Patents

Literature

52results about How to "Solve the problem of uneven drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

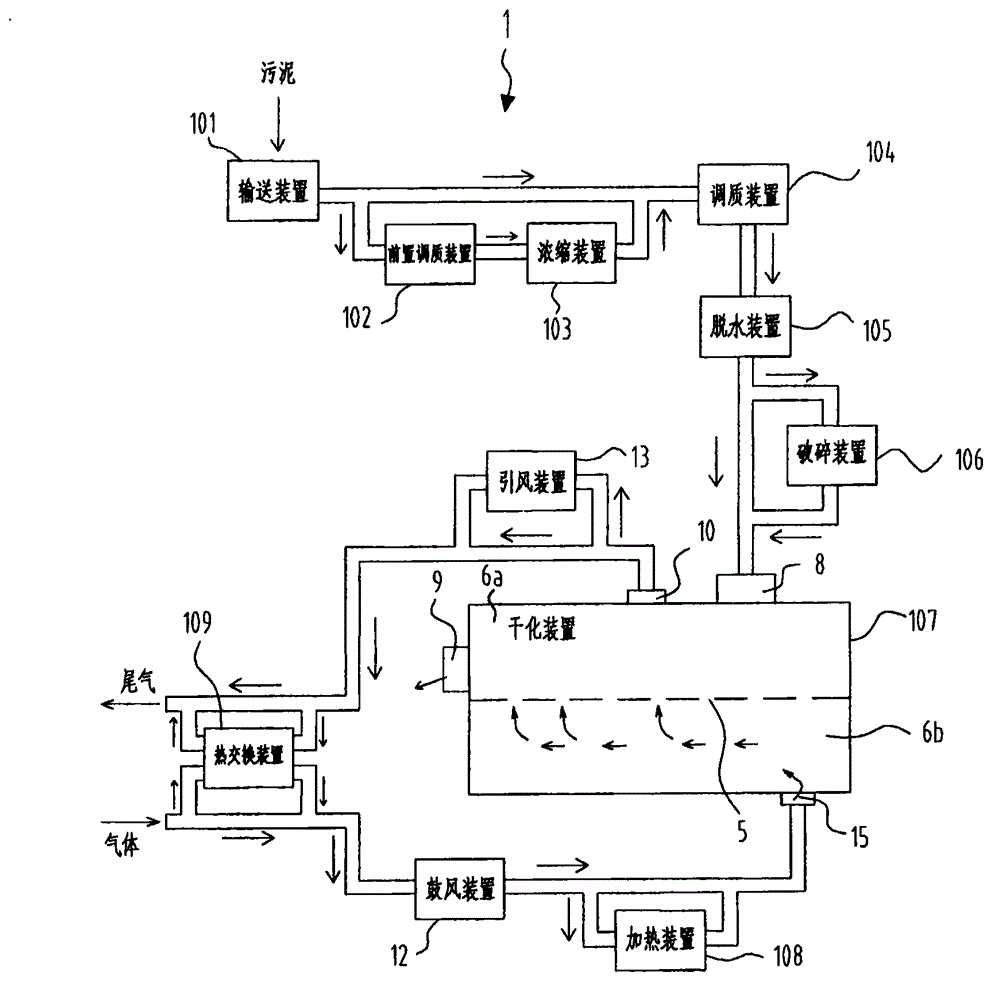

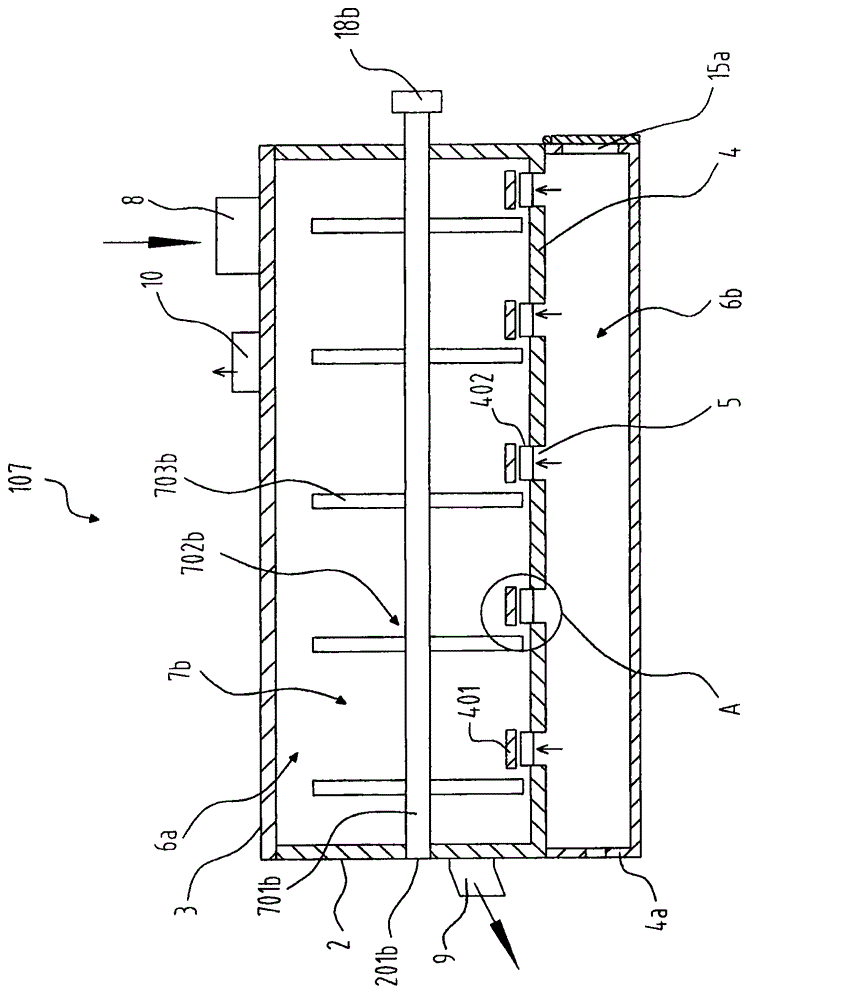

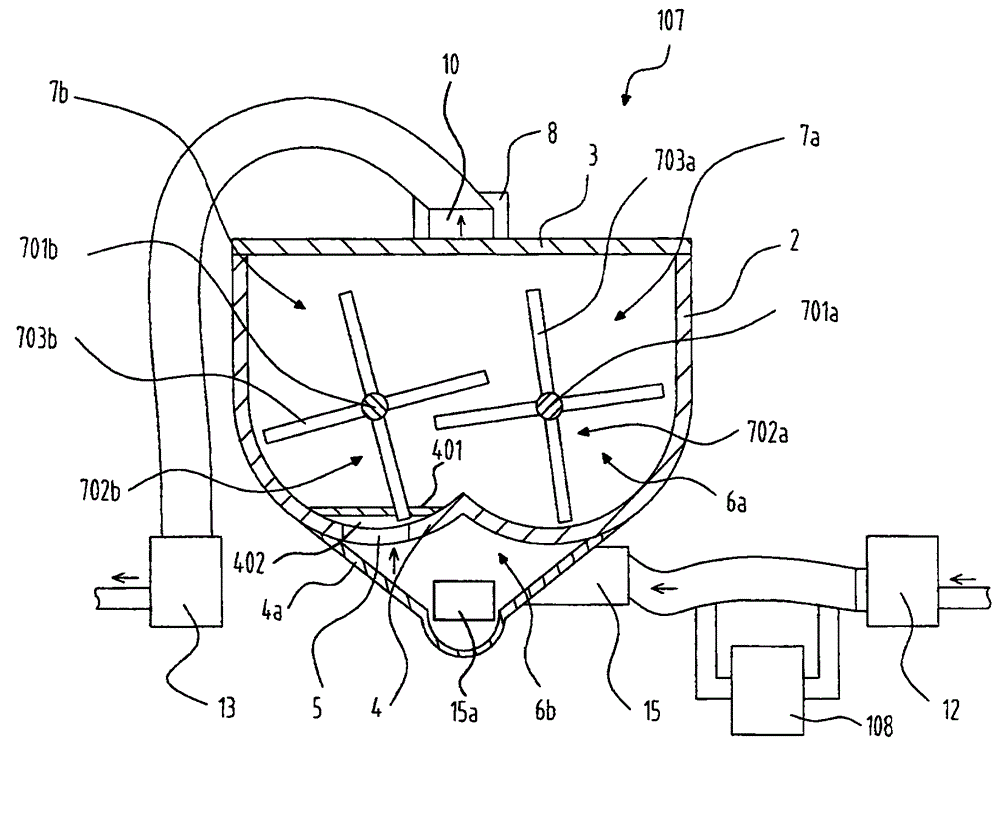

Sludge drying system and sludge drying method

PendingCN105819652AReduce moisture contentMore separationSludge treatment by de-watering/drying/thickeningDrying machinesSludgeDehydration

The invention provides a sludge drying system, which comprises a conveying apparatus, a tempering apparatus, a dehydration apparatus and a drying apparatus. The drying apparatus comprises a housing, the housing comprises a separation wall used for dividing the housing into a first drying chamber and a second drying chamber, and a communication port is formed on the separation wall and used for communicating the first drying chamber with the second drying chamber. A feed inlet and an air outlet are arranged on the upper part of the first drying chamber, and a discharge hatch is arranged on the circumferential wall of the first drying chamber. An air inlet is arranged on the circumferential wall of the second drying chamber. A stirring apparatus is arranged in the first drying chamber, wherein, the stirring apparatus comprises a rotation shaft and a stirring component fixed on the rotation shaft, and the stirring component is used for scraping the sludge near the communication port. An air blast apparatus is capable of communicating with the second drying chamber when passes through the air inlet. The invention also provides a sludge drying method by using the sludge drying system.

