Environment-friendly drying equipment for bioengineering

A technology of bioengineering and drying equipment, applied in the field of bioengineering, can solve the problems of drying, incomplete drying, and the device cannot achieve drying and environmental protection, and achieves the effect of reducing workload, improving drying efficiency and strong practicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Any feature disclosed in this specification, unless specifically stated, can be replaced by other alternative features that are equivalent or have similar purposes. That is, unless expressly stated otherwise, each feature is one example only of a series of equivalent or similar features.

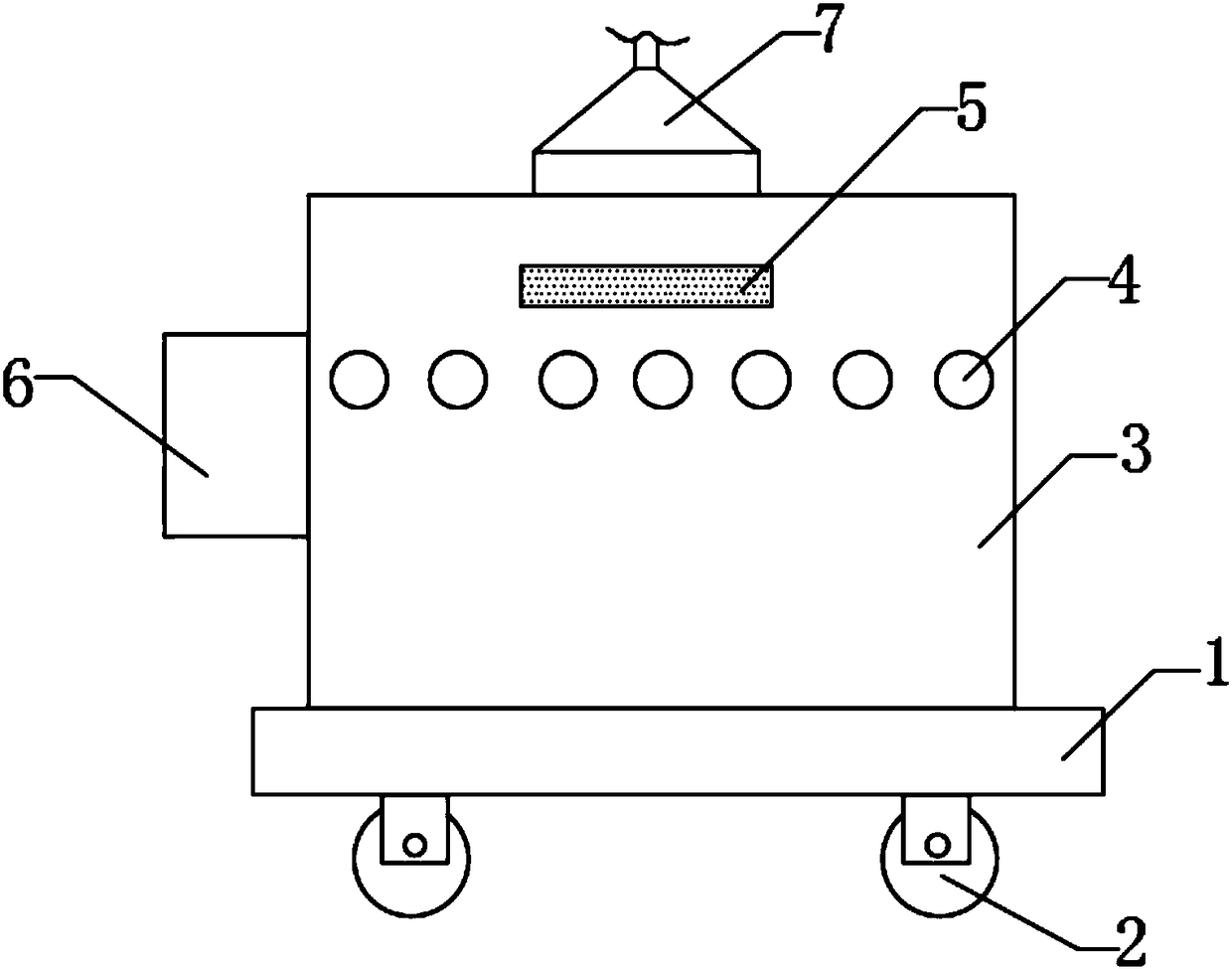

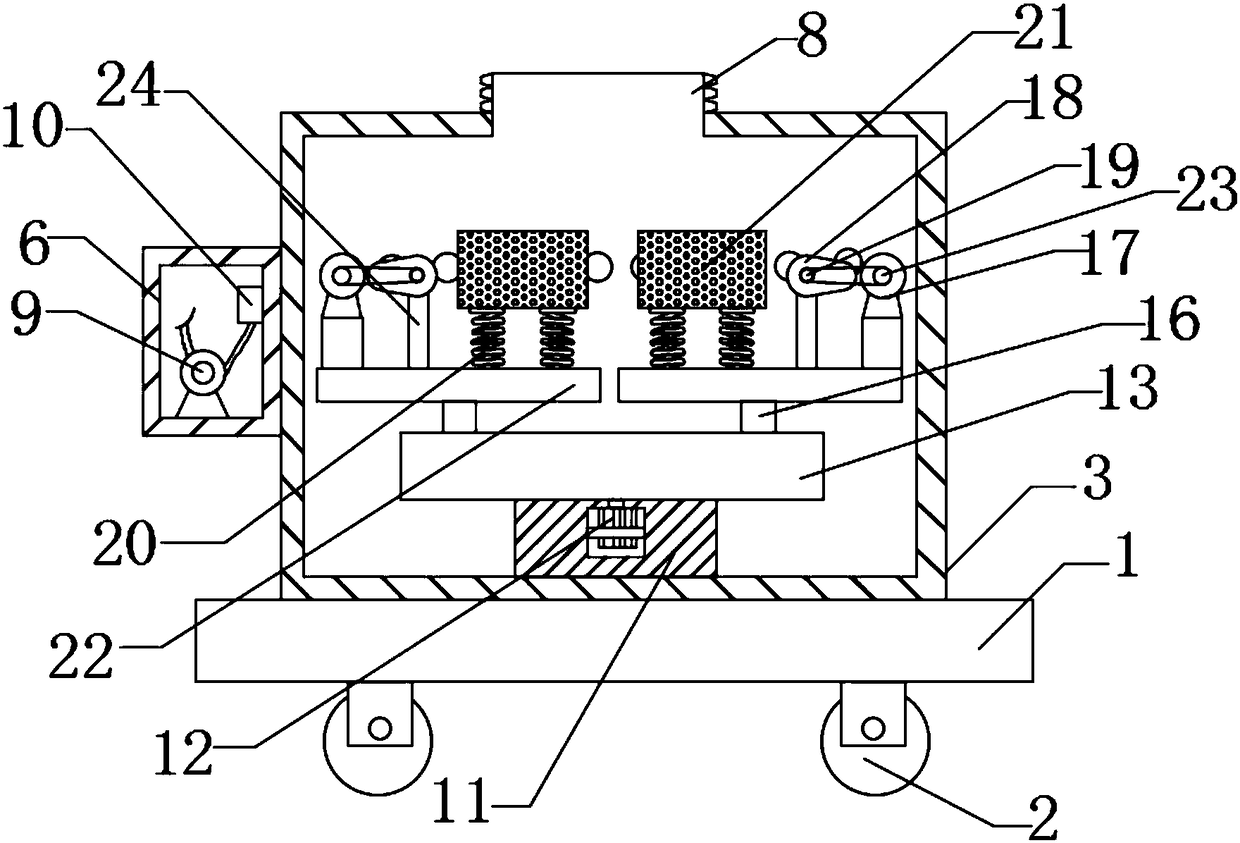

