Patents

Literature

40results about How to "Easy to calcine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

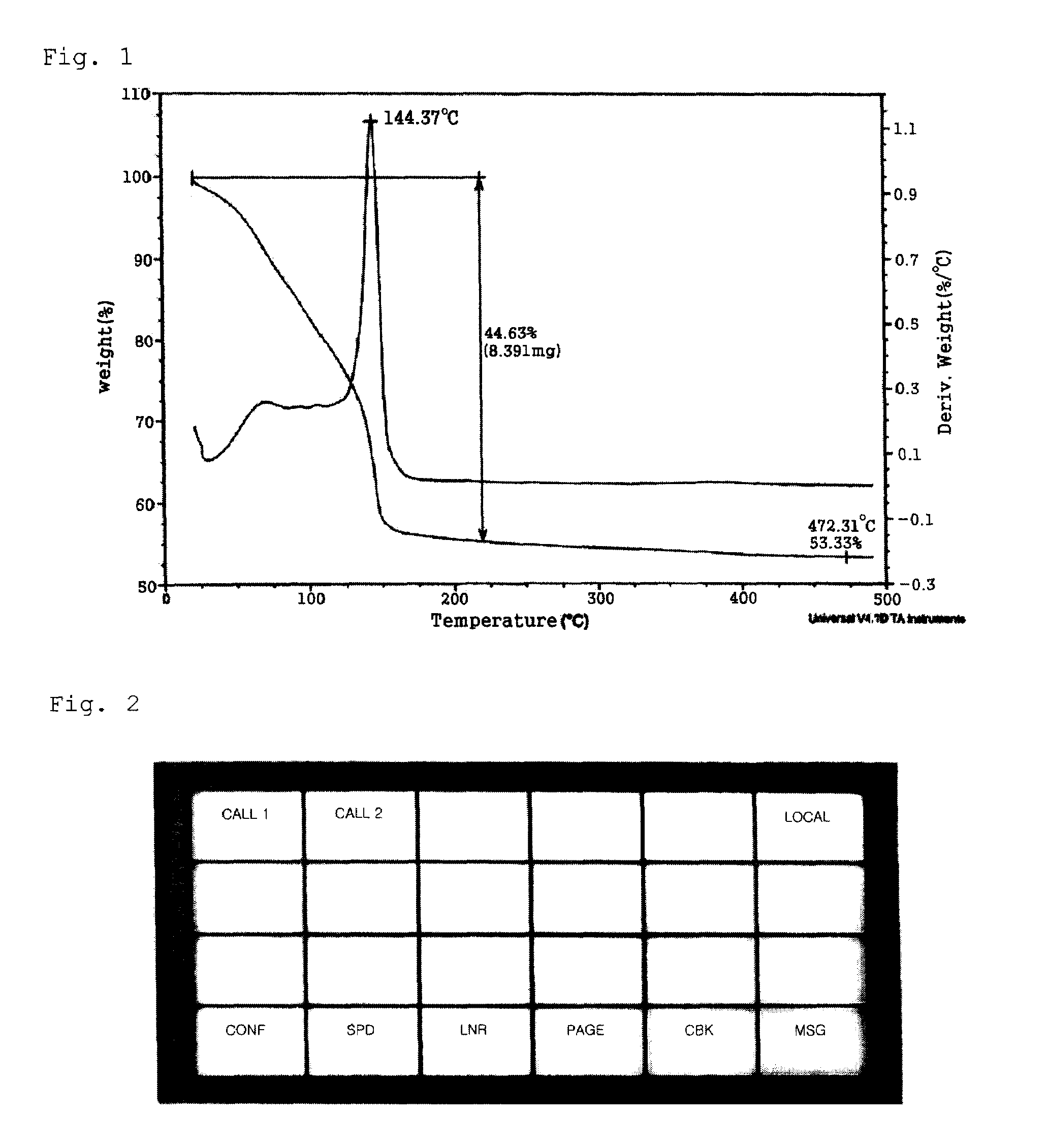

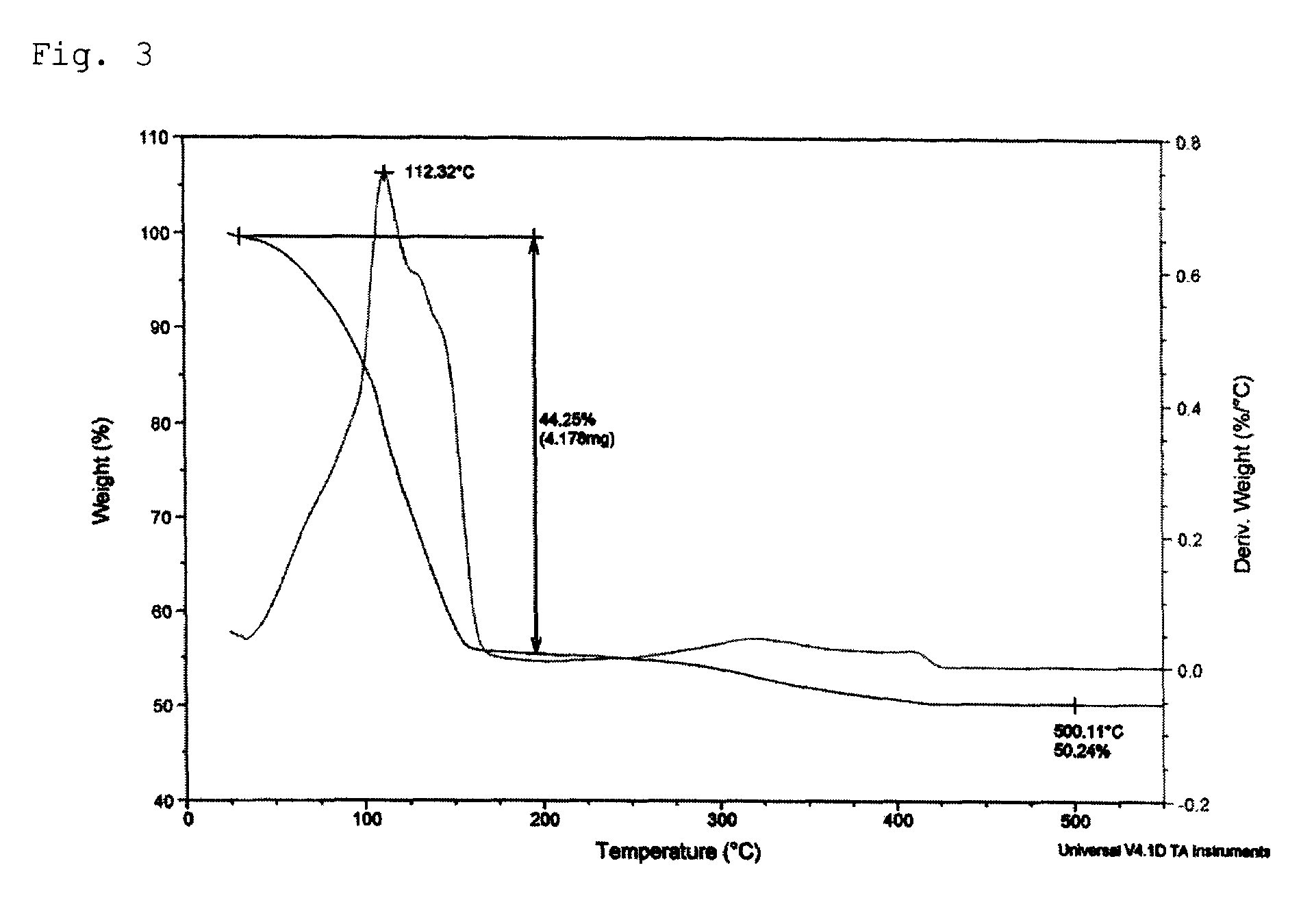

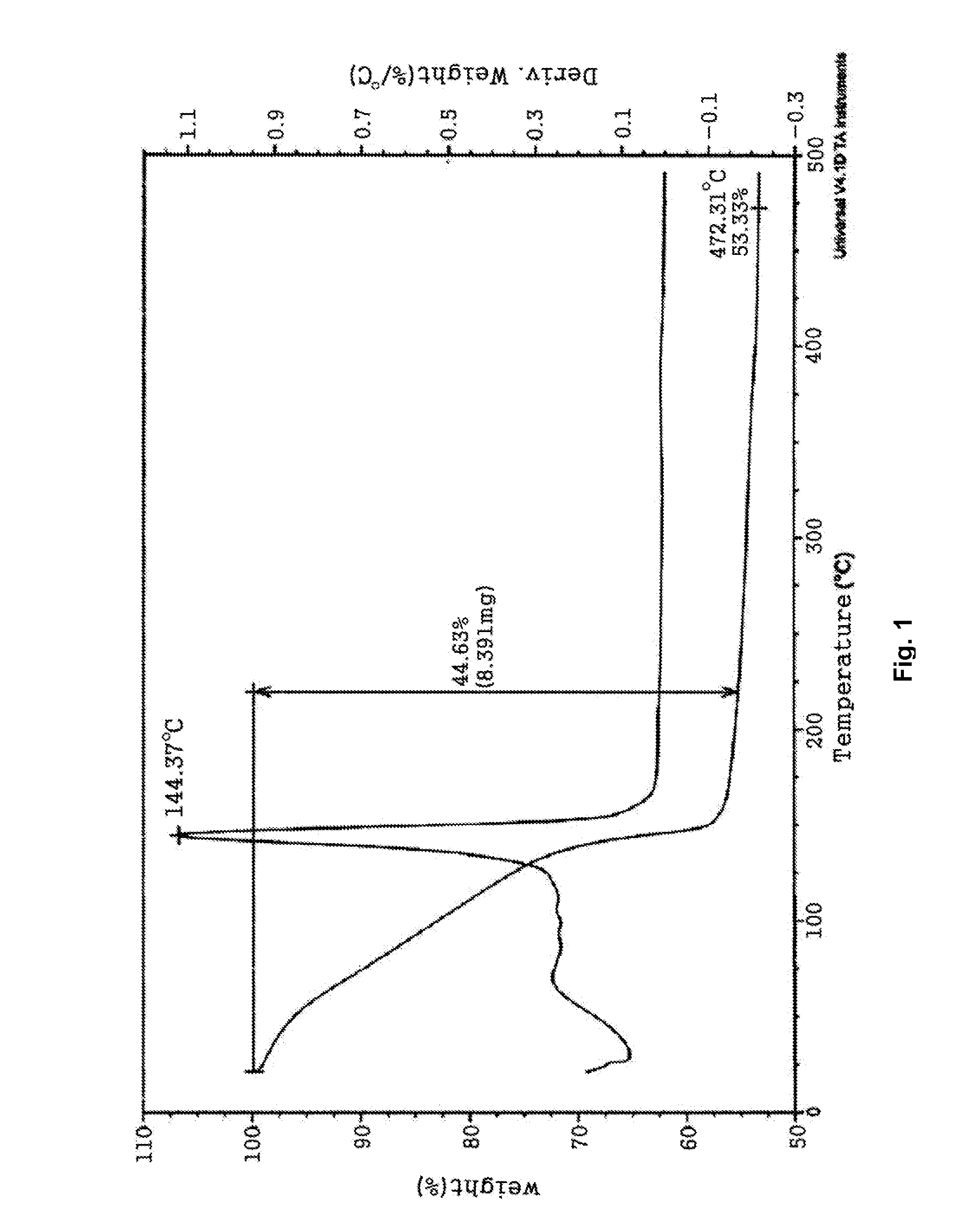

Conductive inks and manufacturing method thereof

ActiveUS7691294B2Easy to controlWell formedElectric discharge heatingFilament handlingAmmonium carbonateAmmonium carbamate

The present invention relates to a variety of conductive ink compositions comprising a metal complex compound having a special structure and an additive and a method for preparing the same, more particularly to conductive ink compositions comprising a metal complex compound obtained by reacting a metal or metal compound with an ammonium carbamate- or ammonium carbonate-based compound and an additive and a method for preparing the same.

