Detecting and screening device for food safety

A screening device and food safety technology, which is applied in the fields of filtering, separating solids from solids with air flow, solid separation, etc., can solve the problems of unable to realize the rapid collection of large waste and small waste, large space, etc., and achieve space utilization. High, accelerated efficiency, strong applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

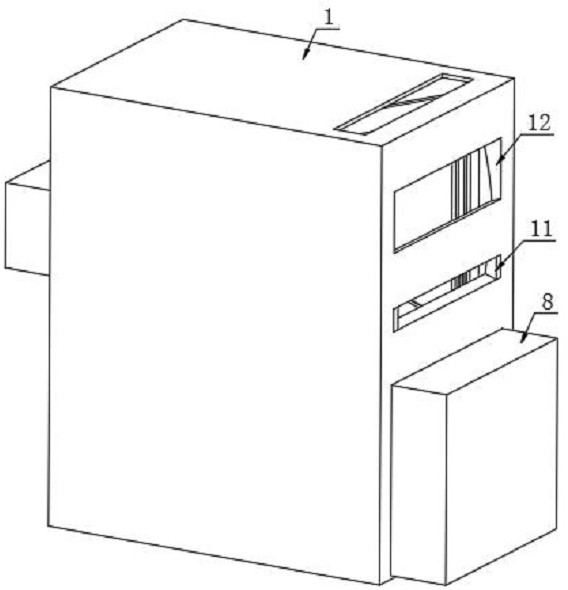

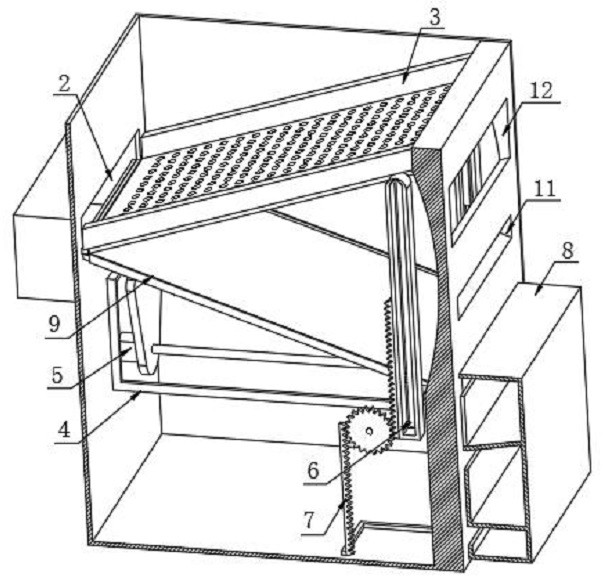

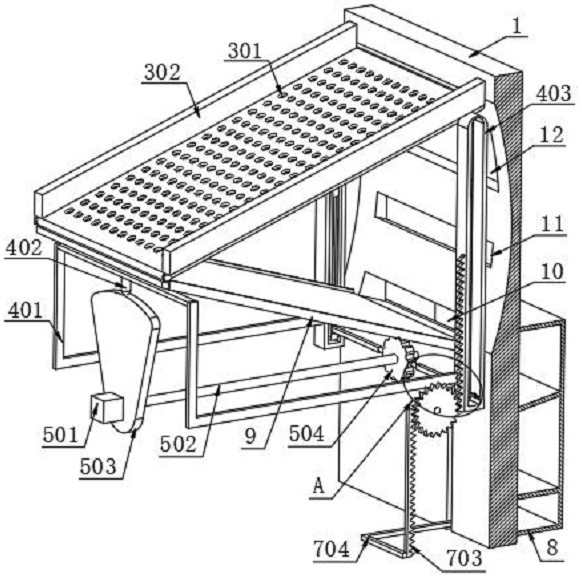

[0038] see Figure 1 to Figure 4 , the embodiment of the present invention provides a detection and screening device for food safety: the detection and screening device for food safety includes a casing 1, and a screening assembly 3 for screening raw materials is mounted on the inside of the casing 1, and the left side of the screening assembly 3 It is rotatably connected with the inner wall of the housing 1, the right side can swing back and forth, it is inclined to the right and the right side is movable, and the inner wall of the right side of the housing 1 is provided with an arc-shaped groove for the normal swing of the screening assembly 3; the inside of the housing 1 A support assembly 4 for supporting the screening assembly 3 and movably attached to the screening assembly 3 is provided, and the support assembly 4 is attached to the right movable end of the screening assembly 3; The combined drive assembly 5, one side of the housing 1 and the position corresponding to t...

Embodiment 2

[0045] see Figure 2 to Figure 12 , on the basis of Embodiment 1, the drive assembly 5 includes a motor 501 fixedly connected to the housing 1, the output shaft of the motor 501 is fixedly mounted with a long rod 502, and the end of the long rod 502 away from the motor 501 is rotationally connected to the housing 1 , to increase stability; the outer surface of the long rod 502 is fixedly mounted with a cam 503 that is movably fitted to the support assembly 4, and the cam 503 is composed of a large radius segment and a small radius segment.

[0046] The support assembly 4 includes a bracket 401, the bracket 401 is fixedly connected with the housing 1 through a telescopic rod, so that the bracket 401 can move up and down along the housing 1, and the bracket 401 can also be fixedly connected with the guide channel 9 through a telescopic rod, as long as the bracket 401 It can move up and down; the surface of the bracket 401 is fixedly equipped with a stub 402 that is movably fitte...

Embodiment 3

[0055] see Figure 2 to Figure 11 , on the basis of the second embodiment, the drive assembly 5 also includes a raised plate 504 fixedly installed on the outside of the long rod 502, and the raised plate 504 has multiple identical protrusions and multiple identical grooves; the inner side of the frame 403 is slidingly installed There is a moving component 6 that fits movably with the raised plate 504 and corresponds to the screening component 3 , and the frame 403 is in a front-to-back through-type design.

[0056] The mobile assembly 6 includes a support rod 601, and both sides of the support rod 601 are fixedly installed with a cross bar 603 that is slidingly fitted with the frame 403, and a spring 604 is fixedly installed between the cross bar 603 and the inner wall of the frame 403, and the cross bar 603 drives the support The rod 601 can slide back and forth along the frame 403, and the spring 604 can realize the reset of the cross bar 603; Sliding up and down, it can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com