Owner:广州正晟科技有限公司

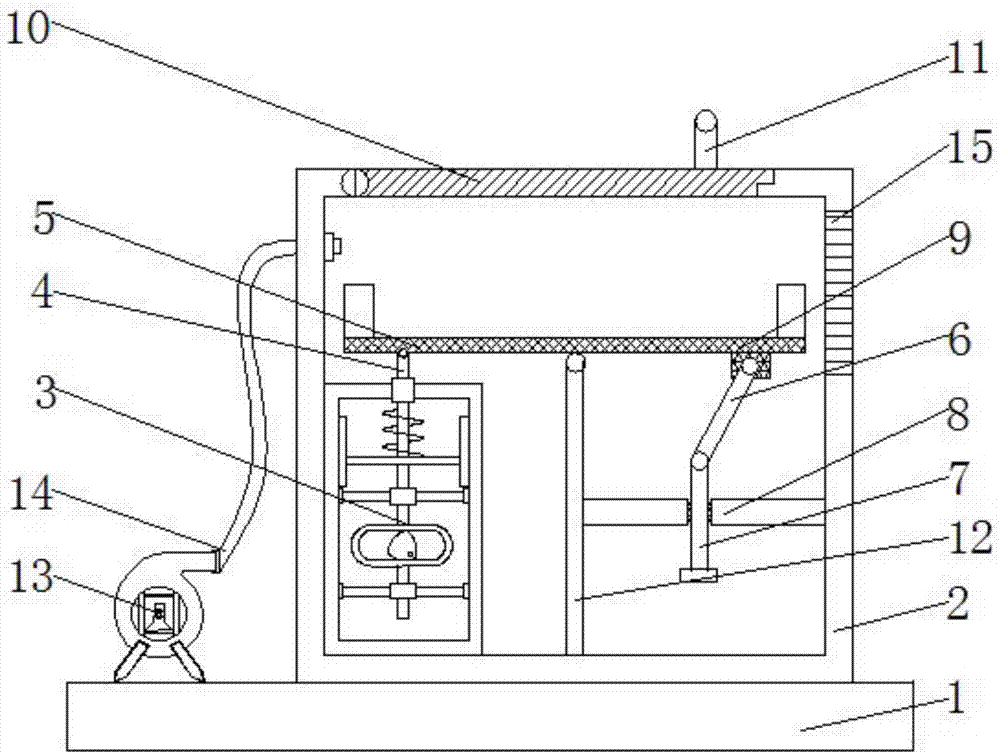

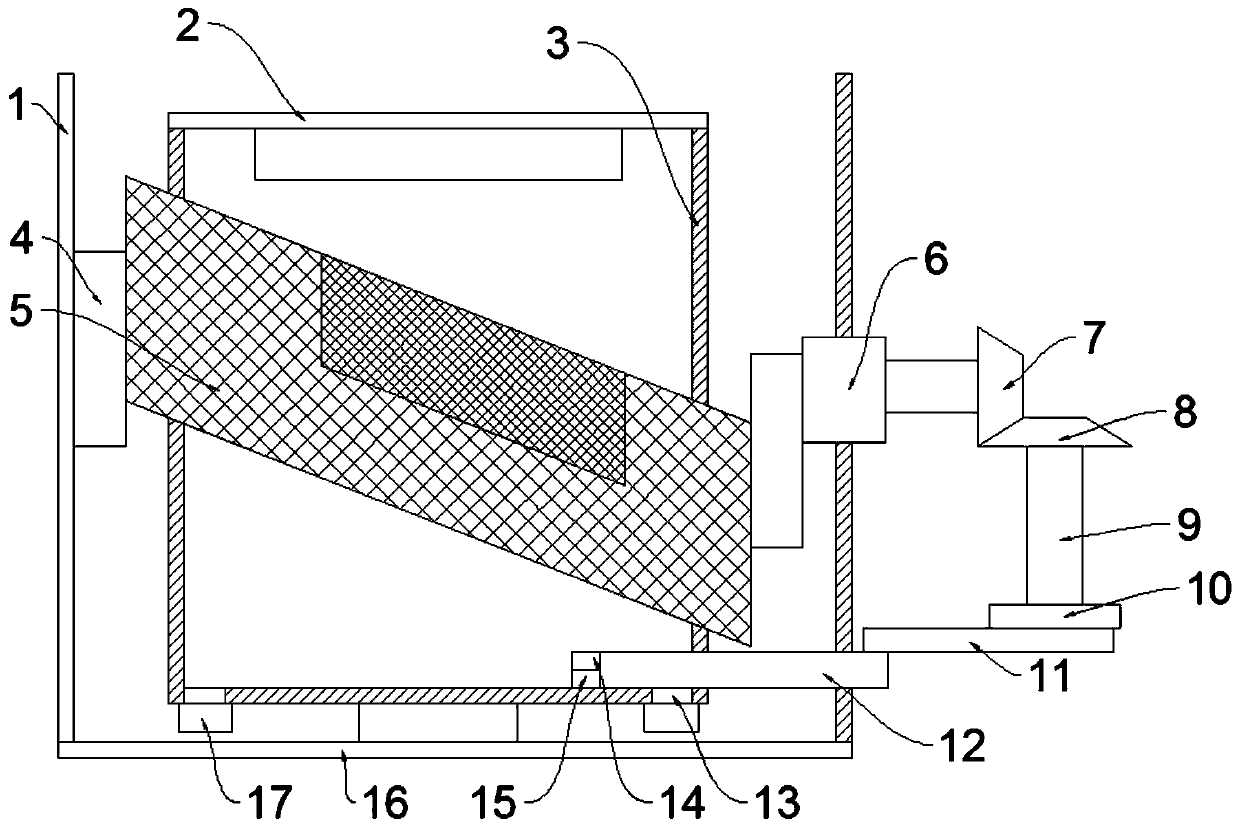

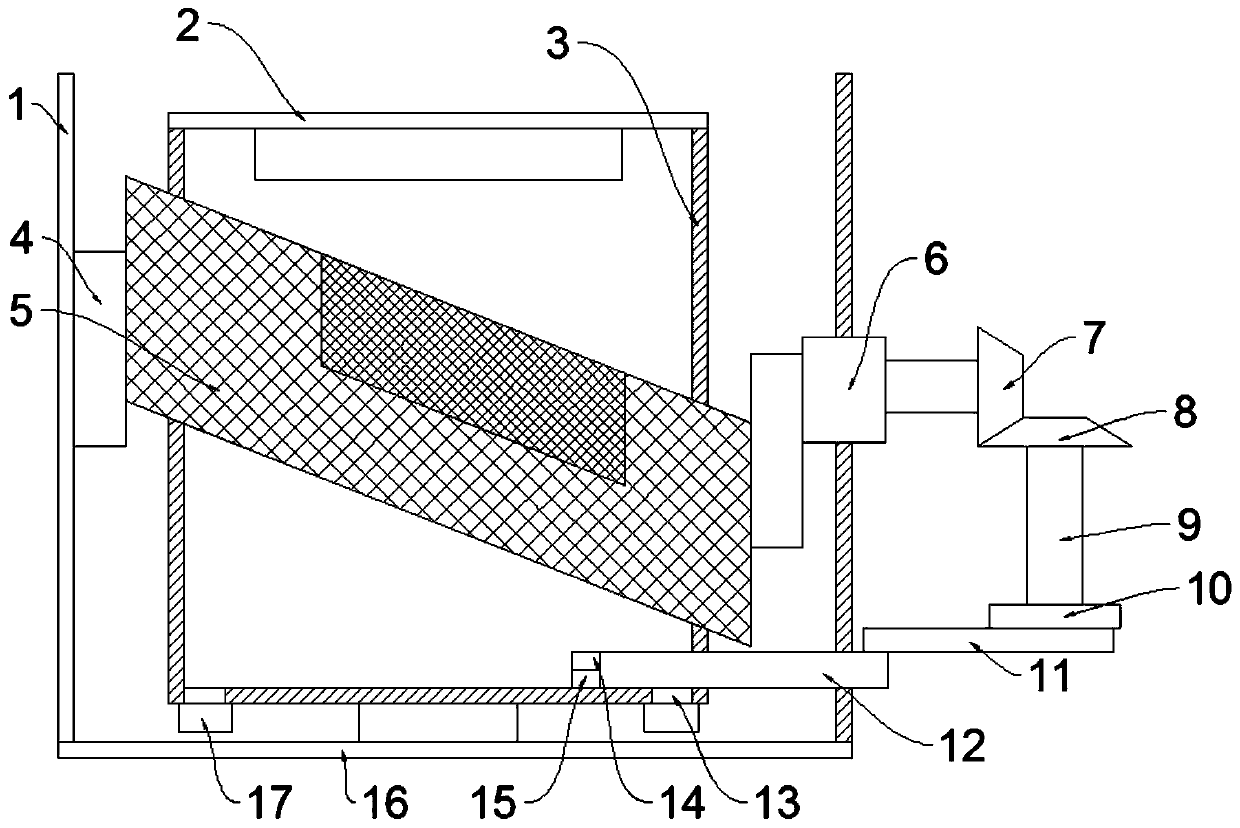

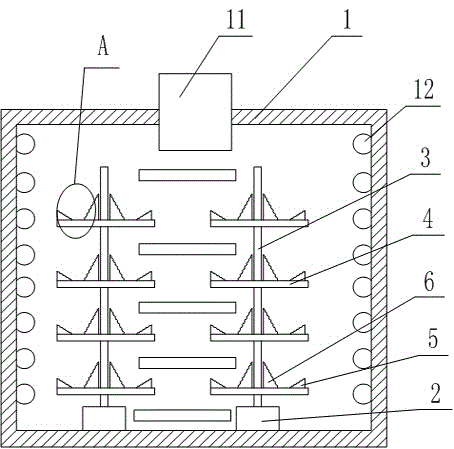

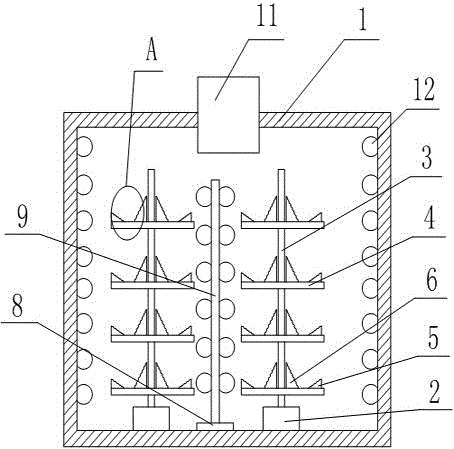

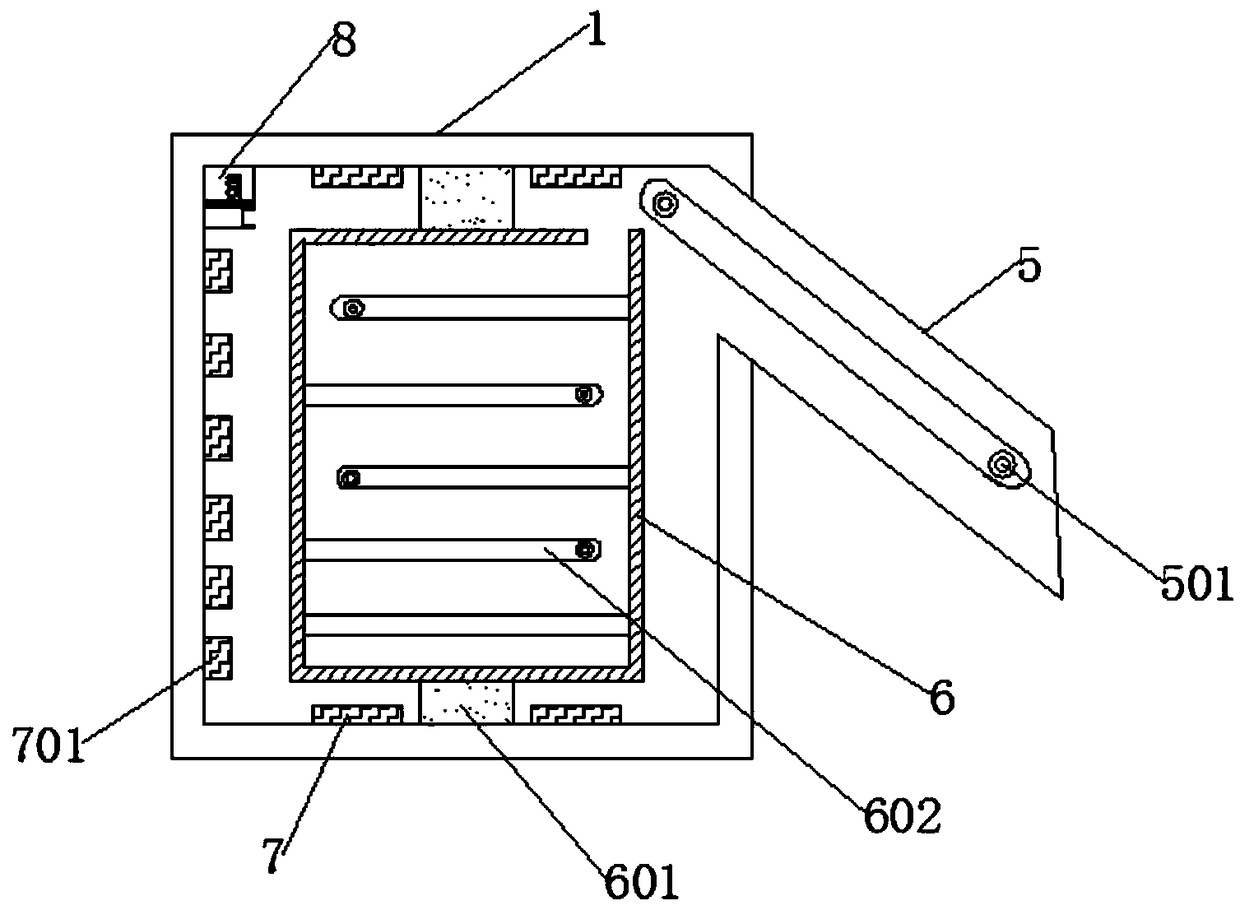

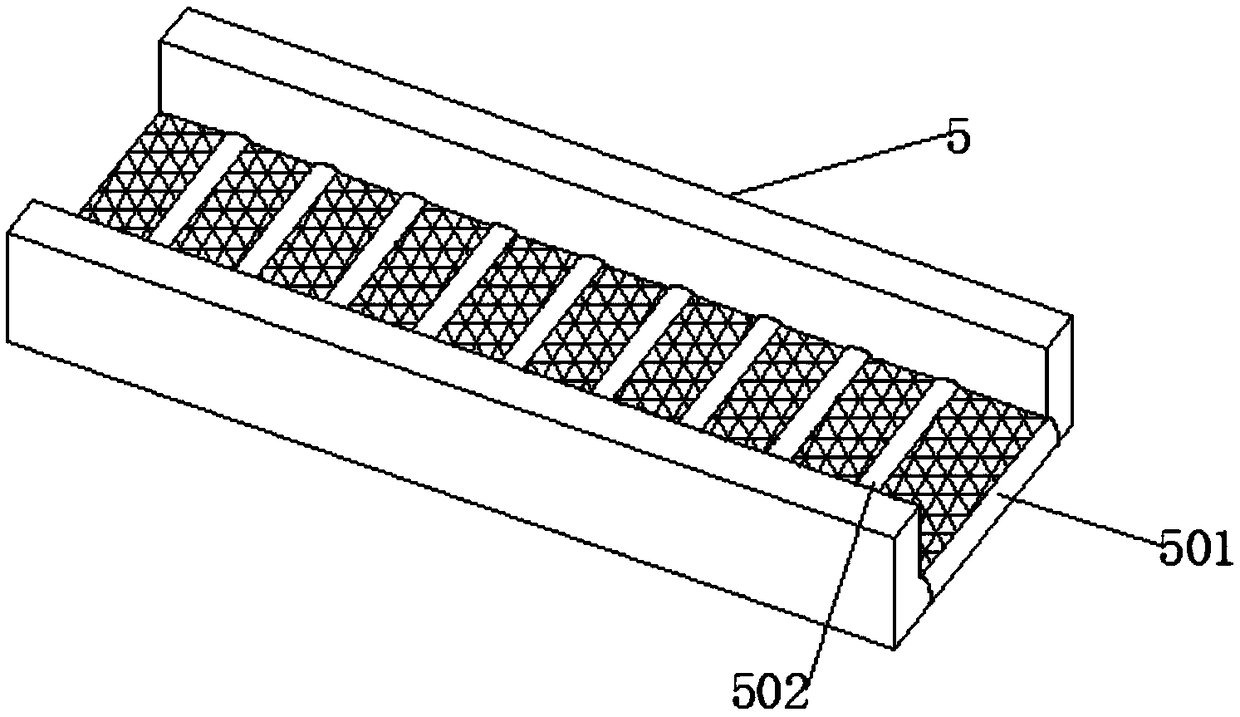

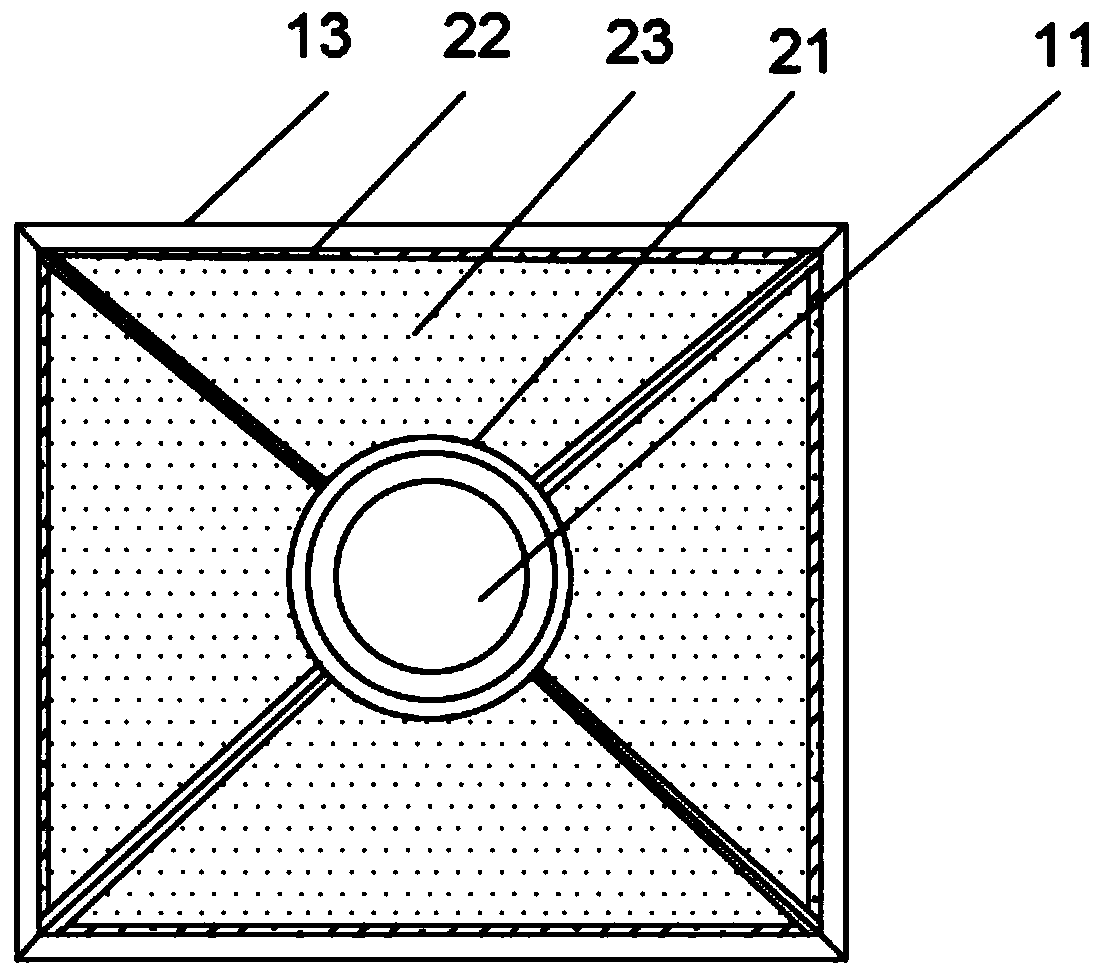

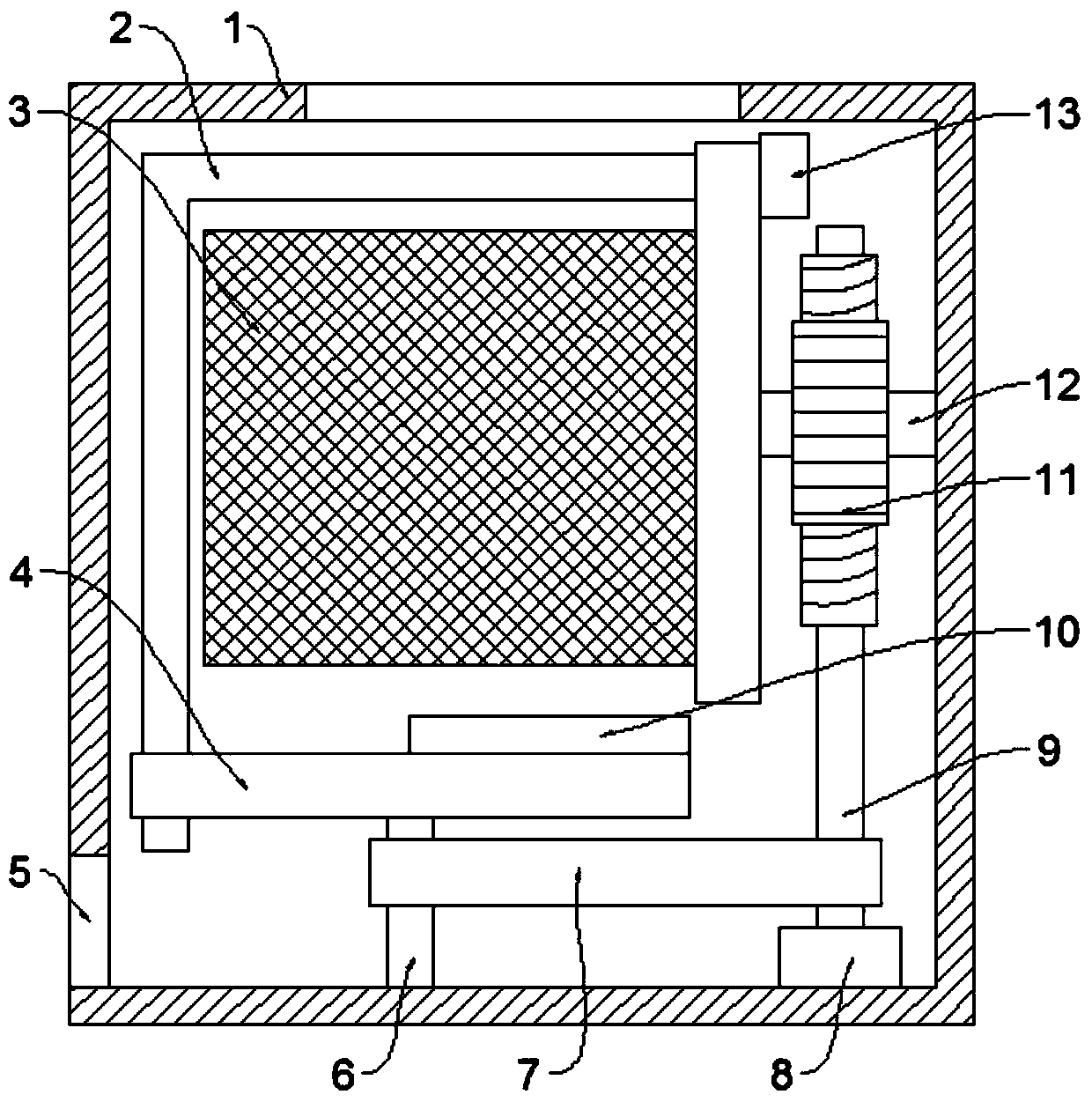

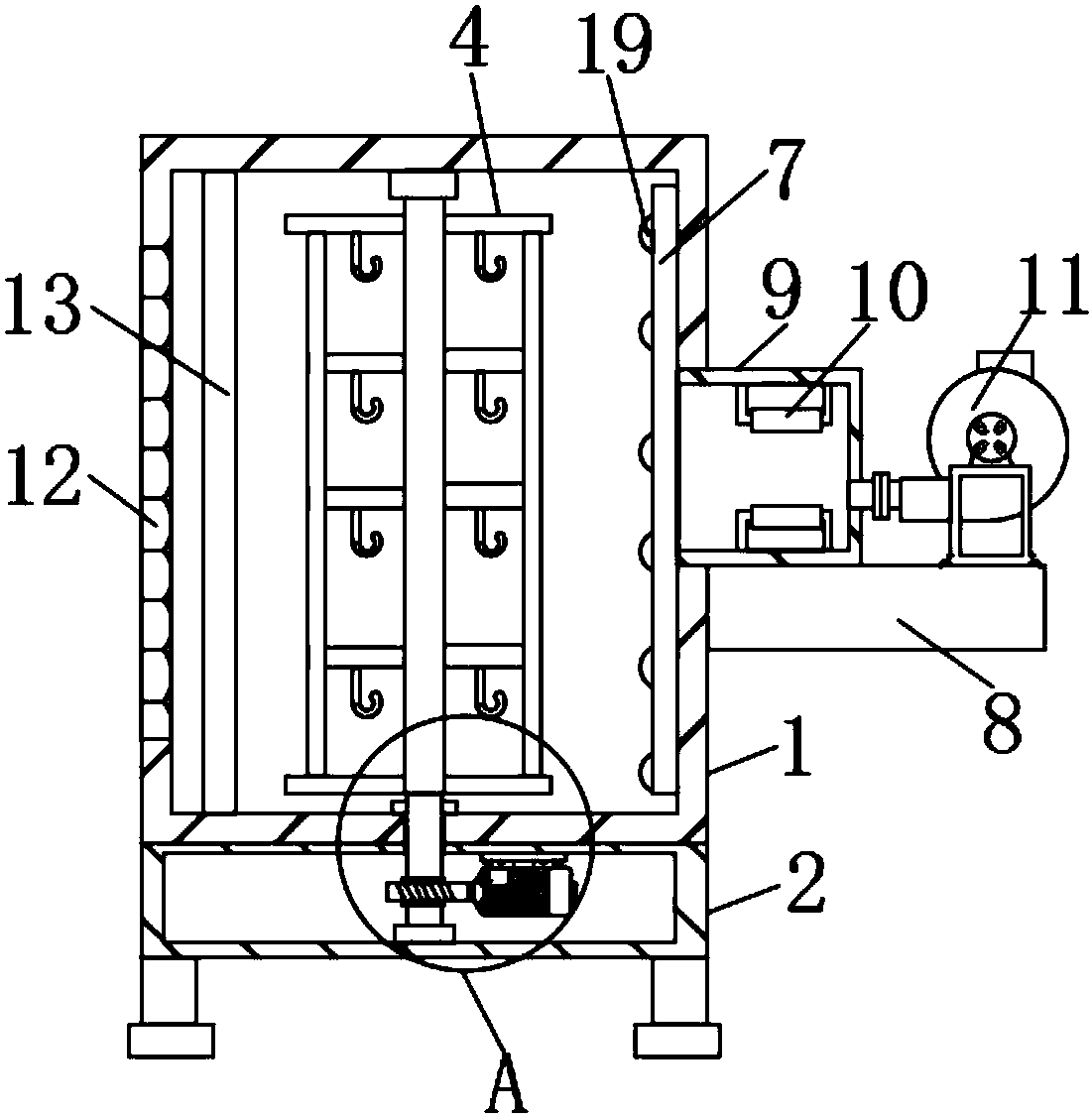

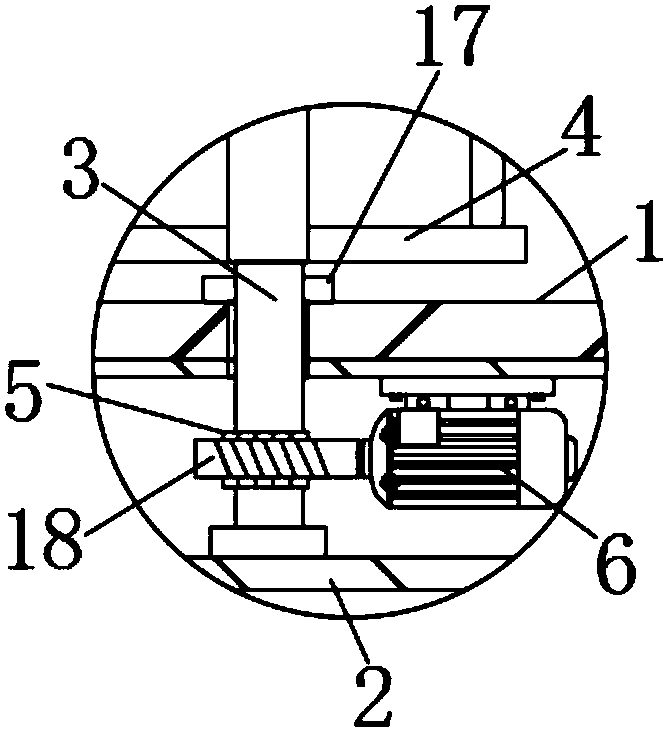

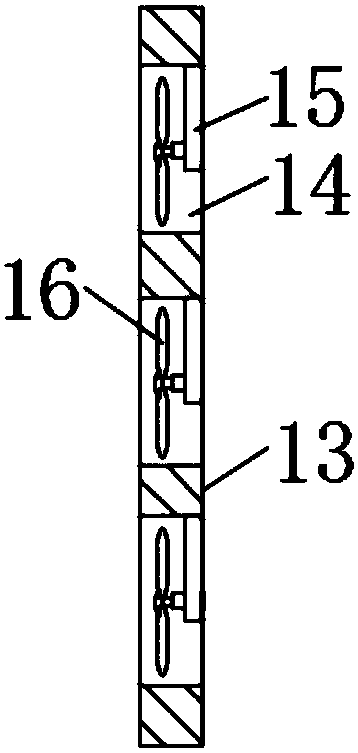

Drying device for medicinal materials

ActiveCN107490259AImprove drying efficiencySolve the problem of uneven dryingDrying gas arrangementsDrying chambers/containersCouplingEngineering

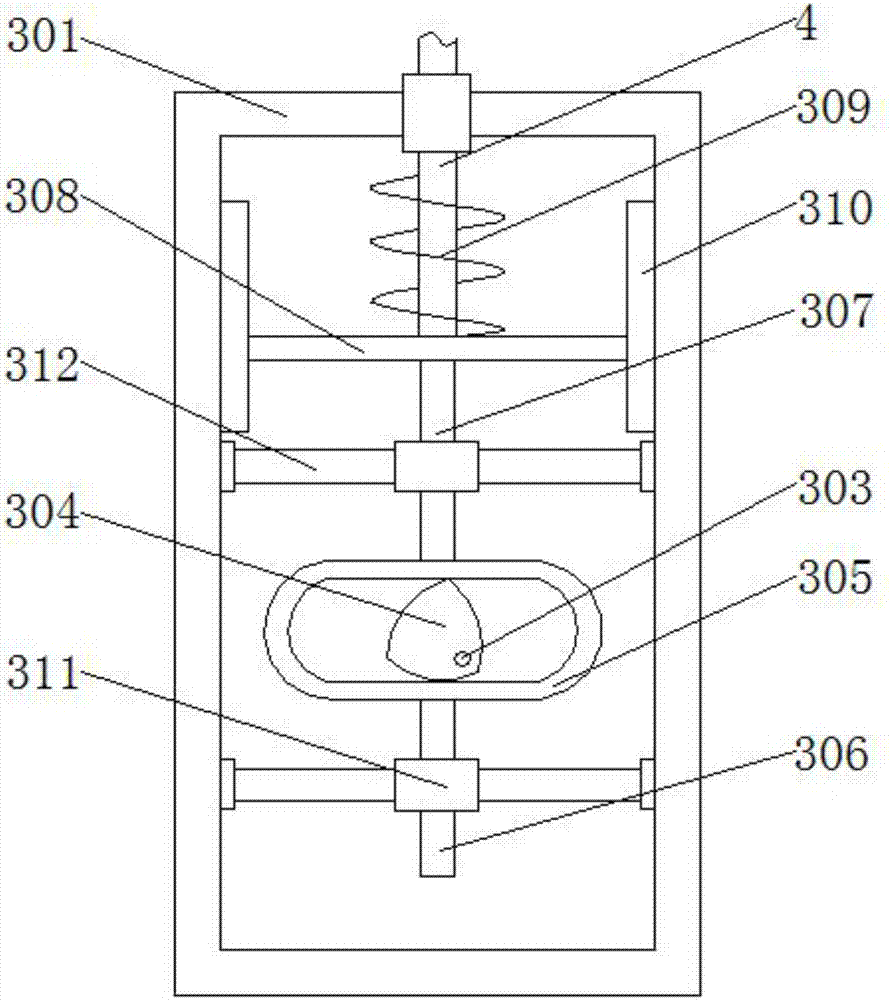

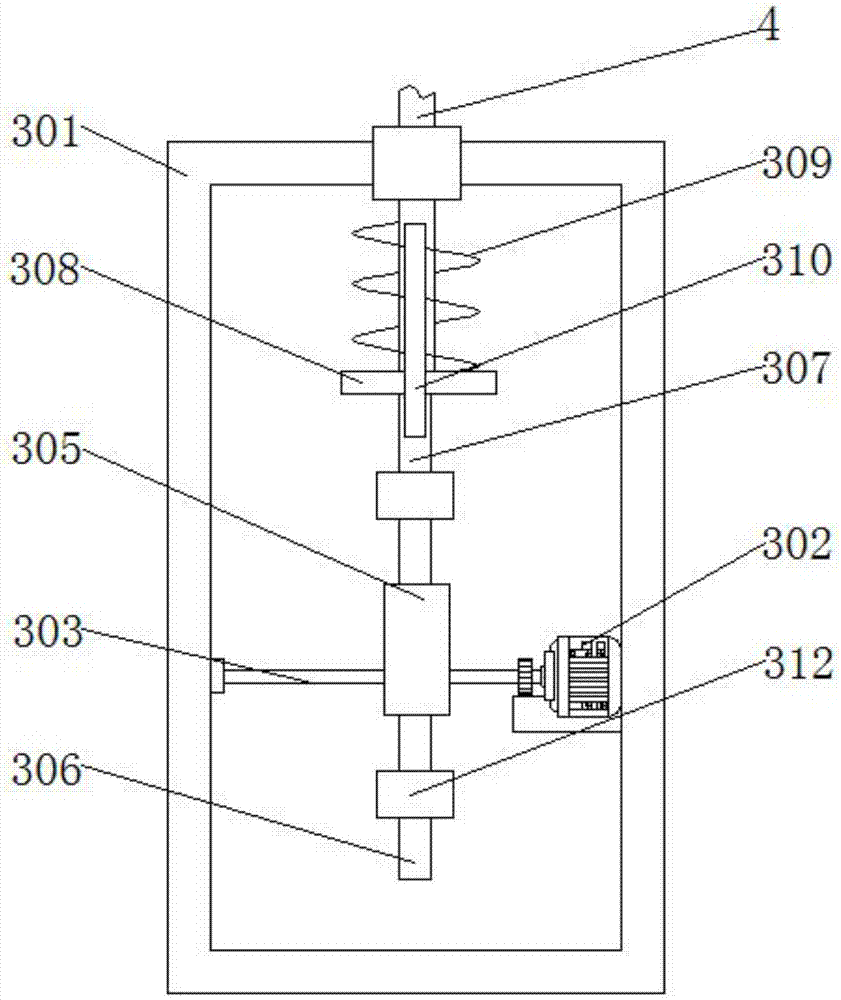

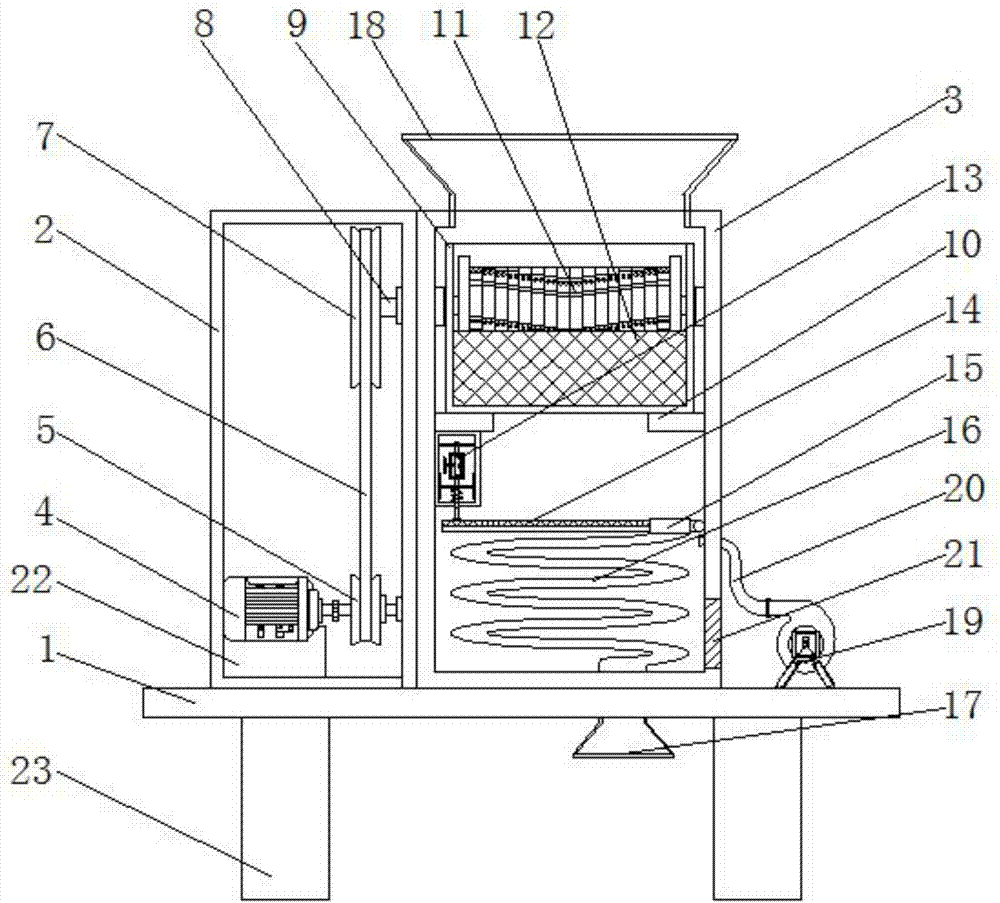

The invention discloses a drying device for medicinal materials and relates to the technical field of mechanical equipment. The drying device comprises a base; a box body is fixedly connected to the top of the base; the left side of the bottom of an inner cavity of the box body is fixedly connected with a transmission device; a supporting rod penetrates through the top of the transmission device; the top end of the supporting rod is rotatably connected with a vibrating plate, and the right side of the bottom of the vibrating plate is rotatably connected with a connecting rod; the bottom end of the connecting rod is rotatably connected with a limiting rod; the right side of the box body is fixedly connected with a limiting plate; the bottom end of the limiting rod penetrates through the limiting plate and extends to the bottom of the limiting plate; the top of the vibrating plate is provided with a heating plate, and the right side of an inner cavity of an outer shell is fixedly connected with a motor; and an output shaft of the motor is fixedly connected with a rotating shaft through a coupler. According to the drying device for the medicinal materials, the problem of uneven drying of a traditional medicinal material drying device is solved, the drying efficiency of the drying device is improved, the work efficiency of workers is improved, and the use effect of users is met.

