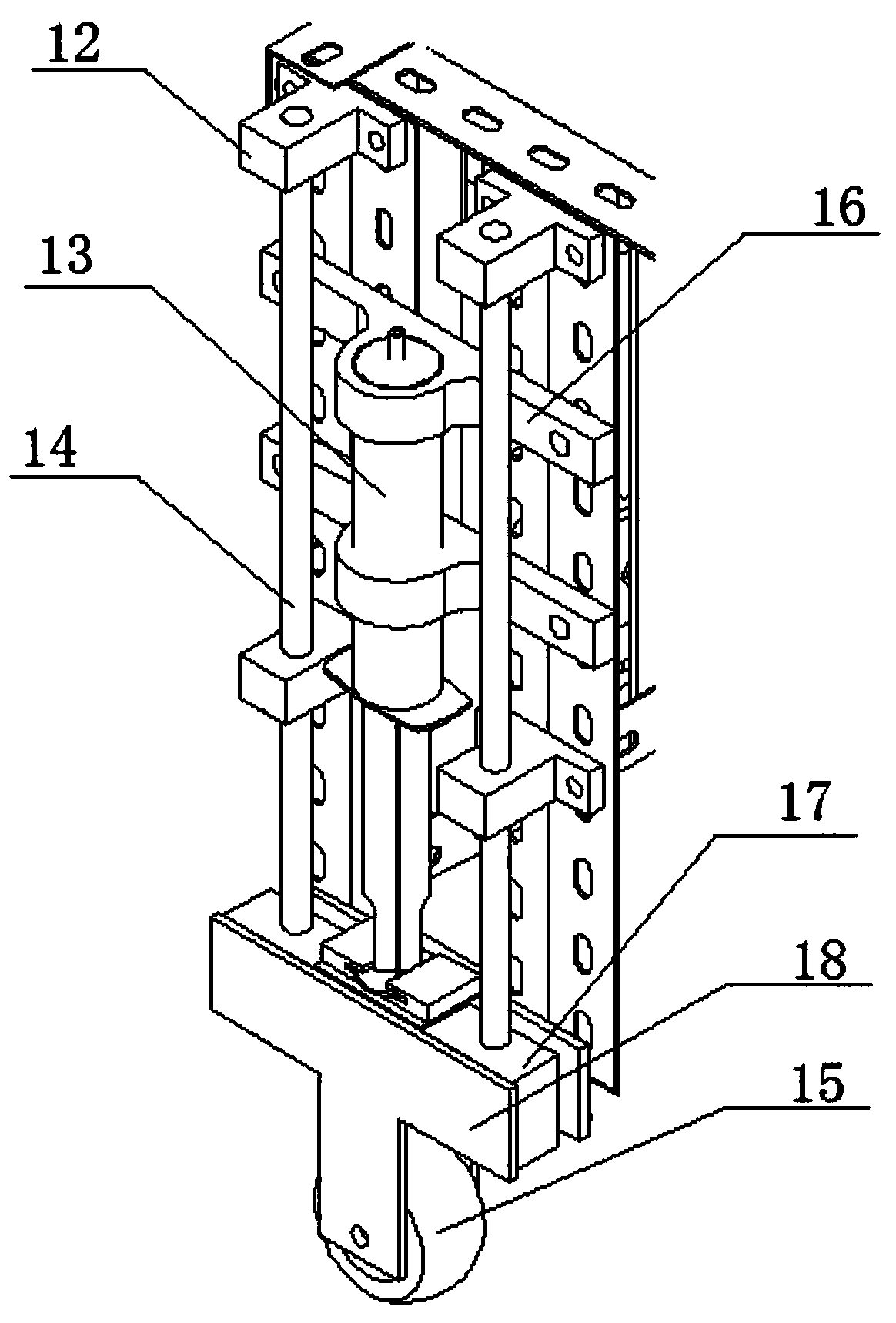

Automatic board conveyer with mistake-proofing system

PendingCN106276279AEasy and fast loadingSmooth transmissionConveyorsDe-stacking articlesControl systemEngineering

The invention discloses an automatic board conveyer with a mistake-proofing system, which comprises a rack, a board storage frame and a control system, a lifting platform which is located on the bottom of the board storage frame is arranged in the lower end of the rack, slide rails are arranged on the inner sides of the uprights of the rack, sliders which are located on the slide rails are arranged on the four corners of the bottom plane of the lifting platform, lifting cylinders which are connected with the bottom plane of the lifting platform are arranged on the bottom of the rack, a driving mechanism is arranged on the left side of the rack, a conveying platform is arranged on the right side of the rack, a horizontal slide way is arranged on the upper plane of the conveying platform, a stop is arranged on one side, which is located in the rack, of the horizontal slide way, a limit switch which corresponds to the stop is arranged on the bottom end of the board storage frame, opposite light curtains which correspond to each other are arranged on the inner sides of the uprights, and the control system is respectively electrically connected with the limit switch, the opposite light curtains, the lifting cylinders and the driving mechanism. Thus, the automatic board conveyer has the advantages of convenient and quick board loading, stable and smooth conveying and good mistake-proofing effect, and guarantees the safe conveying of products.

Owner:FLEXTRONICS ELECTRONICS TECH SUZHOU

A steel coil transport vehicle

ActiveCN106927210BSkew constraintGuaranteed stabilityLoading/unloadingConveyor partsRobot handEngineering

The invention discloses a rolled steel transport vehicle. The rolled steel transport vehicle solves the problems that in the prior art, the steel roll transporting efficiency is not high, and loading and unloading are not easy, and the rolled steel transport vehicle has the beneficial effects that the steel roll transporting process is safe and reliable, the automation degree is high, the loading and unloading efficiency is high, and the labor force is saved. According to the technical scheme of the rolled steel transport vehicle, the rolled steel transport vehicle comprises a vehicle head and a trailer frame, hydraulic elevating devices are arranged on the two sides of the trailer frame, and ascending and descending of the trailer frame are controlled through the hydraulic elevating devices. A sliding device and a mechanical arm are arranged on the top of the trailer frame, and the mechanical arm moves along the sliding device to drag a steel roll into the trailer frame.

