Patents

Literature

79results about How to "Avoid affecting subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

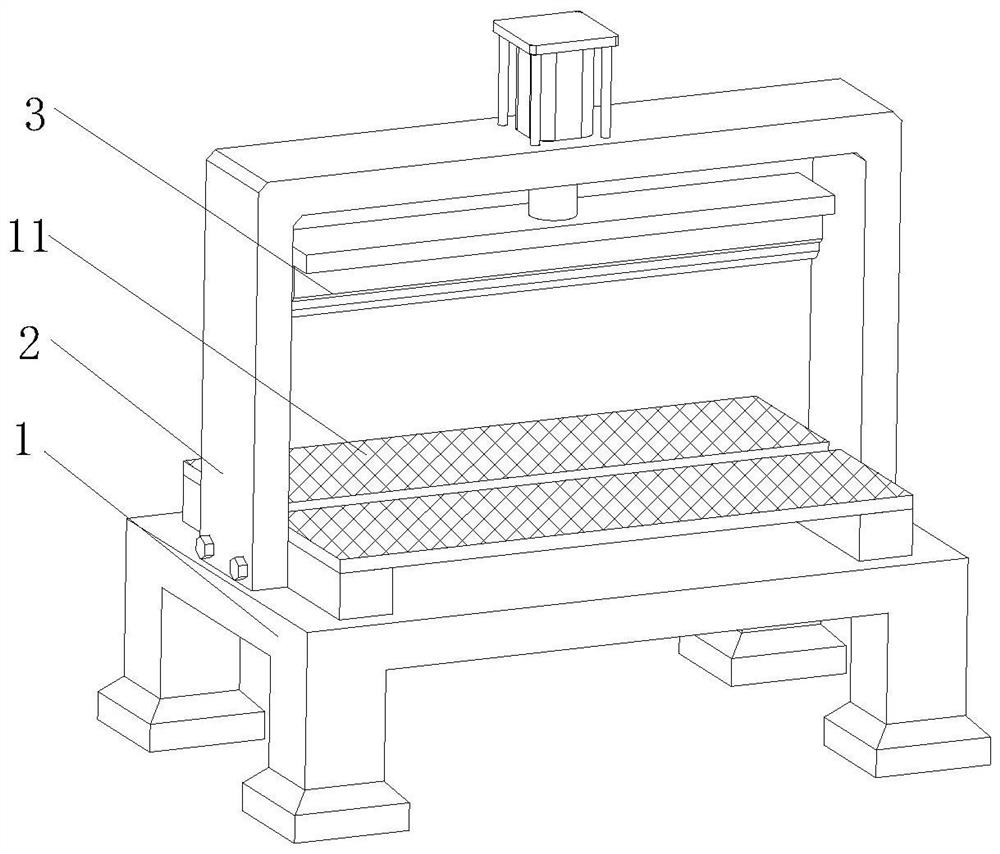

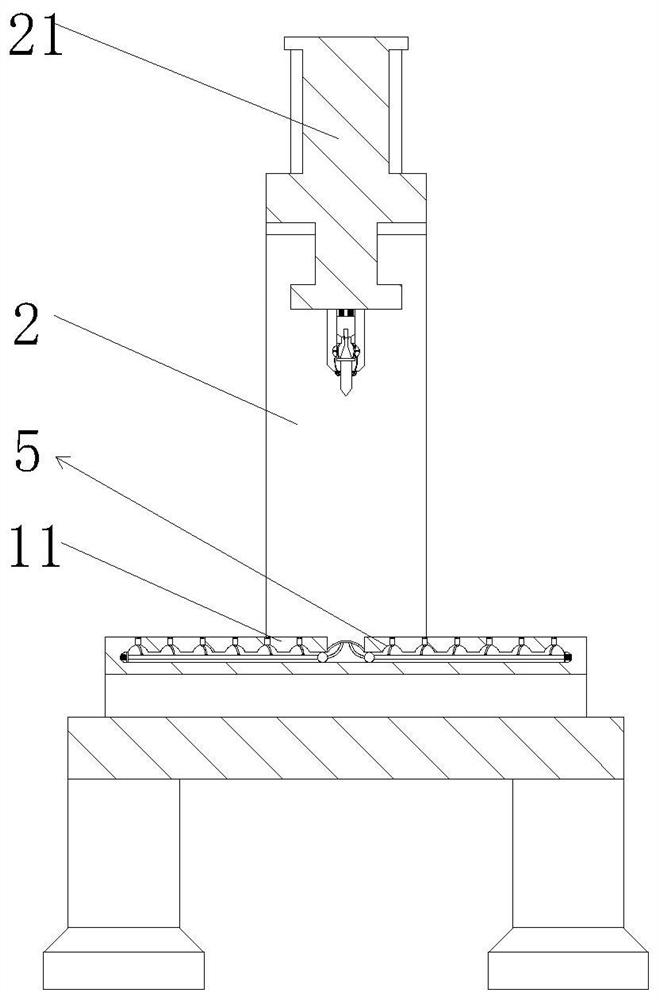

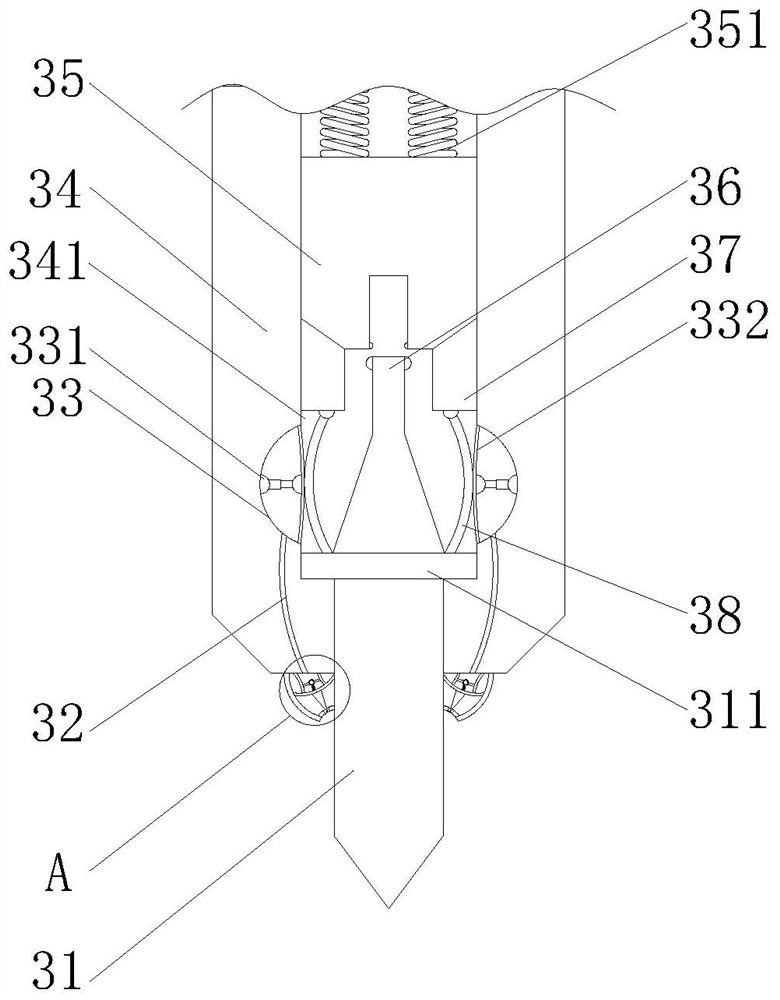

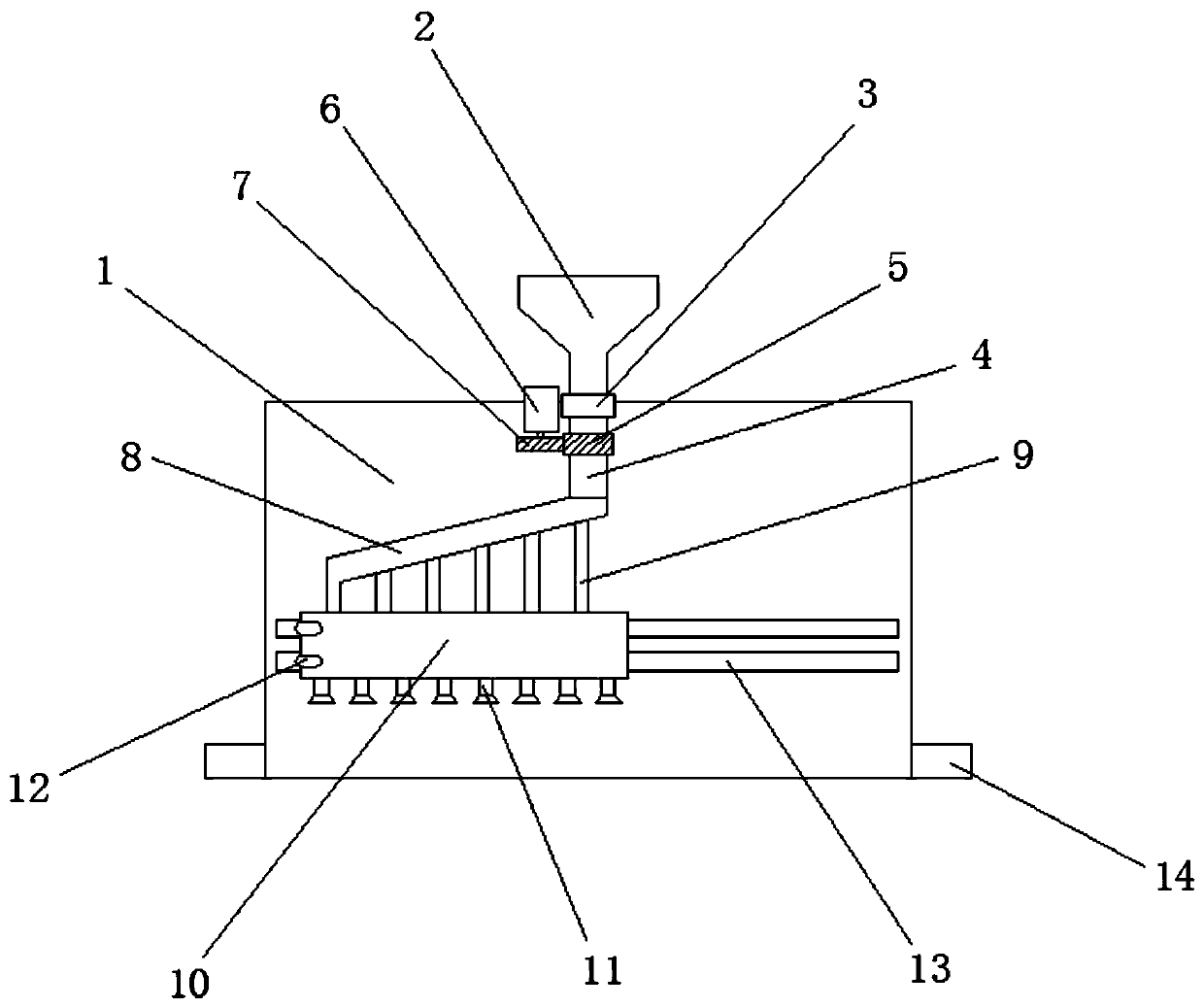

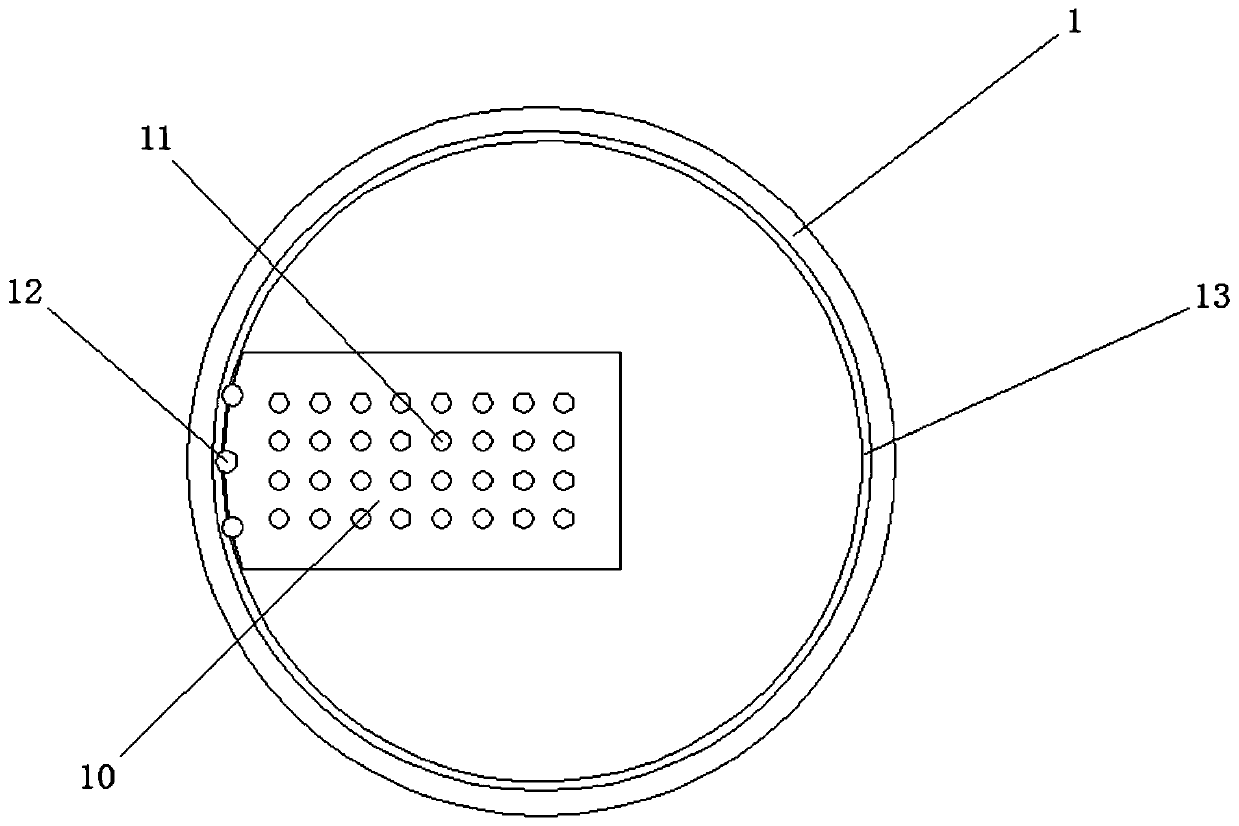

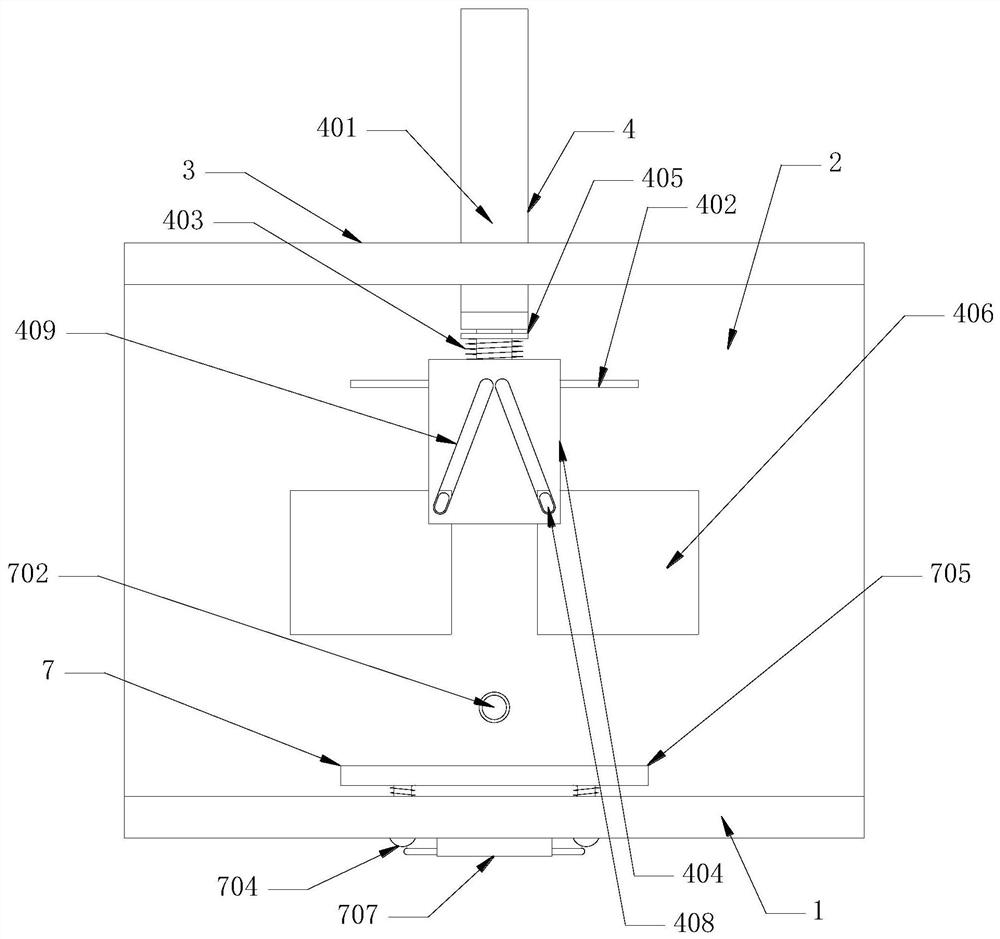

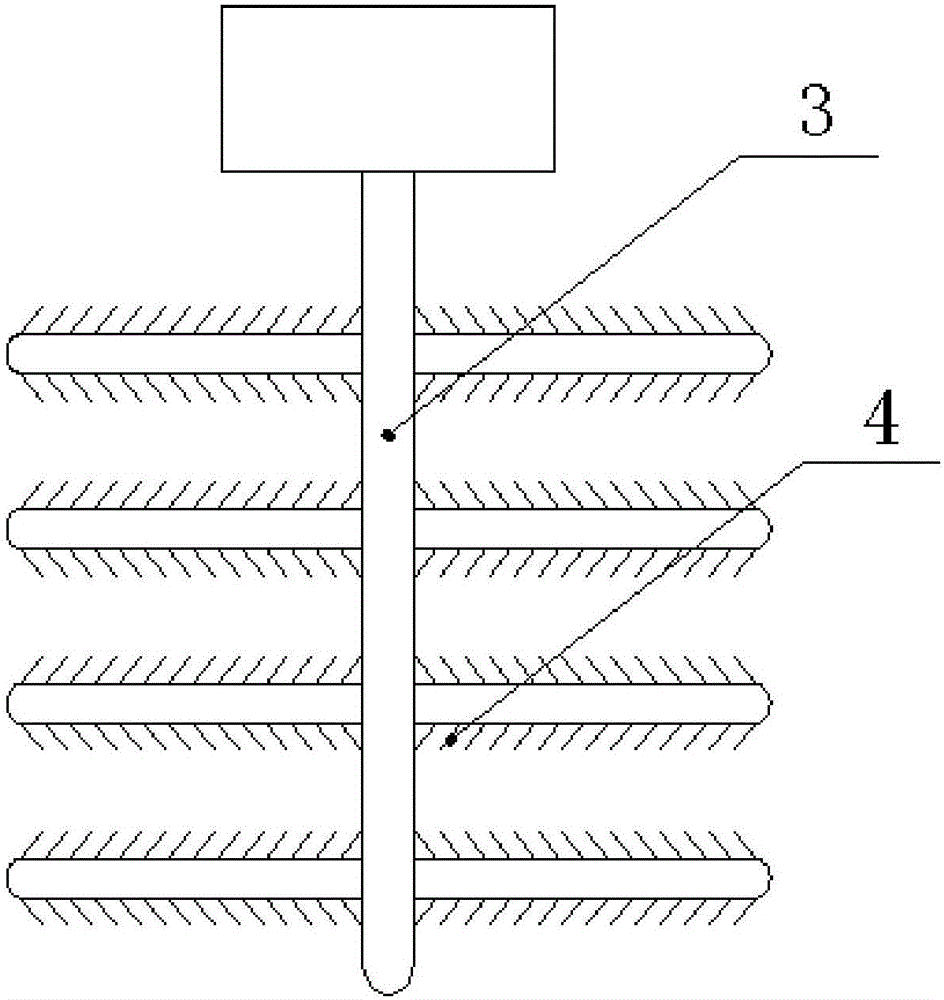

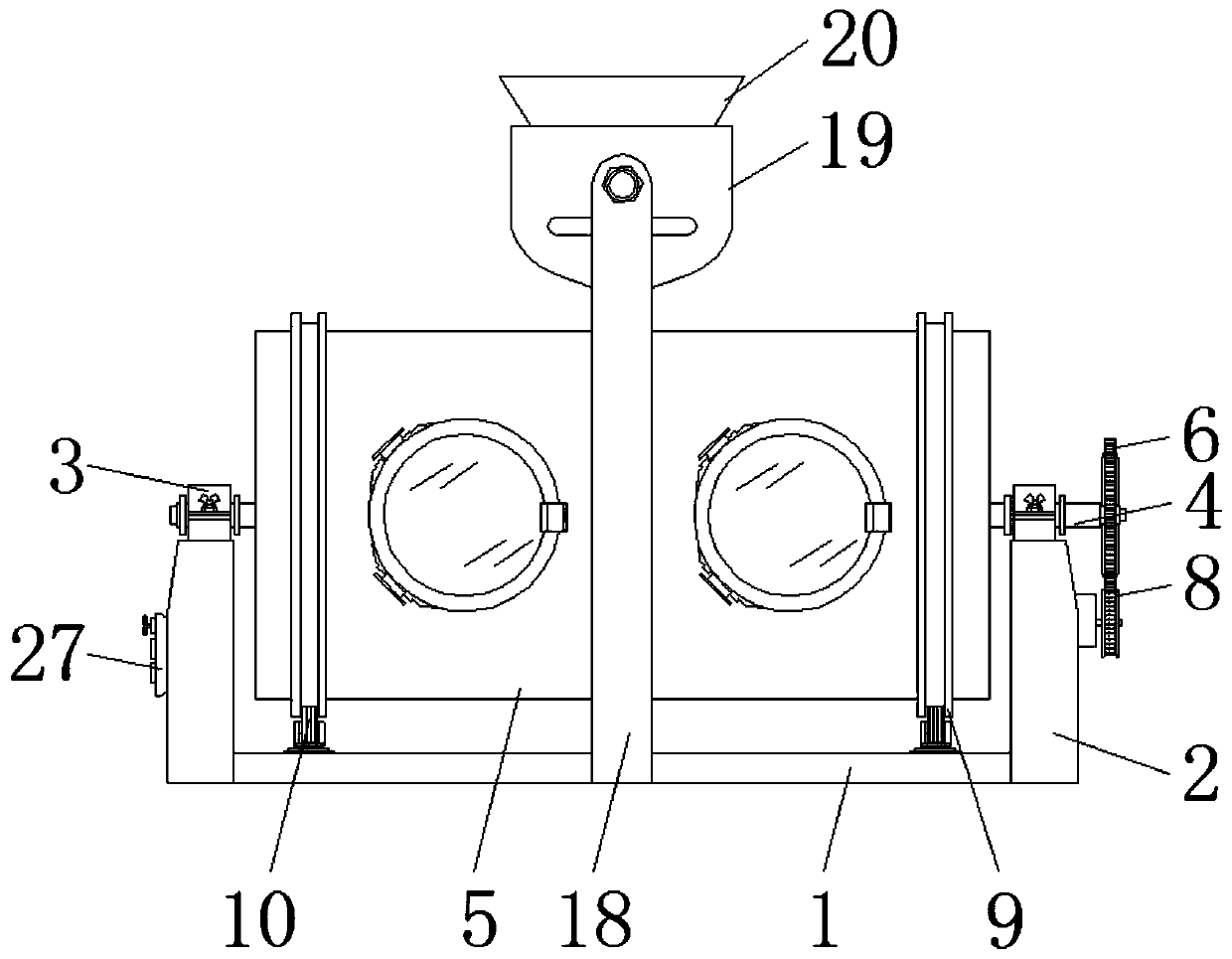

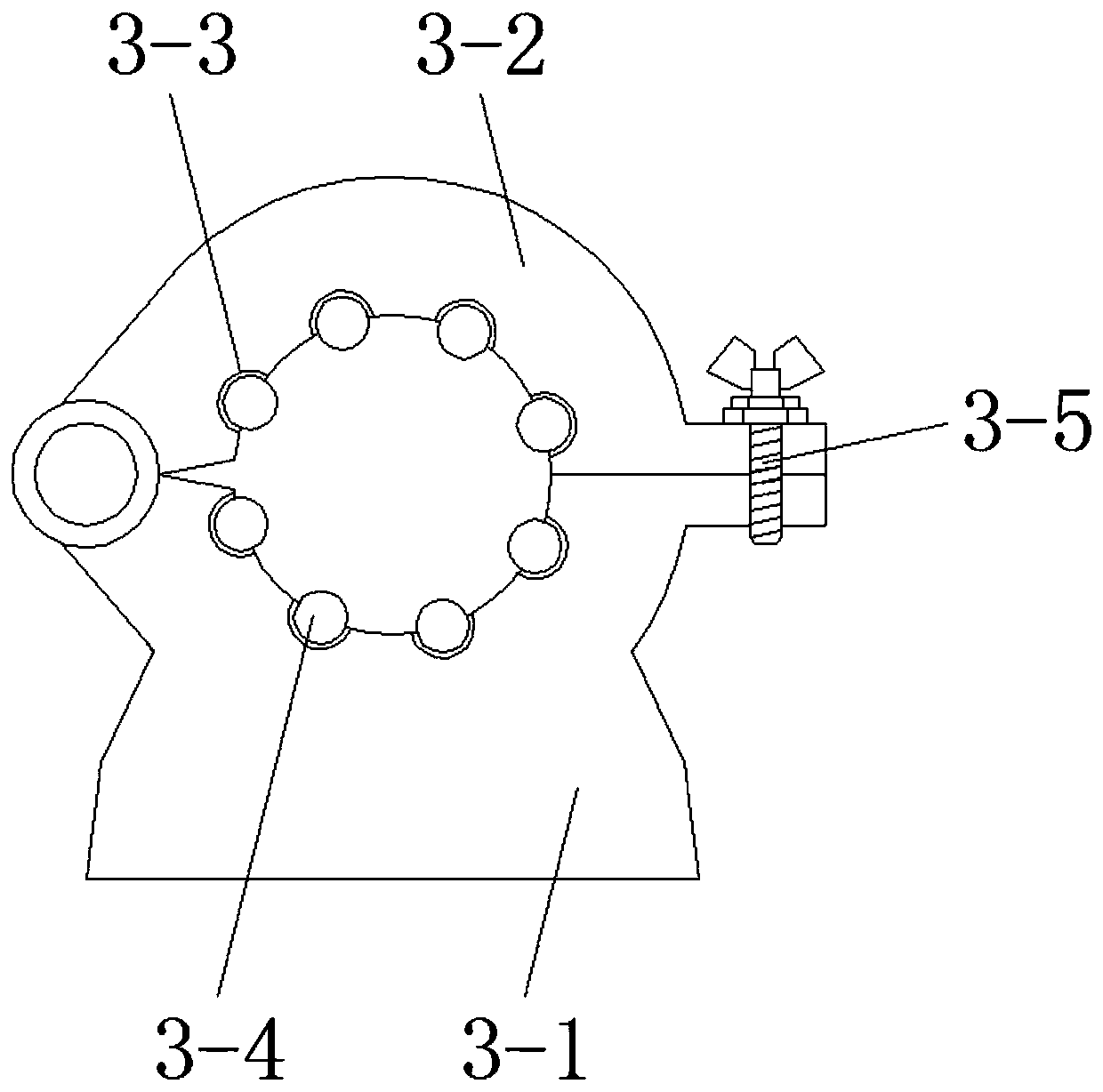

Pipe punching device

InactiveCN105436292AConvenient pipe fitting processingWide applicabilityPerforating toolsEngineeringPunching

The invention discloses a pipe punching device which comprises punching table supporting feet, a punching table, punching supporting arms, a punching supporting beam and a pipe fixing clamp carrying board. Punching tool carrying blocks are arranged at the bottoms of inner punching arms. Punching tools are installed on the inner walls of the punching tool carrying blocks. The pipe punching device integrates transverse punching operation and vertical punching operation, control and adjustment can be performed effectively according to the machining specification and the requirements of a pipe through an adjustment and control device and a hydraulic synchronous closing valve which are installed on the pipe punching device, the punching tools and the punching tool carrying blocks of the pipe punching device are fixed through fixing nuts, the pipe fixing clamp carrying board and a lower pipe fixing die are fixed through fixing nuts, a pipe fixing clamp and the punching tools of the pipe punching device can be conveniently replaced according to the model and the specification of the pipe, the pipe can be machined conveniently through the pipe punching device, and the adaptability of the pipe punching device is higher.

