Patents

Literature

46results about How to "Avoid insufficient drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

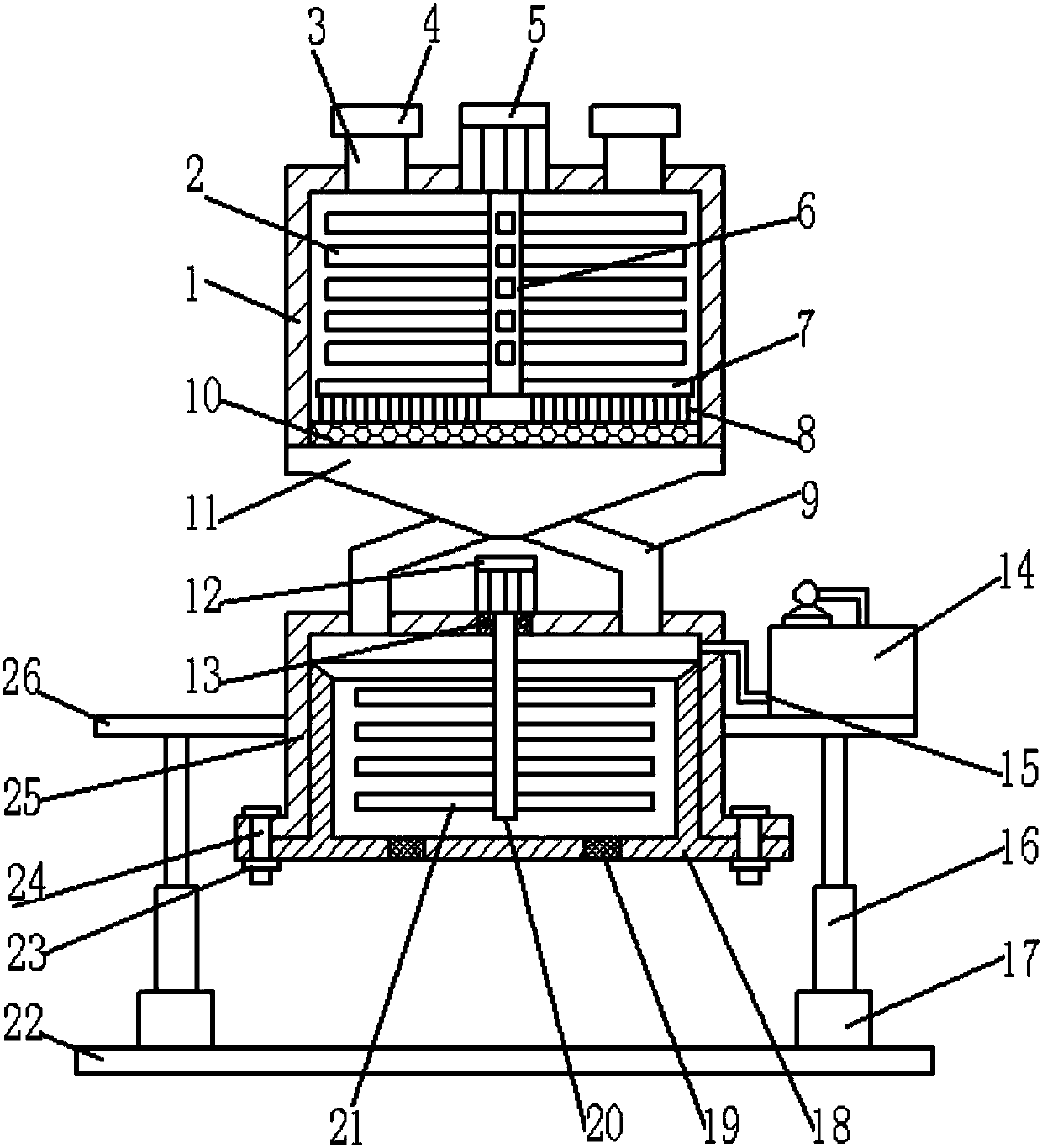

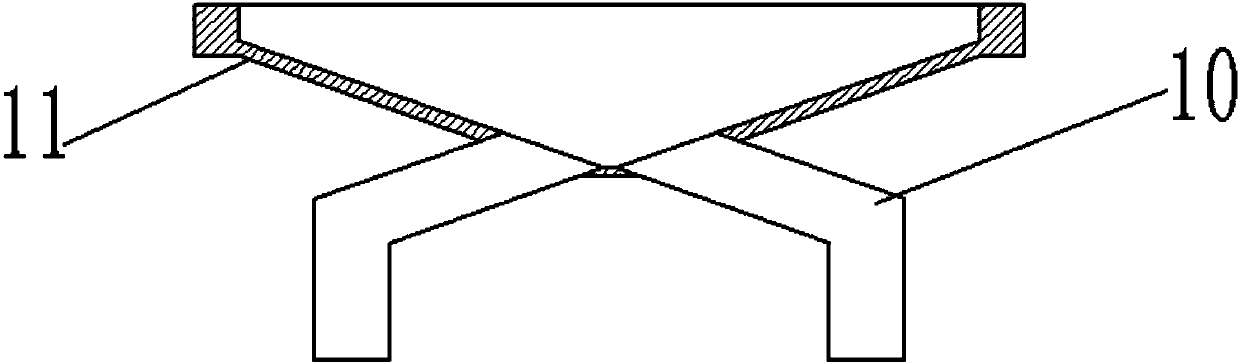

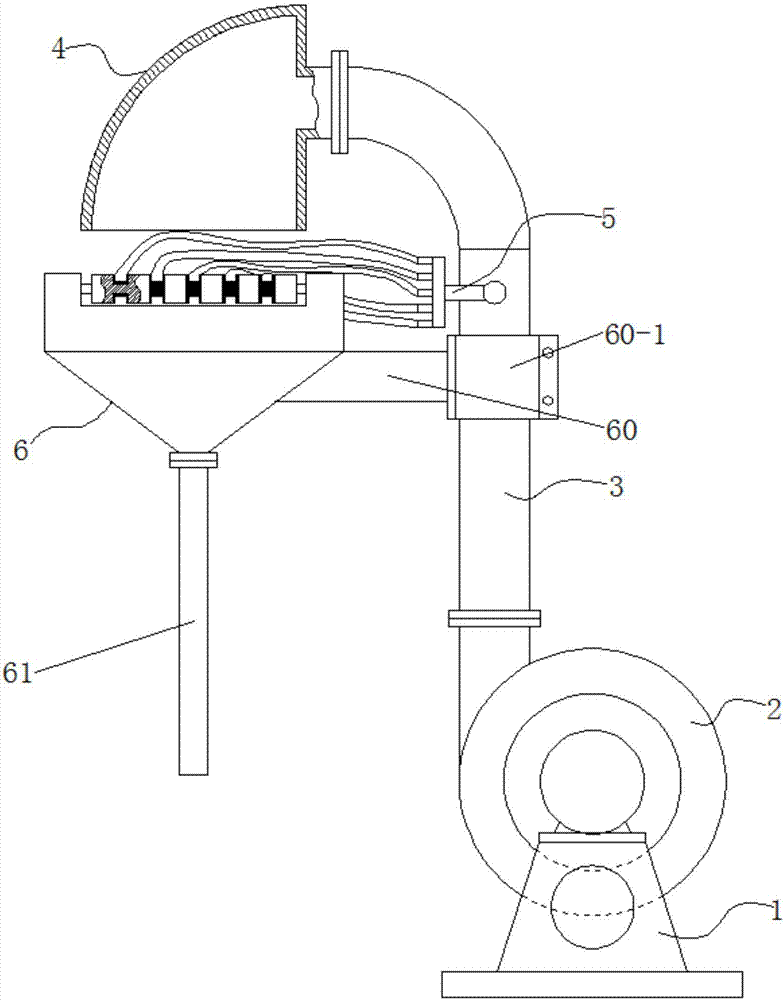

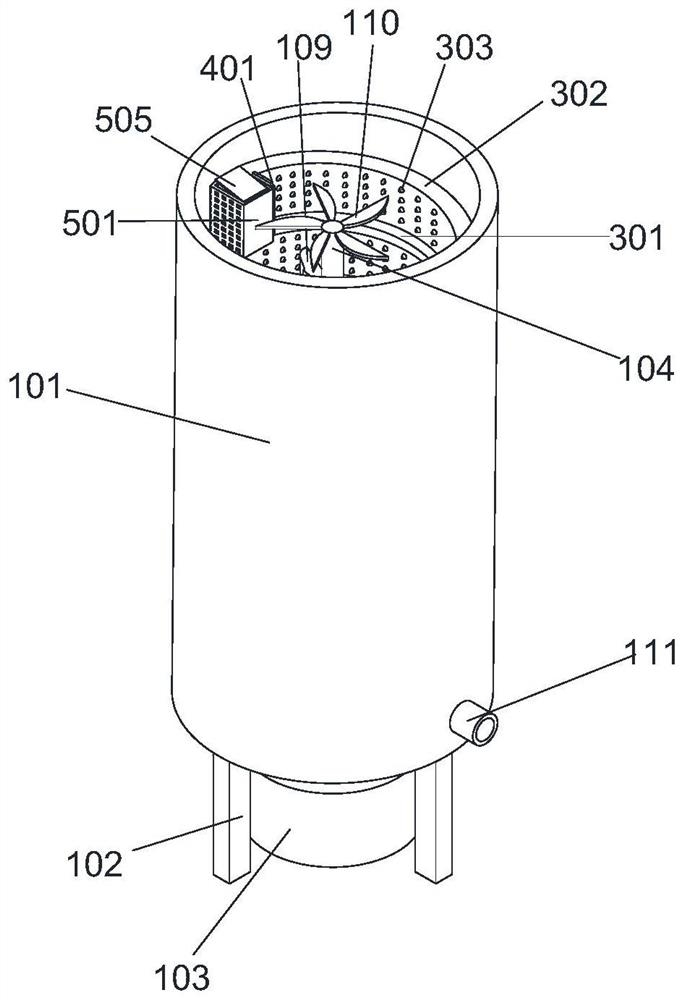

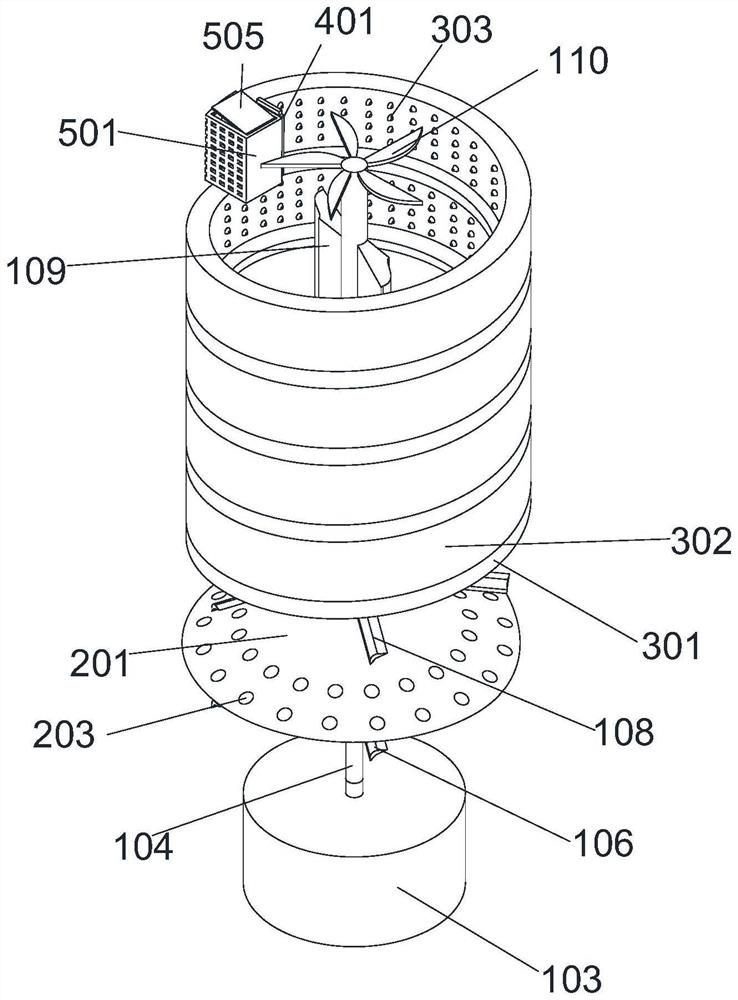

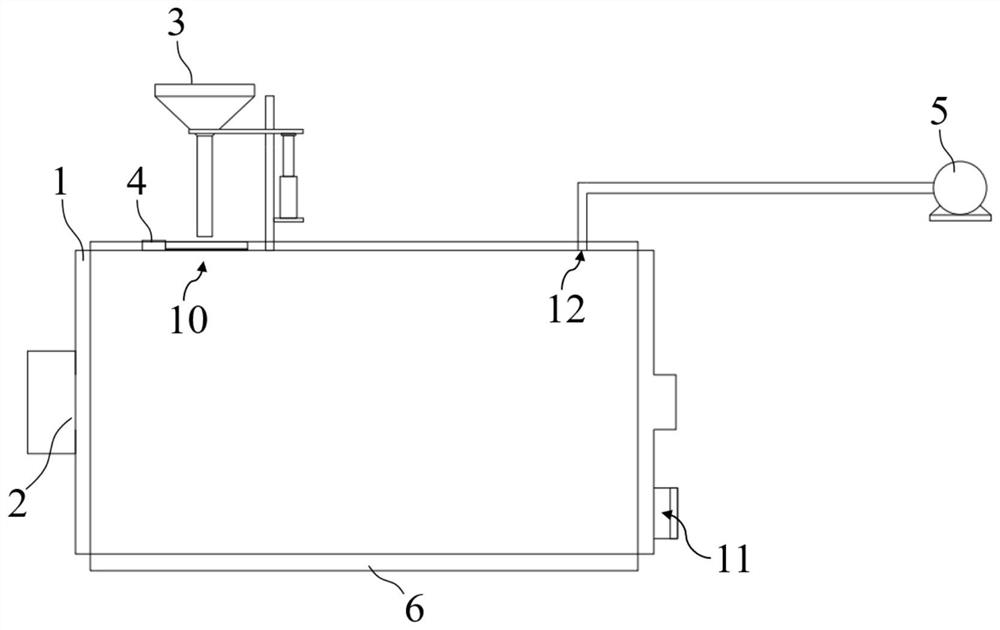

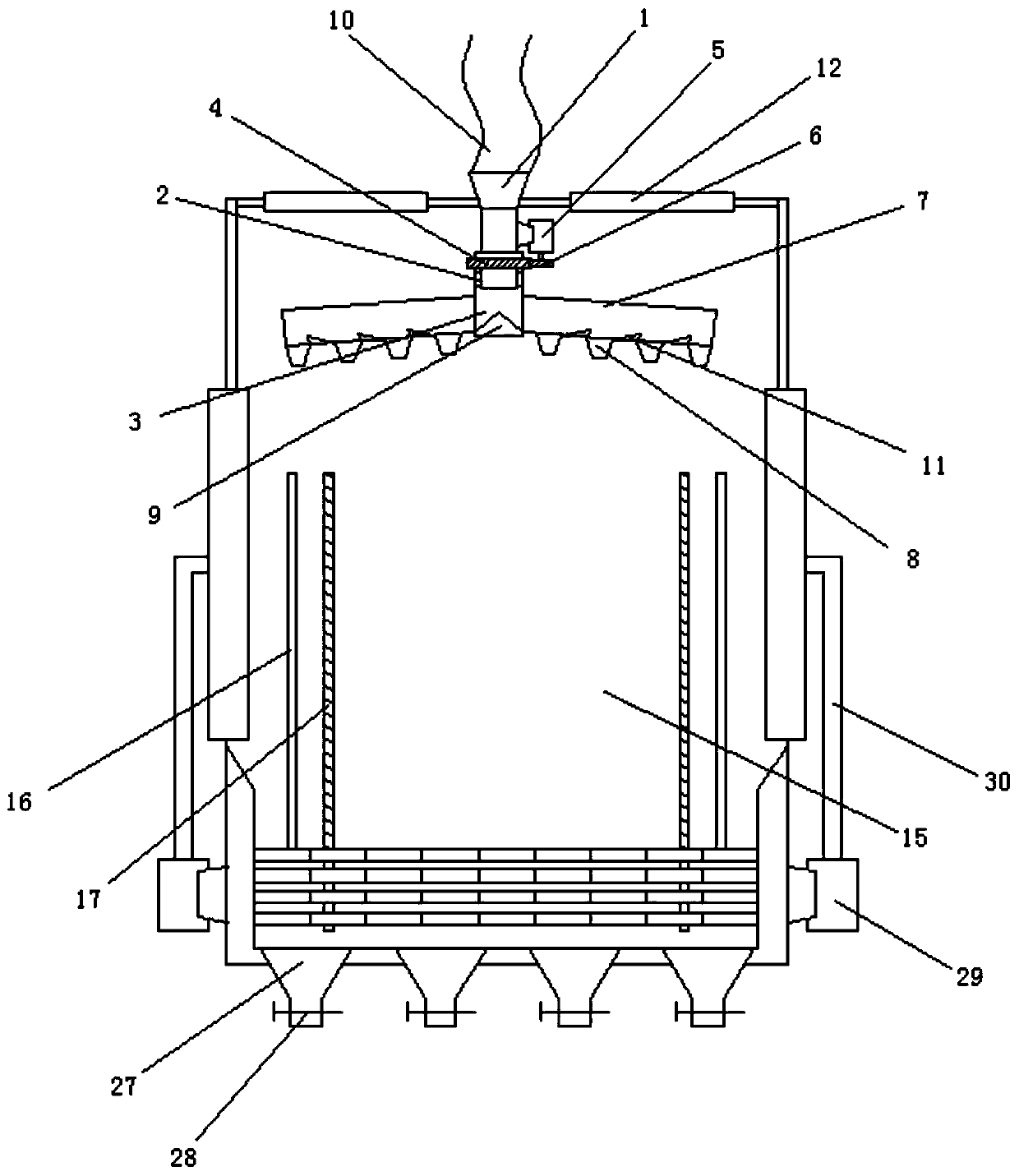

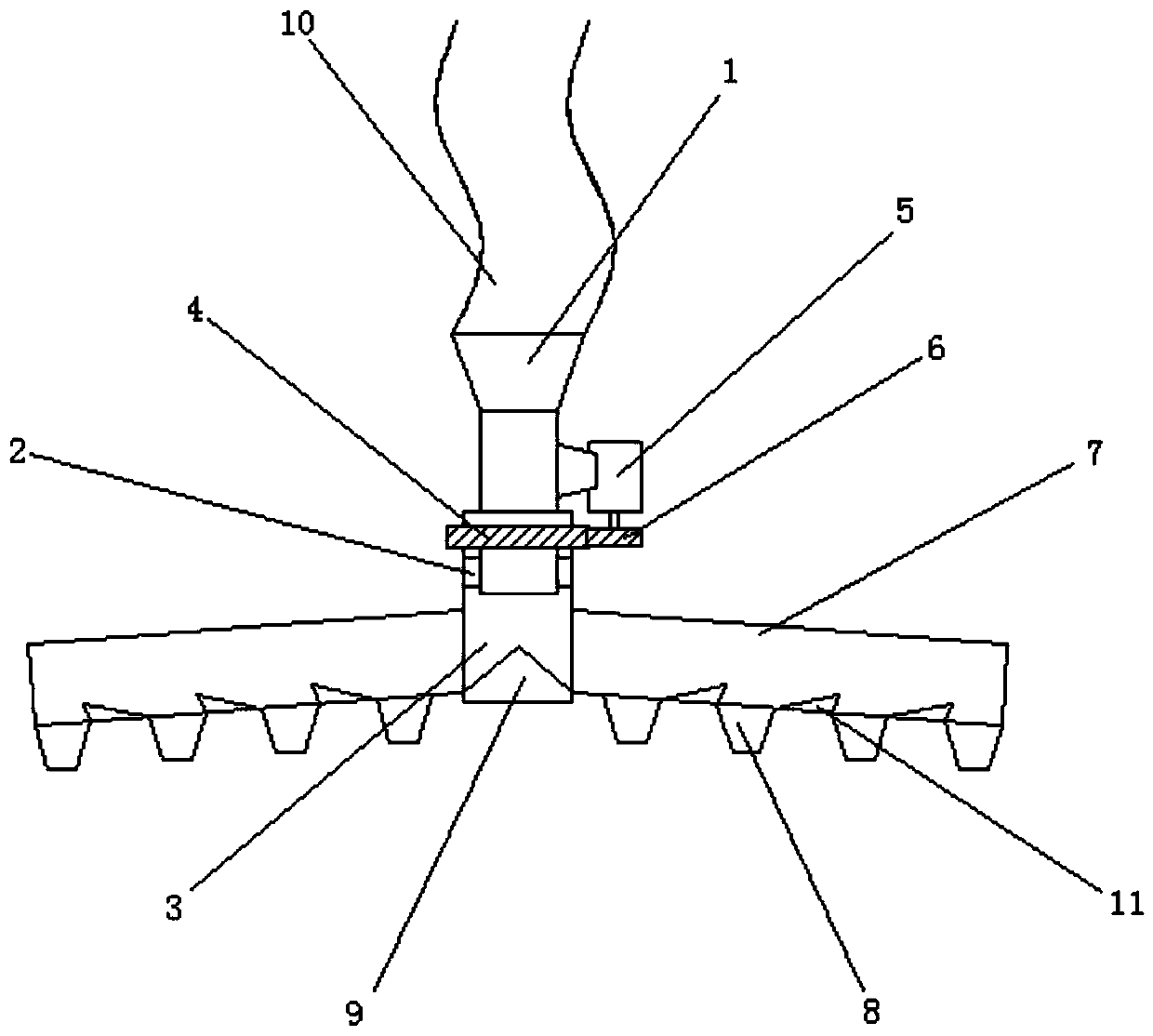

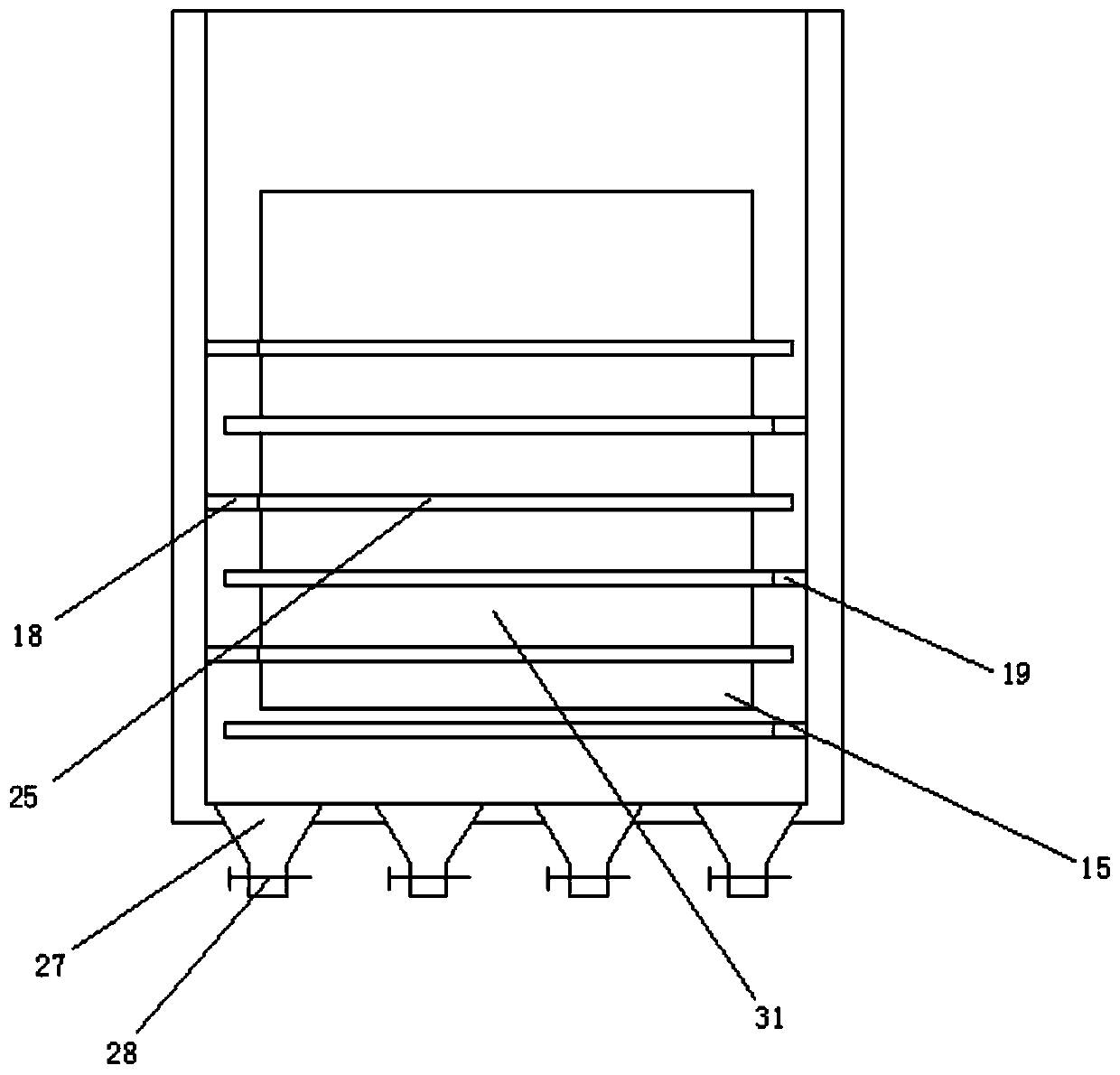

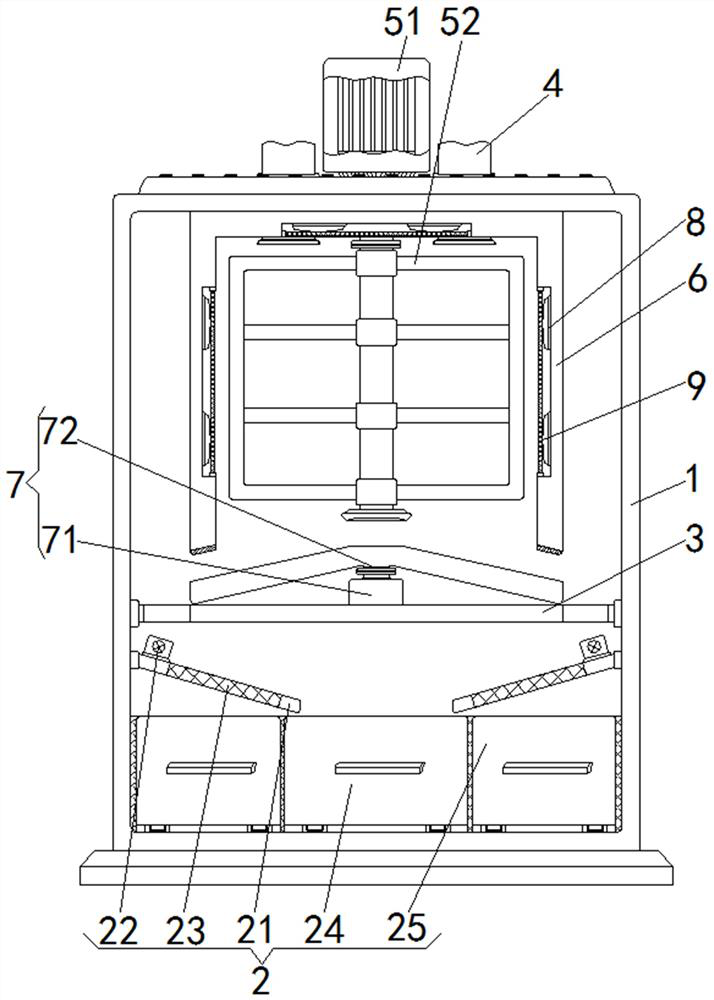

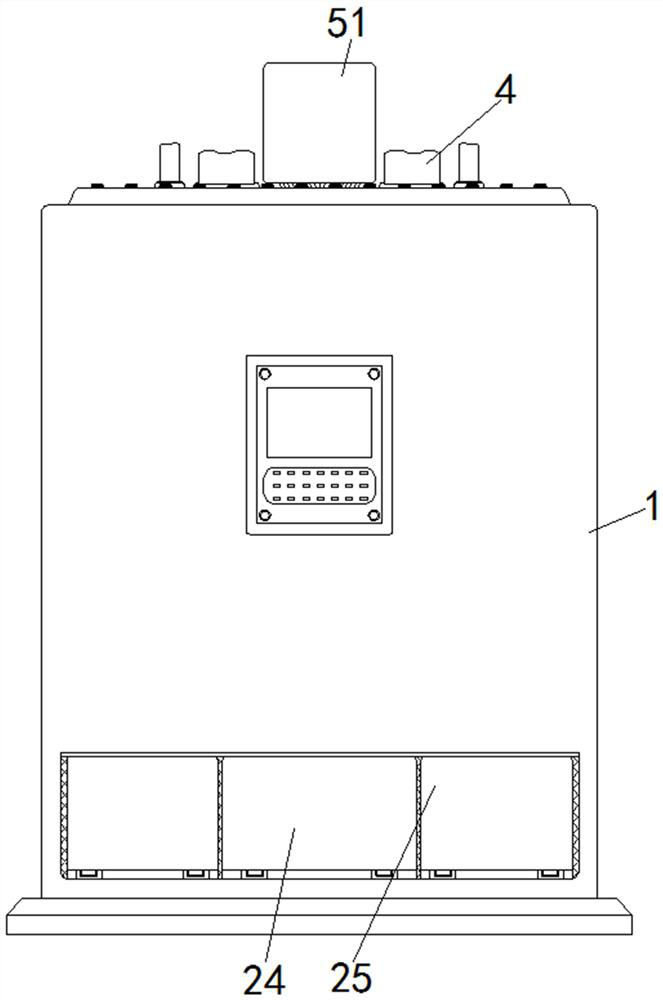

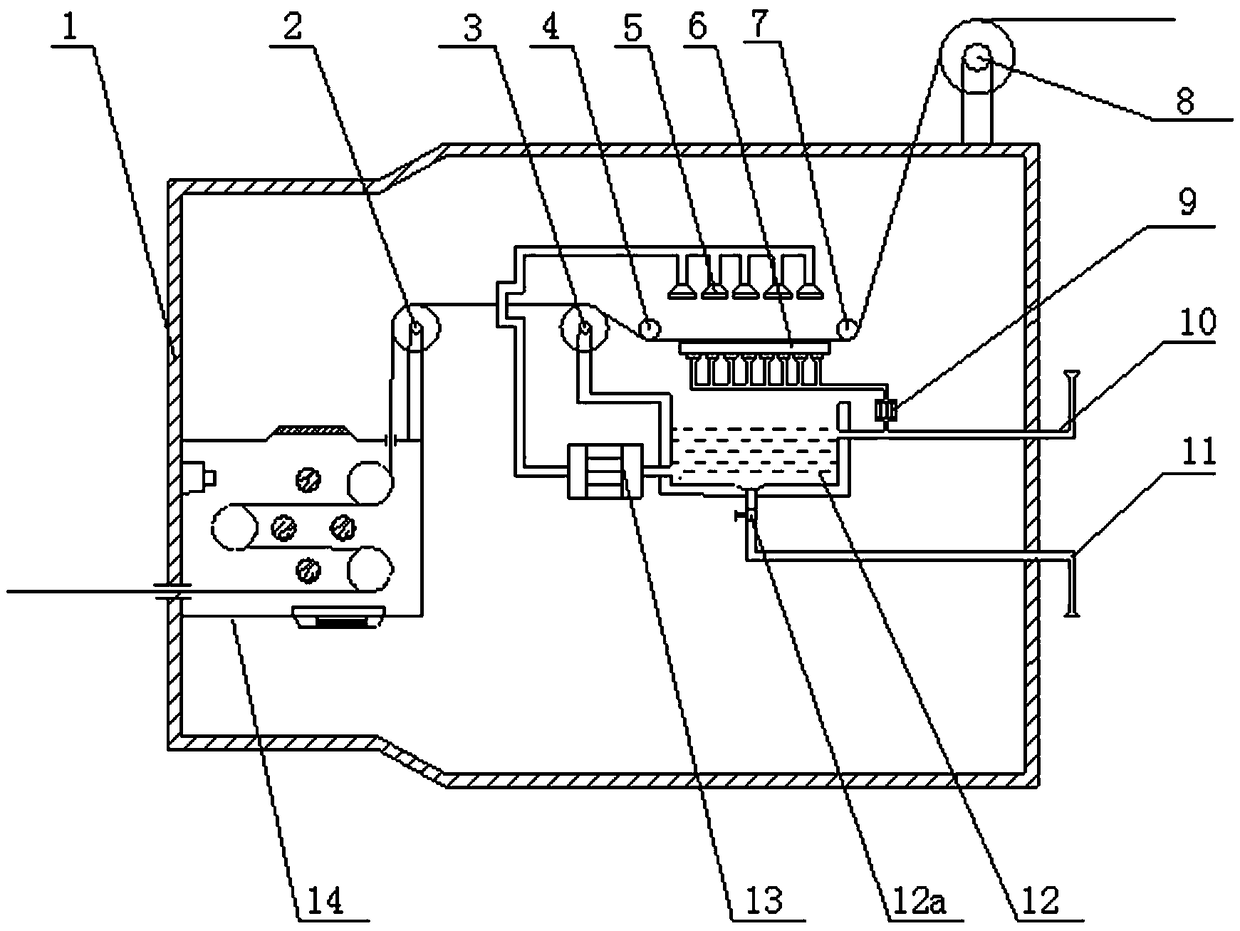

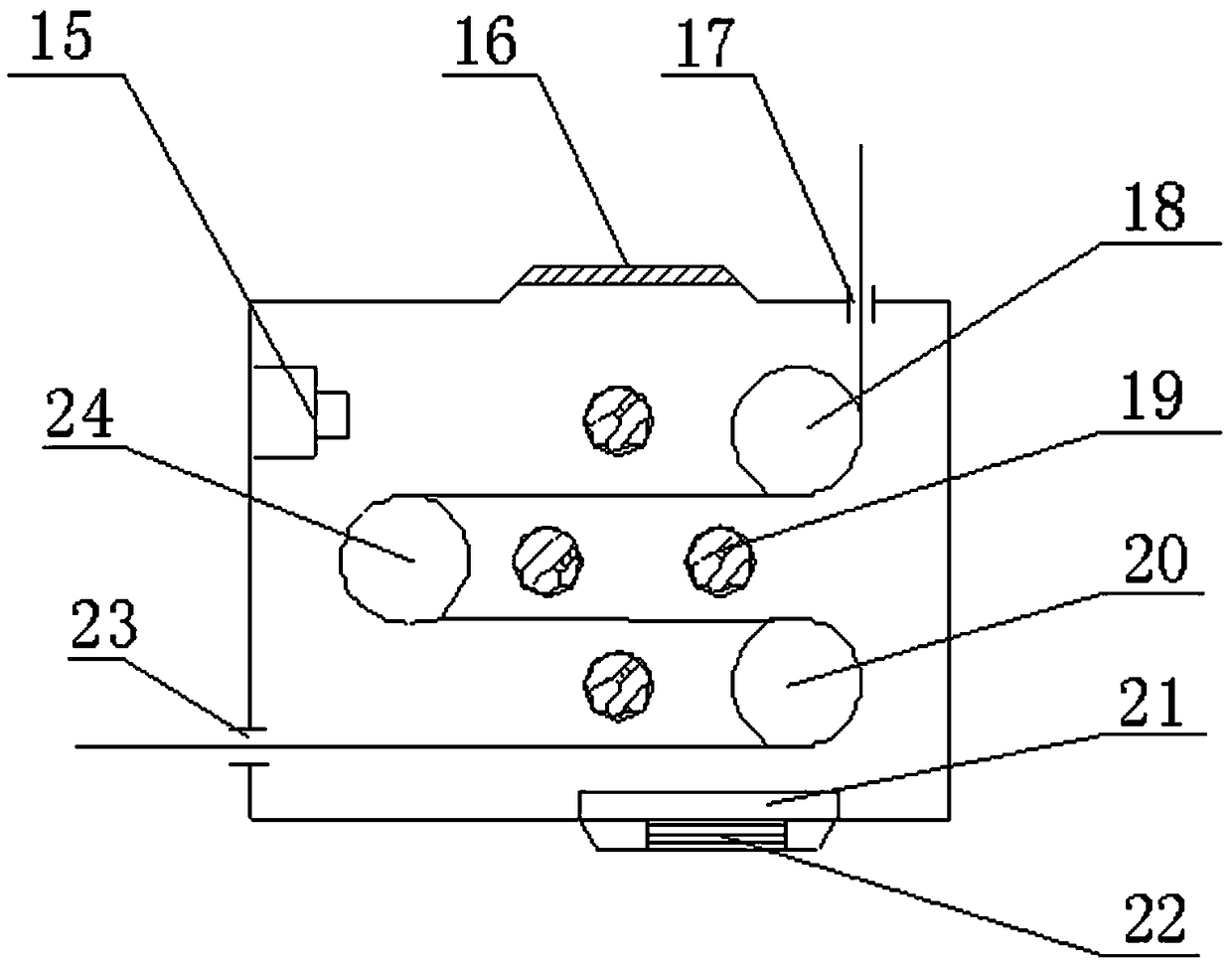

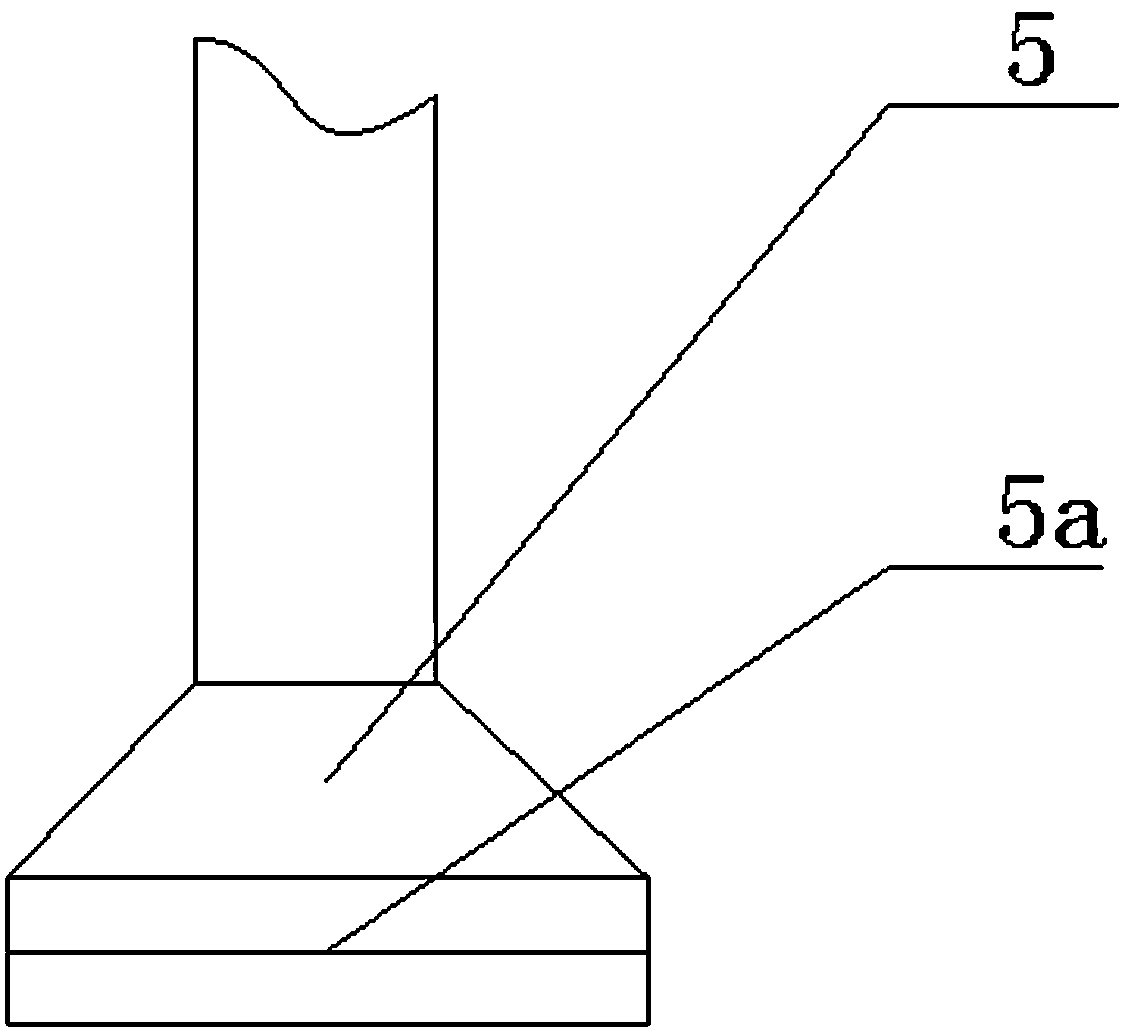

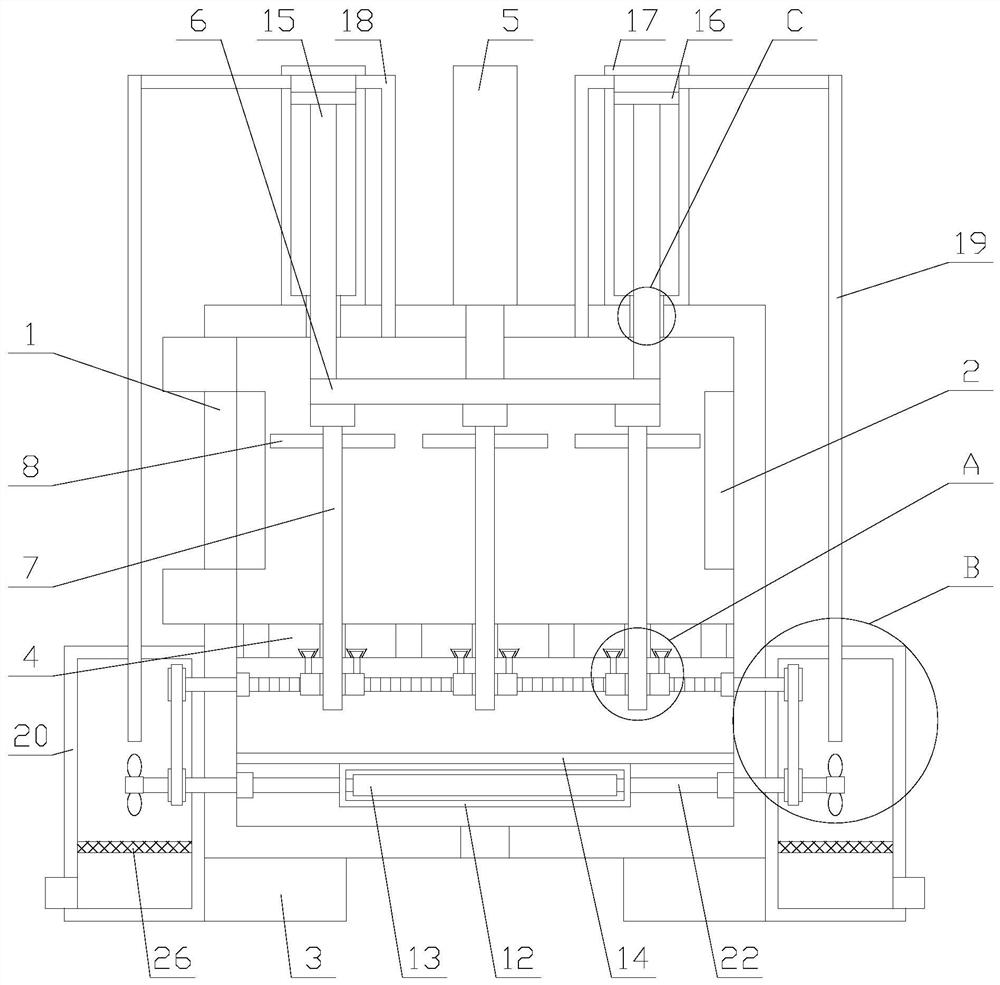

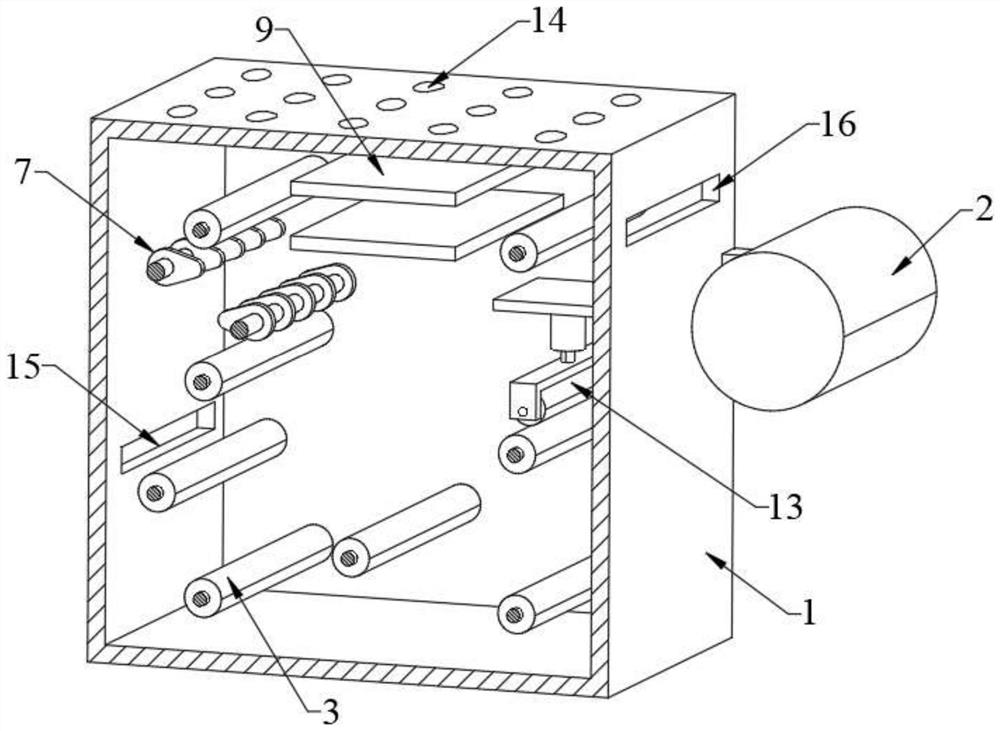

Lifting type traditional Chinese medicine material crushing and stirring drying device

InactiveCN107726733AReasonable designAvoid insufficient dryingDrying gas arrangementsDrying machines with non-progressive movementsReclaimerEngineering

The invention provides an ascending and descending device for pulverizing, stirring and drying traditional Chinese medicinal materials, which belongs to the field of traditional Chinese medicine processing. It includes a crushing box, a crushing blade, a material guide cover, an air heating device, a hydraulic cylinder, a storage box and a stirring and drying box; there are two hydraulic cylinders, which are fixed on both sides of the end surface of the fixed support base; the stirring The drying box is welded on the inner side of two fixed bearing plates; the storage box is fixed on the lower end of the stirring drying box with nuts and bolts; the air heating device is fixed on the right fixed bearing plate; the guide The material cover is welded on the upper ends of the two material guide pipes; the crushing box is welded on the upper end of the material guide cover; the crushing blades are provided with several and welded on the crushing shaft. The device of the invention has a reasonable design. Firstly, the medicinal material is crushed, and after the crushing, it is exported and stirred for drying, so as to avoid insufficient drying of the medicinal material with a large volume, improve product quality, and facilitate drying and taking out materials.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

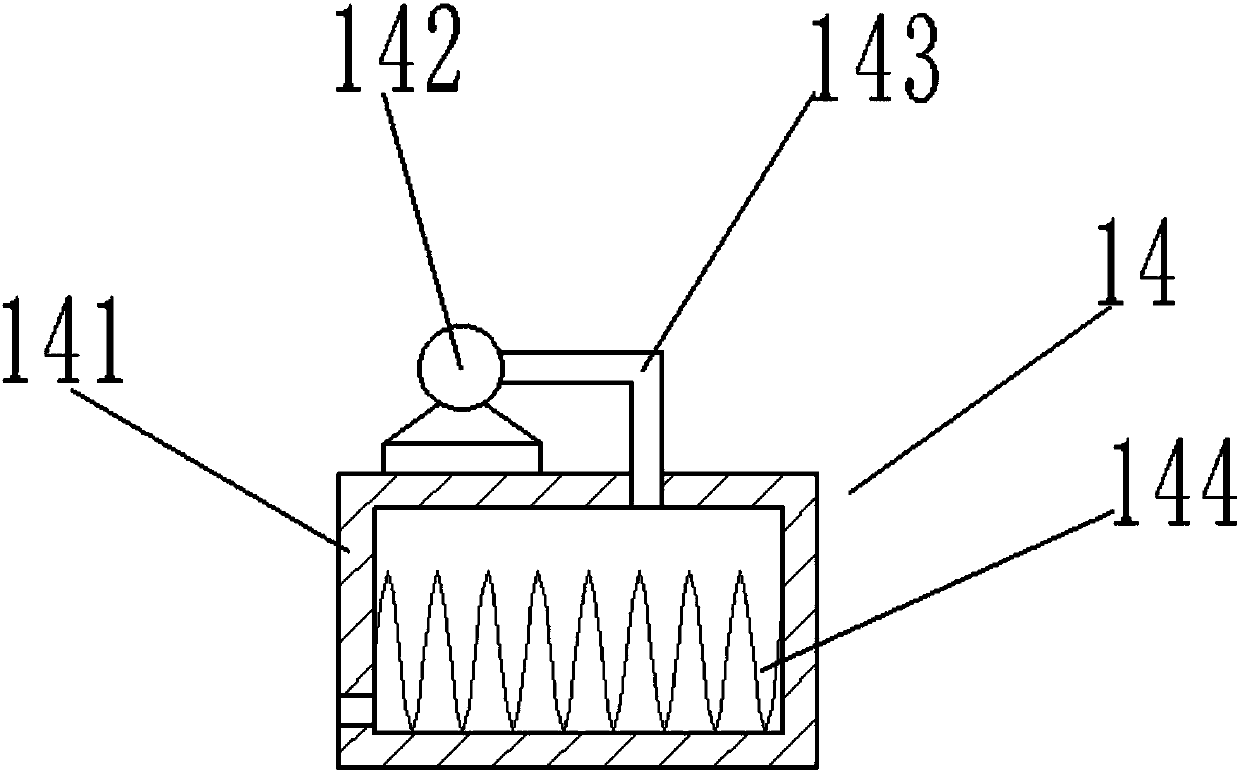

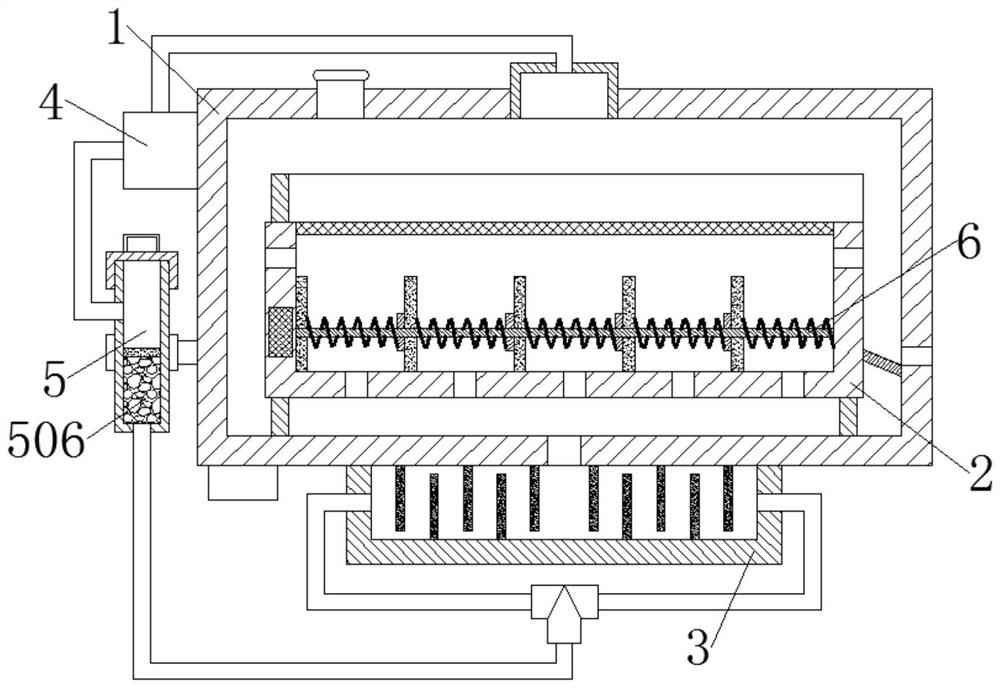

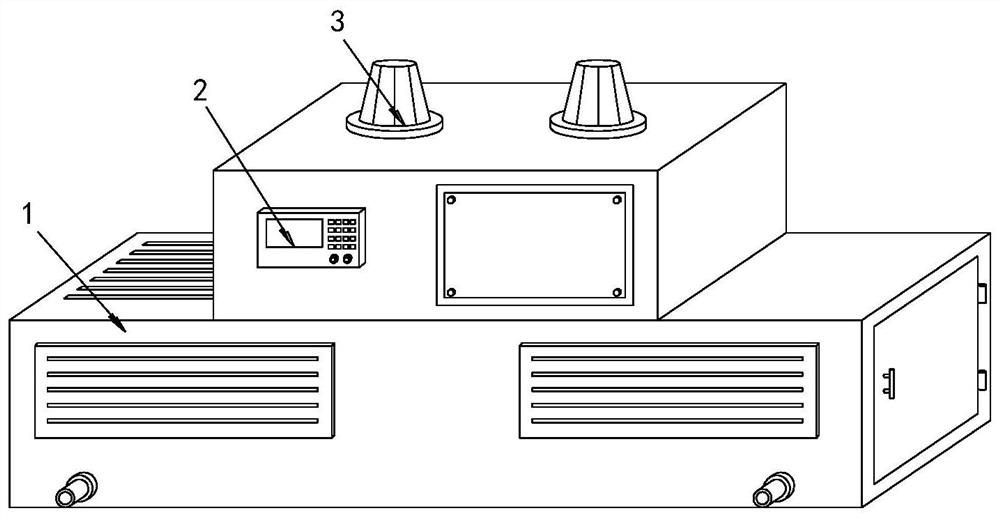

MC (Methyl Cellulose) colorful co-extrusion material drying device

InactiveCN107976030AAchieve dryingAvoid insufficient dryingDrying solid materials without heatDrying gas arrangementsVentilation tubeMethyl cellulose

The invention discloses an MC (Methyl Cellulose) colorful co-extrusion material drying device which comprises a base, a hot air blower, a ventilation tube as well as a guide cover, a diversion valve and a drying tank, wherein the hot air blower is connected with the base; the ventilation tube is communicated with an outlet of the hot air blower; the guide cover is communicated with the end part ofthe ventilation tube; the diversion valve is communicated with the side wall of the ventilation tube; a connecting rod is arranged on the side wall of the drying tank; a hoop is arranged at the end part of the connecting rod; the hoop is fixedly connected with the ventilation tube; a first water absorbing roller, a second water absorbing roller and a third water absorbing roller are rotationallyarranged on the drying tank; two support rods are arranged on the inner wall of the drying tank; a spiral drying air cylinder is arranged between the two support rods; an air inlet is formed in one end of the spiral drying air cylinder; and a spiral air channel is formed in the inner wall of the spiral drying air cylinder. By adopting the device, drying of plastic strips at a tension state is achieved, insufficient drying caused by mutual connection is avoided, meanwhile coactive hot air drying of vertical air blowing and transverse spiral air blowing is achieved, and the drying effect and thedrying efficiency are improved.

