Four-axis clamp capable of finishing turnover in one-step

A flipping and fixture technology, applied in the field of tooling and fixtures, can solve problems such as inaccurate workpiece clamping positions, low production efficiency, and wrong clamping quality, so as to prevent products from falling off and slide, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

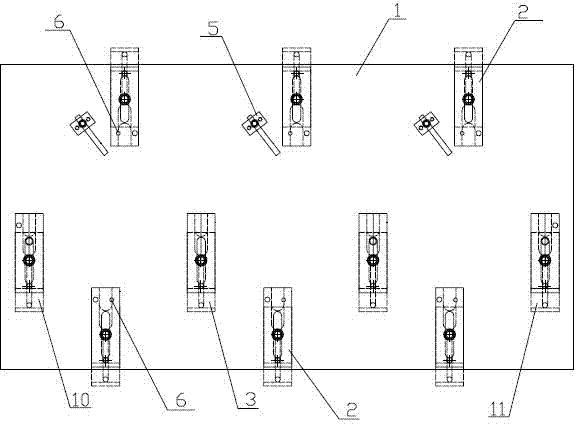

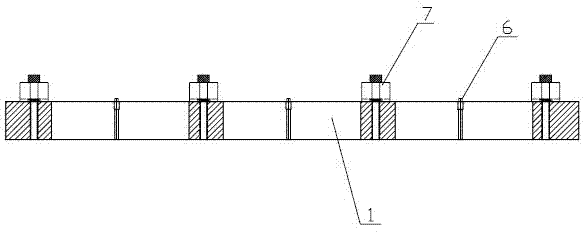

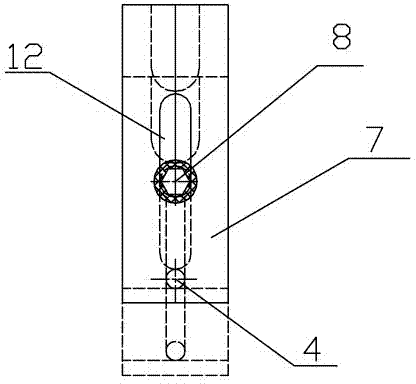

[0012] As shown in the figure, it includes a bottom plate 1, a positioning pin 6, a hold-down device and an error prevention pin 5, and the hold-down device is divided into a side hold-down device 2, a left hold-down device 10, a right hold-down device 11 and In the middle pressing device 3, three side pressing devices 2 are equidistantly arranged on the upper and lower edges of the bottom plate 1, and a left pressing device 10 and a right pressing device 11 are respectively provided in the middle of the left and right edges. In the middle of the base plate 1, there are two intermediate pressing devices 3, the left pressing device 10, the right pressing device 11 and the middle pressing device 3 are located on the same straight line and are equidistantly distributed, on the base plate 1 and each A positioning pin 6 is provided at the corresponding posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com