Owner:无锡西源电力装备厂

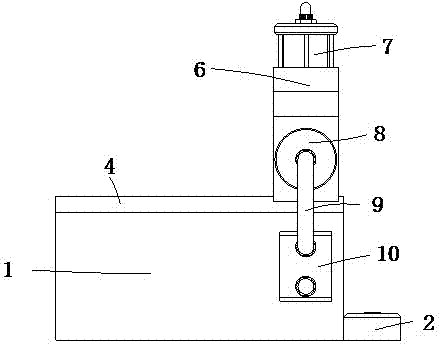

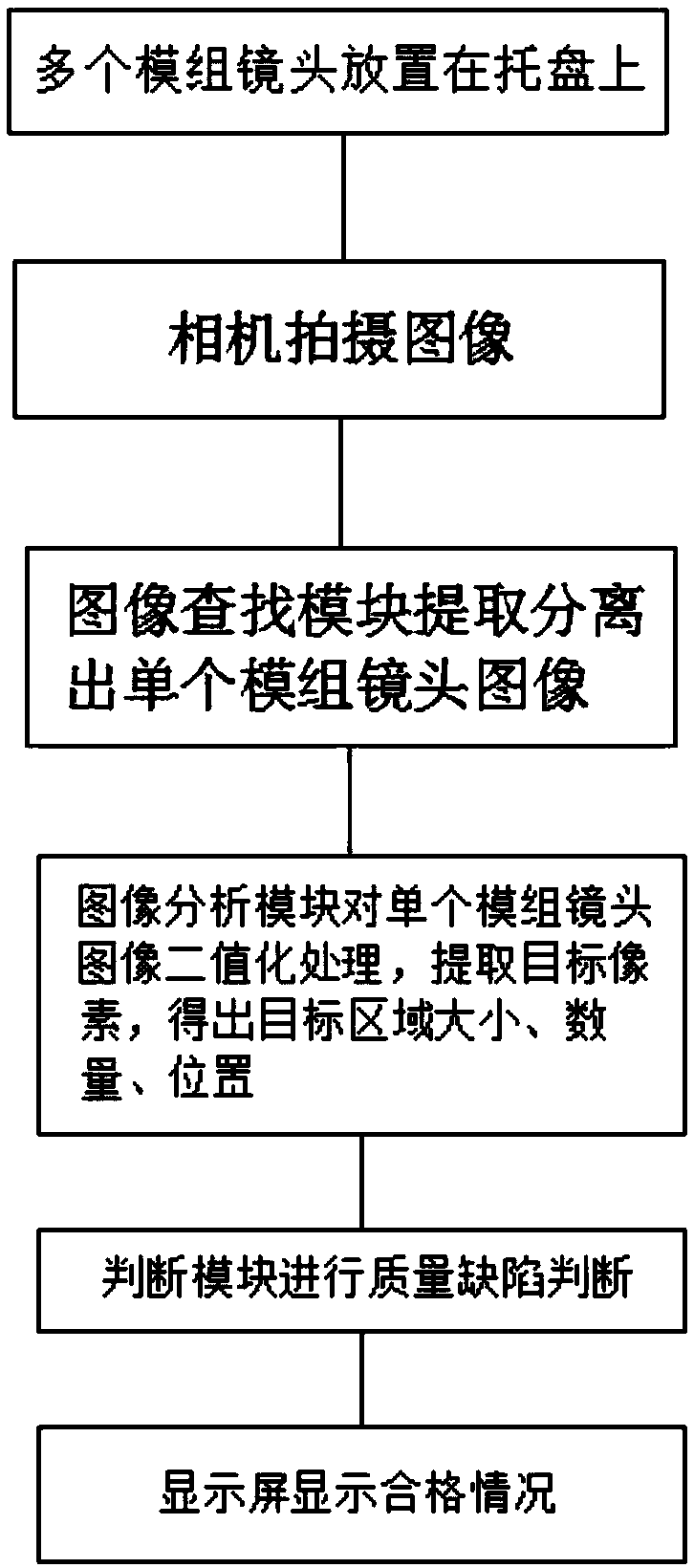

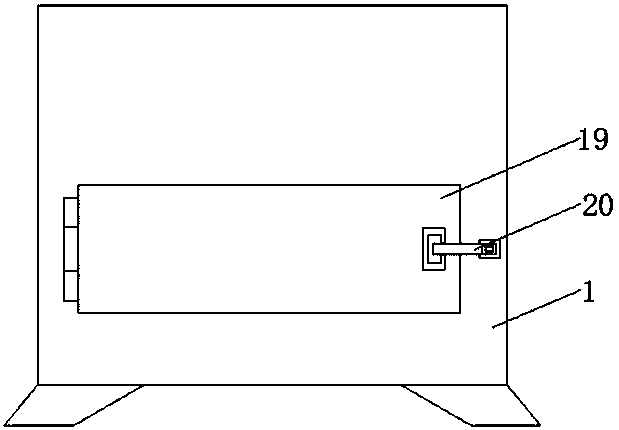

Method for detecting appearance of module lens

InactiveCN108827979AHigh accuracyLow costOptically investigating flaws/contaminationCamera lensImage analysis

The invention relates to a method for detecting the appearance of a module lens. The method comprises: 1, placing a plurality of module lenses on a tray at equal distances, 2, capturing a plurality ofmodule lens images by a camera and extracting and separating a single module lens image from the captured images through an image search module, 3, carrying out binarization processing on the singlemodule lens image through an image analysis module to obtain a black-and-white binary image, dividing the binary image into target pixel and background pixel sets, extracting target pixel features through the image analysis module to obtain the sizes, positions and number of target areas, 4, determining whether the single module lens has a quality defect through a determining module, and 5, displaying the qualified condition of the single module lens through a computer display screen, and accurately determining whether the module lens has lens barrel foreign objects, lens barrel scratches, lens foreign objects and lens scratches. The method produces accurate detection results, timely finds quality defects, prevents subsequent processing, reduces a cost, reduces human interference and meetsproduction demands.

