An experimental system and method for vibrating classification, drying and quality improvement of low-rank coal

A technology of grading drying and experimental system, applied in drying gas arrangement, chemical instruments and methods, drying, etc., can solve the problems of uneven heating of samples, high energy consumption, low dehydration efficiency, etc., to simplify the process and reduce the dehydration energy. The effect of reducing energy consumption and preventing uneven temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

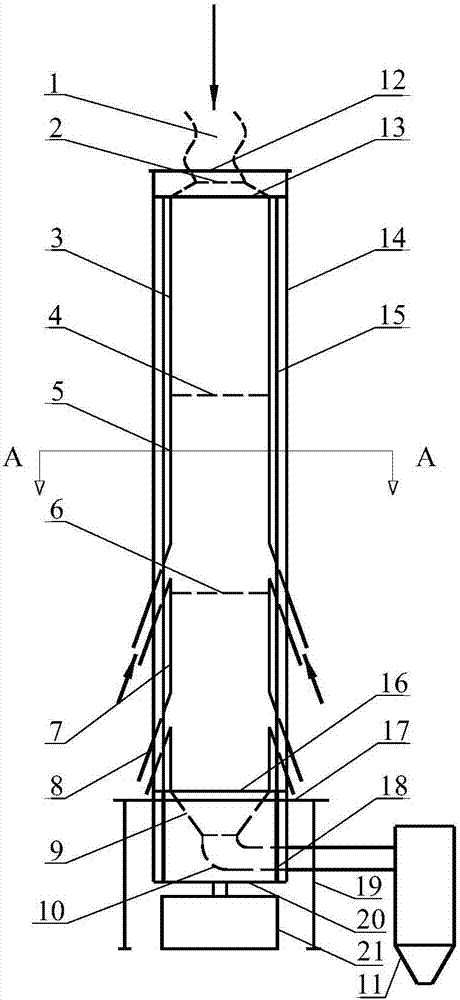

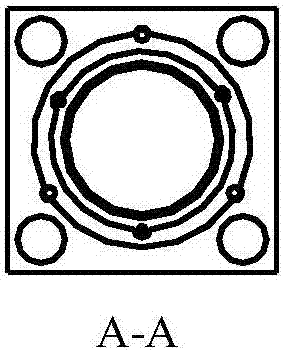

[0032] Example 1: The low-rank coal drying and upgrading experimental system includes: air inlet hose 1, air diffuser 2, primary drying cylinder 3, first layer of sieve surface 4, secondary drying cylinder 5, second layer of sieve surface 6. Three-stage drying cylinder 7, supplementary air pipe 8, discharge port 9, discharge pipeline 10, gas-solid separator 11, slide rail connecting plate 12, cover screen upper pressure plate 13, slide rail 14, fastening plate 15, Set of support plates 16 under the screen, back-shaped support plates 17, casing pipes 18, foot pillars 19, vibration excitation plates 20 and vibration exciters 21;

[0033] The air inlet hose 1, air diffuser 2, primary drying cylinder 3, secondary drying cylinder 5 and tertiary drying cylinder 7 located inside the drying cylinder are connected sequentially from top to bottom; The first layer of sieve surface 4 is connected between the drying cylinders 5, and the second layer of sieve surface 6 is connected between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com