Owner:HEFEI PUZHONG ELECTROMECHANICAL CO LTD

Grass drying, stem and leaf separating device

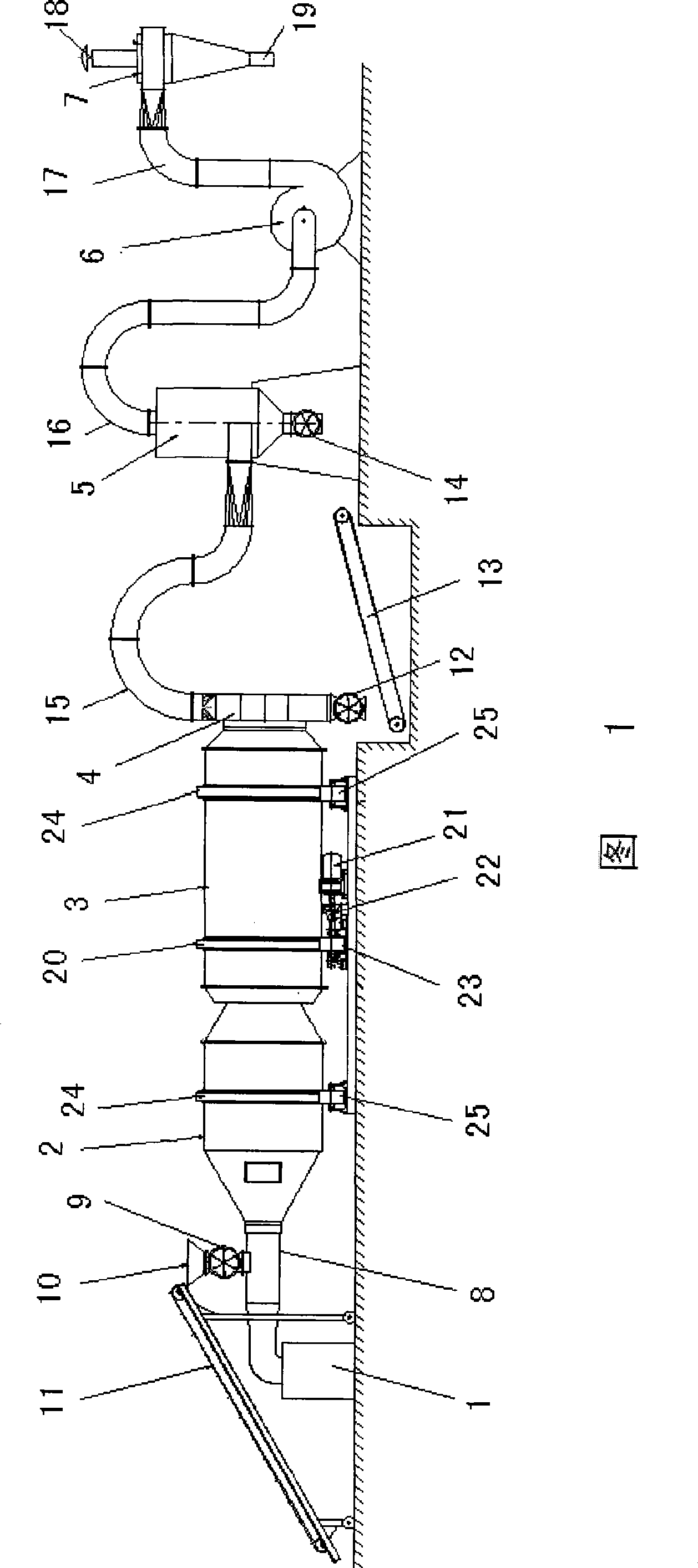

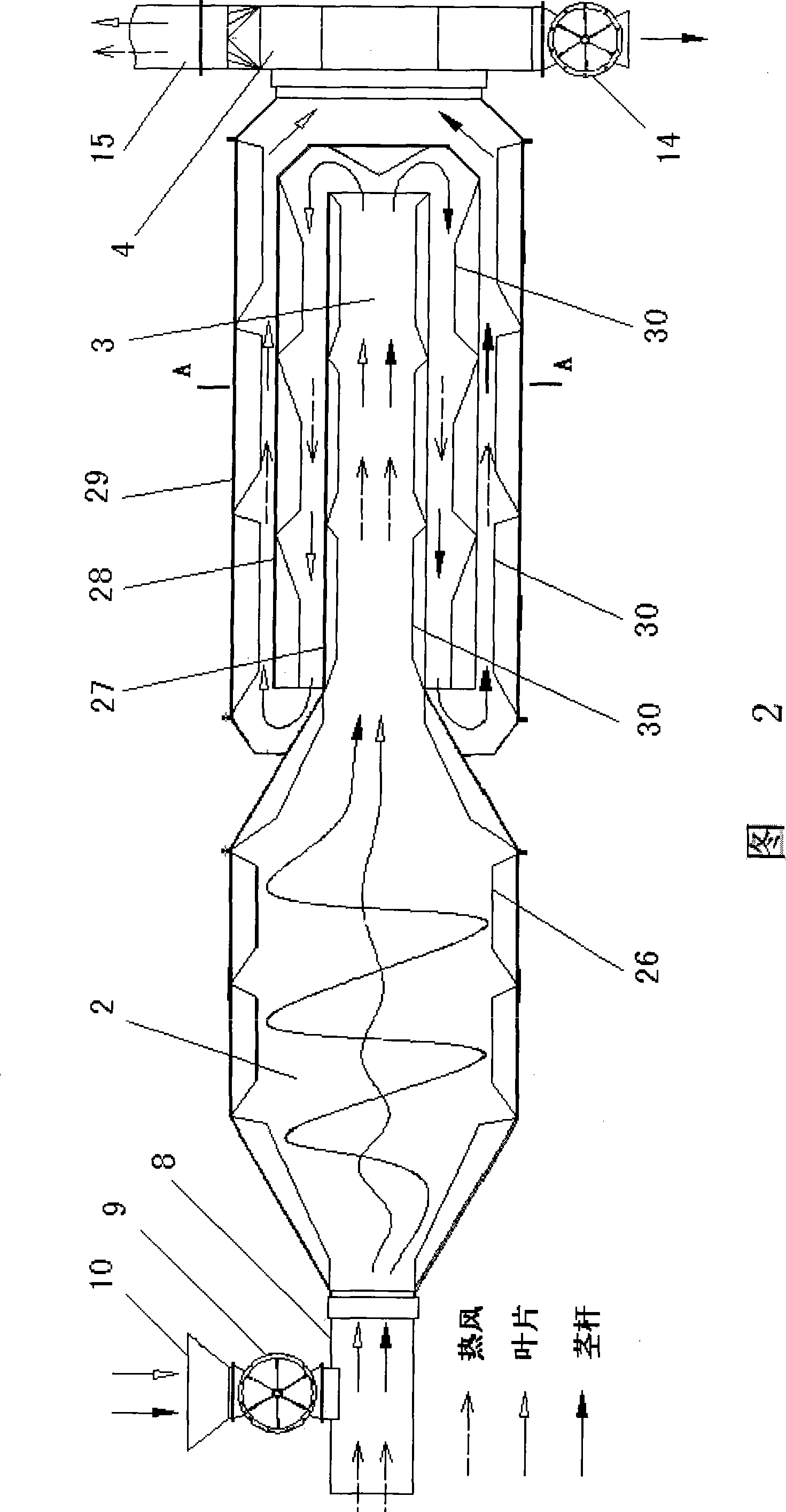

The invention relates to herbage drying and stem-leaf separating device, characterized in that: the device comprises a hot-blast stove, a pre-heating drying roller, a three-pass drying roller, a separating and discharging tank, a cyclone separator, a blower and a dust remover; the hot-blast stove is connected with the pre-heating drying roller through a warm-air pipe provided with a feeding hopper connected with a feeding airlock; the pre-heating drying roller is integrally fixed and connected with the three-pass drying roller rotationally connected with the separating and discharging tank and rotated through the driving of a moter; the lower end of the separating and discharging tank is provided with a discharging airlock, and the upper end is connected with the cyclone separator through a pipeline; the lower end of the cyclone separator is provided with a discharging airlock, and the upper end is connected with the blower through a pipeline; the outlet of the blower is connected with the dust remover with the outlet communicated with atmosphere. The invention decreases unnecessary energy consumption and lowers processing cost.

Owner:CHINA AGRI UNIV

Crushing and drying device for chemical industry raw materials

InactiveCN107270680ASolve the problem of uneven dryingImprove work efficiencyDrying gas arrangementsDrying solid materialsChemical industryPulley

The invention discloses a crushing and drying device for raw materials in the chemical industry, which comprises a base. The top of the base is fixedly connected with a motor box and a crushing box in turn from left to right. The left side of the inner cavity bottom of the motor box is fixedly connected with a first motor. The surface of the output shaft of the first motor is covered with a first pulley, and the surface of the first pulley is connected with a second pulley through a belt transmission. The shaft center on the right side of the second pulley is fixedly connected with a rotating shaft. The right side runs through the right side of the motor box and the left side of the crushing box in turn and is rotationally connected with the right side of the inner chamber of the crushing box. The surface of the rotating shaft located inside the crushing box is covered with a crushing shell, which relates to the field of industrial technology. The crushing and drying device for raw materials in the chemical industry solves the problem of uneven drying in the traditional crushing and drying device for raw materials in the chemical industry, improves the drying effect, improves the work efficiency of the staff, and satisfies the user's use effect .

Owner:HEFEI CHAOYING IND DESIGN CO LTD

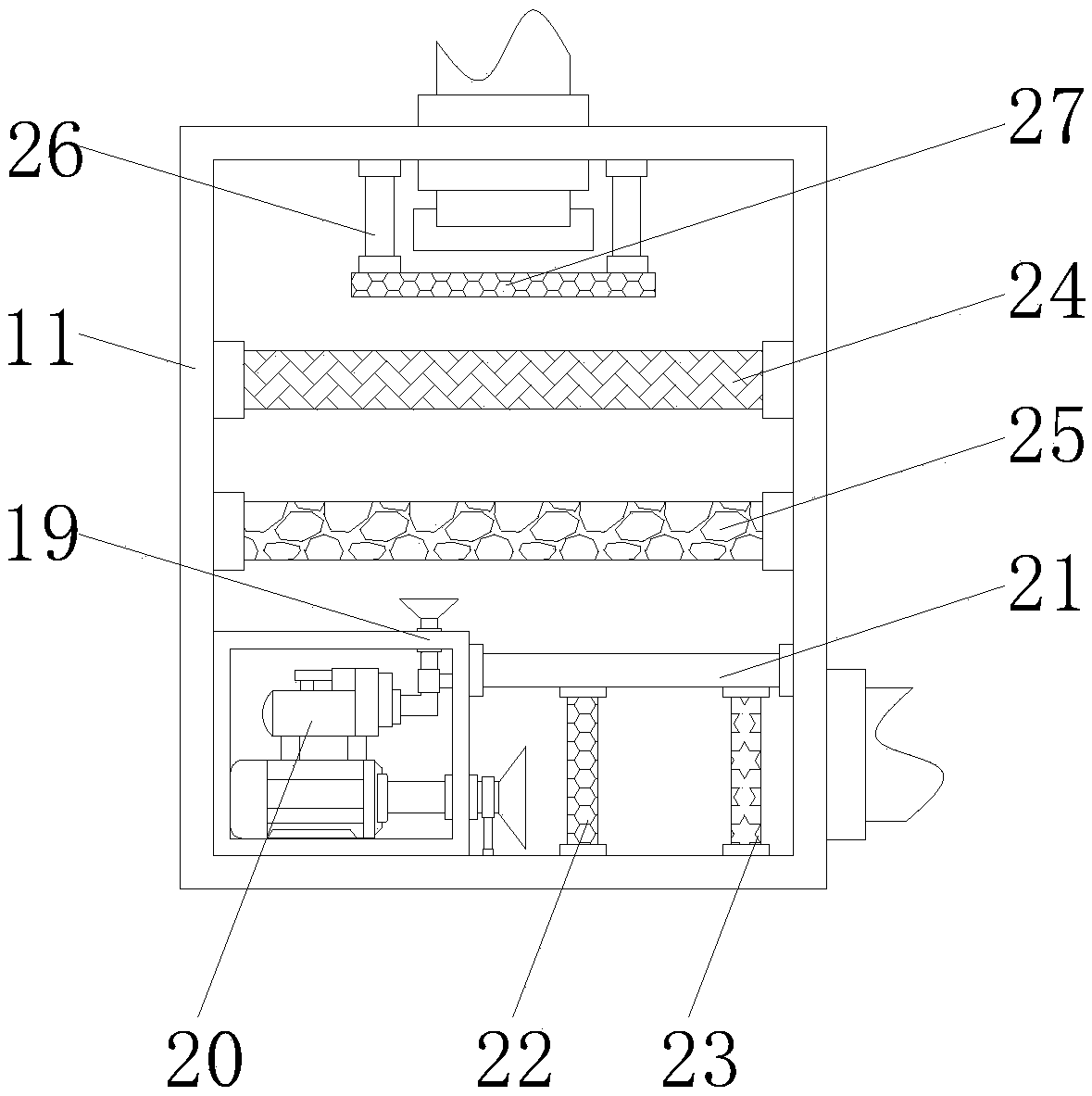

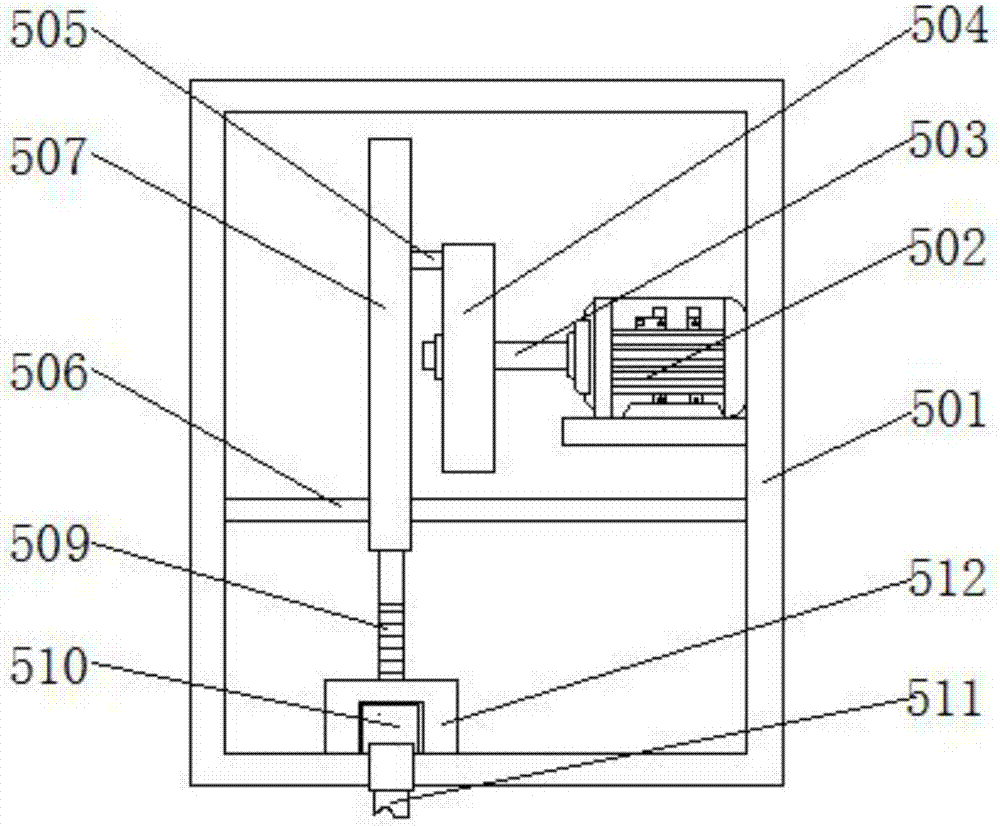

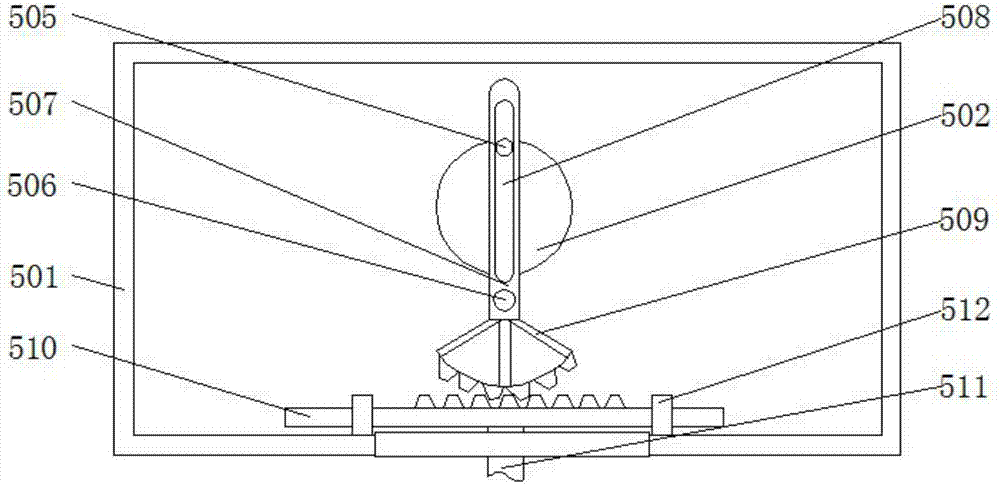

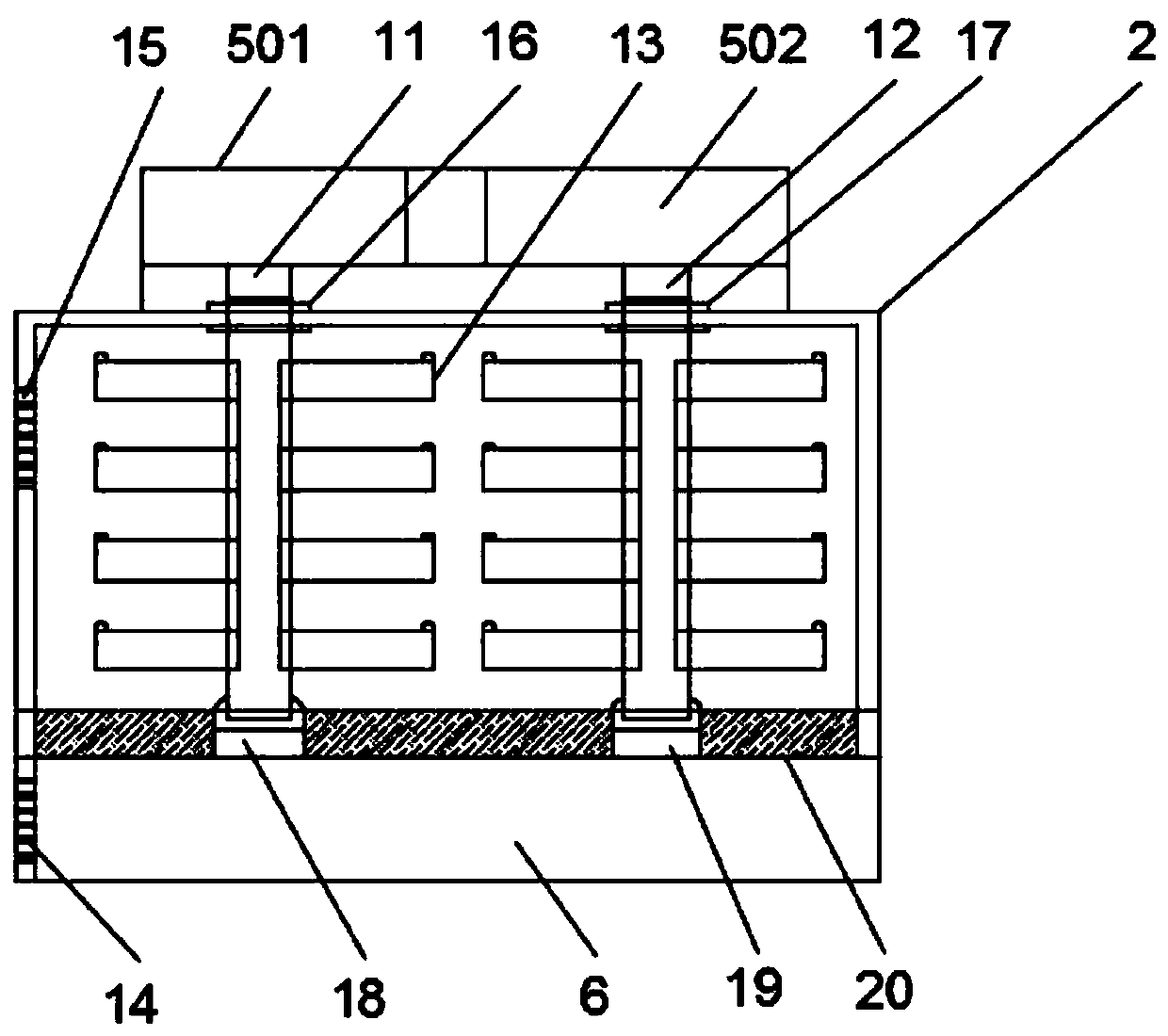

Polar plate drying device for lithium battery production

ActiveCN107342390ASolve the problem of uneven dryingImprove drying effectElectrode thermal treatmentSecondary cellsEngineeringAir blower

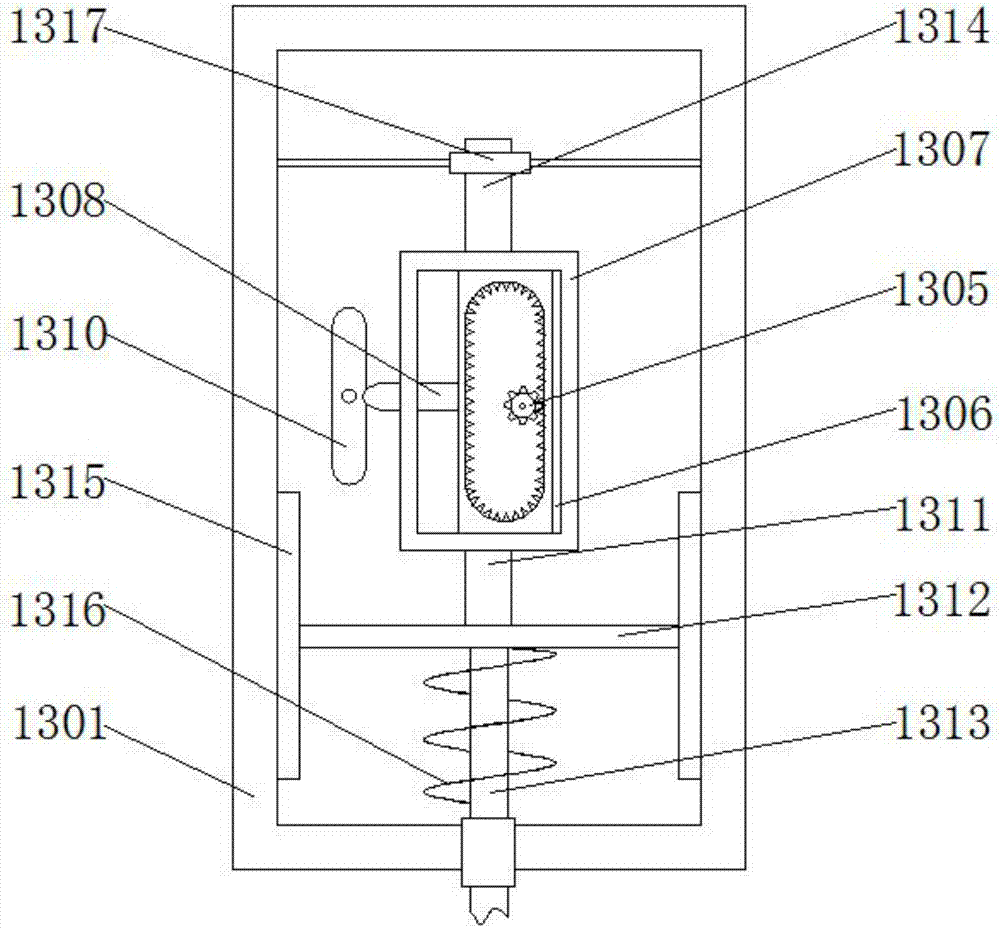

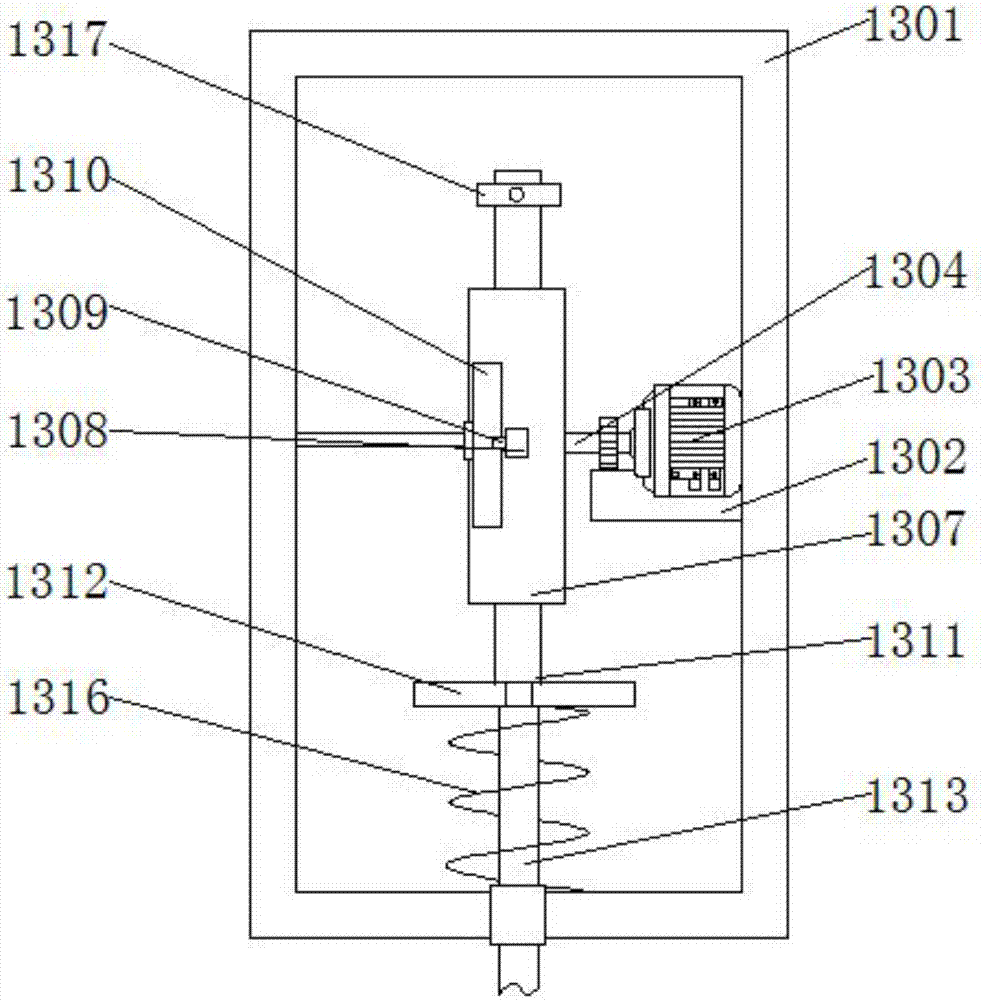

The invention discloses a polar plate drying device for lithium battery production. The polar plate drying device comprises a base, wherein a box body is fixedly connected with the top of the base; a transmission box is fixedly connected with the top of the box body; a motor is fixedly connected with the top of the inner cavity of the transmission box; a gear is sleeved on the output shaft of the motor; a transmission device is in transmission connection with the gear; a bracket is fixedly connected with the bottom of the transmission device; the bottom of the bracket penetrates the bottom of the transmission box and the top of the box body from top to bottom and stretches into the box body; a heater is fixedly connected with the bottom of the bracket; a support plate is fixedly connected with the right side of the box body; and an air blower is fixedly connected with the top of the support plate. The polar plate drying device relates to the technical field of lithium batteries. According to the polar plate drying device for lithium battery production, the problem that a traditional polar plate drying device for lithium battery production is non-uniform is solved, the polar plate drying effect is improved, the working efficiency of a worker is improved, and a use effect of a user is satisfied.