Owner:INKTEC CO LTD

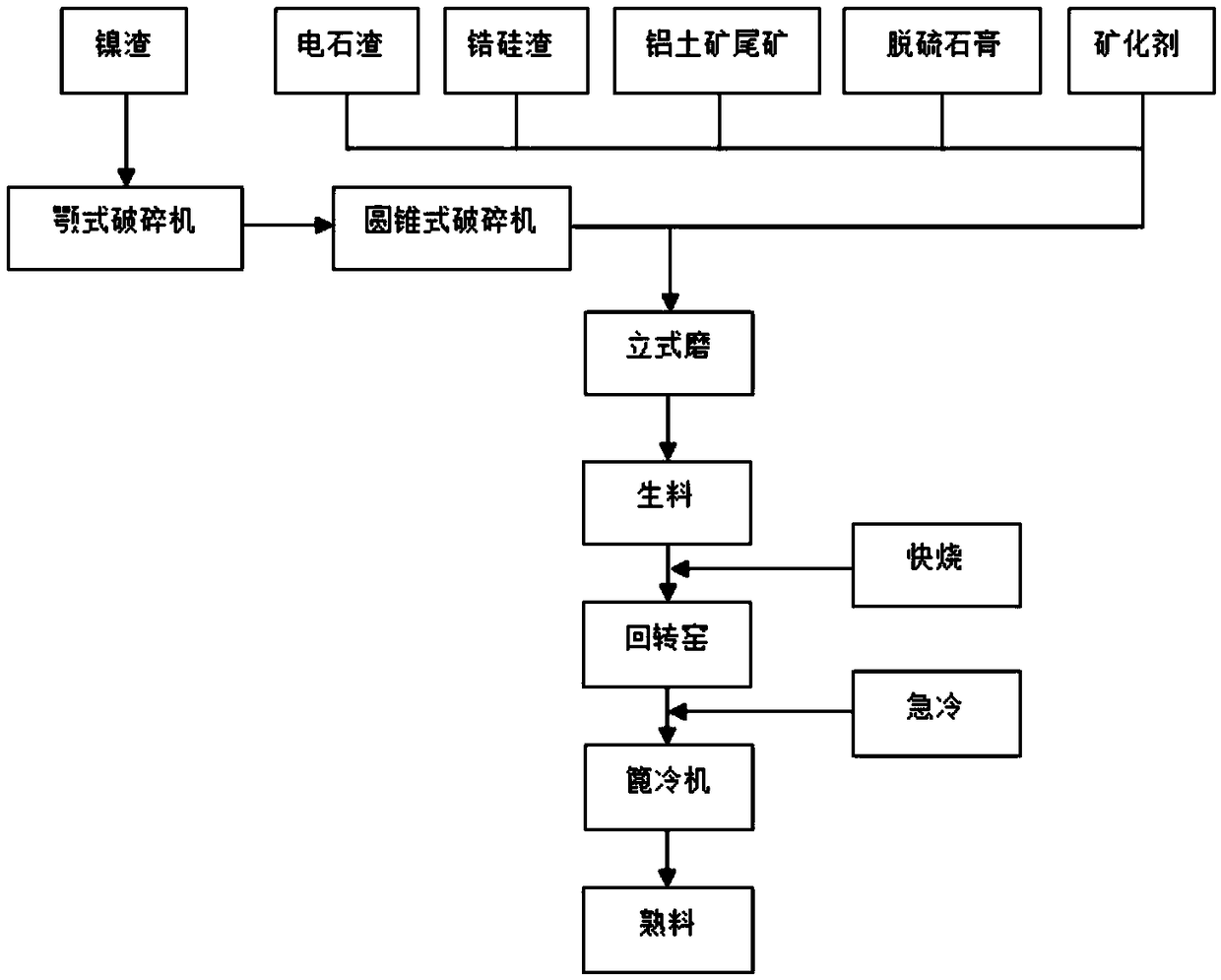

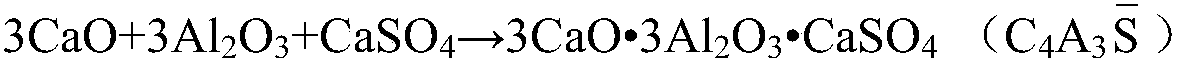

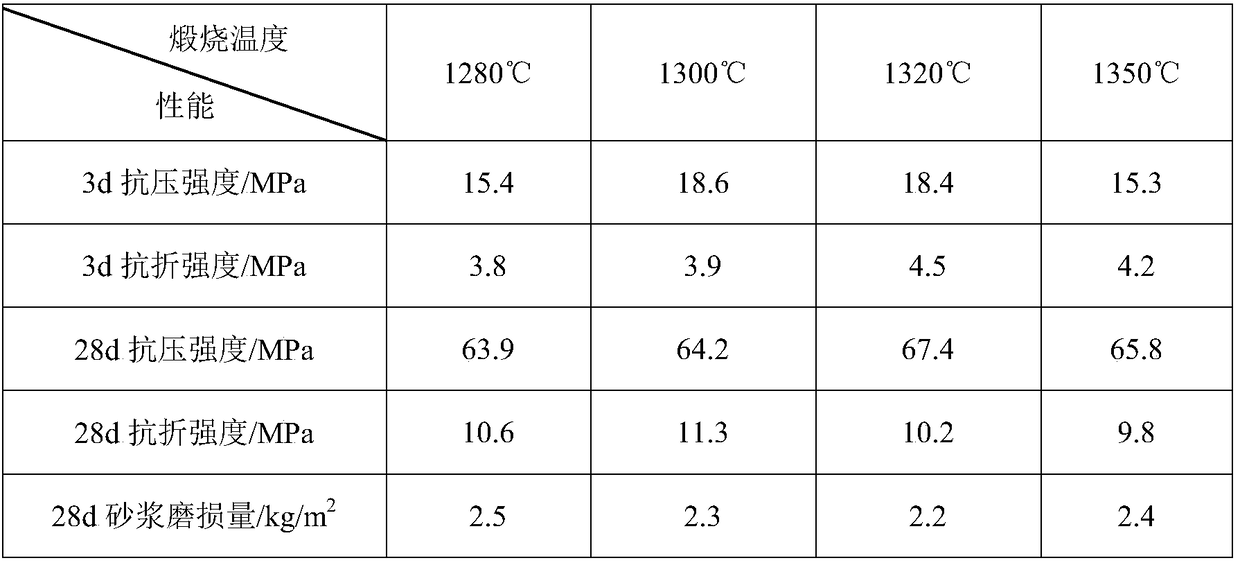

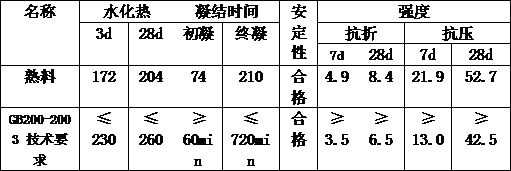

Road silicate cement clinker on basis of industrial waste residues and method for preparing road silicate cement clinker

ActiveCN109081615AStrong mechanical propertiesReduce consumptionCement productionSlagToxic industrial waste

The invention discloses road silicate cement clinker on the basis of industrial waste residues and a method for preparing the road silicate cement clinker. The road silicate cement clinker comprises nickel slag, calcium carbide residues, zirconium-containing silica residues, bauxite tailing, desulfurization gypsum and mineralizers. The method includes mixing, grinding and homogenizing the nickel slag, the calcium carbide residues, the zirconium-containing silica residues, the bauxite tailing, the desulfurization gypsum and the mineralizers to obtain cement raw materials; preheating the cementraw materials, then calcining the cement raw materials under the condition of the temperature of 1280-1350 DEG C for 30-35 min and then carrying out cooling to obtain the road silicate cement clinker.The road silicate cement clinker and the method have the advantages that the 28 d compressive strength of the road silicate cement clinker can reach 63.9-75.2 MPa, the strength grade of the road silicate cement clinker can reach 62.5 grade, the 28 d breaking strength of the road silicate cement clinker can reach 9.8-18.2 MPa, the 28 d mortar abrasion loss of the road silicate cement clinker is lower than 2.5 kg / m<2>, cement is high in stability, and the road silicate cement clinker is high in abrasion resistance and excellent in work performance; the method is simple, complicated working procedures can be omitted, and the road silicate cement clinker and the method are low in cost.

Owner:哈尔滨太行兴隆水泥有限公司

Conductive Inks and Manufacturing Method Thereof

ActiveUS20100247798A1Easy to controlWell formedVacuum evaporation coatingPretreated surfacesAmmonium carbonateAmmonium carbamate

The present invention relates to a variety of conductive ink compositions comprising a metal complex compound having a special structure and an additive and a method for preparing the same, more particularly to conductive ink compositions comprising a metal complex compound obtained by reacting a metal or metal compound with an ammonium carbamate- or ammonium carbonate-based compound and an additive and a method for preparing the same.

Owner:INKTEC CO LTD

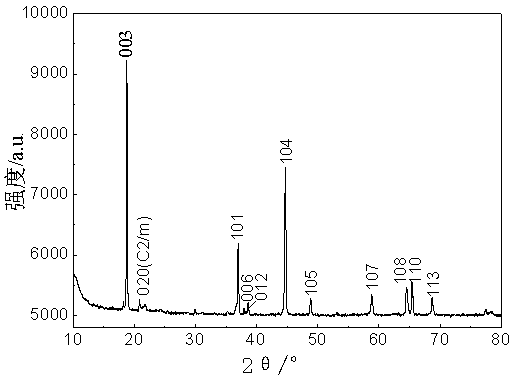

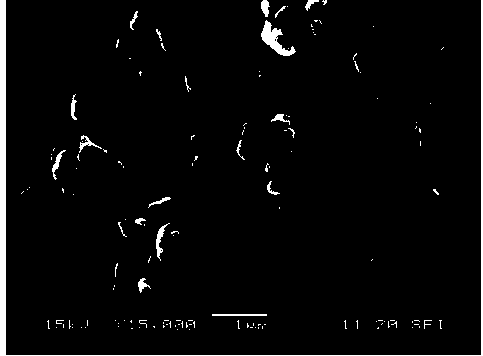

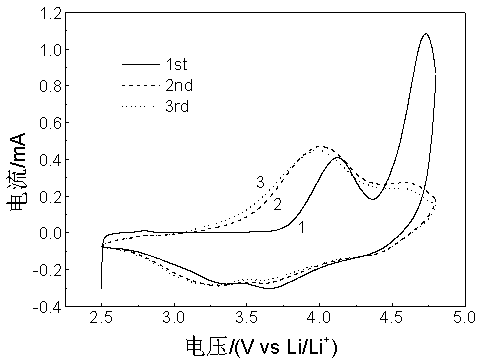

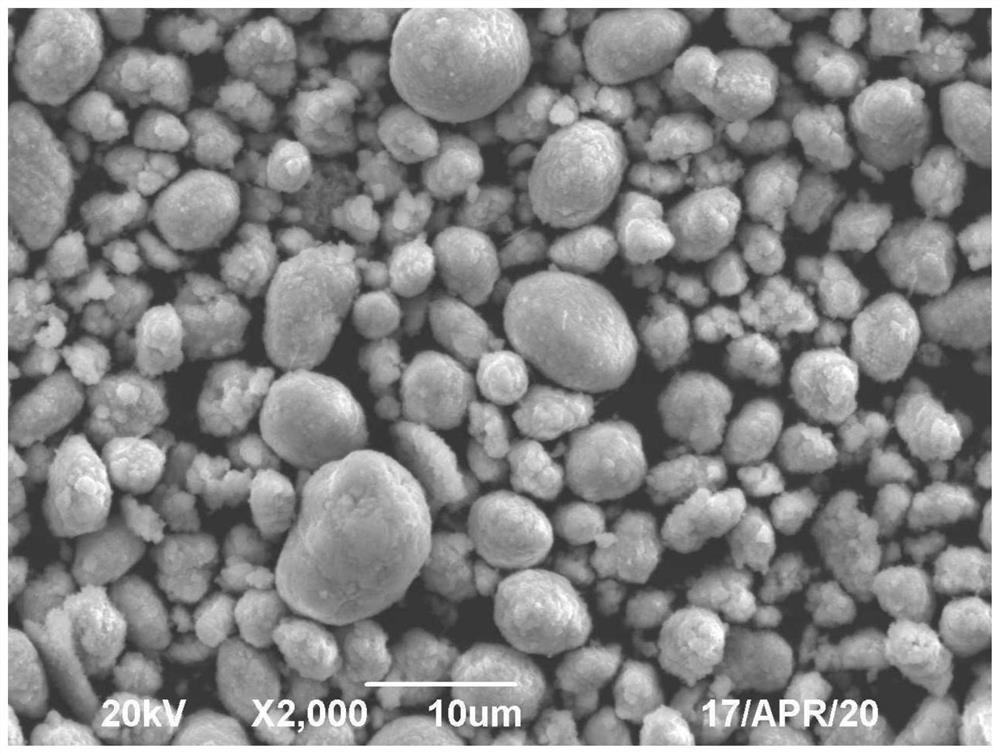

Mg-doped Li-rich anode material and preparation method for same

InactiveCN103441238AGood cycle performanceGood cycle performance and rate performanceCell electrodesCOBALTOUS ACETATEMagnesium nitrate

The invention discloses an Mg-doped Li-rich anode material and a preparation method for the same, wherein the molecular formula of the Mg-doped Li-rich anode material is Li(Li0.2Ni0.13Co0.13Mn0.54)0.98Mg0.02O2. The preparation method comprises the following steps of: dissolving lithium acetate, cobaltous acetate, nickel acetate, manganese acetate and magnesium nitrate in deionized water in a molar ratio of Li to Co to Ni to Mn to Mg being 1.196: 0.1274: 0.1274: 0.5292: 0.02 to obtain solution 1; adding citric acid in deionized water to obtain solution 2 in a ratio of the molar weight of the citric acid to the total molar weight of Ni, Co, Mn and Mg being 1: 1; and adding the solution 2 in the solution 1, adjusting the pH value to be 9, stirring at 80 DEG C until a purple gel is formed, sequentially performing drying, ball-milling, segmented calcination and grinding, and thus obtaining the Mg-doped Li-rich anode material which is high in specific discharge capacity, good in circulation performance, and excellent in rate performance.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

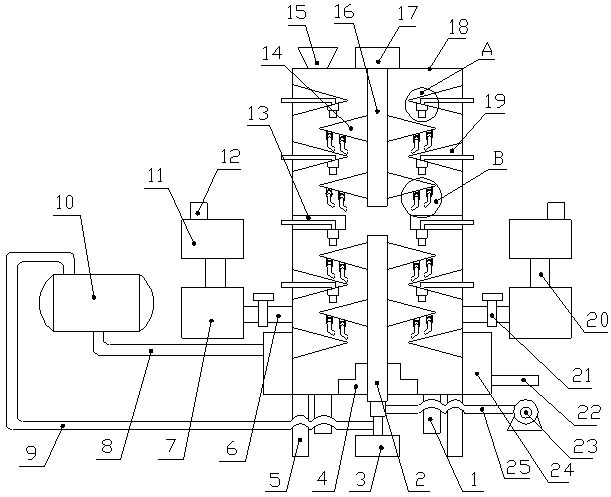

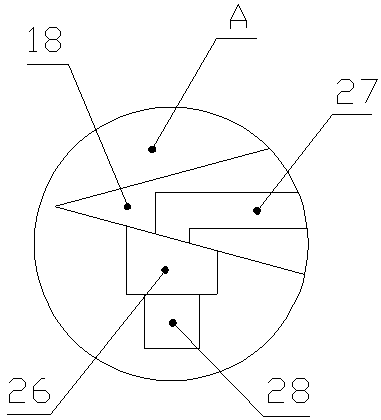

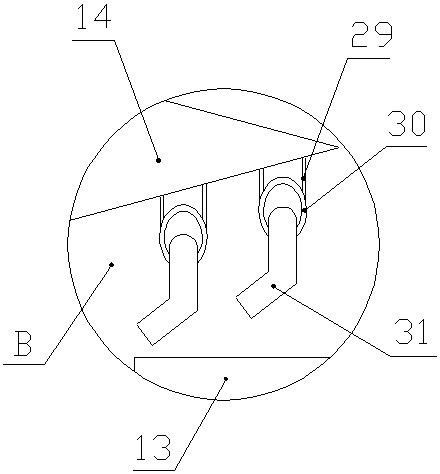

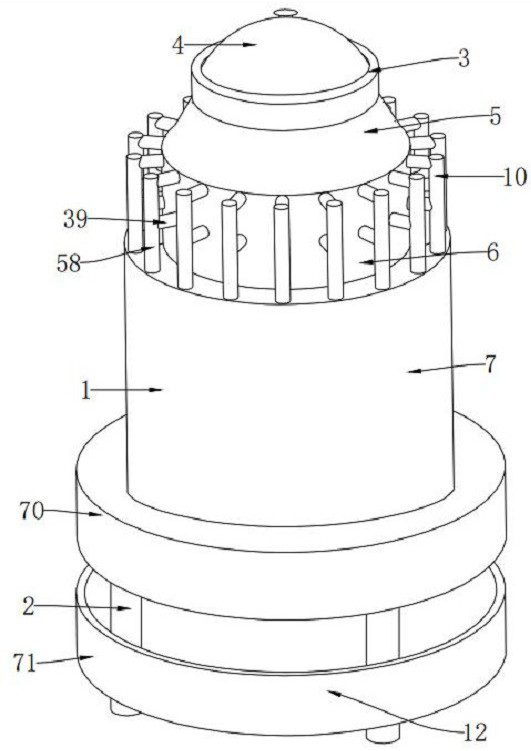

Limestone powder calcining furnace

The invention discloses a limestone powder calcining furnace which comprises a furnace body, wherein the left side and the middle of the upper surface of the furnace body are connected with a feedinghopper and a motor B respectively; a motor A is arranged below the furnace body; output shafts of the motor A and the motor B are respectively connected with a stirring shaft A and a stirring shaft B;stirring blades are connected to the stirring shaft A and the stirring shaft B; high-temperature belts are connected to the middle of the inner side wall of the furnace body; the upper and lower parts of the inner side wall of the furnace body are connected with guide plates; the lower surfaces of the guide plates and the high-temperature belts are connected with material blowing devices; the lower surfaces of the stirring blades are connected with poking devices; the outer side of the stirring shaft A is connected with a discharge tower through a bearing; the outer side of the lower part ofthe furnace body is sleeved by a cooling sleeve; the lower part of the right side of the cooling sleeve is connected with a liquid inlet pipe; the upper part of the left side of the cooling sleeve isconnected with the inlet end of a steam drum through a liquid outlet pipe; the outlet end of the steam drum is connected with the stirring shaft A through a steam pipe; and the left side and the rightside of the lower surface of the furnace body are connected with discharge tubes. The limestone powder calcining furnace has the advantages of thorough calcination, wall adhesion prevention, high discharge efficiency, energy conservation and environment protection.