Owner:SHANDONG XIEHE UNIV

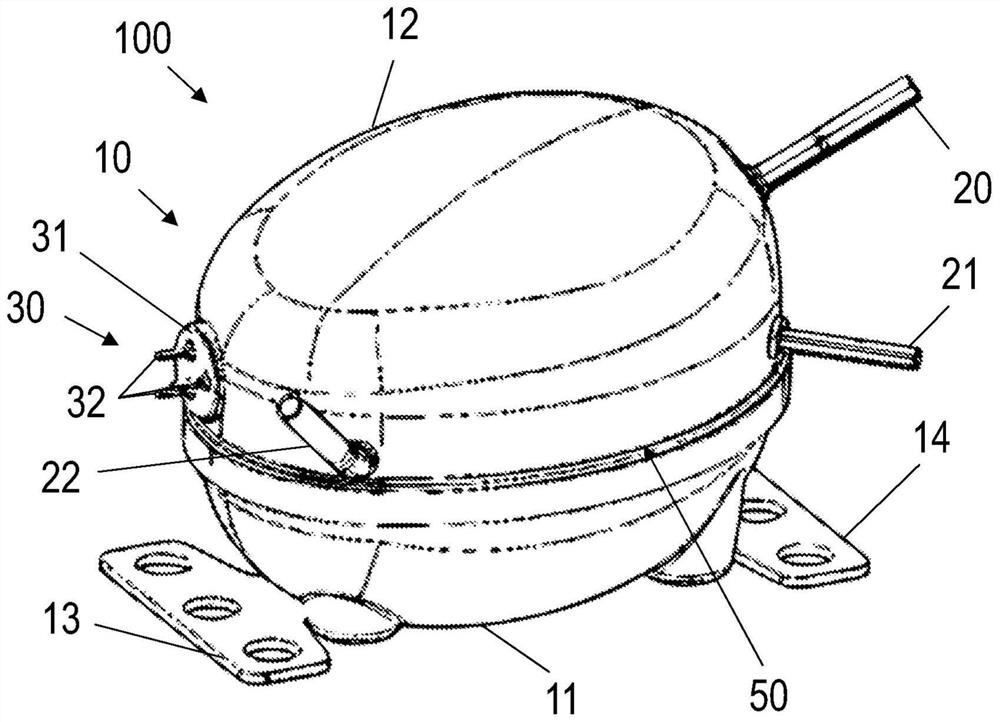

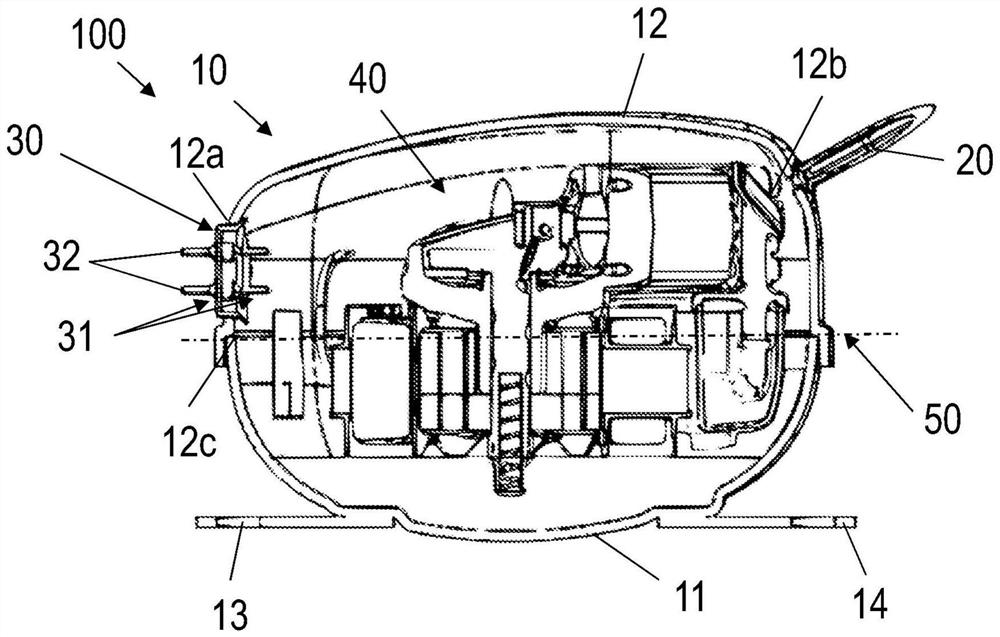

Hermetically encapsulated refrigerant compressor

PendingCN114829773ASave materialEasy to transportPositive displacement pump componentsPiston pumpsElectrical connectionControl cell

The invention relates to a hermetically sealed refrigerant compressor (100), comprising: a housing (10) having a lower part (11) and a cover (12), the cover (12) being connectable to the lower part (11); an electrical connection (30) passing through the housing (10); and a piston pump (40) arranged in the housing (10) and electrically connectable to the control unit via a connection (30). The cover (12) of the housing (10) has a through-opening (12a) in which the electrical connection element (30) is arranged. The housing (10) is configured such that, when the housing (10) is opened, the piston pump (40) can be placed into a cover (12) of the housing (10) and can be connected to the electrical connection (30).

Owner:ANHUI MEIZHI COMPRESSOR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com