Owner:东莞高伟光学电子有限公司

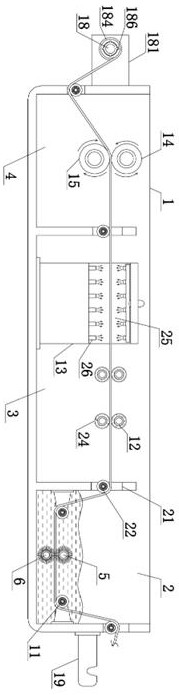

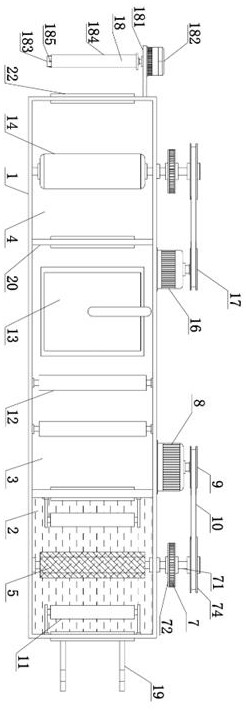

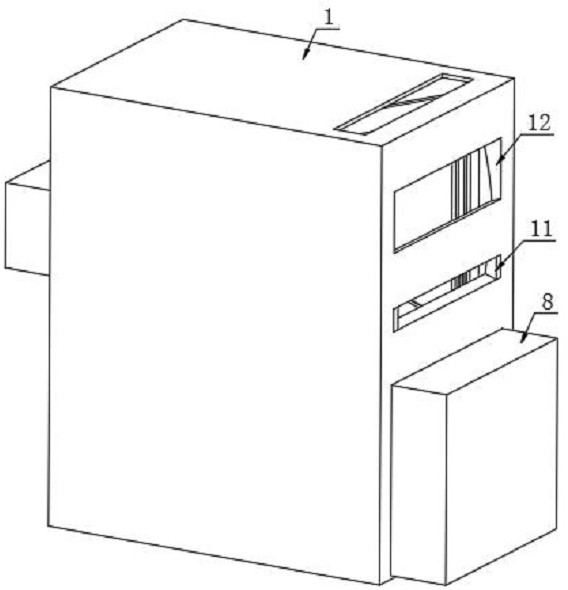

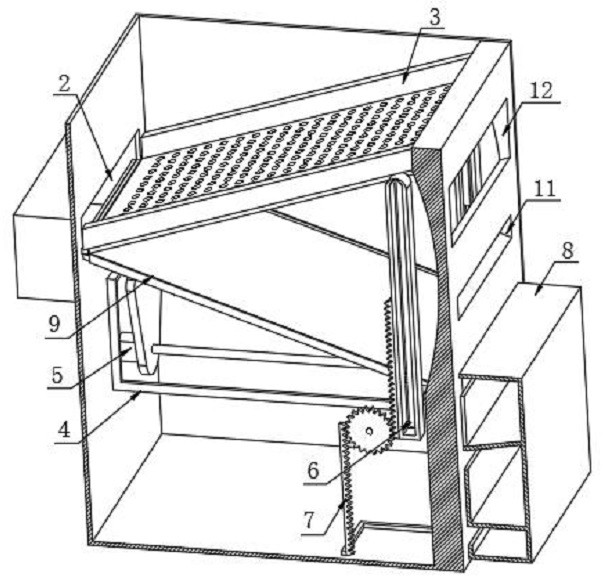

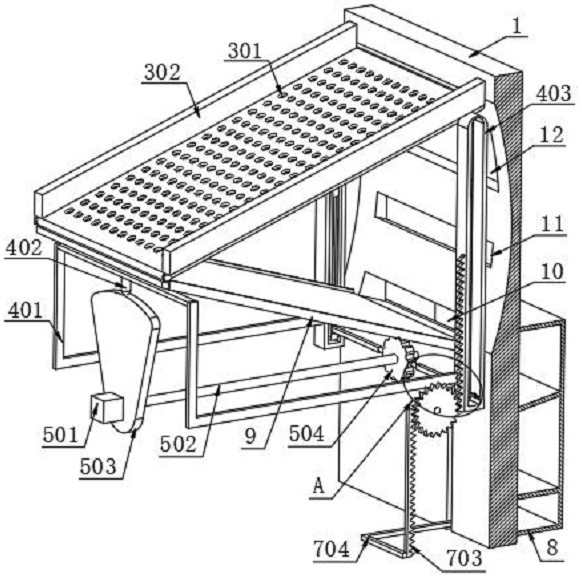

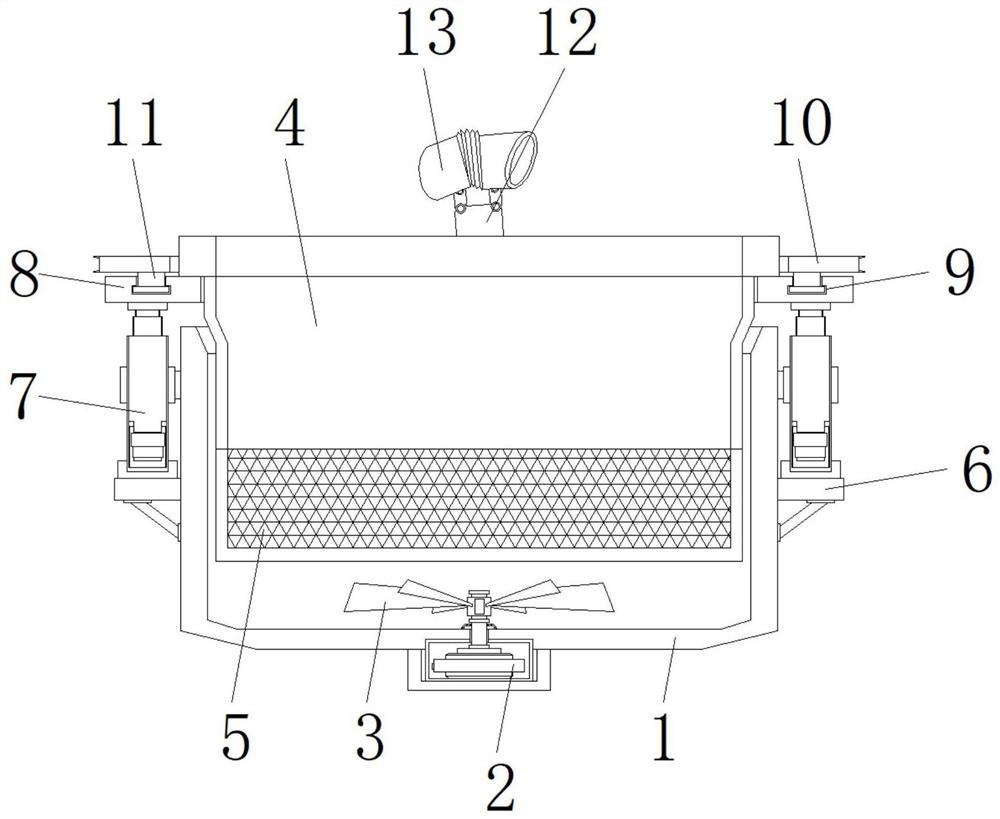

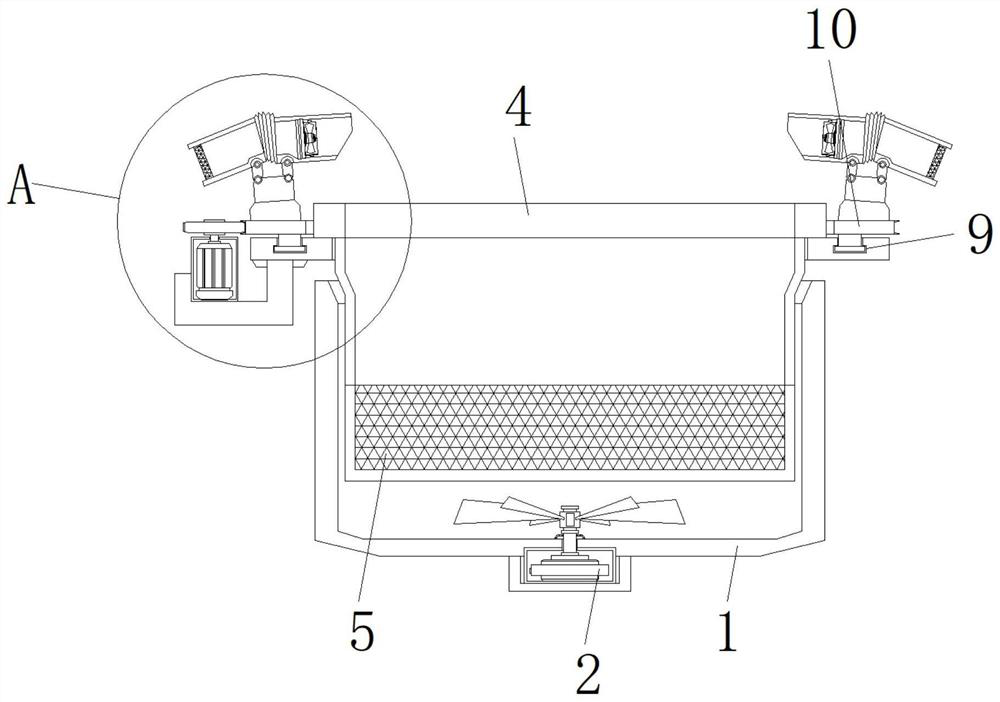

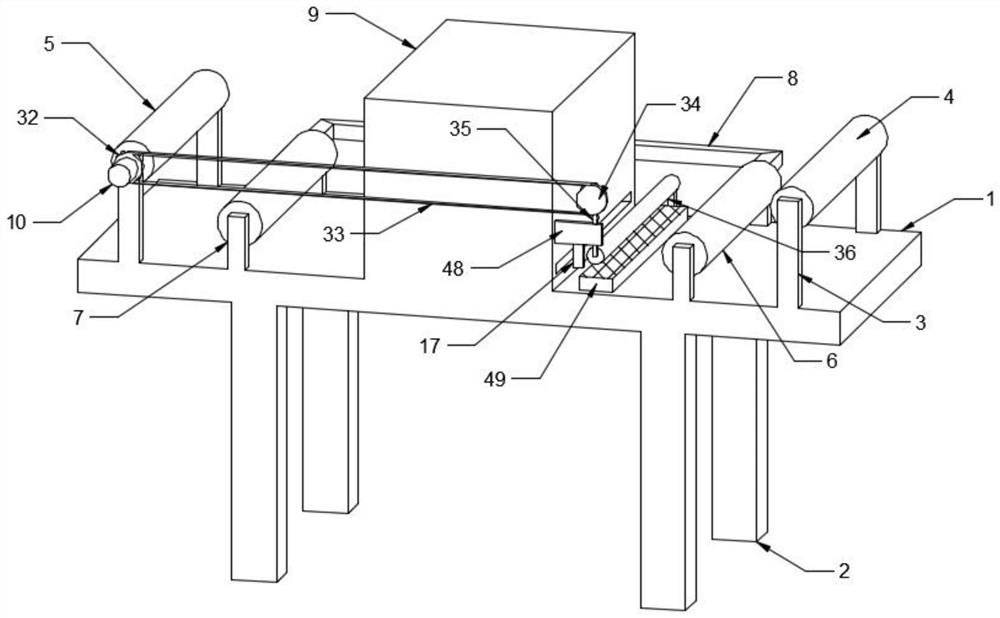

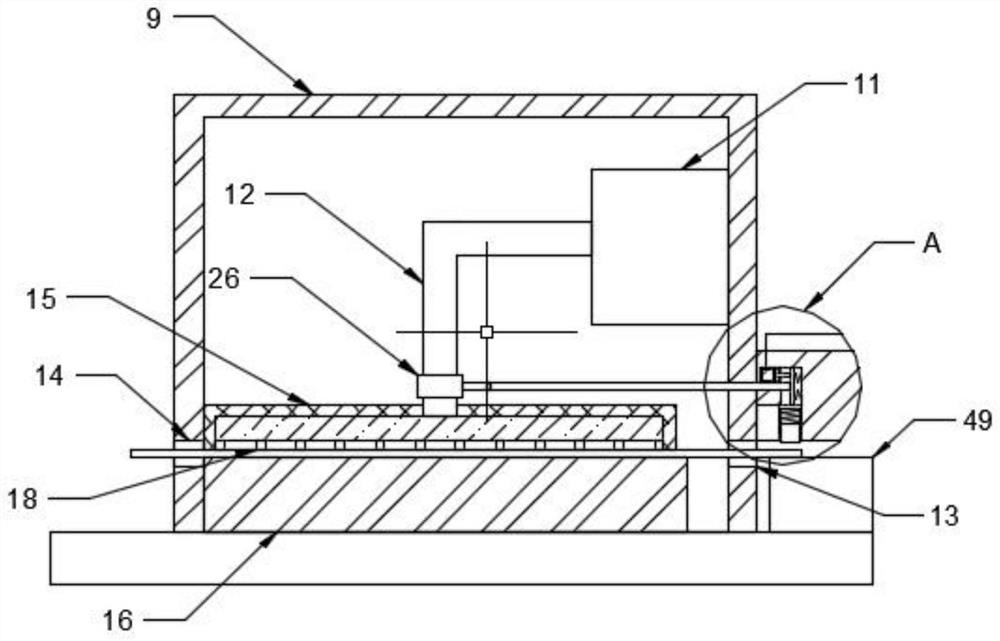

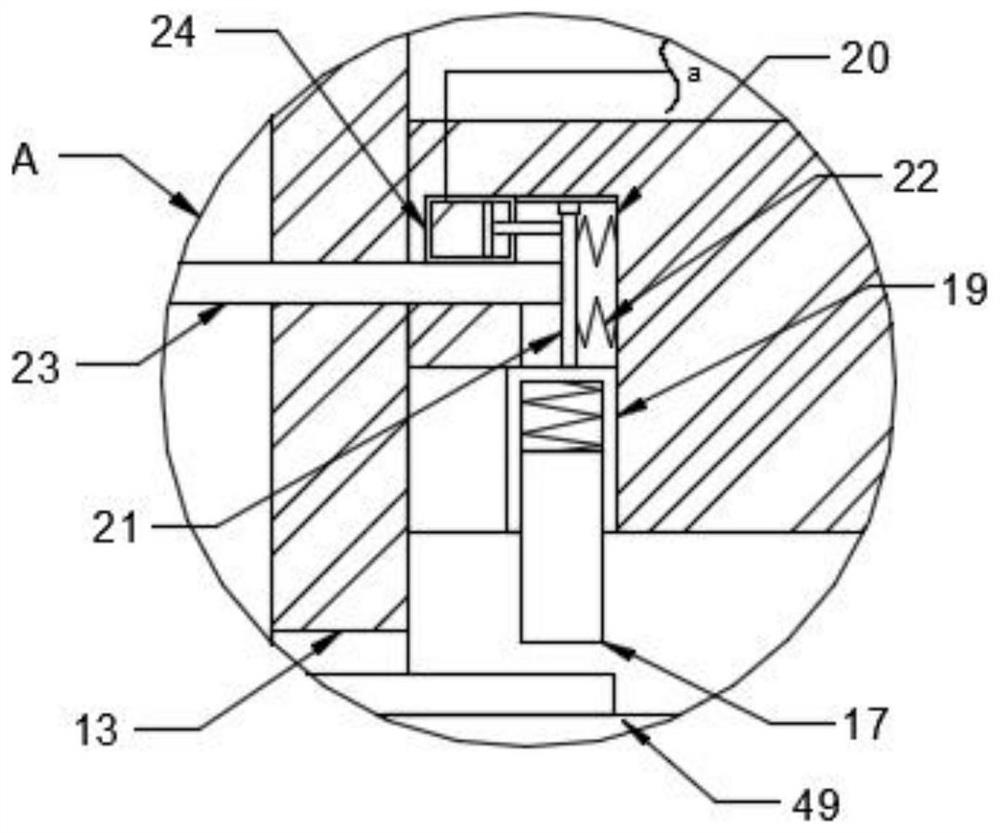

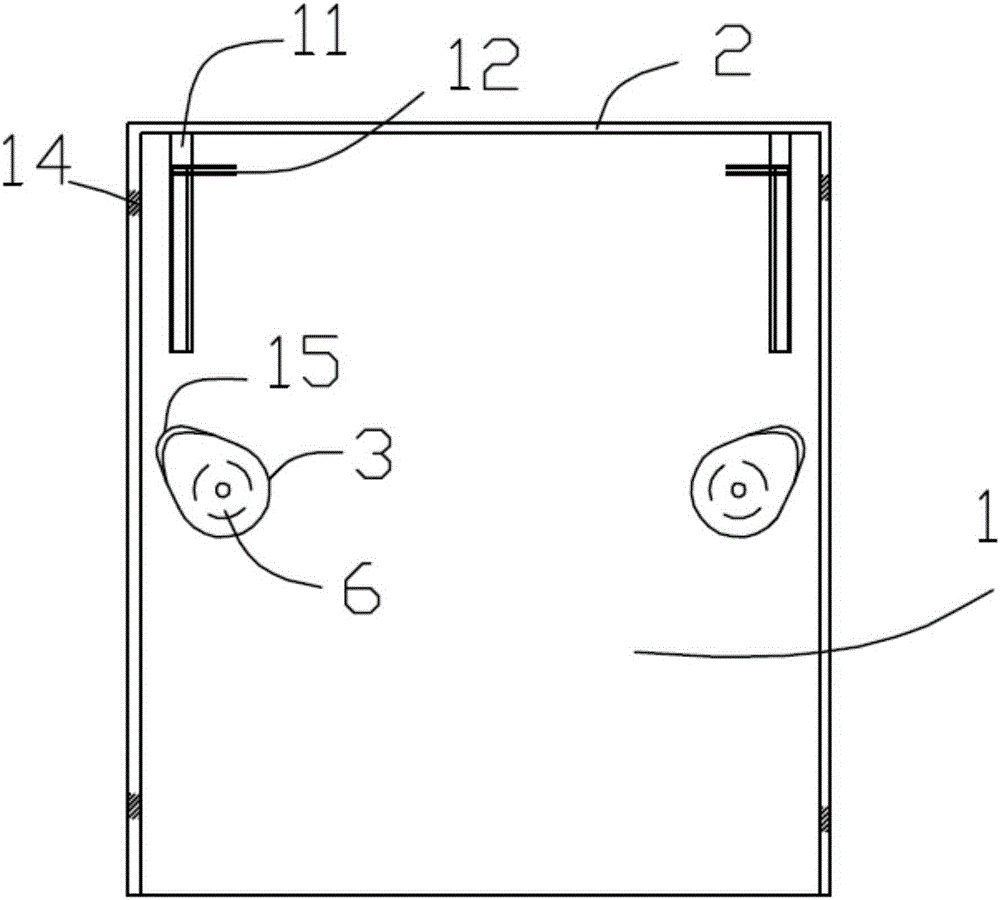

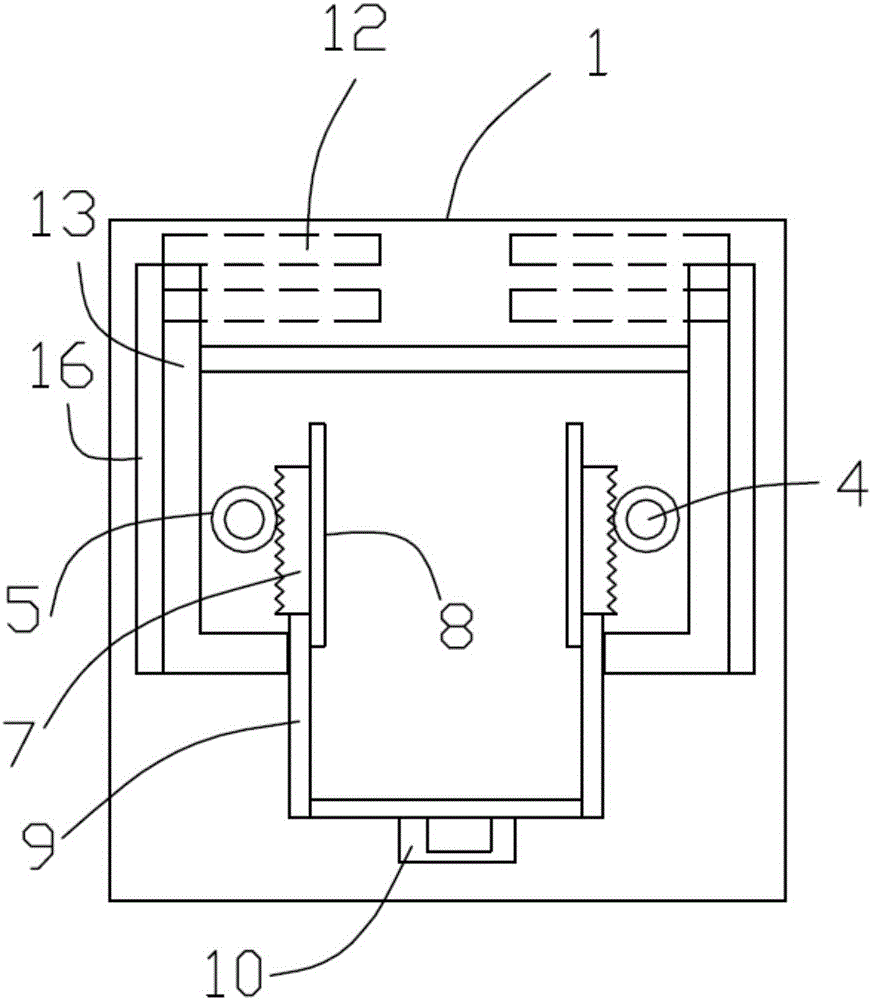

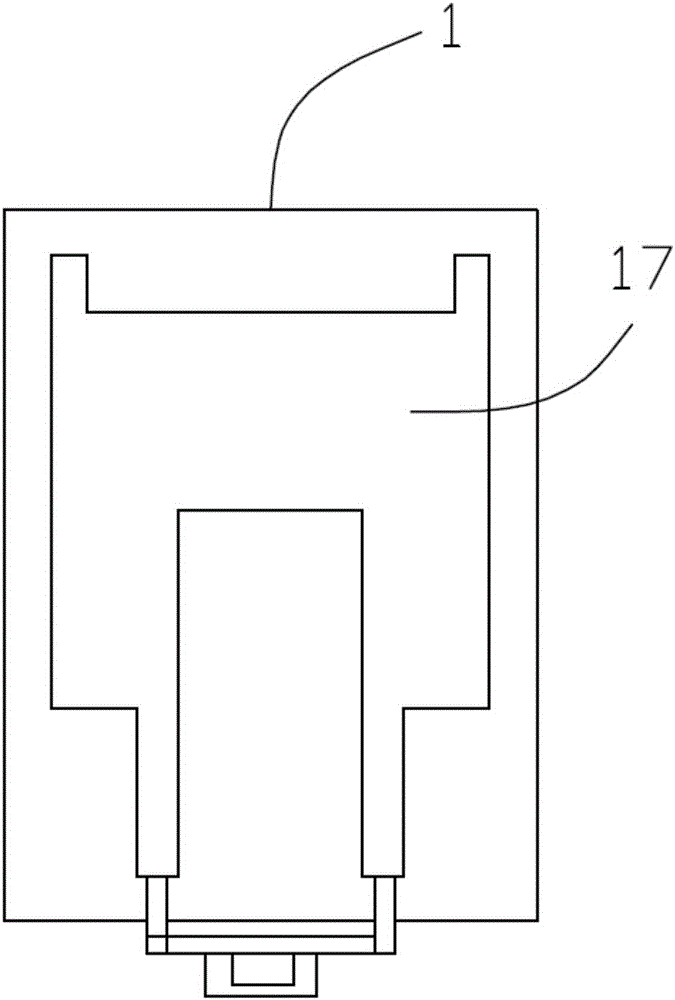

Aluminium strip anode oxidized surface pre-treatment equipment

InactiveCN111809212AEasy to cleanImprove oxidation capacityPolishing machinesGrinding drivesElectric machineryPre treatment

The invention discloses aluminium strip anode oxidized surface pre-treatment equipment and belongs to aluminium strip anode oxidization. The aluminium strip anode oxidized surface pre-treatment equipment comprises a device body; an oil removing chamber, a drying chamber and a polishing chamber are formed in the device body; the oil removing chamber in the device body removes oil from an aluminiumstrip first; a first washing roll and a second washing roll in the oil removing chamber are driven by a first motor to rotate to wash off oil stains on the surface of the aluminium strip so that the aluminium strip is conveniently cleaned; the washed aluminium strip is driven into the drying chamber; an adsorption liquid in the drying chamber adsorbs liquid, brought from the oil removing chamber,on the surface of the aluminium strip; and then the aluminium strip passes through the interior of the drying chamber to be dried for the second time so as to prevent the surface of the aluminium strip from being wet to affect oxidization; the dried aluminium strip enters into the polishing chamber to be polished so that the surface of the aluminium strip is clean and smooth; during the follow-upoxidization of the aluminium strip anode, the aluminium strip oxidization effect is improved to avoid flaws.

Owner:王东亮

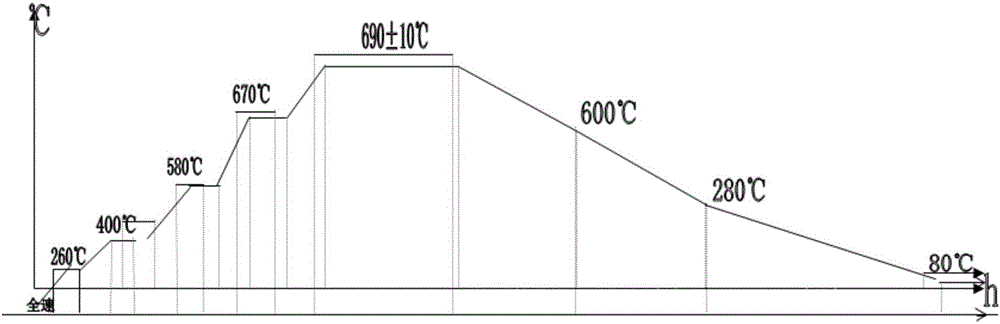

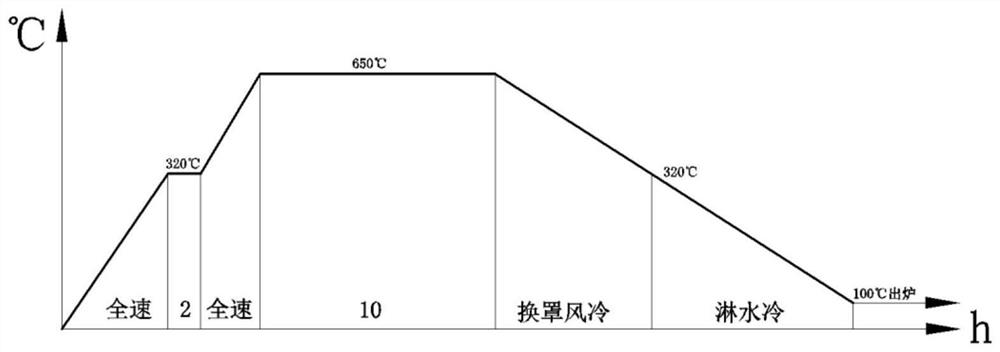

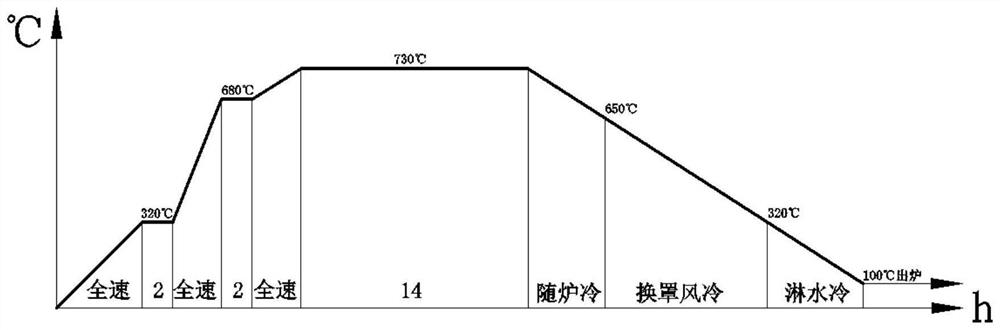

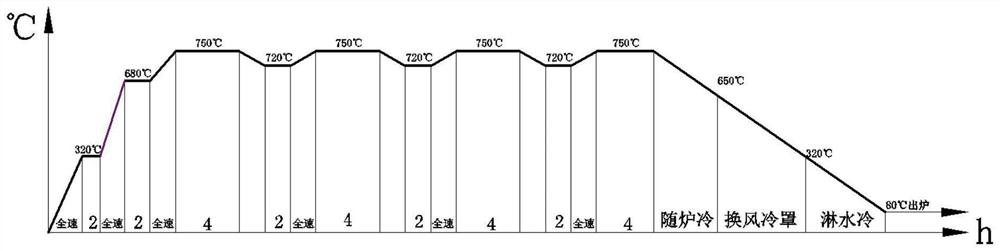

Method for machining hot rolled steel strips

ActiveCN106140812AControl heating timeControl holding timeMeasuring devicesFurnace typesStrip steelManufacturing line

The invention relates to a method for machining hot rolled steel strips. The method includes the following steps that a hot-rolled coiled plate with the grade being BJS15C is selected; the first time of longitudinal-shearing splitting is conducted through a first large longitudinal-shearing production line to prepare split coiled plates; acid pickling is conducted on the split coiled plates obtained through the first time of longitudinal-shearing splitting to prepare acid-pickled coiled plates; rolling is conducted on the acid-pickled coiled plates obtained through acid pickling, to prepare rolled coiled plates; spheroidizing annealing is conducted on the rolled coiled plates obtained through rolling to prepare spheroidizing-annealed coiled plates; fine rolling is conducted on the spheroidizing-annealed coiled plates obtained through spheroidizing annealing to prepare fine-rolled coiled plates; the second time of longitudinal-shearing splitting is conducted on the fine-rolled coiled plates obtained through fine rolling to prepare split coiled plates; and the split coiled plates are packaged and put in storage. The method has the beneficial effects that the product quality can be stabilized, and the labor productivity can be improved.