Owner:河南越尔环保科技有限公司

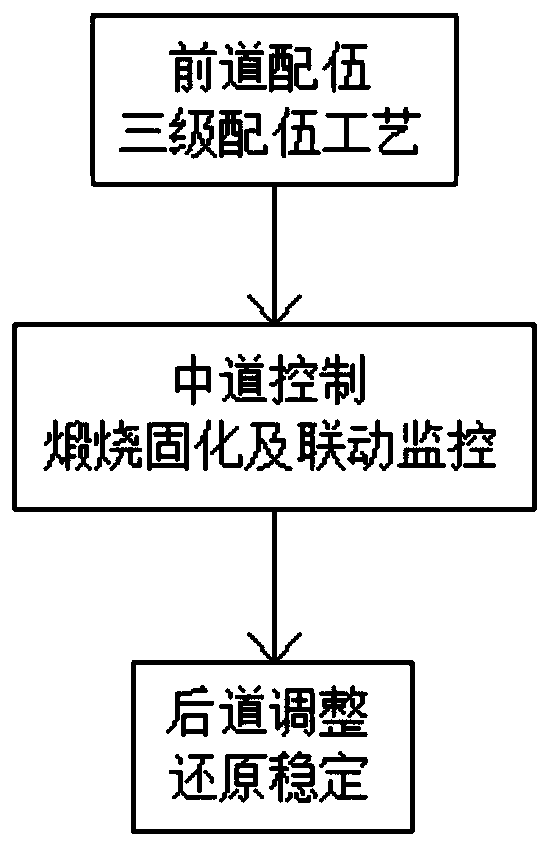

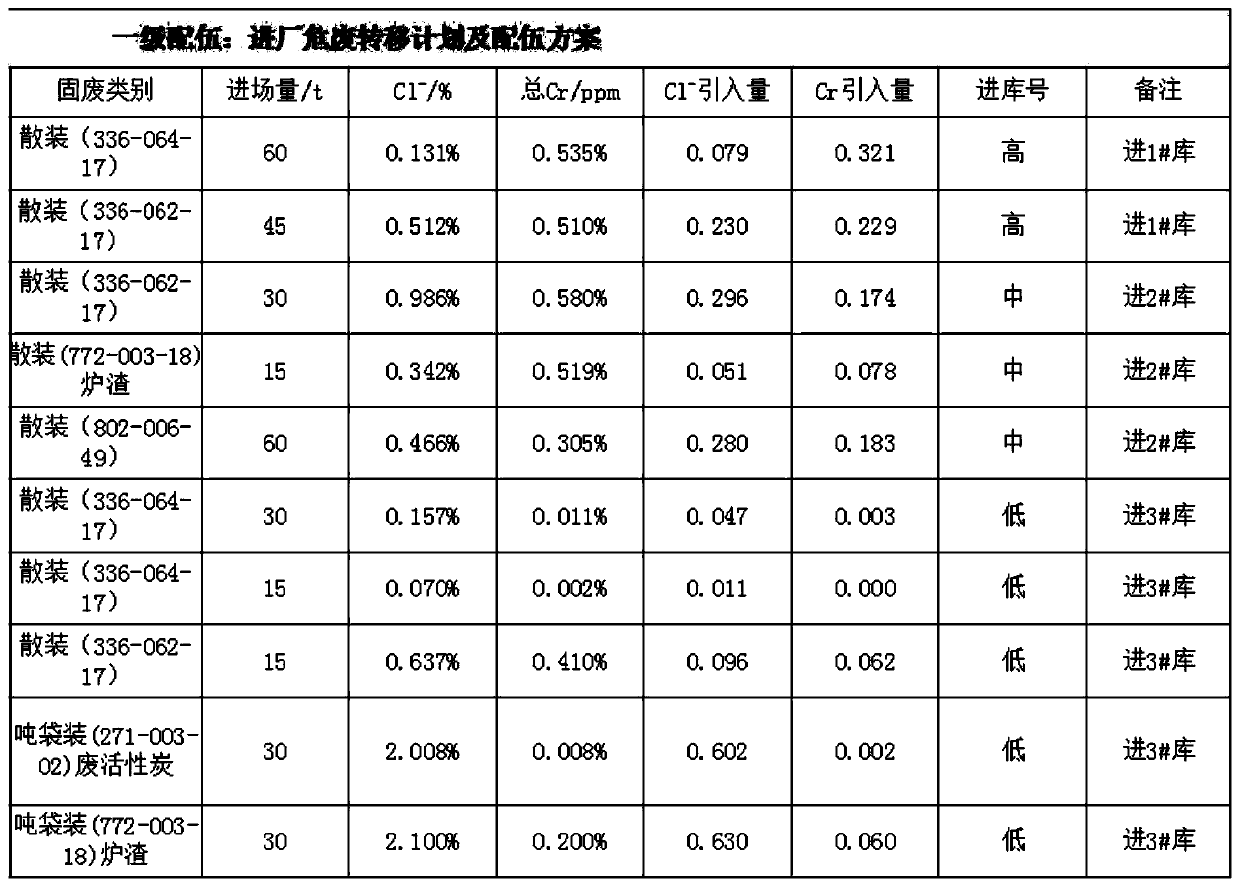

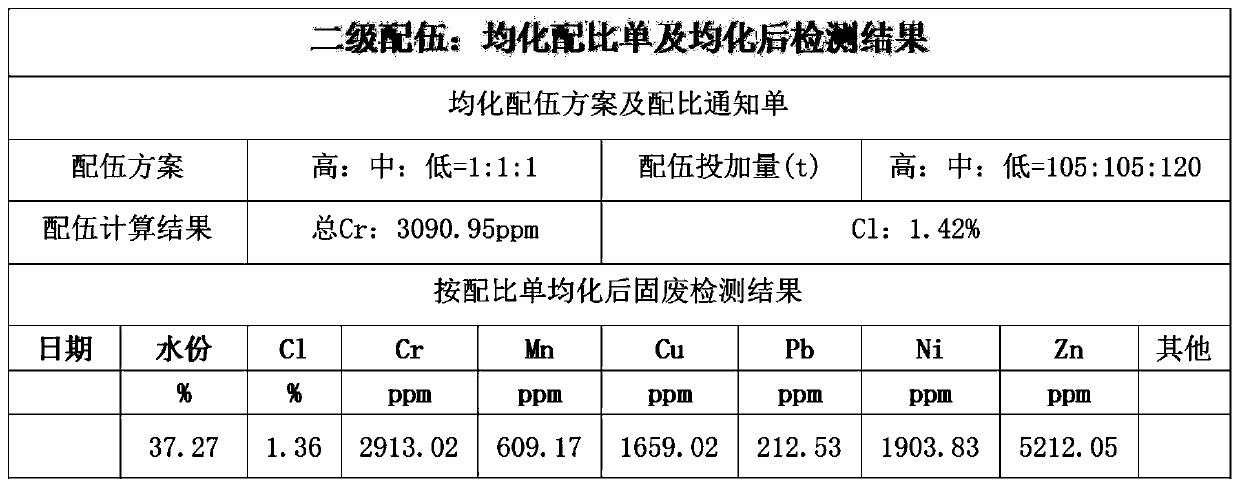

Method for treating chromium-containing waste in cooperation with cement kiln

The invention discloses a method for treating chromium-containing waste in cooperation with a cement kiln. The method comprises the steps of primary proportioning, tertiary proportioning, intermediatecontrol, calcining, curing and linkage monitoring, secondary adjustment, and reductive stabilization, wherein in the primary proportioning, the components of the chromium-containing waste is uniformthrough three control links of source control, classified piling and multiple homogenization, and reasonable adding; in the intermediate control process, a calcining clinker lattice in the cement kilncan cure heavy metal ions, and cure Cr ions in dangerous waste into the lattice; under the weaker calcining-oxidizing atmosphere of the cement kiln, the ratio of oxidization from Cr<3+> to Cr<6+> islowered, and the Cr6<6+> content is lowered; in the secondary adjustment, a composite reduction agent is added in the cement grinding process to reduce the Cr<6+> in the cement. The method for treating chromium-containing waste in cooperation with the cement kiln runs stably, is green and environmentally friendly, achieves the effects of solid waste reduction, energy conservation and emission reduction, lowers the influence of chromium-containing dangerous waste, and has good social benefit and economic benefit.

Owner:浙江红狮环保股份有限公司

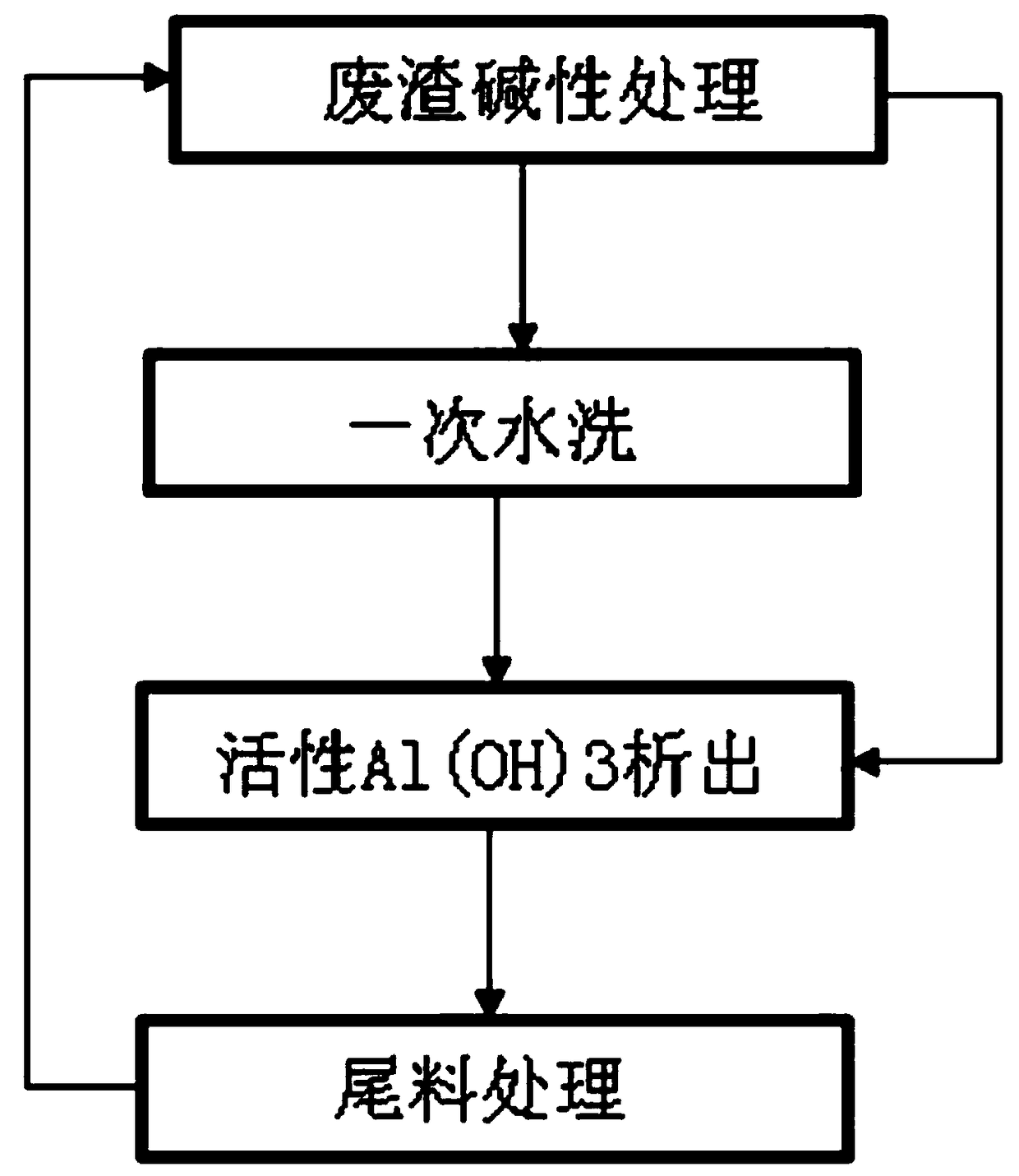

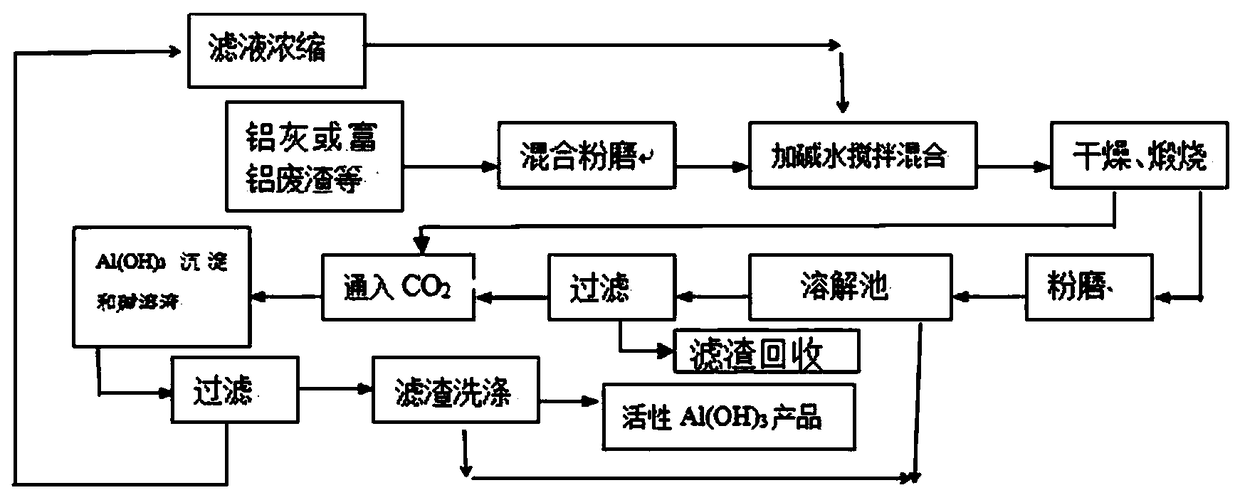

Process for extracting active Al(OH)3 product by utilizing aluminum ash or aluminum-rich waste residue

InactiveCN109437266AAdaptableFlexible adjustmentAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationEngineeringFire retardant

The invention relates to a process for extracting active Al(OH)3 product by utilizing aluminum ash or aluminum-rich waste residue, which comprises four steps, i.e. alkaline treatment of waste residue,primary washing, separation of active Al(OH)3 and treatment of tailings. The process disclosed by the invention can effectively utilize aluminum-rich waste residue as a material for the production ofactive Al(OH)3, extracted active Al(OH)3 can lead to a revolutionary progress in the production of polyaluminium chloride, moreover, active Al(OH)3 can also be used as flame retardant and the like, so the application prospect is broad. The effective utilization of waste residue (such as aluminum ash) is realized, and the influence of waste residue piling on the environment is solved. Waste gas, waste water and waste residues in the process of production are effectively applied, so the process is a technique which particularly has practical value.