Owner:WUHU CHUANGKE NEW MATERIAL TECH CO LTD

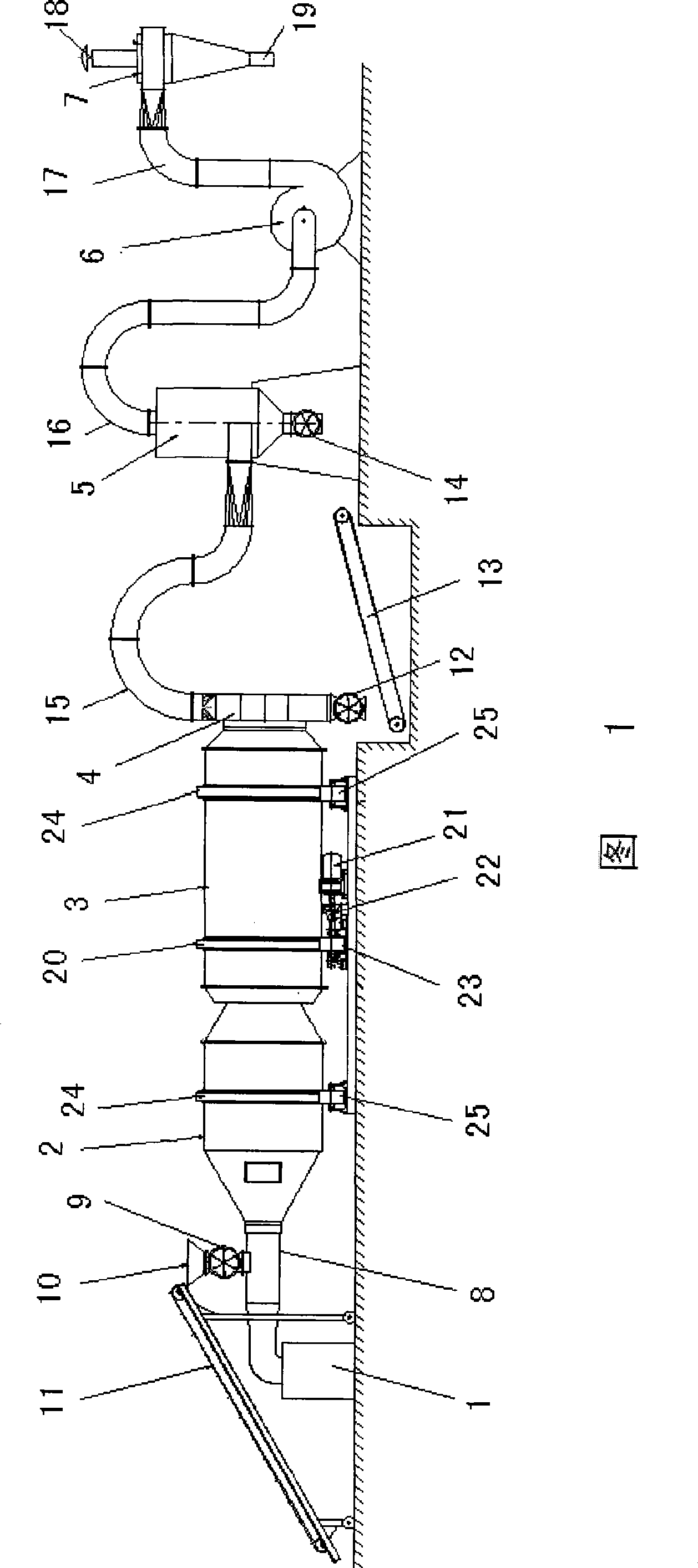

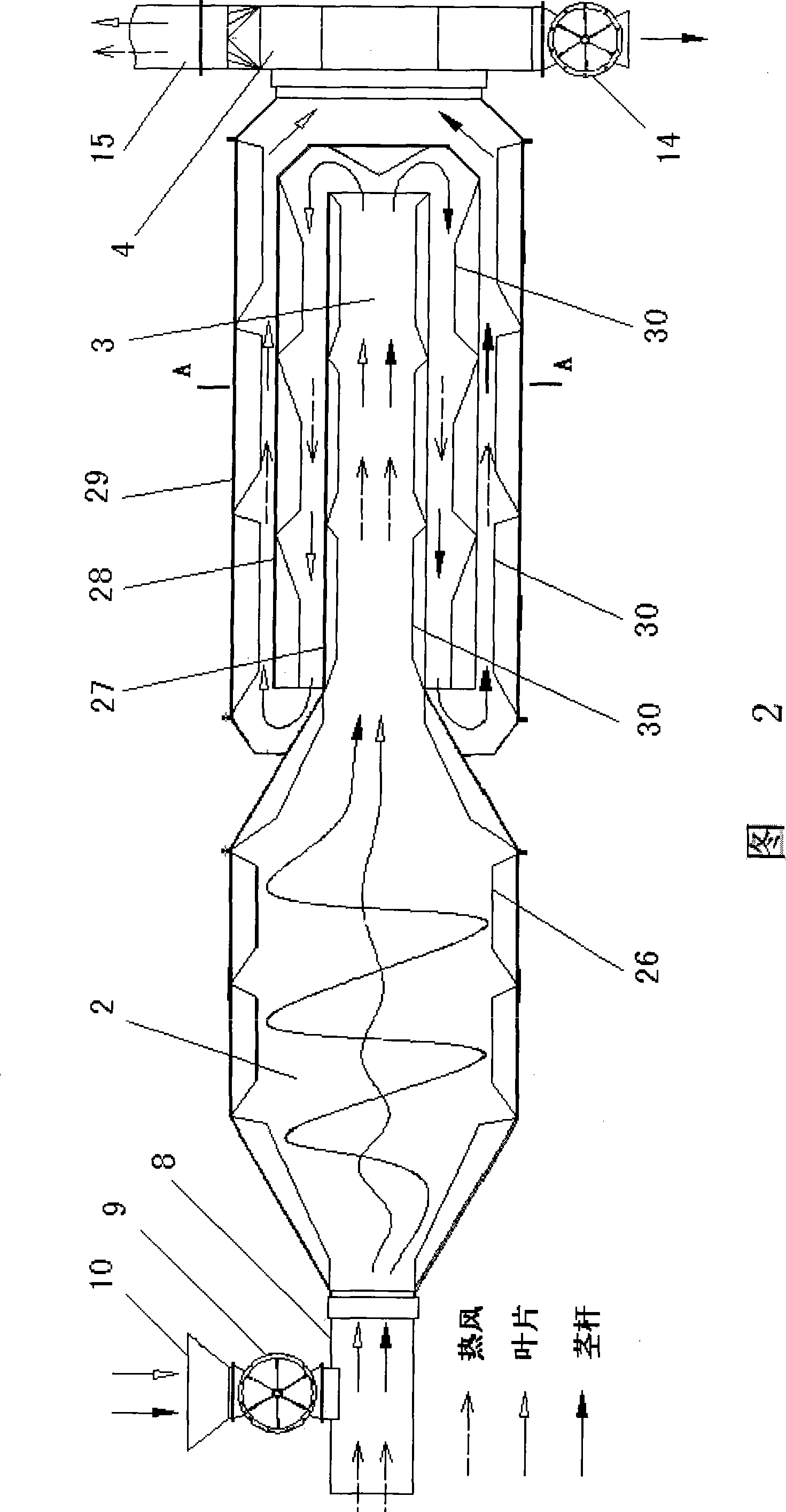

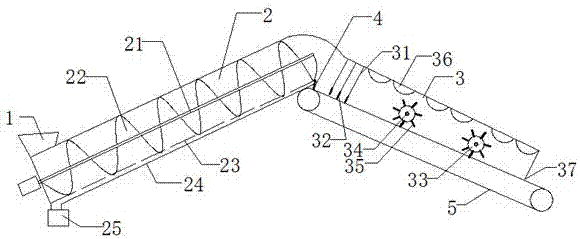

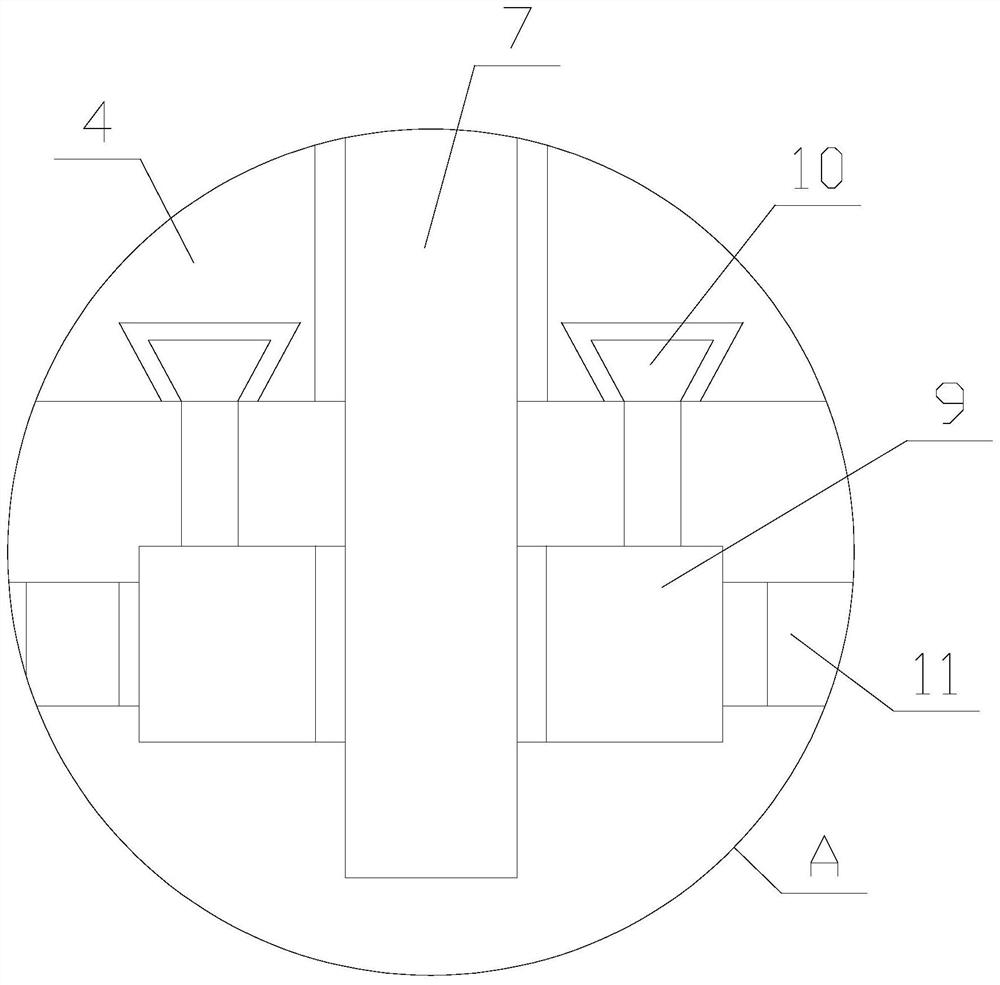

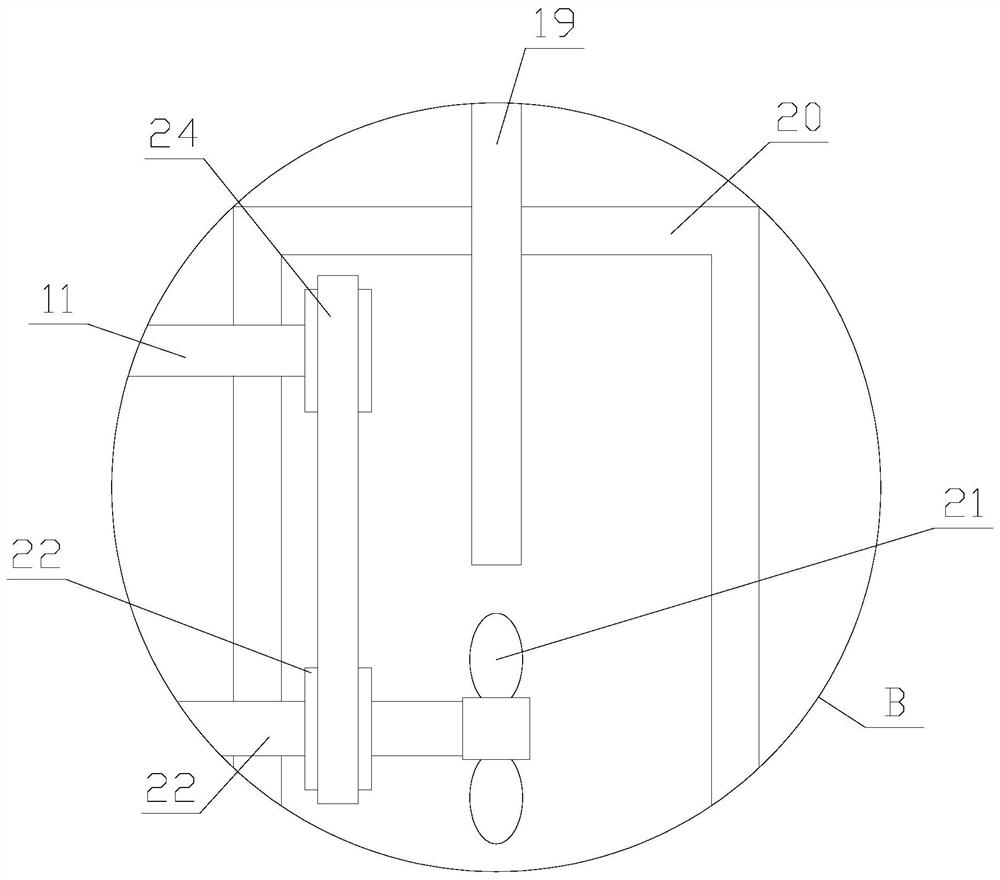

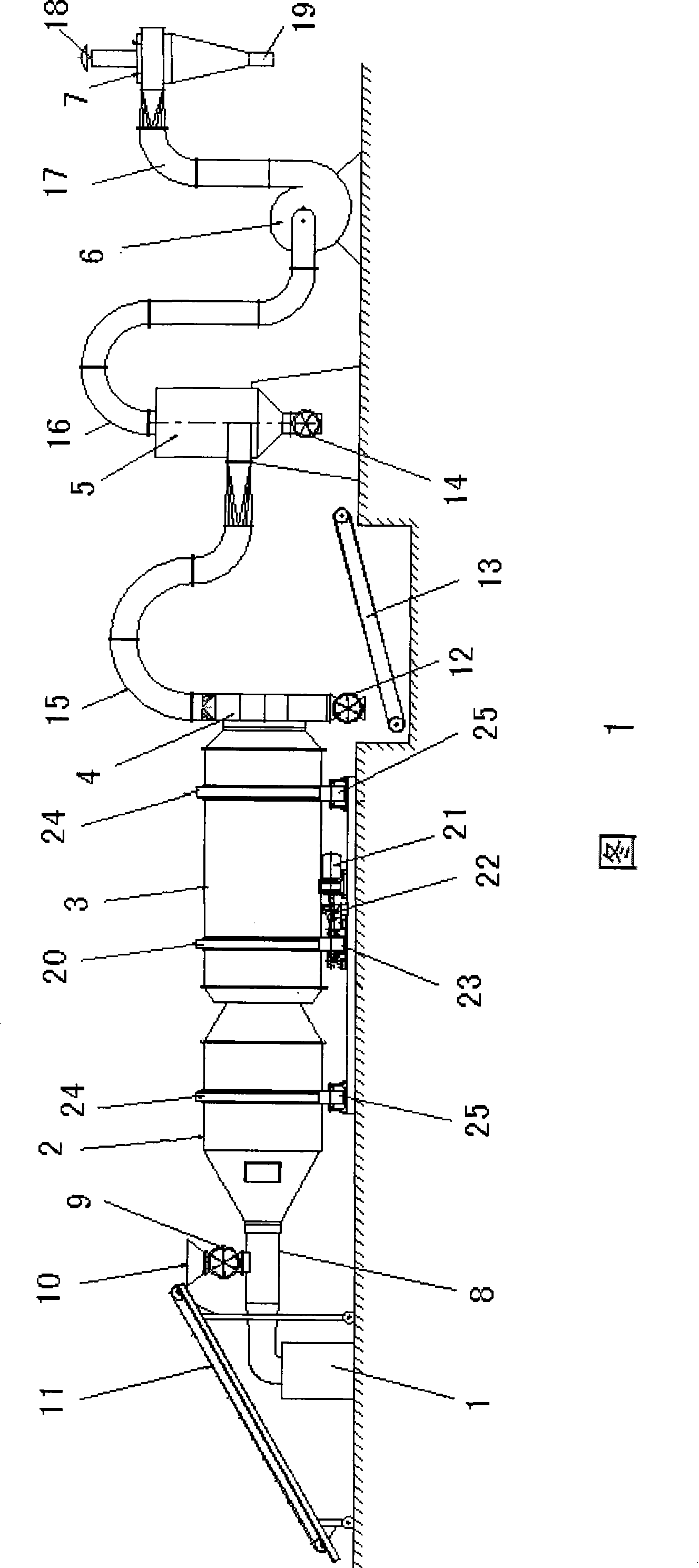

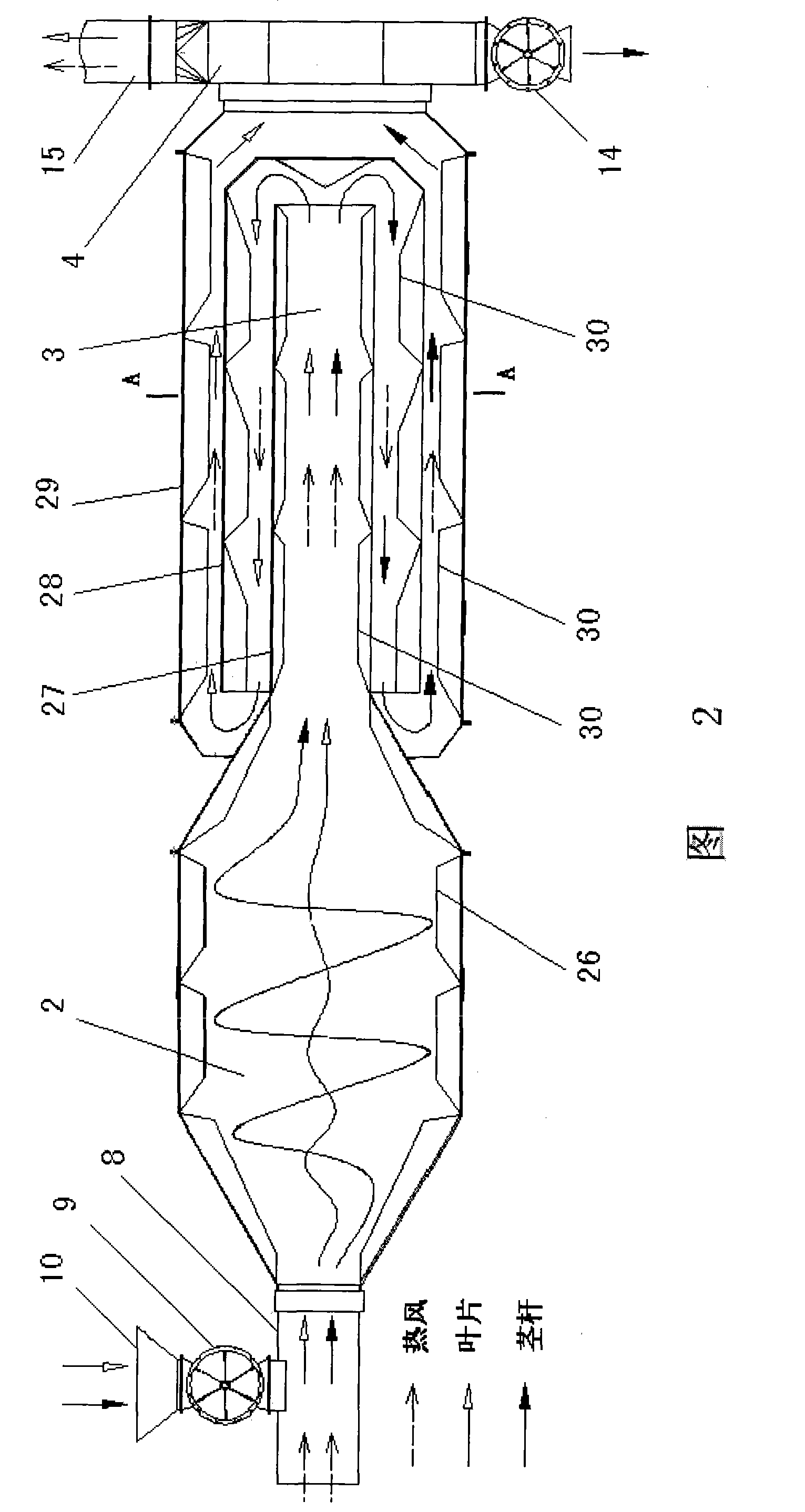

Grass drying, stem and leaf separating device

The invention relates to herbage drying and stem-leaf separating device, characterized in that: the device comprises a hot-blast stove, a pre-heating drying roller, a three-pass drying roller, a separating and discharging tank, a cyclone separator, a blower and a dust remover; the hot-blast stove is connected with the pre-heating drying roller through a warm-air pipe provided with a feeding hopper connected with a feeding airlock; the pre-heating drying roller is integrally fixed and connected with the three-pass drying roller rotationally connected with the separating and discharging tank and rotated through the driving of a moter; the lower end of the separating and discharging tank is provided with a discharging airlock, and the upper end is connected with the cyclone separator through a pipeline; the lower end of the cyclone separator is provided with a discharging airlock, and the upper end is connected with the blower through a pipeline; the outlet of the blower is connected with the dust remover with the outlet communicated with atmosphere. The invention decreases unnecessary energy consumption and lowers processing cost.

Owner:CHINA AGRI UNIV

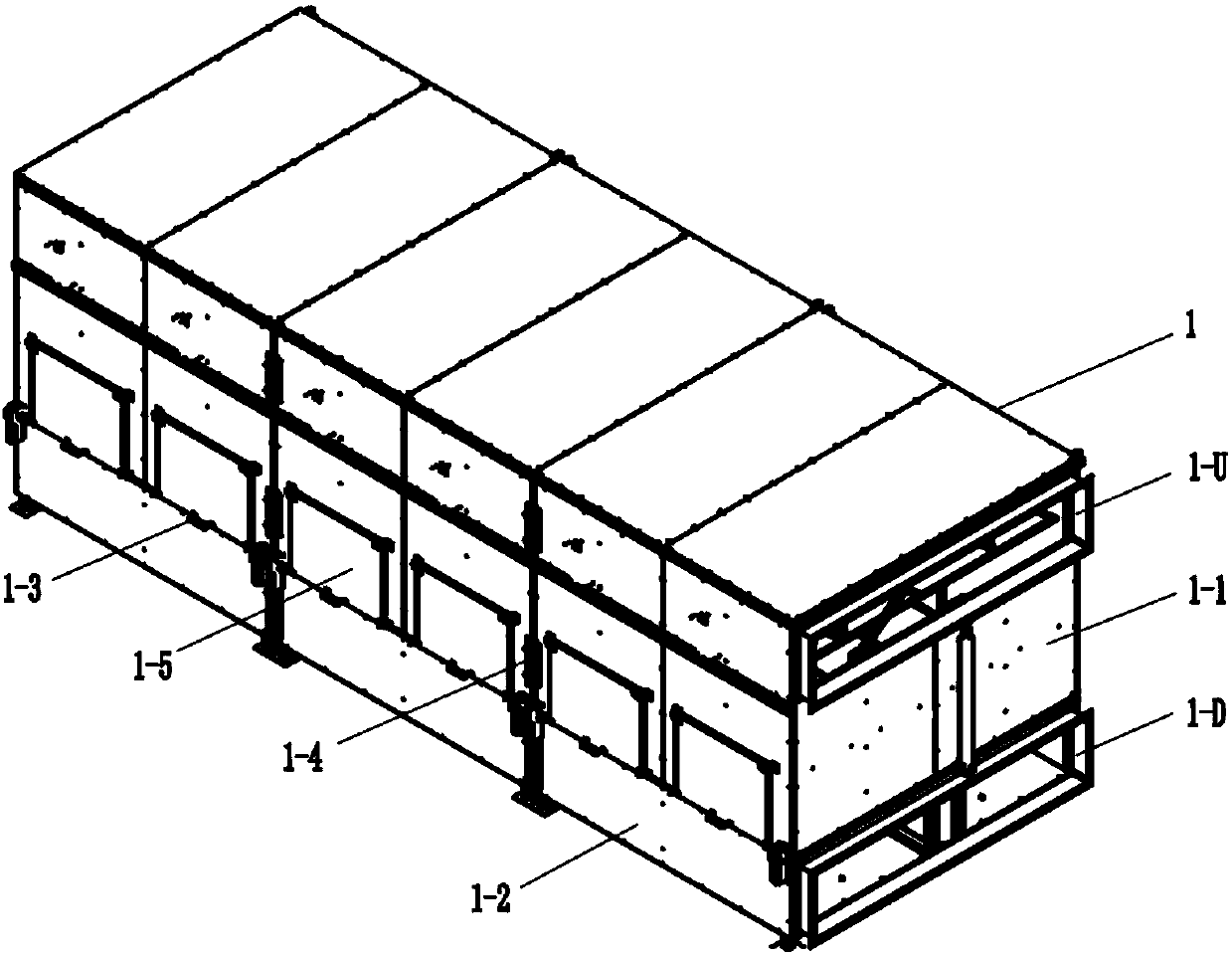

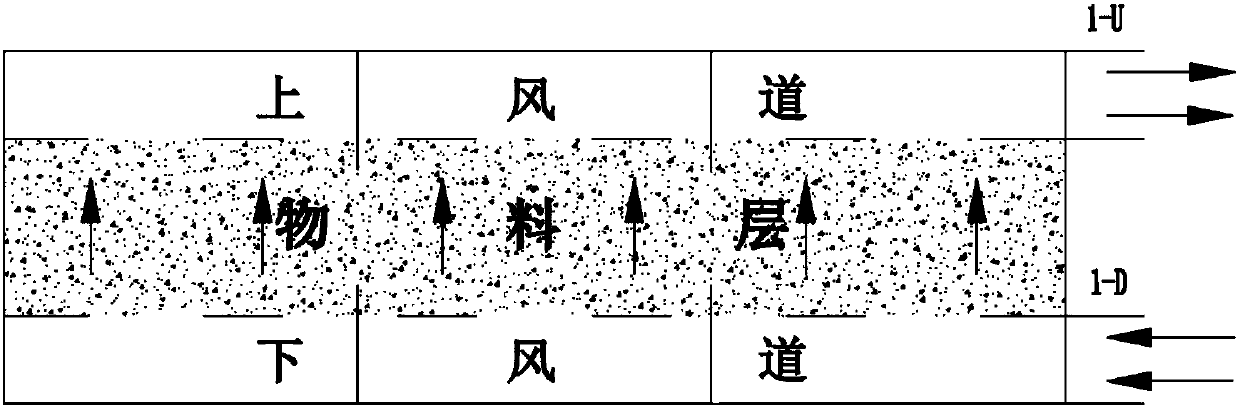

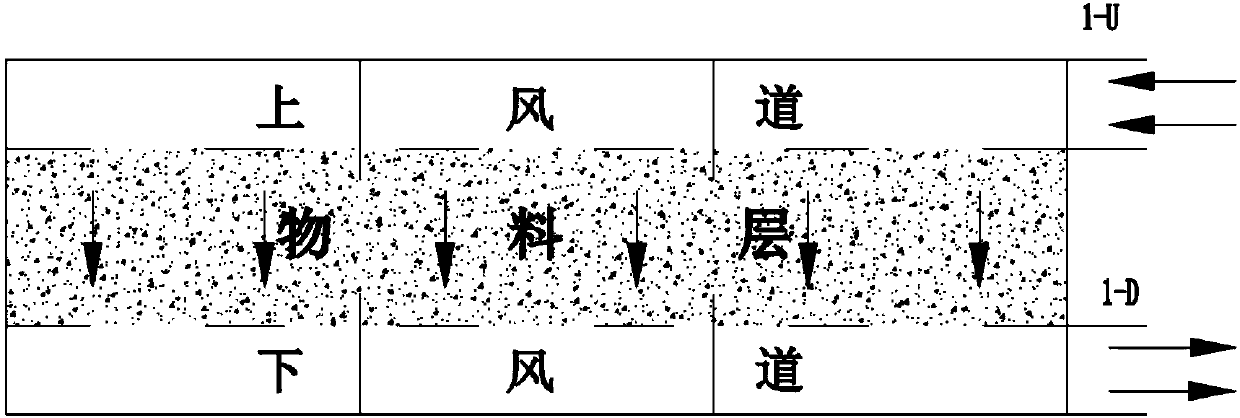

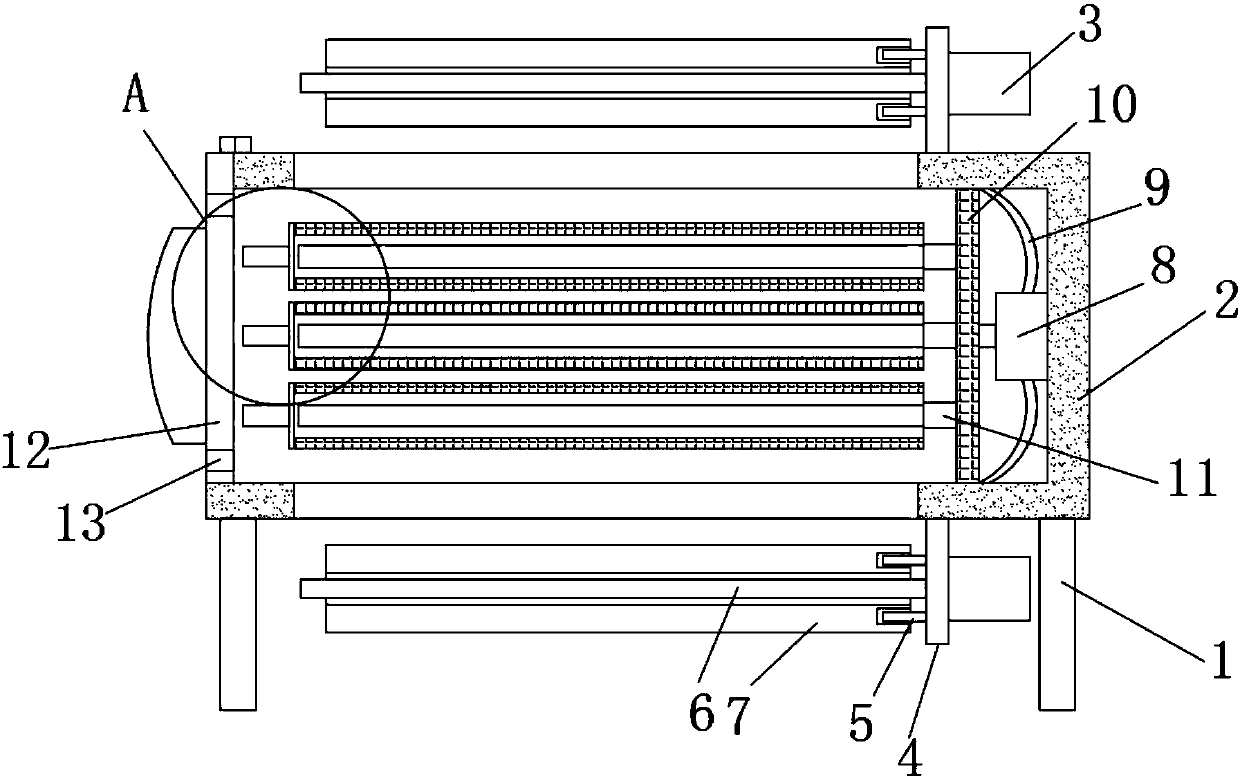

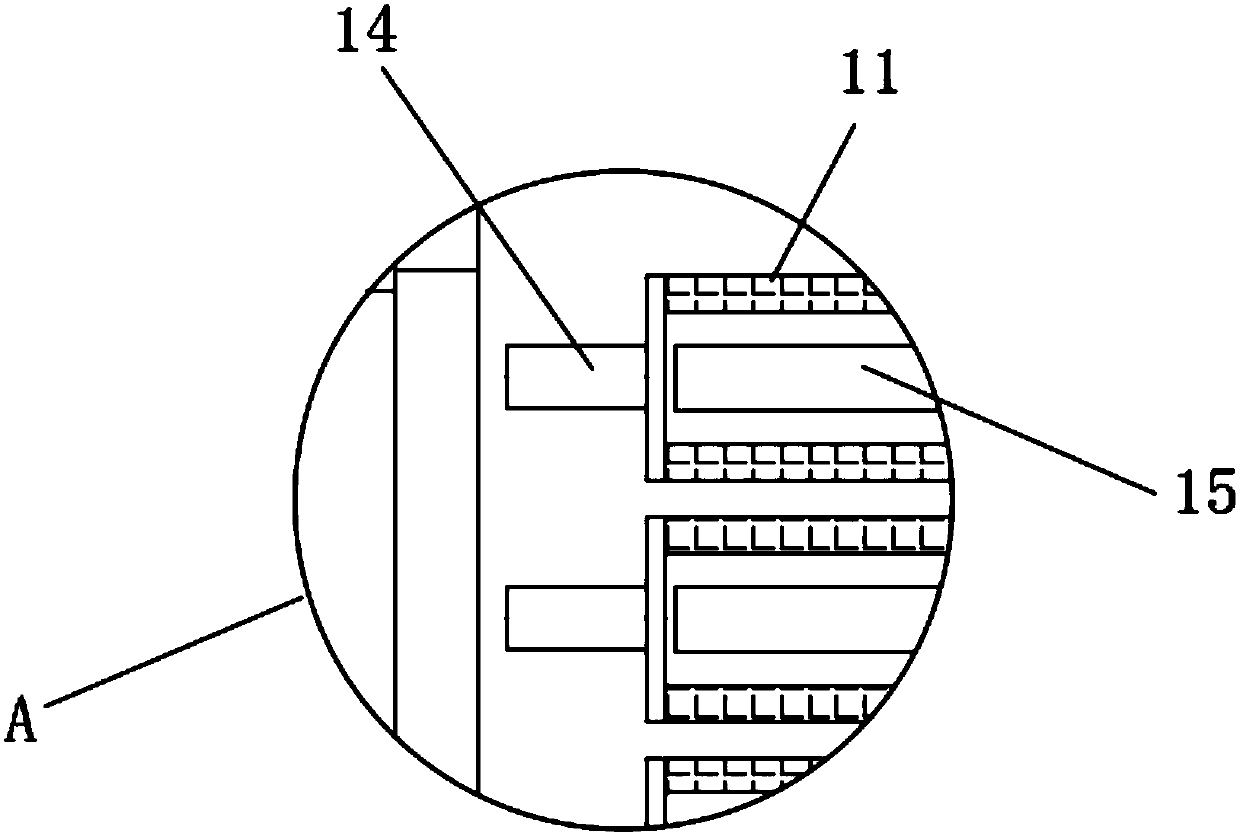

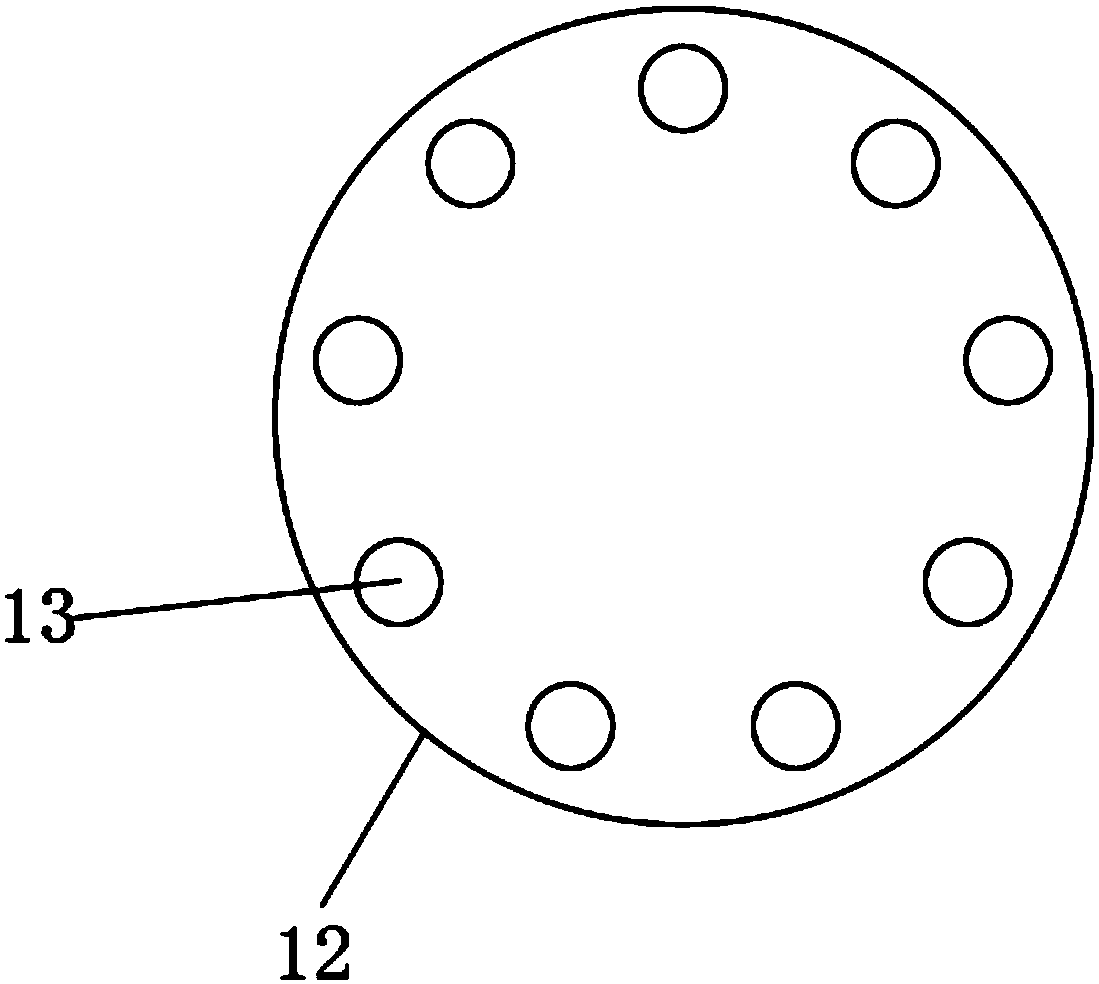

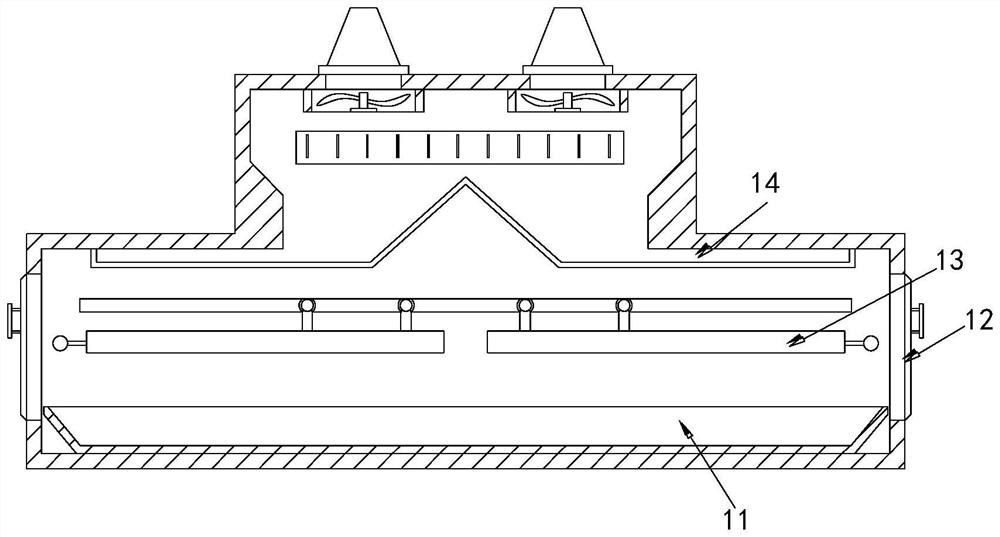

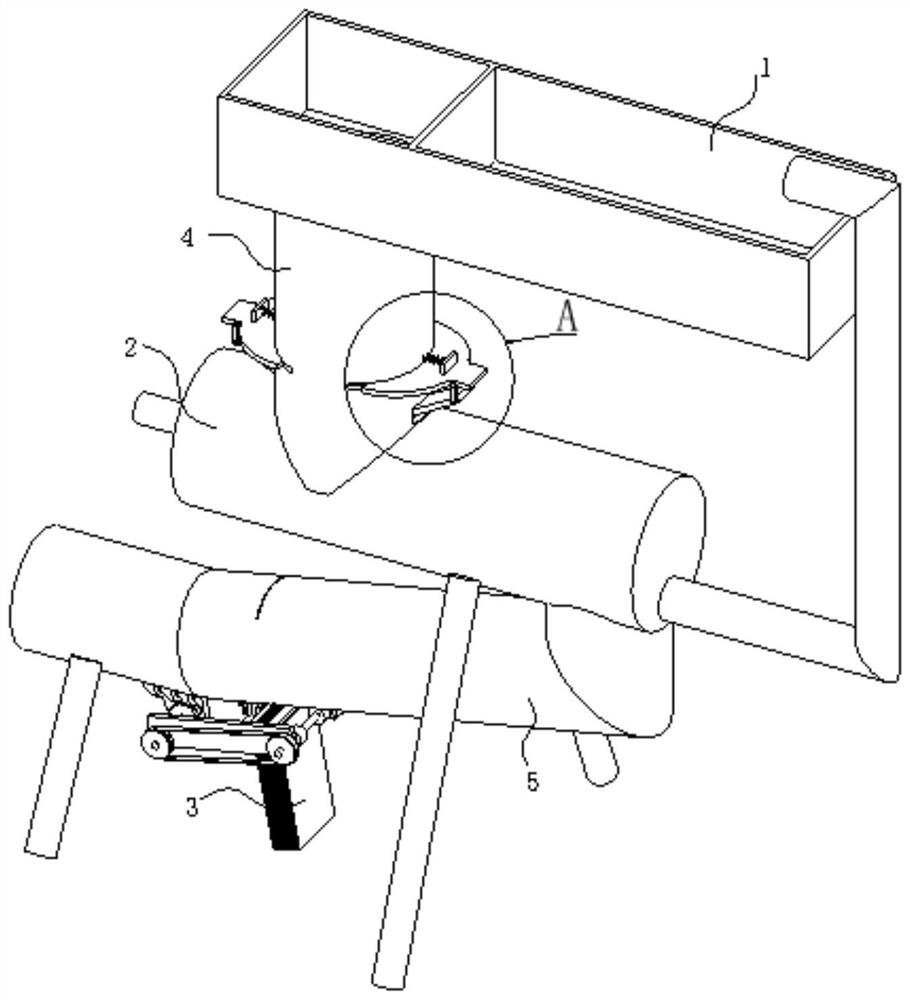

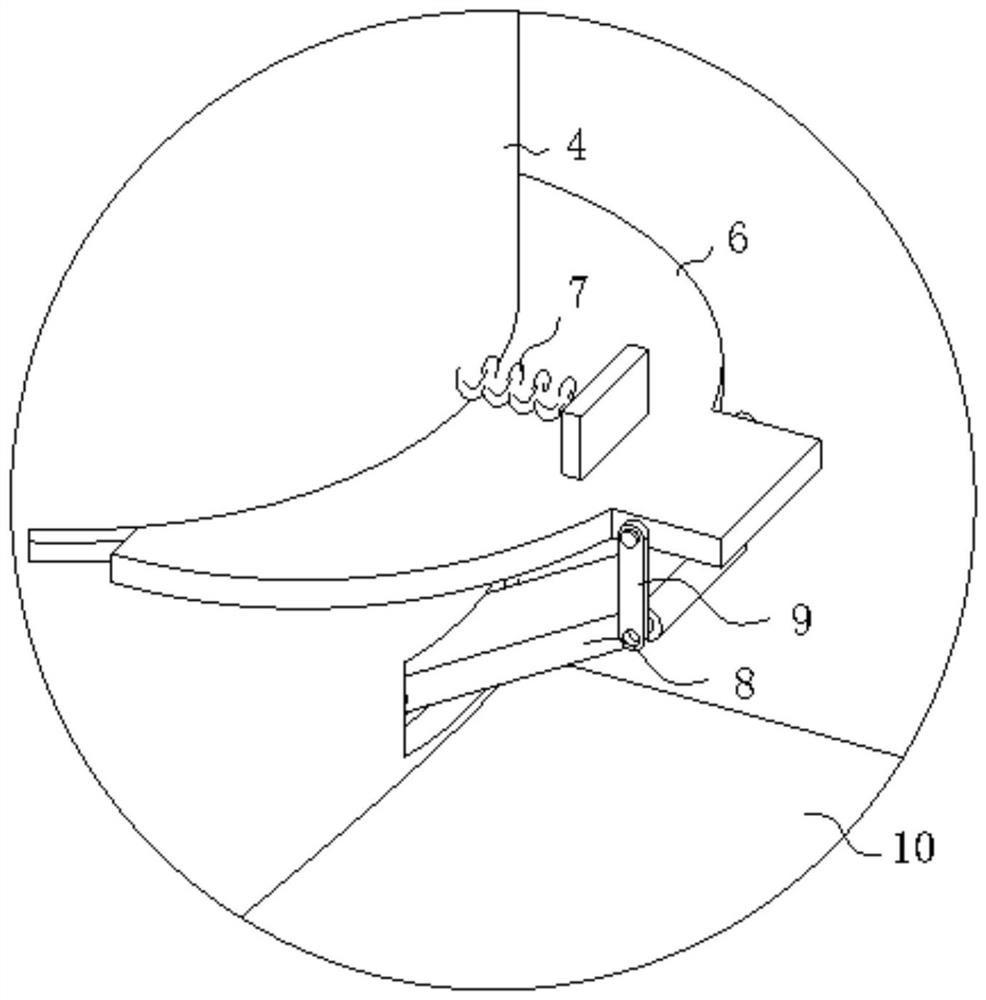

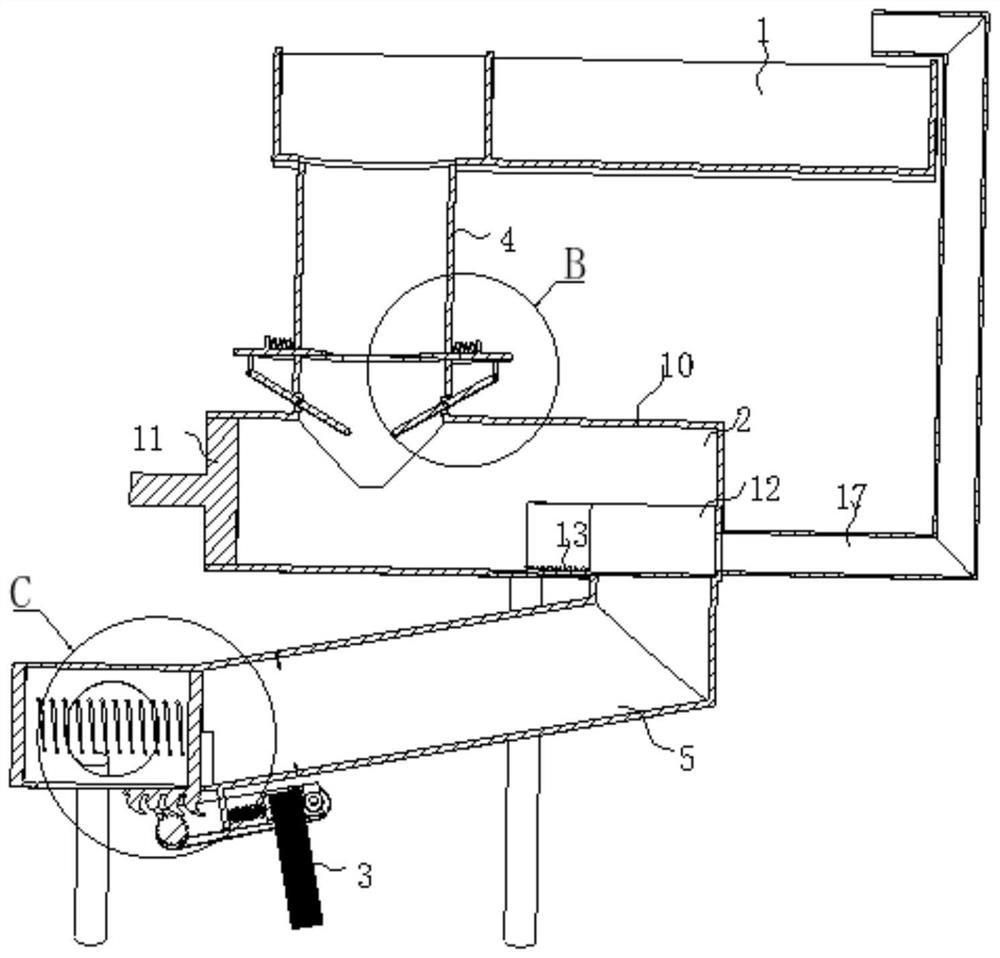

Modular reversing ventilation drying machine

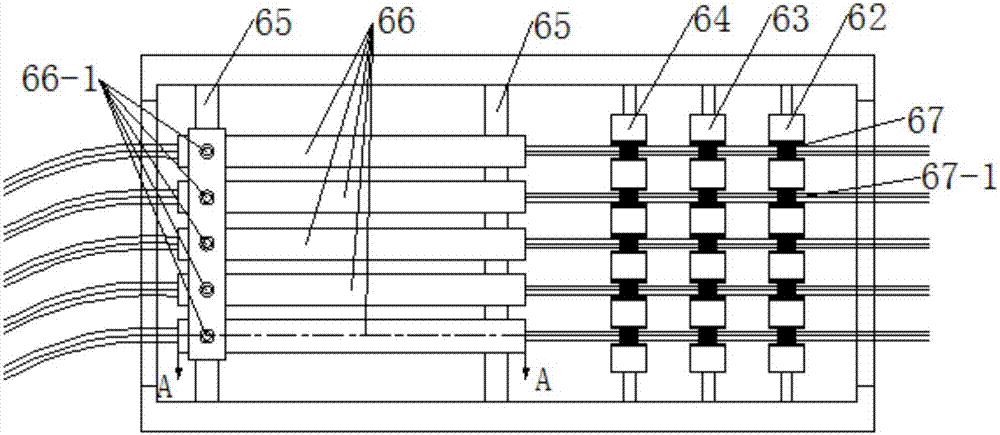

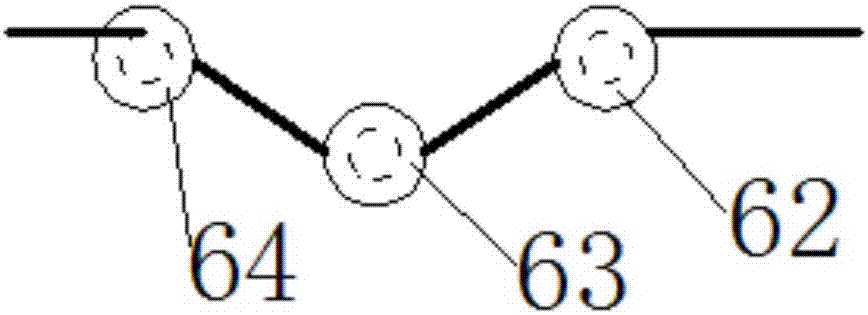

ActiveCN107830696AAvoid insufficient dryingDry evenlyDrying gas arrangementsDrying solid materialsEngineeringMechanical engineering