Owner:湖北大帆金属制品有限公司

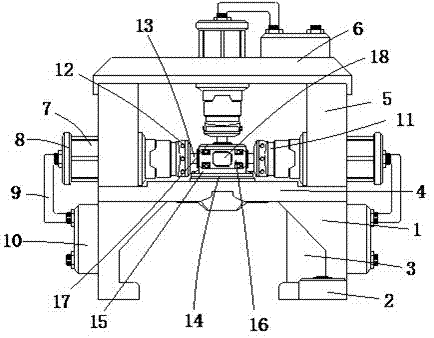

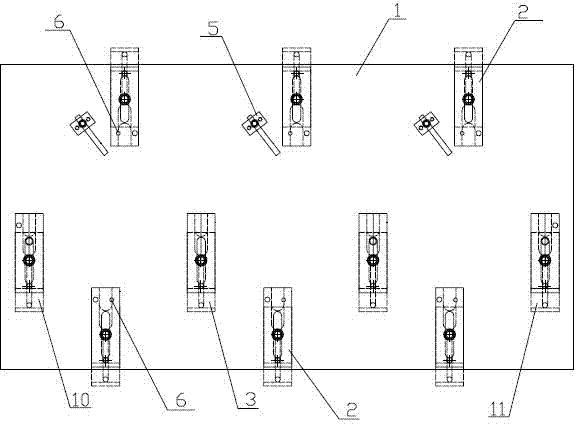

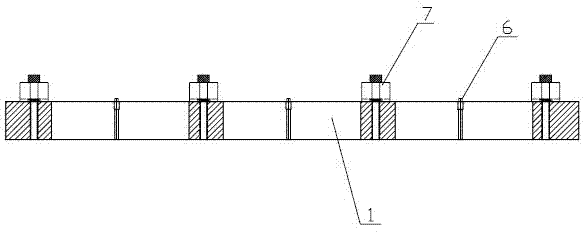

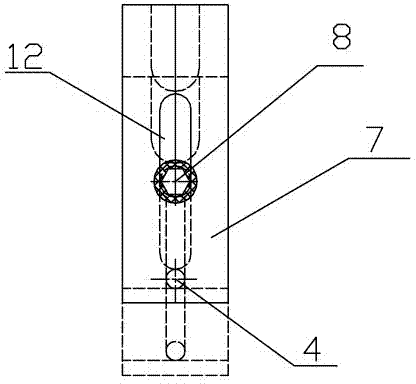

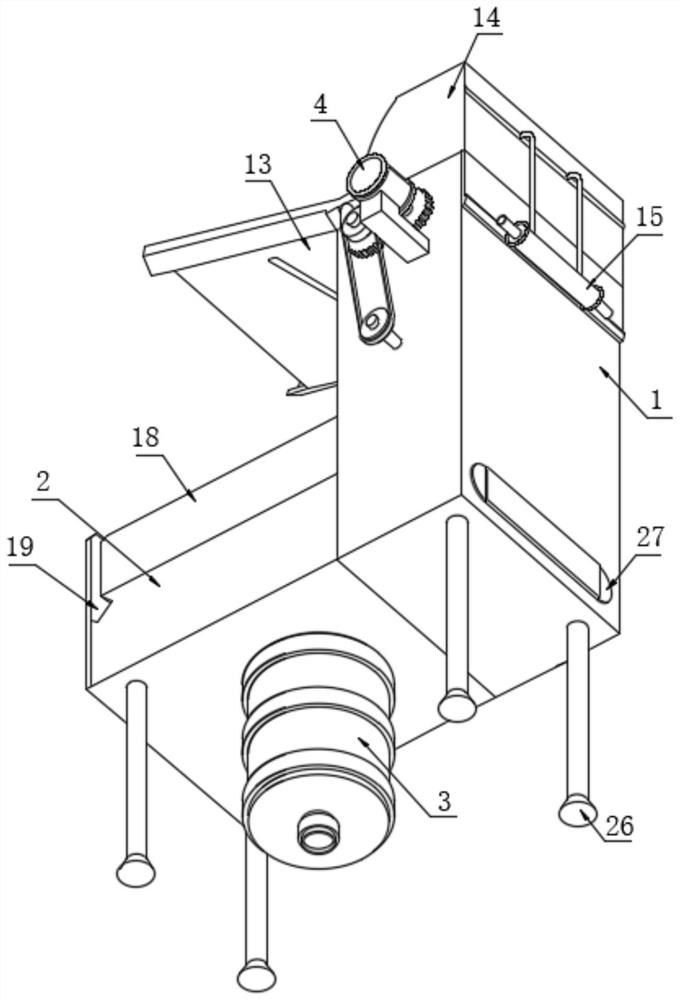

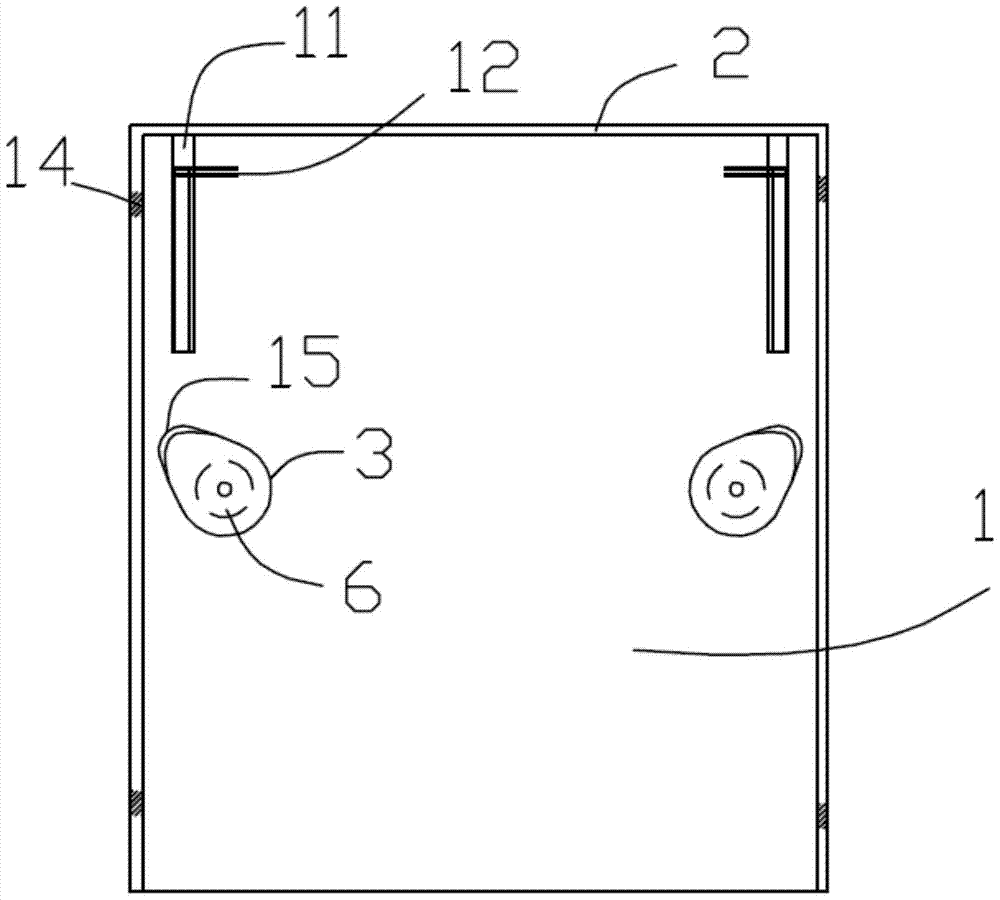

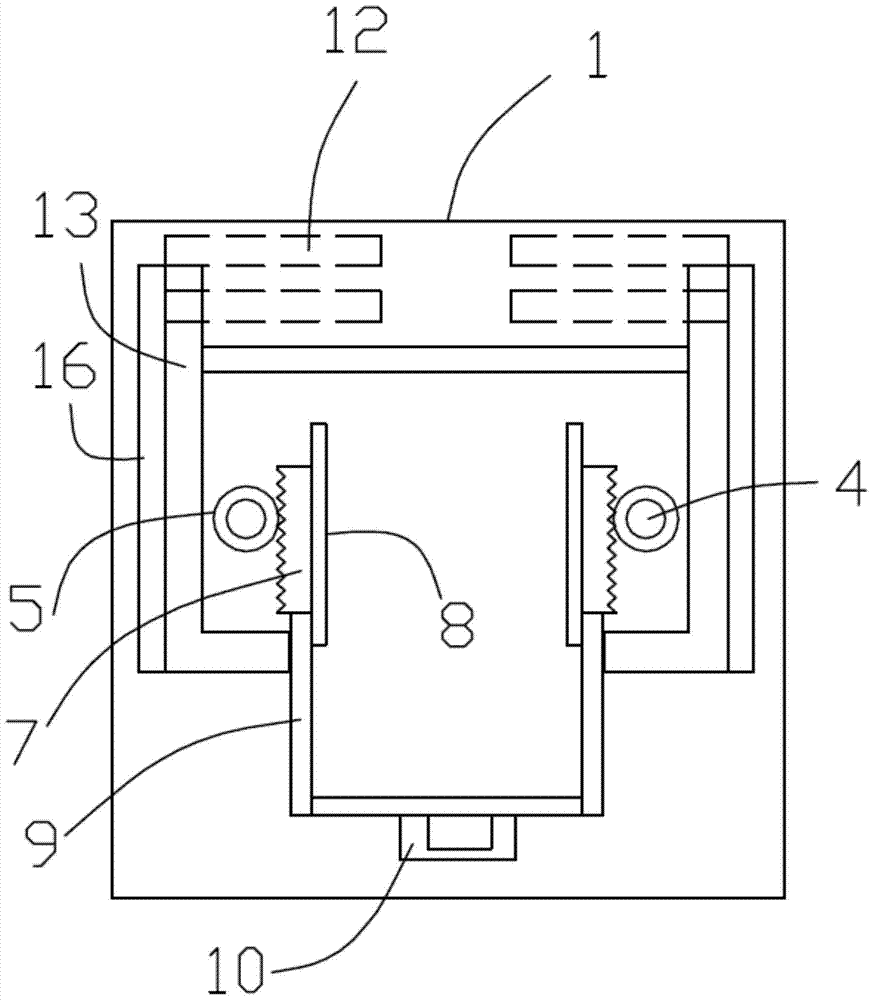

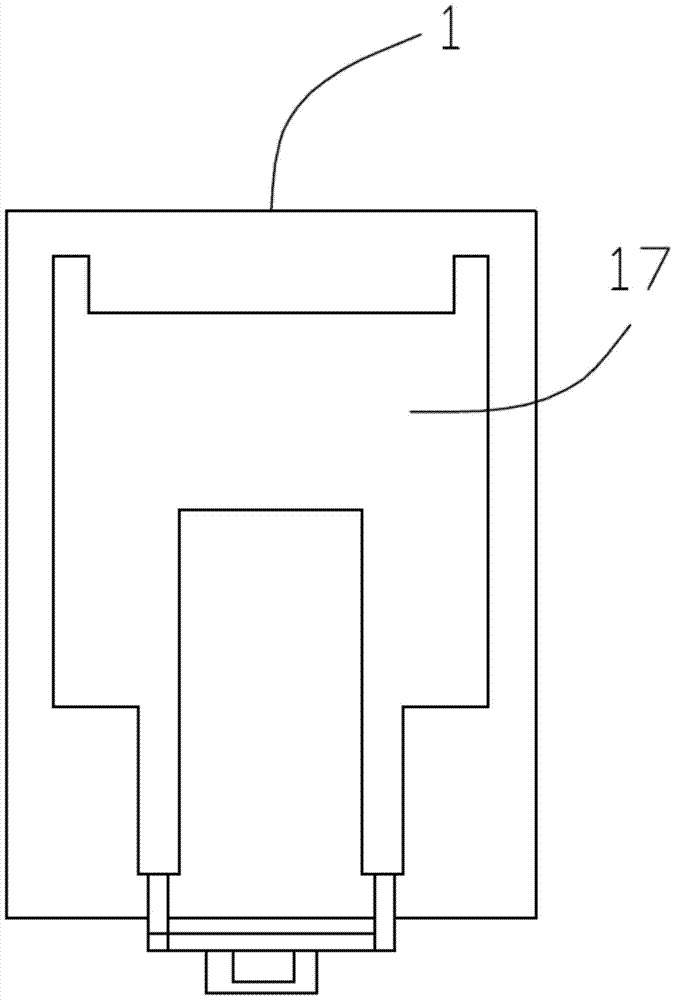

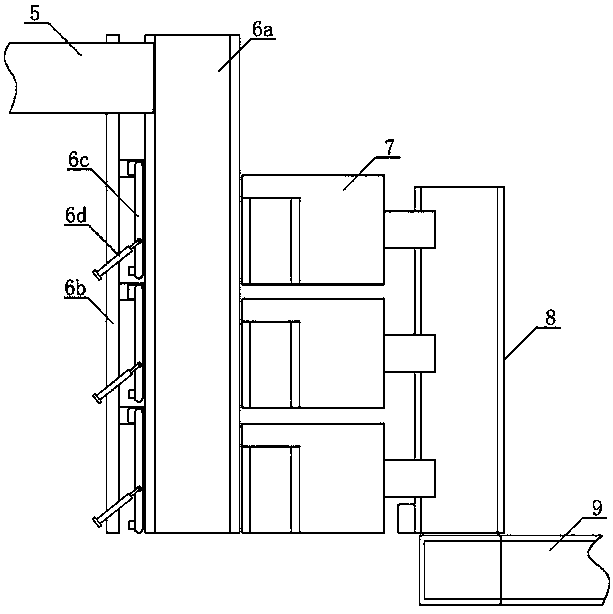

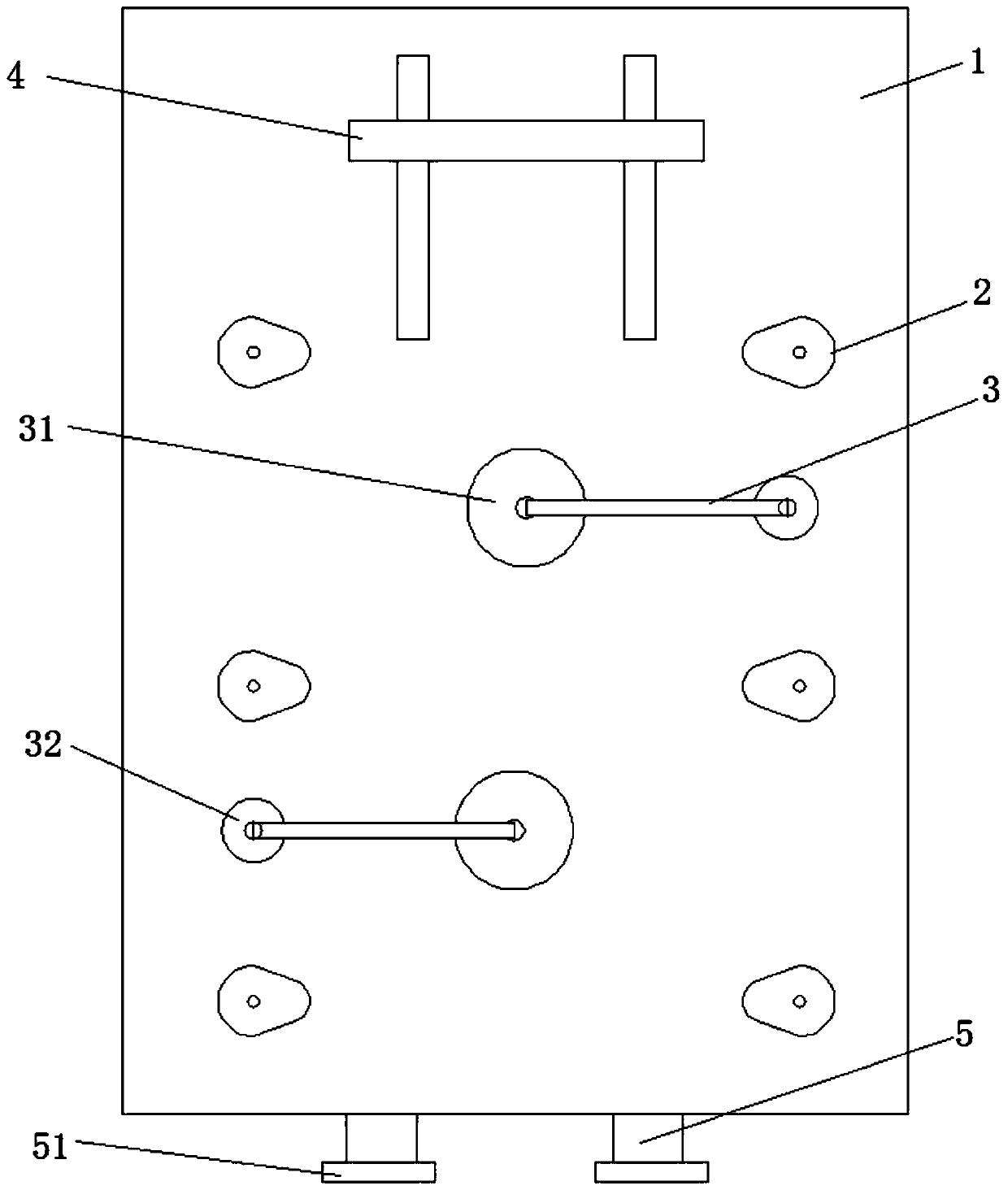

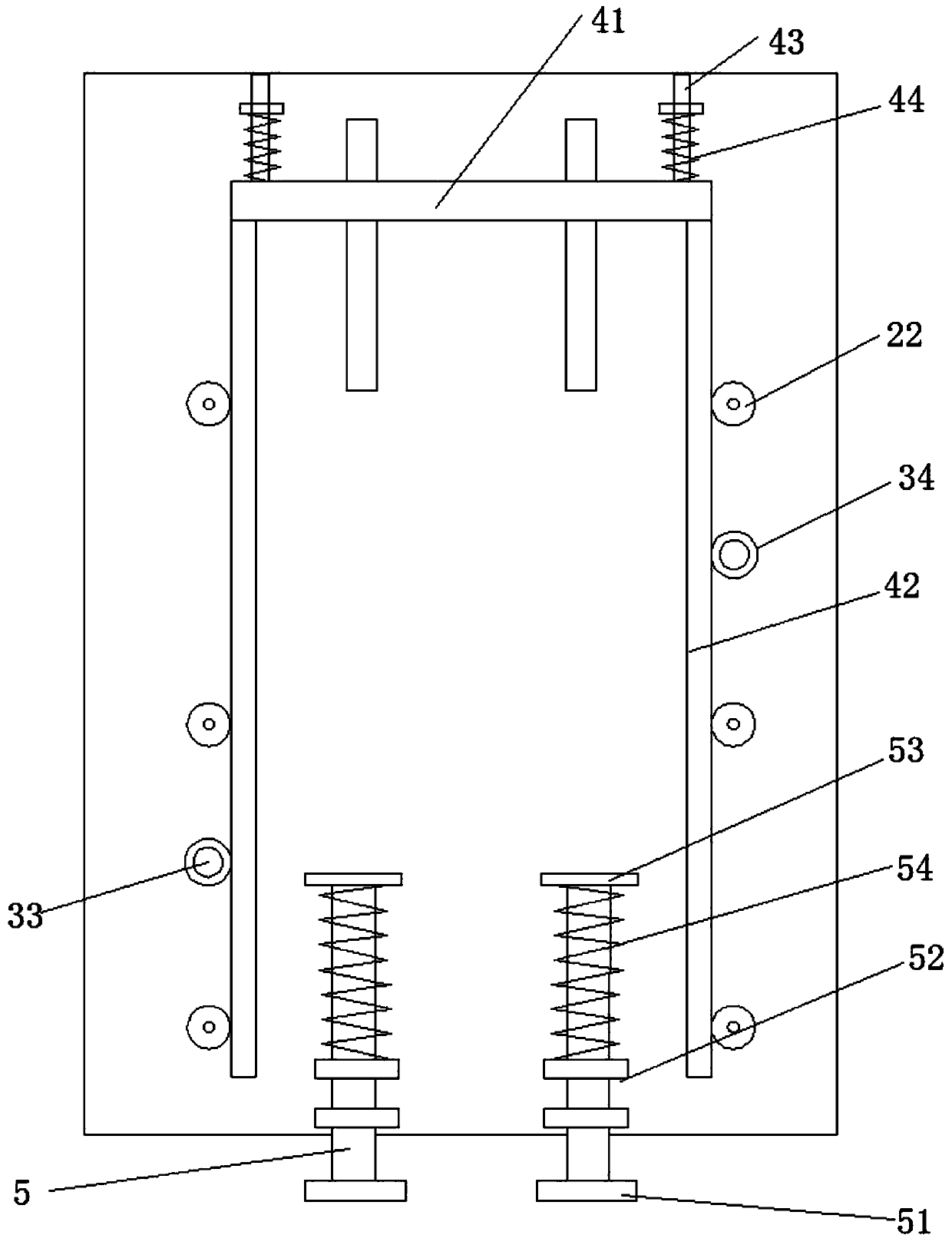

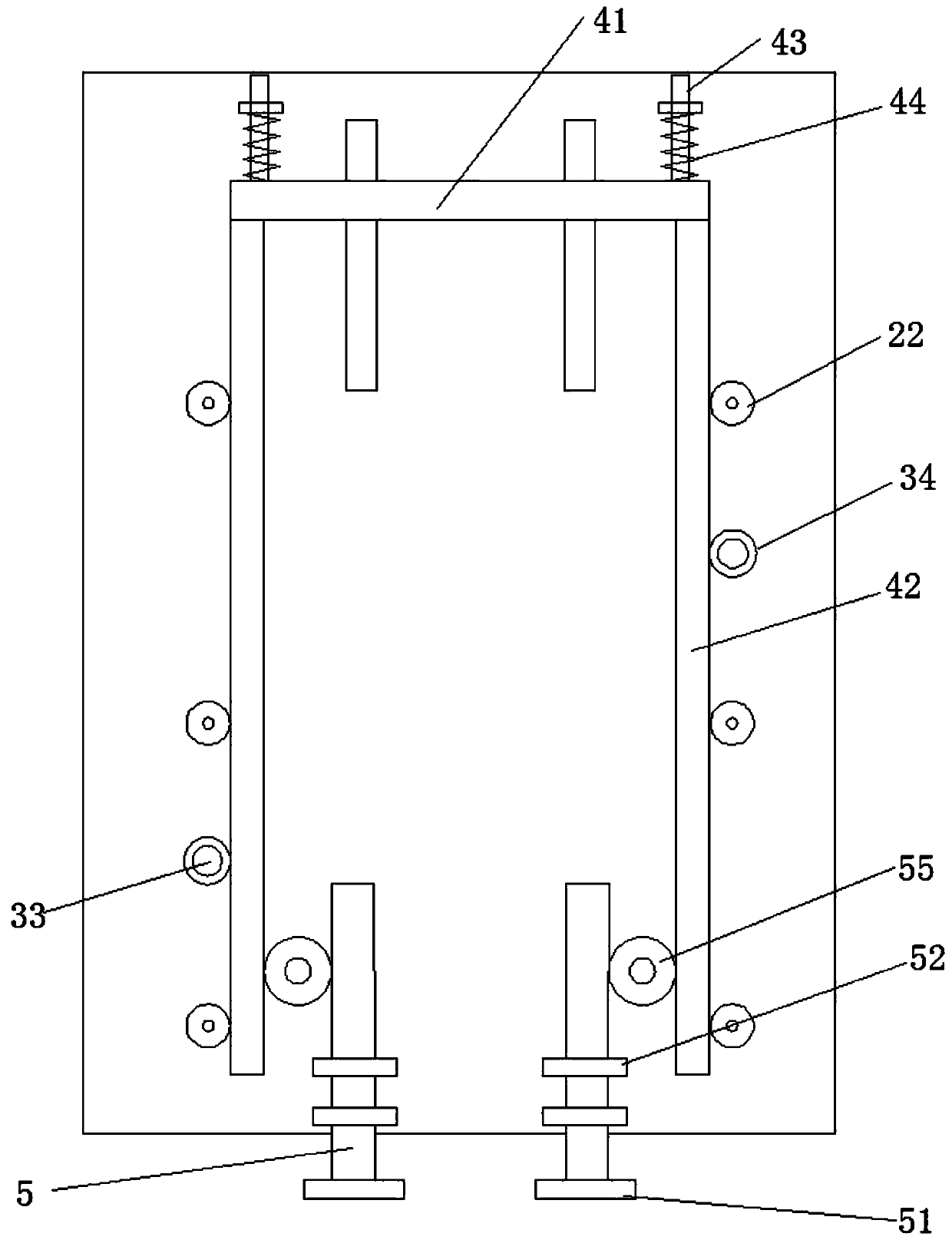

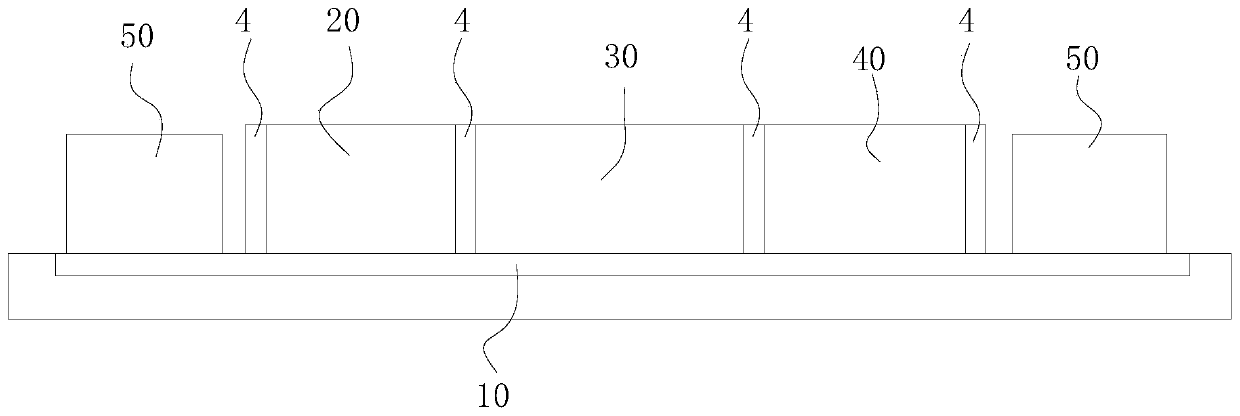

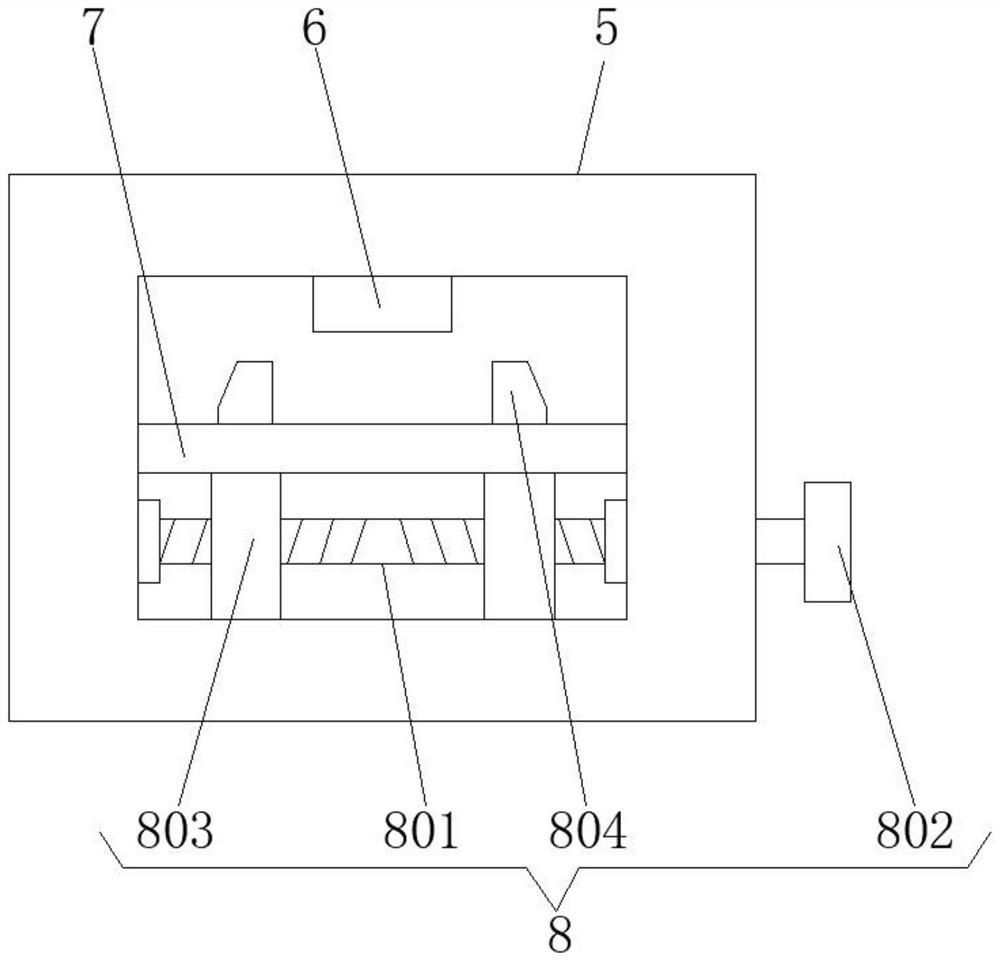

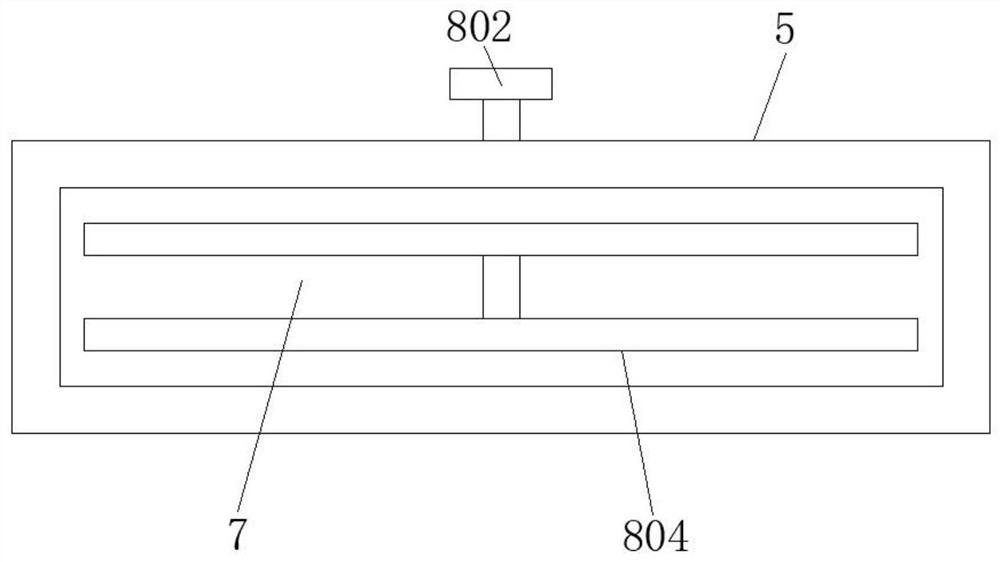

Four-axis clamp capable of finishing turnover in one-step

InactiveCN103203637AAvoid affecting subsequent processingAvoid compromising qualityPositioning apparatusMetal-working holdersEngineering

The invention discloses a four-axis clamp capable of finishing turnover in one-step. The four-axis clamp comprises a baseplate, positioning pins, compressing devices and mistake-proofing pins. The compressing devices include side compressing devices, a left compressing device, a right compressing device and two middle compressing devices. Three side compressing devices are equidistantly at each of the upper edge and the lower edge of the baseplate. The left compressing device and the right compressing device are respectively arranged in the middle of each of the left edge and the right edge of the baseplate. The two middle compressing devices are arranged in the middle of the baseplate. The left compressing device, the right compressing device and the middle compressing devices are arranged on a same straight line and equidistantly distributed. One positioning pin is arranged at the position, corresponding to each of the side compressing devices, of the baseplate, and one mistake-proofing pin is arranged on the left of each of the side compressing devices at the upper edge of the baseplate. The four-axis clamp capable of finishing turnover in one-step is simple in structure, convenient to use, and capable of improving producing efficiency by mounting three workpieces at one time, avoiding mounting mistake and improving processing quality.

Owner:PINGHU SHUNCHANG METAL PROD FACTORY

Recovery device and method for recovering rare-earth metal from rare-earth metal slag

InactiveCN113846238AEfficient sortingLow impurity contentMagnetic separationProcess efficiency improvementMischmetalElectrolysis

The invention discloses a recovery device and method for recovering rare-earth metal from rare-earth metal slag, and belongs to the technical field of rare-earth metal. The recovery device comprises a treatment box, wherein a calcining chamber is arranged on the front surface of the treatment box; an electrolysis tank is arranged on the lower surface of the calcining chamber; and a first driving assembly is arranged on the right side surface of the treatment box, and the lower surface of the first driving assembly is fixedly connected with the upper surface of a fixing block. According to the recovery device disclosed by the invention, crushed materials are fully ground and processed, the materials are ground into fine particles by a sieve plate, the materials containing metal materials can be adsorbed by an electromagnetic plate, and other materials can fall to the inner bottom of the treatment box through discharge holes in the electromagnetic plate, so that automatic feeding is achieved; and meanwhile, the ground and processed materials are effectively sorted, so that the impurity content of the rare-earth metal materials is reduced, subsequent calcination and electrolytic machining are facilitated, the machining efficiency is improved, meanwhile, the quality of recycled rare-earth metal is improved, and the recovery device is quite applicable.