Owner:JIAOZUO UNIV

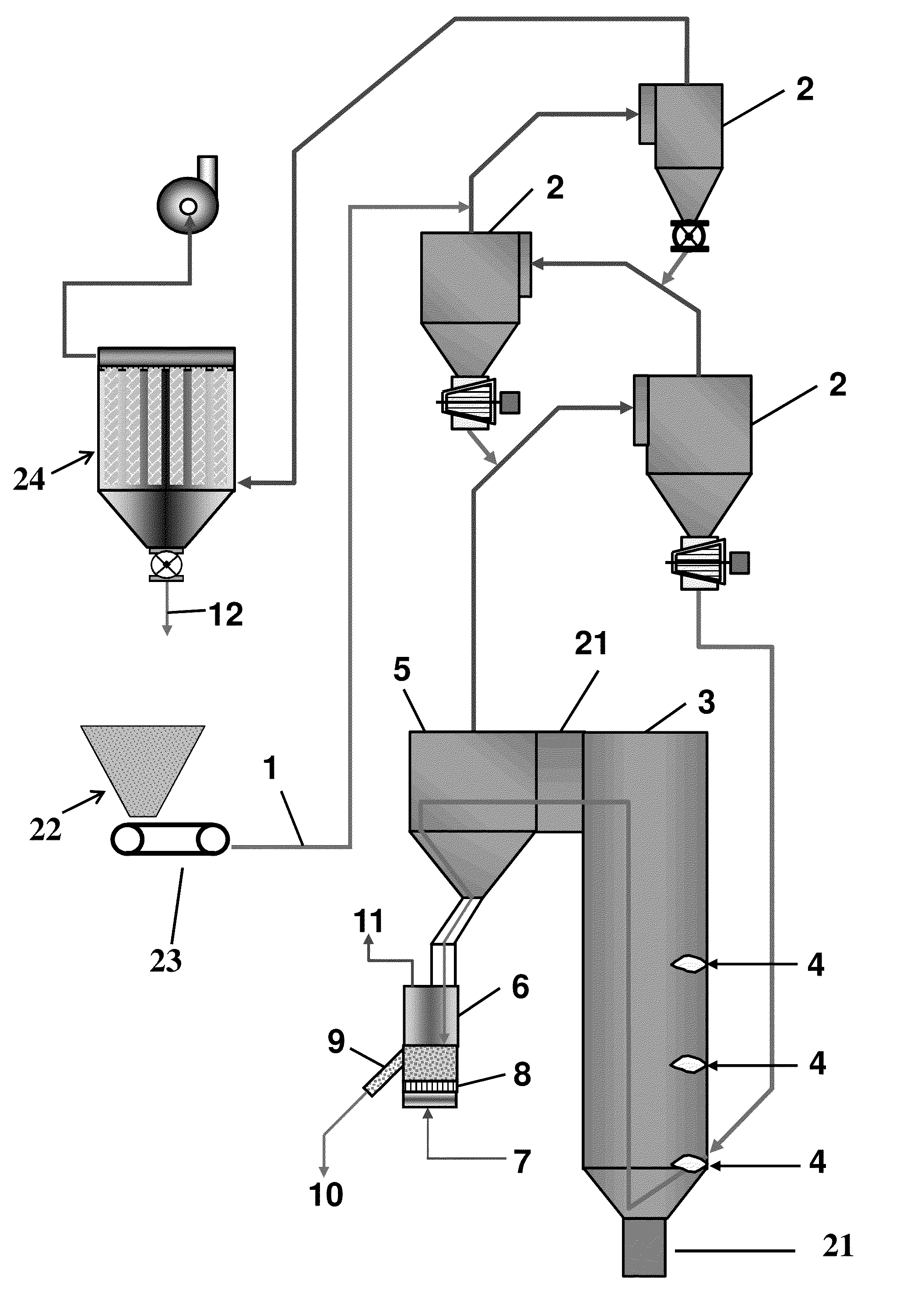

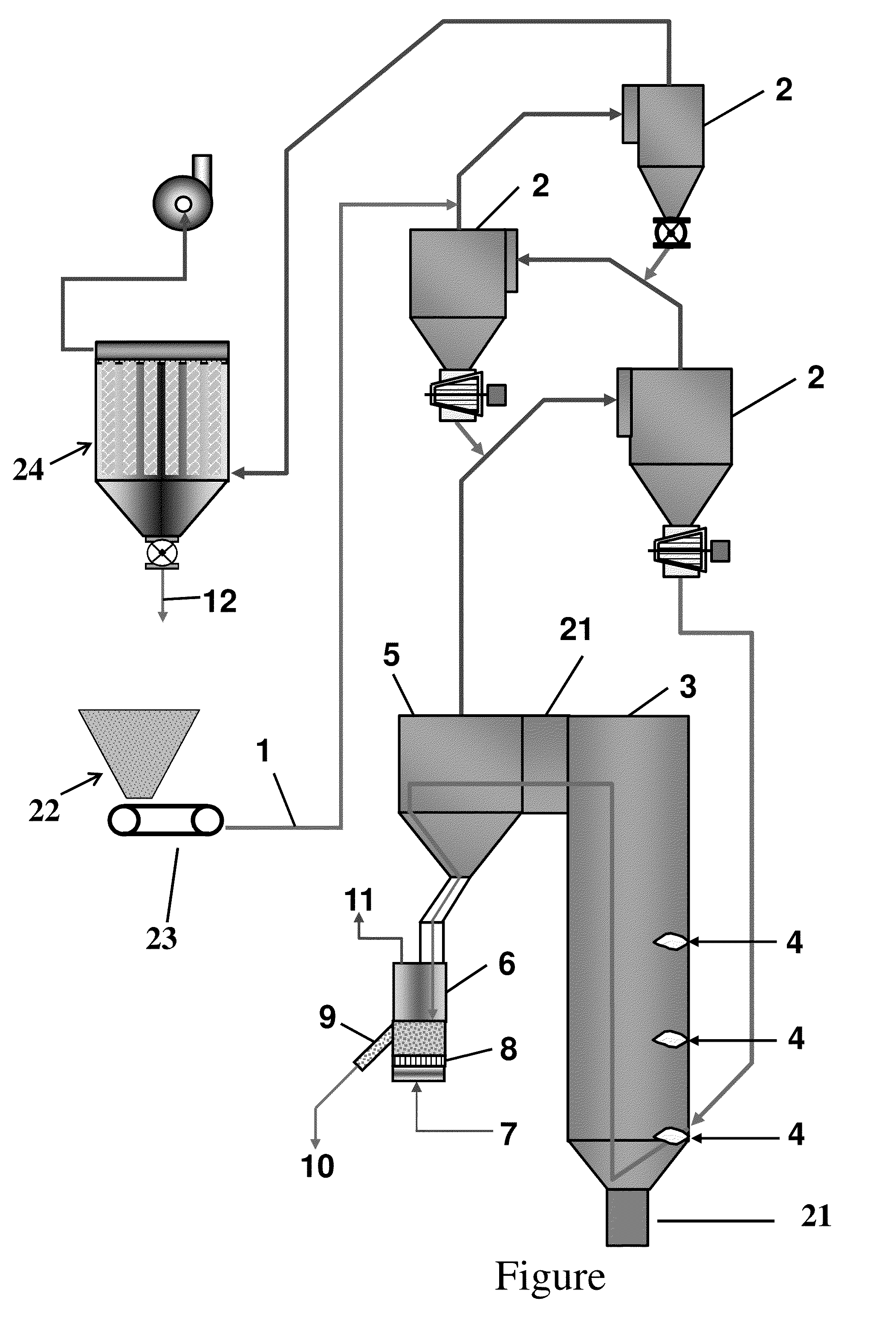

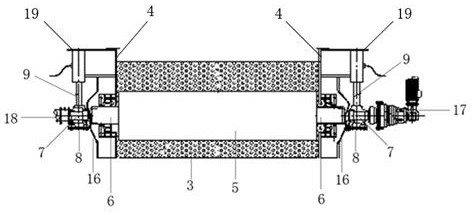

System for the production of fine lime

The present invention is directed to a method of continuously calcining a limestone particle mix comprising a fine fraction of limestone particles and a coarser fraction of limestone particles. The limestone particles heat treated in a flash calciner in which the mixture is entrained and heated in process gas for an amount of time sufficient to fully calcine the fine fraction but not the coarser fraction. The process gas is separated from the heated limestone mixture. The mixture is directed to a retention vessel in which the mixture is retained for an amount of time sufficient to fully calcine the coarser fraction utilizing the process heat present in the limestone mixture. No external heat needs to be added to the retention vessel during the retention step to promote calcination.

Owner:F L SMIDTH & CO AS

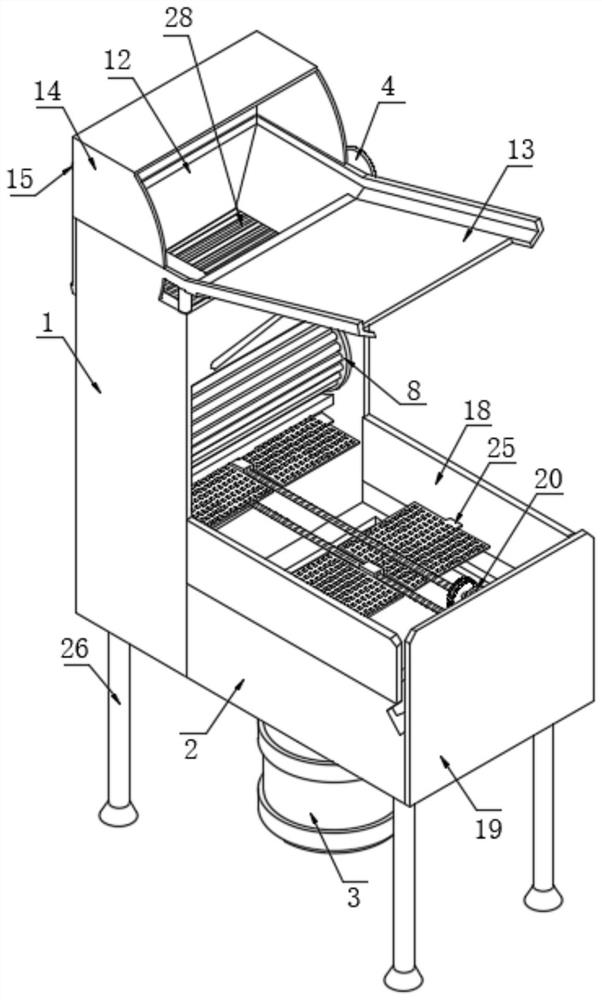

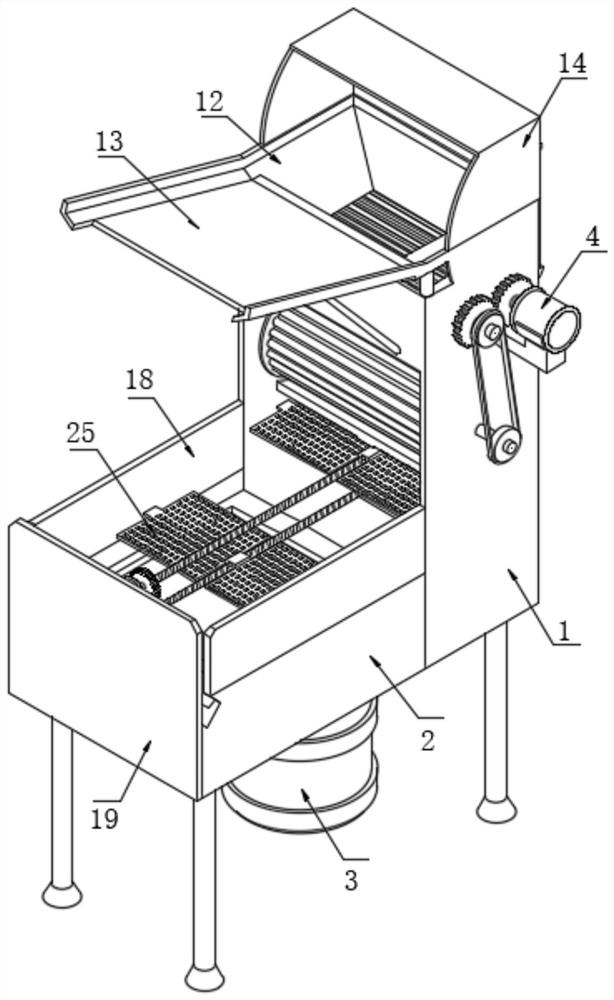

Recovery device and method for recovering rare-earth metal from rare-earth metal slag

InactiveCN113846238AEfficient sortingLow impurity contentMagnetic separationProcess efficiency improvementMischmetalElectrolysis

The invention discloses a recovery device and method for recovering rare-earth metal from rare-earth metal slag, and belongs to the technical field of rare-earth metal. The recovery device comprises a treatment box, wherein a calcining chamber is arranged on the front surface of the treatment box; an electrolysis tank is arranged on the lower surface of the calcining chamber; and a first driving assembly is arranged on the right side surface of the treatment box, and the lower surface of the first driving assembly is fixedly connected with the upper surface of a fixing block. According to the recovery device disclosed by the invention, crushed materials are fully ground and processed, the materials are ground into fine particles by a sieve plate, the materials containing metal materials can be adsorbed by an electromagnetic plate, and other materials can fall to the inner bottom of the treatment box through discharge holes in the electromagnetic plate, so that automatic feeding is achieved; and meanwhile, the ground and processed materials are effectively sorted, so that the impurity content of the rare-earth metal materials is reduced, subsequent calcination and electrolytic machining are facilitated, the machining efficiency is improved, meanwhile, the quality of recycled rare-earth metal is improved, and the recovery device is quite applicable.

Owner:LIANYUNGANG ZHAOYU NEW MATERIAL IND

Calcining furnace for surgical knife blade

InactiveCN105004181AEasy to calcineExtended service lifeCharge supportsFurnace typesButt jointEngineering

The invention discloses a calcining furnace for a surgical knife blade. The calcining furnace comprises an outer furnace body. An installation ring is arranged at the end of the outer furnace body and is provided with a cover ring. An insertion column is arranged at the axial position of the cover ring. A calcining groove is arranged on the bottom of the outer furnace body. An inner furnace body is arranged in the outer furnace body and is provided with a clamping groove and an end cover. The inner furnace body is in butt joint with the insertion column. The surgical knife blade can be inserted into the positions of the inner furnace body and the clamping groove, and the calcining furnace can be placed at the position of a fire source, so that the temperature in the calcining furnace can rise through the fire source, the surgical knife blade is convenient to calcinate, and the service life of the surgical knife blade can be prolonged.

