Recovery device and method for recovering rare-earth metal from rare-earth metal slag

A rare earth metal and recovery device technology, applied in chemical instruments and methods, process efficiency improvement, solid separation and other directions, can solve the problem of reducing the quality of rare earth metals, inability to integrate processing procedures, and inability to effectively achieve metal and non-metal sorting Treatment and other problems to achieve the effect of improving the grinding effect and reducing the impurity content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

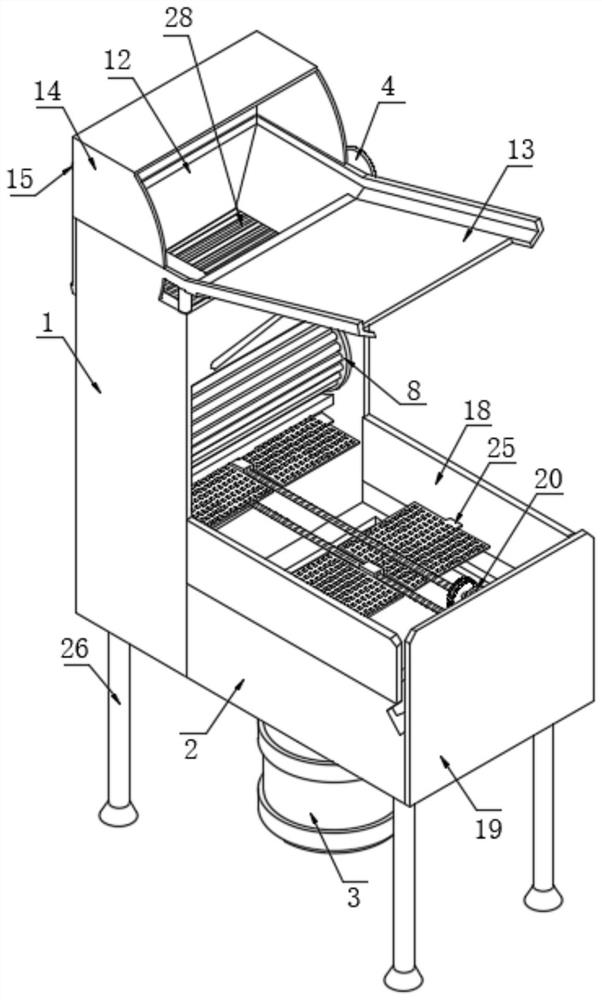

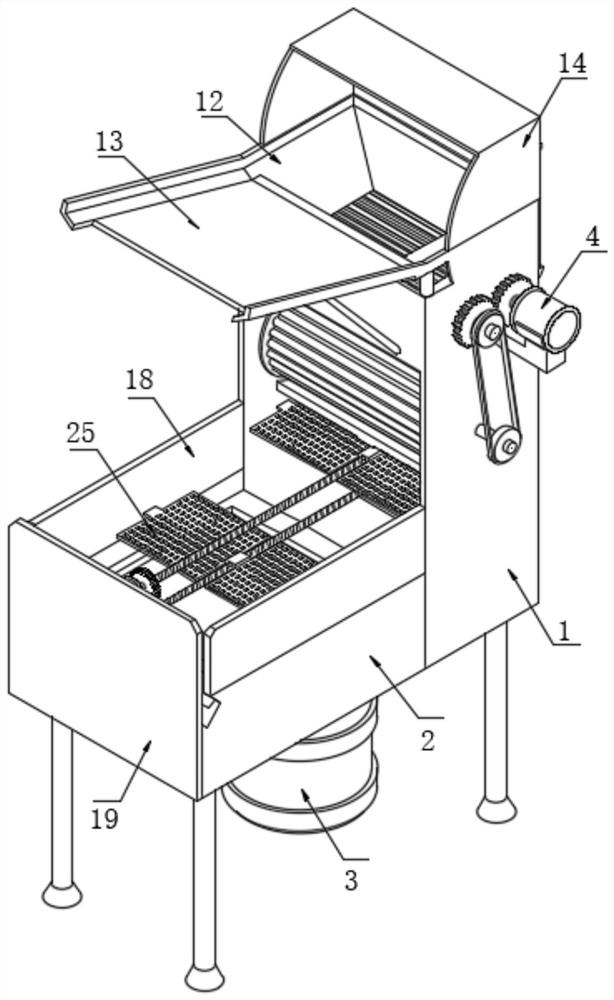

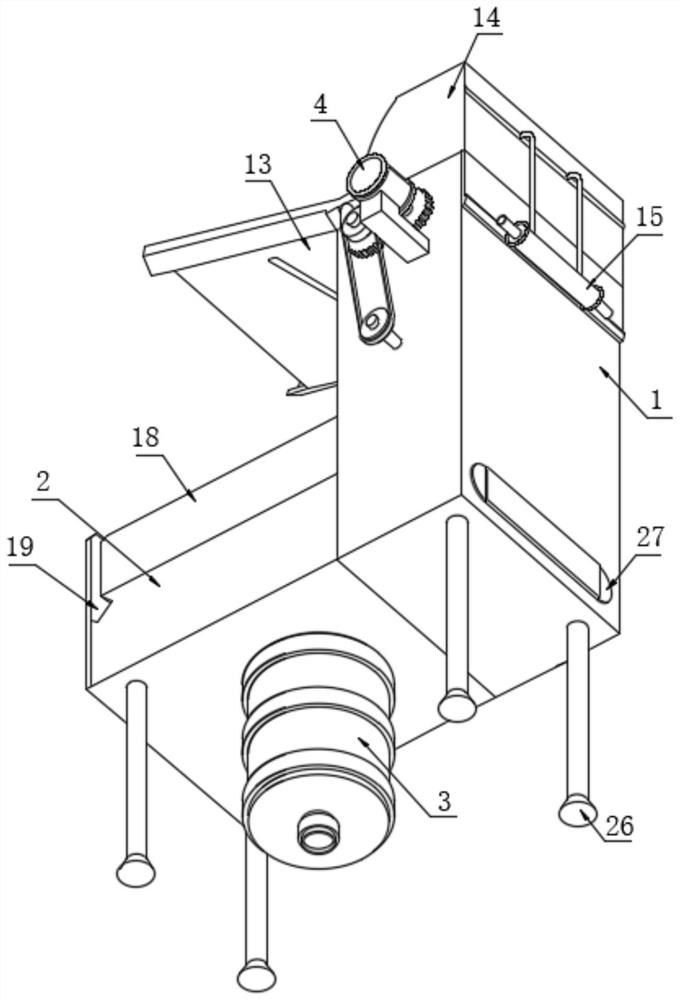

[0042] Such as Figure 1-9 As shown, the present invention provides a technical solution: a recovery device for recovering rare earth metals from rare earth metal slags, comprising a treatment box 1, a calciner 2 is arranged on the front of the treatment box 1, and an electrolysis chamber 2 is arranged on the lower surface of the calciner 2 Box 3, the right side of processing box 1 is provided with first driving assembly 4, and the lower surface of first driving assembly 4 is fixedly connected with the upper surface of fixed block 5, and the left side of fixed block 5 and the right side of processing box 1 The surface is fixedly connected, the first driving assembly 4 is meshed with the first driven gear 22, the left side of the first driving assembly 4 and the first driven gear 22 are fixedly connected with a crushing roller 28, and the two sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com