Owner:LIANYUNGANG ZHAOYU NEW MATERIAL IND

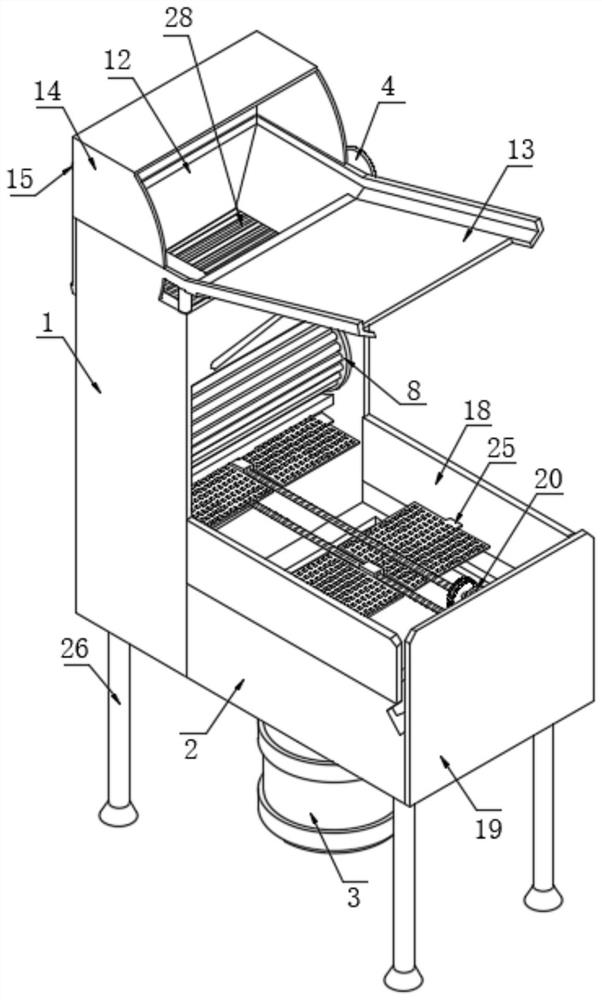

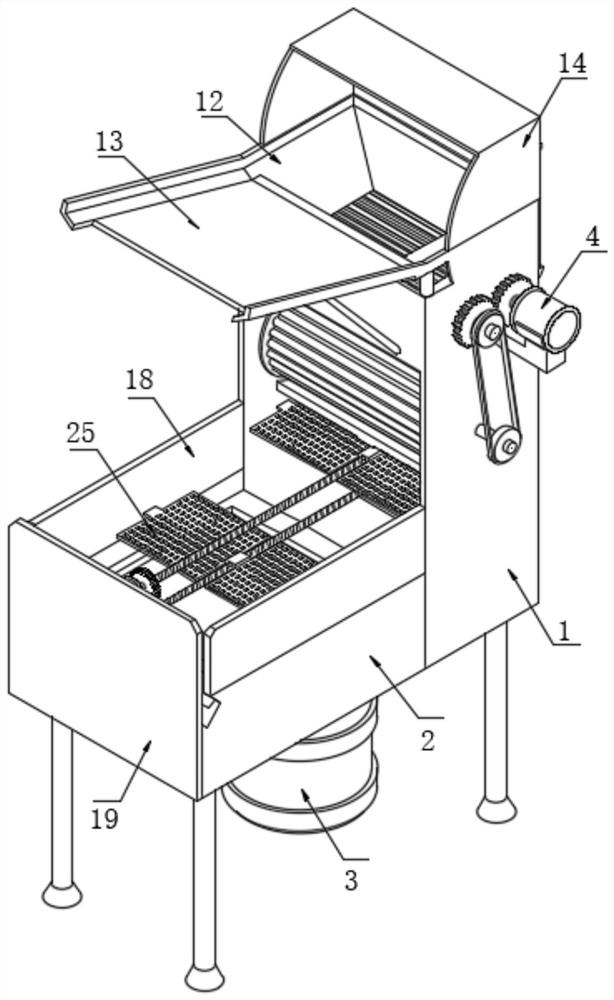

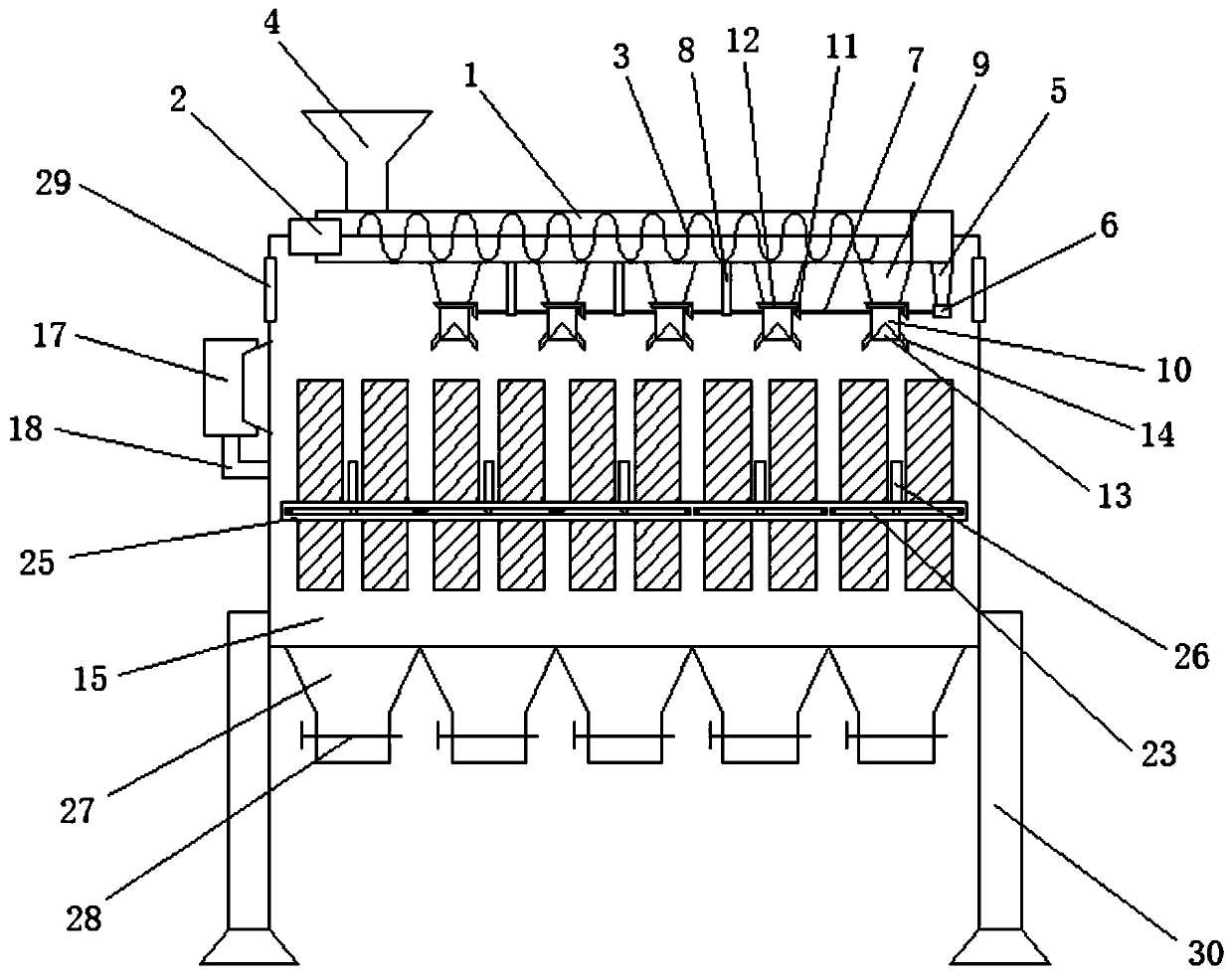

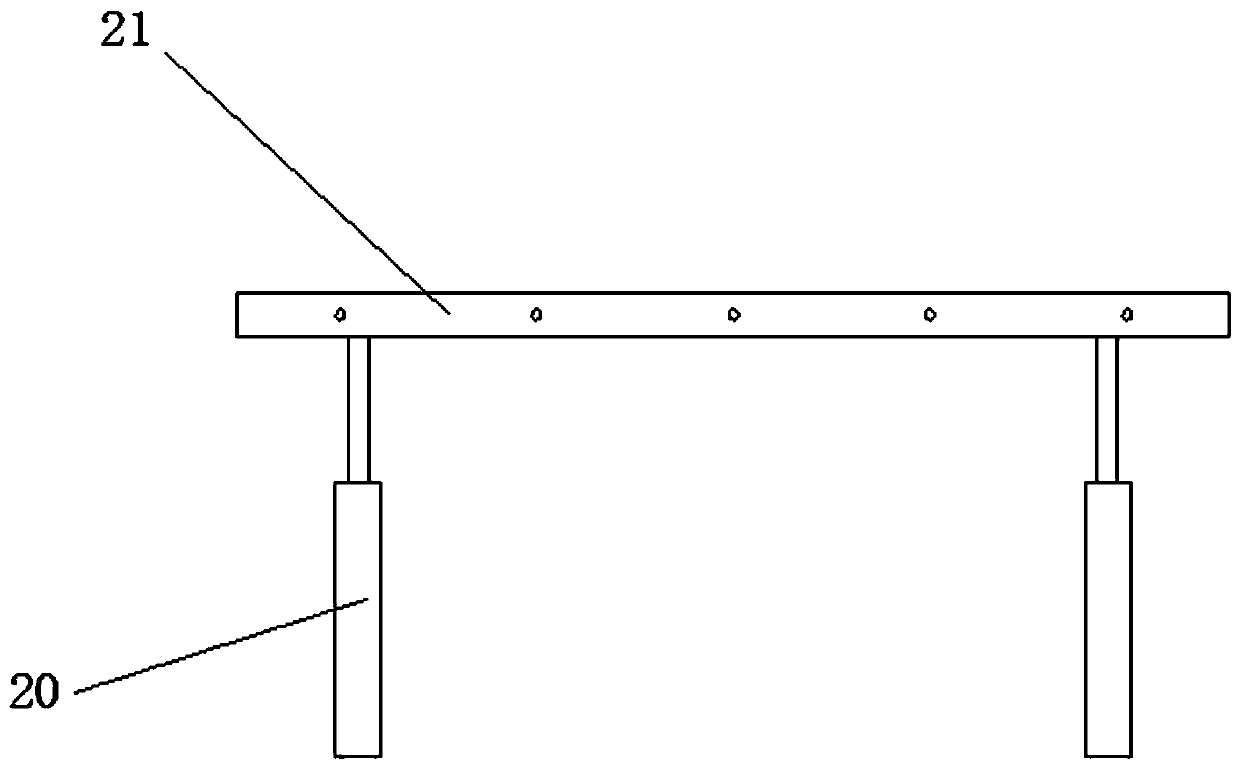

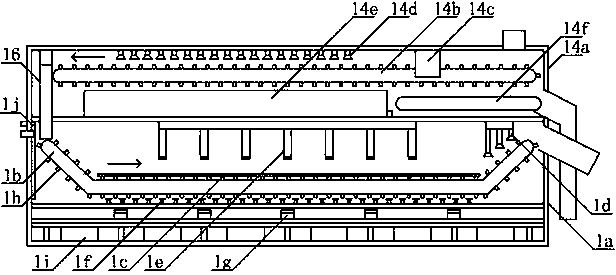

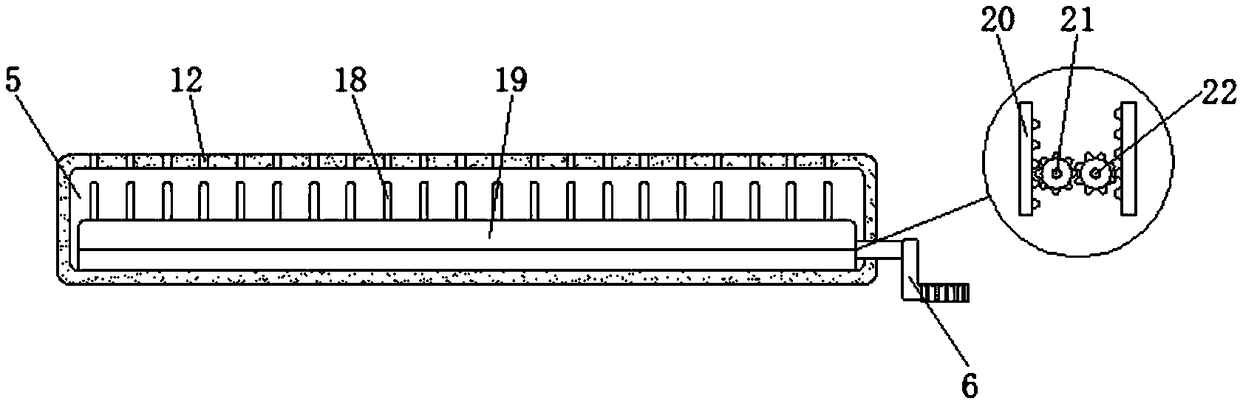

Discharging and drying device for wolfberry fruits

InactiveCN111238210AEvenly distributedPrevent affecting subsequent processingDrying gas arrangementsDrying chambers/containersAgricultural engineeringStructural engineering

The invention discloses a discharging and drying device for wolfberry fruits. The device comprises a conveying pipe and a drying bin, the conveying pipe is horizontally arranged at the top of the drying bin, a plurality of discharging pipes are fixedly arranged at the bottom of the conveying pipe, an air cavity is arranged outside the drying bin, an air heater is fixedly arranged on the left sideof the drying bin, and clamping rails are fixedly arranged on the two sides of an inner cavity of the drying bin; air cylinders are fixedly arranged at the bottoms of the portions, on the two sides ofthe drying bin, of the air cavity, the tops of the air cylinders are fixedly connected with lifting beams, and the two ends of each group of connecting rods penetrate through limiting grooves and arefixedly connected between the two groups of lifting beams; the two sides of each group of the connecting rods are rotatably hinged with bearing screen plates, the two sides of the side wall of the end, far away from the connecting rods, of each group of the bearing screen plates are fixedly provided with clamping wheels, and the clamping wheels on the two sides are movably clamped with the corresponding clamping rails respectively. The device can achieve a dispersed discharging effect in the wolfberry fruit discharging process, increase the drying area and improve the drying efficiency.

Owner:于国玺

Rubber cutting device

PendingCN113752309AReduce security risksAvoid rigid contactNon-rotating vibration suppressionMetal working apparatusStructural engineeringWorkbench

The invention discloses a rubber cutting device. The rubber cutting device comprises a workbench, a plurality of supporting legs are fixedly connected to the bottom of the workbench, anti-skid bases are fixedly connected to the bottoms of the supporting legs, a limiting plate is fixedly installed on the workbench, supporting frames are fixedly installed at the two ends of the limiting plate, the supporting frames are fixedly installed on the workbench, and air cylinders are fixedly installed on the supporting frames. The bottoms of the cylinders are fixedly connected with a driving rod, and the bottom of the driving rod is fixedly connected with a cutting mechanism. Compared with the prior art, a cutting knife abuts against a buffer plate, the cutting knife retracts inwards, the cutting knife retracts to drive a connecting plate to move inwards, an arc-shaped plate pair deforms, the arc-shaped plate extrudes an elastic film, gas in an air pressure cavity is conveyed into a cleaning cavity through a connecting pipeline, and an elastic plate can deform; and a scraper blade is pushed to move outwards, one end of the scraper blade can abut against the surface of the cutting knife, and residual rubber on the surface of the cutting knife can be scraped off in the retracting process of the cutting knife and is prevented from being accumulated on the surface of the cutting knife.

Owner:王清平

Automotive polyvinyl chloride interior trimming panel and preparation method thereof

InactiveCN109161132AHigh hardnessHigh bending strengthChemical industryFlexural strengthPolyvinyl chloride

The invention discloses an automotive polyvinyl chloride interior trimming panel and a preparation method thereof, belongs to the technical field of polyvinyl chloride panels, and solves the problemsthat the thickness, the hardness, the bending strength and the like of existing wood-plastic panels cannot meet the requirements of automotive interior trimming panels. The polyvinyl chloride interiortrimming panel is prepared from 80-100 parts of polyvinyl chloride SG8-type resin, 40-50 parts of heavy calcium carbonate, 10-20 parts of a wood-plastic reclaimed material, a foaming regulator as well as ingredients including a calcium-zinc stabilizer, an interior lubricant, an exterior lubricant, a foaming agent, wood flour and the like. The preparation method of the panel comprises steps as follows: the polyvinyl chloride SG8-type resin and the ingredients are put into a hot-mixing pot for hot-mixing, then the foaming regulator and calcium powder are put sequentially for hot-mixing, the wood-plastic reclaimed material is put finally, the mixture is put into a cold-mixing pot for cooling after hot-mixing, is sent to a mold for extrusion finally after being plasticized by seven sections of double screws of a barrel, is subjected to cooling press-fitting shaping by a shaping platform and is pulled out by a pulling machine for cutting forming, and a finished product is obtained. The invention is applicable to the automotive interior trimming panel.

Owner:SHANDONG HUIFENG NEW MATERIAL TECH CO LTD

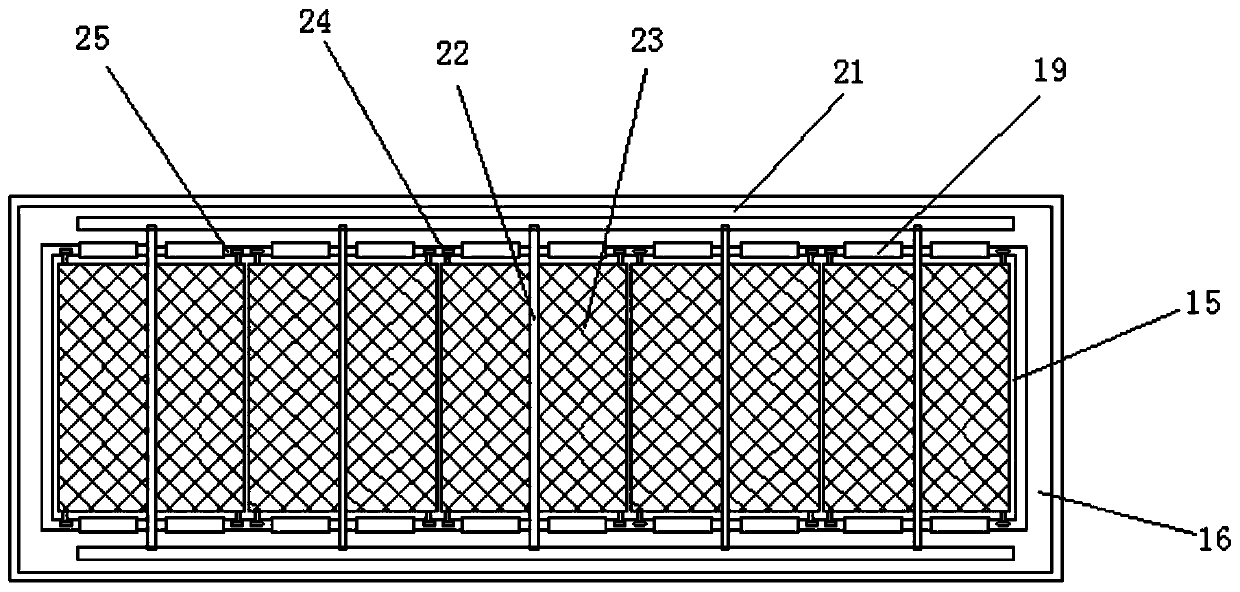

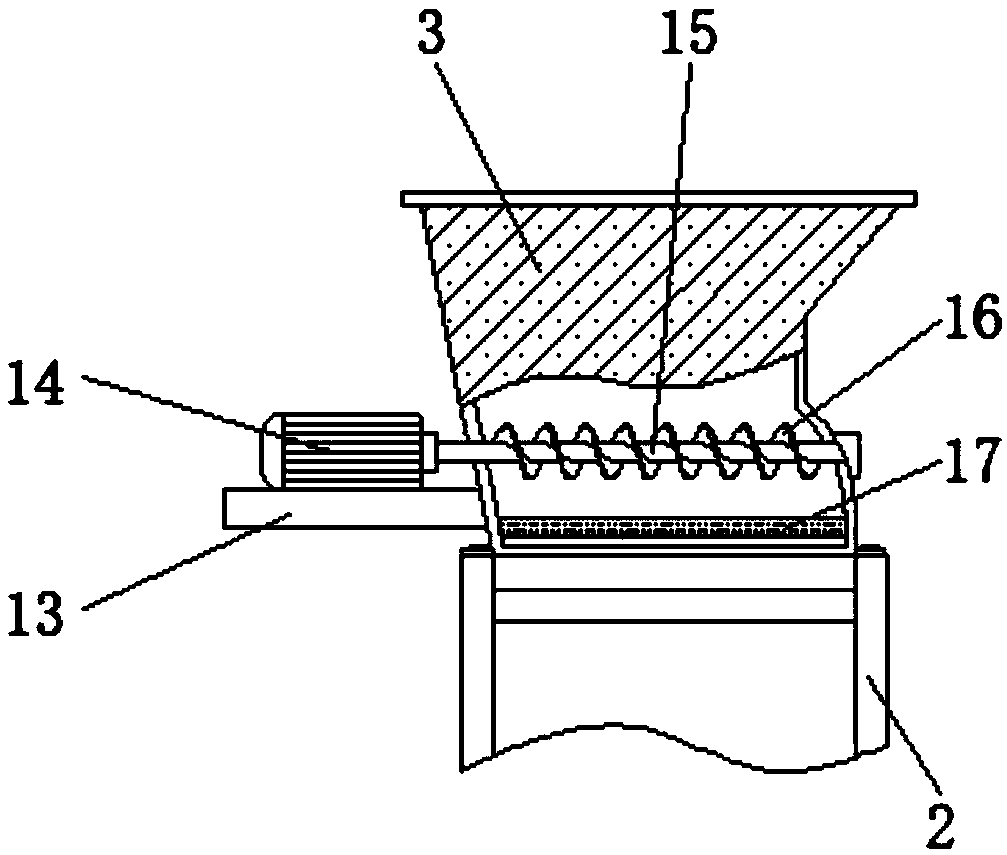

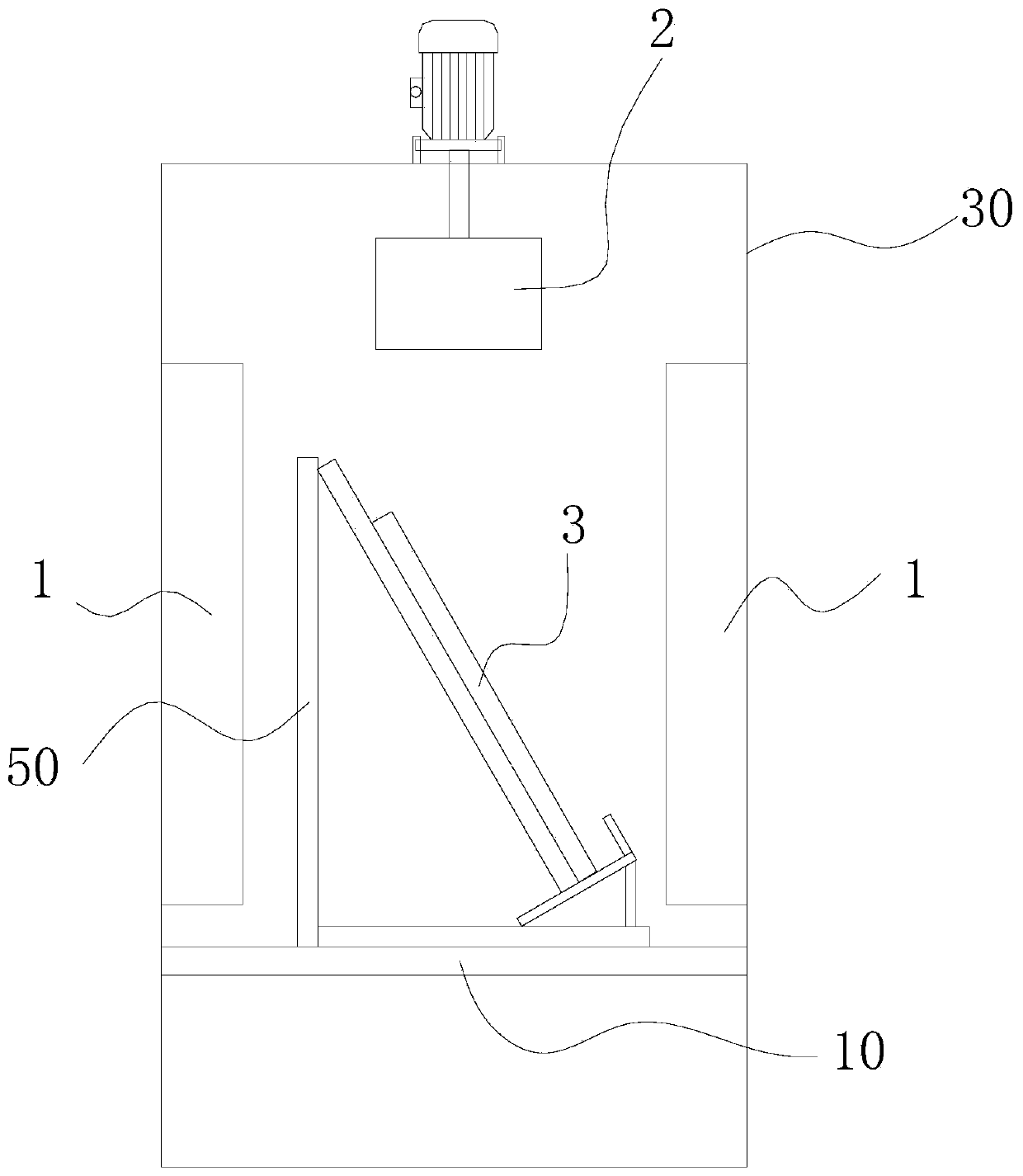

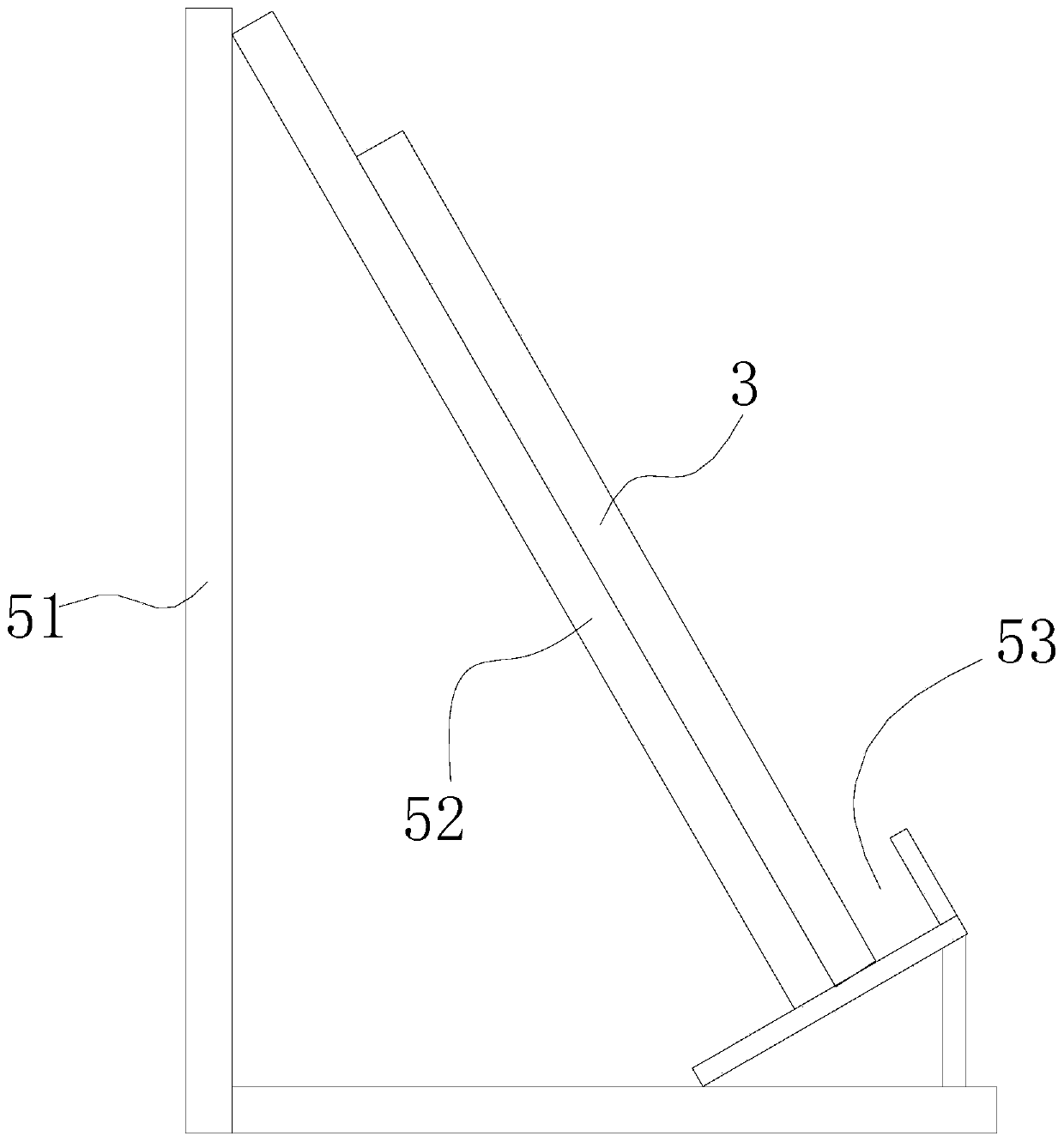

Rotary discharging and drying device of traditional Chinese medicinal materials

InactiveCN111238190ASimple structureAvoid local accumulationDrying gas arrangementsDrying machines with non-progressive movementsEngineeringMechanical engineering

The invention discloses a rotary discharging and drying device of traditional Chinese medicinal materials. The rotary discharging and drying device comprises a discharging bin and a drying bin, wherein the bottom of a feeding hopper is rotatably connected with a rotating pipe through a bearing, a drainage pipe is obliquely mounted at the bottom end of the rotating pipe, a blanking bin is fixedly connected with the bottom of the drainage pipe, an air cavity is formed in the outer portion of the drying bin, the drying bin is fixedly provided with a hot-air blower, and clamping rails are fixedlymounted on the sides of the inner cavity of the drying bin; air cylinders are fixedly installed on the two sides, located at the bottom of the air cavity, of the drying bin, lifting beams are fixedlyconnected with the top of the air cavity, and two ends of each connecting rod penetrate through limiting grooves to be fixedly connected between the two groups of lifting beams; and bearing net platesare rotatably hinged to the two sides of each group of connecting rods, clamping wheels are fixedly installed on the two sides of the side walls, away from one ends of the connecting rods, of each group of bearing net plates, and the clamping wheels are movably connected with the corresponding clamping rails in a clamped mode. According to the rotary discharging and drying device, the effect of dispersing and discharging can be achieved in the process of discharging the traditional Chinese medicinal materials, the drying area is increased, and the drying efficiency is improved.