Owner:李西营

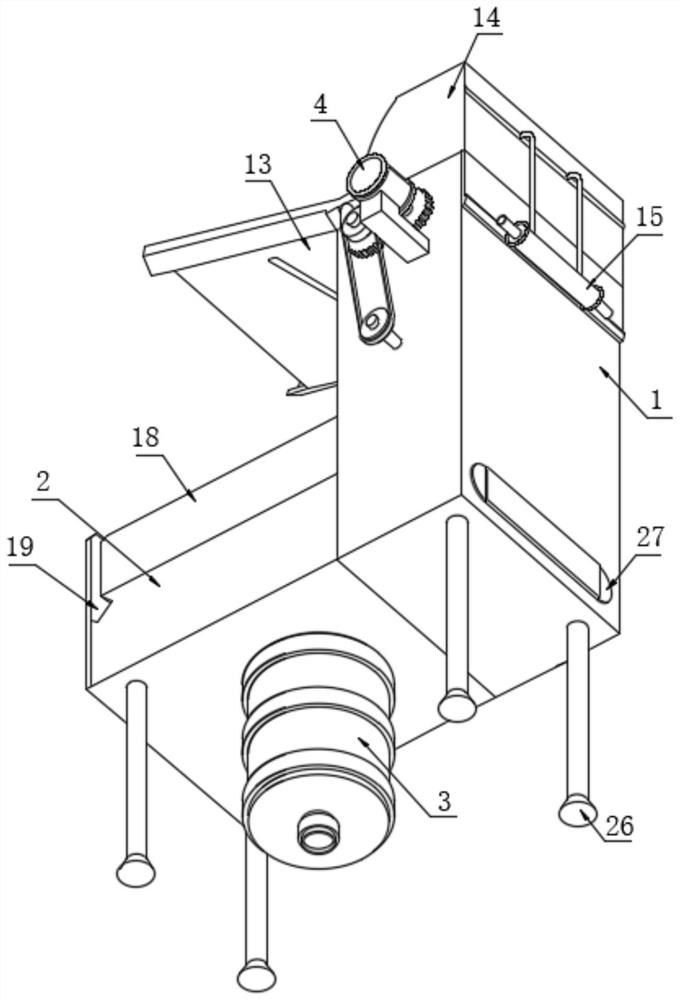

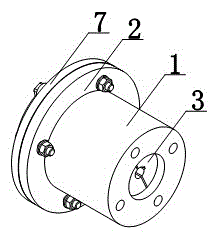

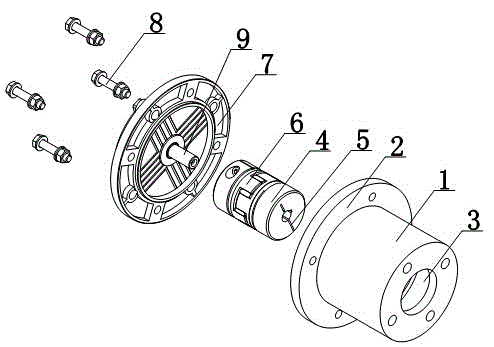

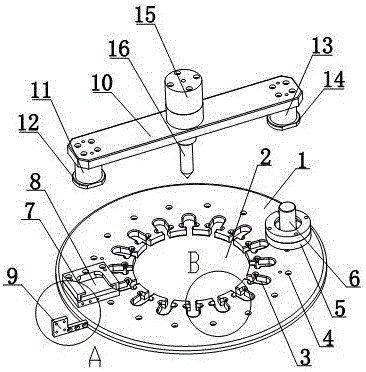

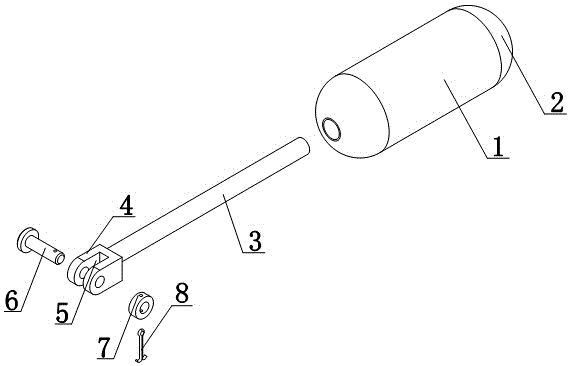

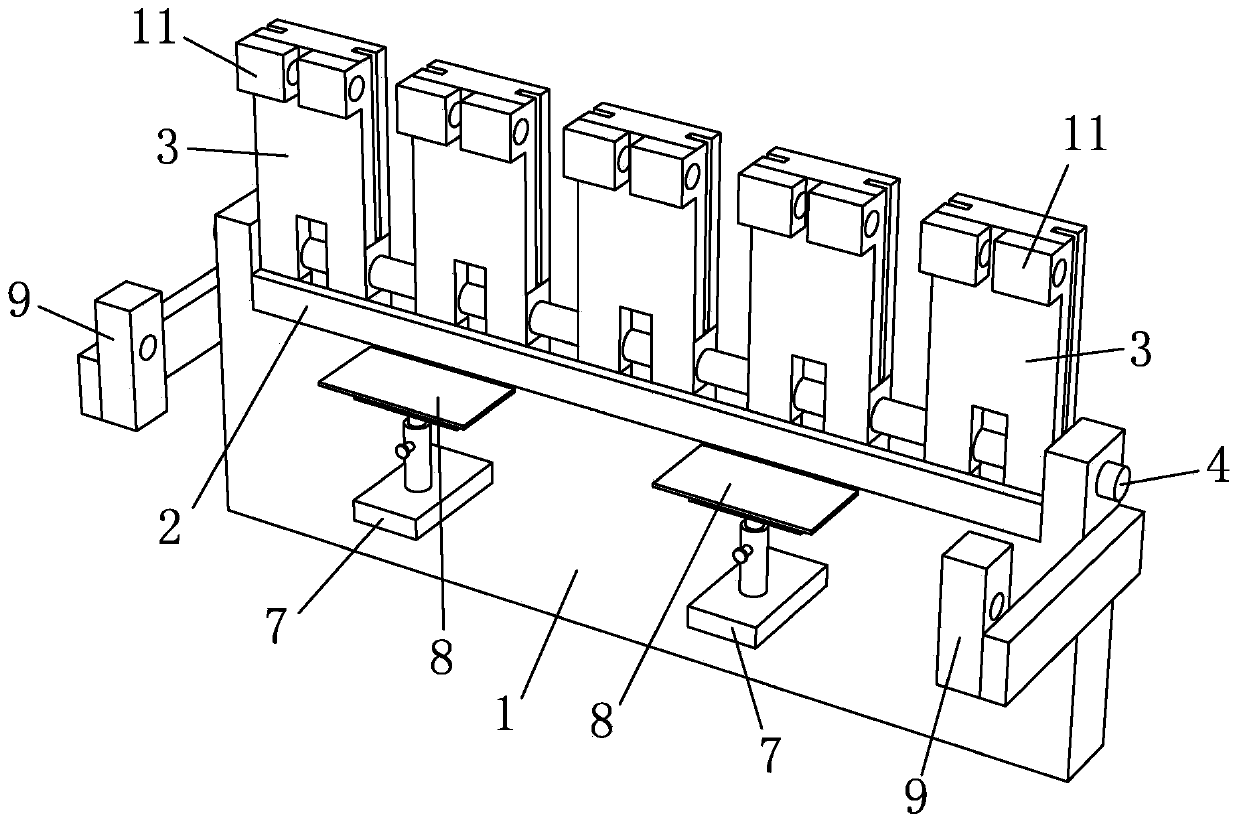

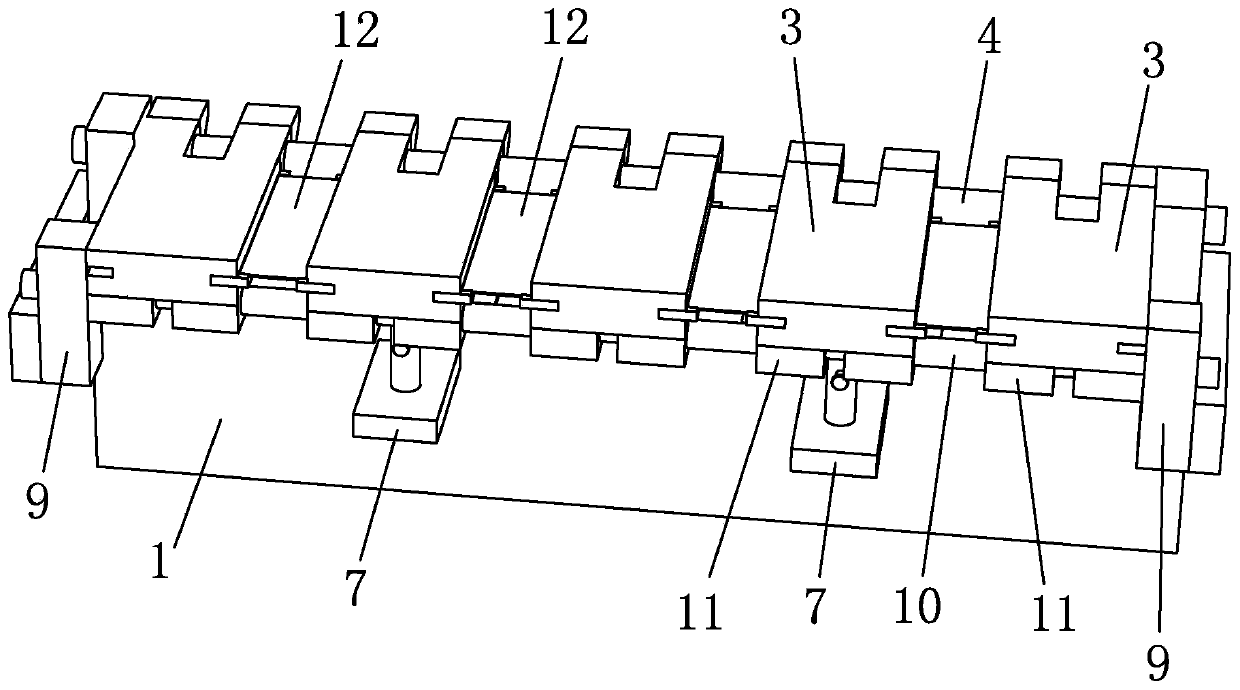

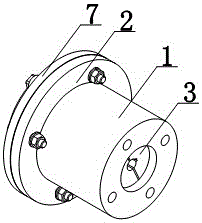

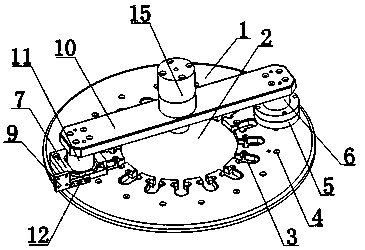

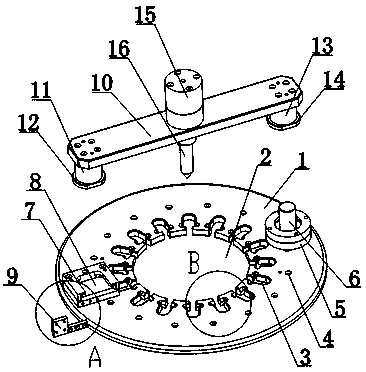

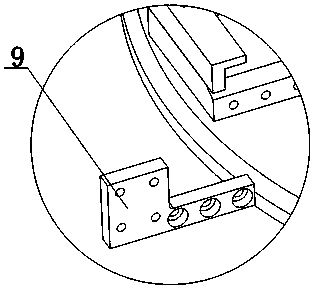

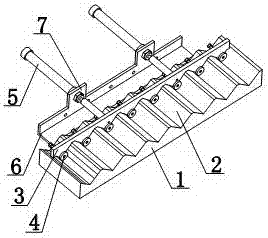

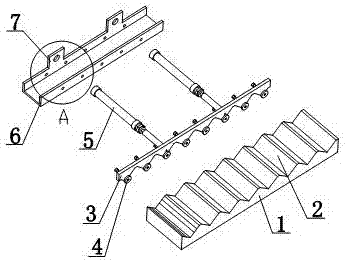

Clamping-connection rotary disc for calcination of U-shaped bolt

ActiveCN106288818AEasy to calcineConvenient and secure card connectionCharge supportsClamp connectionButt joint

The invention discloses a clamping-connection rotary disc for calcination of a U-shaped bolt. The clamping-connection rotary disc comprises a chuck, and an open groove is formed in the axial position of the chuck. Multiple clamping grooves are formed in the axial position of the chuck, and the clamping grooves communicate with the open groove. A fixing ring is arranged on one side of the chuck, a positioning shaft is arranged on the fixing ring, a clamping base is arranged on the other side of the chuck, and a clamping cavity is formed in the clamping base. A first connecting column is arranged on the clamping base, a clamping ring is arranged at the lower end of the first connecting column, and the clamping ring is connected to the position of the clamping cavity in a clamped manner. The outer circumferential face of the positioning shaft is sleeved with a second connecting column, the second connecting column is parallel to the first connecting column, and a butt joint plate is arranged between the end of the second connecting column and the end of the first connecting column. A fixing cap is arranged on the upper portion of the butt joint plate, and a drive shaft is arranged on the lower portion of the butt joint plate. The lower end of the drive shaft serves as a free end, and the upper end of the drive shaft is connected with the fixing cap. The rotary disc is installed in a calcinator, so that the U-shaped bolt is convenient to calcine.

Owner:靖江市西来农创运营管理有限公司

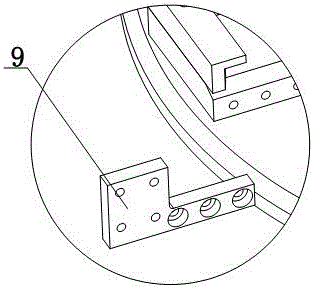

Method for producing feed-grade tricalcium phosphate by utilizing low-calorific-value tail gas

PendingCN111377423AReduce processing costsFacilitate the decomposition and defluorinationDrying solid materials with heatEnergy inputExhaust gasChemistry

The invention discloses a method for producing feed-grade tricalcium phosphate by utilizing low-calorific-value tail gas. The method comprises the following steps: (1) burning ground phosphate rock byutilizing the low-calorific-value tail gas and drying; (2) mixing and ball milling; (3) performing disc granulation; (4) calcining and defluorinating the low-calorific-value tail gas; (5) air heat storage and temperature rise; (5) cooling, crushing and sieving; (6) circularly crushing and screening, and ball-milling a semi-finished product; (7) screening and removing iron; and (8) packaging products. The method has the following advantages: (1) the raw material components and the particle size range of the ground phosphate rock are specified; (2) low-calorific-value tail gas combustion is fully utilized for heat storage and temperature rise of combustion-supporting air; (3) a low-calorific-value tail gas combustion technology and a co-combustion technology are fully utilized; (4) steam isadded in the calcining process to promote decomposition and defluorination of the phosphate ore; and (5) saturated steam and superheated steam are produced by fully utilizing calcined tail gas, so that energy is saved, and energy consumption and production cost are reduced. The method is very suitable for being popularized and used in enterprises producing feed-grade tricalcium phosphate products.

