Discharging and drying device for wolfberry fruits

A drying device and material cutting technology, applied in drying, drying machine, drying gas arrangement, etc., can solve the problems of poor drying effect and wolfberry accumulation, achieve simple structure, prevent local accumulation, and be easy to popularize and apply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

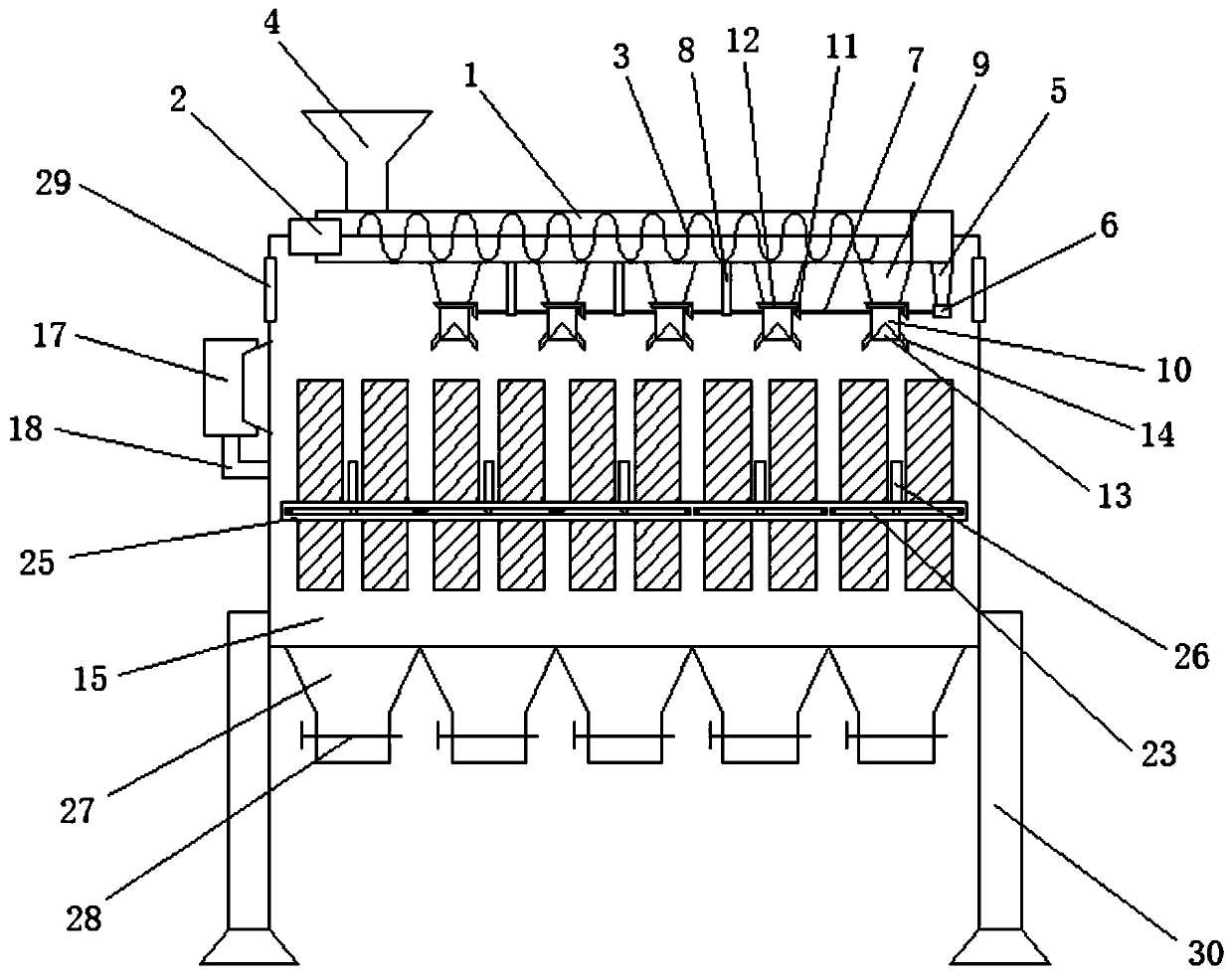

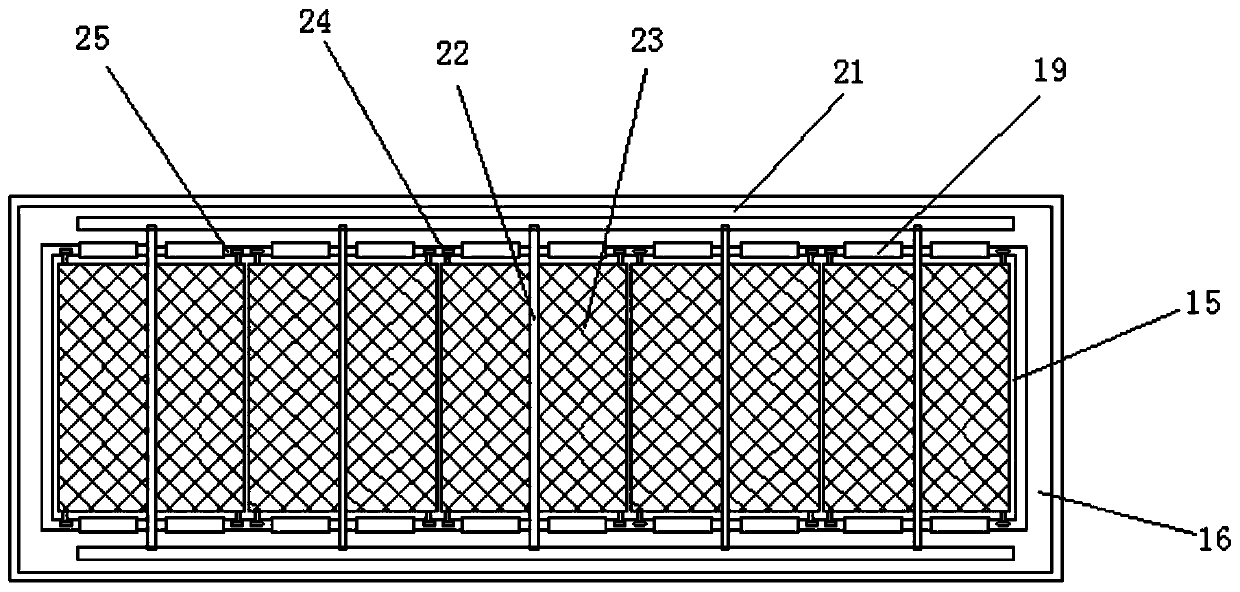

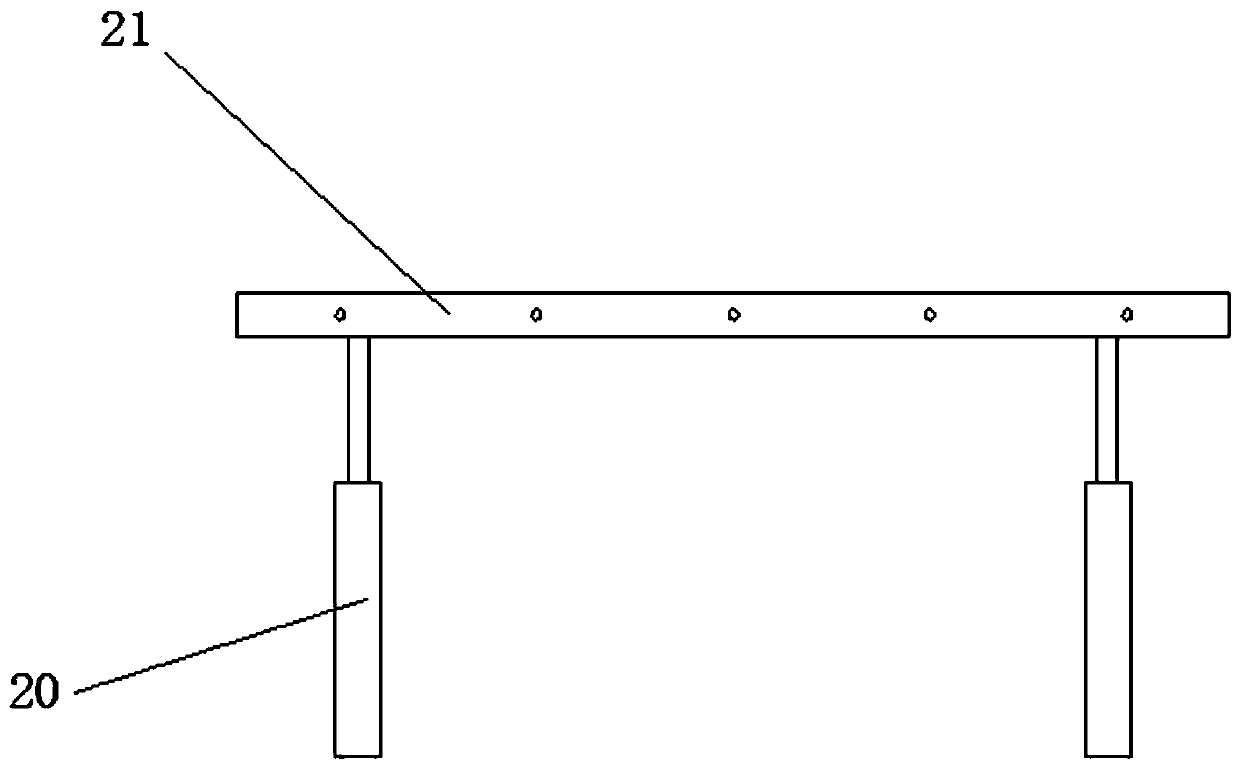

[0033] Embodiment 1: as Figure 1-4 As shown, a cutting and drying device for Chinese wolfberry includes a conveying pipe 1 and a drying bin 15, the conveying pipe 1 is installed horizontally on the top of the drying chamber 15, and the left end of the conveying pipe 1 is fixedly equipped with a first motor 2. The right end of the first motor 