Owner:杨文耀

Broccoli block processing and cleaning treatment device

ActiveCN114451566AReduce usageAvoid damageSievingFruits/vegetable preservation by heatingBroccoli raabElectric machinery

A limiting sealing plate is connected to the bottom end of a fixed supporting plate, a transmission motor is installed at the top end of the fixed supporting plate, a porous cleaning barrel is placed at the top end of a cross-shaped limiting plate, a porous water inlet pipe is welded to the bottom end of the inner side of the porous cleaning barrel, and sealing electric push rods are symmetrically clamped to the bottom end of a fixed barrel; a plurality of rubber rods are clamped on the inner side of the porous cleaning barrel at equal intervals, a booster water pump sprays water into the inner side of the porous cleaning barrel through a conveying pipe and a concentration hopper, and a transmission motor drives a limiting sealing plate, a porous water inlet pipe and the porous cleaning barrel to rotate, so that tubers rotate at a high speed in the porous cleaning barrel, and impurities attached to the surfaces of the tubers are separated; and sewage can be discharged through a discharging plate during cleaning, and a sealing electric push rod drives a protective sealing plate to seal the fixed barrel, so that the tubers can be effectively soaked during cleaning, and the use of water is effectively reduced.

Owner:JINZHOU MEDICAL UNIV

A high-efficiency anti-bake fixture for base panels

ActiveCN105170370BImprove firmnessAvoid problems such as scratchesSpraying apparatusEngineeringFlange