Owner:WENGFU (GRP) CO LTD

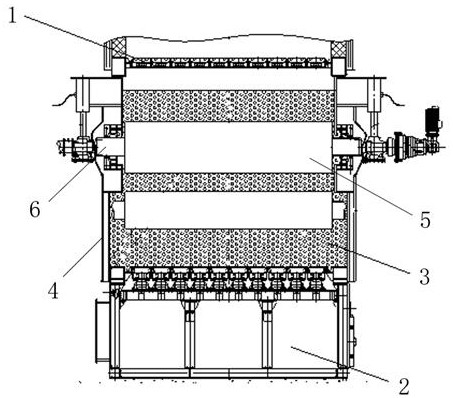

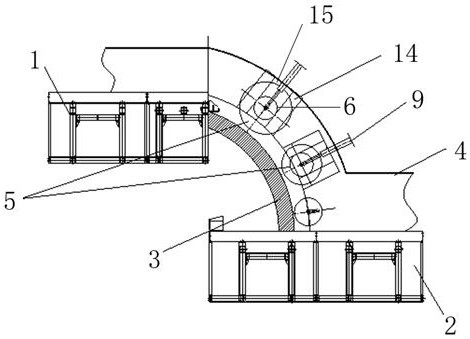

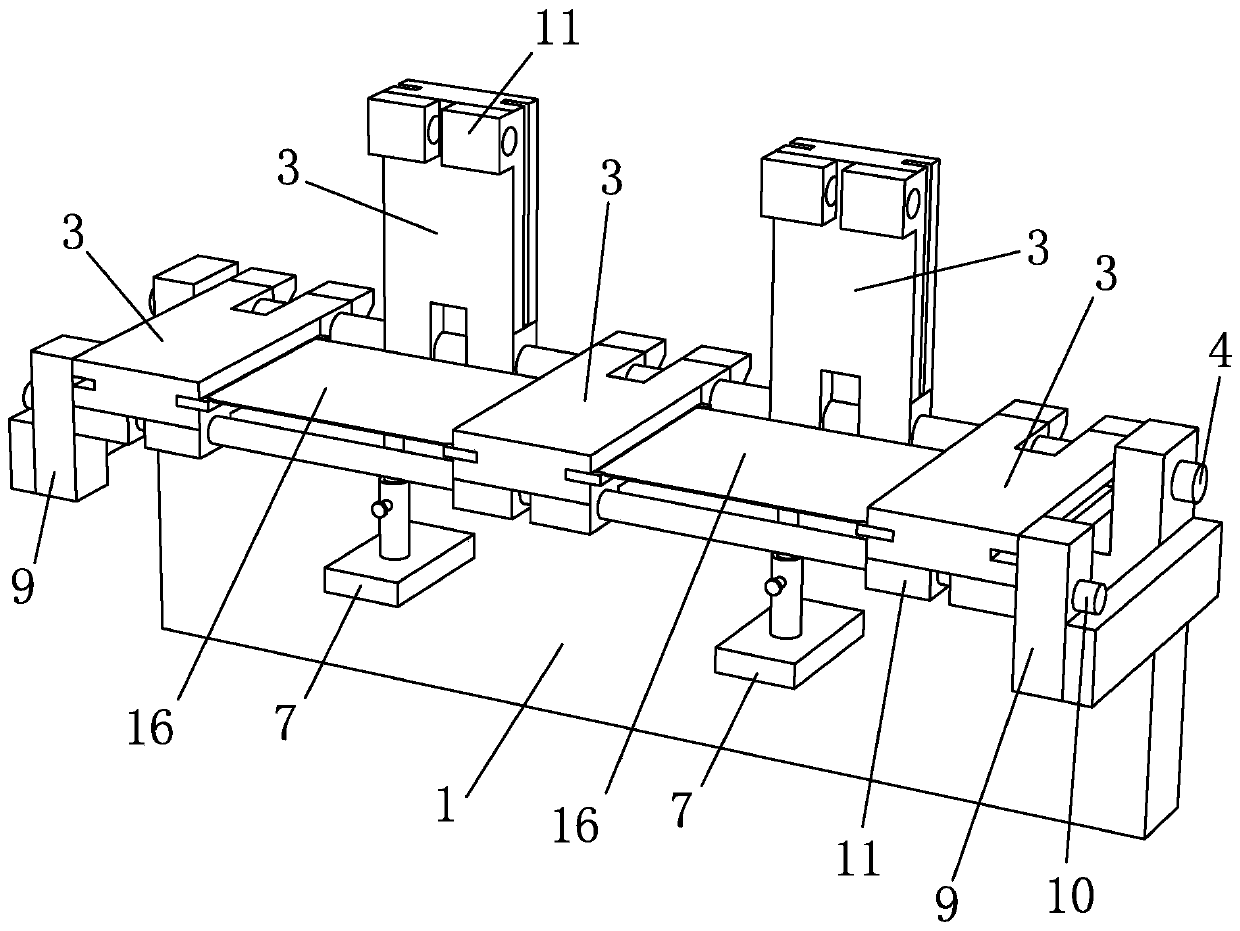

Middle-section cement clinker fine crushing device

A middle-section cement clinker fine crushing device relates to the technical field of cement processing, aims to solve the technical problem of adjustable material crushing size, and adopts the technical scheme as follows: the middle-section cement clinker fine crushing device comprises a front-section grate bed, a rear-section grate bed and an outer shell, a grinding bed is arranged between the front-section grate bed and the rear-section grate bed; and a roller device is arranged on the upper surface of the grinding bed, the front-section grate bed, the rear-section grate bed, the grinding bed and the roller device are all located in the outer shell, and a gap adjusting device is arranged between the roller device and the grinding bed. Compared with an existing middle-section clinker crusher, materials can be crushed into smaller particles, high-pressure grinding is achieved, and the yield and efficiency are improved; and energy conservation and consumption reduction are realized, the finished product granularity is adjustable on line, the thermal efficiency of a rotary kiln is improved, the calcination of materials in the kiln is facilitated, and the power consumption of clinker grinding is reduced.

Owner:山东博研粉体技术装备有限公司

Intensifier for adjusting congelation of cement prepared from ardealite

This invention relates to a method for producing cement thickening control enhancer for cement from phosphogypsum. The method comprises: mixing phosphogypsum with lime and limestone, pressing, calcining at 800-1000 deg.C to obtain a semi-product, and mixing with grinding aid to obtain the product. The method has such advantages as simple process, reasonable formula, and low cost. The cement thickening control enhancer can control the thickening time of cement, increase the strength of cement, increase the doping amounts of mixed materials in cement, decrease the consumption of cement clinker, save energy and resources, and increase profit.

Owner:UNIV OF JINAN

Surface bearing calcination furnace

The invention discloses a surface bearing calcination furnace. The surface bearing calcination furnace comprises a furnace body, wherein furnace lids are arranged at the two ends of the furnace body, and a sleeved rod is inserted in the axial positions of the furnace body and the furnace lids; one end of the sleeved rod is a free end, an installation frame is arranged at the other end of the sleeved rod, and an installation groove is formed in the installation frame; a fixing bolt is arranged at the position of the installation groove, and the fixing bolt is provided with a nut. According to the surface bearing calcination furnace, the furnace body can be installed on a calcination frame, a surface bearing to be processed can be arranged on the outer surface of the sleeved rod in a sleeving mode and placed in the furnace body, the furnace body can be installed on the calcination frame conveniently through the installation frame, and then the surface bearing can be calcinated conveniently.

Owner:郭斌

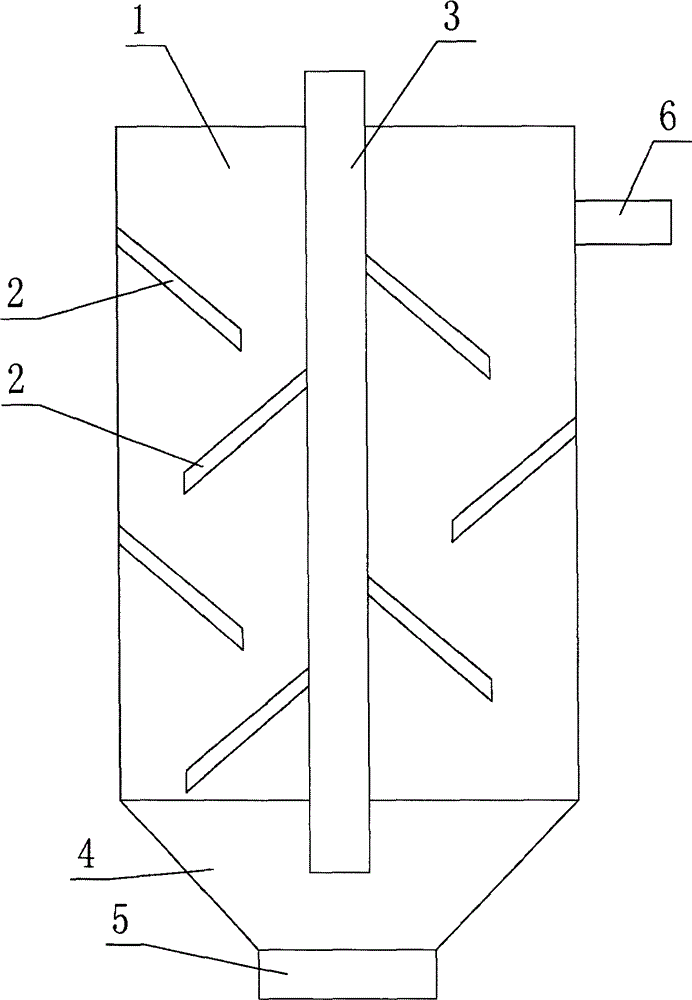

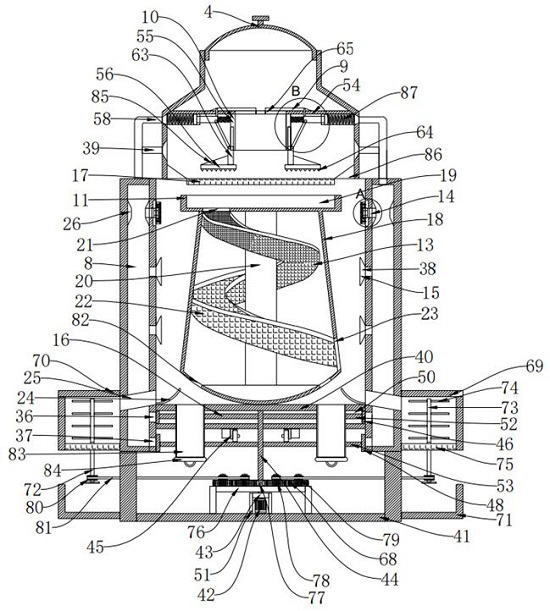

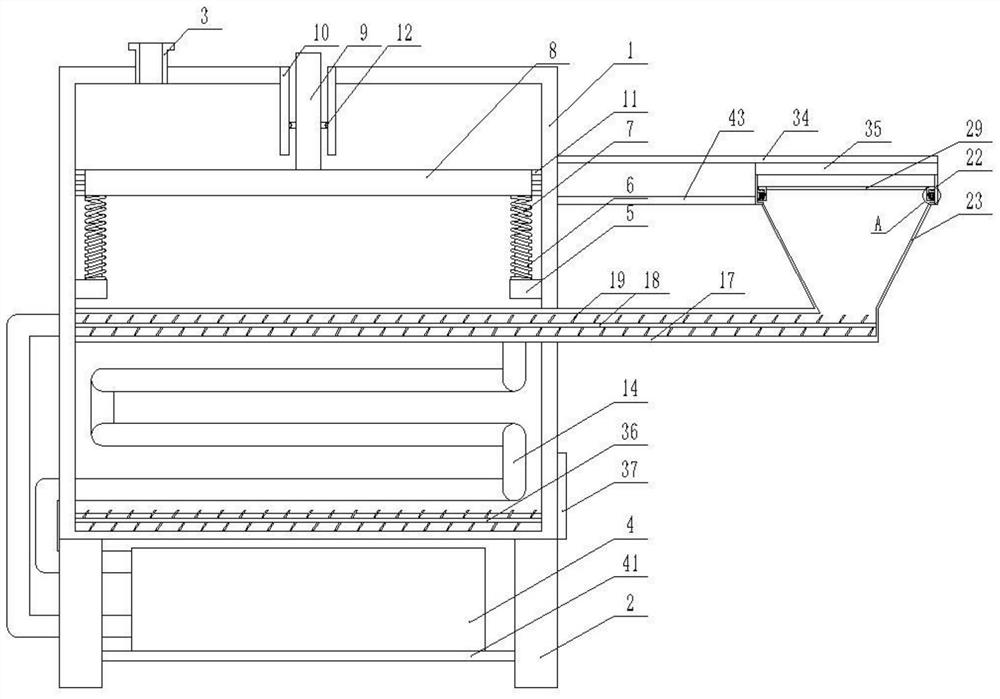

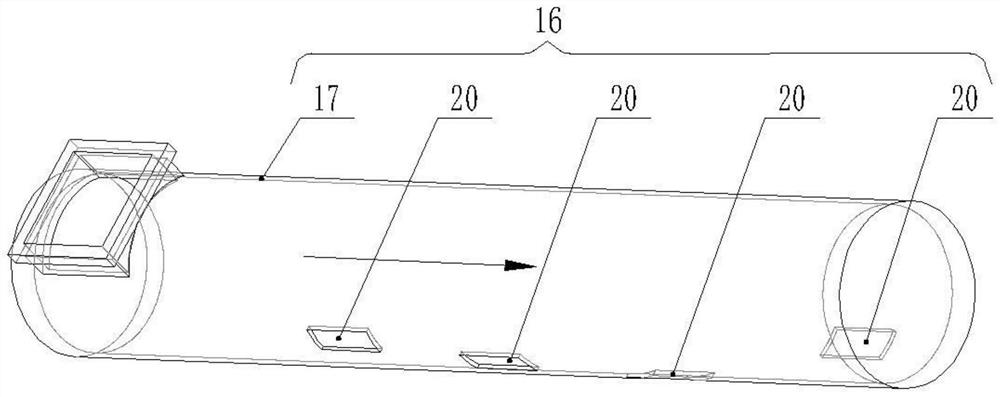

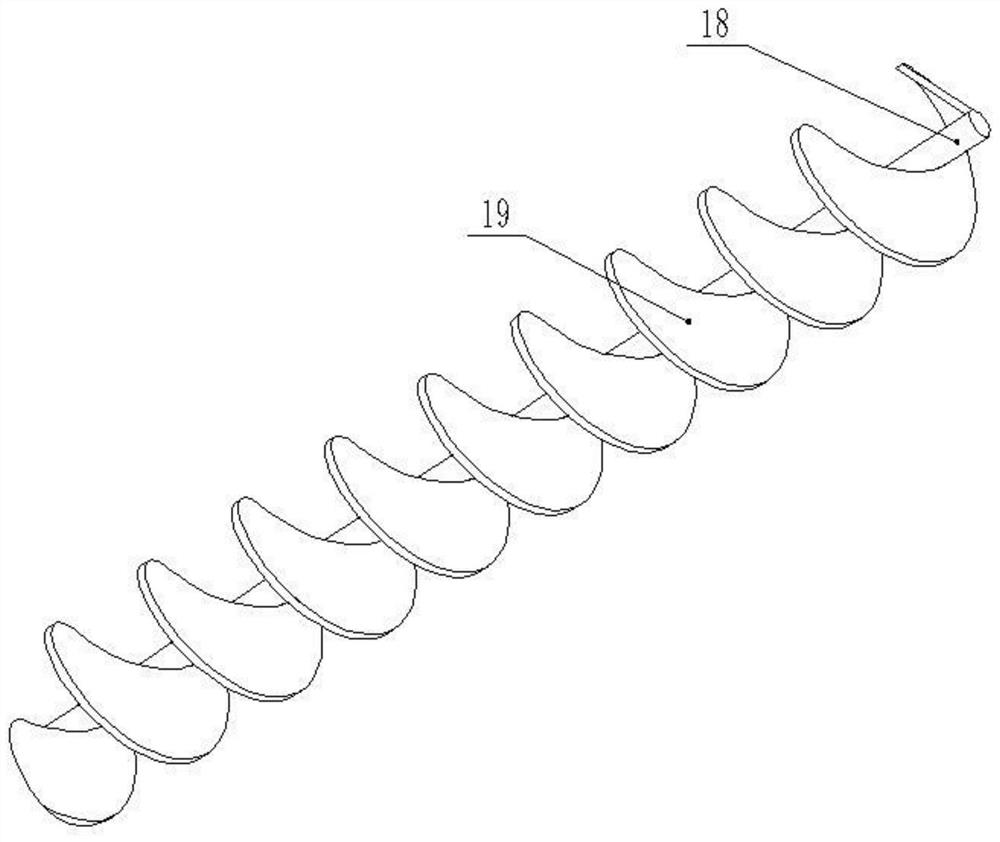

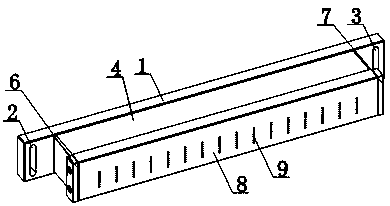

Feeding device for achieving active calcium calcination conveniently

InactiveCN105651058AEasy to calcineReduce falling speedCharge manipulationElectric heating for furnacesEngineeringElectromagnetic heating