The invention relates to a modular reversing ventilation drying machine, and relates to the technical field of agricultural machines. The machine comprises a drying channel formed by splicing at leasttwo drying chamber modules. Each drying chamber module is formed in the manner that a bottom air flue with the top face opened is hinged to one side of a chamber body with the bottom face provided with a screen. One end of the drying channel is provided with an upper air supply port and a lower air supply port which lead to the corresponding bottom air flue and the upper portion of the corresponding chamber body correspondingly. The bottom face of each bottom air flue and the top face of the corresponding chamber body are provided with air guiding mechanisms distributed at intervals in the air supply direction. The air guiding mechanisms adjacent to the air supply ports are composed of adjustable-angle double-rocker air deflectors, and the air guiding mechanisms away from the air supply ports are composed of adjustable-angle hinge support deflectors. The top face of each chamber body is provided with a box cover capable of being opened, wherein the lower portion of the side face adjacent to the hinged position is provided with unloading doors capable of being opened. According to the modular reversing ventilation drying machine, the phenomenon that bottom materials are excessivelydried while top materials are insufficiently dried is avoided, and the drying quality is guaranteed. Meanwhile, transporting and installing are greatly convenient, and peanuts and other materials poor in mobility are poured and unloaded very conveniently.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

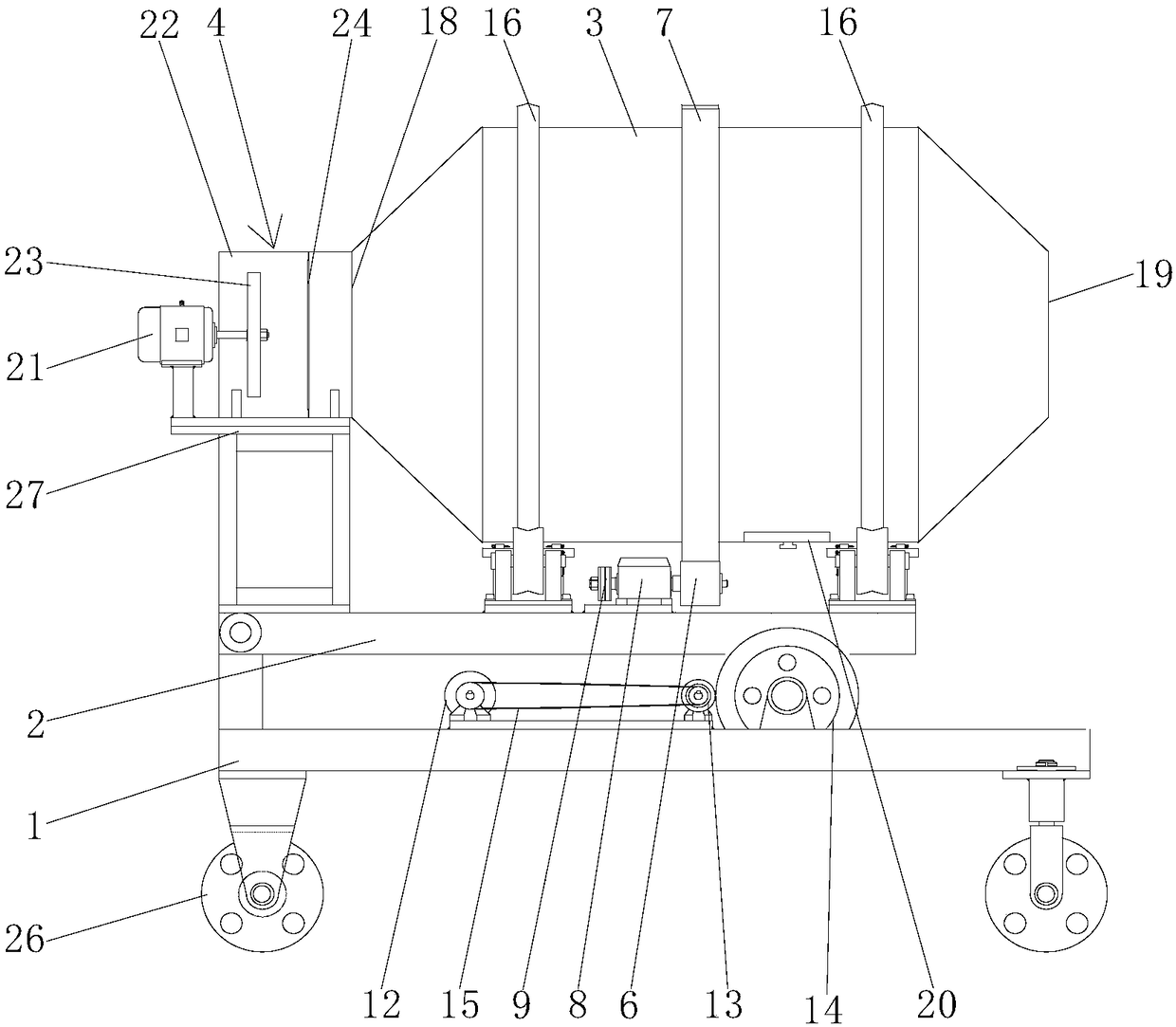

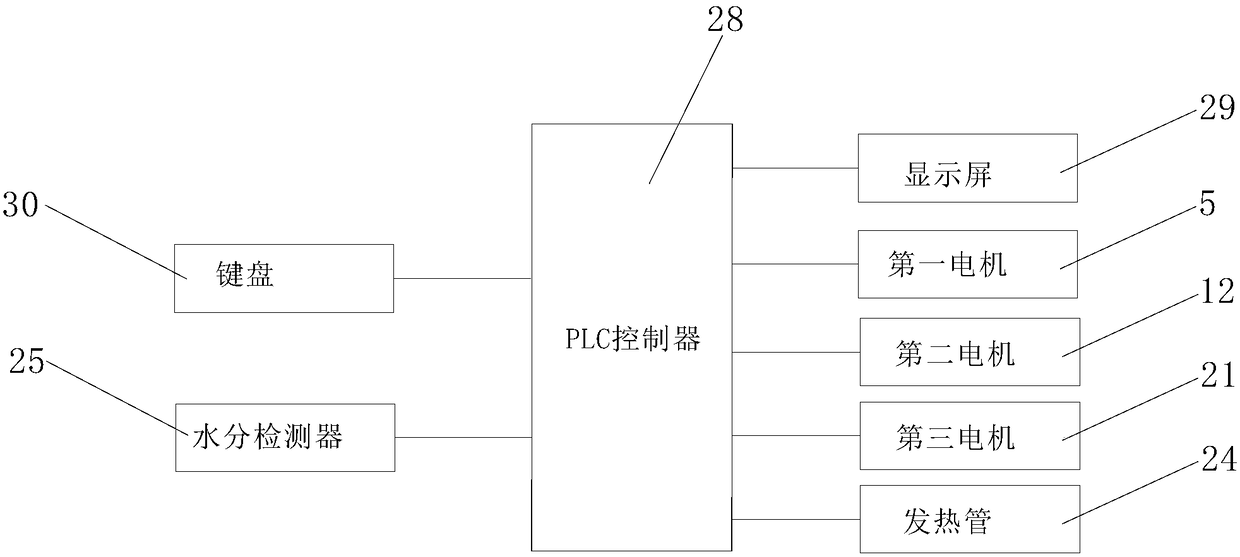

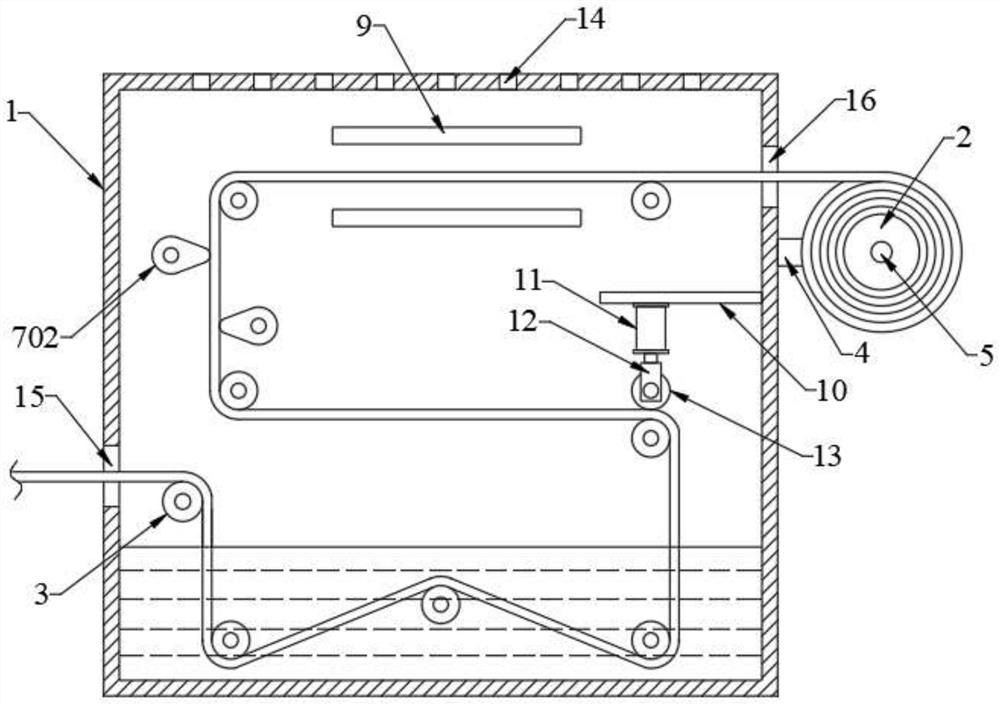

Grain drying device

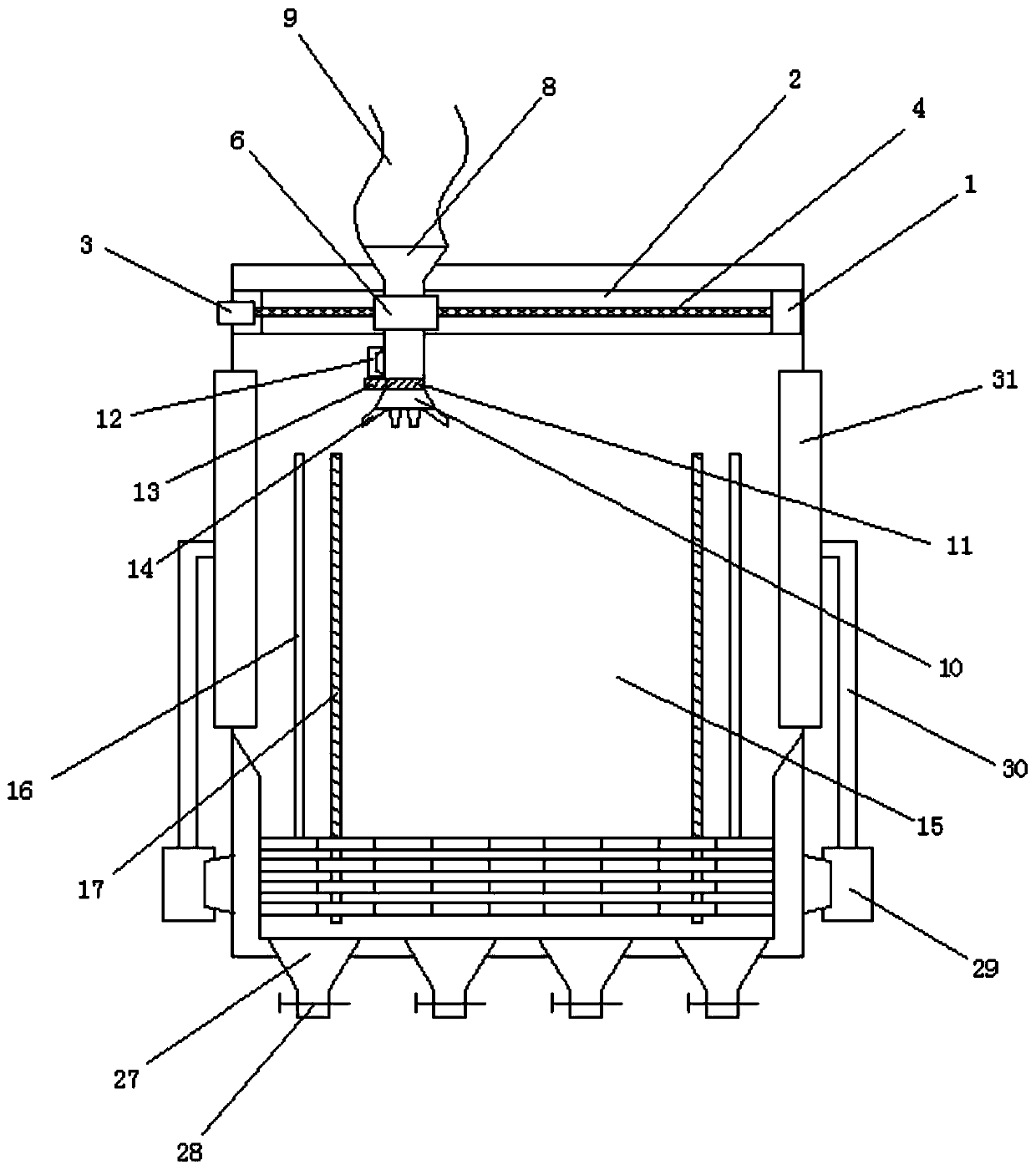

InactiveCN111156795AUniform feedingAvoid insufficient dryingDrying gas arrangementsSeed preservation by dryingGear wheelAgricultural engineering

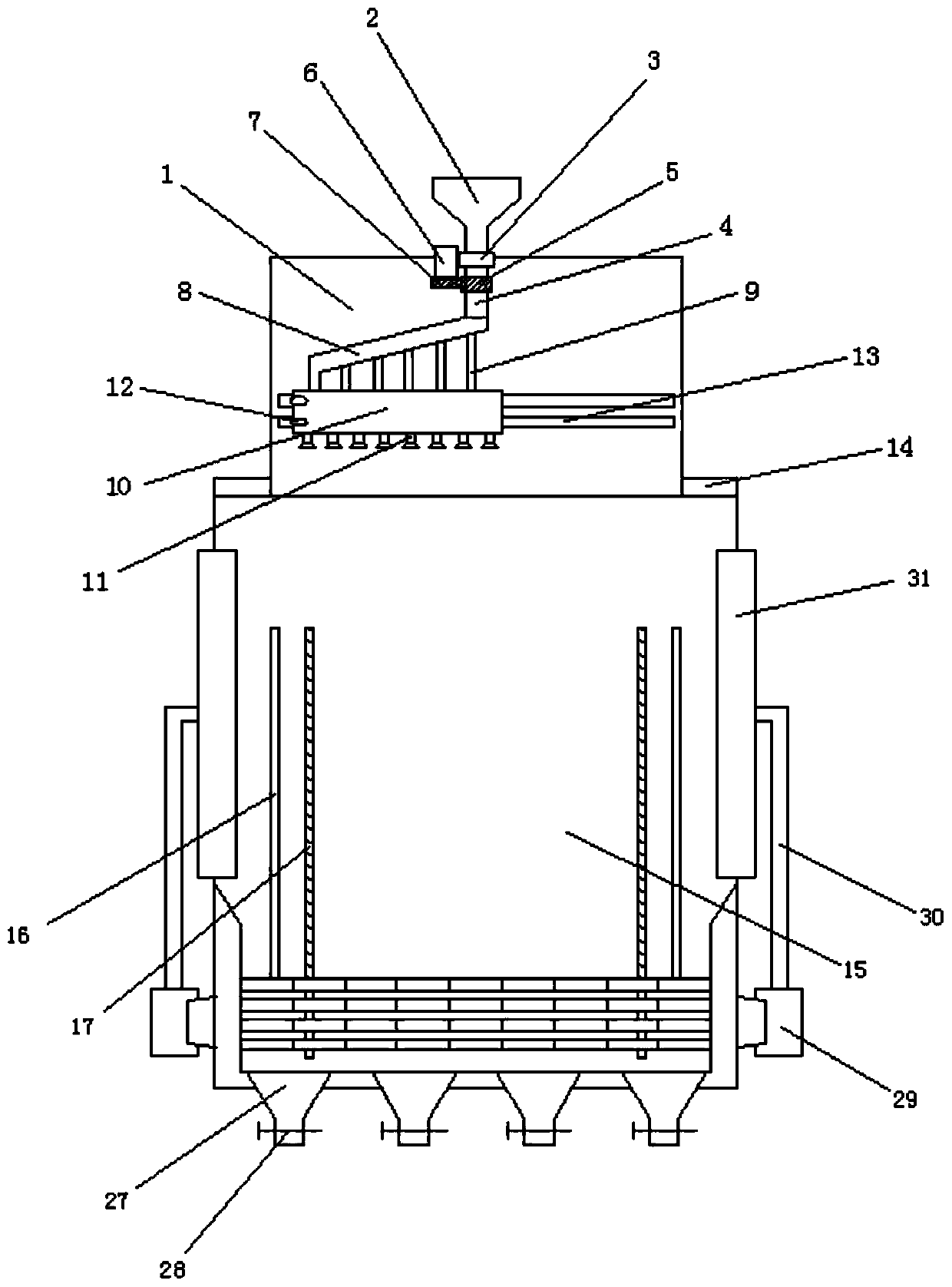

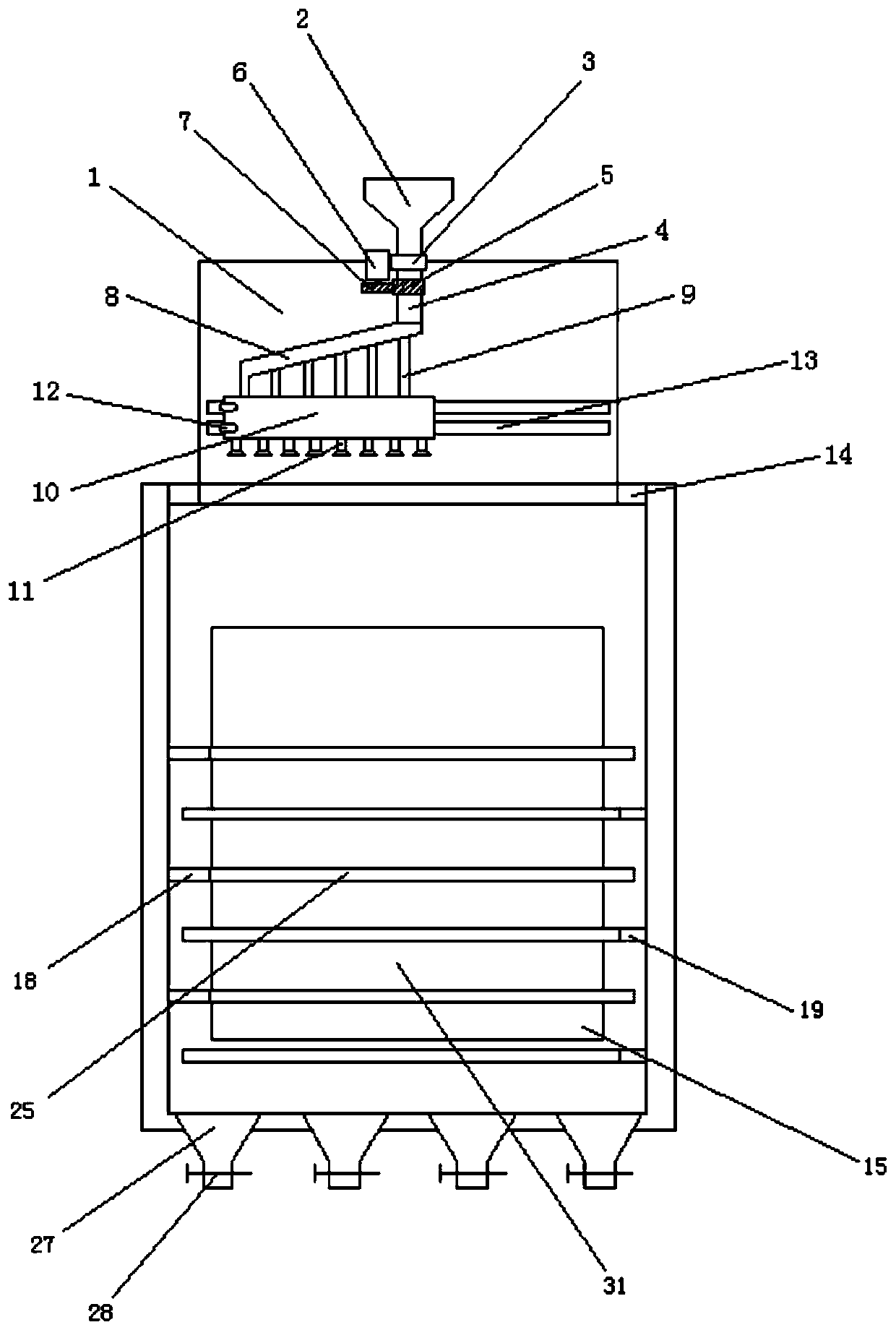

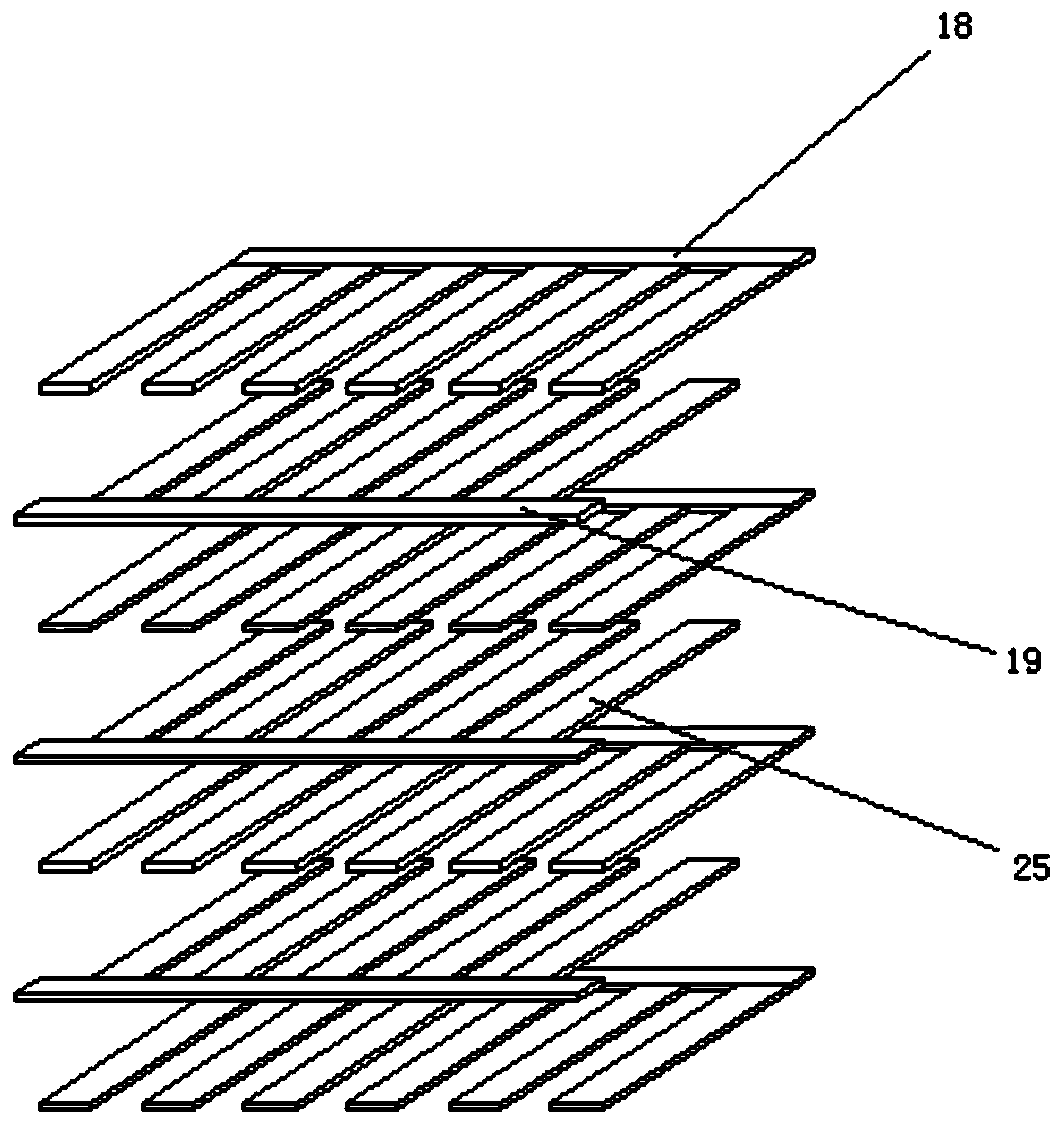

The invention discloses a grain drying device. The grain drying device comprises a feeding bin and a drying bin, and the feeding bin is located at the top of the drying bin; a feed hopper is fixedly mounted in the top center of the feeding bin; a first motor is fixedly mounted on the side wall of the feed hopper; two sets of rails and two sets of toothed rails are mounted on the side walls of thetwo sides of an inner cavity of the drying bin correspondingly, the rails on the side walls of the two sides of the inner cavity of the drying bin are movably connected with three sets of first lifting frames and second lifting frames correspondingly, two sets of second motors are fixedly mounted on the rear sides of the first lifting frame and the second lifting frame of each set, one sides of the second motors are fixedly connected with second gears, the second gears are mutually engaged with the corresponding toothed rails, and the inner side walls of the first lifting frames and the secondlifting frames are horizontally provided and connected with a plurality of sets of bearing plates; and a plurality of discharge hoppers are fixedly mounted at the bottom of the drying bin. The graindrying device is simple in structure, convenient and practical, grain can be distributed on all the bearing plates layer by layer, the drying area is increased, and the drying efficiency is improved.

Owner:杨文耀

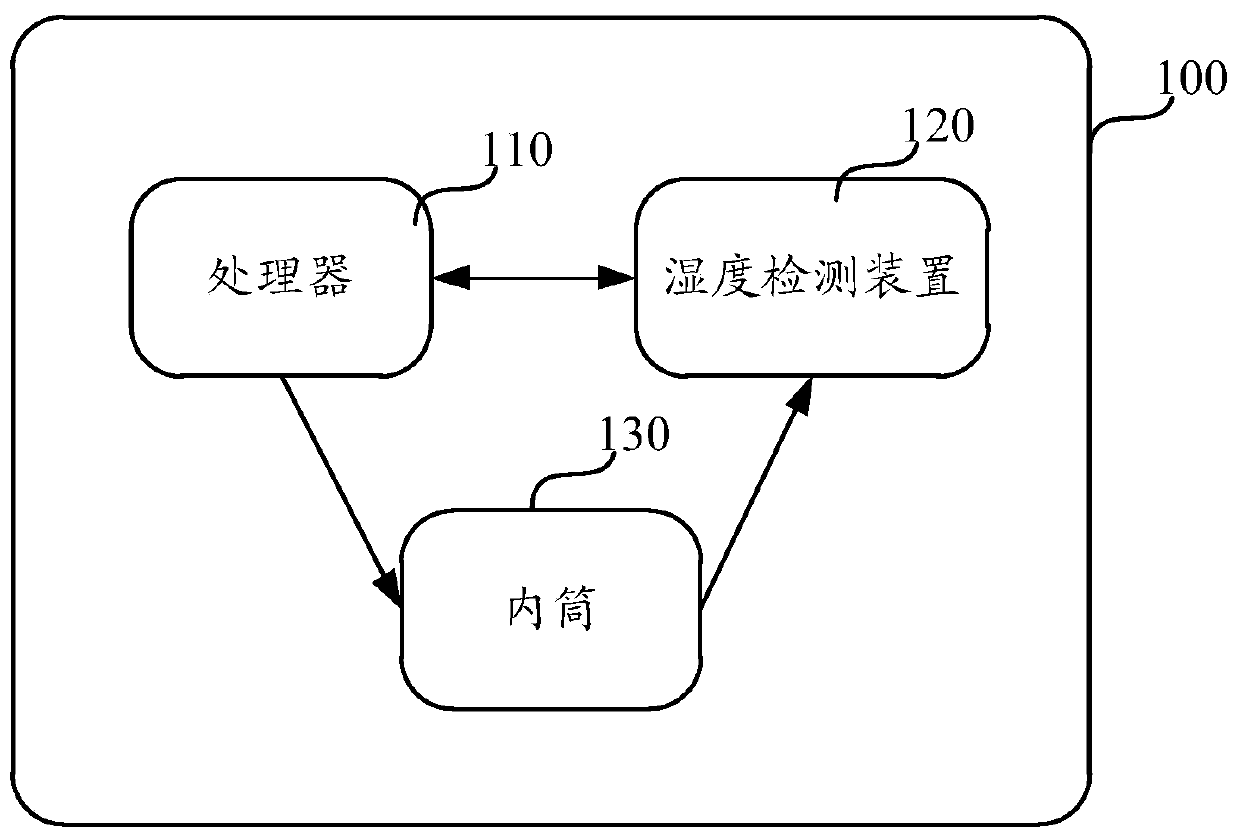

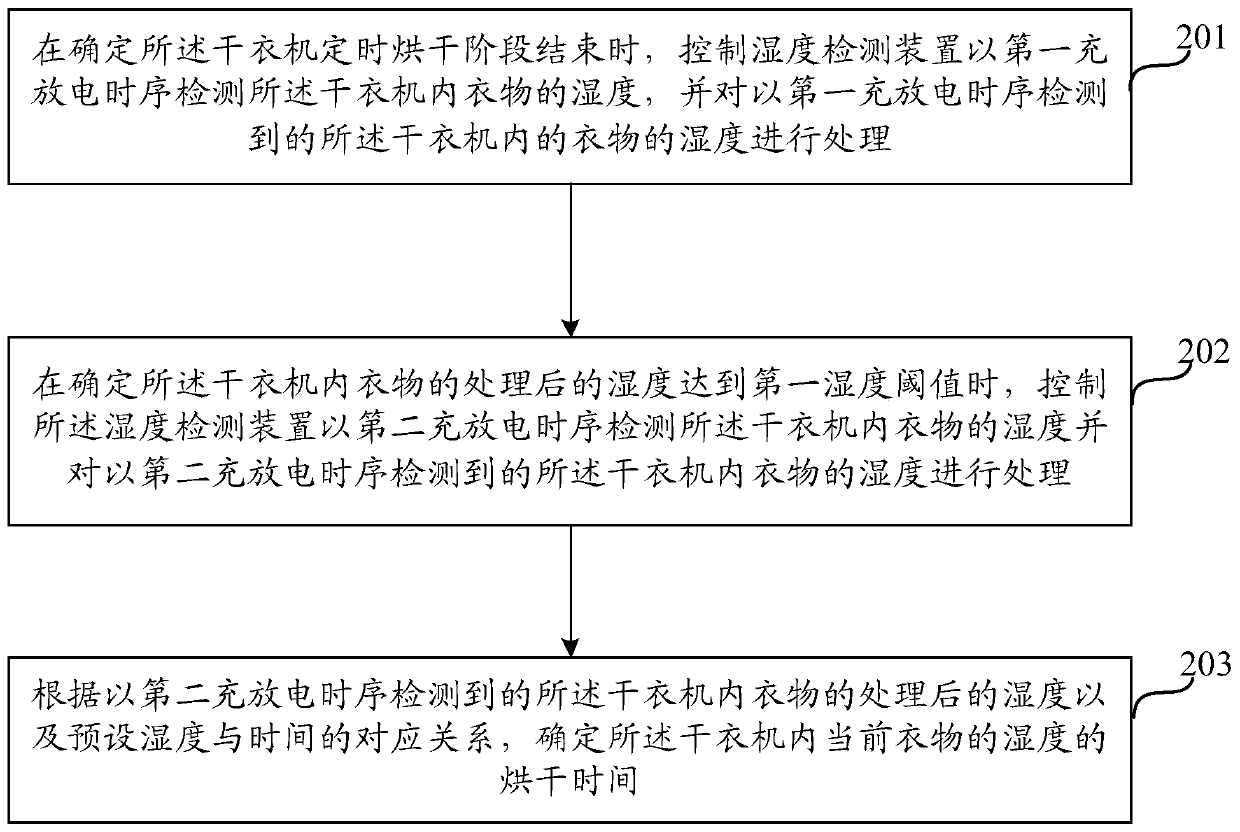

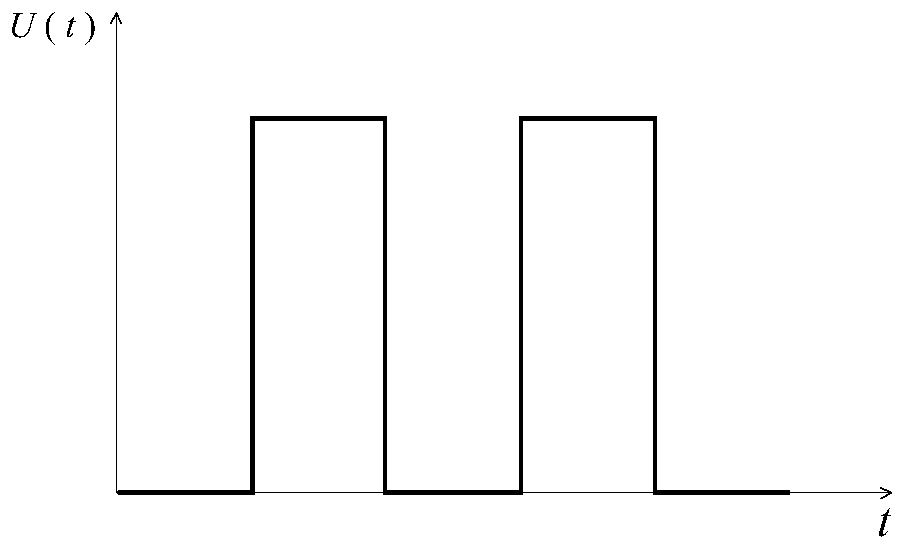

Drying method and device for clothes dryer

ActiveCN110685137ALarge humidity differenceImprove legibilityTextiles and paperLaundry driersHigh humidityProcess engineering

The invention discloses a drying method and device for a clothes dryer. The method includes: when determining the end of a regular drying phase of the clothes dryer, controlling a humidity detection device to detect humidity of clothes in the clothes dryer according to a first charging-discharging time sequence, and processing; when determining that the processed humidity of the clothes in the clothes dryer reaches a first humidity threshold, controlling a humidity detection device to detect humidity of the clothes in the clothes dryer according to a second charging-discharging time sequence,and processing the humidity; and determining drying time of the humidity of the current clothes in the clothes dryer according to a corresponding relation between the processed humidity and preset humidity with time . When it is determined that the humidity of the clothes reaches the first humidity threshold, the charging-discharging time sequence of an internal capacitor of the humidity detectiondevice is changed, so that a humidity difference collected by the humidity detection device after the first humidity threshold becomes greater; identifiability of the humidity is improved, the accuracy of humidity detection can be improved, the drying effect is improved, and insufficient drying or over-drying of the clothes is avoided.

