Sludge drying system and sludge drying method

A sludge drying and sludge technology, which is applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc. Drying efficiency and energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

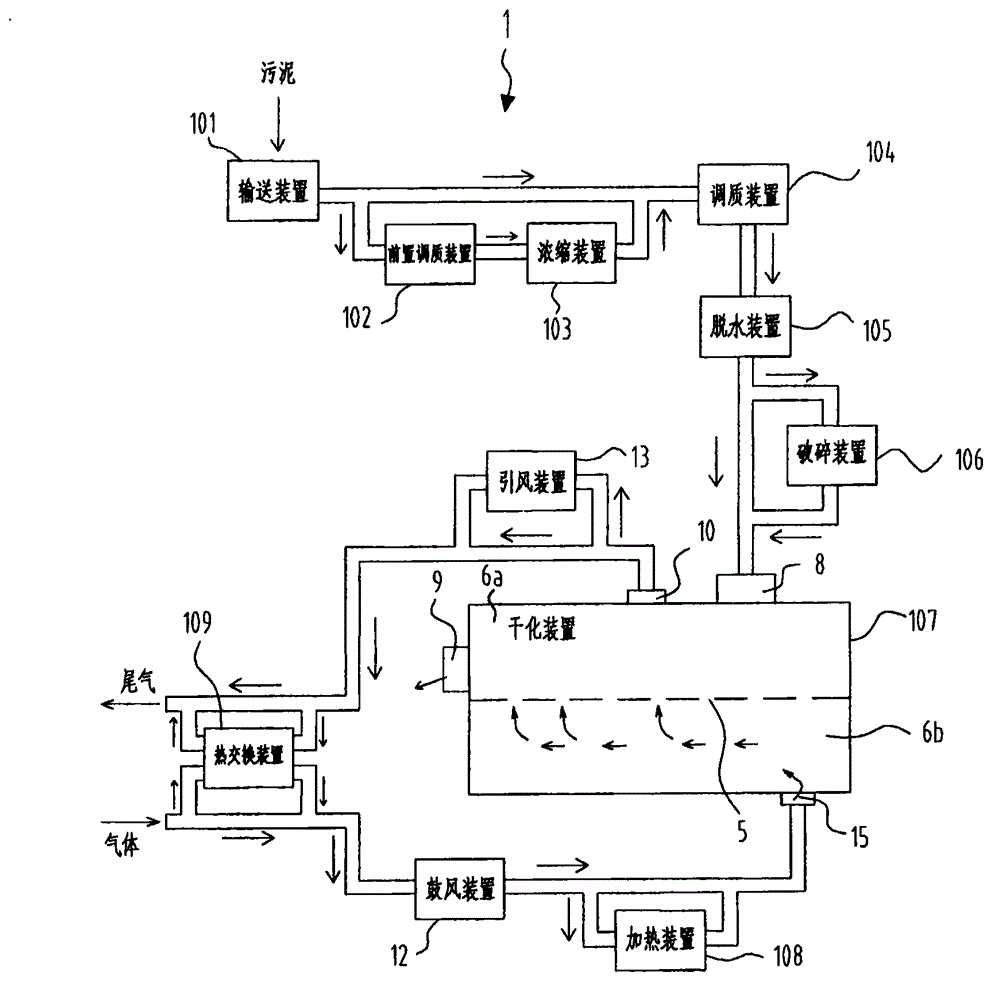

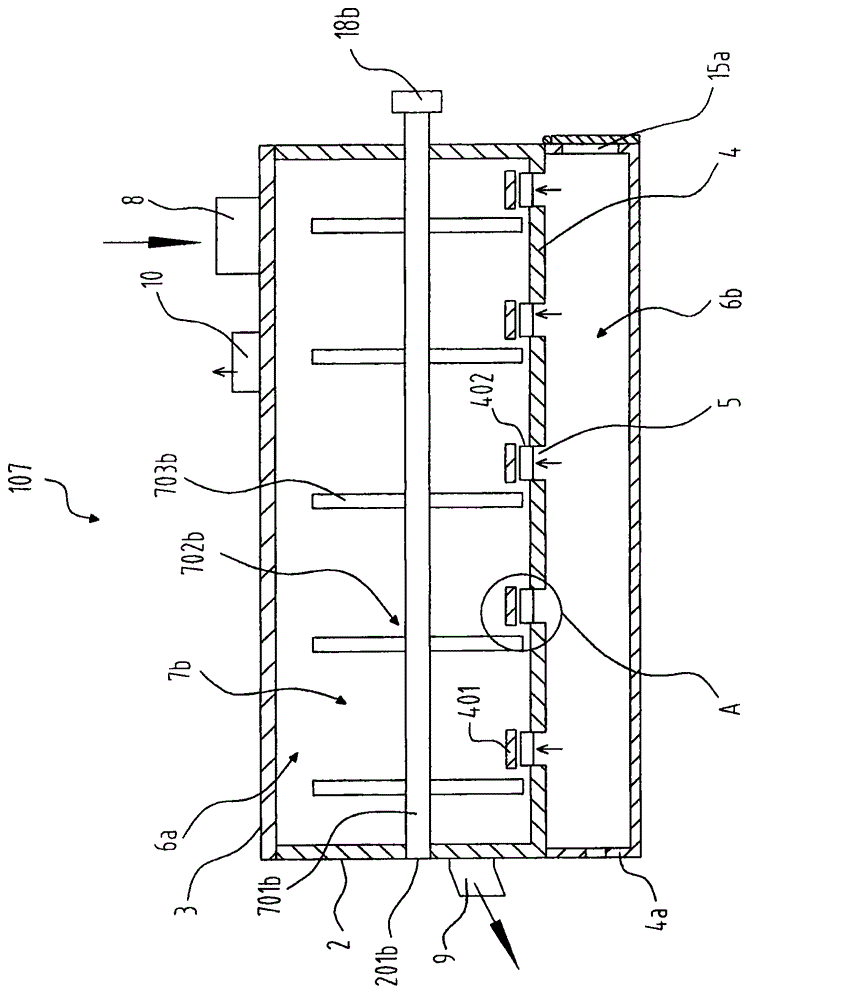

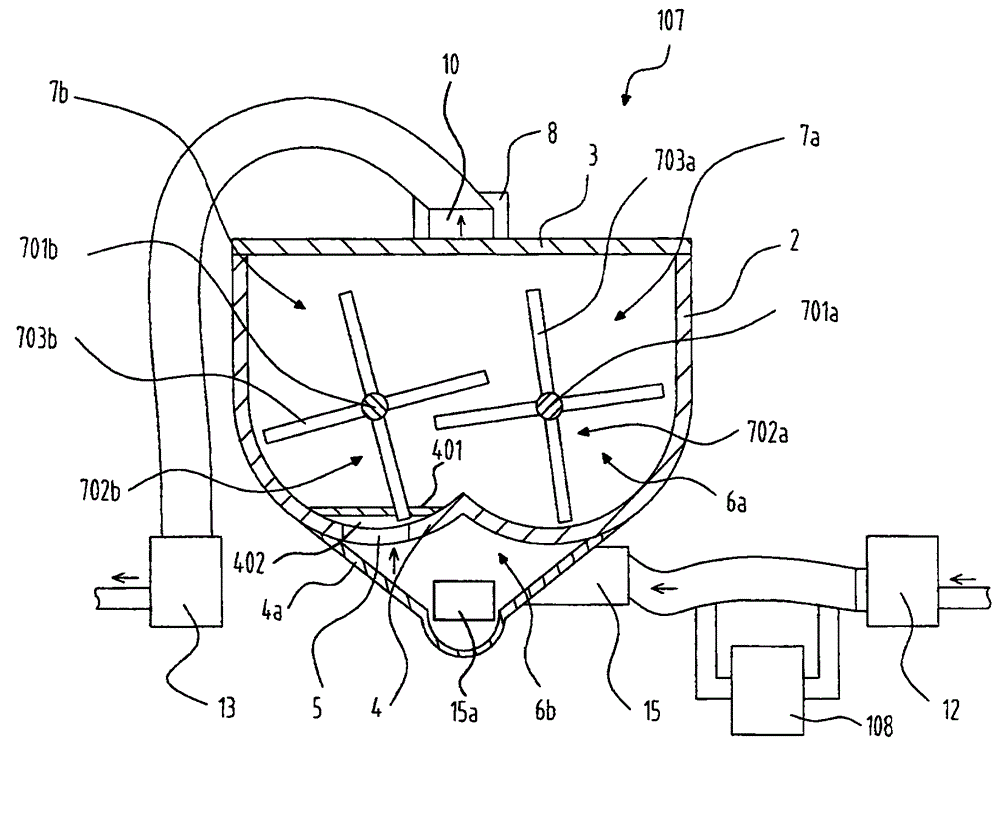

[0045] figure 1 A preferred embodiment of the sludge drying system of the present invention is shown, wherein the sludge drying system 1 can reduce the water content of the sludge from above about 90% to below about 40%, thereby obtaining powdery sludge .

[0046] The sludge drying system 1 generally includes a conveying device, a conditioning device (or a secondary conditioning device), a dehydration device, a drying device and an air blowing device, and also includes a pre-conditioning (or primary conditioning) device and a concentration devices, crushing devices, etc. The sludge drying system 1 of the present invention may also include an air induction device, a heating device and a heat exchange device.

[0047] Usually the water content of liquid sludge from sewage treatment equipment is above 90%. After receiving the liquid sludge, the conveying device 101 can transport the liquid sludge to the conditioning device or the secondary conditioning device 104 through the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com