Owner:SPRING ELECTRONICS WUJIANG

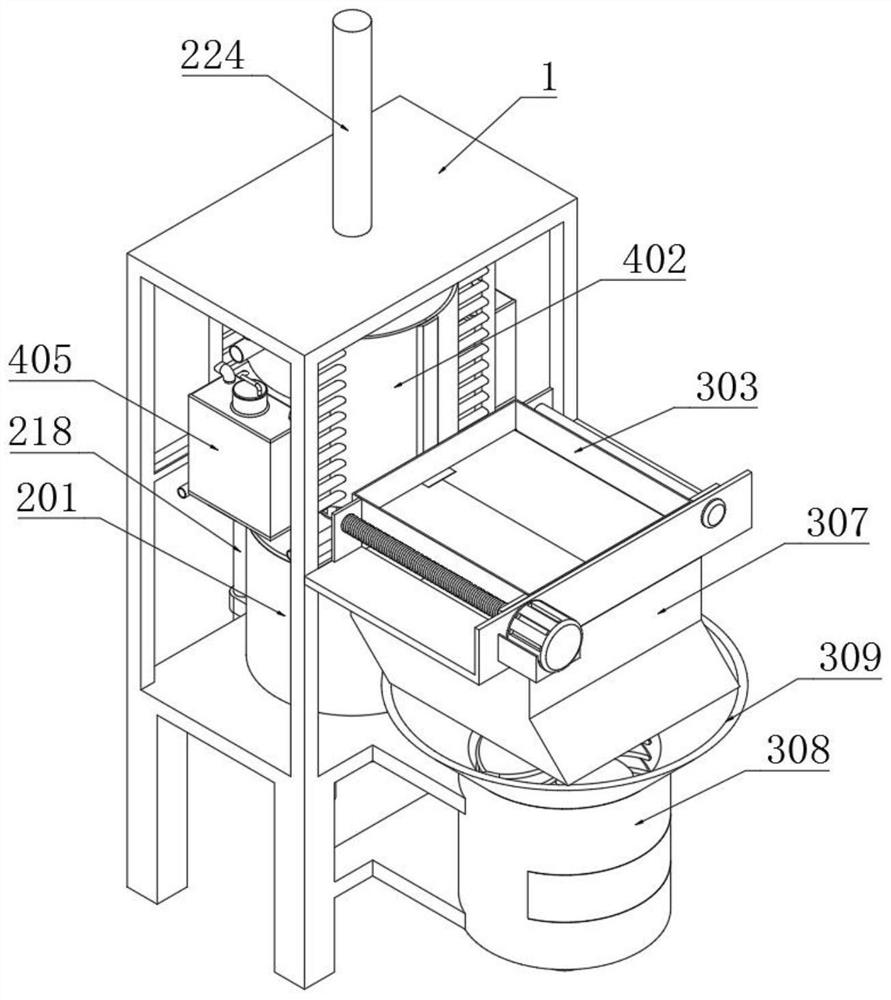

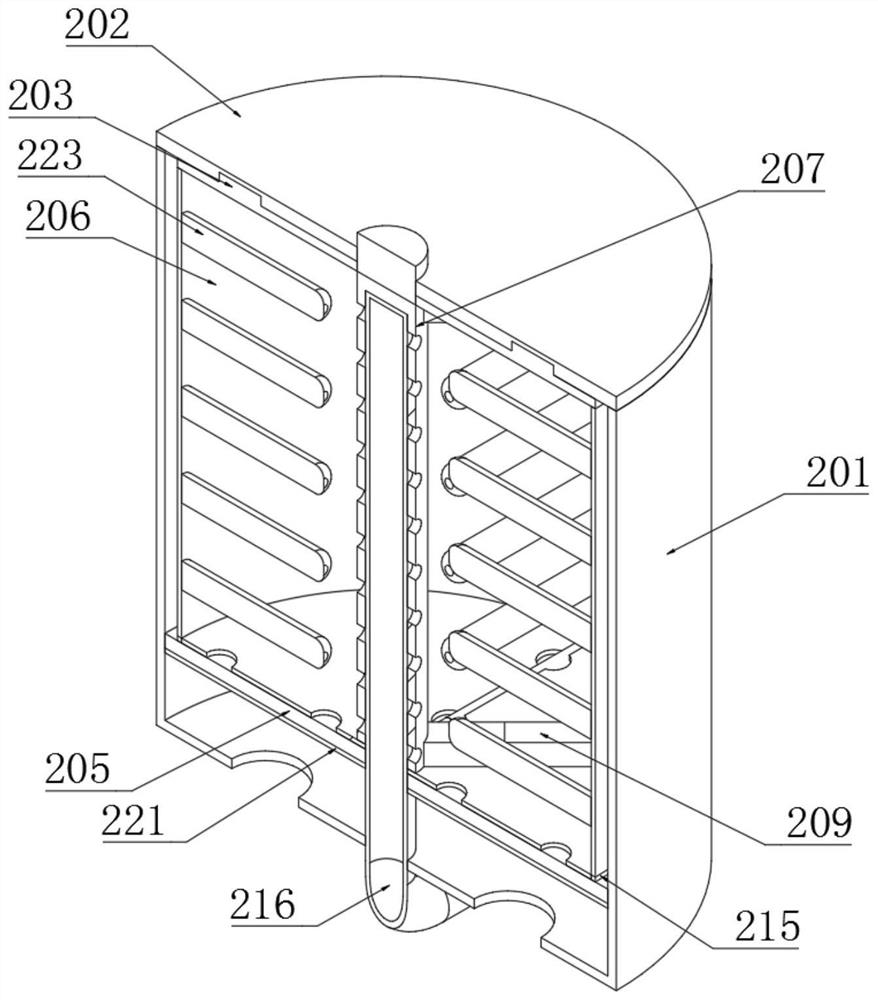

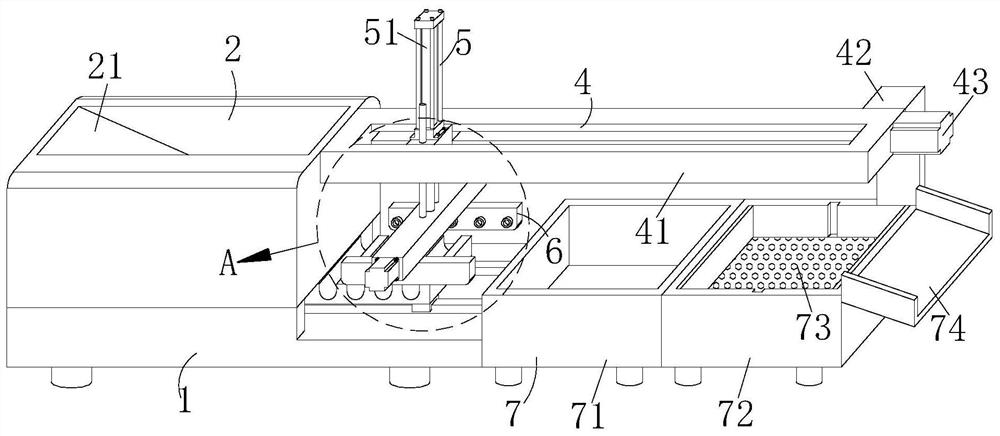

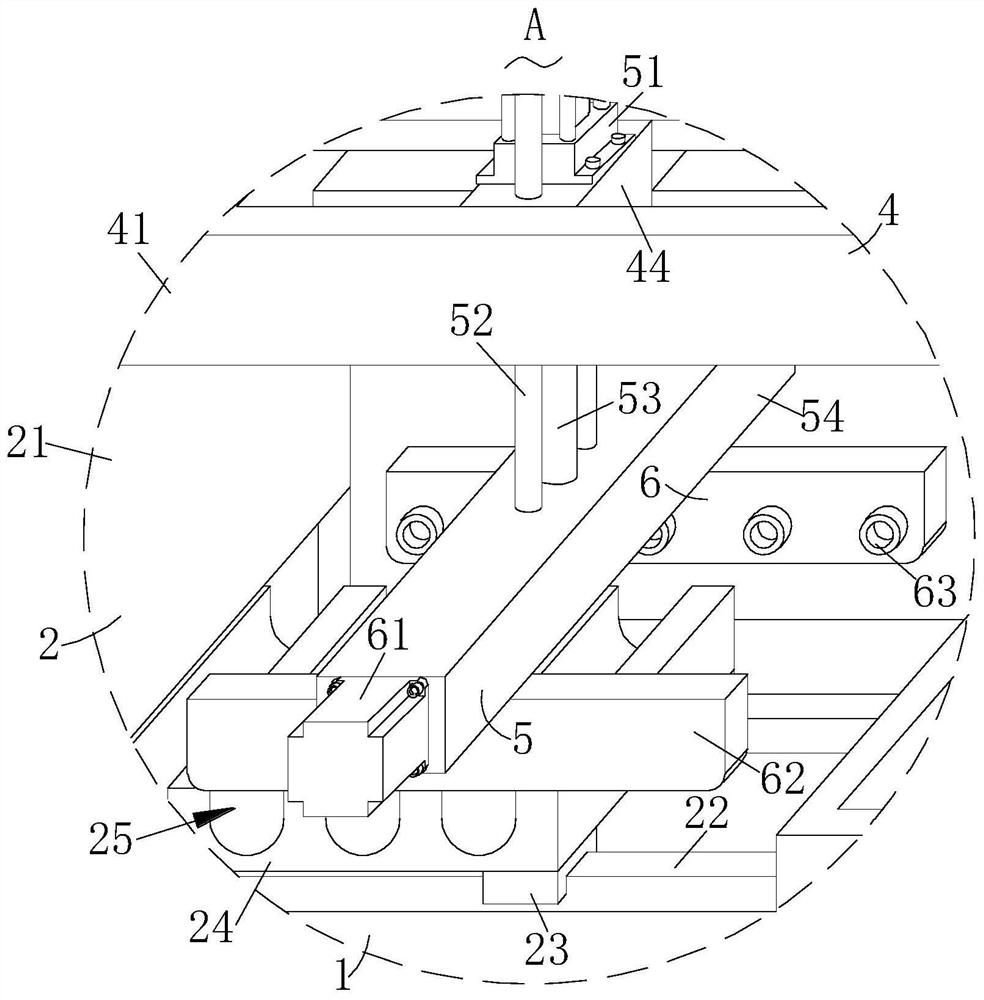

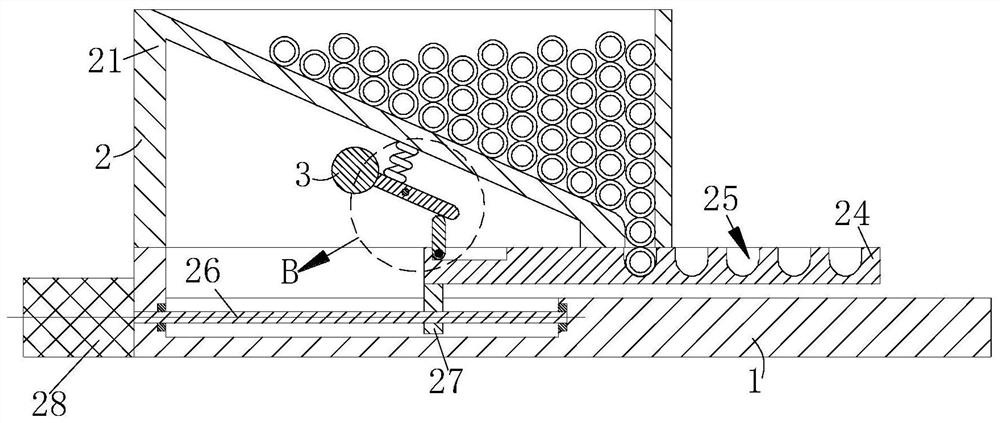

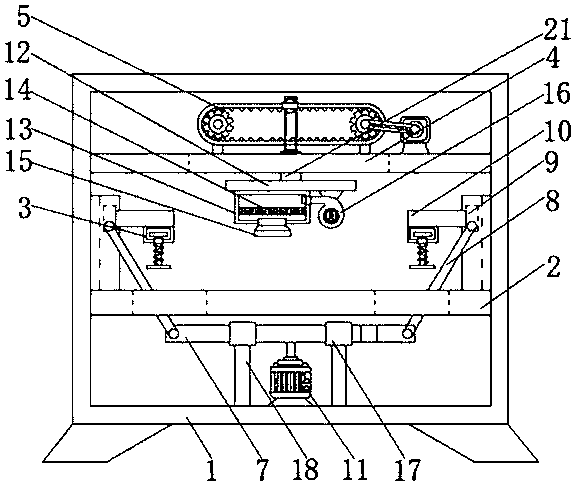

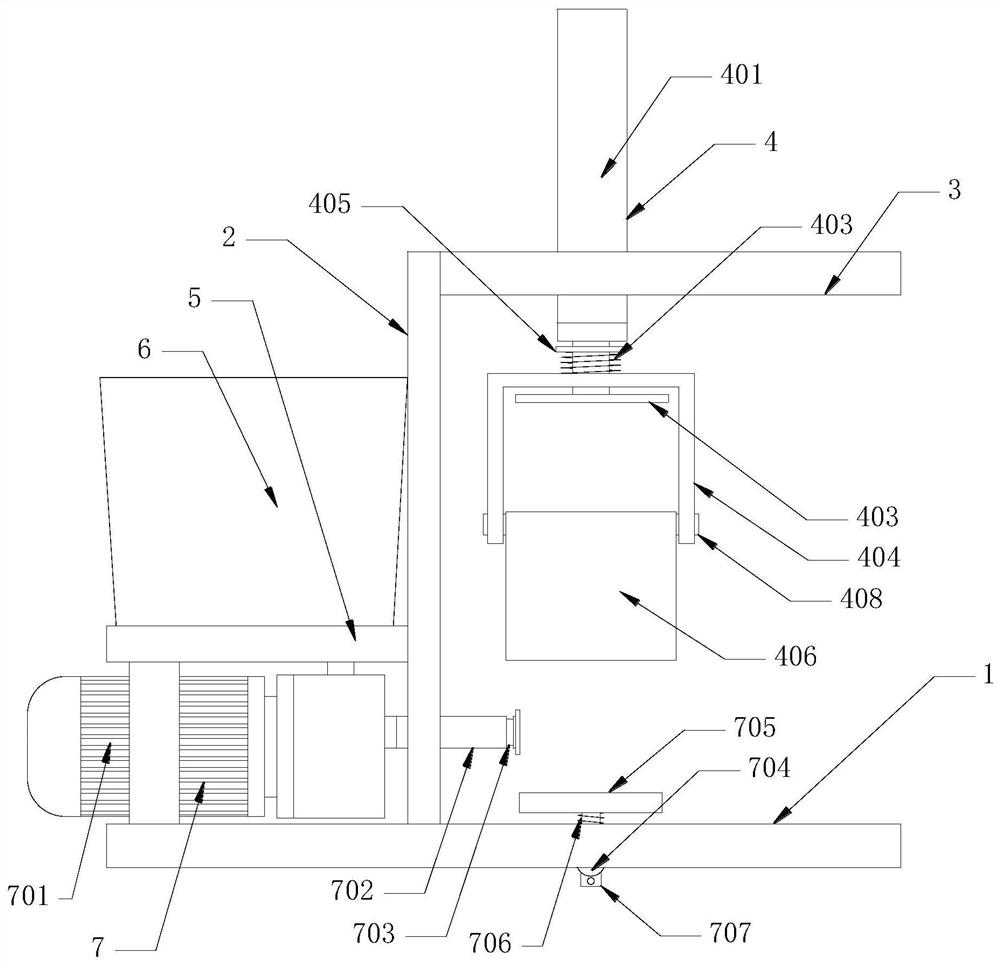

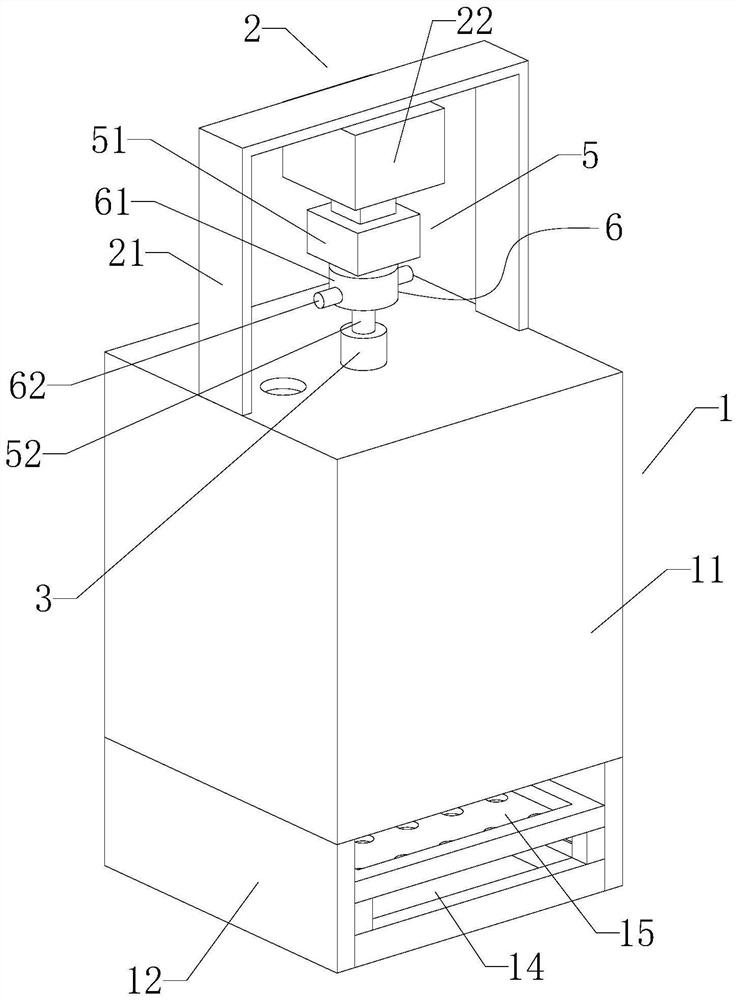

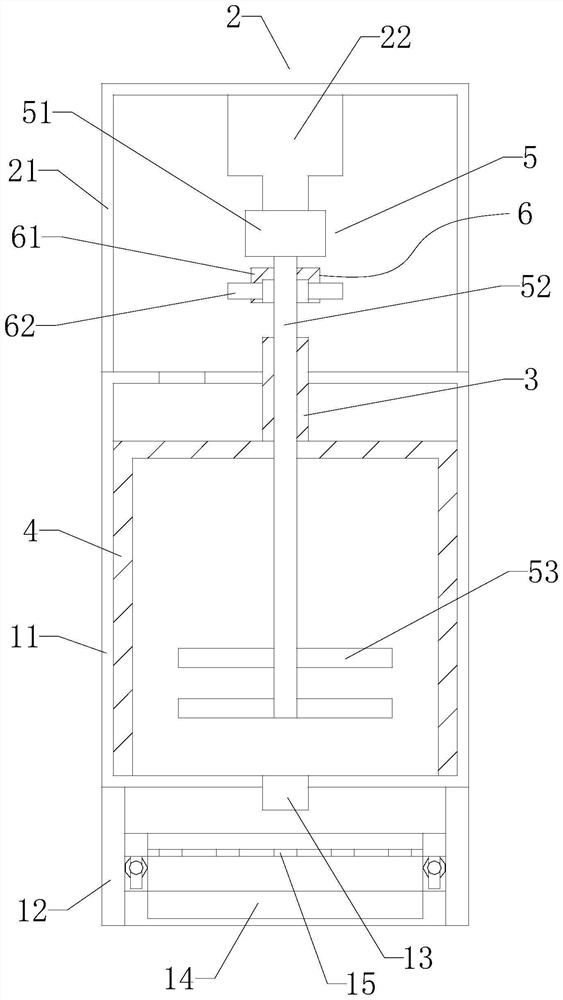

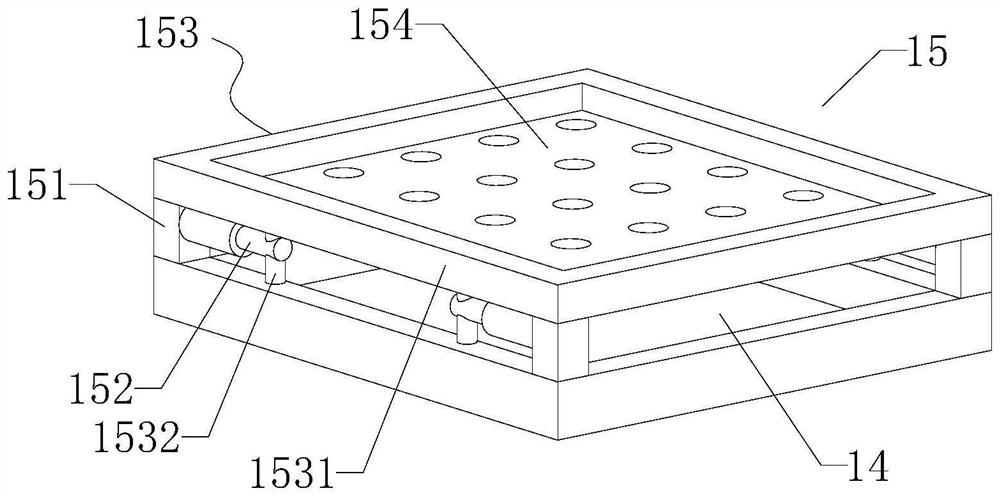

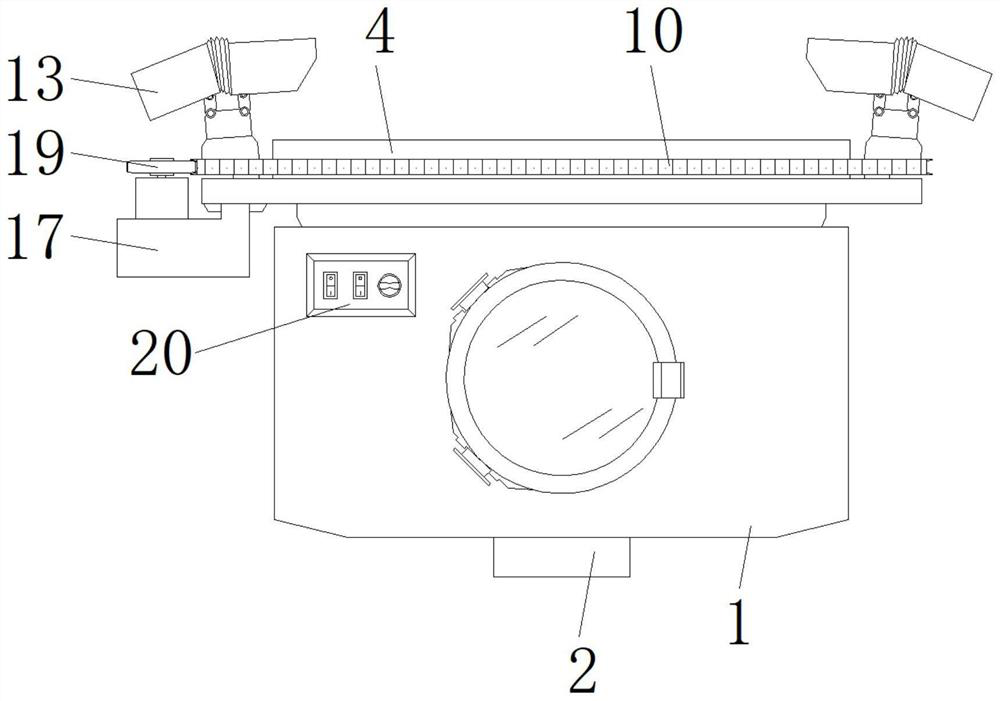

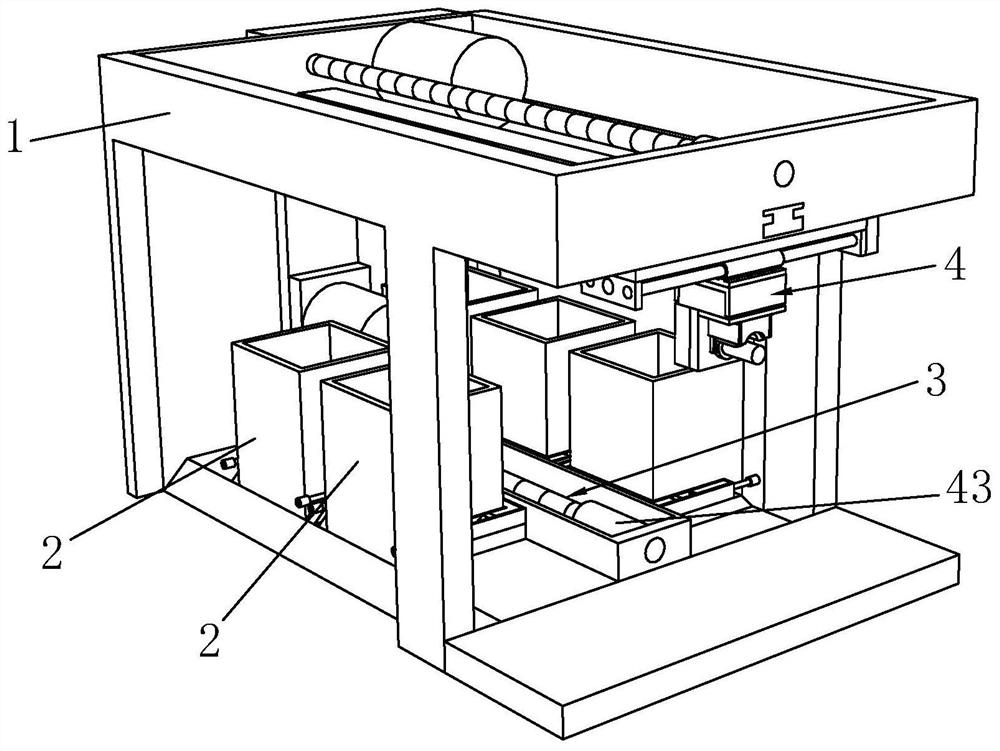

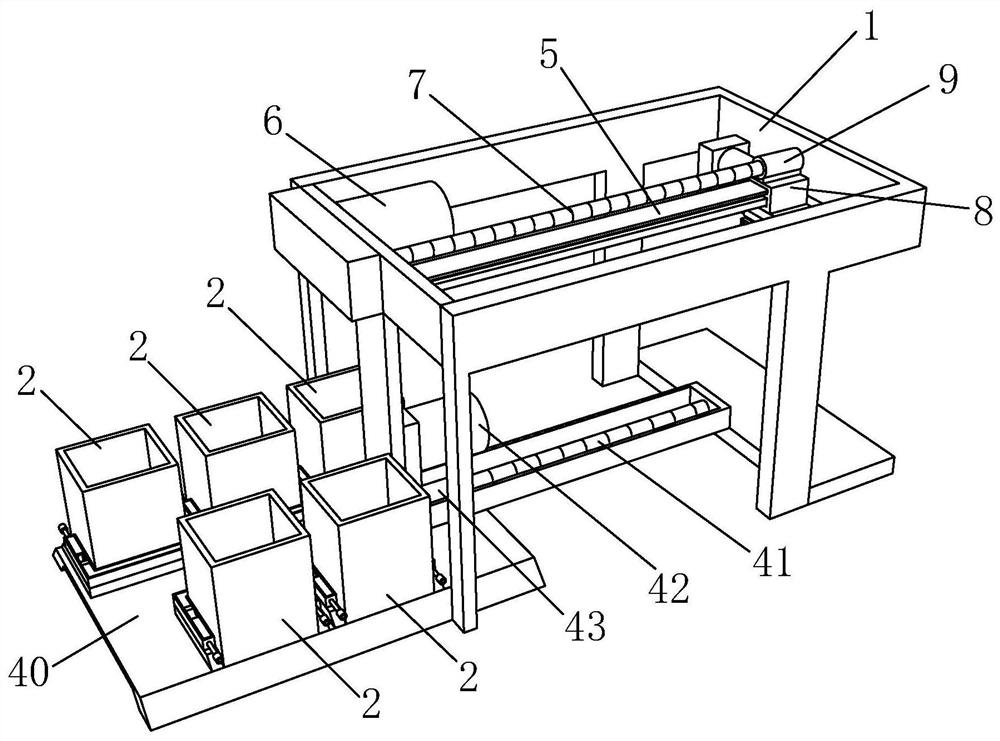

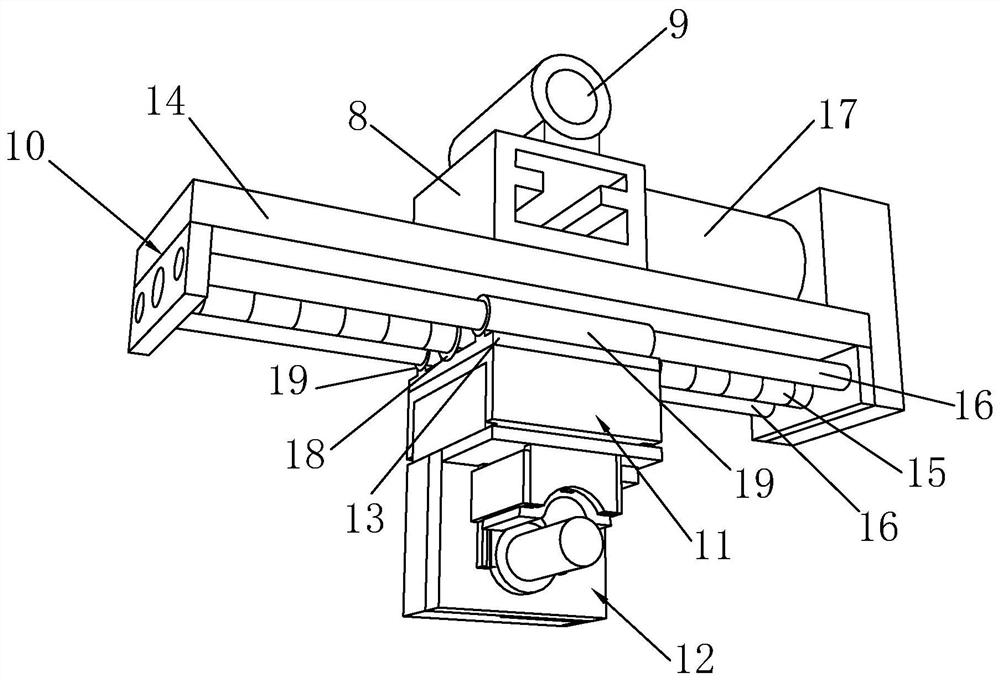

Magnesium alloy micro-arc oxidation treatment device

InactiveCN113201777ARealize automatic sorting and feedingImprove feeding efficiencyAnodisationElectrolysis componentsPipeMachining

The invention relates to the field of magnesium alloy oxidation treatment equipment, in particular to a magnesium alloy micro-arc oxidation treatment device. The device comprises a base, a feeding structure, a vibration structure, a moving structure, a material taking structure, a clamping structure and a treatment structure. The feeding structure is installed at the top end of the base, automatic feeding can be achieved, automatic sequencing feeding of steel pipes can be achieved, accordingly, the feeding efficiency of the steel pipes can be improved, when the feeding structure works, the vibration structure can be driven to work, through work of the vibration structure, a feeding assembly can be impacted to generate vibration, and therefore the situation that the steel pipes are difficultly fed can be avoided; and the treatment structure is mounted at one end of the base, so that not only can the steel pipes be oxidized, but also the treated steel pipes can be cleaned, the situation that an agent is attached to the outer surfaces of the steel pipes to affect subsequent machining is avoided, the cleaned steel pipes can be automatically jacked up and discharged, and discharging is convenient.

Owner:王菲

Production system for dewatered chives and production method of system

InactiveCN109770286ARealize non-stop transportationHigh degree of automationFruits/vegetable preservation by dehydrationFood treatmentSodium hypochlorite solutionProcess engineering

The invention discloses a production system for dewatered chives. The system comprises a cleaning device, a first lifting conveying device, a cutting device, a sterilization rinsing device, a second lifting conveying device, a material distribution device, a centrifugal dewatering device, a material guide conveying device, a third lifting conveying device, a vibration cloth device and a conveyingdrying device which are arranged in sequence. The production system has the advantages of being high in automation degree and processing treatment amount. The invention further discloses a productionmethod of the production system for the dewatered chives. The method comprises the steps that firstly, the chives are cleaned and then cut into chive particles, the chive particles are put into a sodium hypochlorite solution for sterilization and rinsing, the sterilized chive particles are blown with air and pre-dewatered, then centrifugal dewatering is conducted, the centrifuged and dewatered chive particles are preheated, after preheating, the chive particles are flat laid and dried, and the dewatered chives are obtained. According to the production method, the food hygiene and safety of thefinished product dewatered chives are guaranteed, which helps to shorten the production time.

Owner:YUNNAN LONGYUN DAYOU IND CO LTD

Drying device for fabric processing

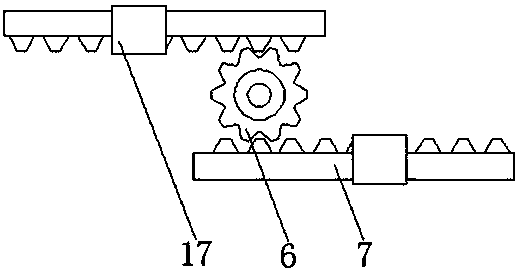

ActiveCN108151452AHeating evenlyAvoid affecting subsequent processingDrying solid materials with heatDrying gas arrangementsEngineeringMachining process

The invention discloses a drying device for fabric processing. The drying device comprises a shell, a workbench is fixedly connected between the two sides of the inner wall of the shell, and the bottom of the shell is fixedly connected with a motor; the output shaft of the motor is fixedly connected with a gear, the two sides of the surface of the gear are correspondingly meshed with toothed bars,one ends of the two toothed bars are rotationally connected with rotary rods, and the top ends of the rotary rods are rotationally connected with movable blocks; and one sides of the movable blocks are fixedly connected with supporting plates, and material pressing devices are fixedly connected to the bottoms of the supporting plates. The drying device for fabric processing relates to the technical field of fabric drying. According to the drying device for fabric processing, the device is used for uniformly heating fabric, so that the situation that uneven heating and drying of the fabric influence subsequent processing is avoided, and the processing quality is improved; the fabric is conveniently placed on the workbench, so that the fabric is kept stable in the processing process, the situation that the processing effect is influenced due to deviation caused by air blowing is avoided, and processing efficiency is improved; and the using effect is good, the mechanical mechanism is reasonable, and operation is simple and convenient.

Owner:SHANGHAI BONO CLOTHING

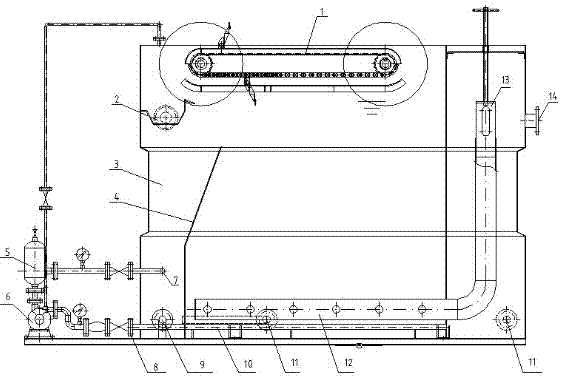

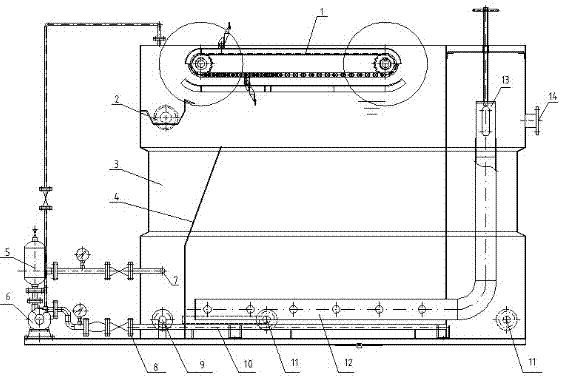

Full-automatic dissolved air floatation device

InactiveCN102583614AAvoid affecting subsequent processingWater/sewage treatment by flotationRefluxSlag

The invention relates to a full-automatic dissolved air floatation device which comprises an air floatation box body, a regulation weir, a water inlet, a water outlet, a sewage outfall, a dissolved air tank, a mud scraper and a slag collection groove, wherein the mud scraper is arranged at the upper part of the air floatation box body; the dissolved air floatation device further comprises a dissolved air pump and a water receiving and air removal system; the dissolved air pump is arranged on the outer side of the lower part of the air floatation box body; one end of the dissolved air pump is connected with the dissolved air tank, and the other end of the dissolved air pump is connected with a reflux pipe and communicated with the inner part of the air floatation box body; and the water receiving and air removal system is arranged at the lower part of the air floatation box body and connected with the regulation weir. The full-automatic dissolved air floatation device improved on the basis of a traditional dissolved air floatation device has the advantages that the dissolved air pump is adopted by the air floatation device to replace a pressure pump, an air compressor, a jet device, a high pressure dissolved air tank, an air-water mixer, a release head, and the like of the traditional device, so that the problems of complex system, operation instability and large air bubble overturn of the traditional device are overcome; and the reflux pipeline is scientifically arranged at the inner part of the equipment, and the internal water receiving and air removal system is additionally arranged, so that air bubble entrainment of outlet water, which influences subsequent treatment, is avoided.

Owner:扬州绿都环境工程设备有限公司

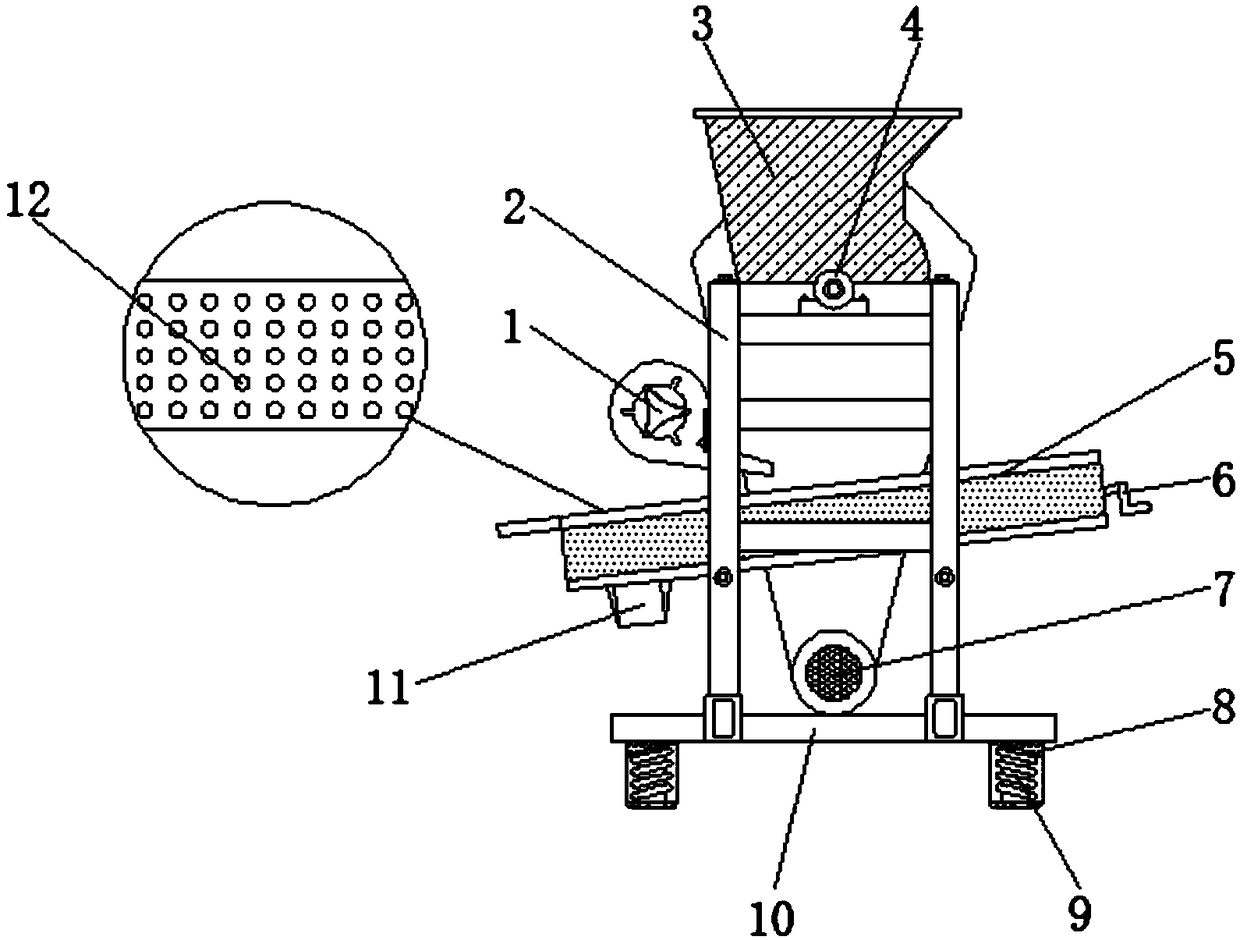

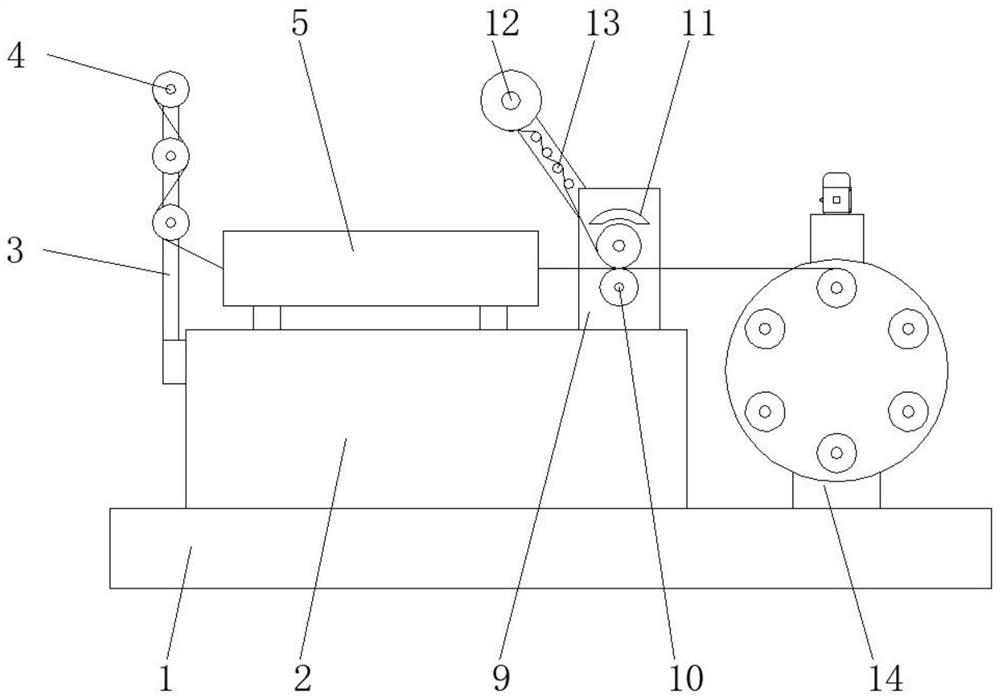

Automatic peanut sheller

The invention discloses an automatic peanut sheller, comprising a support frame, wherein a blow dryer is fixed to the position, close to the top, of one side of the support frame through fixing screws; a feeding inlet is fixed to the top of the support frame through the fixing screws; a rotary shaft inserted block is welded to the center of the top of the support frame; a vibration sieve plate iswelded to the position, close to the bottom, of the rear surface of the support frame; a rotary handle is rotationally connected to the center of one side of the vibration sieve plate; one end of therotary handle is welded with a driving wheel; and one side of the driving wheel is connected with a driven wheel in a rotary manner. A fixing plate is inserted inside the vibration sieve plate in a sliding manner, and a plurality of ramming rods which can directly rotate the rotary handle on the vibration sieve plate to drive the fixing plate to move up and down are welded to the fixing plate, sothat sieve holes on the vibration sieve plate can be rammed.