Owner:HISENSE(SHANDONG)REFRIGERATOR CO LTD

High-efficiency rice draining and drying device

InactiveCN107883733ASimple structureReduce manufacturing costDrying chambers/containersSeed preservation by dryingEngineeringWater layer

The invention belongs to the technical field of cleaned rice drying equipment, and particularly relates to a high-efficiency rice draining and drying device. The high-efficiency rice draining and drying device comprises an inclined draining cavity. A feeding port is formed in the upper portion of the bottom end of the draining cavity. The draining cavity is internally provided with a rotation shaft. The rotation shaft is provided with a rubber packing auger. A draining layer is arranged at the bottom of the draining cavity. A flow guiding layer is arranged on the outer side of the draining layer. A water receiving groove is formed in the bottom of the flow guiding layer. The top end of the draining cavity communicates with an inclined drying cavity. An inclined conveying belt is arranged at the bottom of the drying cavity. A plurality of partition plates perpendicular to the surface of the conveying belt are fixedly arranged at the upper end of the drying cavity, and the bottoms of thepartition plates are fixedly connected with paving brushes. A plurality of heating devices are arranged on the top of the drying cavity, and the position, close to the conveying belt, of the bottom end of the drying cavity is provided with a discharging port. Compared with the prior art, the high-efficiency rice draining and drying device has the following beneficial effects that the device structure is simple and reasonable, the manufacturing cost is low, the rice drying efficiency can be improved, and compared with the prior art, the phenomena of uneven drying and the like are effectively avoided.

Owner:许志颍

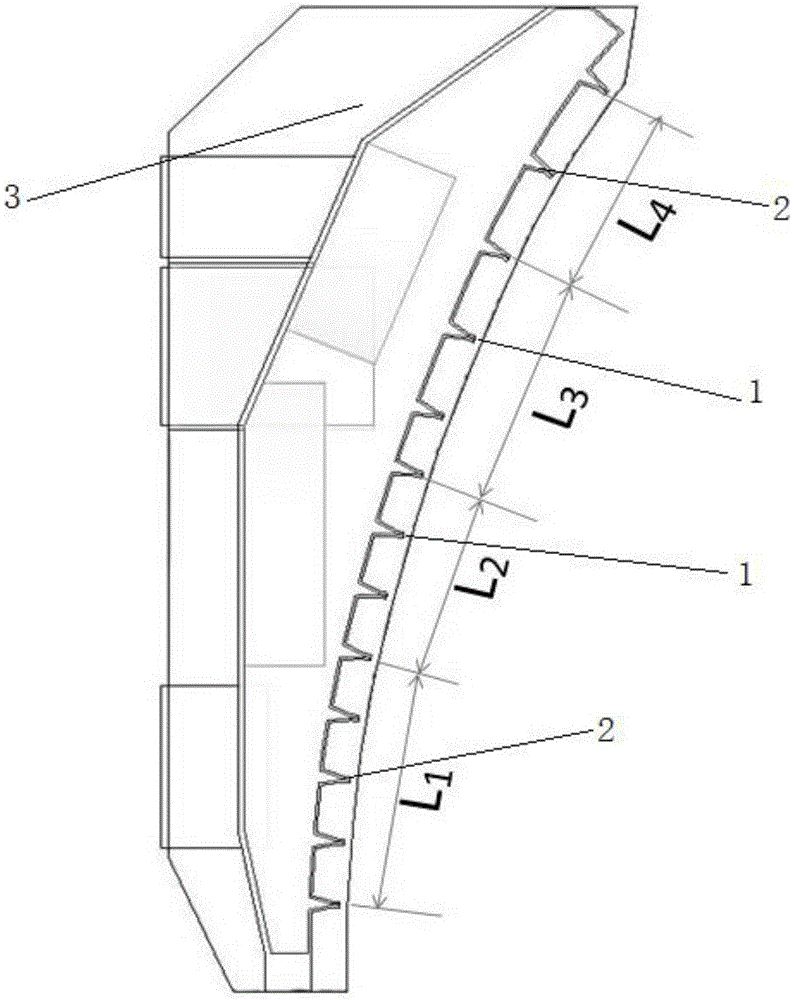

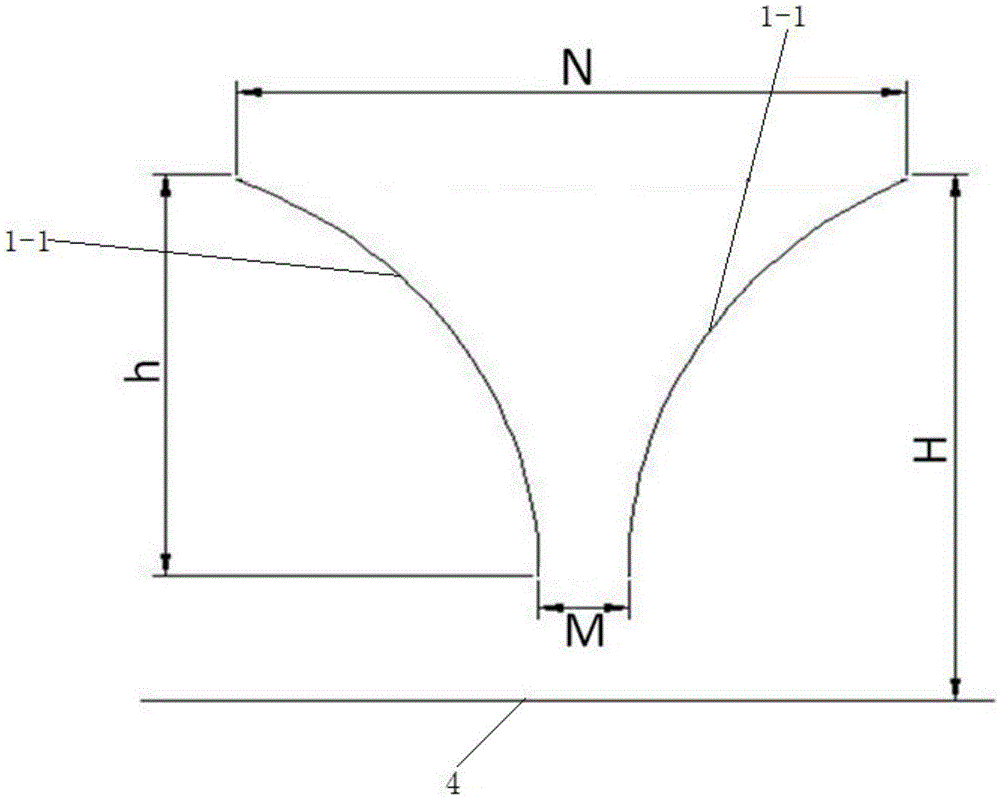

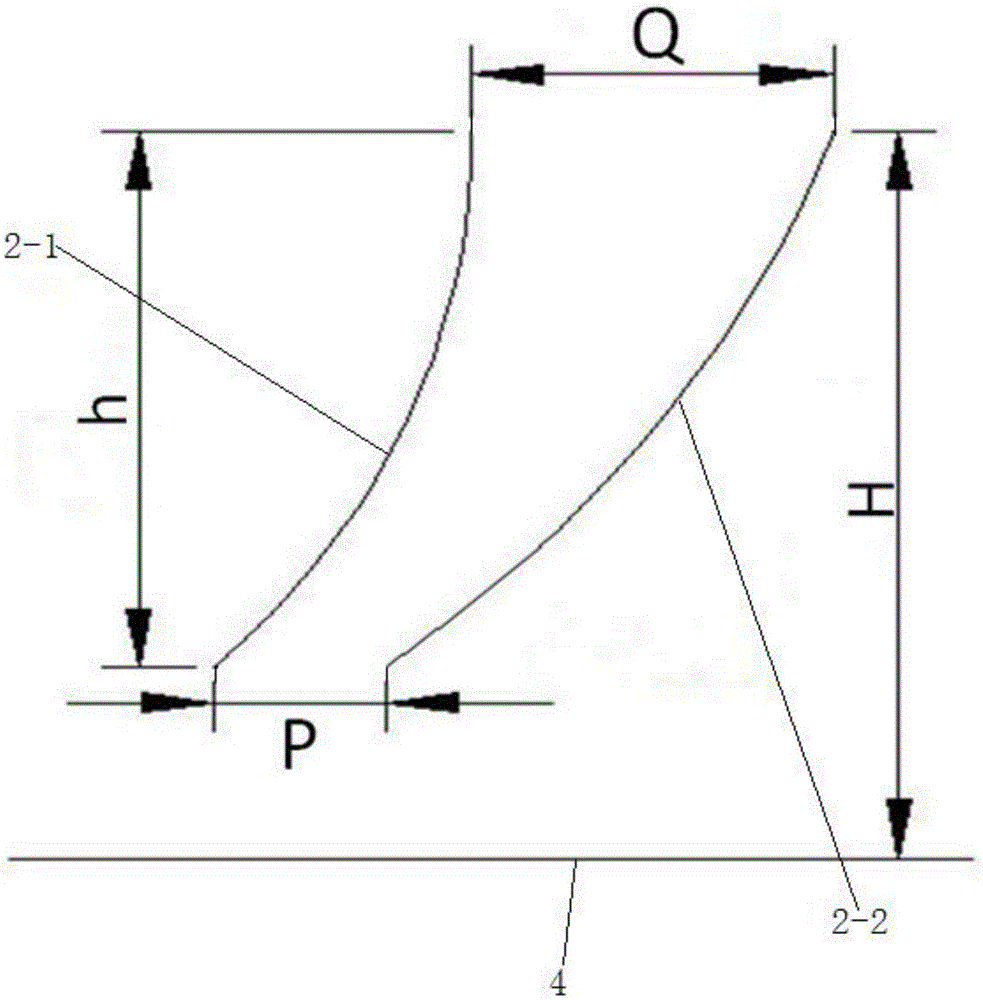

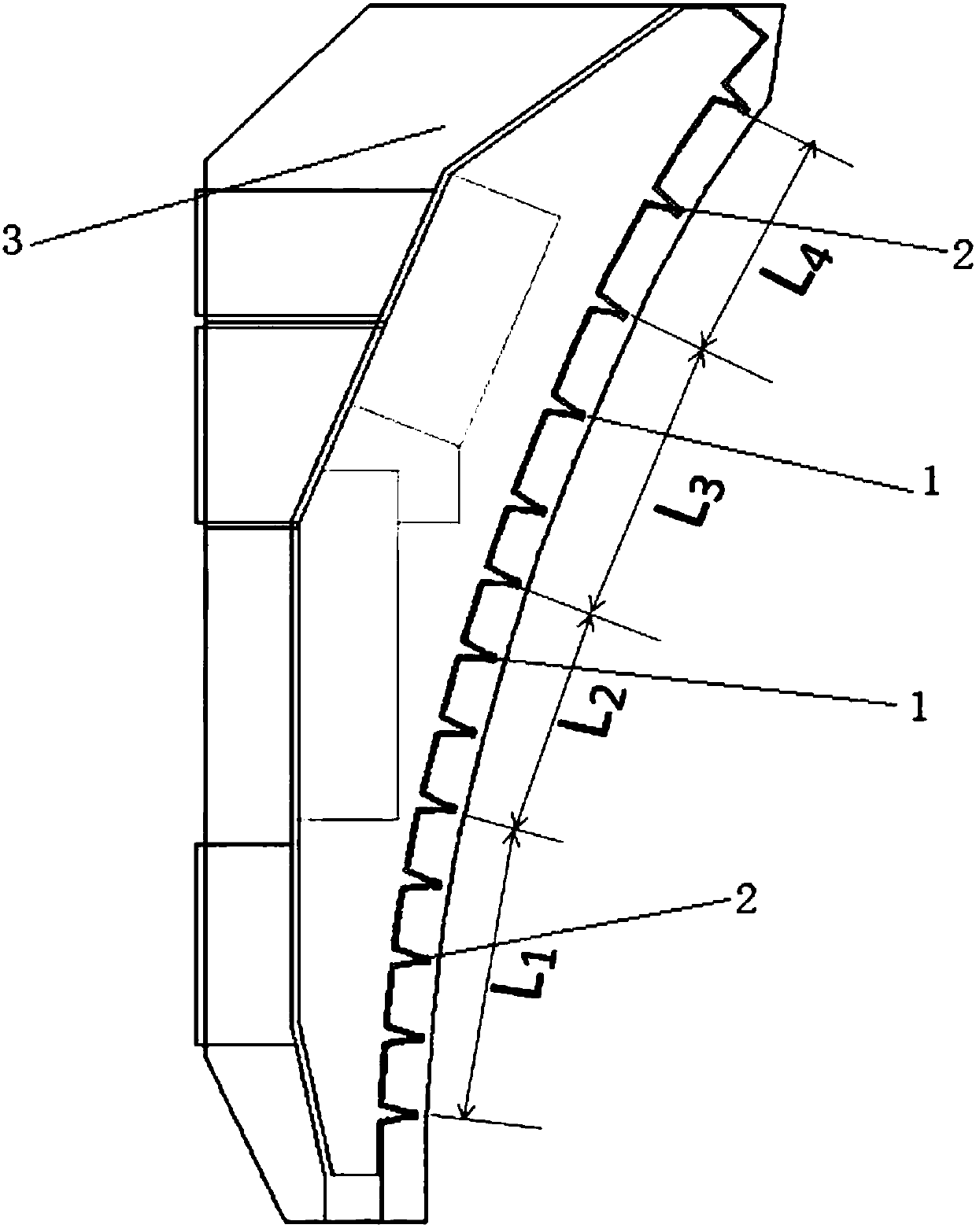

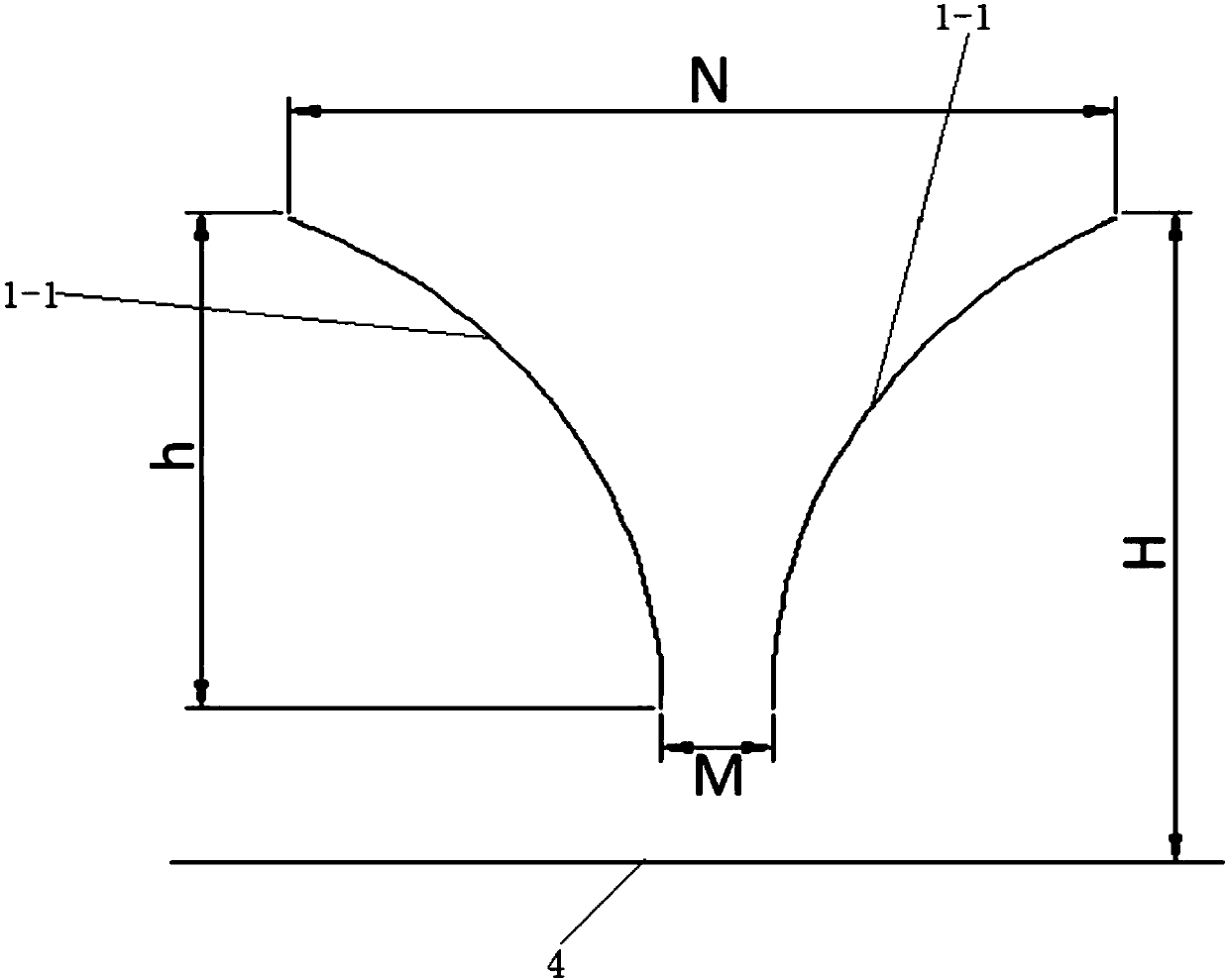

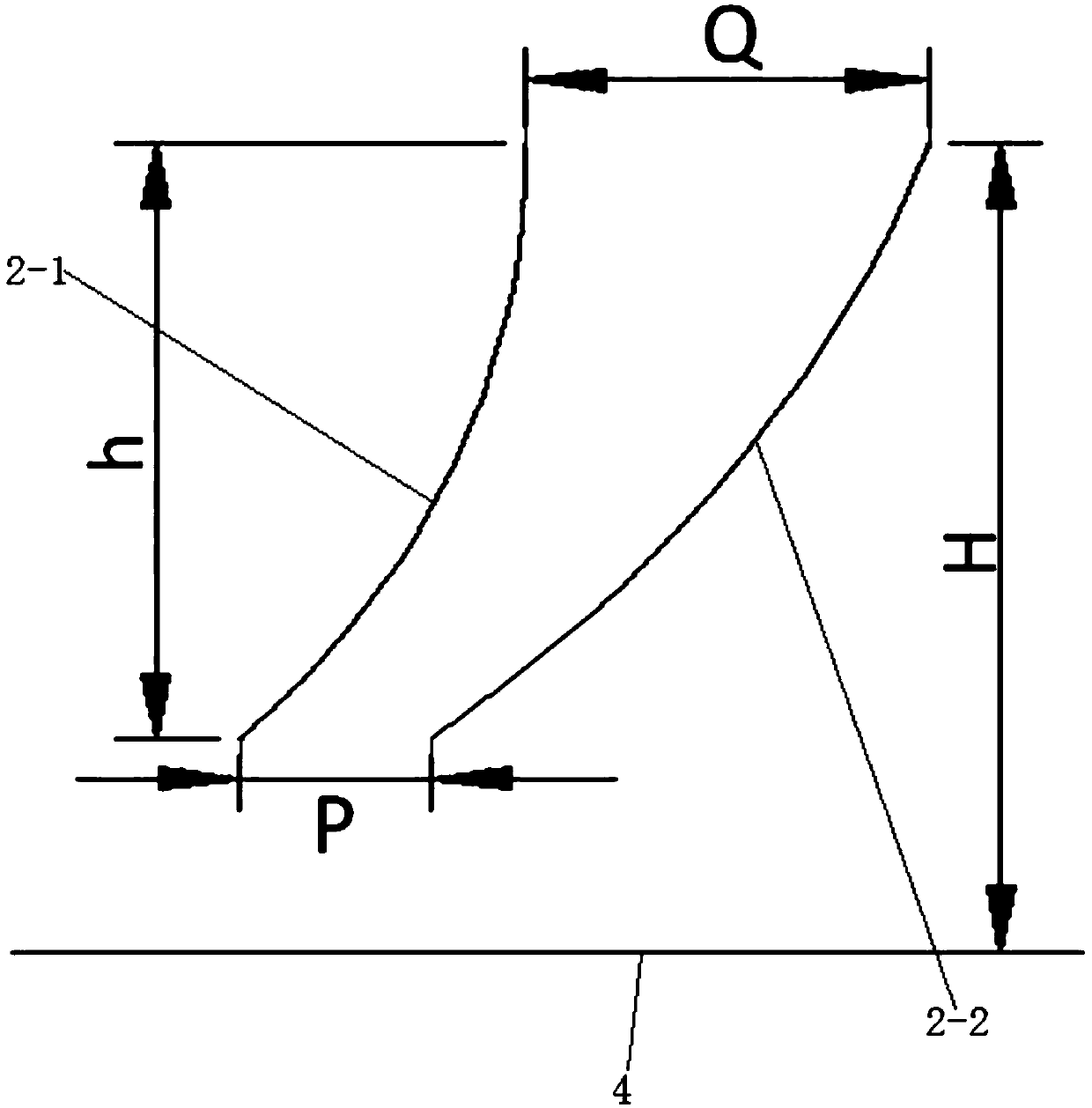

Design method for tuyeres of gravure press drying oven

InactiveCN105584208ADry fastAvoid insufficient dryingPrinting press partsPrinting inkProcess engineering

The invention discloses a design method for tuyeres of a gravure press drying oven. The design method specifically comprises the following steps that the minimum length L of the gravure press drying oven is determined; drying areas of the gravure press drying oven are divided; the length of each divided drying area is calculated according to the obtained minimum length L of the gravure press drying oven; the tuyere number of each drying area is calculated according to the length of the corresponding drying area; and according to the printing ink drying characteristics of all the divided drying areas, tuyere structures suitable for the different drying areas are designed. More reasonable drying air distribution and air-out forms can be obtained through tuyere arrangements and forms which are designed through the method, and air requirements of printing ink drying in different stages are met; uniform and sequential flowing of dried hot air are achieved, and the problems that energy is wasted due to the fact that the tuyere design of an existing drying oven is unreasonable is solved.

Owner:XIAN UNIV OF TECH

Discharging and drying device for wolfberry fruits

InactiveCN111238210AEvenly distributedPrevent affecting subsequent processingDrying gas arrangementsDrying chambers/containersAgricultural engineeringStructural engineering

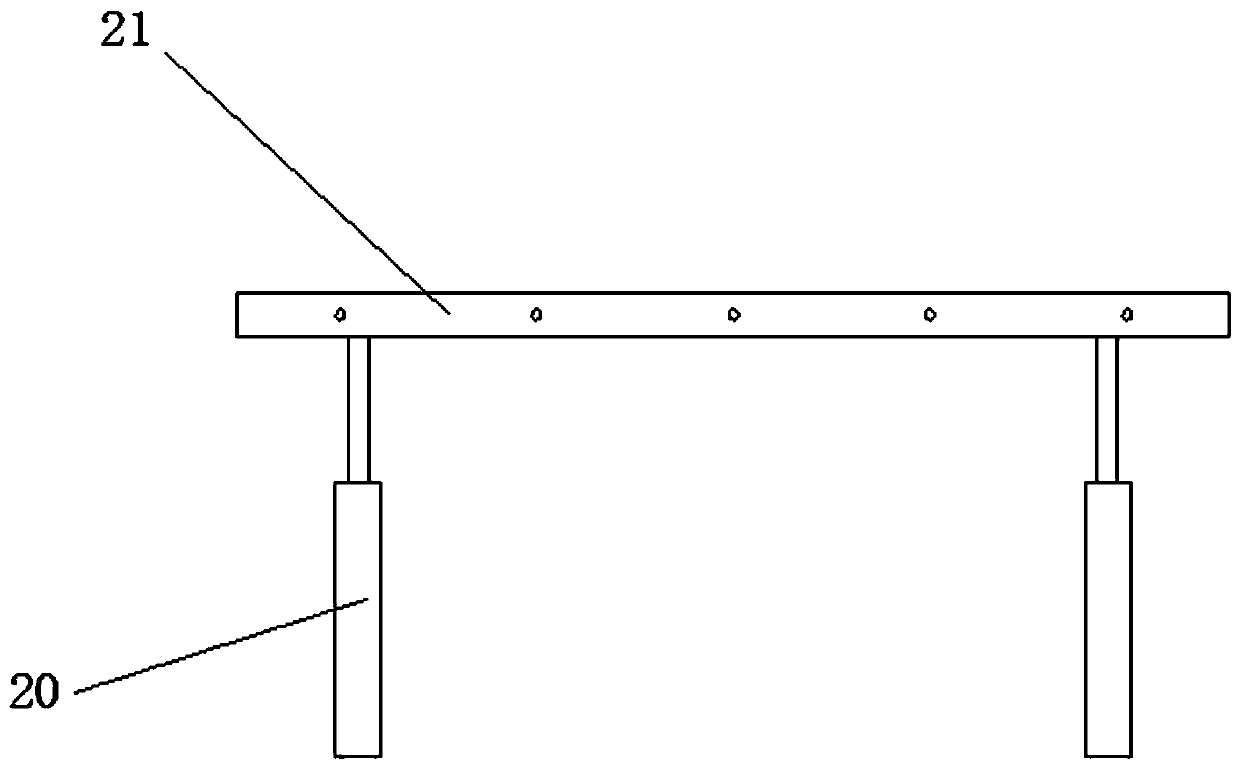

The invention discloses a discharging and drying device for wolfberry fruits. The device comprises a conveying pipe and a drying bin, the conveying pipe is horizontally arranged at the top of the drying bin, a plurality of discharging pipes are fixedly arranged at the bottom of the conveying pipe, an air cavity is arranged outside the drying bin, an air heater is fixedly arranged on the left sideof the drying bin, and clamping rails are fixedly arranged on the two sides of an inner cavity of the drying bin; air cylinders are fixedly arranged at the bottoms of the portions, on the two sides ofthe drying bin, of the air cavity, the tops of the air cylinders are fixedly connected with lifting beams, and the two ends of each group of connecting rods penetrate through limiting grooves and arefixedly connected between the two groups of lifting beams; the two sides of each group of the connecting rods are rotatably hinged with bearing screen plates, the two sides of the side wall of the end, far away from the connecting rods, of each group of the bearing screen plates are fixedly provided with clamping wheels, and the clamping wheels on the two sides are movably clamped with the corresponding clamping rails respectively. The device can achieve a dispersed discharging effect in the wolfberry fruit discharging process, increase the drying area and improve the drying efficiency.

Owner:于国玺

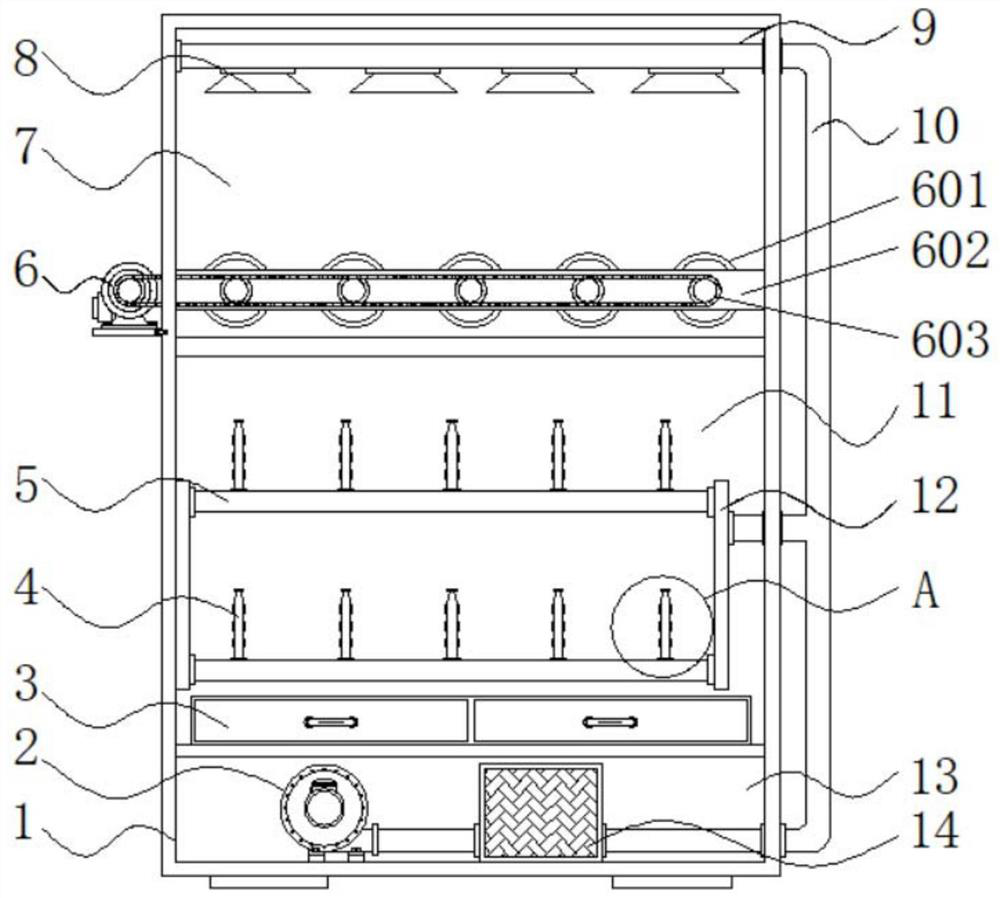

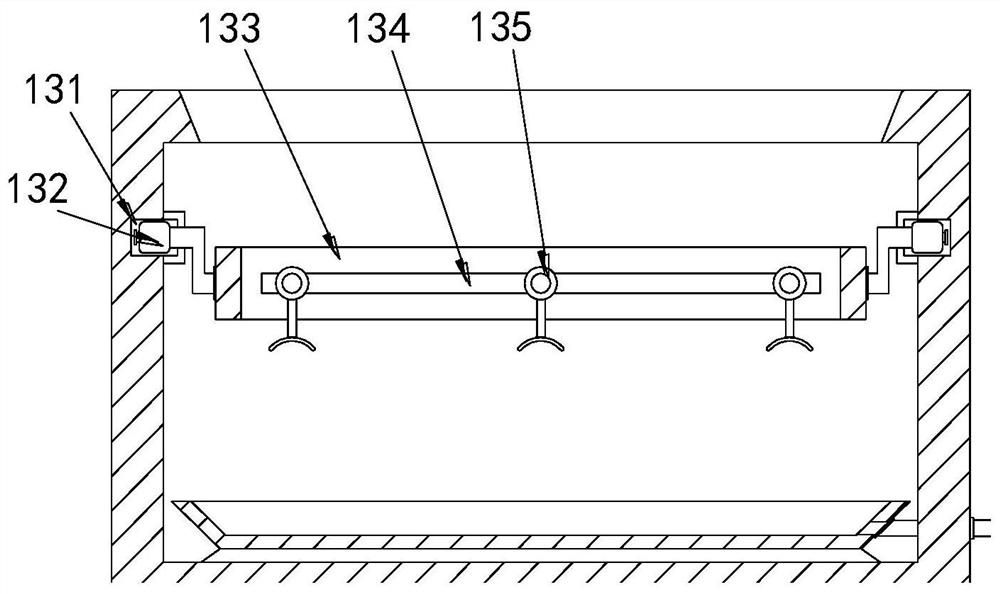

Layering type drying device for grain

InactiveCN111174562ASimple structureAvoid local accumulationDrying gas arrangementsSeed preservation by dryingElectric machineryCereal grain

The invention discloses a layering type drying device for grain. The layering type drying device comprises a drying cabin, wherein the top of the drying cabin is fixedly provided with a discharging frame; a movement block is movably connected in the spacing groove; the top of the movement block is provided with a feeding hopper; the side walls of two sides of the inner cavity of the drying cavityare independently provided with two groups of rails and two groups of toothed rails; the rails on two side surfaces are independently movably connected with three groups of first lifting and loweringframes and second lifting and lowering frames; the rear side of each group of first lifting and lowering frame and the rear side of each group of second lifting and lowering frame are independently fixedly provided with two groups of third motors; one side of each third motor is fixedly connected with a second gear, and the second gear and the corresponding toothed rail are mutually meshed; the inner side wall of each first lifting and lowering frame and the inner side wall of each second lifting and lowering frame are independently horizontally provided with multiple groups of bearing plates;and the bottom of the drying cabin is fixedly provided with a plurality of discharging hoppers. According to the layering type drying device disclosed by the invention, the grain can be distributed on each bearing plate layer by layer, a drying area is enlarged, drying efficiency is improved, and a situation that the grain on the bottom can not be fully dried is avoided.