Owner:大庆宇奥科技有限公司

Drying device for computer accessory manufacturing

InactiveCN107218773ASolve the problem of uneven dryingImprove drying effectDrying gas arrangementsPretreated surfacesAir blowerComputer engineering

The invention discloses a drying device for computer accessory manufacturing. The drying device comprises a base. The top of the base is fixedly connected with a box body. The top of the box body is fixedly connected with a transmission device. A support penetrates the bottom of the transmission device, and the bottom of the support penetrates the top of the box body and extends into the box body. A heater is fixedly connected to the bottom of the support. A supporting plate is fixedly connected to the right side of the box body, and the top of the supporting plate is fixedly connected with an air blower. An air inlet of the air blower communicates with an air conveying hose, and the left end of the air conveying hose penetrates the right side of the box body and communicates with an air inlet of the heater. The invention relates to the technical field of computers. According to the drying device for computer accessory manufacturing, the problem that a traditional drying device for computer accessory manufacturing is not uniform in drying when drying damp accessories or accessories with paint spraying just finished is solved; the drying effect on pole plates is improved; the working efficiency of workers is improved; and the use effect of a user is met.

Owner:合肥北顾信息科技有限公司

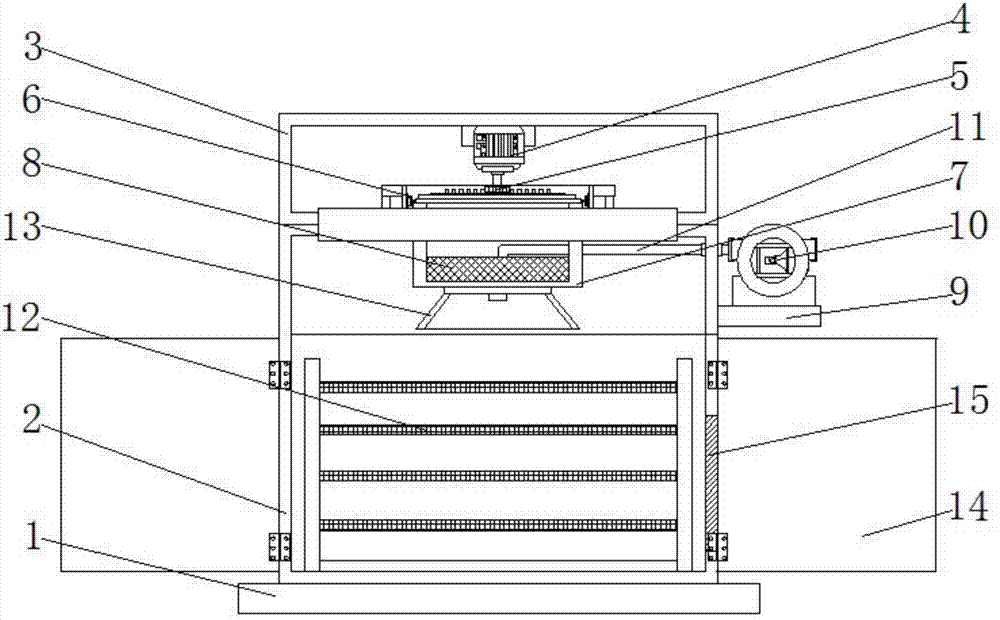

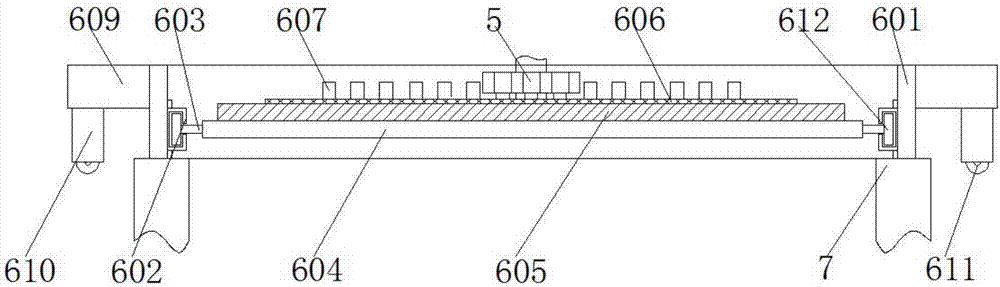

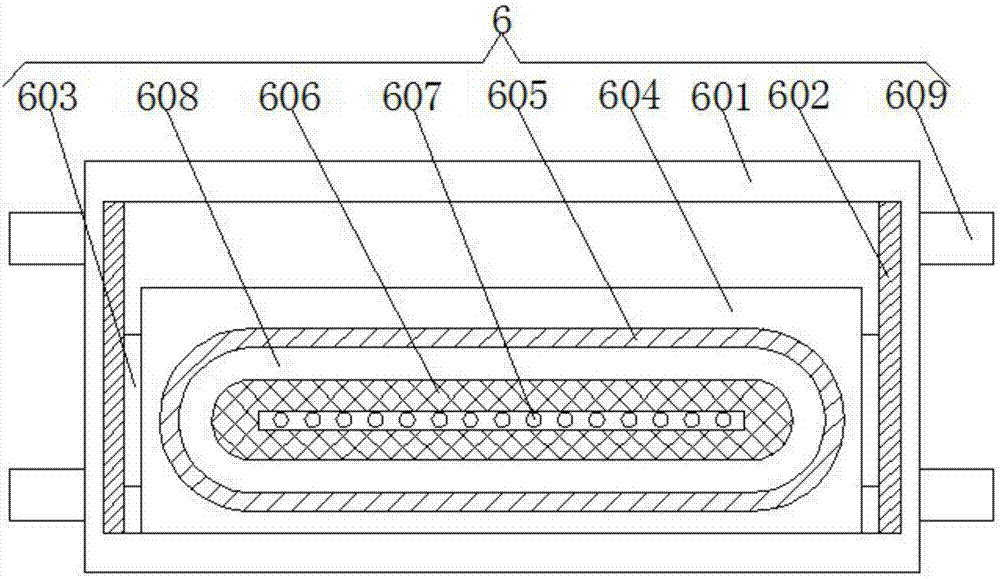

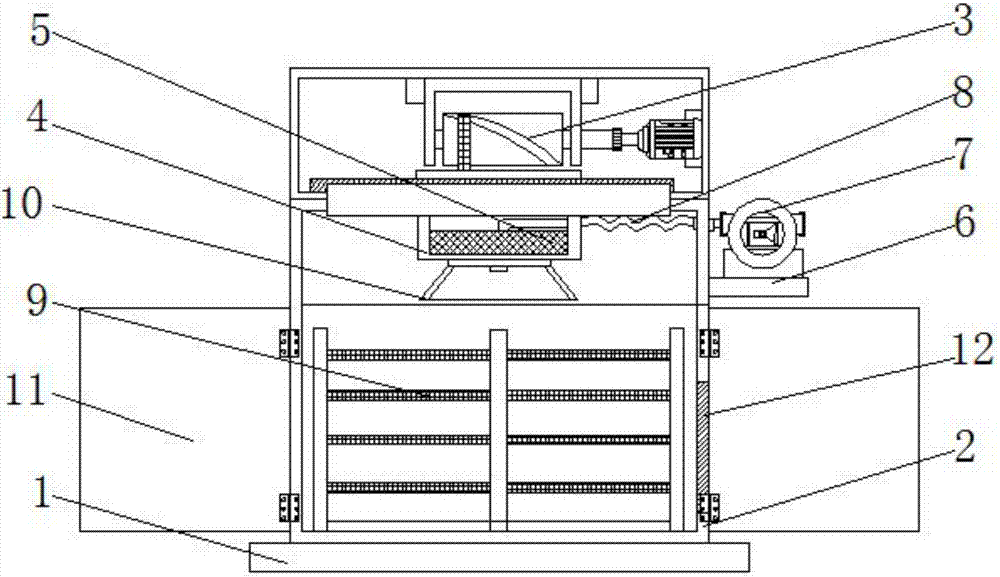

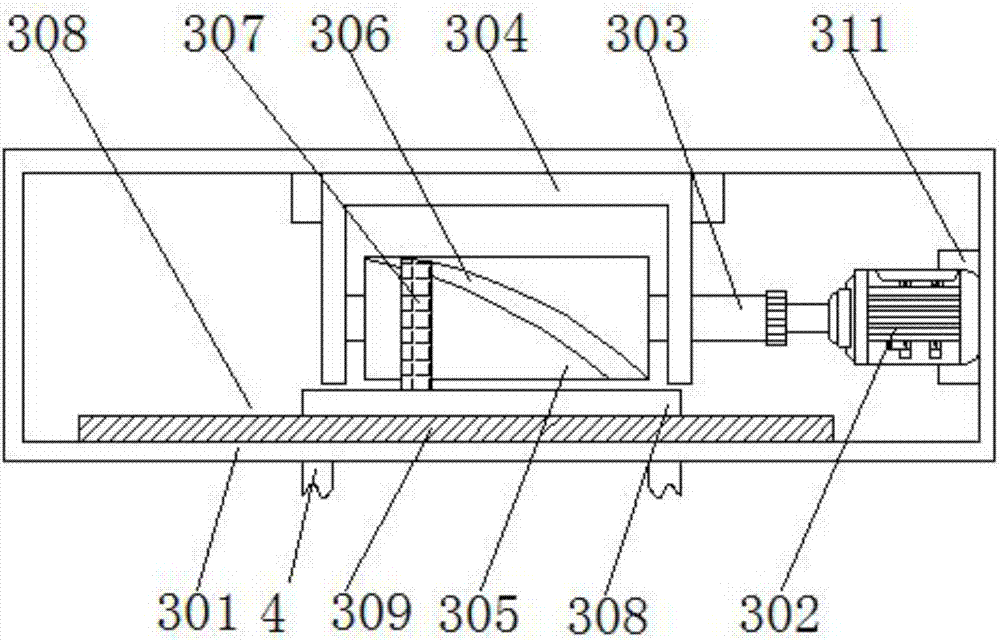

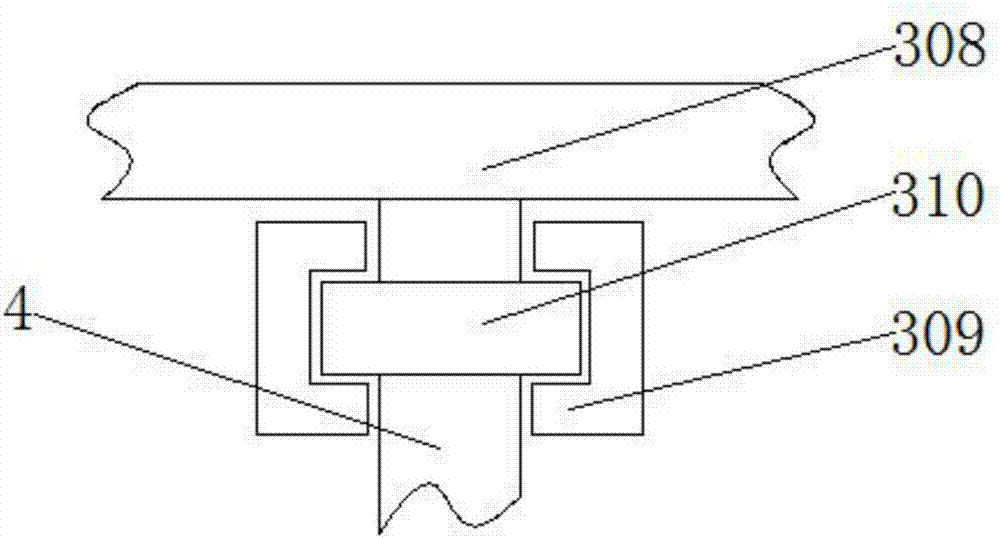

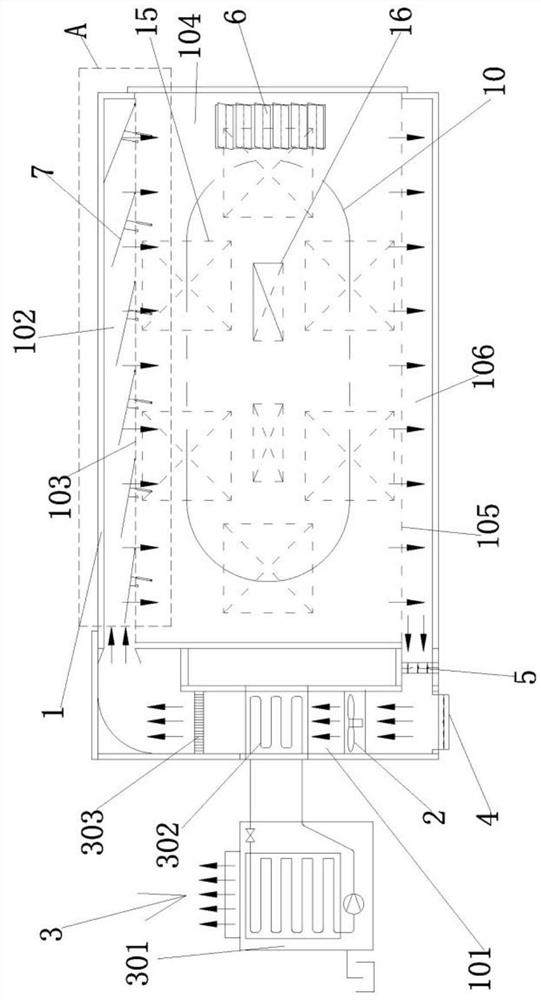

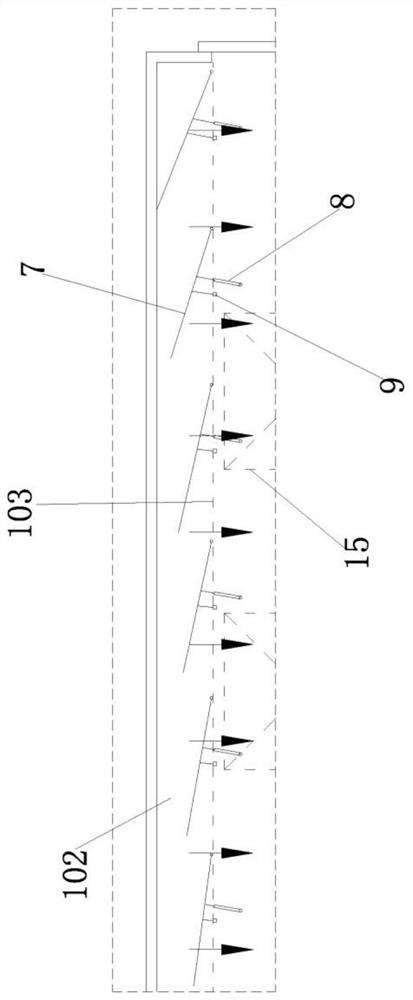

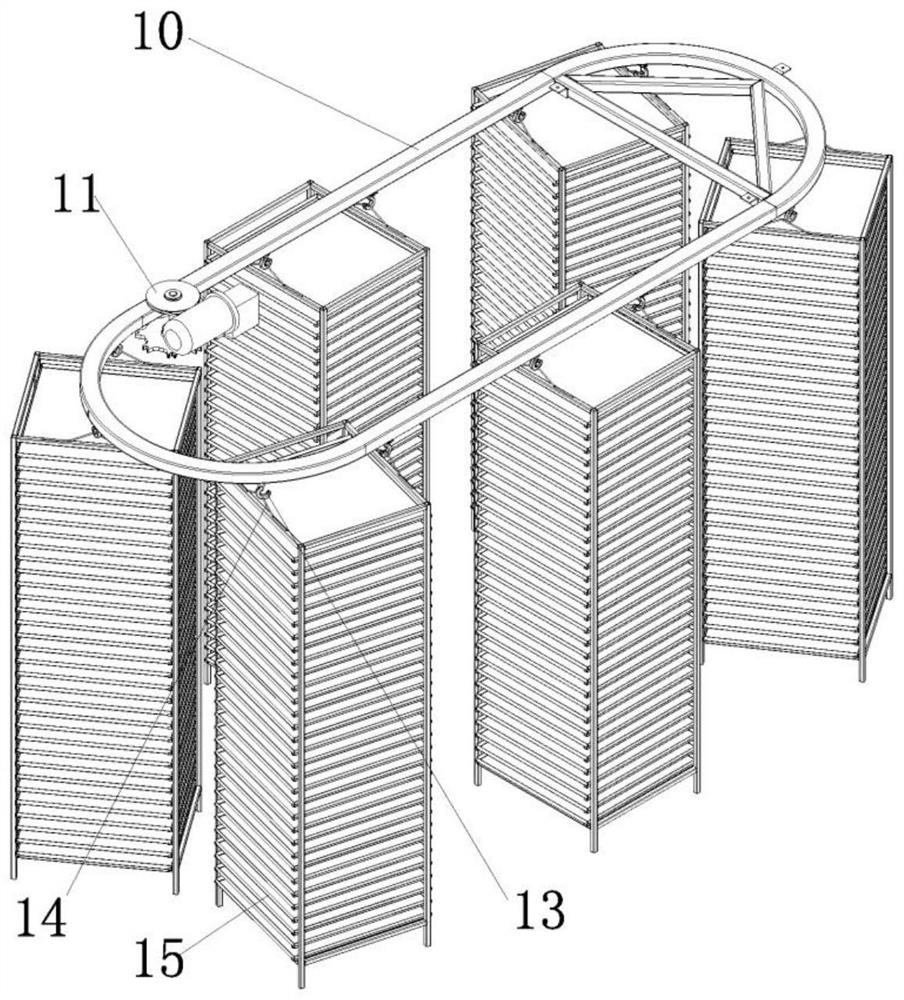

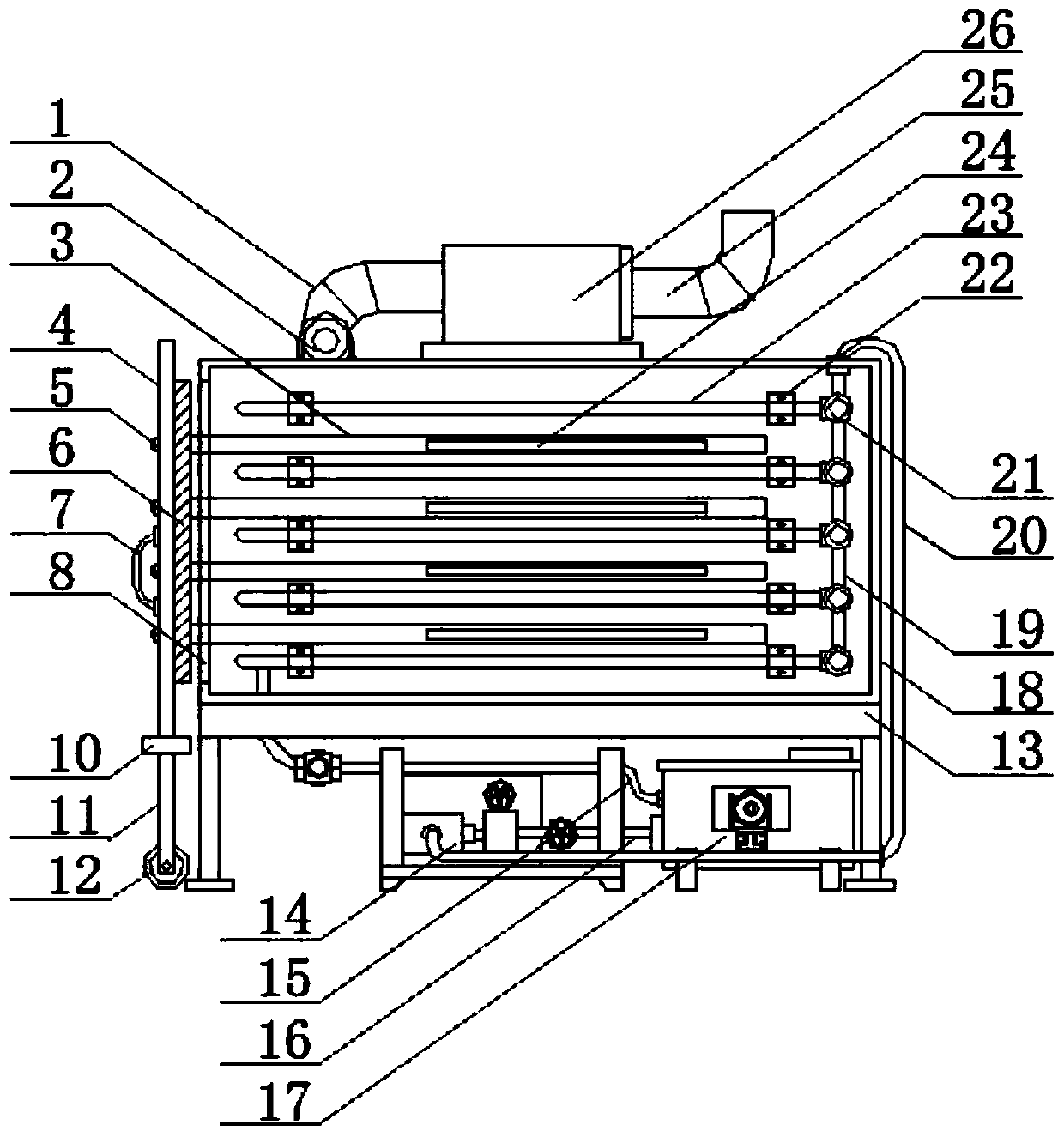

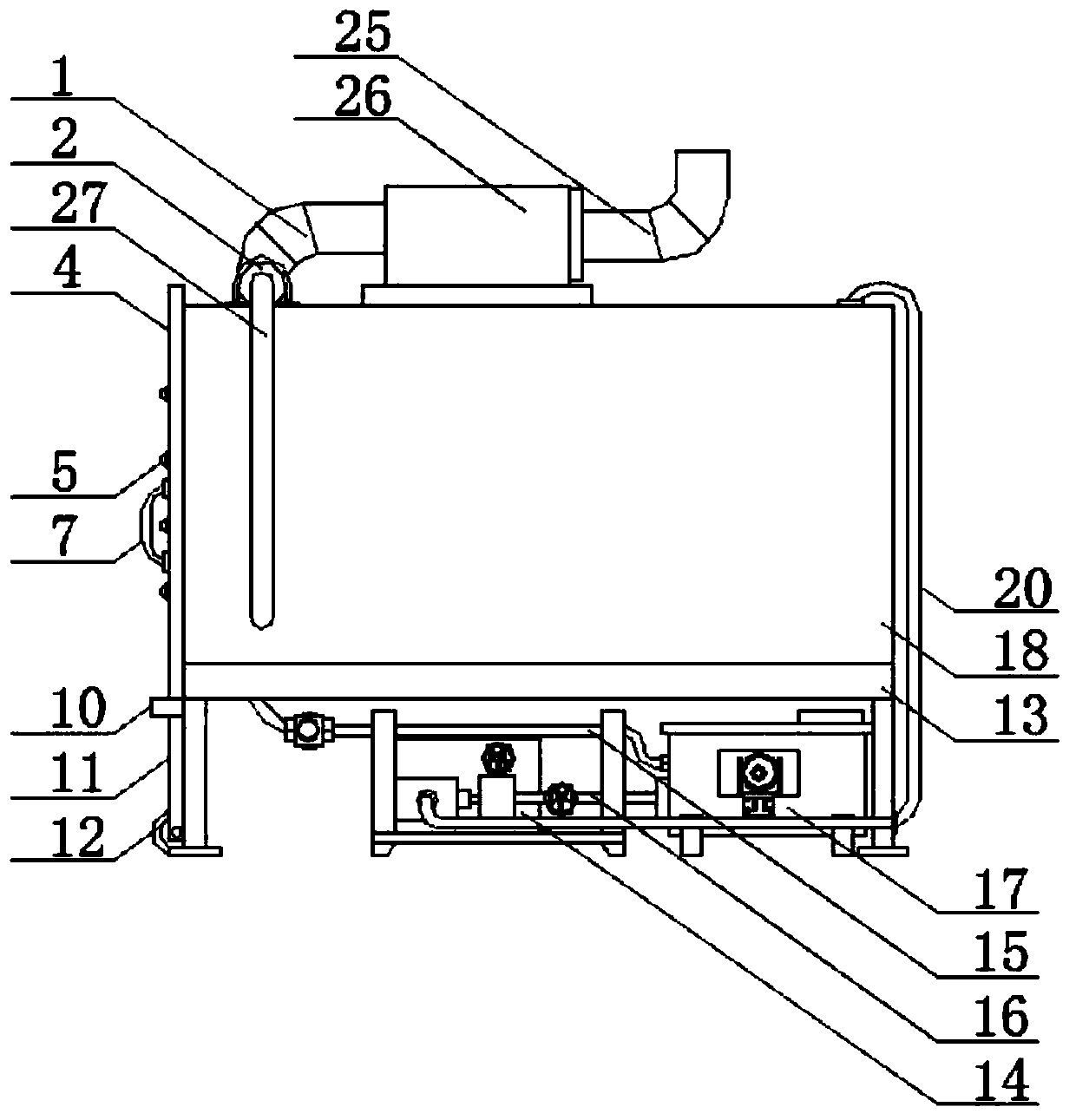

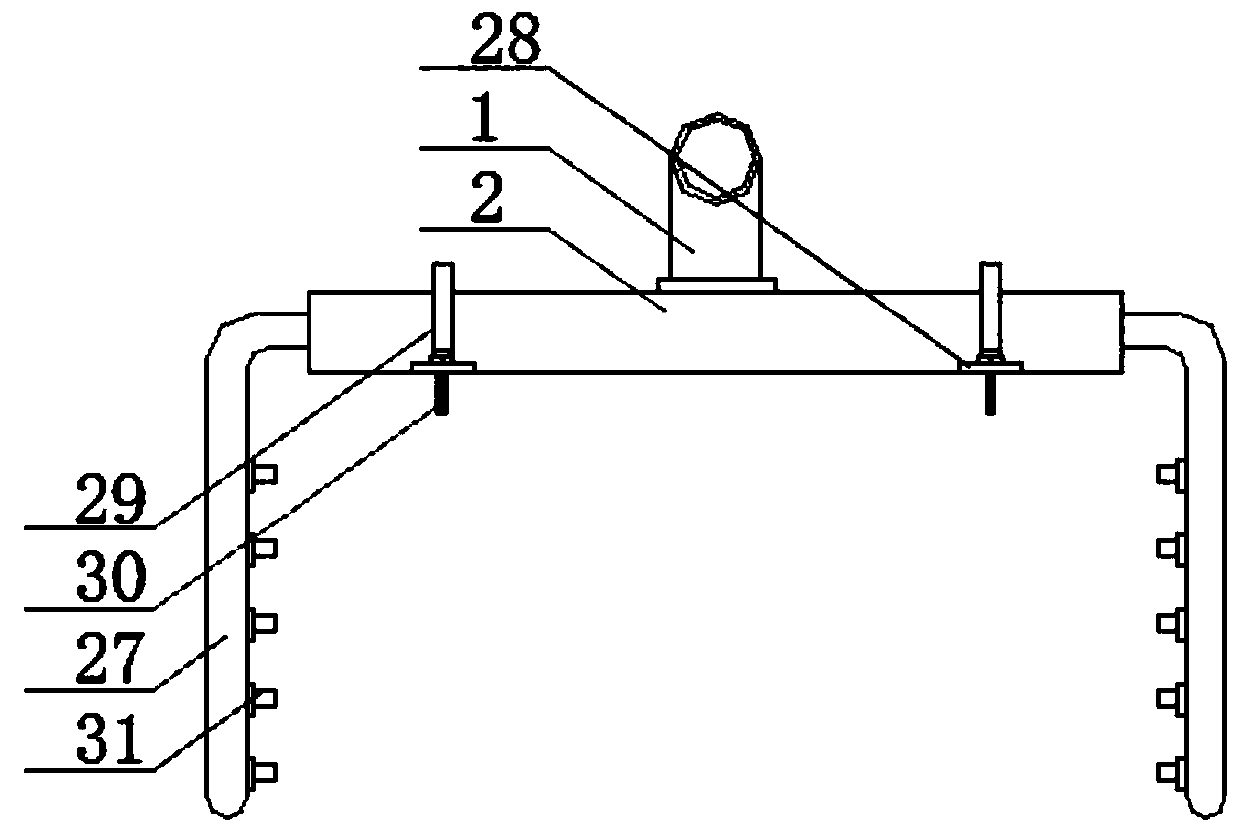

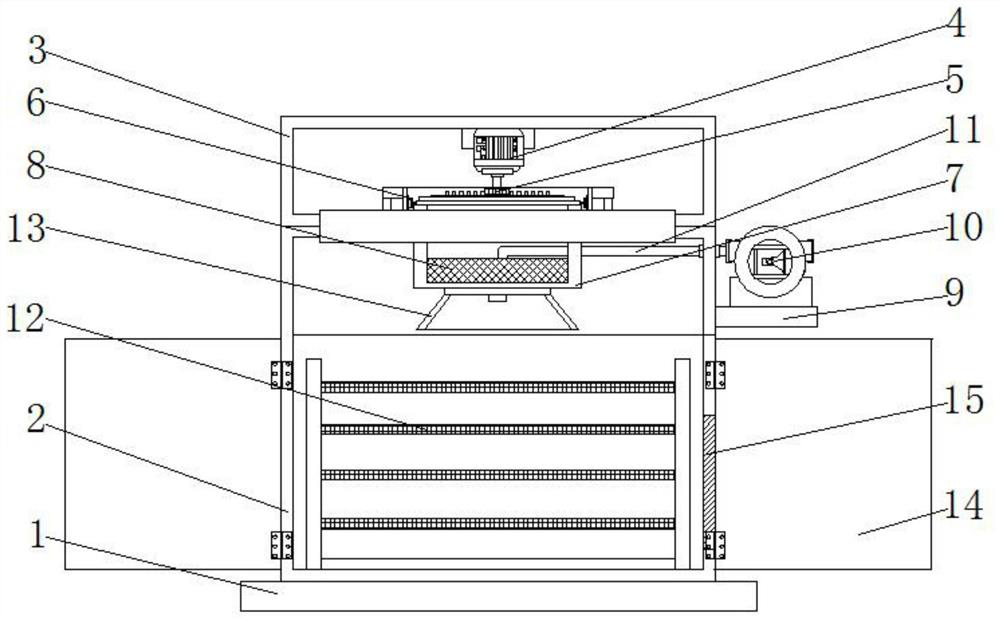

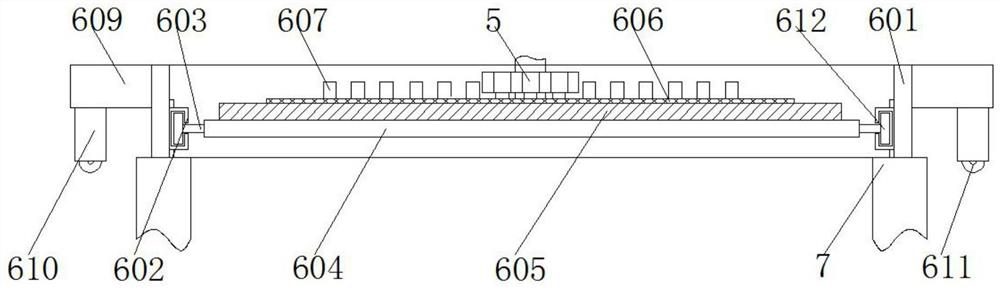

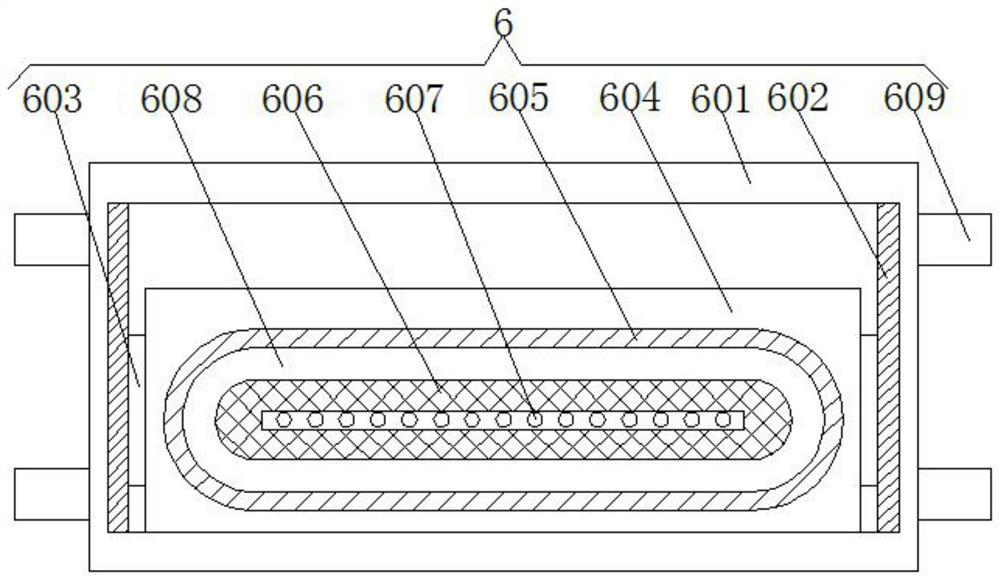

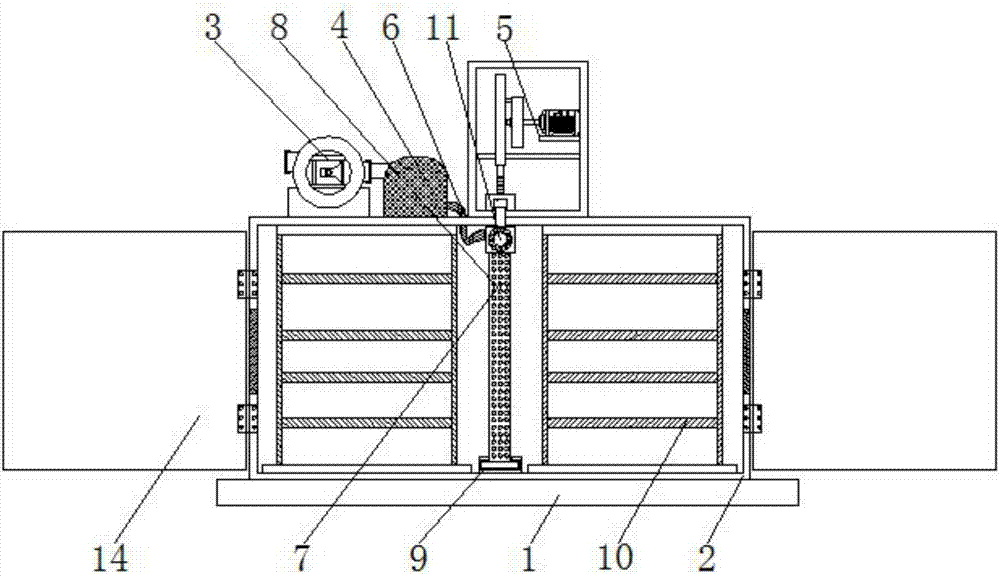

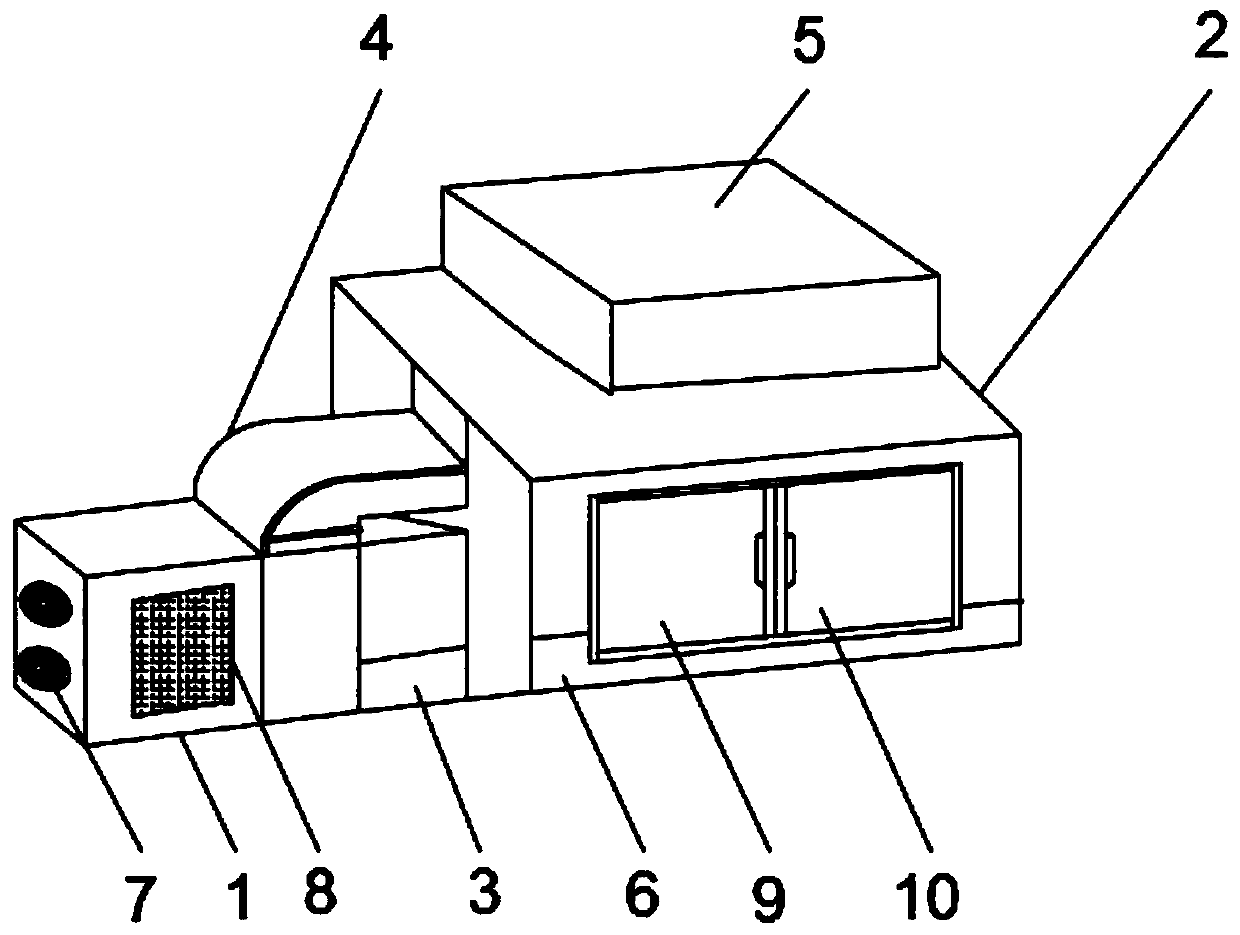

Tray frame fixed rail moving dryer based on side ventilation structure

PendingCN111780534AEvenly distributedSolve the problem of uneven dryingDrying gas arrangementsDrying chambers/containersAgricultural engineeringStructural engineering

The invention relates to a tray frame fixed rail moving dryer based on a side ventilation structure in the technical field of agricultural product drying. A fan chamber, an air inlet chamber, a dryingchamber and an air return chamber communicate according to a circulating airflow sequence; an intake air side punching plate is arranged between the air inlet chamber and the drying chamber; an exhaust air side punching plate is arranged between the drying chamber and the air return chamber; multiple air guide plates with automatically adjusted opening angles are uniformly distributed in the horizontal direction of the intake air side punching plate, so that drying airflow can reach a relatively uniform state in the horizontal direction; and as the vertical section structure of the fan chamber is a rectangular structure, all fans are arranged as a vertical column in the height direction of the fan chamber at equal intervals, and the drying airflow can keep a relatively uniform state in the vertical direction. Such schemes as vertical ventilation of an axial flow fan set, air distribution and homogenization of multi-grade air guide plate combination and movement of a tray frame along aguide rail are adopted to solve the problems of nonuniform ventilation and drying in the vertical direction and the horizontal direction.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

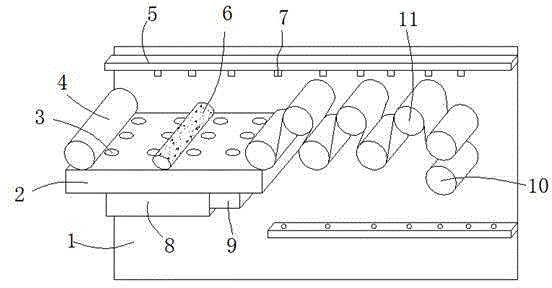

Paper drying and cleaning device

InactiveCN106149444AIncrease the drying areaSolve the problem of uneven dryingDryer sectionCleaning using toolsFiberPulp and paper industry