Owner:张永亮

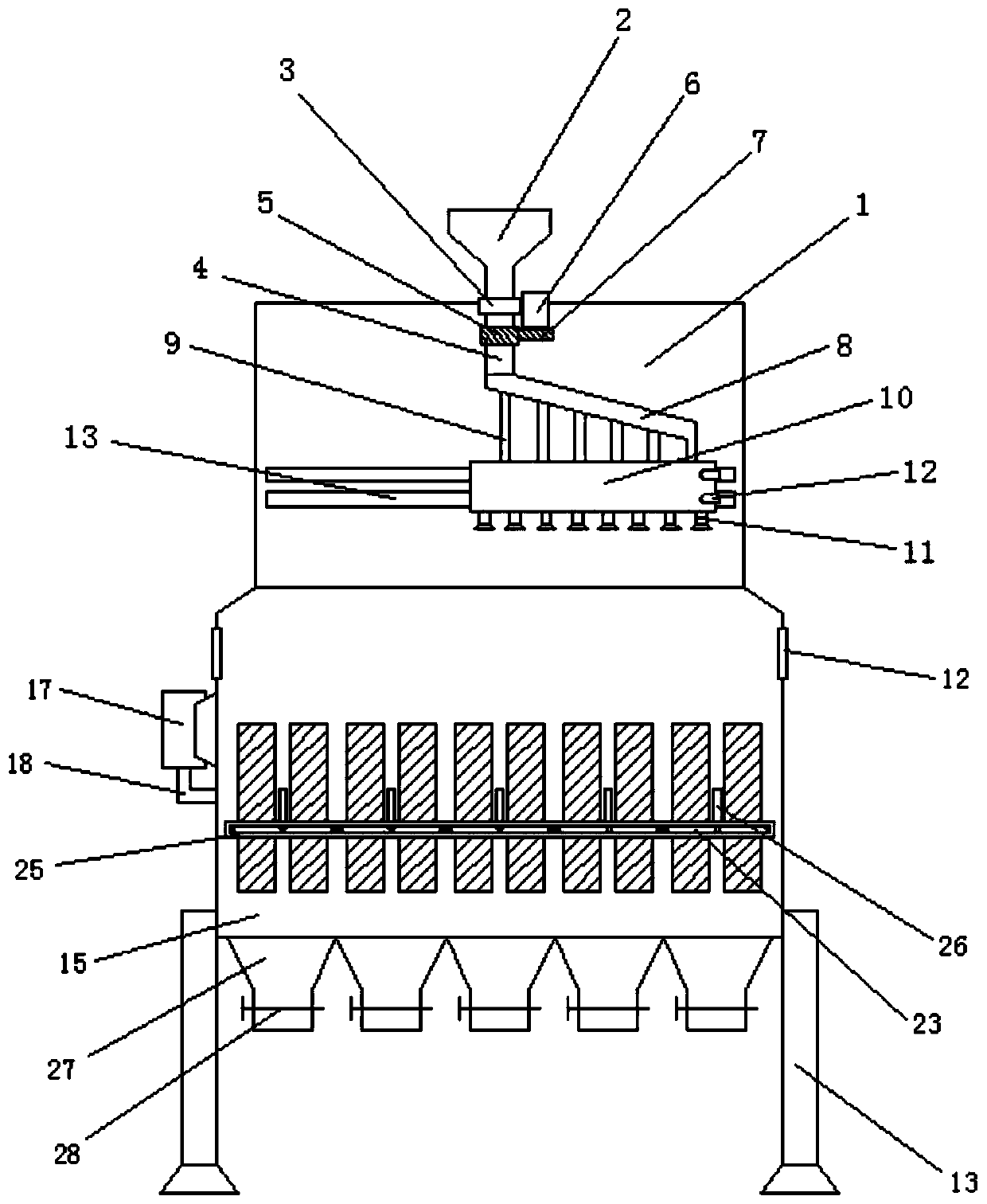

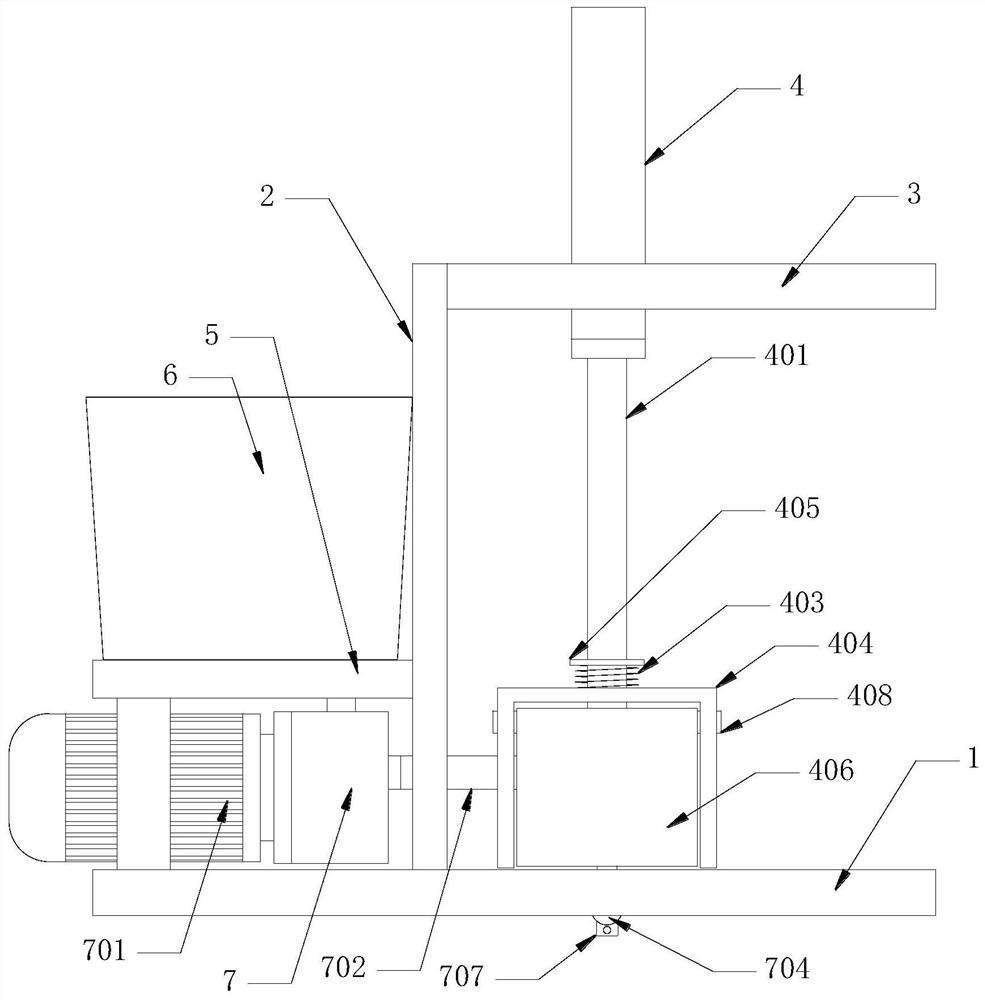

Constructional engineering brick pressing device with automatic feeding function

InactiveCN112092149AWith automatic feeding functionAvoid huge consumptionDischarging arrangementShaping press ramBrickMachining

The invention discloses a constructional engineering brick pressing device with the automatic feeding function. The constructional engineering brick pressing device comprises a base; a partition plateis fixedly connected to the middle of the top face of the base; and a supporting frame is fixedly connected to the right side of the surface of the partition plate. The invention relates to the technical field of constructional engineering. According to the constructional engineering brick pressing device with the automatic feeding function, huge consumption in the aspect of manpower is effectively avoided, manpower occupied by production is reduced, the labor cost is reduced, and the machining and production efficiency is greatly improved; in addition, operation of a conveying pump can be automatically cut off after filling a bearing plate with raw materials with the preset weight, so that the difference of the filling amount each time is avoided, the uniformity of the brick quality is guaranteed, and selling and using of bricks are better facilitated; and moreover, a telescopic rod for pressing the bricks is in linkage with molds, the telescopic rod can drive the two molds to relatively obliquely move and expand when being recycled after pressing is completed, and the situation that subsequent machining is affected due to the fact that the molds take up the bricks is avoided.

Owner:罗代平

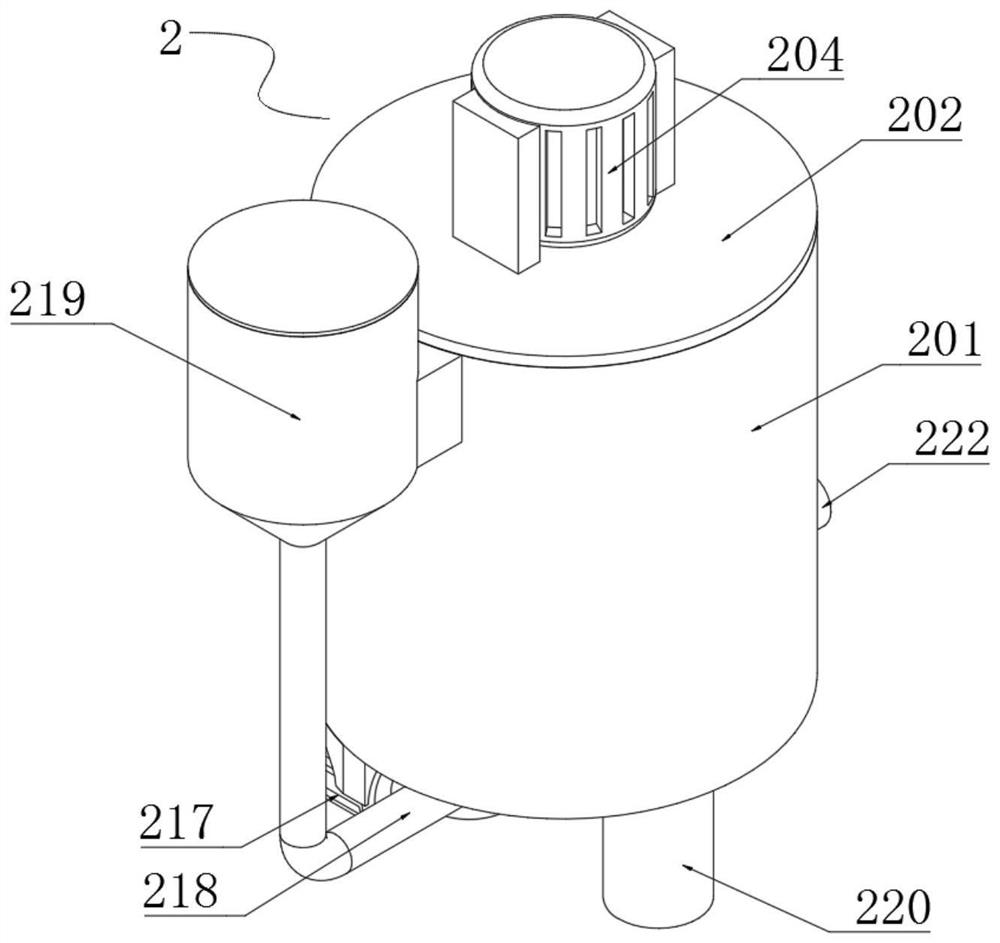

Production equipment for synthesizing phenolic resin

PendingCN114749246AAvoid affecting subsequent processingHollow article cleaningGrain treatmentsPolymer scienceEngineering

The invention relates to the technical field of mixing equipment, in particular to production equipment for synthesizing phenolic resin, which comprises a crushing box, a lifting mechanism, a sleeve, a cleaning part, a rotating mechanism and an abutting sleeve, the lifting mechanism is fixedly connected with the crushing box, the sleeve is rotationally connected with the crushing box, the cleaning piece is fixedly connected with the sleeve, the rotating mechanism is arranged on one side of the lifting mechanism, and the abutting sleeve is fixedly connected with the rotating mechanism; after phenolic resin is ground, the lifting mechanism drives the rotating mechanism to move downwards, so that the abutting sleeve moves downwards to be arranged on the outer side of the casing pipe in a sleeving mode and abuts against the casing pipe, the rotating mechanism drives the abutting sleeve to rotate, the abutting sleeve drives the casing pipe to rotate, and the casing pipe drives the multiple cleaning pieces to rotate along the inner wall of the smashing box. Thus, phenolic resin attached to the inner wall of the crushing box is scraped off, and cleaning of the crushing box is achieved.

Owner:湖州雨辰复合材料有限公司

Sheet metal machining tooling

Owner:SUZHOU MACHINING PRECISION ELECTRONICS

SK85 carbon tool steel

The invention relates to a processing technology of SK85 carbon tool steel. The processing technology of the SK85 carbon tool steel comprises the following steps of: selecting a hot-rolled coil plate with the mark of SK85, and carrying out stress relief annealing on the hot-rolled coil plate through a cover annealing furnace to obtain a hot-rolled stress relief annealed coil plate; carrying out acid pickling on the annealed coiled plate and preparing an acid-pickled coiled plate; and carrying out softening annealing on the acid pickling coiled plate through the cover type annealing furnace. The processing technology of the SK85 carbon tool steel has the beneficial effects that material surface scratching in the processing process of the carbon-content hot-rolled plate and cracks caused by edge stress concentration in the acid pickling and coiling process are prevented, spheroidizing annealing is conducted after the plate is rolled to the finished product size, the cold-rolled material is rolled to a state that broken and elongated flaky pearlite grains are recombined and transformed into uniformly distributed granular or globular pearlitic structures; the technology is suitable for normal proceeding of the follow-up fine blanking procedure, tissue preparation before quenching is conducted on punched parts, the product quality can be stabilized, the durability of products can be improved, the force value of the produced elastic parts is more stable, attenuation is small, and the service life is prolonged in a multiplied mode.

Owner:湖北大帆金属制品有限公司

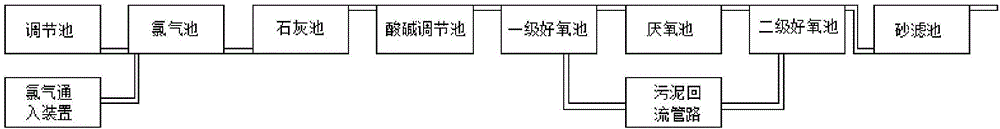

Special wastewater treatment device for hospitals

InactiveCN106810025AReduce the impactGuaranteed normal breedingTreatment using aerobic processesTransportation and packagingPh regulationAntibiotic Y

The invention belongs to the field of sewage treatment and discloses a special wastewater treatment device for hospitals. The special wastewater treatment device comprises a chlorine tank and a lime tank, which are connected in sequence, wherein the lime tank is connected with a pH regulation tank; the pH regulation tank is connected with a primary aerobic tank; the primary aerobic tank is connected with an anaerobic tank; the anaerobic tank is connected with a sand filter; and the sand filter is connected with a sterilizing device. The special wastewater treatment device for the hospitals is suitable for treating wastewater of the hospitals, can effectively reduce not only the probability of pestilences caused by germ reproduction but also the impact of antibiotics on wastewater treatment of the hospitals, and guarantees regular microbial multiplication during sewage treatment, the sewage treatment effect is improved, and the treatment efficiency is improved by improving the treatment capacity per unit time.

Owner:CHENGDU YANXINGGUO TECH CO LTD

Pyrolysis device

ActiveCN111076176AEffectively block spillsPrevent Spill HazardsIncinerator apparatusElectronic waste recyclingExhaust gasProcess engineering

The invention provides a pyrolysis device. The pyrolysis device comprises a conveying system, a preheating box, a high temperature decomposition box, a cooling box and loading devices; the preheatingbox, the high temperature decomposition box and the cooling box communicate in sequence and are all arranged on the conveying system; the conveying system can convey the loading devices to enter the preheating box, the high temperature decomposition box and the cooling box in sequence; the loading devices are used for bearing pyrolyzed pieces; a heating piece is arranged in each of the preheatingbox, the high temperature decomposition box and the cooling box; an openable / closable airtight door is arranged at each of an inlet of the preheating box, the position between the preheating box and the high temperature decomposition box, and an outlet of the cooling box; and the airtight door is used for closing the preheating box, the high temperature decomposition box and the cooling box. Through the scheme, the overflow of gases in various areas is effectively partitioned by matching separated heating areas and the airtight doors; the hazard of the overflow of high temperature toxic exhaust gas is prevented; continuous mass production can be realized; and moreover, the production capacity can be adjusted by adjusting the length of each heating area.

Owner:北京京能清洁能源电力股份有限公司北京分公司 +1

Detecting and screening device for food safety

ActiveCN113909115AImprove efficiencyImprove space utilizationSievingGas current separationStructural engineeringManufacturing engineering

The invention discloses a detecting and screening device for food safety. The detecting and screening device for food safety comprises a shell, wherein a screening assembly used for screening raw materials is rotatably installed in the shell, and a supporting assembly used for supporting the screening assembly and movably attached to the screening assembly is arranged in the shell; and a driving assembly movably attached to the supporting assembly is fixedly installed in the shell, an opening allowing large waste materials to flow out is formed in the position, corresponding to the screening assembly, of one side of the shell in a penetrating mode, and a first through hole, a second through hole and a third through hole are sequentially formed in the other side of the shell from bottom to top in a penetrating mode. Through the cooperation of the screening assembly, the supporting assembly, a lifting assembly, a collecting assembly and the like, effective screening and centralized collection of large waste materials, normal materials and small waste materials in raw materials can be achieved, multiple screens do not need to be sequentially arranged from top to bottom, and the space utilization rate is higher.

Owner:广州膳智科技有限公司

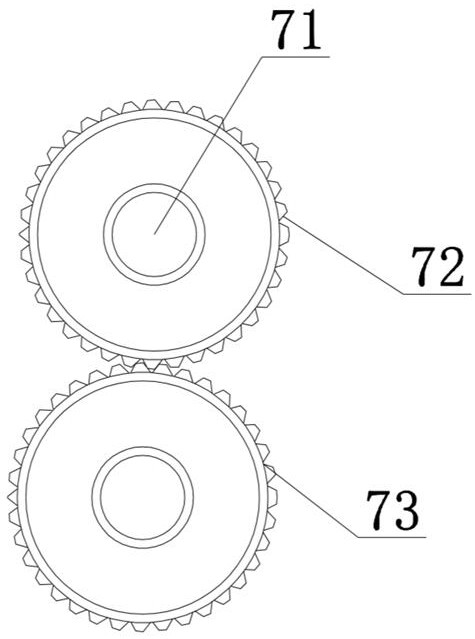

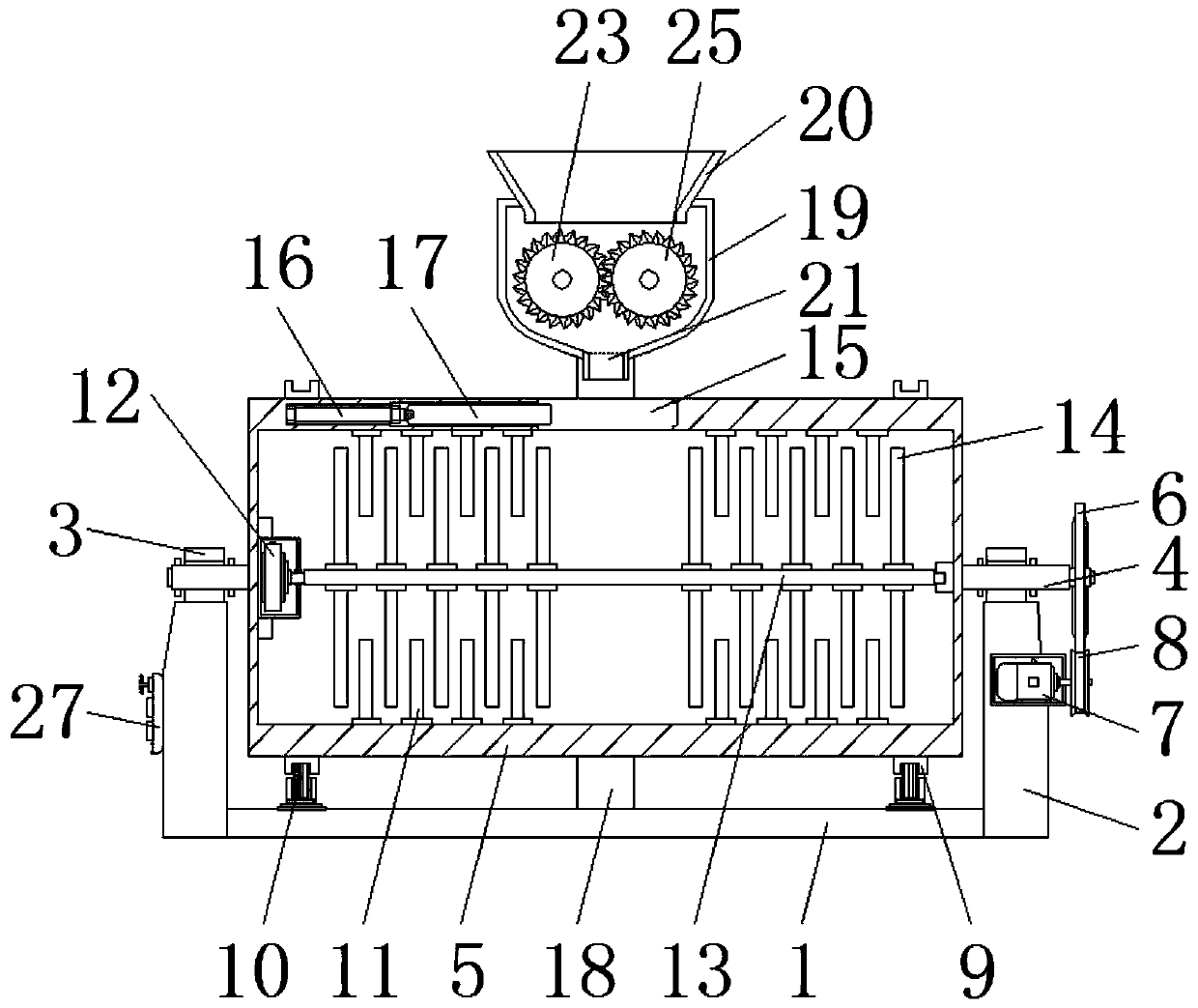

Efficient carbon molecular sieve raw material pretreatment equipment

InactiveCN110743655AAvoid cakingImprove stabilityTransportation and packagingMixersMolecular sieveGear wheel

The invention discloses efficient carbon molecular sieve raw material pretreatment equipment. The equipment comprises a baseplate, supporting rods are installed on the two ends of the top of the baseplate, the tops of the supporting rods are provided with buckling assemblies, and the inner sides of the buckling assemblies are provided with rotation rods. A stirring bin is arranged between the rotation rods, one end of one rotation shaft is provided with a driven gear A, one side of one supporting rod is provided with a driving motor A, and an output end of the driving motor A is provided witha drive gear A. According to the equipment, by installing a drive smashing roller, a drive gear B, a driven smashing roller and a driven gear B, a driving motor B drives the drive smashing roller to continuously rotate, the drive gear B and the driven gear B drive the driven smashing roller to reversely rotate, the drive smashing roller and the driven smashing roller crush raw materials, the crushed raw materials are added into the stirring bin through a discharging port and a feeding groove, and before stirring is performed, the raw materials are crushed and pretreated.

Owner:广德世博合成碳材料有限公司

Soaking bin for automobile part machining

PendingCN112827931AImprove efficiencyGood effectDrying gas arrangementsCleaning using liquidsGear wheelElectric machinery

The invention discloses a soaking bin for automobile part machining. The soaking bin comprises a soaking bin body, wherein a drive motor is arranged at the bottom of the soaking bin body; the output end of the drive motor extends into the soaking bin body; stirring blades are arranged at the output end of the drive motor; a lifting bin matched with the soaking bin body is arranged at the bottom in the soaking bin body; a water draining net is arranged at the bottom of the lifting bin; installing plates are symmetrically arranged on the two sides of the soaking bin body; and pneumatic cylinders are arranged on the tops of the installing plates. The soaking bin is provided with a rotation ring, an installing frame, the drive motor and a gear, the drive motor drives the rotation ring to continuously rotate through the gear, rotation air blowing water draining is achieved, the overall water draining speed and uniformity are further improved, and the situation that part of parts cannot be effectively drained is avoided. According to the device, the processes of soaking, water draining, discharging and the like are automatically conducted, intelligence and automation of the device are improved, the machining requirement is met, and meanwhile waste of manpower resources is reduced.

Owner:安徽名正汽车部件有限公司

Sanding machine ironing device based on network big data

ActiveCN114592304AAvoid excessive humidityAvoid excessive trafficLiquid/gas/vapor removal by squeezing rollersRougheningCrankElectric machinery

The invention discloses a sueding machine ironing device based on network big data, which comprises a workbench, support frames are fixedly mounted at two ends of the workbench, a feeding roller is connected to the inner side of the support frame at the front end through a bearing, a receiving roller is connected to the inner side of the support frame at the rear end through a bearing, a motor is fixedly mounted on the side surface of the receiving roller, and the motor is fixedly mounted on the side surface of the feeding roller. A wheel disc is fixedly installed between the motor and the material collecting roller, a belt is meshed with the outer portion of the wheel disc, a driven wheel is connected to the other end of the belt, a crank connecting rod is connected to the inner side of the driven wheel through a bearing, a fixing block is slidably connected to the outer side of the crank connecting rod, and an extrusion roller is connected to the tail end of the crank connecting rod through a bearing. A telescopic rod is connected to the other end of the extrusion roller through a bearing, a top table is arranged below the extrusion roller, a guide roller is arranged on the inner side of the discharging roller and the inner side of the collecting roller, and an ironing bin is arranged on the inner side of the guide roller.

Owner:JIANGSU HUAYI MACHINERY CO LTD

Efficient anti-roasting jig for base panel

The invention discloses an efficient anti-roasting jig for a base panel. The efficient anti-roasting jig comprises a jig bottom plate, and three side edges of the jig bottom plate are provided with flanges respectively; abutting cams are arranged at the positions, located on one sides of two corresponding flanges, of the jig bottom plate, and are fixed to one end of a rotating shaft, and the other end of the rotating shaft penetrates the jig bottom plate to be connected with a gear; a bearing is arranged between the rotating shaft and the jig bottom plate, and the gear is in meshed connection with racks which are arranged on rails; ends of the racks are connected with a handle through a connecting arm, and sliding grooves are further formed in the positions, located on one sides of the abutting cams, of the jig bottom plate; clamping plates are arranged above the sliding grooves, one sides of the bottoms of the clamping plates penetrate the sliding grooves to be connected with long ends of the L-shaped sliding grooves, and the short ends of the L-shaped sliding grooves are arranged on one side of the connecting arm; and the gear, the racks, the connecting arm and the L-shaped sliding arms are all arranged in a protection cover. The efficient anti-roasting jig is novel in structure, easy and convenient to operate, capable of being circularly used and environment-friendly and saves energy.

Owner:SPRING ELECTRONICS WUJIANG

A medical waste classification collection device and its collection method

ActiveCN112298853BEasy to sort and collectEasy to classifyWaste collection and transferCo-operative working arrangementsMedical wasteElectric machinery

The invention discloses a sorting and collecting device for medical waste. The device includes a frame, a collection bucket, an ejection mechanism and a clamping and transporting mechanism. The conveying motor and the conveying screw rod are connected in rotation with the frame, and the conveying motor drives the conveying screw rod to rotate. The block is provided with a conveying thread sleeve, the conveying thread is sleeved on the conveying screw rod, and the conveying thread sleeve is threadedly connected with the conveying screw rod. The method adopts a, delivery of medical waste; b, classification of medical waste; c, cleaning of medical waste, a total of three steps are adopted to simplify the process of classified collection of medical waste, facilitate the classified collection of medical waste and later transfer treatment, and improve the efficiency of classified collection of medical waste Efficiency improves the effect and accuracy of medical waste classification and collection, effectively avoids the wrong placement of medical waste, and facilitates the supervision of medical waste.

Owner:浙江融家科技有限公司

Zipper gilding press

ActiveCN112937112AInhibit sheddingAvoid bronzing effectsRotary pressesWebs handlingEngineeringRotating disc

The invention discloses a zipper gilding press. The zipper gilding press comprises a base, an adjusting mechanism, a gilding device, a material collecting mechanism, a rotating disc, a fixing mechanism and a fixing frame, a machine box is fixed to the top of the base, a first lead screw is rotationally connected to the lower portion of the inner side of a preheating box, a gear is rotationally connected to the surface of a fixing base, the gear is connected with the rotating disc, the rotating disc is rotatably connected to the surface of the fixing base, a movable rod is slidably connected to the inside of a material collecting disc. The zipper gilding press is provided with a heating pipe and clamping plates, the heating pipe in the preheating box can preheat zippers when the zippers are conveyed, so that the gilding effect is improved, the phenomenon that the gilding foil falls off from the zippers after gilding is avoided, and the first screw rod in the preheating box is matched to drive two groups of first movable blocks and the clamping plates to adjust the distance between the first movable blocks and the clamping plates, so that the zippers can be conveniently kept in the middle in the conveying process, the situation that the zippers and the gilding foil are misplaced due to deviation, and the gilding effect is affected is avoided, and the practicability is improved.

Owner:义乌市旭丰拉链有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com