Owner:杨文耀

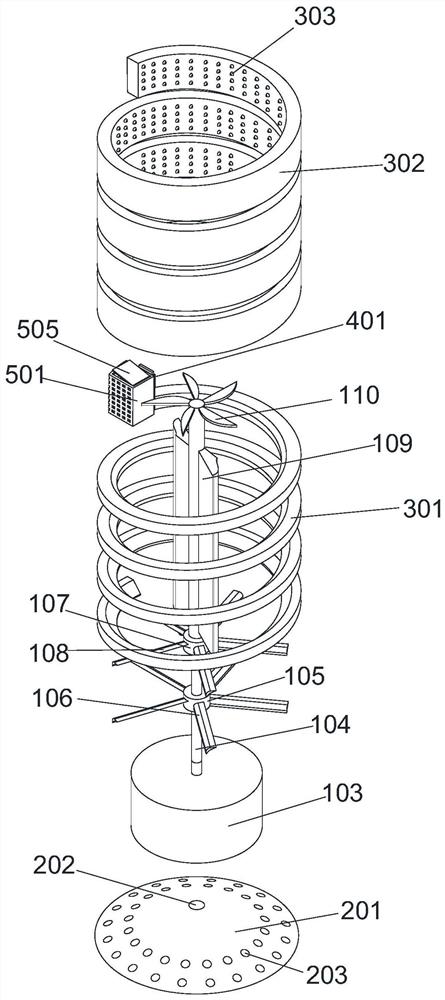

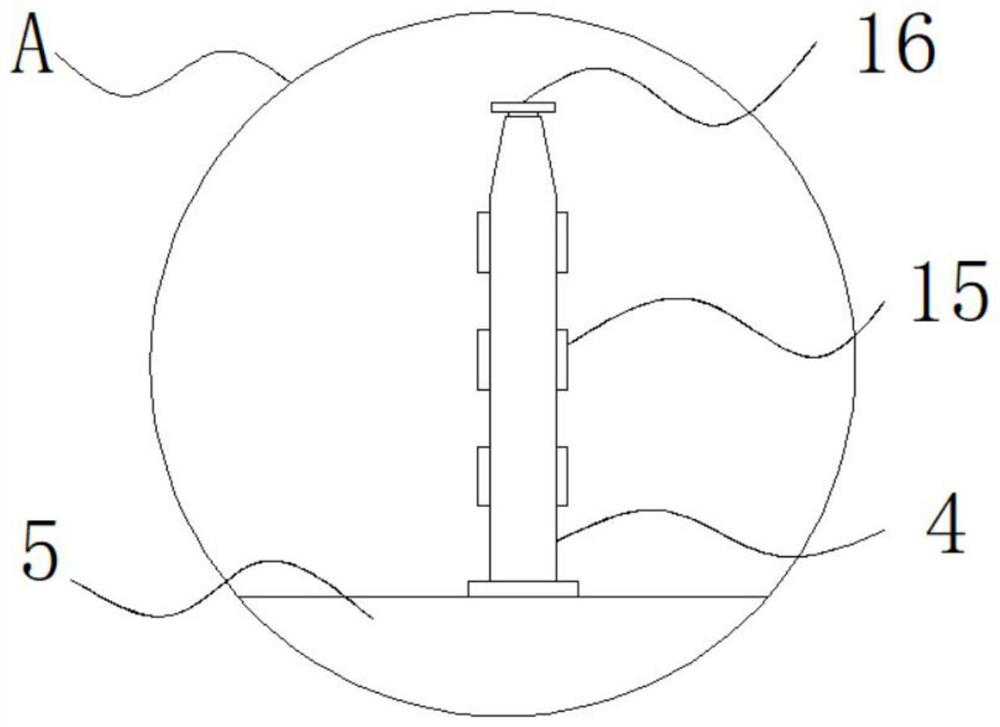

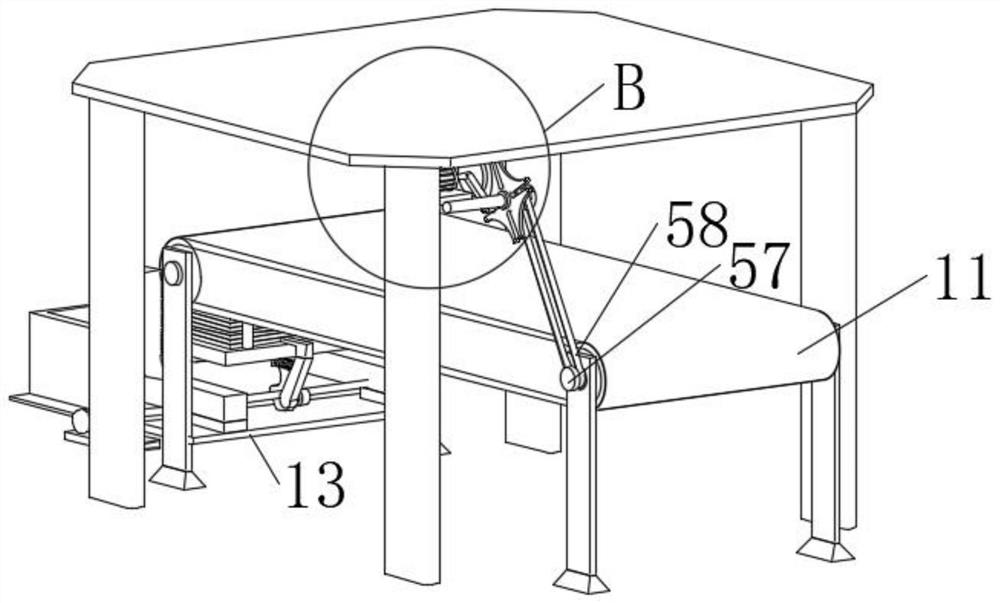

Self-material-turning type traditional Chinese medicine airing system capable of producing multiple kinds of medicine materials at same time

InactiveCN114111285AEfficient dryingAvoid insufficient dryingDrying chambers/containersDrying machines with non-progressive movementsMedicinal herbsProcess engineering

The automatic material turning type traditional Chinese medicine airing system comprises a bottom plate and a control mechanism fixedly installed at the top of the bottom plate, and is characterized in that a supporting assembly is fixedly installed at the position, located on one side of the control mechanism, of the top of the bottom plate, and an airing mechanism is arranged at the top of the supporting assembly; the invention relates to the technical field of traditional Chinese medicine processing. According to the self-material-turning type traditional Chinese medicine airing system capable of producing multiple kinds of medicine materials at the same time, different kinds of traditional Chinese medicine materials can be aired at the same time, the use range is wide, the use functions are rich, manual timed material turning is not needed, it can be guaranteed that all the traditional Chinese medicine materials are aired sufficiently, a large amount of manpower and material resources are saved, and the airing efficiency is high; according to the traditional Chinese medicinal material airing device, the automatic material overturning mechanism is arranged in the airing device, so that the airing device can automatically overturn materials, the purpose of quickly and efficiently airing traditional Chinese medicinal materials is well achieved, and great convenience is brought to use of people.

Owner:朱彦伟

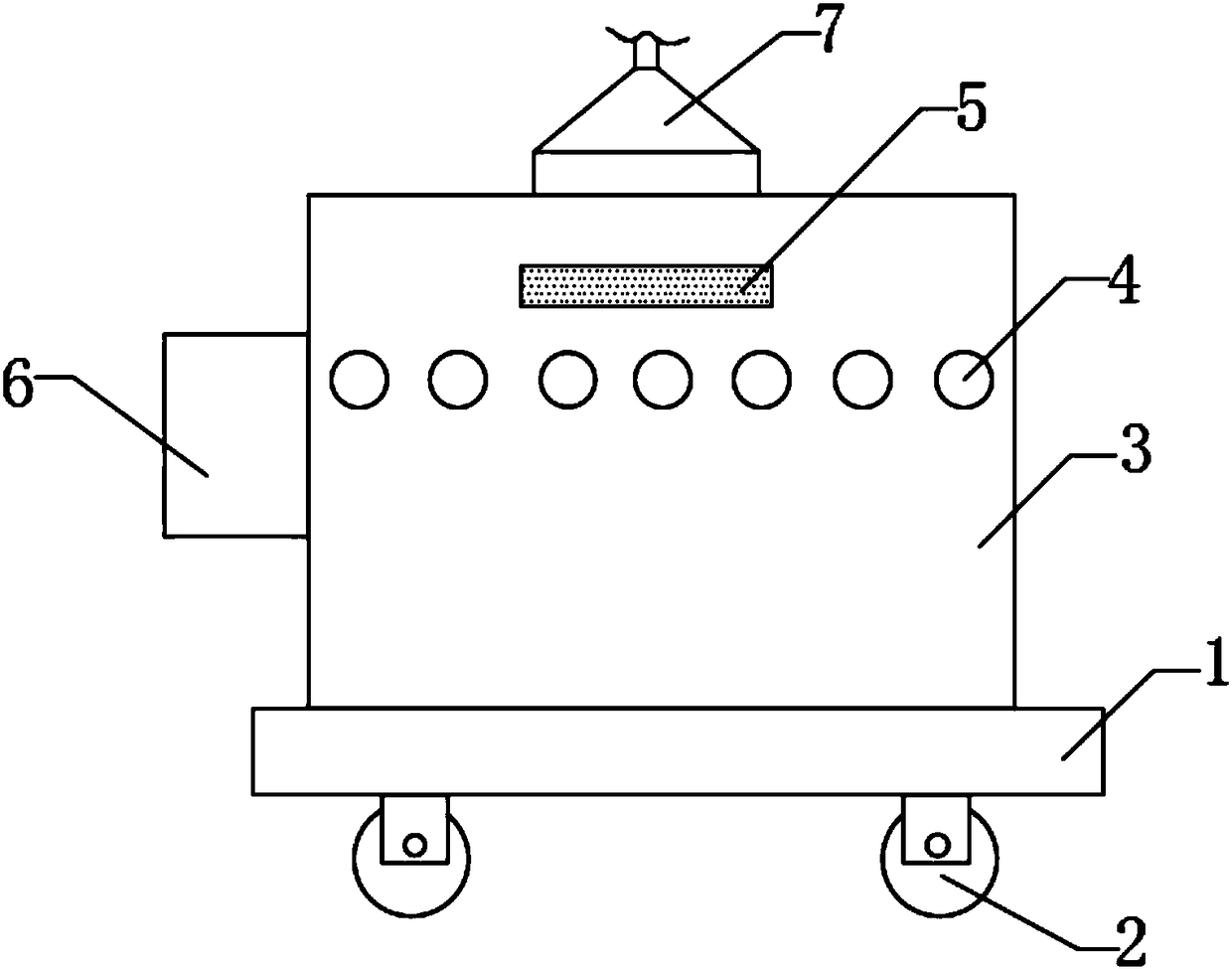

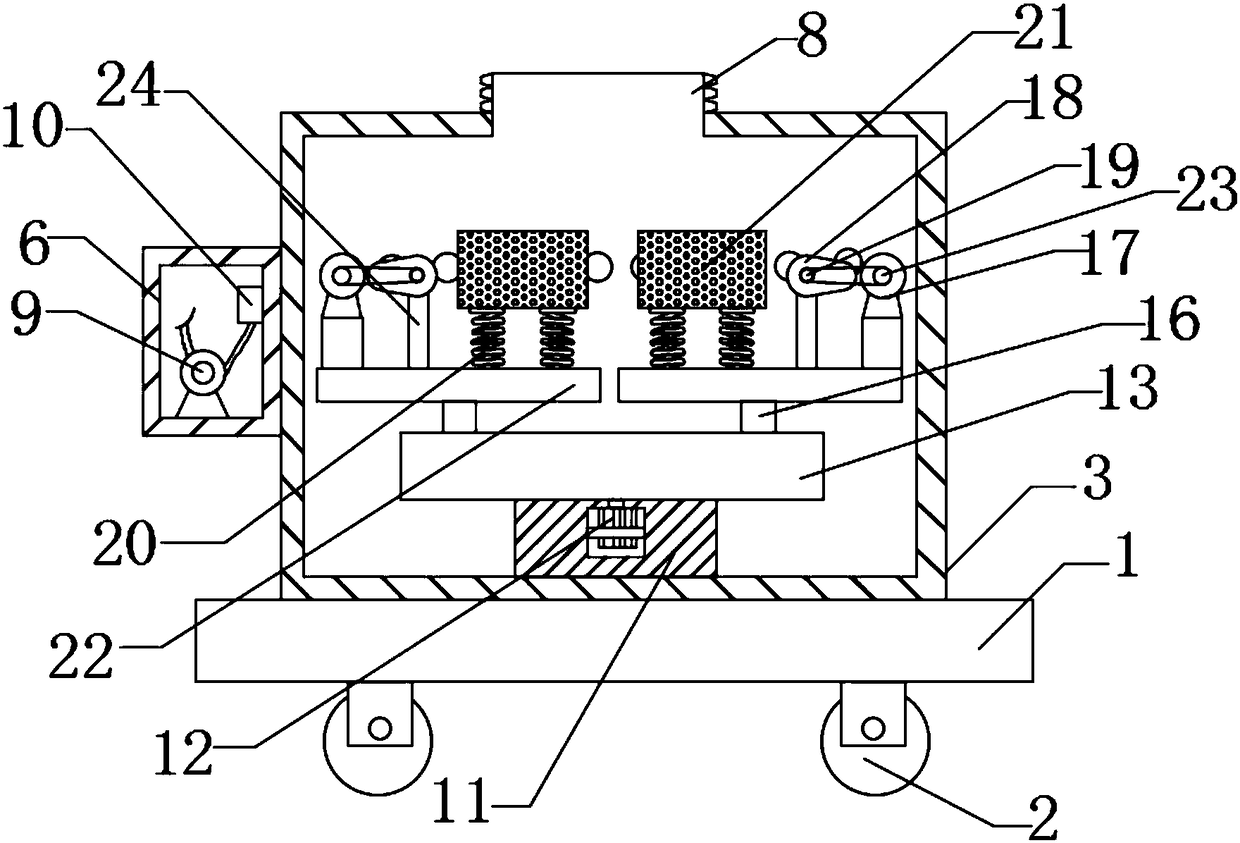

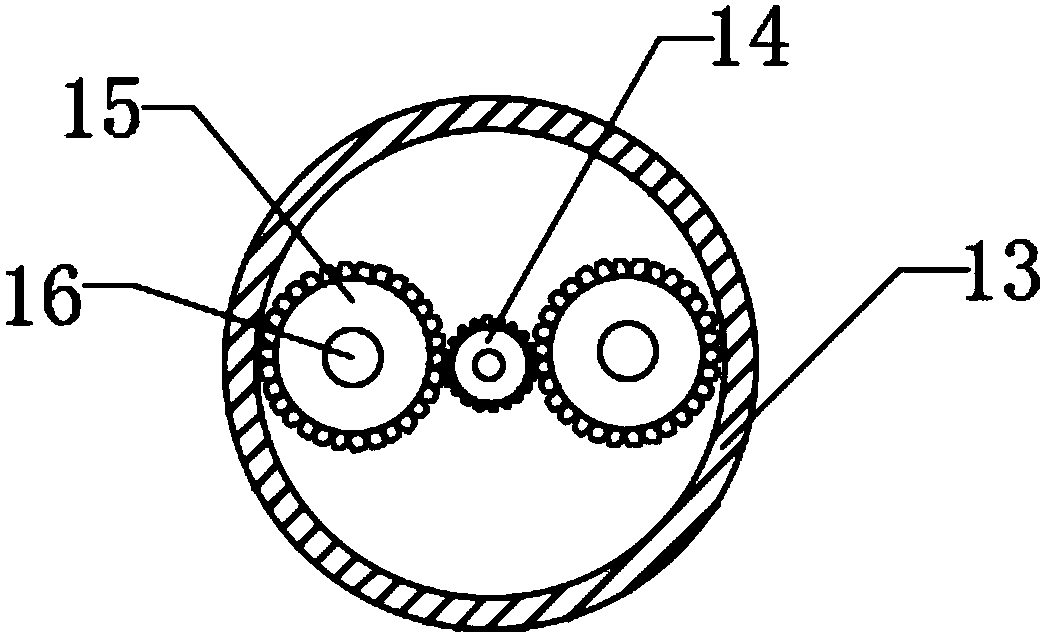

Environment-friendly drying equipment for bioengineering

PendingCN108548402ARealize repeated pushingReduce workloadDrying gas arrangementsDrying machines with non-progressive movementsEngineeringSelf locking

The invention discloses environment-friendly drying equipment for bioengineering. The drying equipment comprises a base, a self-locking wheel, a drying box, drying holes, a pull hand, a power box, a suction cover, an air outlet, a fan, a heating box, a supporting base, a first motor, an installation box, a sun gear, planetary gears, rotating shafts, a second motor, a cam, a driven roller, a telescopic spring, a drying basket, a supporting plate, a driving roller and a fixing rod. The drying box is fixedly connected to the top of the base, the drying holes are formed in the side faces of the drying box, the supporting base is fixedly connected to the bottom of the inner wall of the drying box, the first motor is fixedly installed inside the supporting base, the installation box is fixedly connected to the top of the supporting base, an output shaft of the first motor penetrates through the supporting base and the installation box to be fixedly connected with the sun gear, the rotating shafts are symmetrically and rotationally connected to the portions, on the two sides of the sun gear, of the bottom of the inner wall of the supporting base, and the planetary gears are connected to the portions, on the outer sides of the rotating shafts, inside the supporting base. The drying equipment is simple in structure, good in drying effect and environmentally friendly.

Owner:江西省食品发酵研究所

High-quality dehydrated vegetable treatment equipment and treatment process thereof

InactiveCN113424970AEasy to cleanRealize the effect of automatic flippingFood treatmentBiotechnologyAgricultural science

The invention discloses high-quality dehydrated vegetable treatment equipment and a treatment process thereof, and relates to the technical field of food processing. The high-quality dehydrated vegetable treatment equipment comprises a cleaning cylinder; supporting legs are fixedly connected to the edge of the lower surface of the cleaning cylinder; a motor is arranged below the cleaning cylinder; a valve is fixedly connected to the lower end of the front side face of the cleaning cylinder; a rotating rod is fixedly connected to the upper surface of a rotating shaft of the motor; the circumferential side face of the rotating rod is fixedly sleeved with a first fixing block and a second fixing block; and the circumferential side face of the first fixing block is fixedly connected with a first stirring paddle. The high-quality dehydrated vegetable treatment equipment solves the problems that in the existing dehydrated vegetable processing and cleaning process, vegetables are large in quantity and fragmentary in shape, most chopped vegetable slices are put into a cleaning pool, the vegetables are cleaned by stirring clean water in the pool, and the surfaces of the vegetables are not brushed, resulting in that silt or pesticide residues on the surfaces of the vegetables are difficult to clean away, and the human health is harmed after the vegetables are eaten by people.

Owner:新疆华丹原牧农业科技有限公司

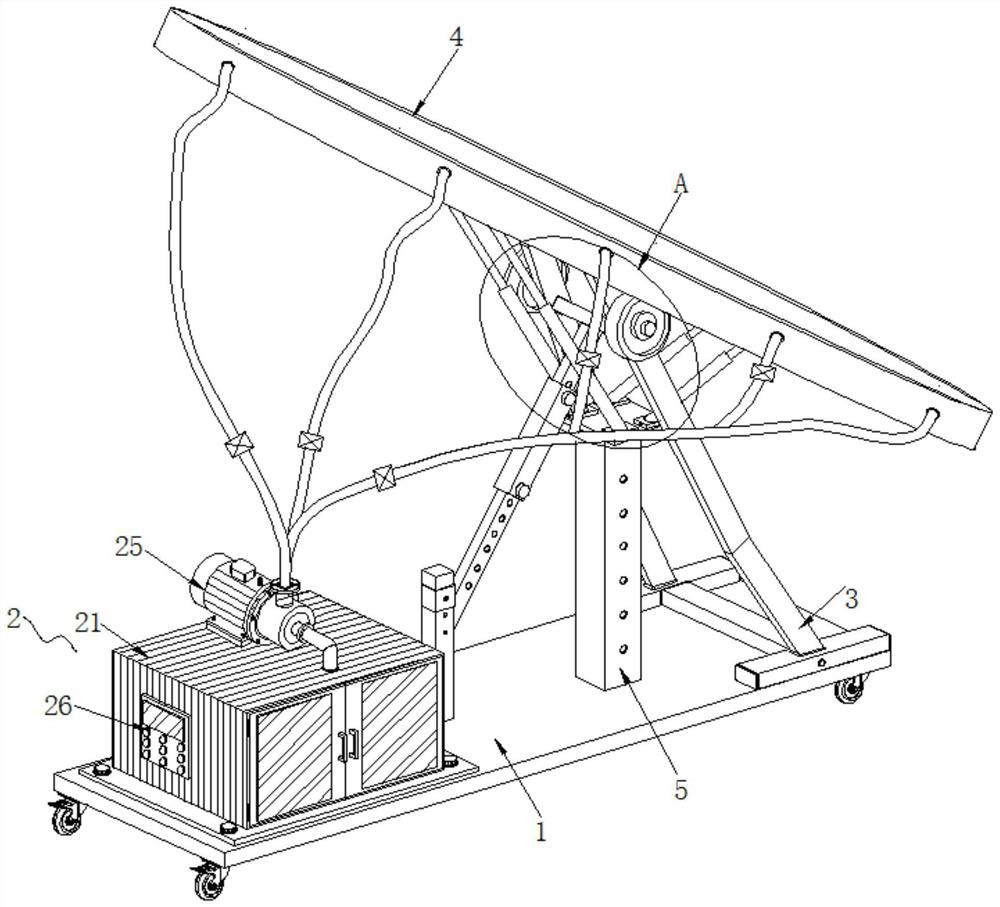

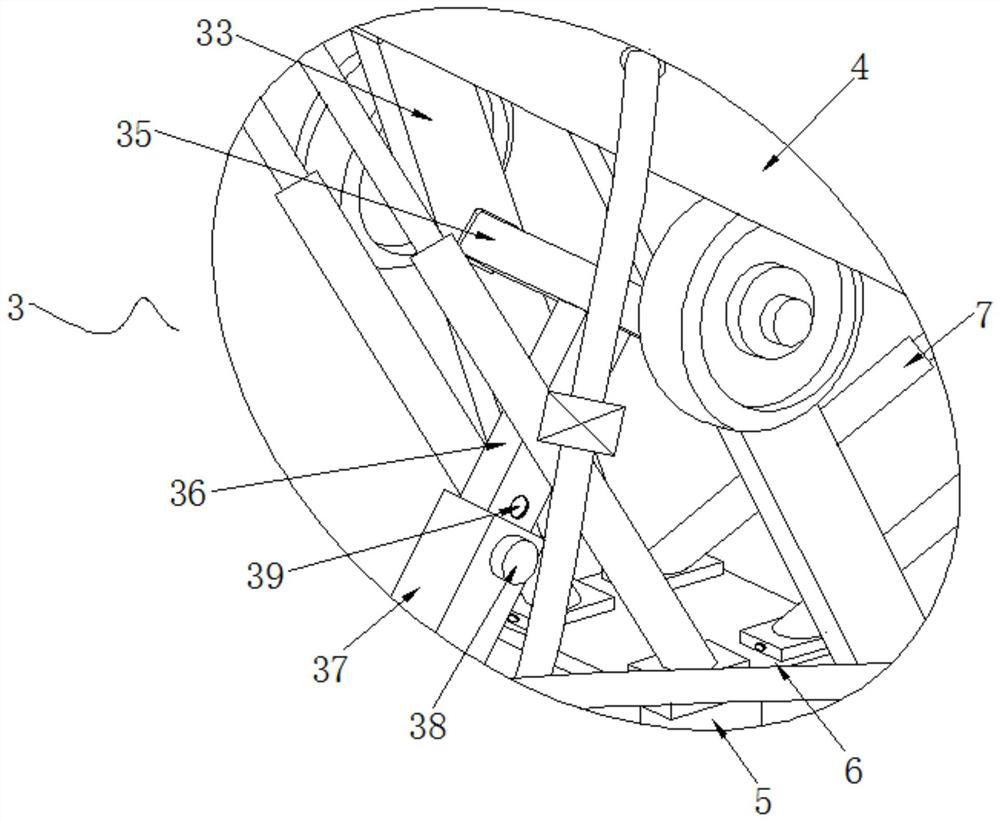

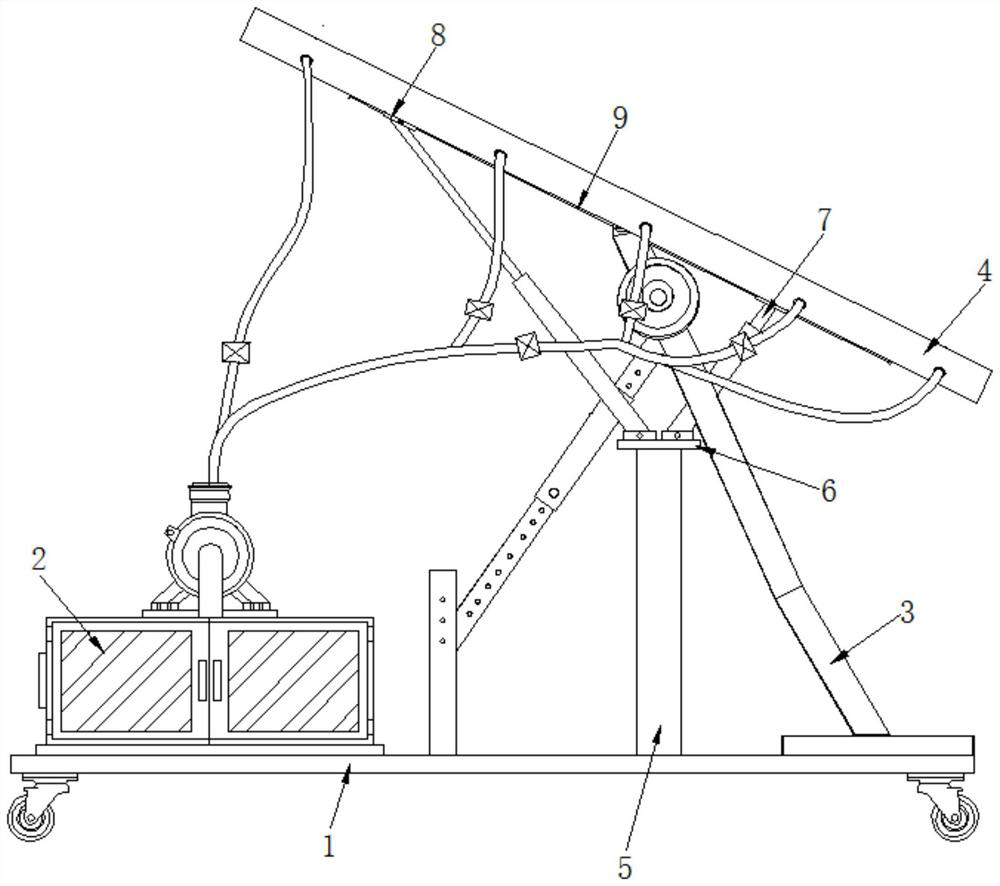

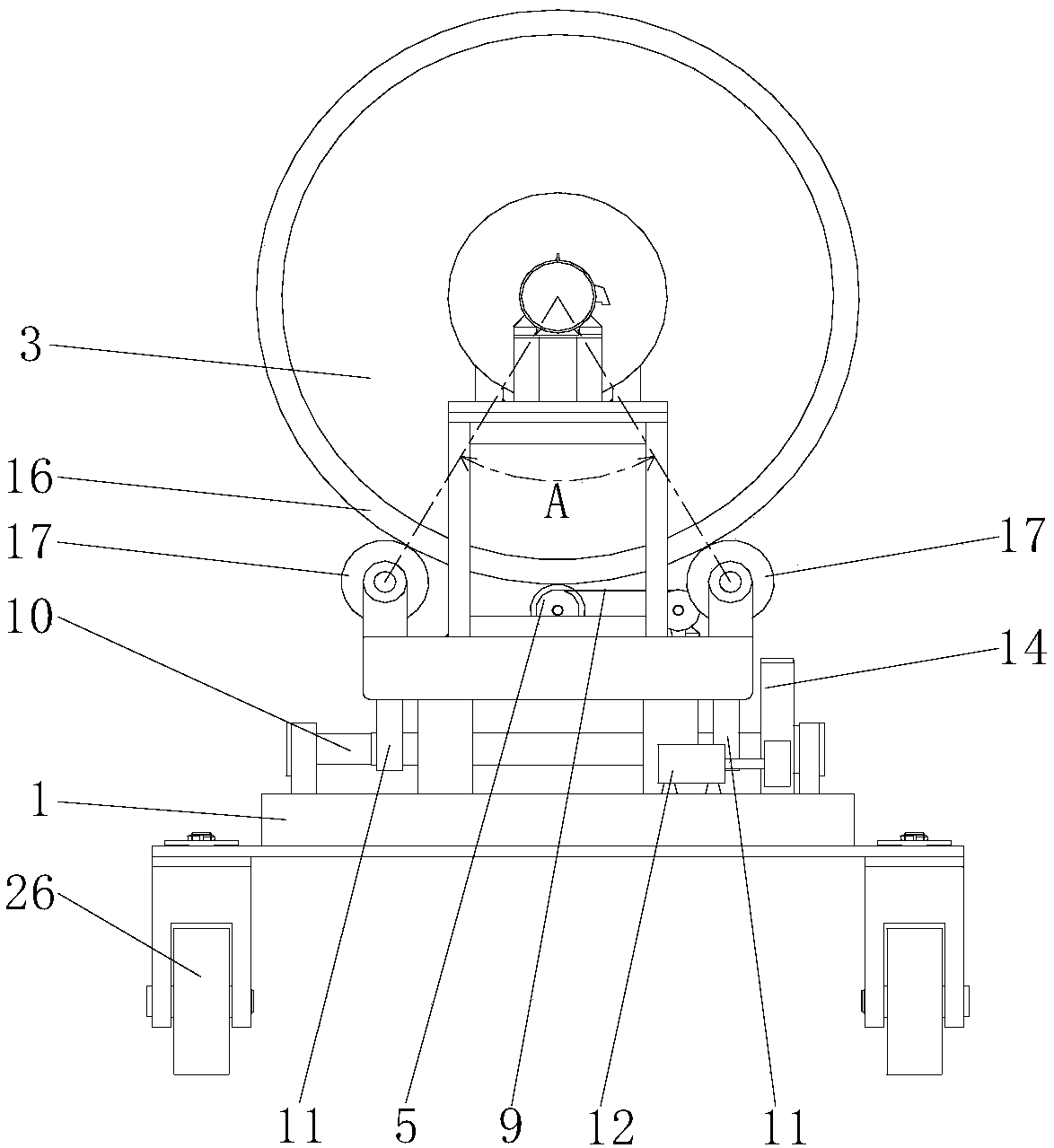

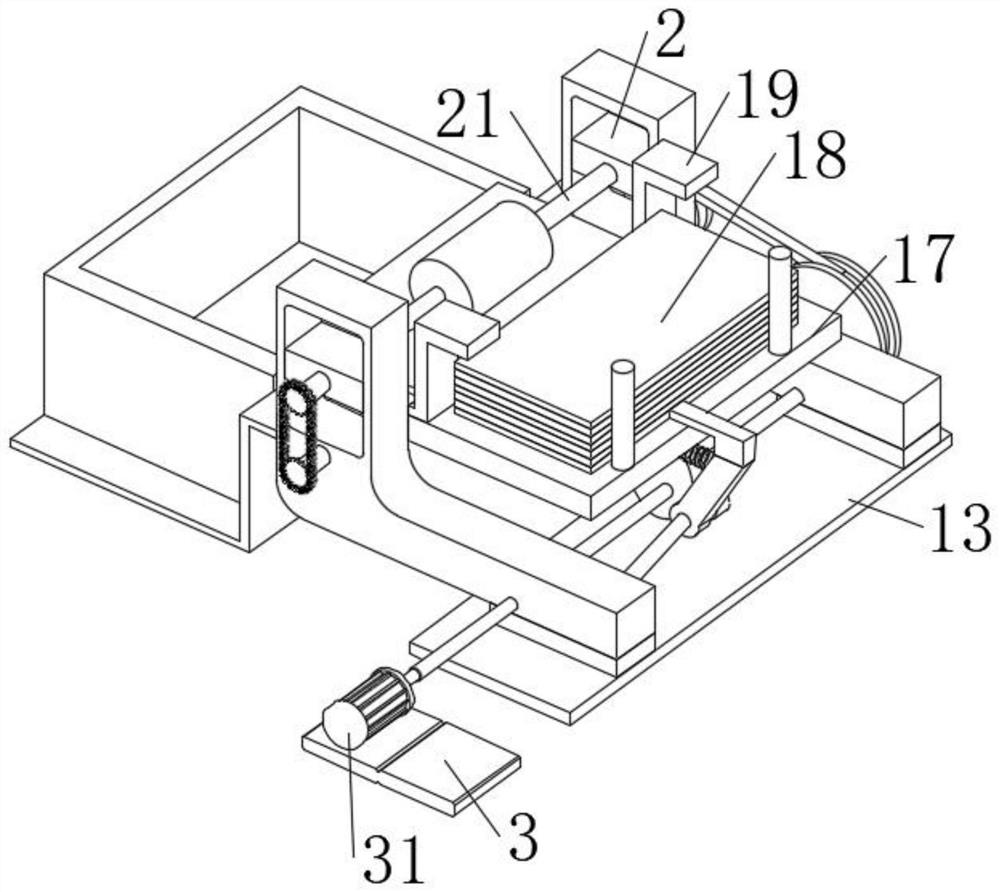

Unhulled rice dryer

PendingCN108489223AEasy to useNo pollution in the processDrying gas arrangementsDrying solid materialsEngineeringPower component

The invention discloses an unhulled rice dryer. The unhulled rice dryer comprises a first rack, a second rack located above the first rack, a rolling barrel used for drying unhulled rice, a first power component used for driving the rolling barrel to rotate and a hot air mechanism used for providing hot air for the rolling barrel, one end of the second rack is hinged to the first rack, the other end of the second rack is provided with a lifting mechanism used for driving the second rack to swing up and down, and the hot air mechanism and the rolling barrel are horizontally arranged on the second rack. The unhulled rice dryer is convenient to use, high in heat efficiency, of no pollution and low in fabrication cost and use cost.