The invention discloses a feeding device for achieving active calcium calcination conveniently. The feeding device for achieving active calcium calcination conveniently comprises a feeding cylinder. A plurality of baffles inclining downwards are arranged on the inner wall of the feeding cylinder. The baffles are distributed in the axial direction and circumferential direction of the feeding cylinder in a staggered mode. An electromagnetic heating roller is arranged in the feeding cylinder. The electromagnetic heating roller extends to the bottom end of the feeding cylinder from the top end of the feeding cylinder. A necking opening is formed in the bottom end of the feeding cylinder. A valve which can be opened and closed automatically is installed at the necking opening.

Owner:HUZHOU ZHEBAO METALLURGY AUX MATERIALS

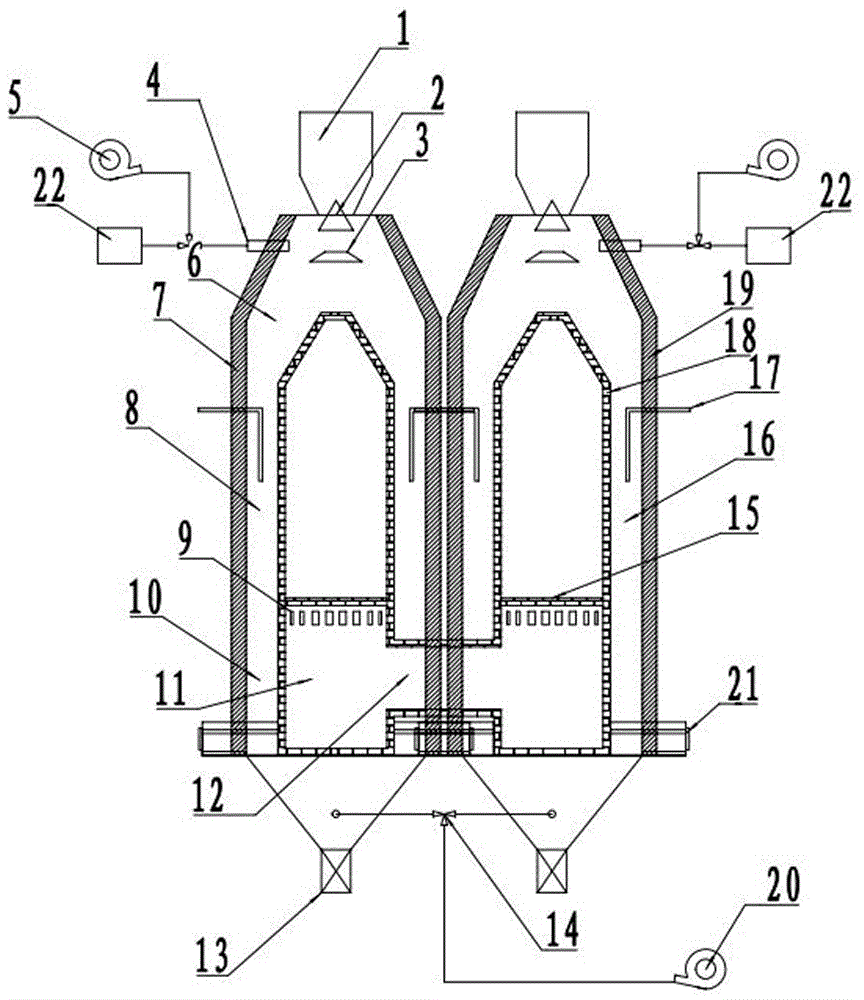

A double chamber kiln with low power consumption

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

A kind of gel preparation method of gel forming zirconia ceramic plunger rod

The invention discloses a gel moulding zirconia ceramic plunger rod gel preparation method. The method comprises the following steps: a) formation of a hydroxide sol; b) gel preparation; c) primary drying of a gel; d) colloid collection; e) secondary drying of the gel; f) re-collection of the colloid; and g) moulding and calcining of a zirconia ceramic plunger rod. The method is capable of uniformly drying the colloid, can reduce the destroy on colloid tissue structure, reduces the cracking and structural shedding phenomena of the calcimined ceramic plunger rod, increases the preparation quality of the ceramic plunger rod, is in favor of connection of the ceramic plunger rod and a water injection pump, and increases the production efficiency of the water injection pump.

Owner:衢州飞瑞特种陶瓷有限公司

Tumbler periodic self-driven petroleum coke screening device

PendingCN114558648AImprove screening efficiencyReduce cokingSievingGas current separationPotential energyPetroleum

The invention discloses a tumbler periodic self-driven petroleum coke screening device which comprises a screening bin, supporting legs, a feeding opening and a bin cover. The screening bin comprises a material preparation layer, a crushing layer, a screening layer, a ventilation layer, a quantitative feeding device, a self-service type gravitational potential energy crushing mechanism, a self-service type equipotential dust removal swing screening mechanism and an intermediate belt type driving secondary screening preheating device. The invention belongs to the technical field of petroleum coke calcination screening devices, and particularly relates to a tumbler periodical self-driven petroleum coke screening device. The self-service principle, the equipotential principle, the tumbler principle and the Venturi principle are combined and applied to the technical field of petroleum coke calcination screening devices, and the problems that in the petroleum coke screening process, petroleum coke needs to fall through a screen to be screened, and the screening efficiency is low are thoroughly solved. And meanwhile, the contradictory technical problem that the residence time of the petroleum coke on the screen needs to be prolonged in order to improve the screening effect is solved, and the problem that the screening effect of the petroleum coke is not ideal in the screening process is solved.

Owner:内蒙古卓越高新材料有限公司

Preparation method of calcined portland cement clinker using oil-based drilling cuttings

The invention discloses a preparation method for calcining low-hydration heat portland cement clinker by using oil-based drilling cuttings, and relates to the technical field of oil-based drilling cuttings processing. The present invention pretreats diesel-based drilling cuttings, mixes limestone, high-iron-aluminum waste rock, pre-treated diesel-based drilling cuttings, and non-ferrous metal slag according to a certain proportion and grinds them uniformly to prepare raw meal, and then feeds the raw meal to Put it into the new dry method rotary kiln, calcined at high temperature, and get clinker after cooling. The present invention can deal with major difficulties that plague oilfield drilling and mining, reduce the natural enrichment of heavy metal ions such as copper, zinc, lead, chromium, mercury, and barium in diesel-based drilling cuttings, and reduce the harm to groundwater and soil; The diesel oil and organic matter in the swarf can provide heat during the calcination process of clinker, which can significantly reduce clinker energy consumption, reduce CO 2 emissions, reduce clinker calcination temperature, significantly increase the output of cement mill and rotary kiln, and enhance raw meal production. Easy to burn, increase the liquid phase content of clinker, increase the lattice defects of dicalcium silicate in clinker, improve the activity of dicalcium silicate, and reduce the hydration heat value of cement.

Owner:JIAHUA SPECIAL CEMENT

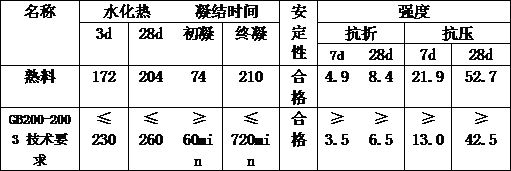

Industrial byproduct gypsum calcining machine

The invention belongs to the technical field of gypsum production, and particularly relates to an industrial byproduct gypsum calcining machine, which is characterized in that a movable plate is arranged in a machine body shell, the upper end of the movable plate is connected with a driving device output shaft, at least one sealing ring groove is formed in the periphery of the movable plate, a sealing ring is arranged in the sealing ring groove in an interference manner, a through hole is formed in the movable plate, the through hole communicates with the sealing ring groove and is connected with a gas device, a heat exchange pipeline is arranged at the lower end of the movable plate, a plurality of evenly-distributed fins with the heat conduction function are arranged on the heat exchangepipeline, the fins face the interior of the machine shell, and the heat exchange pipeline is connected with a steam generator. According to the invention, by sealing a calcining machine, heat is conveyed into the machine shell of the calcining machine through a heat exchange pipeline, and is provided in a heat exchange mode, and due to the arrangement of a movable plate in the machine shell, thespace where an industrial byproduct gypsum raw material is located can be changed, so that the time and space for calcining industrial byproduct gypsum are shortened, and the temperature for calciningthe industrial byproduct gypsum is increased.

Owner:ZIBO JINGXIN ELECTRICAL & MECHANICAL MFG CO LTD

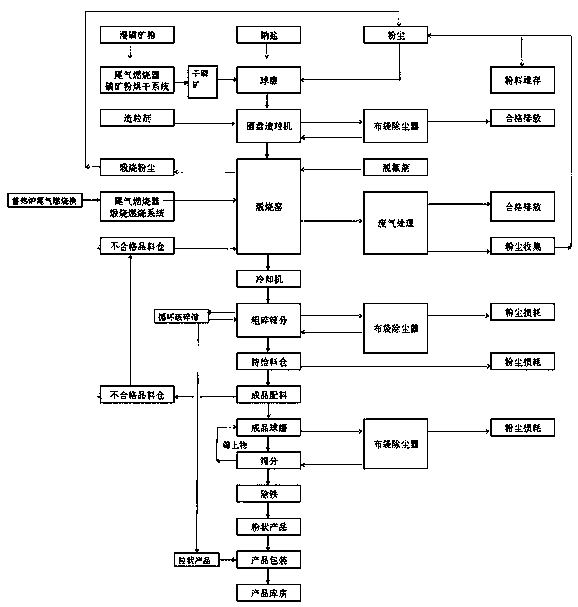

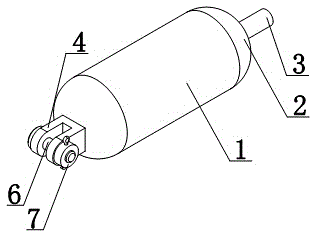

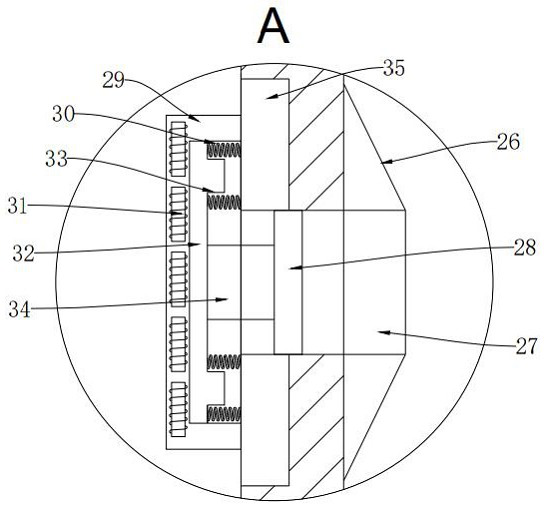

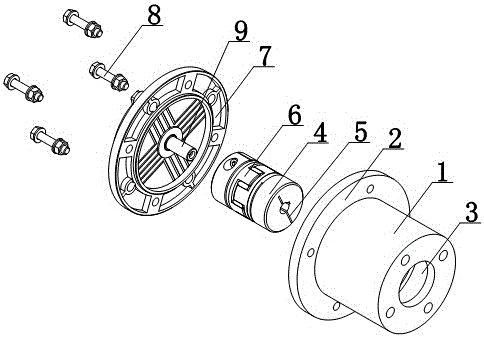

Clamping device for calcination machining of operating knife

ActiveCN106108983AEasy to calcineEasy to installIncision instrumentsCharge supportsEngineeringElectrical and Electronics engineering

The invention discloses a clamping device for calcination machining of an operating knife. The clamping device comprises a fixing plate, wherein a casing is arranged in an inward surface position of the fixing plate; an open cavity is formed in the inward surface position of the casing; a first limiting block is arranged in an inward surface position of one side of the casing; a second limiting block is arranged in an inward surface position of the other side of the casing, and is parallel to the first limiting block; a sealing cover is arranged in an outer sidewall position of the casing, and is arranged between the first and second limiting blocks; a plurality of open holes are formed in the sealing cover; a groove is formed in an inward surface position of the sealing cover, and is communicated with the open cavity. According to the clamping device, the sidewall position of the casing is sealed by the sealing cover; the fixing plate can be conveniently mounted through mounting grooves, and the clamping device can be mounted in a calciner, so that calcination machining can be conveniently performed on the operating knife in the casing.

Owner:刘伟萍

A calciner for surgical blades

InactiveCN105004181BEasy to calcineExtended service lifeCharge supportsFurnace typesSurgical bladeButt joint

The invention discloses a calcining furnace for a surgical knife blade. The calcining furnace comprises an outer furnace body. An installation ring is arranged at the end of the outer furnace body and is provided with a cover ring. An insertion column is arranged at the axial position of the cover ring. A calcining groove is arranged on the bottom of the outer furnace body. An inner furnace body is arranged in the outer furnace body and is provided with a clamping groove and an end cover. The inner furnace body is in butt joint with the insertion column. The surgical knife blade can be inserted into the positions of the inner furnace body and the clamping groove, and the calcining furnace can be placed at the position of a fire source, so that the temperature in the calcining furnace can rise through the fire source, the surgical knife blade is convenient to calcinate, and the service life of the surgical knife blade can be prolonged.