The invention discloses a paper drying and cleaning device. The paper drying and cleaning device comprises an installation plate. Two or more rows of drying pipelines are fixedly arranged on the upper portion of the installation plate, two or more rows of drying rollers are arranged at the lower ends of the drying pipelines from top to bottom and rotationally installed on the surface of the installation plate, a cleaning platform is arranged at the position, at the lower ends of the drying pipelines, of the surface of the installation plate, a brush is arranged on the upper portion of the cleaning platform, and the brush part of the brush is in contact with the surface of the cleaning platform. According to the paper drying and cleaning device, the drying rollers are installed on the installation plate, and paper passes through the surfaces of all the drying rollers, so that the paper drying area is effectively increased, and the problem of non-uniform drying is effectively solved; the cleaning platform is arranged on one side of the drying rollers, the brush is arranged on the surface of the cleaning platform, suction holes are formed in the surface of the cleaning platform, and thus small particles and fibers remaining on the surface of paper in the drying process can be effectively removed.

Owner:TIANJIN JINRUIDA PAPER PROD CO LTD

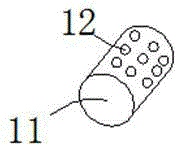

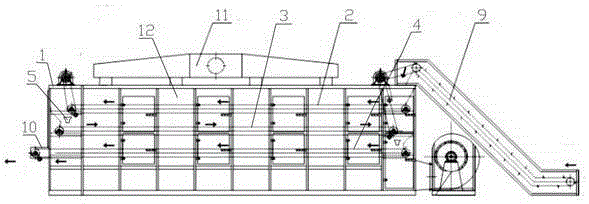

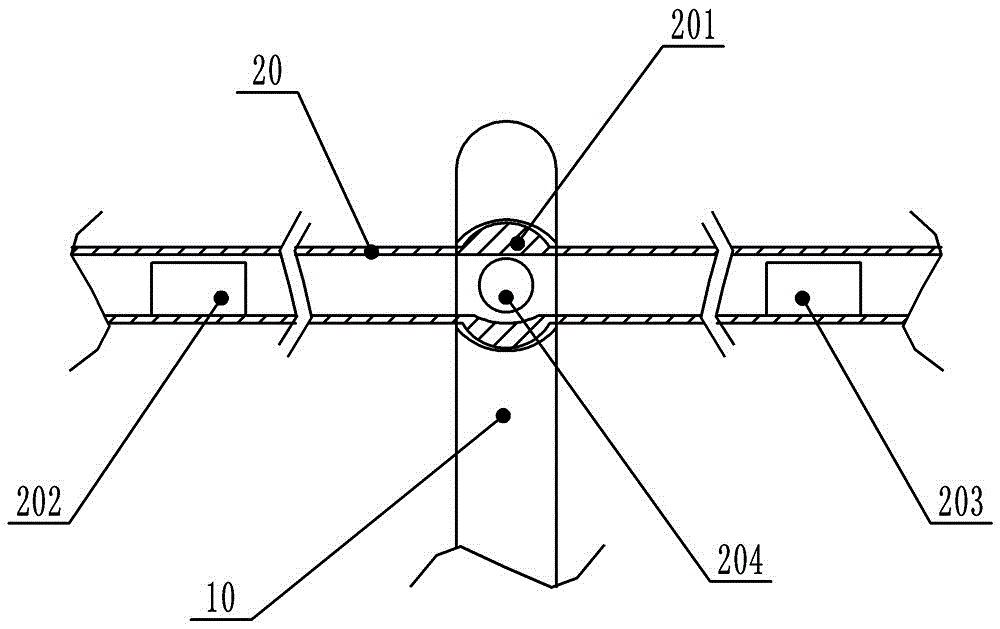

Net belt drying machine

ActiveCN104215055ADry evenlySolve the problem of uneven dryingDrying solid materialsDrying machinesPulp and paper industry

The invention provides a net belt drying machine, which solves the problem of nonuniform drying of materials in the thickness direction. The drying machine comprises an oven, a material feeding machine and a hot air conveying device, wherein the material feeding machine and the hot air conveying device are respectively communicated with the oven, the oven is provided with a hollow casing, the interior of the casing is provided with a net belt conveying unit for conveying the material, the net belt conveying unit comprises an upper net belt and a lower net belt which are vertically staggered and can continuously and circularly rotate, the material outlet end of the upper net belt is correspondingly arranged above the material inlet end of the lower net belt, a material turnover device is arranged between the material outlet end of the upper net belt and the material inlet end of the lower net belt, the material turnover device mainly consists of a hydraulic oil cylinder and a material hopper, the telescopic direction of the hydraulic oil cylinder is vertical to the movement direction of the lower net belt, a material inlet of the material hopper is fixedly arranged under the material outlet end of the upper net belt, a material outlet of the material hopper is provided with a metal flexible pipe, and a telescopic head of a hydraulic oil cylinder is fixedly connected with the metal flexible pipe. The drying machine has the advantage that when the materials are conveyed at the upper and lower layers, the material is turned over by the swinging material discharging of the material hopper, and caking is avoided.

Owner:NANJING TONGHAO DRYING EQUIP

Beef air-drying device

PendingCN109699728ASolve the problem of uneven dryingMeat/fish preservation by dryingEngineeringAir drying

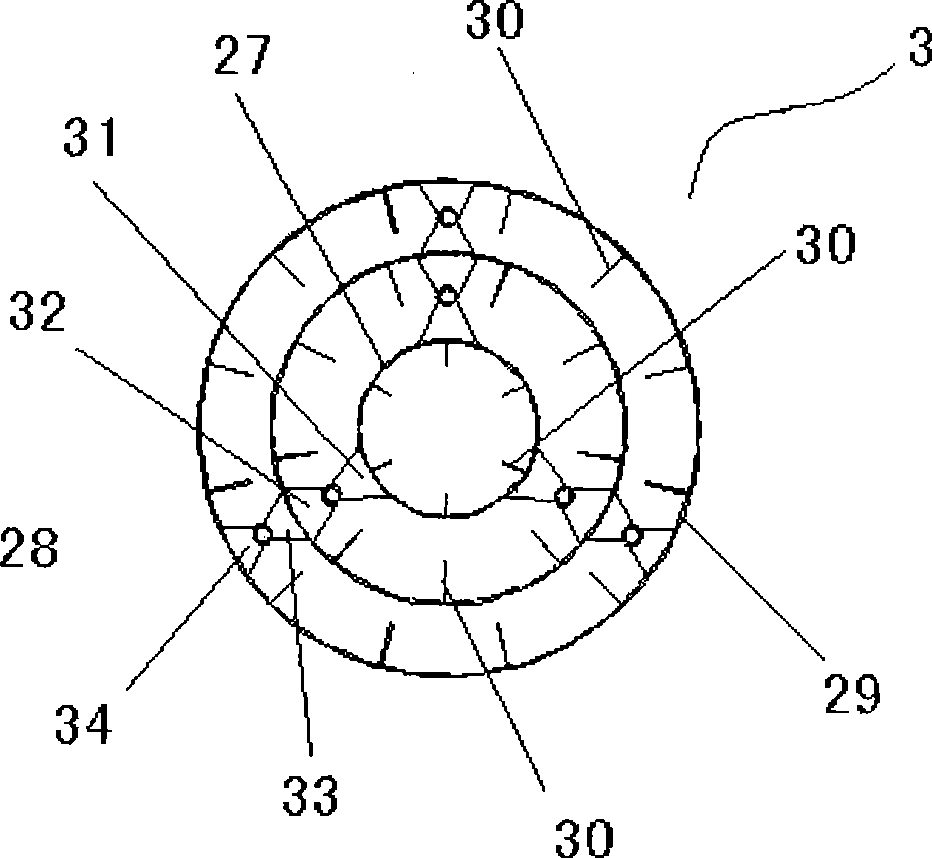

The application discloses a beef air-drying device belonging to the technical field of beef processing. The beef air-drying device comprises a base and two fixing rods, wherein a processing mechanismis arranged on the base, and comprises a dual-shaft motor, a processing box and a netlike processing cylinder; the processing box is horizontally and rotatably connected to the base; grooves are formed in the processing box; the processing cylinder penetrates through the box body through the grooves, rotating rods are connected to two ends of the processing cylinder, one rotating rod is rotatablyconnected to the corresponding fixing rod, and the other rotating rod is fixedly connected with the dual-shaft motor; the dual-shaft motor is connected to the other fixing rod; a driving bevel gear isfixedly connected to the dual-shaft motor; a driven bevel gear is meshed with the driving bevel gear; a rotating shaft is fixed to the driven bevel gear; a rotating table is connected to the rotatingshaft; a connecting rod is rotatably connected to the non-center part of the rotating table, and a push rod is connected to the connecting rod; and the push rod penetrates through the fixing box andthe processing box, and a push plate is connected to the push rod. The beef air-drying device disclosed by the invention can uniformly air dry beef.