Owner:WUZHOU UNIV

Cloth shaping drying system

InactiveCN110017679AAvoid overheatingAvoid insufficient dryingDrying gas arrangementsDrying machines with progressive movementsTextileCotton material

The invention discloses a cloth shaping drying system, which comprises a supporting seat. A drying box is fixedly connected to the supporting seat, long strip through openings are formed in the upperend and the lower end of the drying box correspondingly, the upper side and the lower side of the drying box are fixedly connected with mounting plates correspondingly, motors are fixedly connected tothe two mounting plates correspondingly, the output ends of the two motors penetrate through the two mounting plates correspondingly and extend towards one end, the extending ends of the output endsof the two motors are fixedly connected with rotating shafts correspondingly, gauze winding cylinders are movably connected to the rotating shafts in a sleeving mode, and the side edge of the drying box is rotationally connected with an open-close door. By arranging the gauze winding cylinders at the upper end and the lower end of the drying box correspondingly, gauze needing to be dried can be guided into the drying box, wound around a plurality of filter cylinders in a staggered mode and then guided out to be wound around the other gauze winding cylinder, through the effect of the motors, the gauze is rapidly and uniformly heated, excessive heating is avoided, the two gauze winding cylinders can be guided out and guided in repeatedly, an air blower is arranged to improve the drying effect, and the drying quality of textile fabrics is ensured through the drying box.

Owner:唐海元

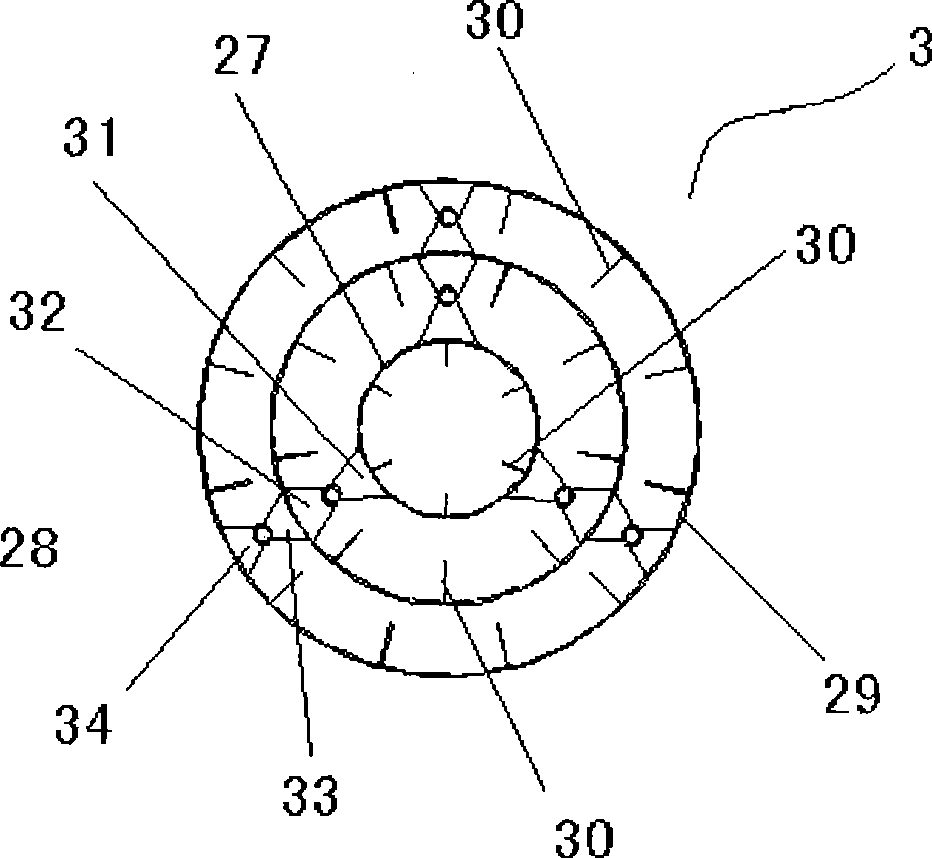

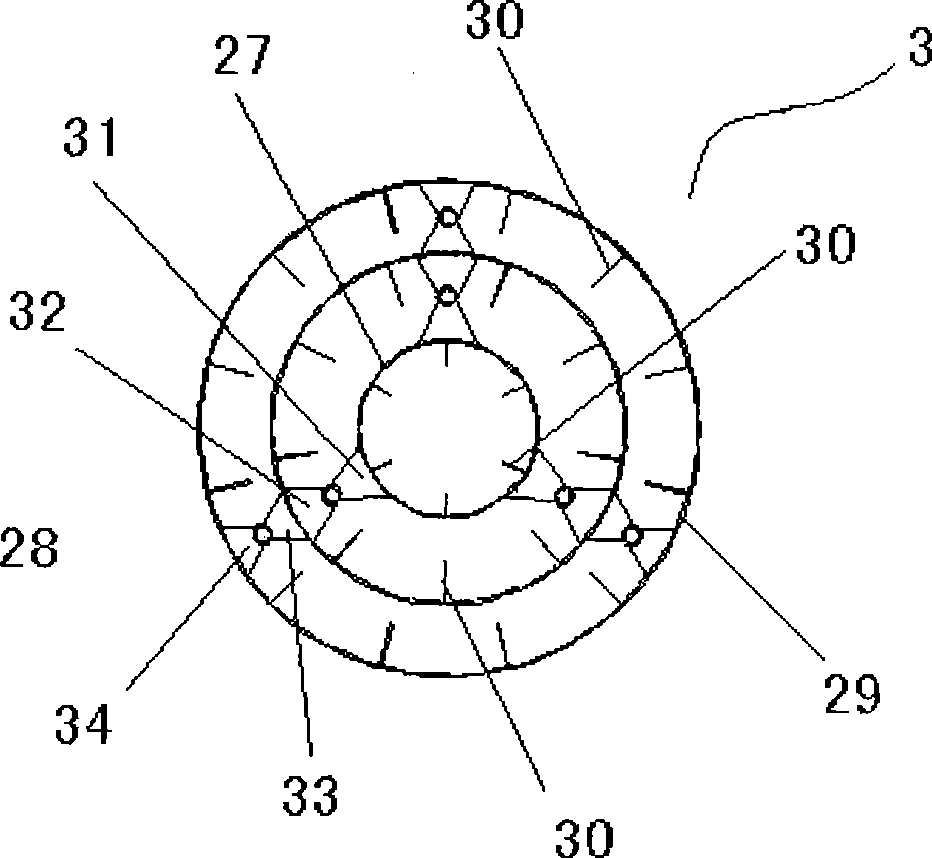

Energy-saving drying device for inner wall of pipeline

PendingCN112815682ACan be dried coarseRealize the collectionDrying gas arrangementsDrying chambers/containersThermodynamicsEngineering

The invention discloses an energy-saving drying device for the inner wall of a pipeline, and particularly relates to the technical field of pipeline drying. The energy-saving drying device comprises a machine body and a first cavity, wherein the first cavity, a second cavity and a third cavity are formed in the machine body, the bottom end in the third cavity is fixedly connected with a fan, and the output end of the fan is fixedly connected with a heater. According to the energy-saving drying device, drying pipes, air conveying pipes, a second exhaust pipe, air outlets and silica gel sheets are arranged, the inner walls of some pipelines with small pipe orifice diameters are difficult to dry, the drying pipes are arranged in several sets on the to-be-dried drying pipeline, the drying pipes are sleeved with the pipeline firstly, then the fan and the heater convey hot air into the conveying pipes, and the hot air in the conveying pipes is conveyed into the drying pipes through the second exhaust pipe and then is discharged from the air outlets of the drying pipes to dry the inner wall of the pipeline. According to the structure, the inner wall of the pipeline is directly dried, and the situation that the inner wall of the pipeline is insufficiently dried is avoided.