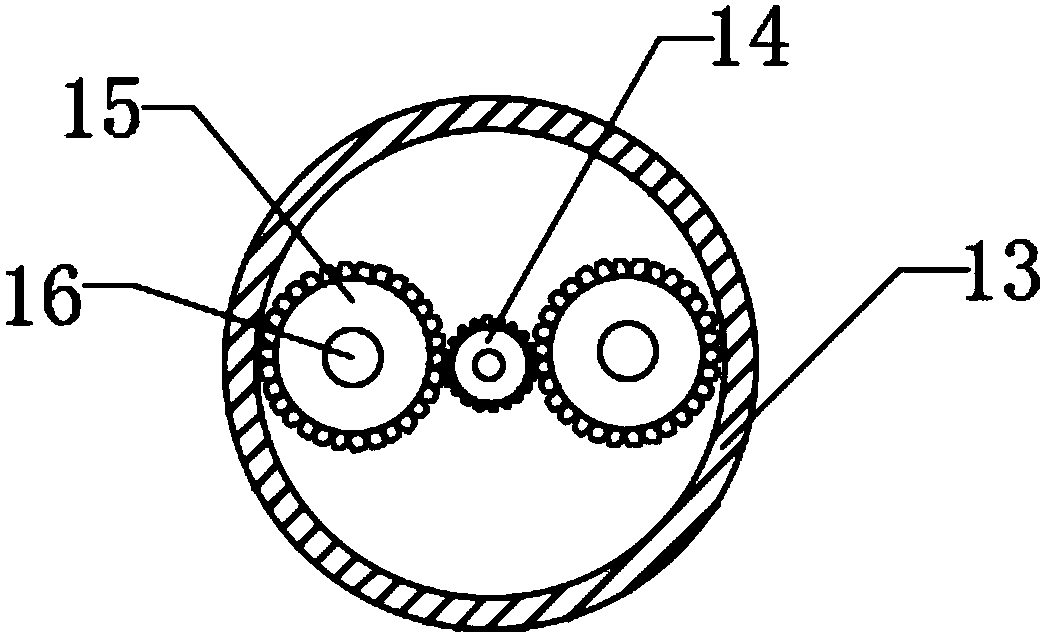

[0016] Such as Figure 1-Figure 3 An environmentally friendly drying equipment for bioengineering is shown, including base 1, self-locking wheel 2, drying box 3, drying hole 4, handle 5, power box 6, suction cover 7, air outlet 8, fan 9, heating Box 10, support base 11, first motor 12, installation box 13, sun gear 14, planetary gear 15, rotating shaft 16, second motor 17, cam 18, driven roller 19, telescopic spring 20, drying basket 21, support plate 22. The driving roller 23 and the fixed rod 24, the top of the base 1 is fixedly connected with a drying box 3, the sides of the drying box 3 are provided with drying holes 4, and the bottom of the inner wall of the drying box 3 is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com