Mesh Belt Dryer

A dryer and mesh belt technology, applied in dryers, drying solid materials, drying and other directions, can solve problems such as easy agglomeration, and achieve the effects of preventing agglomeration, reducing contact area and improving drying efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

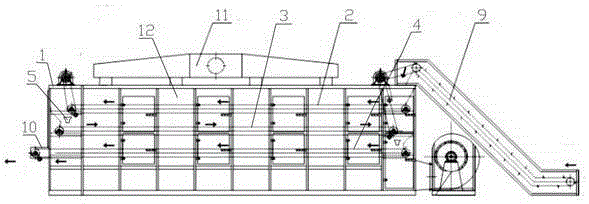

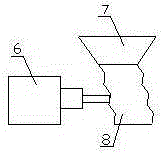

[0015] A kind of mesh belt dryer provided in this embodiment, such as figure 1 As shown, the oven has a hollow shell 1, and a mesh belt conveying unit for conveying materials is horizontally provided in the shell 1. The mesh belt conveying unit includes a first layer of mesh belts 2 and a second layer of mesh belts that are staggered up and down and connected head to tail. 3 and the third layer of mesh belt 4, between the discharge end of the first layer of mesh belt 2 and the feed end of the second layer of mesh belt 3, and the discharge end of the second layer of mesh belt 2 and the feed of the third layer of mesh belt 4 A material turning device 5 is respectively arranged between the ends, and the structure diagram of the material turning device 5 is as follows: figure 2 As shown, it is mainly composed of a hydraulic cylinder 6 and a hopper 7 whose telescopic direction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com