Owner:住重福惠动力机械有限公司

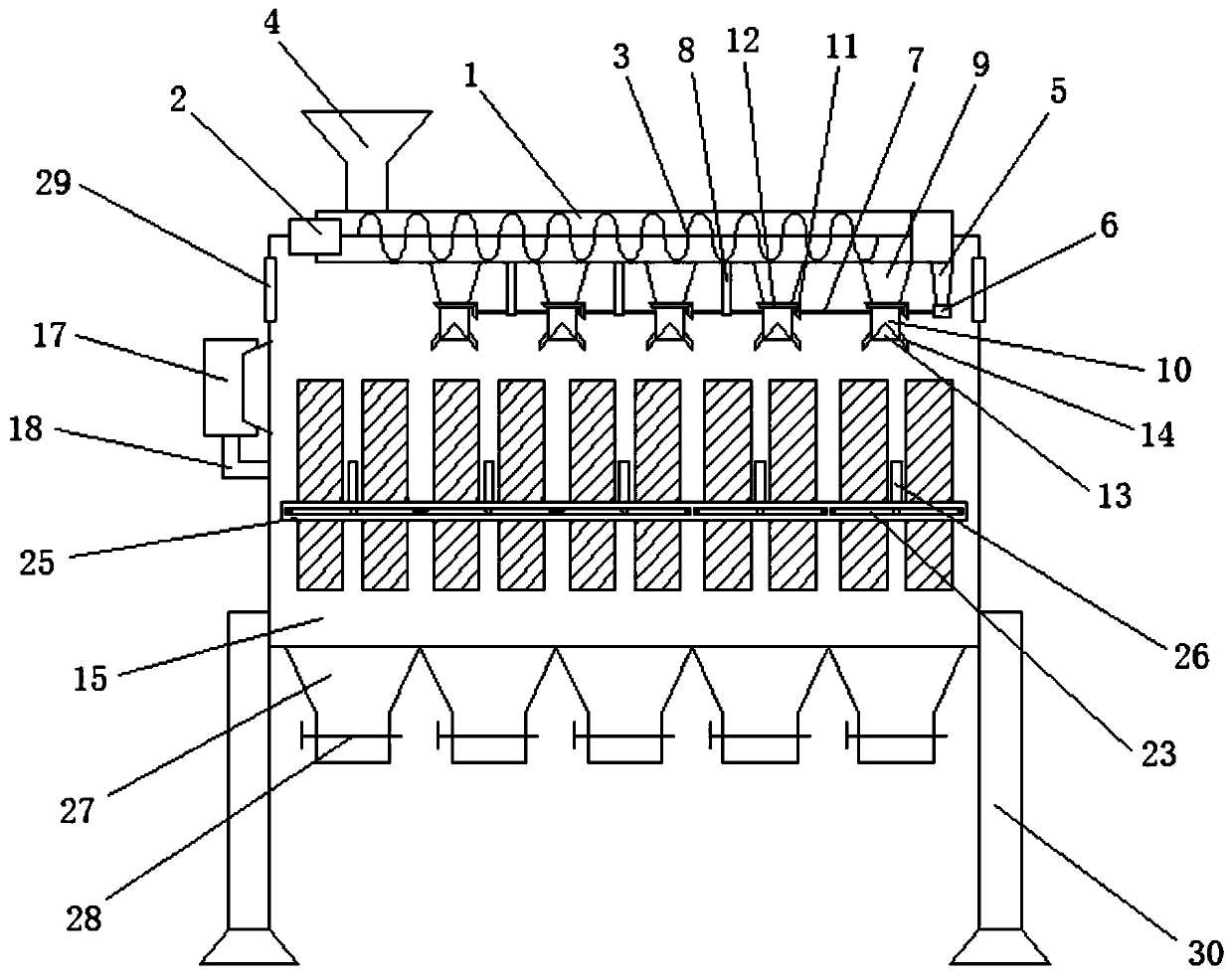

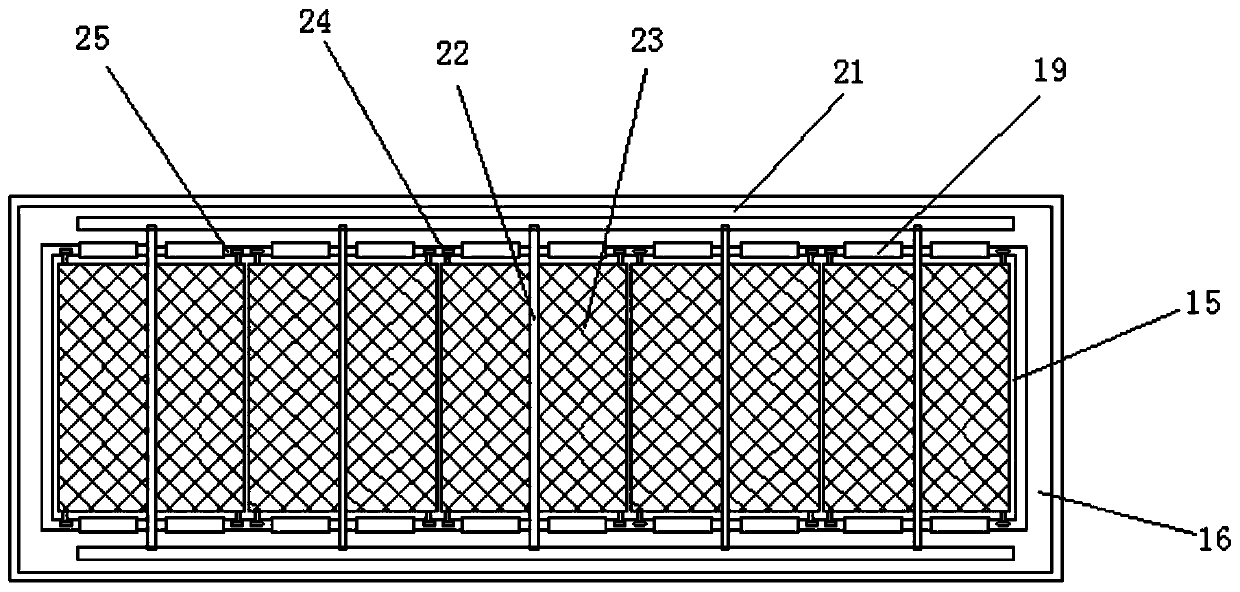

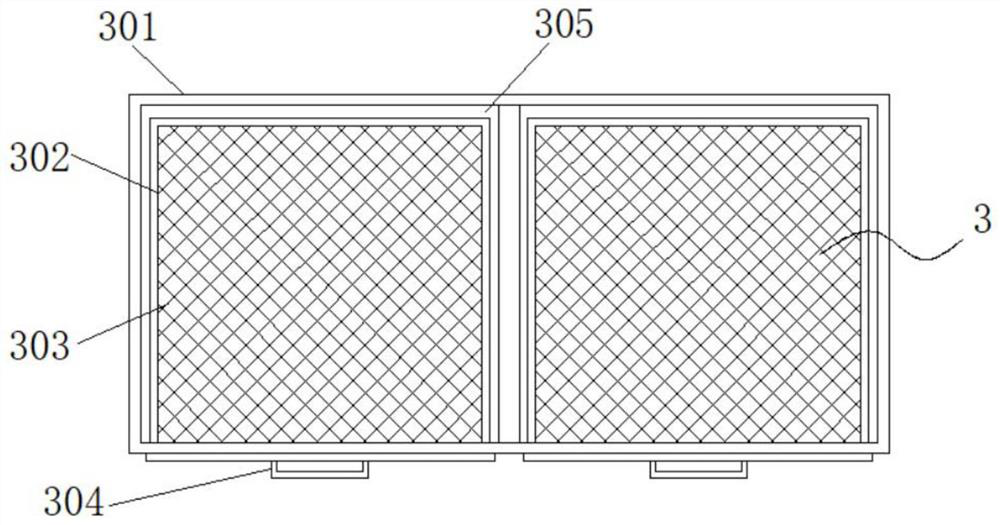

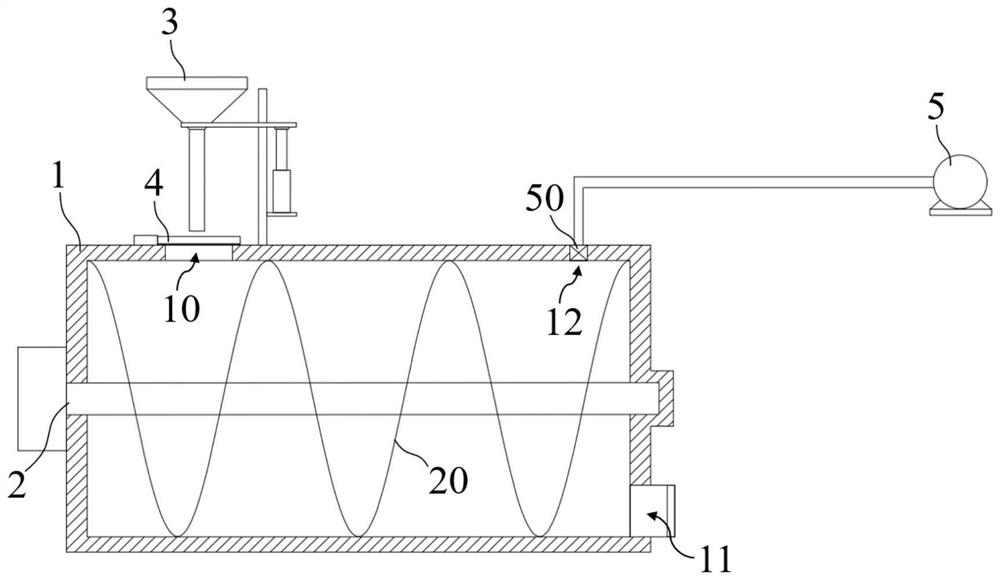

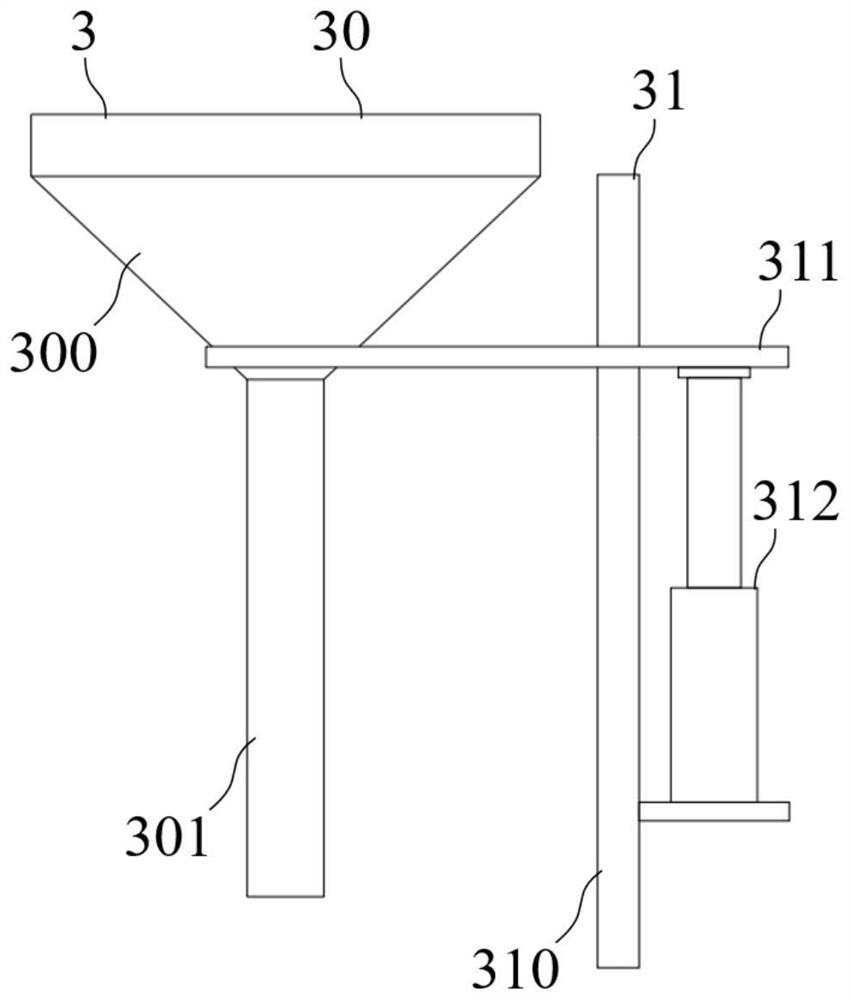

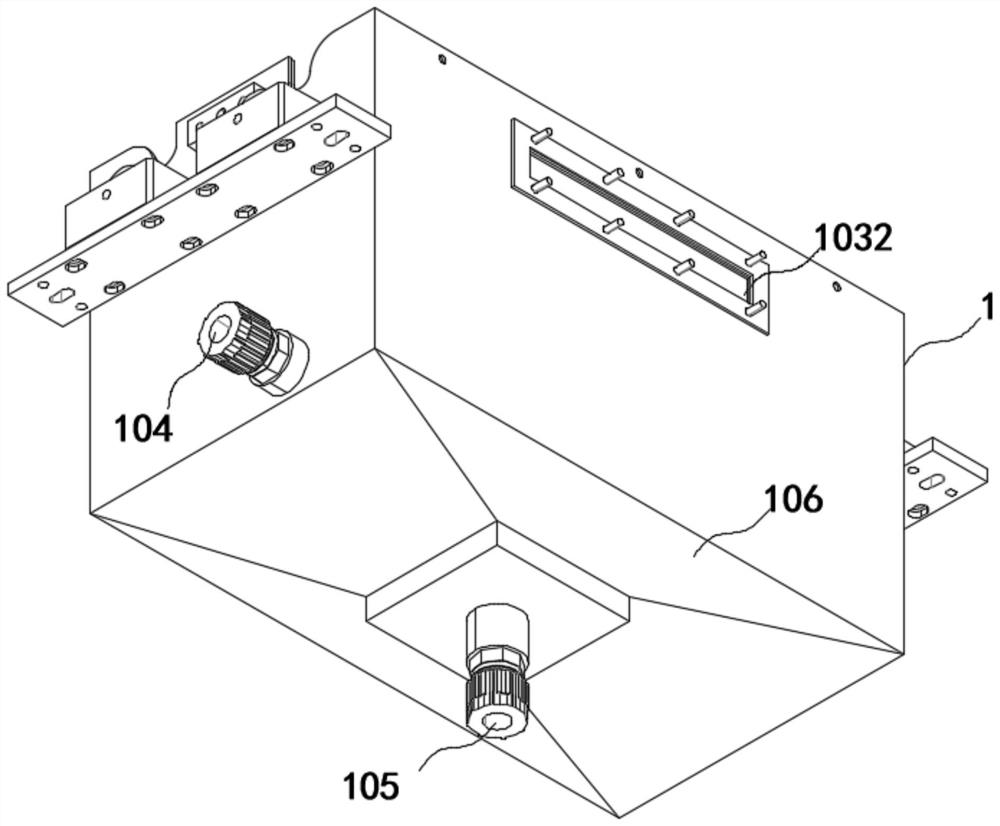

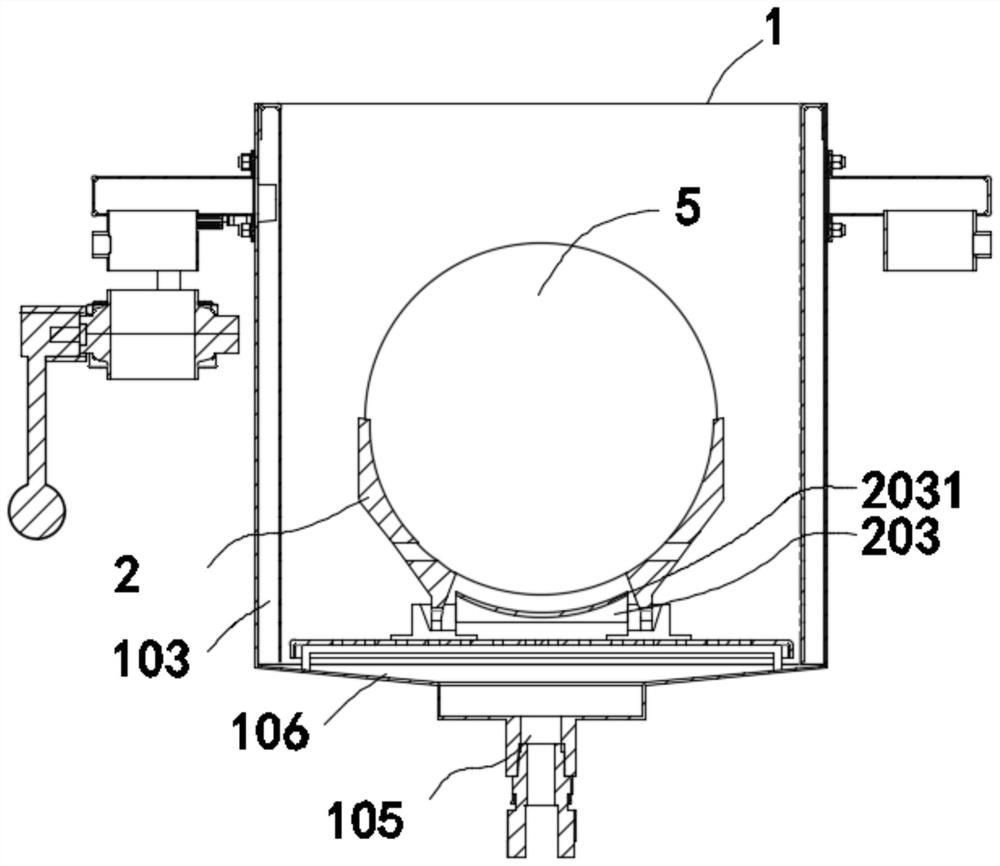

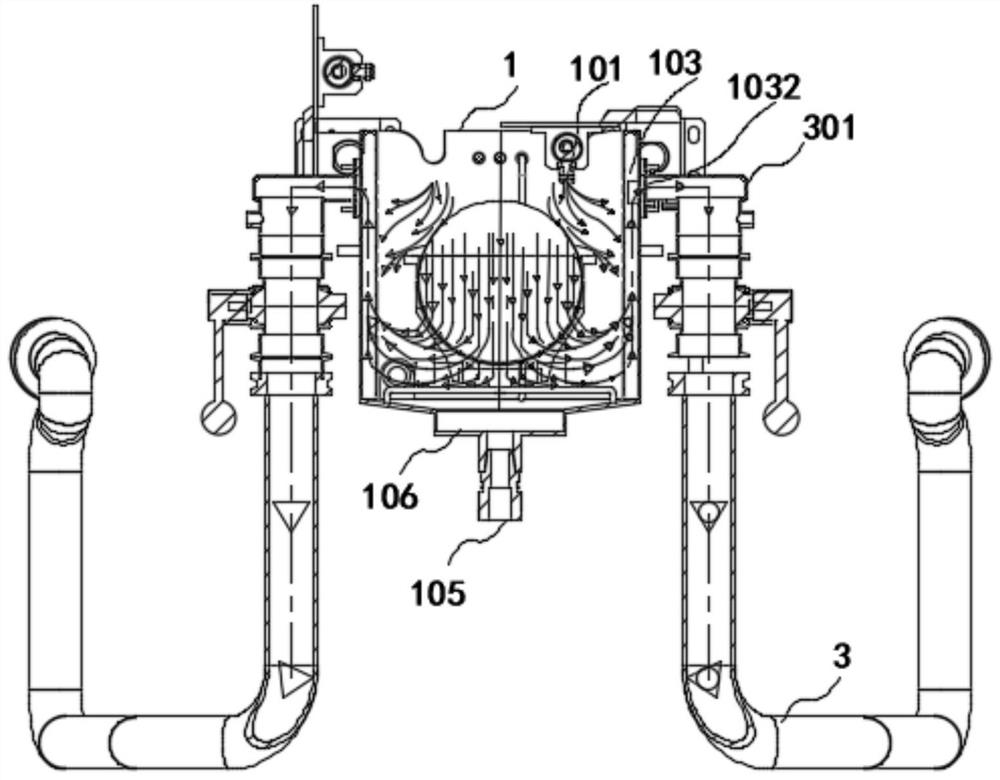

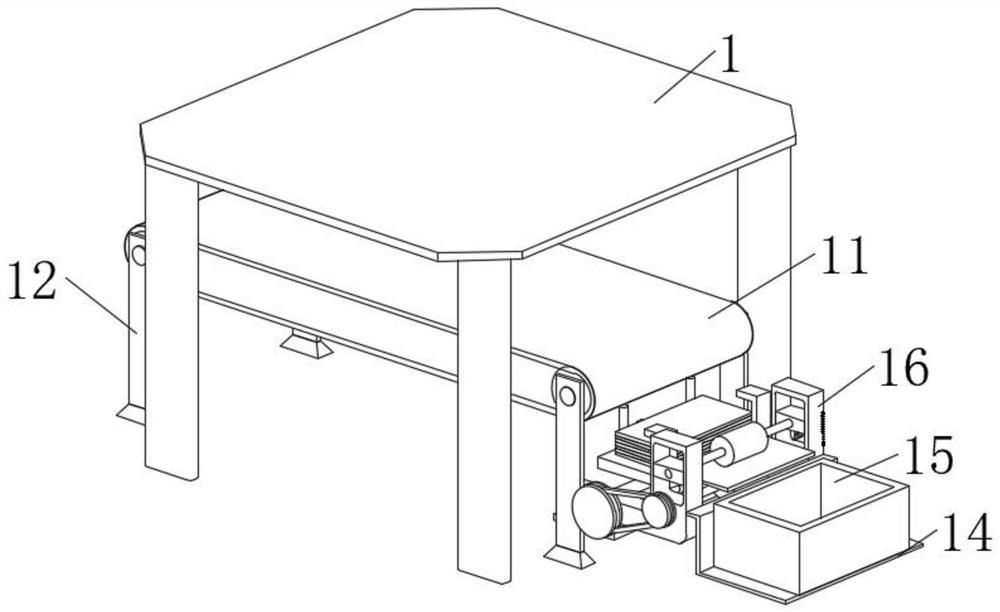

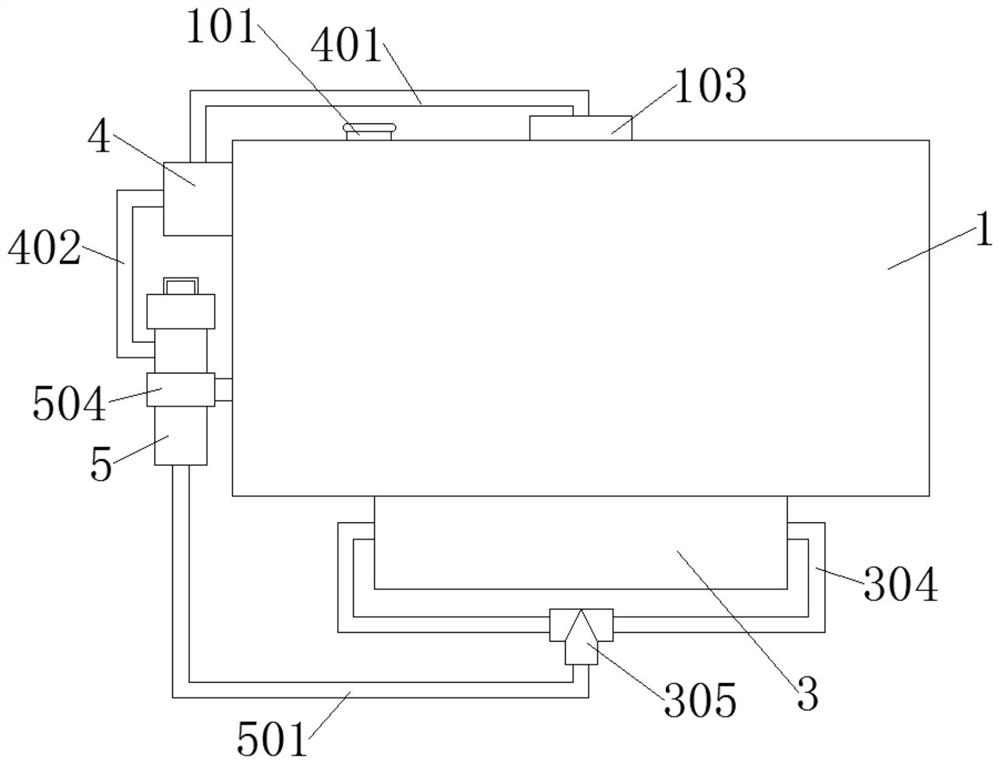

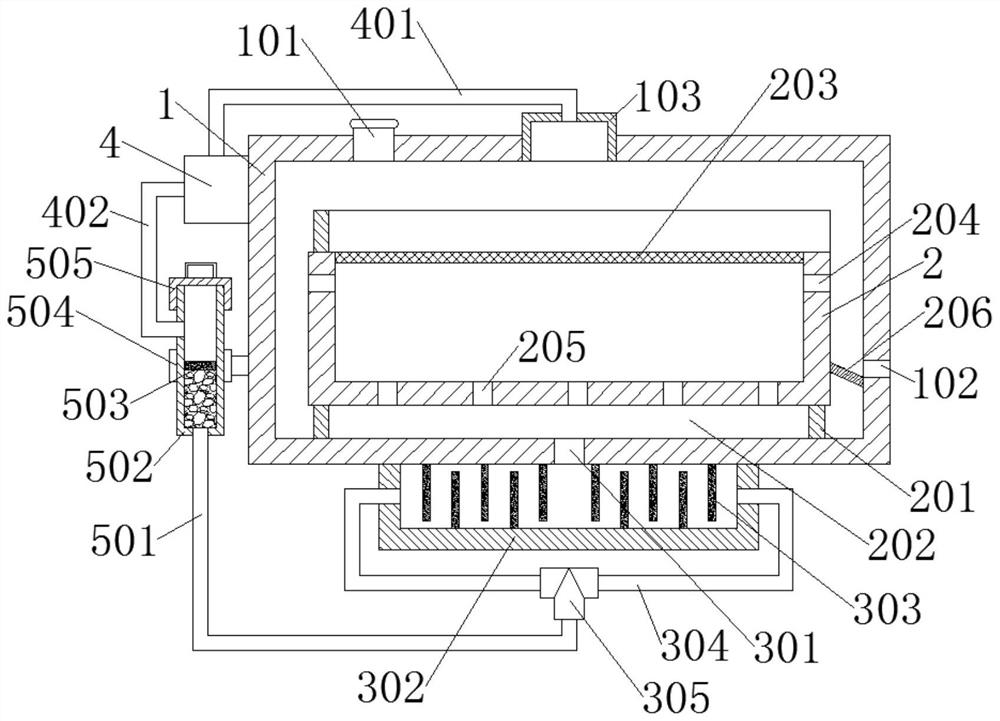

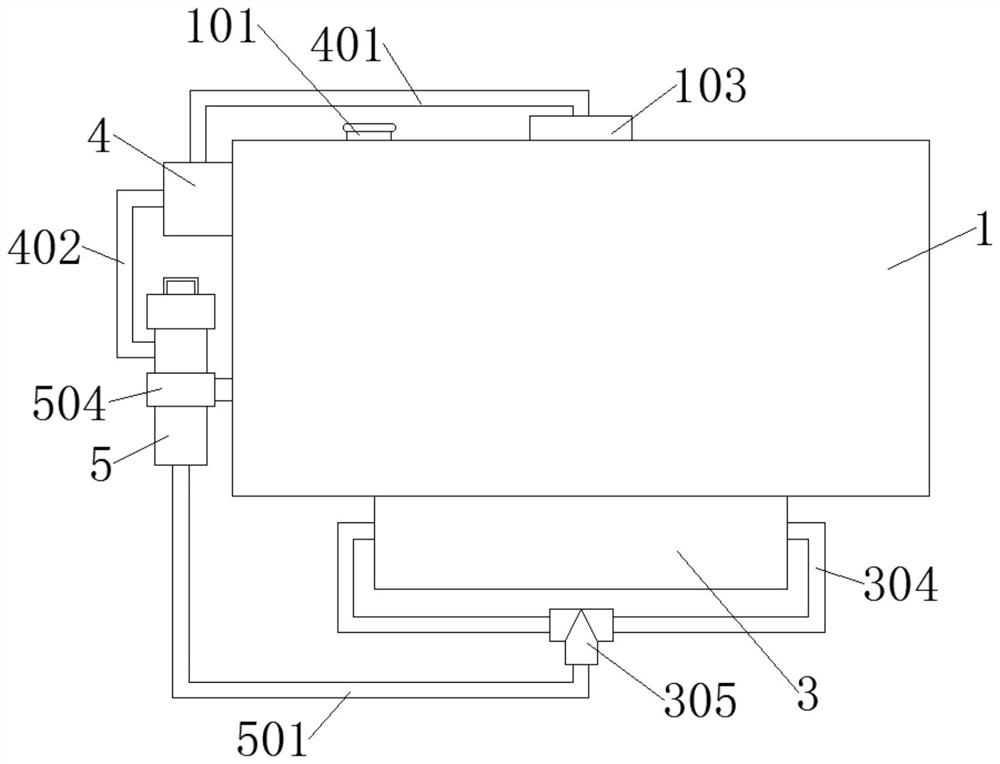

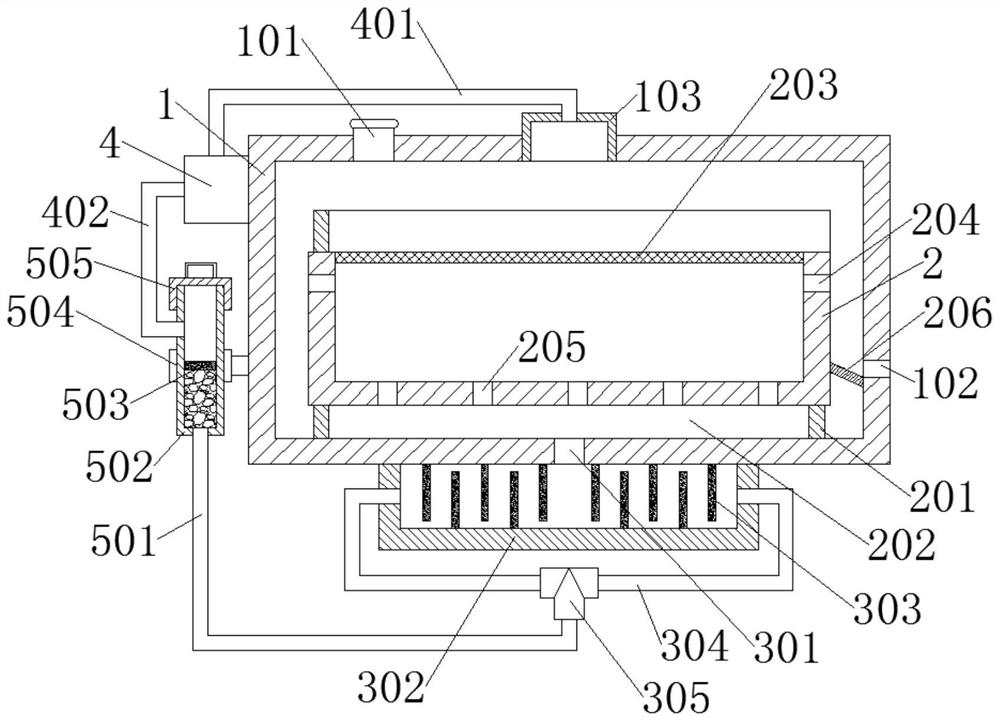

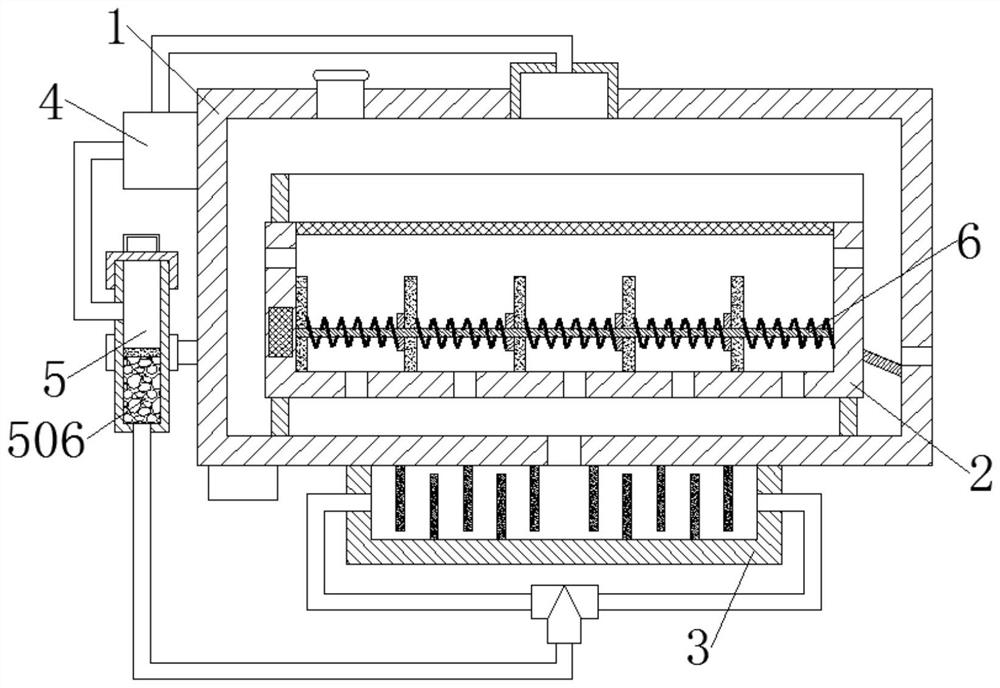

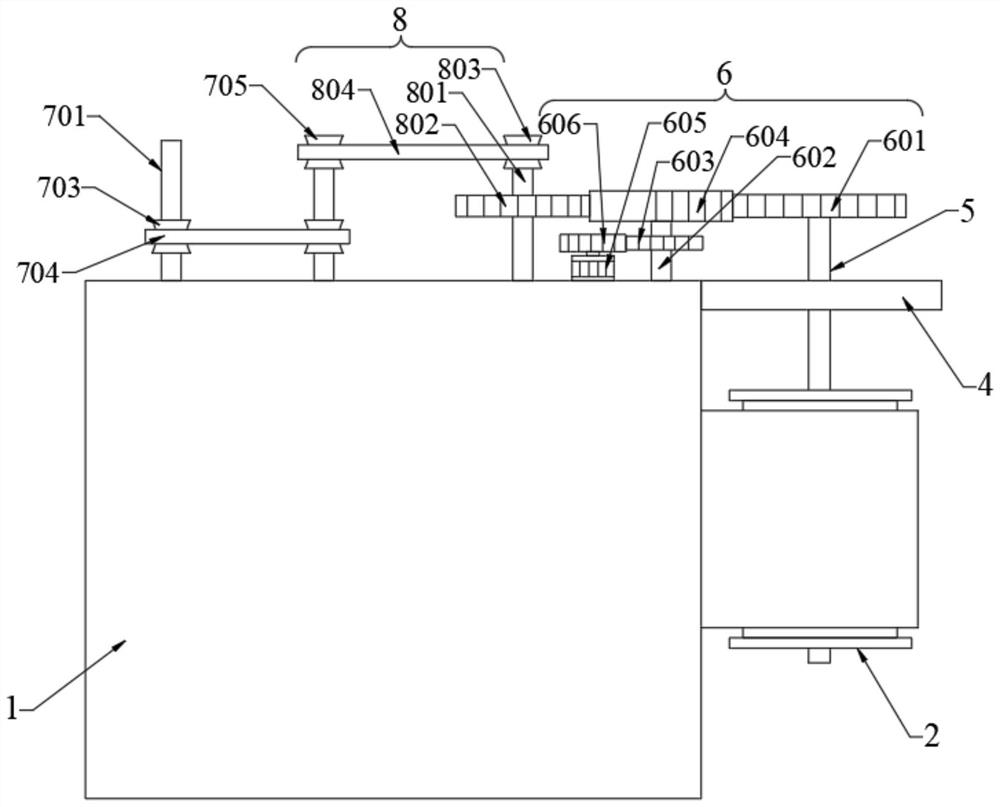

Vacuum drying furnace

InactiveCN112484398ASolve the real problemGuaranteed drynessSludge treatment by de-watering/drying/thickeningDrying solid materials without heatSludgeProcess engineering

The invention discloses a vacuum drying furnace, and belongs to the field of heating and drying equipment. The vacuum drying furnace comprises a furnace body provided with a charging port and an air outlet port in the top, and provided with a discharging port in the bottom, a stirring mechanism arranged in the furnace body; and a vacuum device communicating with the air outlet port of the furnacebody to keep a negative pressure environment in the furnace body. The vacuum drying furnace further comprises a feeding device, wherein the feeding device comprises a feeding hopper which is funnel-shaped, composed of a horn mouth and a material guide pipe vertically communicated to the bottom of the horn mouth, and arranged over the charging port, a lifting mechanism which is arranged at one sideof the feeding hopper and controls the lifting of the feeding hopper, and a sealing gate which is arranged at the charging port and controls the opening and closing of the charging port. According tothe invention, through the design for the feeding device, no sludge adheres to the charging port in a feeding process, the sealing gate is closed after feeding is completed, and the sealing performance of the furnace body can be effectively guaranteed, so that the sealing performance problem existing in an existing vacuum drying furnace is solved, the vacuum drying effect is guaranteed, and energy consumption for maintaining a vacuum degree is reduced.

Owner:WUXI XIYUAN BOILER

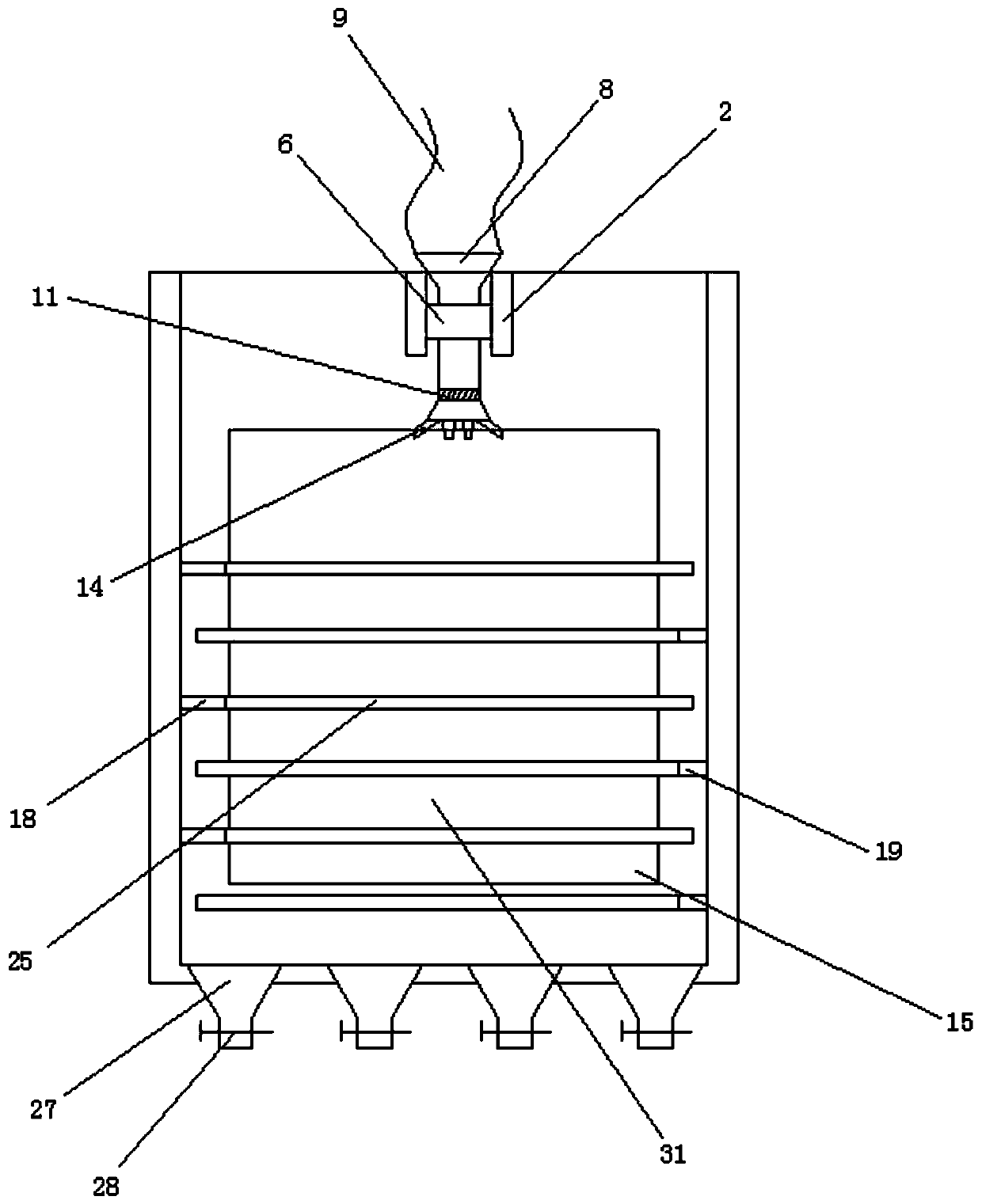

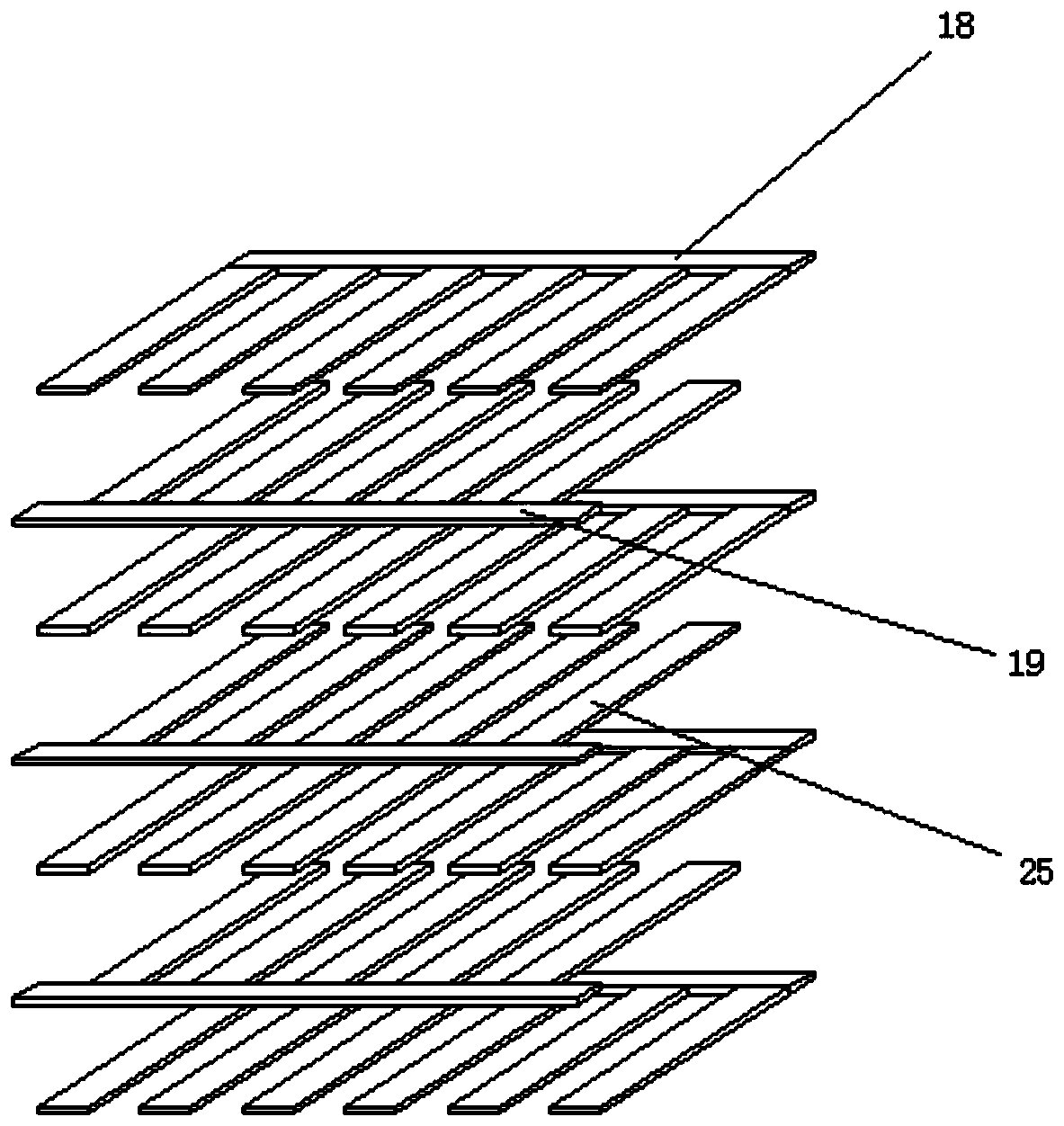

Grain rotary discharging type drying device

InactiveCN111174561ASimple structureIncrease the drying areaDrying gas arrangementsDrying solid materialsElectric machineryAgricultural engineering

The invention discloses a grain rotary discharging type drying device. The grain rotary discharging type drying device comprises a feed hopper and a drying bin, wherein the feed hopper is positioned at the top of the drying bin, a bearing is fixedly arranged on the outer side of the bottom of the feed hopper, a rotary drum is rotatably connected to the bottom of the feed hopper through the bearing, discharging pipes are fixedly arranged on two sides of the rotary drum, two groups of rails and two groups of toothed rails are arranged on two side walls of two sides of an inner cavity of the drying bin, three groups of first lifting frames and second lifting frames are separately movably connected to the rails on the two side walls, two groups of third motors are fixedly arranged on the rearsides of each group of first lifting frame and second lifting frame, one side of each third motor is fixedly connected with a second gear, and a plurality of groups of bearing plates are horizontallyarranged on the inner side walls of the first lifting frames and the second lifting frames; and the bottom of the drying bin is fixedly provided with a plurality of discharging hoppers. Grains can bedistributed on all the bearing plates layer by layer, the drying area is increased, and the drying efficiency is improved.

Owner:杨文耀

A patterned wafer drying method

ActiveCN111312626BImprove drying efficiencyAvoid insufficient dryingSemiconductor/solid-state device manufacturingJet flowWafer

The invention discloses a patterned wafer drying method. The wafer drying method includes setting a top module for converging hot nitrogen flow to the bottom of the wafer at the bottom of the wafer holding chamber and between the washing tanks. An exhaust slit communicating with the inside and outside of the wafer holding chamber is provided, and a gas jet module is set at the first inlet so that the hot nitrogen can provide sufficient kinetic energy, and there is a gap between the top module and the wafer. In the first interval, the gas jet module includes several nozzles with adjustable jet flow rate, and the hot nitrogen gas is discharged from the wafer accommodation chamber through the exhaust slot and the gap between the wafer accommodation chamber and the top film module. The present invention can fully dry the edge part of the bottom of the wafer by setting a top module for converging the hot nitrogen flow to the bottom of the wafer at the bottom of the wafer holding chamber, so that the hot nitrogen can flow in the gas jet flow module, A circulating airflow field is formed between the wafer holding chamber and the top sheet module to improve the drying efficiency.

Owner:ULTRON SEMICON (SHANGHAI) CO LTD +1

Drying device for art media printing

InactiveCN113492577ABatch drying achievedAvoid insufficient dryingPrinting press partsGear driveGear wheel

The invention discloses a drying device for art media printing. The drying device includes a support frame. A first motor is started; the first motor drives a rotating rod to rotate; the rotating rod drives a rotating block to rotate; the rotating block drives a stop block to rotate; the stop block drives a moving rod to move; the moving rod drives an elastic rod to move; and the elastic rod pushes a bottommost printing plate out of a dryer. The rotating rod drives the rotating block to rotate and drives a first rotating wheel to rotate at the same time; the first rotating wheel drives a second rotating wheel to rotate through a connecting belt; the second rotating wheel drives a second connecting rod and a second rolling shaft to rotate; the second connecting rod drives a second gear to rotate; the second gear drives a first gear to rotate through a chain; the first gear drives a first connecting rod to rotate; the first connecting rod drives a first rolling shaft to rotate; and when the elastic rod pushes the printing plate and the printing plate moves to the position between the first rolling shaft and the second rolling shaft, the printing plate can be pushed into a collecting box by the rotations of the first rolling shaft and the second rolling shaft, and collection of the dried printing plate is facilitated.

Owner:JIANGSU INST OF ECONOMIC & TRADE TECH

A kind of high-efficiency drying equipment for quartz sand for optical lens production

ActiveCN112556368BAvoid the problem of uneven drying effectAvoid getting lostDrying gas arrangementsDrying chambers/containersThermodynamicsWater vapor

The invention discloses a high-efficiency drying equipment for quartz sand for optical lens production, comprising an outer box, a heating box, a hot air heater, a fan and a filter, as well as a disturbance device. The disturbance device includes a sliding rod and an electromagnet. The drying cloth is sealed. The beneficial effect of this equipment is that the quartz sand falls on the elastic drying cloth for drying, and the air in the fan drives the equipment to circulate. When passing through the filter position, the air is filtered and the water vapor in it is absorbed. When passing through the position of the hot air heater, the air is heated, and the hot air is disturbed by the disturbing device, which makes the elastic drying cloth vibrate, thus avoiding the accumulation of quartz sand during the drying process, making the drying more comprehensive and efficient, and at the same time disturbing The device can not only realize the shaking of the elastic drying cloth, but also realize the effect of discharging.

Owner:万川环境科技(广东)有限公司

A Design Method of Oven Nozzle for Gravure Printing Machine

The invention discloses a design method for tuyeres of a gravure press drying oven. The design method specifically comprises the following steps that the minimum length L of the gravure press drying oven is determined; drying areas of the gravure press drying oven are divided; the length of each divided drying area is calculated according to the obtained minimum length L of the gravure press drying oven; the tuyere number of each drying area is calculated according to the length of the corresponding drying area; and according to the printing ink drying characteristics of all the divided drying areas, tuyere structures suitable for the different drying areas are designed. More reasonable drying air distribution and air-out forms can be obtained through tuyere arrangements and forms which are designed through the method, and air requirements of printing ink drying in different stages are met; uniform and sequential flowing of dried hot air are achieved, and the problems that energy is wasted due to the fact that the tuyere design of an existing drying oven is unreasonable is solved.

Owner:XIAN UNIV OF TECH

Drying equipment for green tea processing

PendingCN112815662AAvoid insufficient dryingSpeed up dryingSievingPre-extraction tea treatmentGreen teasEngineering

The invention discloses drying equipment for green tea processing, and relates to the technical field of green tea processing equipment. The drying equipment comprises an outer shell assembly, wherein the outer shell assembly comprises a casing, a collecting device, a partition plate and two feeding hoppers, wherein the collecting device is slidably connected to the inner bottom wall of the casing; the partition plate located above the collecting device is fixedly connected to the inner wall of the casing; material guiding openings corresponding to the collecting device are symmetrically formed inside the partition plate; the two feeding hoppers communicate with the casing; a mixing mechanism extending into the casing is fixedly connected onto the casing; a U-shaped heating table located on the outer side of the mixing mechanism is fixedly connected to the inner top wall of the casing; and a jacking mechanism attached to the U-shaped heating table is fixedly connected onto the partition plate. The drying equipment for green tea processing solves the problems that in the drying process of green tea, a common green tea drying machine uses an electric heating wire, the drying efficiency is low, and green tea is inconvenient to collect.

Owner:HUBEI YOUHUA XUN TEA FLORICULTURE SCI & TECH

Drying equipment for bamboo charcoal fiber fabric

InactiveCN112984967AAvoid standing waterDry evenlyDrying solid materials without heatDrying gas arrangementsMechanical engineeringElastic rods