Owner:桐梓县燎原镇金诚食品有限公司

Uniform drying device for electronic products

InactiveCN107906905ADry evenlySolve the problem of uneven dryingDrying gas arrangementsDrying chambers/containersCold airEngineering

The invention discloses a uniform drying device for electronic products, and relates to the technical field of electronic product drying. The uniform drying device for the electronic products comprises a fixing plate; a drying barrel is arranged in the middle of the fixing plate in a penetrating mode; a connecting plate is fixedly connected to the bottom of the drying barrel; a first fixing rod and a second fixing rod are fixedly connected to the two sides of the connecting plate; hot air heads are fixedly connected to the surface of the first fixing rod through rotary bearings; cold air headsare fixedly connected to the surface of the second fixing rod through rotating bearings; and filtering plates are fixedly connected between the fixing plate and the connecting plate and are located on the two sides of the drying barrel. According to the uniform drying device for the electronic products, a pushing device is placed at the bottom of the drying barrel so that the device can be conveniently pushed to work, the pushing device can conveniently push the drying barrel to move at any time, the electronic products in the drying barrel can be dried more uniformly, and therefore the problem that an existing uniform drying device for the electronic products is not uniform in drying can be solved.

Owner:合肥璨然电子科技有限公司

Formula and drying device of health tea for maintaining beauty, keeping young and benefiting qi and blood

InactiveCN110178948APromote recoverySolve problems with little benefitDrying solid materials with heatTea substituesSide effectFlos chrysanthemi

The invention discloses a formula of health tea for maintaining beauty, keeping young and benefiting qi and blood. The health tea is prepared from the following raw materials in parts by weight: 0.1-0.5 g of radix ginseng, 0.3-0.7 g of radix angelicae sinensis, 1.6-2.0 g of roselle, 0.8-1.2 g of rose, 0.8-1.2 g of fructus lycii, 0.6-1.0 g of fructus jujubae, 0.1-0.5 g of osmanthus flower, 0.3-0.7g of typha angustifolia root, 0.1-0.5 g of flos chrysanthemi, and 3.4-3.8 g of rock sugar. The invention further provides a drying device of the health tea for maintaining beauty, keeping young and benefiting qi and blood; the device comprises a support frame, wherein the upper end of the support frame is fixed with a drying box; one side of the drying box is provided with an opening. According tothe formula and the drying device of the health tea disclosed by the invention, the problem that when people who are weak and are deficient in qi and blood drink health tea, very little effect is produced is solved; meanwhile, the problem that when the raw materials of the health tea are dried, the quality of the health tea is affected by uneven heating is solved; the drying efficiency of the rawmaterials is improved; the health tea can also be applicable to different people; the effects of promoting qi circulation and removing obstruction in the collateral, nourishing blood for tranquillization, tonifying the kidney and warming the lung, activating blood and removing stasis, and maintaining beauty and keeping young are realized; the taste is slightly sweet; the health tea has slight Chinese herbal medicine aroma and no toxic and side effects.

Owner:行唐县柏栎贸易有限公司

Shoe-making process based on increasing drying uniformity

The invention discloses a shoe-making process based on increasing drying uniformity. The technology comprises following steps: 1) sole forming: preparing soles in moulds; 2) upper material preparing: composite formation of vamps and linings through gluing; 3) upper material cutting: cutting the upper material prepared in step 2) into uppers matched with the soles; 4) gluing or stitching the uppers prepared in step 3) into the soles; 5) paint spraying and waxing for the vamps; 6) placing the shoes after paint spraying and waxing in a drying system for drying; 7) shoe edge correcting: removing burr and gluing projection on shoe edges with tools. According to the drying system of the shoe-making process of the present invention, through the installation of the cooperated first sloping panel and the second sloping panel, a certain incline angle is formed between the shoes placed on the first sloping panel and the second sloping panel and the shoe placing plate so that all side surfaces of the shoes can be exposed to heat irradiation and the uniformity of heat irradiation on shoes is increased.

Owner:CHENGDU LIXIN SCI & TECH

Mesh Belt Dryer

ActiveCN104215055BDry evenlySolve the problem of uneven dryingDrying solid materialsDrying machinesMechanical engineering

The invention provides a net belt drying machine, which solves the problem of nonuniform drying of materials in the thickness direction. The drying machine comprises an oven, a material feeding machine and a hot air conveying device, wherein the material feeding machine and the hot air conveying device are respectively communicated with the oven, the oven is provided with a hollow casing, the interior of the casing is provided with a net belt conveying unit for conveying the material, the net belt conveying unit comprises an upper net belt and a lower net belt which are vertically staggered and can continuously and circularly rotate, the material outlet end of the upper net belt is correspondingly arranged above the material inlet end of the lower net belt, a material turnover device is arranged between the material outlet end of the upper net belt and the material inlet end of the lower net belt, the material turnover device mainly consists of a hydraulic oil cylinder and a material hopper, the telescopic direction of the hydraulic oil cylinder is vertical to the movement direction of the lower net belt, a material inlet of the material hopper is fixedly arranged under the material outlet end of the upper net belt, a material outlet of the material hopper is provided with a metal flexible pipe, and a telescopic head of a hydraulic oil cylinder is fixedly connected with the metal flexible pipe. The drying machine has the advantage that when the materials are conveyed at the upper and lower layers, the material is turned over by the swinging material discharging of the material hopper, and caking is avoided.

Owner:NANJING TONGHAO DRYING EQUIP

Drying device for textile printing and dyeing

InactiveCN108532179AReasonable structureSolve the problem of not being able to partition heatingLiquid/gas/vapor removalTextile printerEngineering

The invention discloses a drying device for textile printing and dyeing. The drying device comprises a box body, wherein a first cavity is formed in the box body, dustproof covers are fixed to the upper end and the lower end of the box body, third holes are formed in one end side wall of each dustproof cover, dustproof lids are hinged to the side walls of two ends of each third hole, first supporting legs are fixed to four corners of the lower end of one dustproof cover, first through holes are formed in the side walls of two ends of each of four first supporting legs, and second supporting legs penetrate into the first supporting legs. The drying device for textile printing and dyeing is reasonable in structure, utilizes cooperation of a first gear, a first rack, a second screw and a movable plate to achieve vertical and horizontal movements of a first air outlet, the problem is solved that zoned heating cannot achieved, the ununiform drying problem is solved through adjustment of a seal plate in a second air pipe, the working efficiency is improved, the cost is reduced, the operation is simple, the practicability is good, and the drying device is suitable for popularization.

Owner:杨孝耀

Drying system

InactiveCN106174902AAvoid uneven heatingEasy dischargeShoemaking devicesPulp and paper industryRidge

The invention discloses a drying system. The drying system comprises an infrared drying chamber and a rack arranged in the infrared drying chamber, wherein the infrared drying chamber comprises a drying body, multiple infrared heating lamp tubes are arranged in the drying body, an exhaust tube is arranged on the top of the drying body, and a draught fan is arranged in the exhaust tube; the rack comprises a base arranged on the bottom of the drying body, a motor is arranged in the base, a rotary shaft is connected to a power output end of the motor, and a shoe accommodating plate is arranged on the rotary shaft; a first oblique plate and a second oblique plate are oppositely arranged on the shoe accommodating plate, and ridge bodies are arranged on the oblique surface of the first oblique plate and the oblique surface of the second oblique plate respectively. The drying system solves the problems of existing drying systems that shoe drying is not uniform, and drying efficiency is low.

Owner:CHENGDU LIXIN SCI & TECH

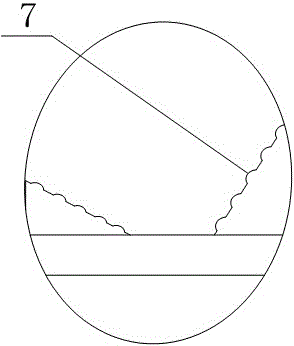

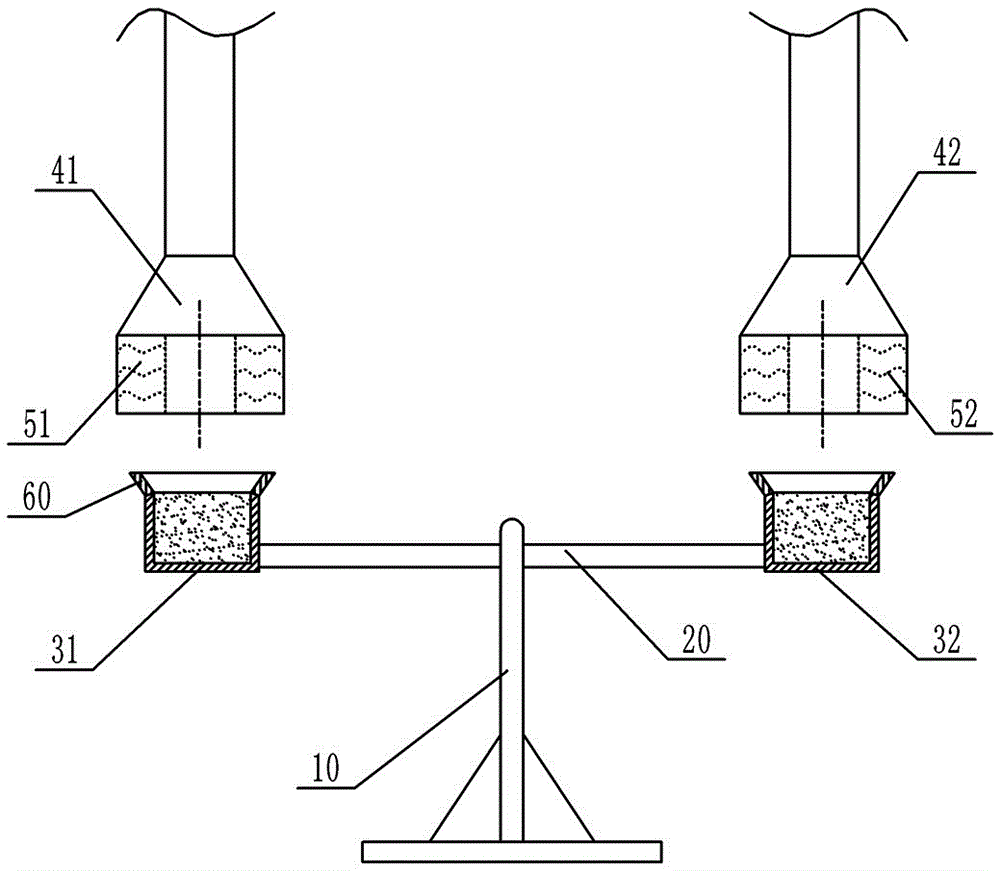

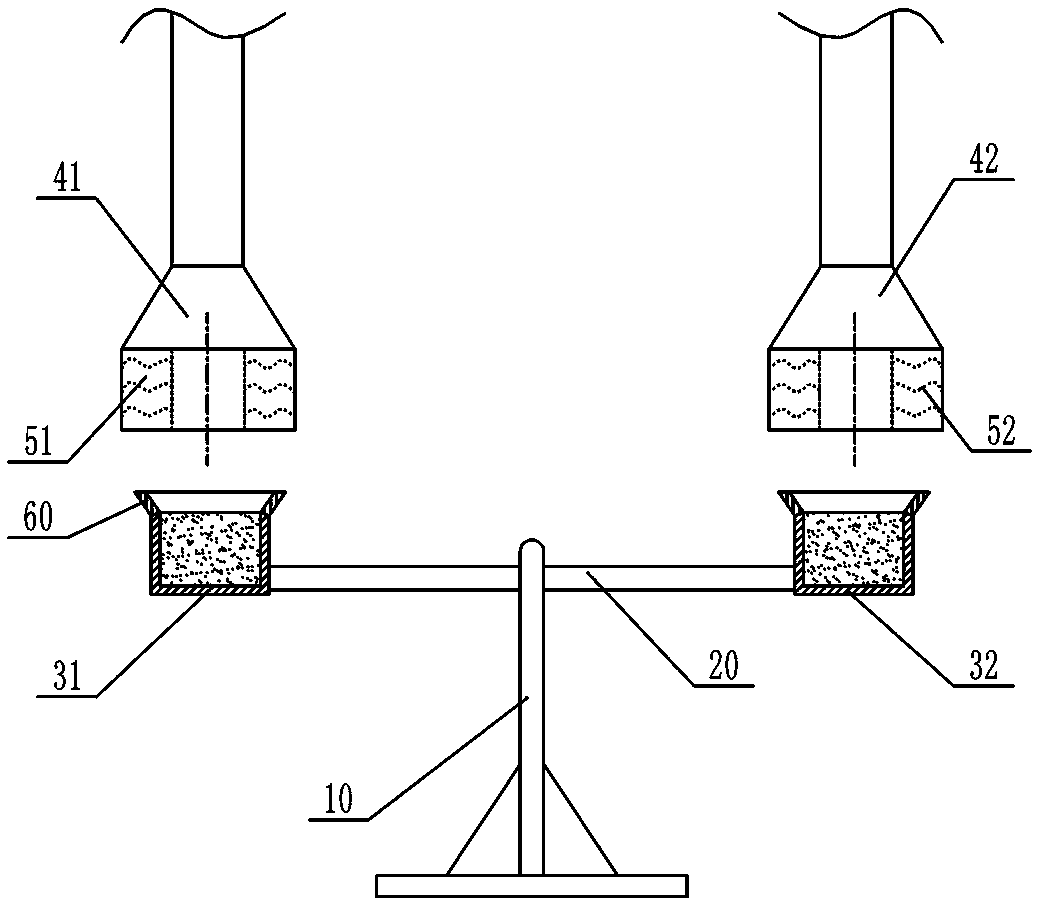

Fertilizer drying device

ActiveCN106839671ASolve the problem of uneven dryingThe problem of uneven drying does not needManure dryingDrying gas arrangementsEngineeringMechanical engineering

The patent application belongs to the technical field of solid material or product drying and particularly discloses a fertilizer drying device. The fertilizer drying device comprises a rack, a support, a balance bar, a first material box, a second material box, a first fan and a second fan, wherein the first material box and the second material box are fixed at the two ends of the balance bar correspondingly; the middle of the balance bar is hinged to the support; the first fan is positioned above the first material box; the second fan is positioned above the second material box; first heating devices are arranged around the first fan; and second heating devices are arranged around the second fan. According to the scheme, the fans can take away dried materials while driving the material boxes to move, so that manual collection is not needed, and accordingly, the operation is convenient.

Owner:重庆依尔双丰科技有限公司

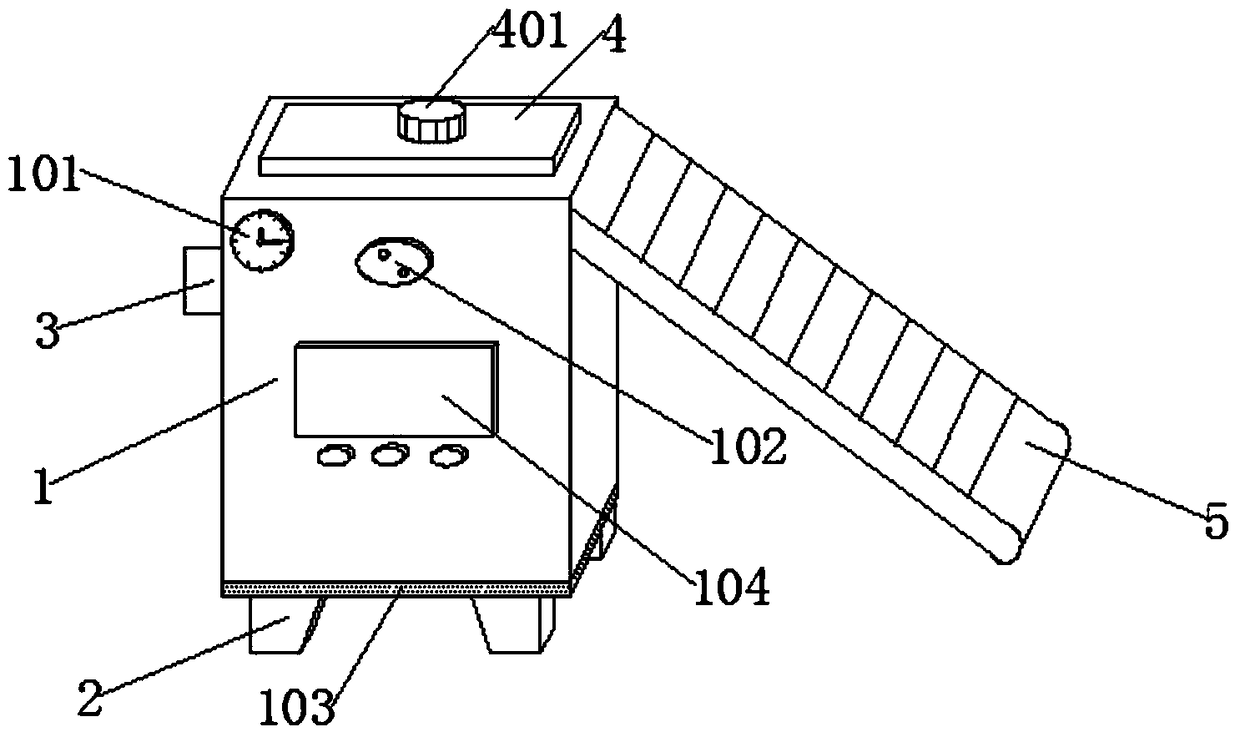

Special tea leaves drying device for planting tea leaves

InactiveCN108850208ASolve the problem of inconvenient internal observationSolve the problem of needing to add tea leaves manuallyPre-extraction tea treatmentLoading/unloadingThermometerEngineering

The invention discloses a special tea leaves drying device for planting tea leaves. The special tea leaves drying device comprises a drying box, a thermometer, a steam outlet, a control screen, supporting legs, a steam inlet, a top cover and a rotating switch, wherein the left upper corner of the front surface of the drying box is fixedly connected with the thermometer, the bottom end of the drying box is respectively fixedly connected with four supporting legs, the bottom end of the drying box is provided with the steam outlet in a penetrating manner, the middle portion of the front surface of the drying box is fixedly connected with the control screen, the left side of the drying box is provided with the steam inlet in a penetrating manner, the top end of the drying box is fixedly connected with the top cover, the middle portion of the top cover is connected with a rotating switch in a rotating manner, the middle portion of the front surface of the drying box is fixedly connected with sight glass, the sight glass is disposed above the control screen, and the middle portion of the drying box is connected with a tea leaves drying frame in a rotating manner. The special tea leaves drying device is stable in structure, capable of automatically transporting tea leaves to the drying box for drying, also capable of sensing the inner drying temperature and performing the voice prompting, and very high in popularization value.

Owner:福州立农环保科技有限公司

Fertilizer drying device

ActiveCN106839671BSolve the problem of uneven dryingThe problem of uneven drying does not needManure dryingDrying gas arrangementsMechanical engineeringFertilizer

The patent application belongs to the technical field of solid material or product drying and particularly discloses a fertilizer drying device. The fertilizer drying device comprises a rack, a support, a balance bar, a first material box, a second material box, a first fan and a second fan, wherein the first material box and the second material box are fixed at the two ends of the balance bar correspondingly; the middle of the balance bar is hinged to the support; the first fan is positioned above the first material box; the second fan is positioned above the second material box; first heating devices are arranged around the first fan; and second heating devices are arranged around the second fan. According to the scheme, the fans can take away dried materials while driving the material boxes to move, so that manual collection is not needed, and accordingly, the operation is convenient.