2 is fixedly connected with a screw 3, and the screw 3 is located in the inner cavity of the delivery pipe 1, and the screw is driven by the first motor to rotate, and the wolfberry is transported from left to right;

[0034] The top of the left end of the conveying pipe 1 is fixedly connected with a feeding port 4, and the bottom of the conveying pipe 1 is fixedly equipped with a plurality of feeding pipes 9, and the bottom of each group of the feeding pipes 9 is connected with a rotating barrel 10, so The bottom side wall of the rotary barrel 10 is fixedly equipped with some discharge pipes 14, which can lead out the wolfberry from each...

Embodiment 2

[0049] Embodiment 2: as Figure 1-5 As shown, a cutting and drying device for Chinese wolfberry includes a conveying pipe 1 and a drying bin 15, the conveying pipe 1 is installed horizontally on the top of the drying chamber 15, and the left end of the conveying pipe 1 is fixedly equipped with a first motor 2. The right end of the first motor 2 is fixedly connected with a screw 3, and the screw 3 is located in the inner cavity of the delivery pipe 1, and the screw is driven by the first motor to rotate, and the wolfberry is transported from left to right;

[0050] The top of the left end of the conveying pipe 1 is fixedly connected with a feeding port 4, and the bottom of the conveying pipe 1 is fixedly equipped with a plurality of feeding pipes 9, and the bottom of each group of the feeding pipes 9 is connected with a rotating barrel 10, so The bottom side wall of the rotary barrel 10 is fixedly equipped with some discharge pipes 14, which can lead out the wolfberry from each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com