The invention discloses drying equipment for bamboo charcoal fiber fabric. The drying equipment for the bamboo charcoal fiber fabric structurally comprises a main body, a control panel and air inlets; the control panel is arranged at the front end of the main body; the two air inlets are arranged and are formed in the two ends of the top of the main body respectively; the main body comprises a water collecting tank, a feeding opening, an opening device and an air outlet groove; the opening device comprises a first sliding groove, a sliding shaft, a supporting plate, a second sliding groove and a clamping device; the clamping device comprises a material carrying plate, a connecting rod, a rolling wheel, a limiting block and a downward pressing device; the downward pressing device comprises a supporting column, a movable groove, a reset spring and a downward pressing block; and the downward pressing block comprises a downward pressing body, an elastic rod, a rubber ball and a vent hole. According to the drying equipment for the bamboo charcoal fiber fabric, the distance between the clamping devices is adjusted to open the fabric, so that the end face of the fabric can be flatly spread on the end faces of the clamping devices, the situation that water is accumulated in the fabric is avoided, and the fabric can be evenly impacted by hot air to be dried.

Owner:苑文娜

Fresh-keeping equipment for agricultural products and fresh-keeping method thereof

InactiveCN113040406ASmall footprintEasy to transportWrappingPackaging fruits/vegetablesAgricultural scienceAgricultural engineering

The invention discloses a fresh-keeping equipment for agricultural products and a fresh-keeping method thereof in the field of intelligent production. The fresh-keeping equipment mainly comprises a cleaning mechanism, a drying mechanism and a packaging mechanism, the cleaning mechanism is connected with the drying mechanism through a first communicating pipe, the first communicating pipe is vertically arranged, one end of the first communicating pipe is connected with the cleaning mechanism, and the other end of the first communicating pipe is connected with the middle of the drying mechanism; the drying mechanism is connected with the packaging mechanism through a second communicating pipe, the second communicating pipe is obliquely arranged, the higher end of the second communicating pipe is connected with the drying mechanism, the lower end of the second communicating pipe is provided with a first opening used for discharging agricultural products, and the packaging mechanism is arranged in the middle of the second communicating pipe. According to the invention, the cleaning, drying and packaging of agricultural products can be automatically completed in single equipment, and the fresh-keeping equipment for agricultural products has simple structure, small occupied area and is convenient to transport. The agricultural products can be directly dried and packaged in the fresh-keeping equipment after being cleaned, so that the agricultural products are prevented from being in contact with the outside, the agricultural products are prevented from being polluted by external pollutants, and the fresh-keeping effect is improved.

Owner:右江民族医学院

A sizing machine with uniform sizing and its application method

ActiveCN105256484BReduce handlingQuality improvementSucessive textile treatmentsLiquid/gas/vapor removalYarnElectricity

The invention discloses a slasher capable of sizing uniformly and an application method thereof. The slasher comprises a housing, a sizing tank, a drying room and a DC (Direct Current) power supply; a front guide roller is arranged at the front end of the top of the housing; the front guide roller is of a conductor and is connected with the cathode of the DC power supply; the sizing tank is fixedly arranged in the housing; a front compression roller is arranged at the position close to the front guide roller above the sizing tank; a back compression roller is arranged at the position far away from the front guide roller above the sizing tank; shower nozzles are arranged uniformly at intervals above a position between the front compression roller and the back compression roller; a metal net is arranged in each shower nozzle, and is connected with the anode of the DC power supply; a catch box is arranged below a position between the front compression roller and the back compression roller; the drying room is installed at the position close to the sizing tank in the housing; due to the fact that the sizing sprayed by the shower nozzles is provided with positive electricity, yarn passes through the front guide roller and is provided with negative electricity, so that the sizing can uniformly cover the yarn, meanwhile the catch box can inhale the redundant sizing on the yarn, so that the condensation points of the sizing on the yarn due to the excessive sizing do not occur, and the uniformity of sizing is guaranteed.

Owner:吴江达飞织造厂

Drying equipment with high reliability

InactiveCN112503866AReduce moisture contentImprove drying effectDrying solid materials without heatLavatory sanitoryPhysicsProcess engineering

The invention relates to drying equipment with high reliability. The drying equipment comprises a body, two heating devices and two fixing blocks, and further comprises an extrusion mechanism and a disinfection mechanism; the extrusion mechanism comprises a draining plate, an air cylinder, a lifting plate, a worm, two first bearings and a plurality of stirring assemblies; the disinfection mechanism comprises an ultraviolet disinfection lamp, a protection box, a scraping plate and two rotating assemblies; and each rotating assembly comprises an air cylinder, a driving rod, a driving plate, a first connecting pipe, a second connecting pipe, a fixing box, blades, a third bearing and a transmission unit. According to the drying equipment with high reliability, through the extrusion mechanism,an extrusion dehydration function is achieved, the water content in organic garbage is reduced, the drying effect is improved, and therefore the drying work efficiency is improved, through the disinfection mechanism, the function of disinfecting and sterilizing the interior of the body is achieved, generation of bacteria and viruses in organic garbage is avoided, and therefore the probability thatworkers contaminate viruses and bacteria on the garbage when discharging the garbage is reduced.

Owner:深圳市迅成科技有限公司

Grass drying, stem and leaf separating device

InactiveCN101416766BPrevent drynessAvoid insufficient dryingFeeding-stuffCyclonePulp and paper industry

The invention relates to herbage drying and stem-leaf separating device, characterized in that: the device comprises a hot-blast stove, a pre-heating drying roller, a three-pass drying roller, a separating and discharging tank, a cyclone separator, a blower and a dust remover; the hot-blast stove is connected with the pre-heating drying roller through a warm-air pipe provided with a feeding hopper connected with a feeding airlock; the pre-heating drying roller is integrally fixed and connected with the three-pass drying roller rotationally connected with the separating and discharging tank and rotated through the driving of a moter; the lower end of the separating and discharging tank is provided with a discharging airlock, and the upper end is connected with the cyclone separator througha pipeline; the lower end of the cyclone separator is provided with a discharging airlock, and the upper end is connected with the blower through a pipeline; the outlet of the blower is connected with the dust remover with the outlet communicated with atmosphere. The invention decreases unnecessary energy consumption and lowers processing cost.

Owner:CHINA AGRI UNIV

Efficient quartz sand drying equipment for optical lens production

ActiveCN112556368AAvoid the problem of uneven drying effectAvoid getting lostDrying gas arrangementsDrying chambers/containersThermodynamicsWater vapor

The invention discloses efficient quartz sand drying equipment for optical lens production, which comprises an outer box body, a heating box, an air heater, a fan and a filter, and further comprises adisturbance device, the disturbance device comprises a sliding rod and an electromagnet, and the heating box is sealed by elastic drying cloth. The equipment has the following beneficial effects thatquartz sand falls on the elastic drying cloth for drying, the fan drives air in the equipment to circulate and pass through the position of the filter, the air is filtered, water vapor in the air isabsorbed, and when the air passes through the position of the air heater, the air is heated, and the hot air is disturbed through the disturbance device, so that the elastic drying cloth shakes, accumulation of the quartz sand is avoided in the drying process, and drying is more comprehensive and efficient; and meanwhile, the disturbance device not only can realize the shaking of the elastic drying cloth, but also can realize the discharging effect.

Owner:万川环境科技(广东)有限公司

Antibacterial filter material production device

PendingCN114232254AAvoid uneven distributionAffect healthMembrane filtersFiltration separationStructural engineeringAnti bacteria

The invention discloses an antibacterial filter material production device, and belongs to the technical field of filter materials, the antibacterial filter material production device comprises a treatment box and a receiving roller for rolling the filter materials, the right wall of the treatment box is fixedly connected with a supporting rod, the supporting rod is rotatably connected with a driving rod, and the receiving roller is fixedly connected to the outer wall of the driving rod; the front end of the supporting rod is connected with a driving mechanism for driving the collecting roller to rotate, a vibrating mechanism for driving the filter material to shake is installed in the treatment box, a linkage mechanism in transmission connection with the driving mechanism is installed on the rear wall of the treatment box, two sets of drying devices are installed in the treatment box, and the driving mechanism drives the collecting roller to drive the filter material to move. The filter material can intrude into the antibacterial agent liquid at the bottom of the treatment box, the adding effect is good, through cooperation of the driving mechanism, the linkage mechanism and the vibration mechanism, when the filter material does not move, the filter material is vibrated and dried through the vibration mechanism and the drying device, and when the filter material moves, the next section of filter material continues to be treated; the treatment effect on the filter material is good.

Owner:浙江玉智德新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com