Owner:重庆依尔双丰科技有限公司

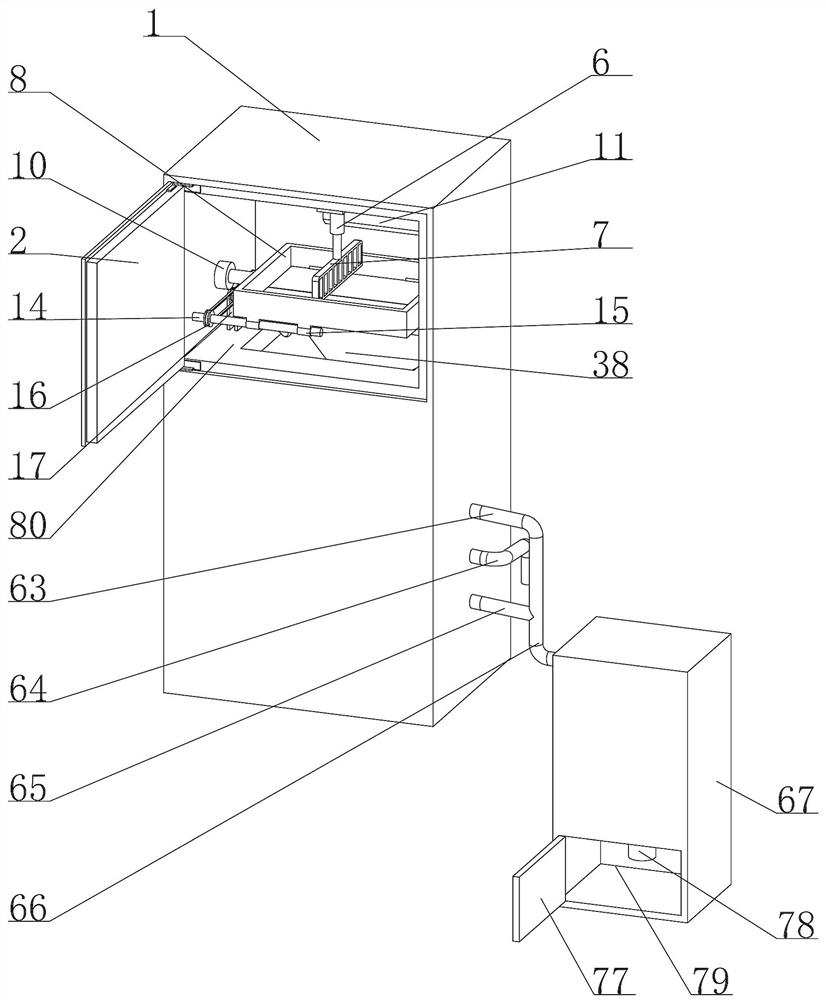

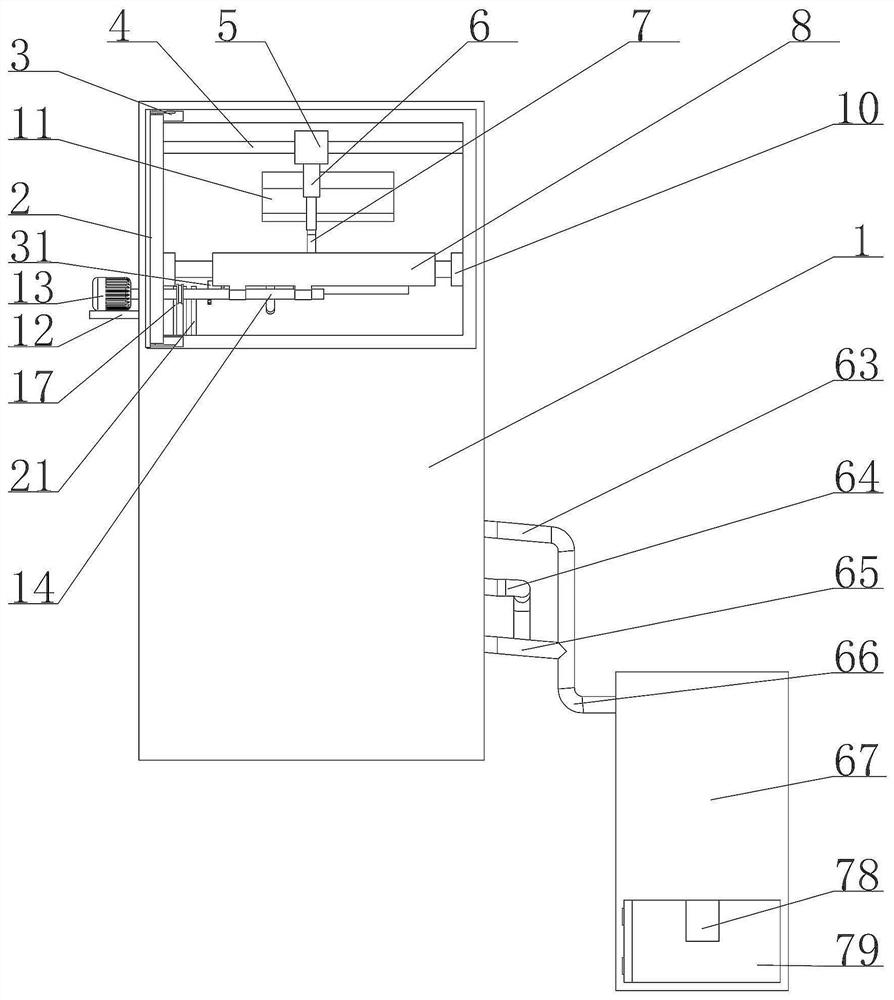

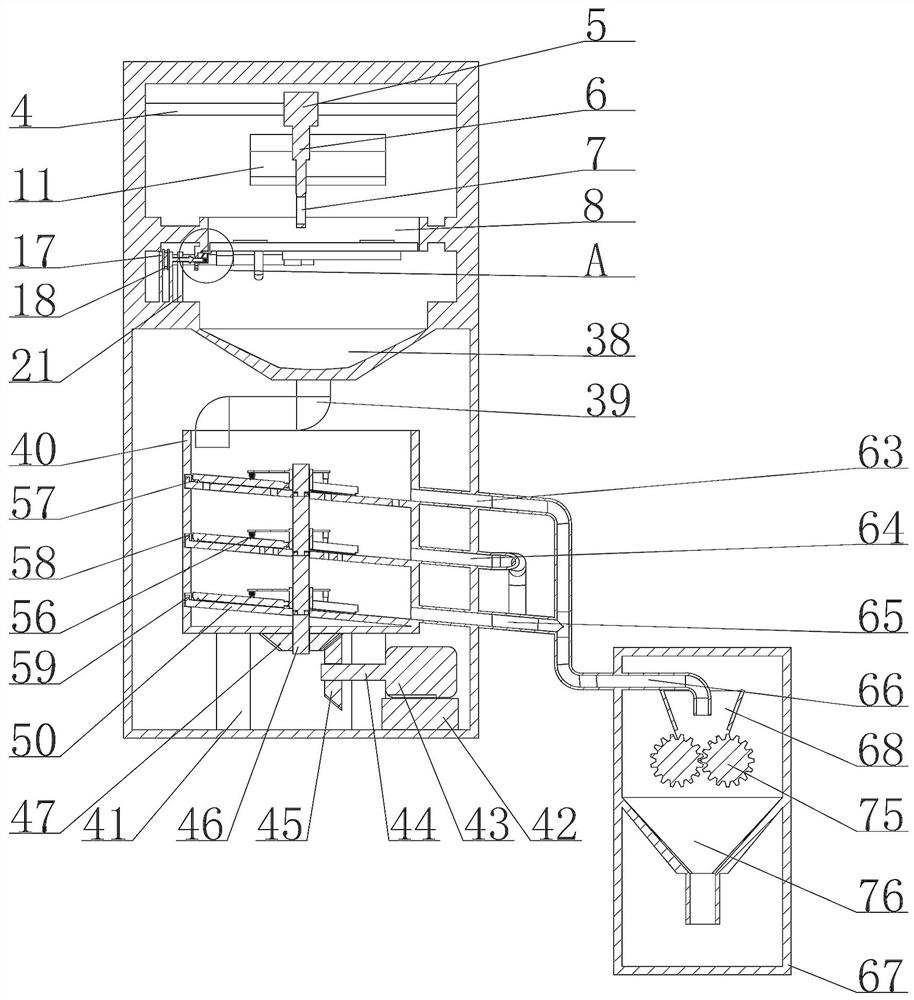

Drying and sorting device for toad-eating pills

ActiveCN114602806AImprove drying efficiencySolve the problem of uneven dryingSievingGas current separationEngineeringMechanical engineering

Owner:黑龙江省蟾宝蟾蜍养殖有限公司

A plate drying device for lithium battery manufacturing

ActiveCN107342390BSolve the problem of uneven dryingImprove drying effectElectrode thermal treatmentSecondary cellsThermodynamicsCell fabrication

The invention discloses a pole plate drying device for lithium battery manufacturing, which comprises a base, the top of the base is fixedly connected with a box body, the top of the box body is fixedly connected with a transmission box, the top of the inner cavity of the transmission box is fixedly connected with a motor, and the top of the box body is fixedly connected with a motor. The output shaft sleeve is provided with a gear, the gear is connected with a transmission device, and the bottom of the transmission device is fixedly connected with a bracket, and the bottom of the bracket runs through the bottom of the transmission box and the top of the box from top to bottom and extends to the bottom of the box. Inside, a heater is fixedly connected to the bottom of the bracket, a support plate is fixedly connected to the right side of the box, and a blower is fixedly connected to the top of the support plate. The present invention relates to the technical field of lithium batteries. The electrode plate drying device for lithium battery manufacturing solves the problem of uneven drying of the traditional electrode plate drying device for lithium battery manufacturing, improves the drying effect of the electrode plate, improves the work efficiency of the staff, and meets the effect of the user.

Owner:大庆宇奥科技有限公司

Drying device for textiles

InactiveCN107462005ASolve the problem of uneven dryingSatisfy the use effectDrying gas arrangementsDrying chambers/containersEngineeringAir blower

The invention discloses a drying device for textiles. The drying device comprises a base; the top of the base is fixedly connected with a box; the left side of the top of the box is fixedly connected with an air blower; an exhaust port of the air blower communicates with a heater; the heater is fixedly connected with the top of the box; the top of the box is fixedly connected with a transmission device on the right side of the heater; an exhaust port of the heater communicates with an air transmission hose; the bottom end of the air transmission hose penetrates through the top of the box, and communicates with a ventilation pipe; the top of the ventilation pipe is fixedly connected with the bottom of the transmission device; a round hole is formed in the ventilation pipe; and the bottom end of the ventilation pipe is slidingly connected with the bottom of an inner cavity of the box through a rail. The drying device relates to the technical field of electromechanical equipment. The drying device for the textiles solves the problem of nonuniform drying in a traditional drying device for the textiles, improves the drying effect, improves the working efficiency, and satisfies the use effect of users.

Owner:合肥恩腾电子科技有限公司

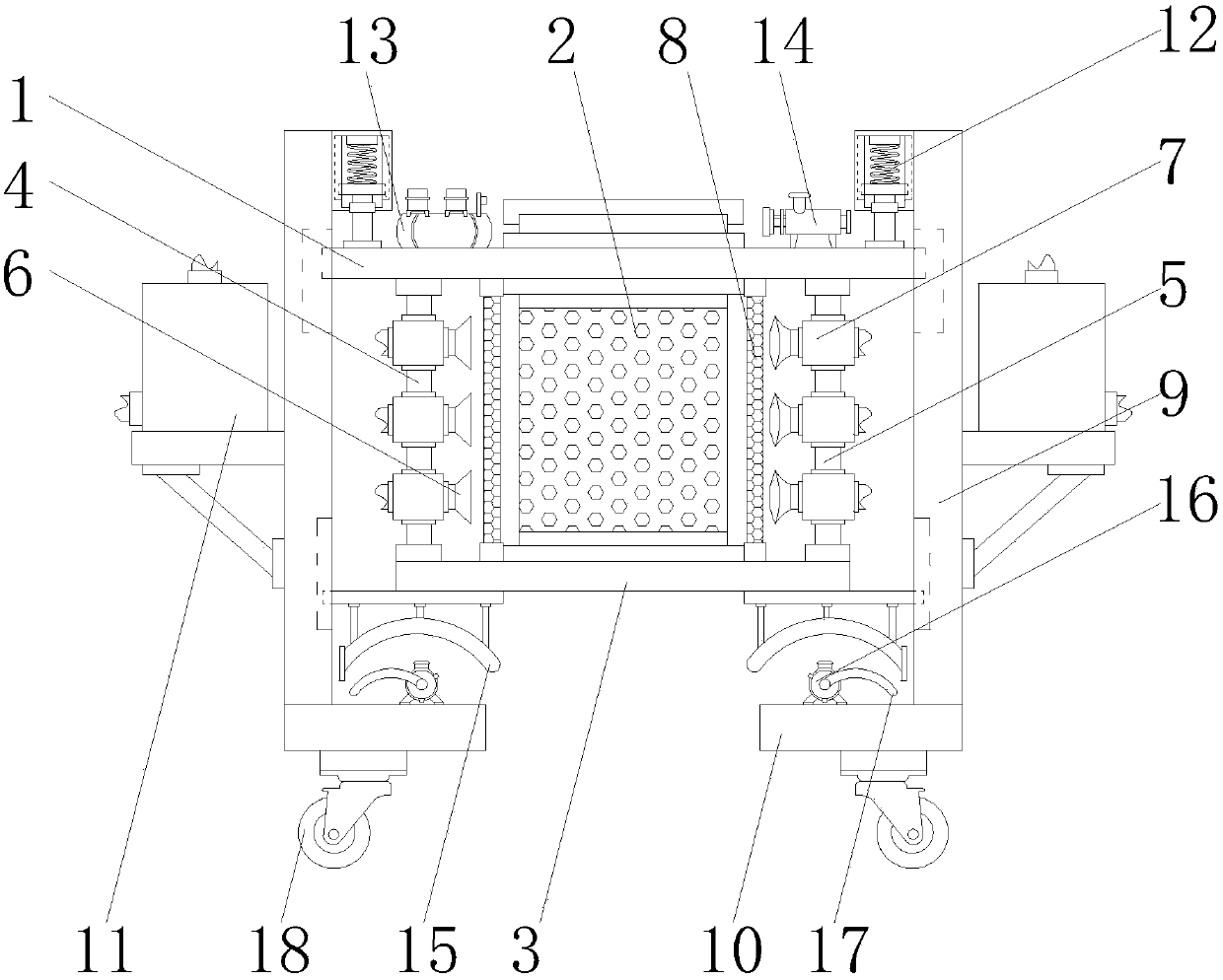

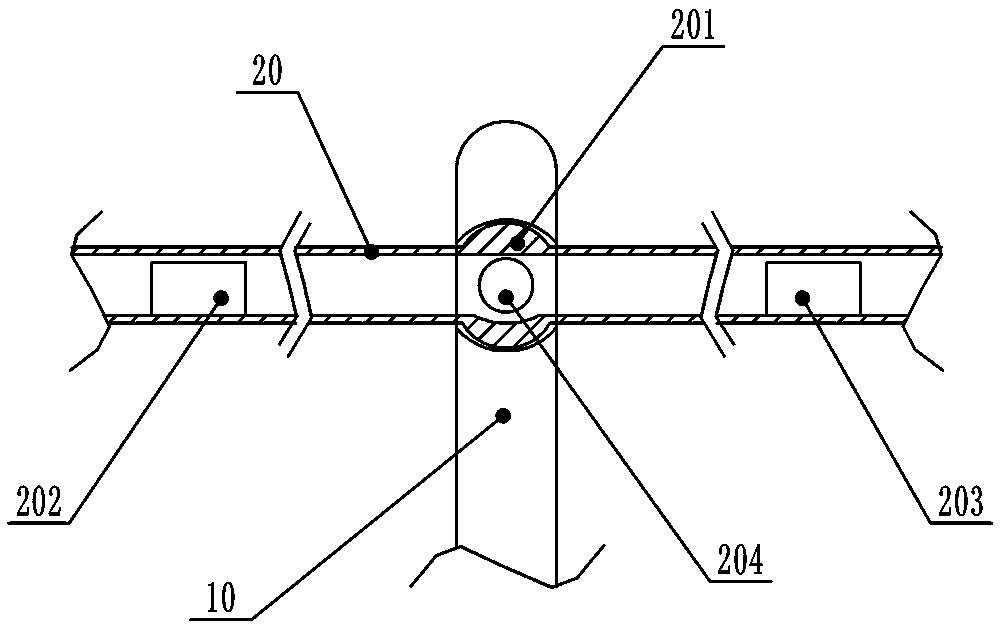

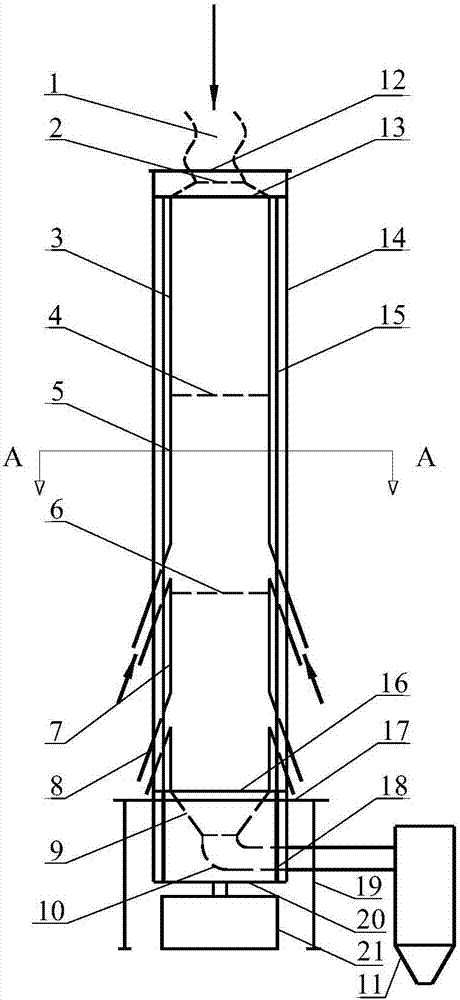

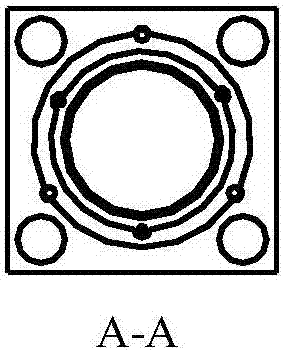

An experimental system and method for vibrating classification, drying and quality improvement of low-rank coal

ActiveCN104941905BSolve the problem of uneven dryingGuaranteed heat and mass transfer effectSievingScreeningEngineeringCoal

An experimental system and method for vibration grading, drying and quality improving of low-rank coal belong to drying and quality improving systems and methods of the low-rank coal. The system is formed by a vibration grading barrel, a grading barrel support, a multi-screening-face mechanism, a grading barrel exciter, a hot smoke input pipeline at the upper portion of a barrel body, a discharging port in the lower portion of the barrel body and a hot smoke replenishing pipeline outside the barrel body, wherein the multi-screening-face mechanism is arranged inside the barrel body. Raw low-rank coal is added into vibration grading drying barrels from the upper portion, pre-grading is carried out by the grading drying barrels under the effect of the exciter, the calibers of screening faces are reduced from top to bottom, the pre-graded low-rank coal forms material layers on the screening faces with different calibers, high temperature hot smoke enters the drying barrels from the upper portion of the barrel body and is in contact with particles of the largest fraction, a coal sample in a vibrating screen is dried, and a screening barrel continuously vibrates to keep the materials loose. The temperature is reduced after the hot smoke passes through the screening face, the hot smoke enters the lower layer of the screening barrel to dry the particles of the next fraction and so on. Finally, the particles of the smallest fraction are discharged into a tail gas separating device along with cooled smoke tail gas.

Owner:CHINA UNIV OF MINING & TECH

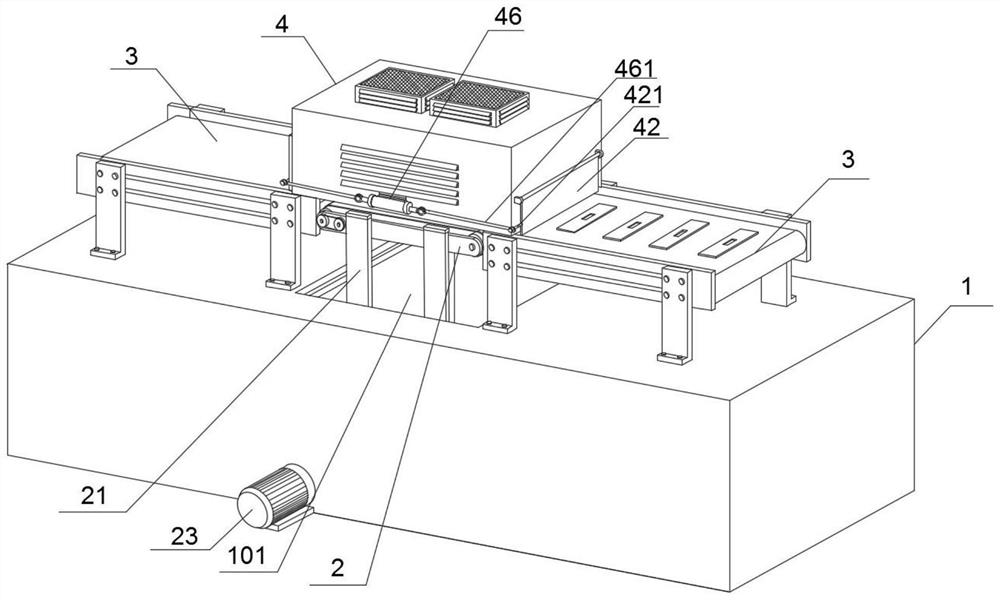

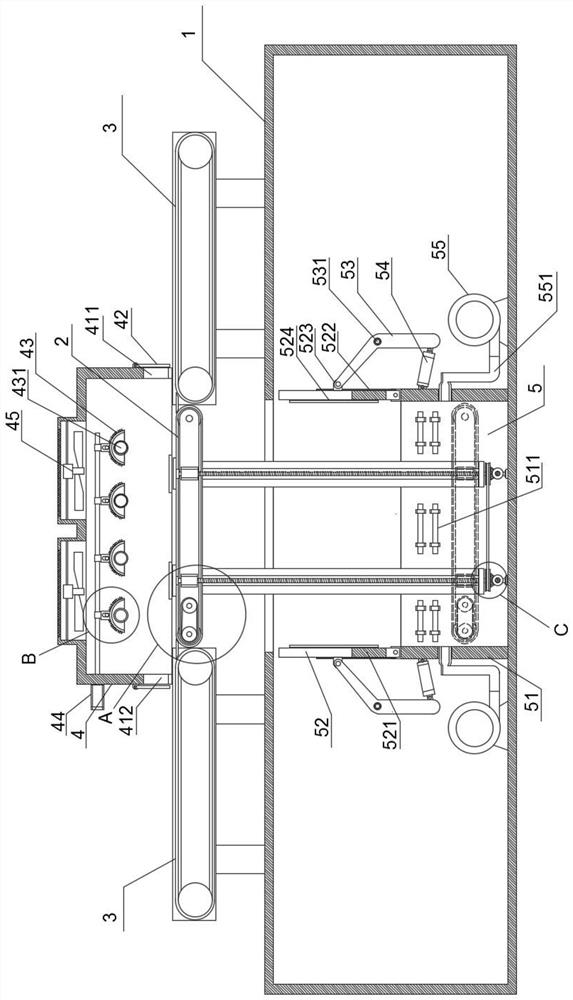

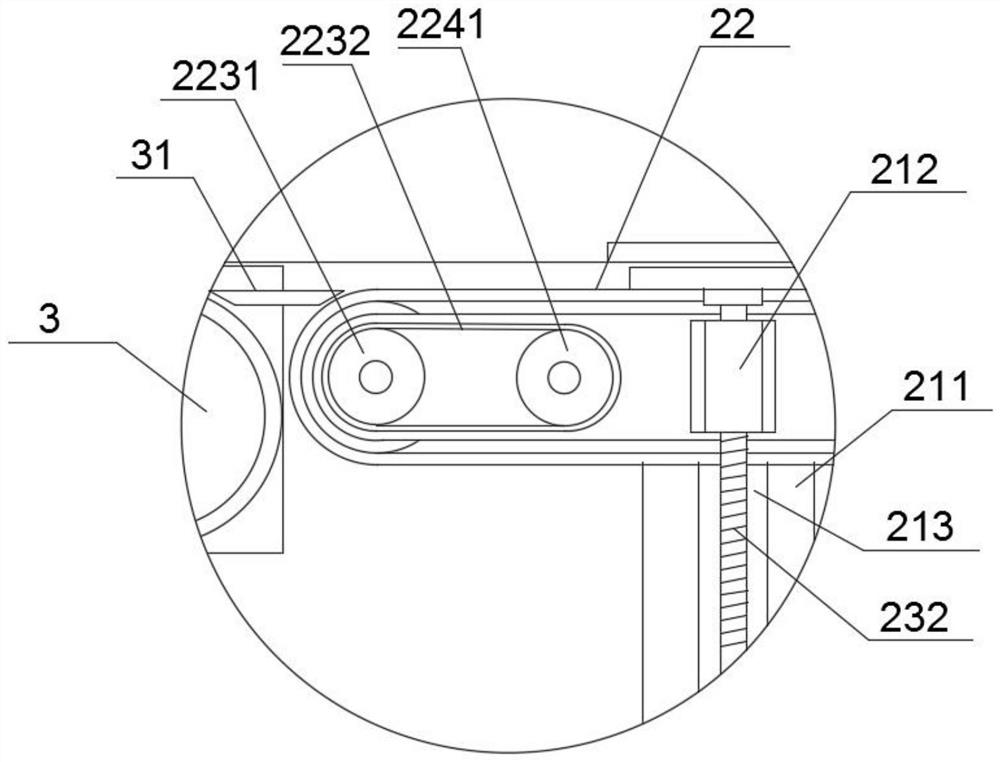

Special high-efficiency curing device for injection molding panel preparation

The invention relates to a special high-efficiency curing device for injection molding panel preparation. The special high-efficiency curing device comprises a machine base, wherein a lifting openingwith a rectangular structure is formed in the upper surface of the machine base, a lifting conveying mechanism is arranged at the lifting opening, two fixed conveying mechanisms are arranged at the positions, located at the two ends of the lifting opening, on the machine base, the two fixed conveying mechanisms are located at the two ends of the lifting conveying mechanism correspondingly, and convey injection molding panels to the lifting conveying mechanism, a curing device body is arranged above the lifting conveying mechanism, the bottom end of the curing device body is fixedly arranged atthe tops of the lifting conveying mechanism and the two fixed conveying mechanisms, the curing device body is used for carrying out UV curing treatment on the injection molding panels on the liftingconveying mechanism, a drying device is arranged below the lifting conveying mechanism, the drying device is arranged at the bottom end in the machine base, and the drying device is used for carryingout thermocuring treatment on the injection molding panels on the lifting conveying mechanism. The occupied space of the curing device is saved, the drying device can effectively reduce heat loss during heating, and the problem of uneven drying is effectively solved.

Owner:丹阳市逸帆电子有限公司

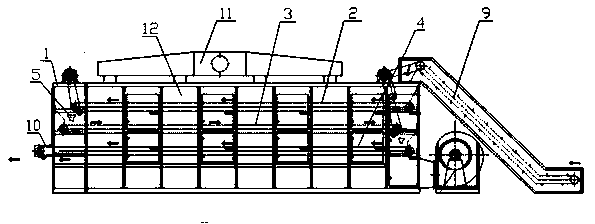

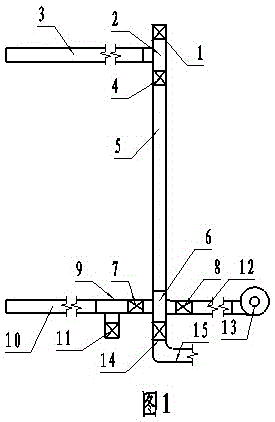

Air supply and exhaust interchange system for thermal insulation sealed grain dryer

InactiveCN106288736ASolve the problem of uneven drying of grainSolve the problem of uneven dryingDrying gas arrangementsSeed preservation by dryingThermal insulationHeat exchanger

The invention discloses an air supply and exhaust interchange system for a thermal insulation sealed grain dryer. The air supply and exhaust interchange system comprises a first air duct (3), a third air duct (10), a cold air blower (13) and a fifth air duct (15), wherein one end of the first air duct (3) is communicated with one joint of a first tee joint (2); the other end of the first air duct (3) is communicated with a cover air inlet and outlet joint; one end of the third air duct (10) is communicated with one joint of a second tee joint (9);the other end of the third air duct (10) is communicated with a bottom inlet and outlet joint; an air outlet of the cold air blower (13) is communicated with a fourth valve (8); one end of the fifth air duct (15) is communicated with a joint of a sixth valve (14), and the other end of the fifth air duct (15) is communicated with a hot air outlet of a heat exchanger of a hot blast heater. Because the thermal insulation sealed grain dryer is equipped with the air supply and exhaust interchange system, the defect that grains are non-uniformly dried is overcome.

Owner:JILIN TEACHERS INST OF ENG & TECH +1

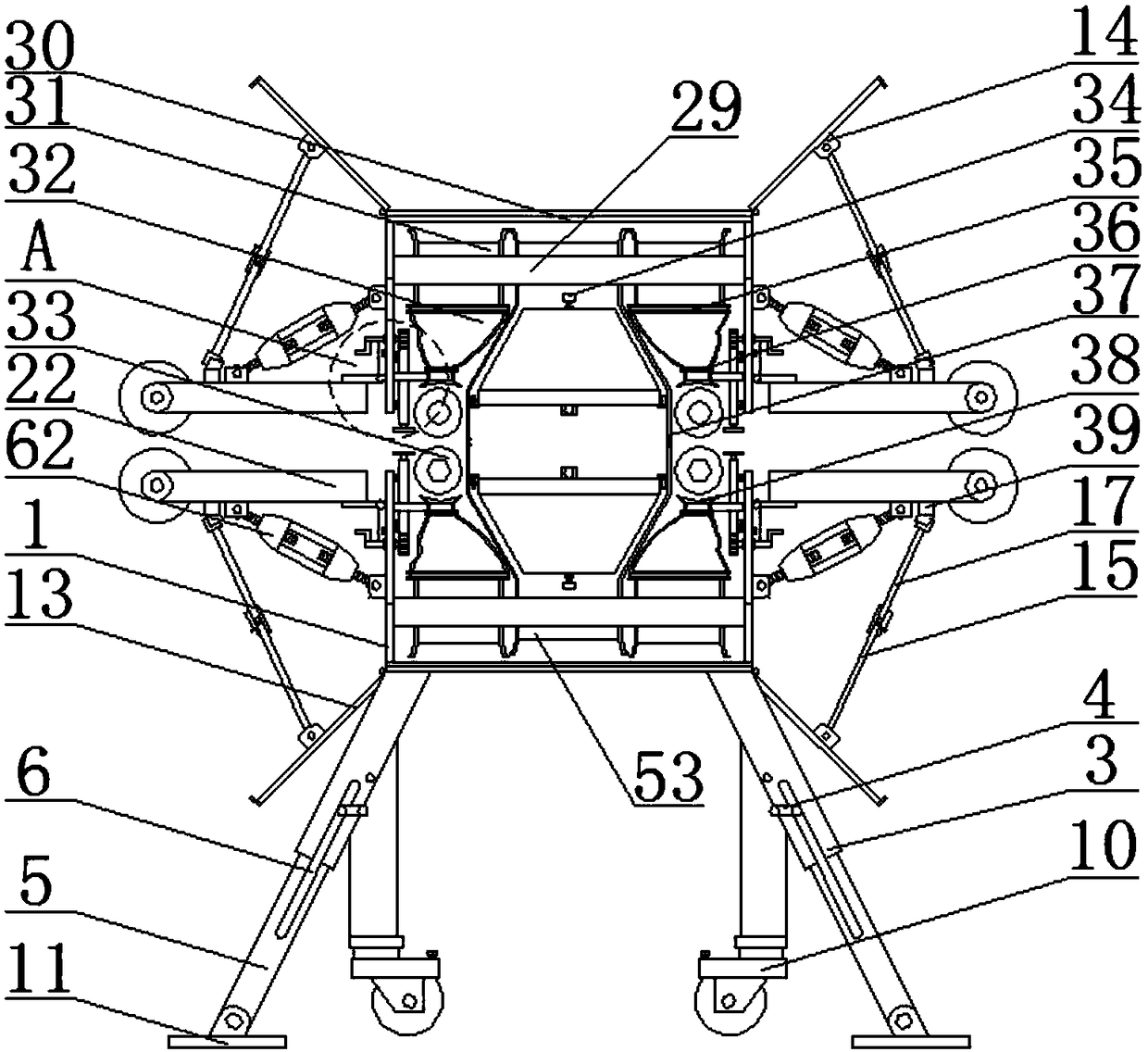

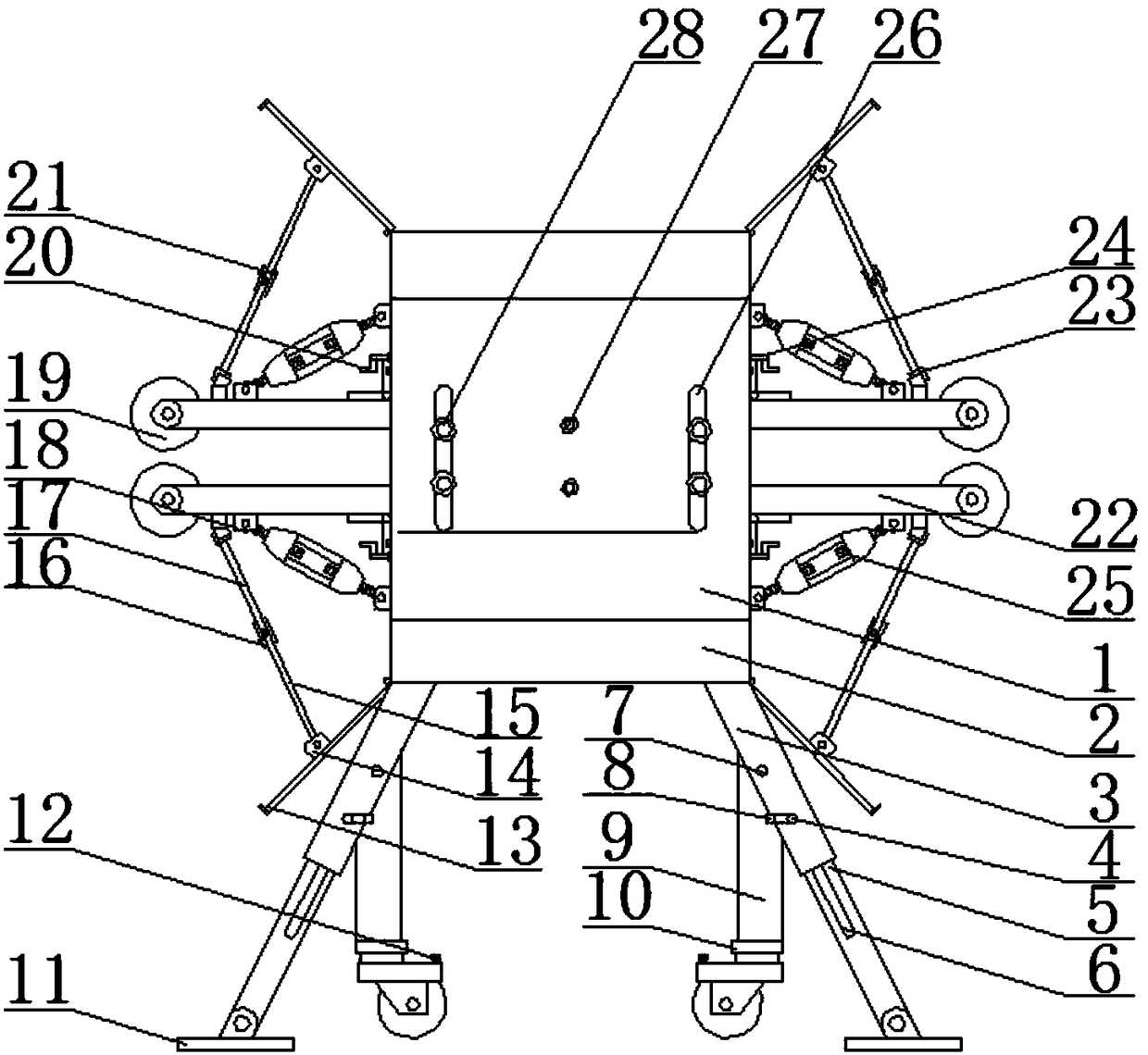

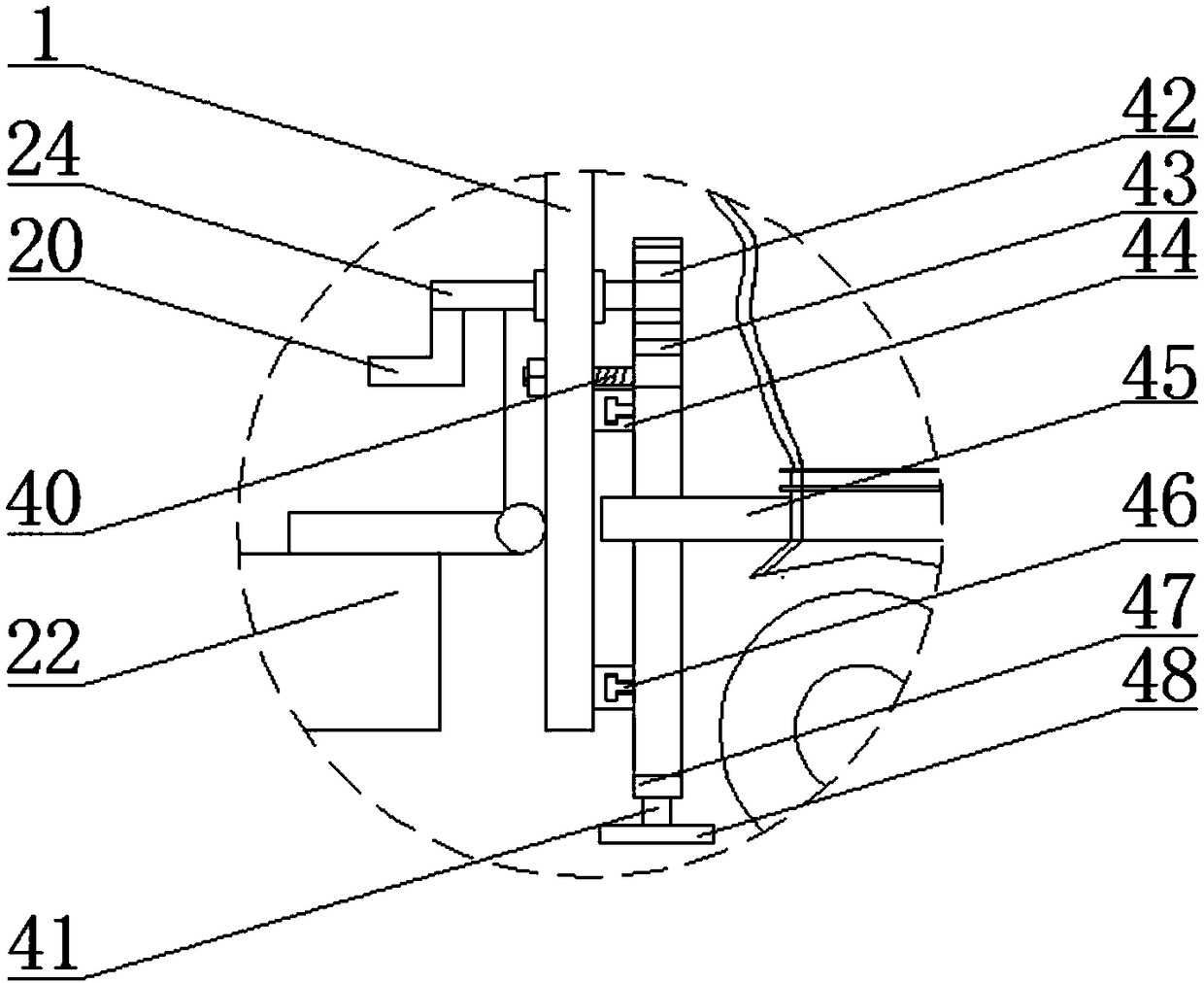

A dual push device for a grain dryer

ActiveCN112503923BEvenly heatedSolve the problem of uneven dryingDrying solid materialsGrains dryingClassical mechanicsControl theory

Owner:合肥三伍机械有限公司

Air energy dryer for grain drying

InactiveCN111536782AImprove drying efficiencySolve the problem of low drying efficiency caused by uneven heatingDrying gas arrangementsDrying chambers/containersThermodynamicsEngineering

The invention discloses an air energy dryer for grain drying. According to the air energy dryer for grain drying, through cooperative use of a first rotating column, a second rotating column, a connecting plate and a drying plate, when hot air rises from an air guide base, grain at different positions on the drying plate can be heated by different degrees of hot air, so that the drying efficiencyof the grain is improved, and the problem that the drying efficiency is low due to uneven heating of grain at different positions in the prior art is solved; through matched use of vibration blocks, connecting columns, clamping plates and heat conducting plates, the grain jump slightly on the drying plate through vibration, so that the heating efficiency between the grain can be improved, and theproblem of uneven drying, caused by static drying of the grains, between the grain in the prior scheme can be solved; and the hot air can effectively and evenly move in a drying box through matched use of an air inlet pipe, an exhaust pipe, the air guide seat and a flow guide plate, and the problem that the hot air in the drying box is uneven in motion in the prior art is solved.

Owner:ANHUI OURUIDA ELECTRICAL APPLIANCE TECH

Green tea processing device

InactiveCN109497184ASolve the problem of uneven dryingPre-extraction tea treatmentTransmission beltAir blower

The invention discloses a green tea processing device in the field of tea leaf processing equipment. The green tea processing device comprises a driving mechanism and a processing box, wherein the processing box is horizontally and rotationally connected with a first rotating shaft; the processing box is vertically and rotationally connected with a second rotating shaft; the first rotating shaft is fixedly connected with a first rotating disc; the first rotating disc is provided with a netty tea leaf containing box; the second rotating shaft is fixedly provided with a second rotating disc; thesecond rotating disc is provided with a hot air blower; the first rotating disc is vertical to the second rotating disc; a connecting rod is connected between end surfaces, which are close to each other, of the first rotating disc and the second rotating disc; two ends of the connecting rod respectively penetrate through noncentral positions of the first rotating disc and the second rotating discand are connected with the first rotating disc and the second rotating disc in a sliding way; the driving mechanism comprises a worm gear, a transmission belt and a worm; the worm gear is fixedly connected with the first rotating disc, and the first rotating shaft, the worm gear and the first rotating disc are coaxial; the worm gear is meshed with the worm; the worm is rotationally connected withthe second rotating shaft through the transmission belt; the worm is connected with a motor for driving the worm to rotate. According to the green tea processing device in the scheme, drying can be more uniform.

Owner:贵州省桐梓县绿康茶业有限公司

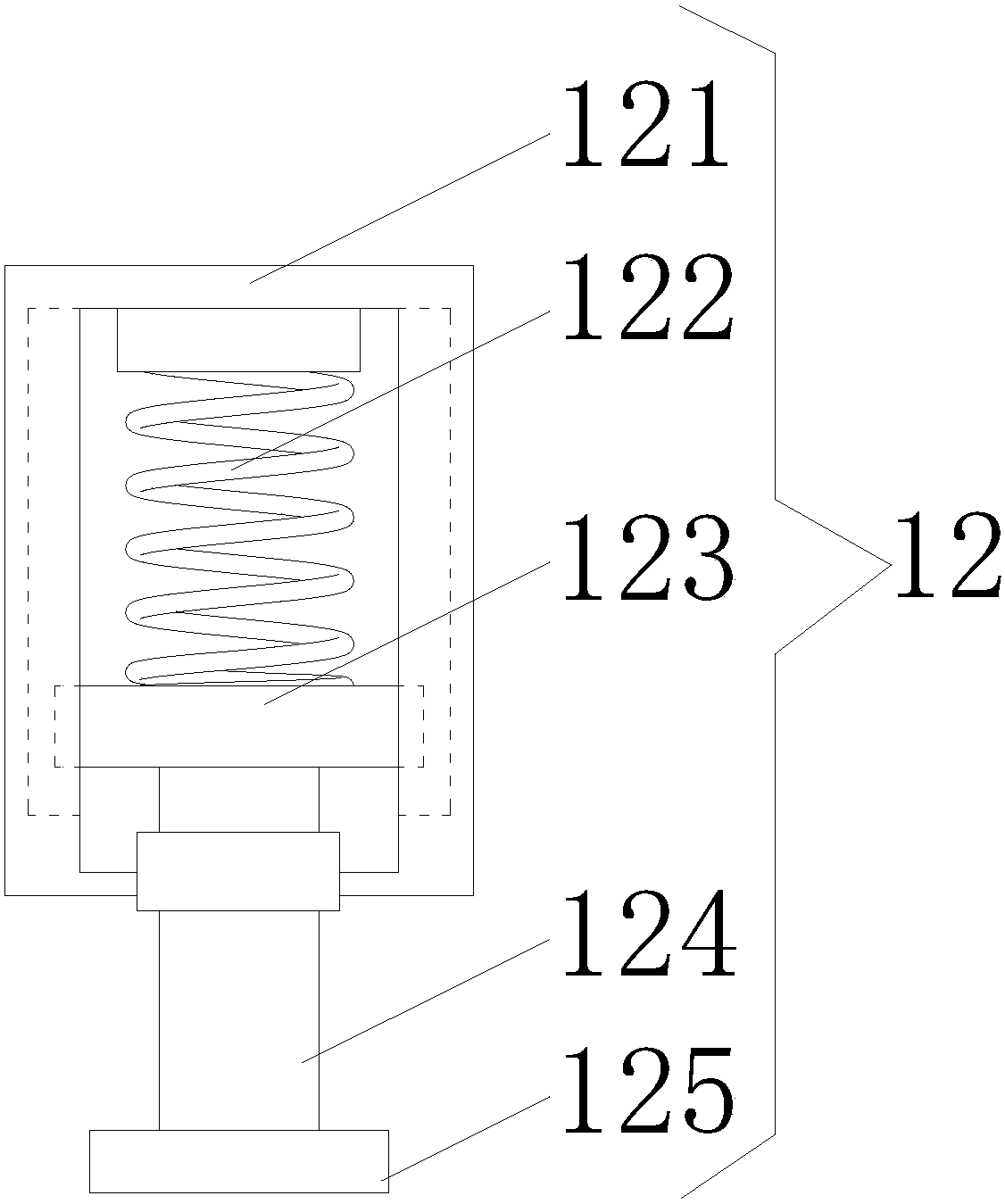

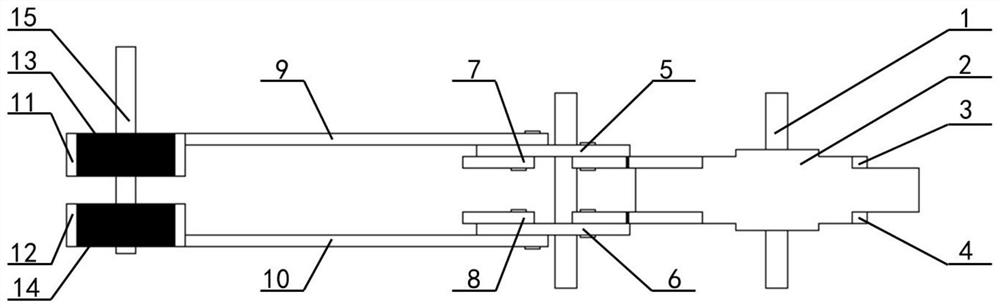

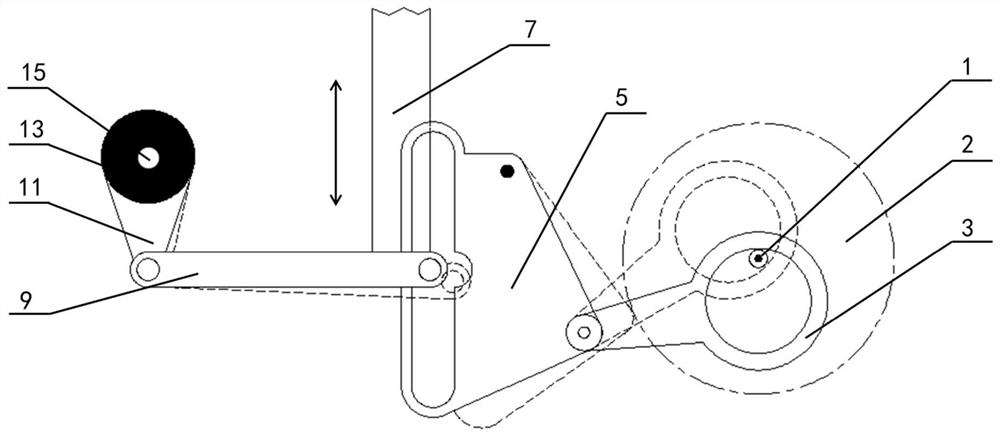

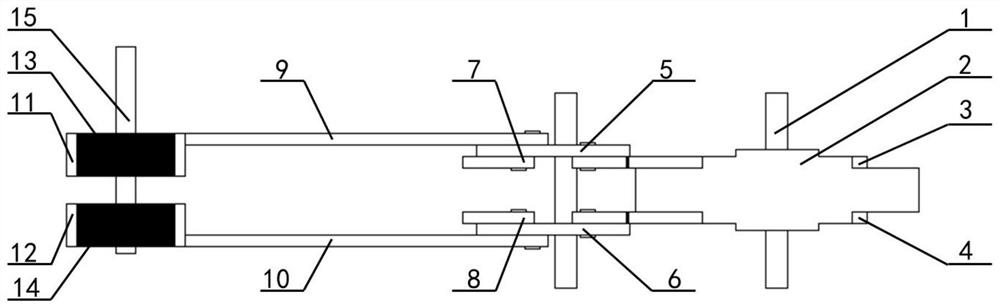

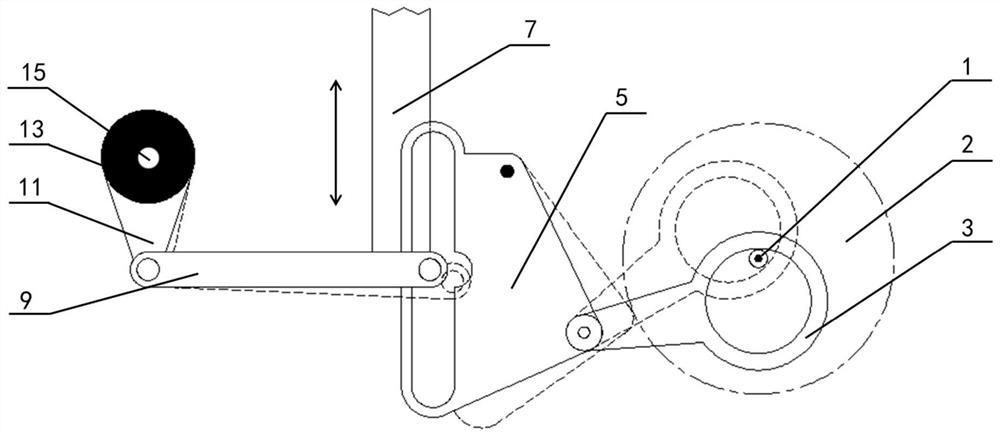

Double-pushing device for grain dryer

ActiveCN112503923AIncrease push frequencyEvenly heatedDrying solid materialsGrains dryingEngineeringMechanical engineering

The invention discloses a double-pushing device for a grain dryer. The double-pushing device comprises an input shaft, eccentric mechanisms, a control mechanism, a transmission mechanism and an outputshaft. The eccentric mechanisms are installed on the input shaft through keys, the eccentric mechanisms are rotatably connected with the transmission mechanism through bolts, the control mechanism isrotatably connected with the transmission mechanism through a bolt, and the transmission mechanism is installed on the output shaft through a key. The double-pushing device comprises the two groups of eccentric mechanisms, the control mechanism and the transmission mechanism; two reciprocating horizontal output driving strokes are generated by the rotation of each group of eccentric mechanism; and the control mechanism controls the output rotation of the output shaft through the transmission mechanism by controlling the reciprocating horizontal output driving stroke lengths of the eccentric mechanisms. The double-pushing device is simple and reasonable in structural design, easy and convenient to operate, high in pushing frequency and adjustable in pushing stroke, and the drying effect ofthe grain dryer is effectively improved.

Owner:合肥三伍机械有限公司

Medical instrument equipment drying device

InactiveCN107917597ASolve the problem of uneven dryingDry evenlyDrying gas arrangementsDrying solid materialsTop driveEngineering

The invention discloses a drying device for medical equipment, which comprises a box body, the bottom of the box body is fixedly connected with a power box, and the bottom of the inner cavity of the power box is movably connected with a transmission column through a bearing, and the transmission column The top runs through the power box and the box body in turn and is movably connected with the top of the box inner cavity through bearings. The surface of the transmission column is sleeved with a placement frame, and the bottom of the surface of the transmission column is sleeved with a worm gear. The present invention adopts box body, power box, transmission column, placement frame, worm gear, motor, nozzle, fixed plate, heating box, heating wire, fan, exhaust port, baffle plate, through hole, fixed frame, driven fan, sealing The cooperation of the ring, the worm and the nozzle solves the problem of uneven drying of the existing medical equipment drying device. The medical equipment drying device has the advantage of uniform drying, which enhances the medical equipment drying device. Practicality, easy for users to use.

Owner:叶侃

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com