Owner:李西营

A clamping device for calcining processing of scalpels

ActiveCN106108983BEasy to calcineEasy to installIncision instrumentsCharge supportsEngineeringOpen cavity

The invention discloses a clamping device for calcination machining of an operating knife. The clamping device comprises a fixing plate, wherein a casing is arranged in an inward surface position of the fixing plate; an open cavity is formed in the inward surface position of the casing; a first limiting block is arranged in an inward surface position of one side of the casing; a second limiting block is arranged in an inward surface position of the other side of the casing, and is parallel to the first limiting block; a sealing cover is arranged in an outer sidewall position of the casing, and is arranged between the first and second limiting blocks; a plurality of open holes are formed in the sealing cover; a groove is formed in an inward surface position of the sealing cover, and is communicated with the open cavity. According to the clamping device, the sidewall position of the casing is sealed by the sealing cover; the fixing plate can be conveniently mounted through mounting grooves, and the clamping device can be mounted in a calciner, so that calcination machining can be conveniently performed on the operating knife in the casing.

Owner:刘伟萍

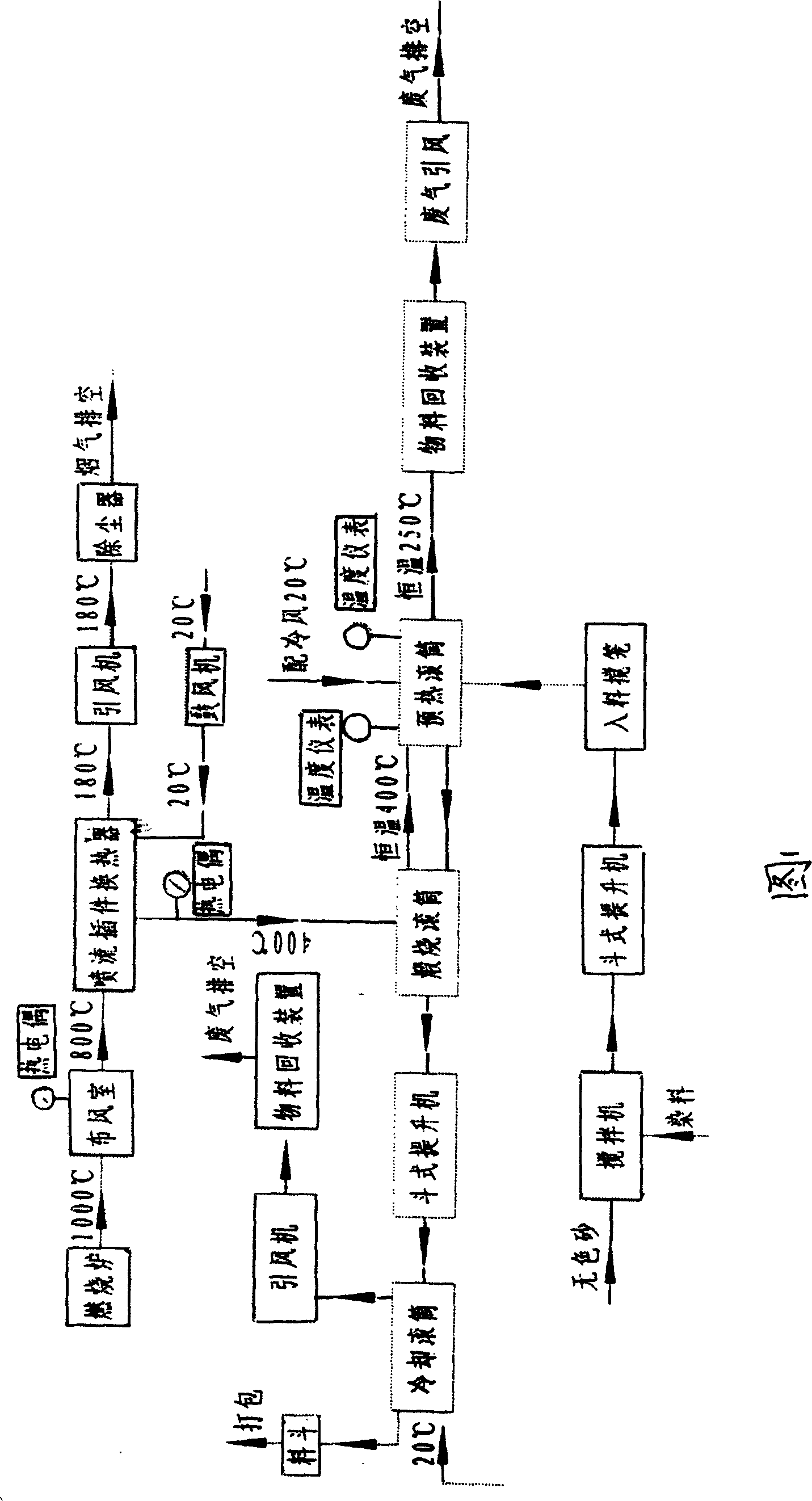

Technique for sintering color sand from basalt particles

The invention relates to a technological method for burning festoon sand with basalt particle, which comprises the following steps: stirring, preheating, perching and cooling. The technological method is characterized in that: in the preheating and the perching steps, the stirred materials are preheated and perched in a preheating roller and a perching roller by using the hot wind provided by a hot blast stove. The technological method for burning festoon sand with basalt particle has the following advantages and active effects: 1. In the invention, coal is taken as raw material; therefore, energy is saved. 2. By adopting the purified wind with constant temperature and constant hot wind to perch the material, the material purification is ensured. 3. The diameter of the roller can be adjusted according to the material yield; therefore, the yield of the production has a certain assurance. 4. The preheating and perching effect is good. 5. The material can be directly packed after being cooled by a cooling roller; therefore, the complicated turning and drying work is avoided. 6. The festoon sand is ensured that the color is even and can not fade for a long time. 7. The technological method for burning festoon sand with basalt particle can be fitted with a coaling machine, an automatic slagging machine and dust collecting equipments, thus not only saving the labor but also meeting the environment protection requirement.

Owner:TIANJIN HUANENG ENERGY EQUIP

A kind of u-bolt calcined clamping rotating disk

ActiveCN106288818BEasy to calcineConvenient and secure card connectionCharge supportsButt jointDrive shaft

The invention discloses a clamping-connection rotary disc for calcination of a U-shaped bolt. The clamping-connection rotary disc comprises a chuck, and an open groove is formed in the axial position of the chuck. Multiple clamping grooves are formed in the axial position of the chuck, and the clamping grooves communicate with the open groove. A fixing ring is arranged on one side of the chuck, a positioning shaft is arranged on the fixing ring, a clamping base is arranged on the other side of the chuck, and a clamping cavity is formed in the clamping base. A first connecting column is arranged on the clamping base, a clamping ring is arranged at the lower end of the first connecting column, and the clamping ring is connected to the position of the clamping cavity in a clamped manner. The outer circumferential face of the positioning shaft is sleeved with a second connecting column, the second connecting column is parallel to the first connecting column, and a butt joint plate is arranged between the end of the second connecting column and the end of the first connecting column. A fixing cap is arranged on the upper portion of the butt joint plate, and a drive shaft is arranged on the lower portion of the butt joint plate. The lower end of the drive shaft serves as a free end, and the upper end of the drive shaft is connected with the fixing cap. The rotary disc is installed in a calcinator, so that the U-shaped bolt is convenient to calcine.

Owner:靖江市西来农创运营管理有限公司

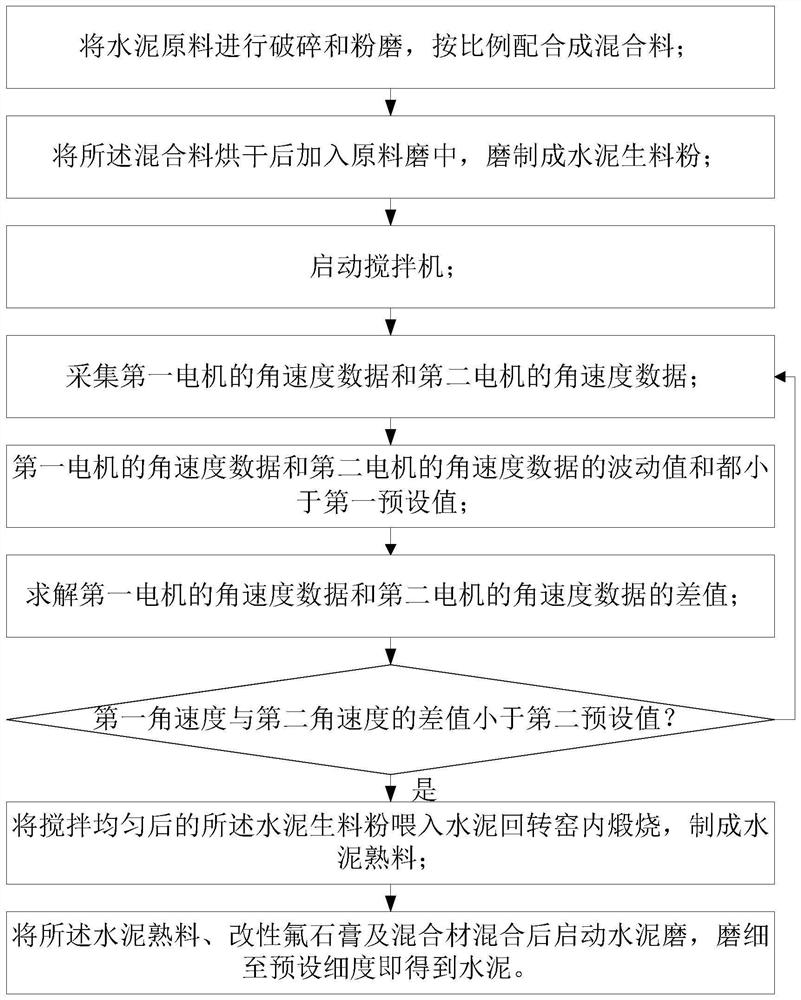

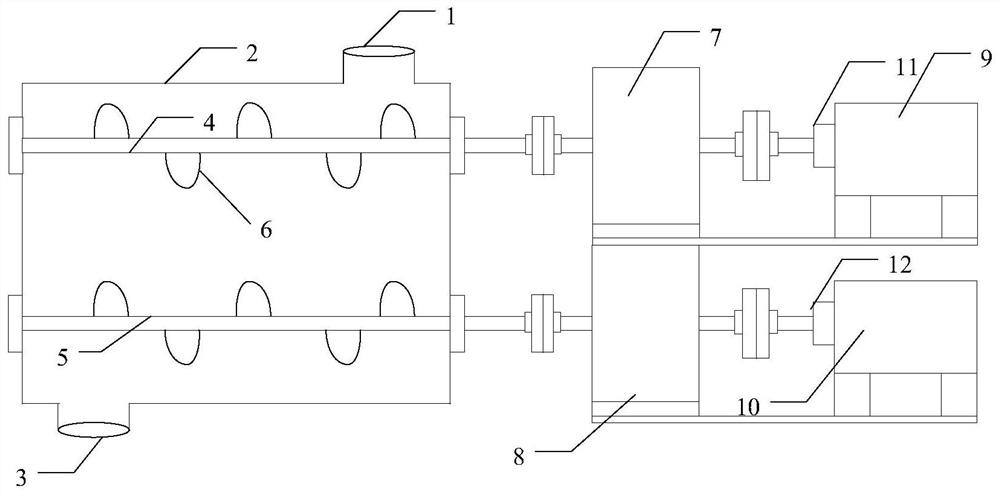

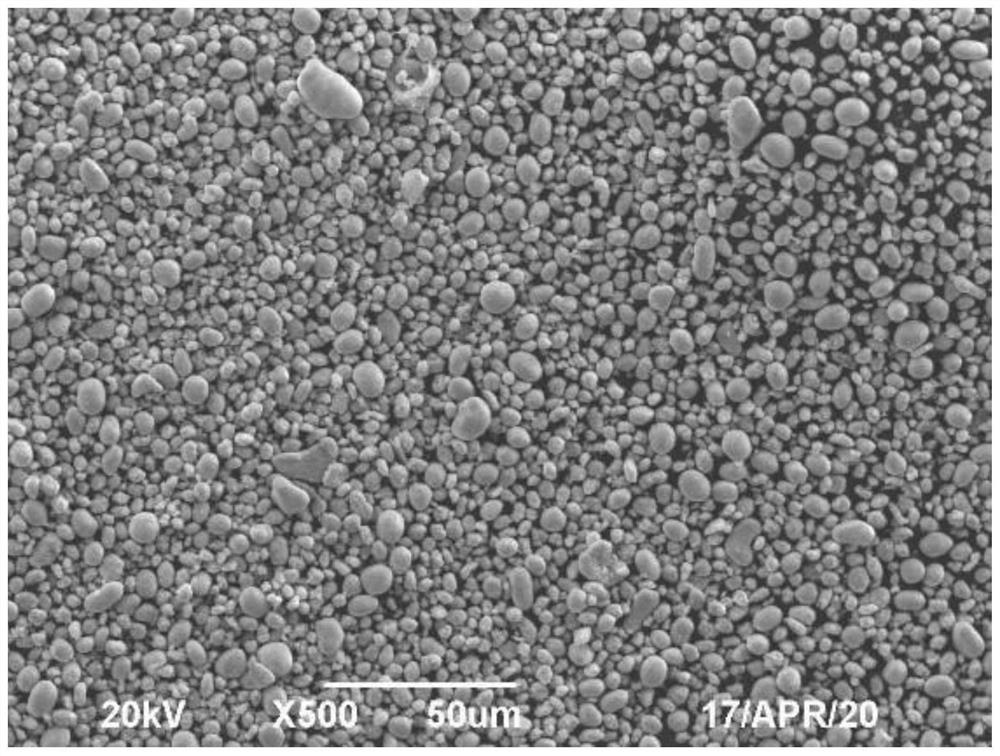

A preparation process of high-grade cement based on modified fluorine gypsum

ActiveCN112094059BAngular velocity fluctuation is smallImprove qualityPhysical chemistryElectric machinery

The invention discloses a high-grade cement preparation process based on modified fluorine gypsum, and relates to the technical field of cement production, including: crushing and grinding cement raw materials to form a mixture in proportion; starting the raw material grinding to make cement raw meal powder; Pour the cement raw meal powder into the mixer for mixing; collect the angular velocity data of the two motors of the mixer, and when the fluctuation values of the angular velocity of the two motors are less than the first preset value, according to the angular velocity data of the two motors at this time Solve the difference; when the difference is less than the second preset value, it is judged that the raw meal powder is evenly stirred and calcined to make cement clinker; the cement clinker, modified fluorogypsum and the mixed material are ground to a preset fineness. Cement is obtained; the present invention characterizes the uniformity of cement raw meal powder by solving the angular velocity difference between the two motors after solving the angular velocity stability, which is convenient for the calcination in the next step, can effectively improve the utilization rate of energy and time, and improve production The quality of the cement that comes out.

Owner:福建三明南方水泥有限公司

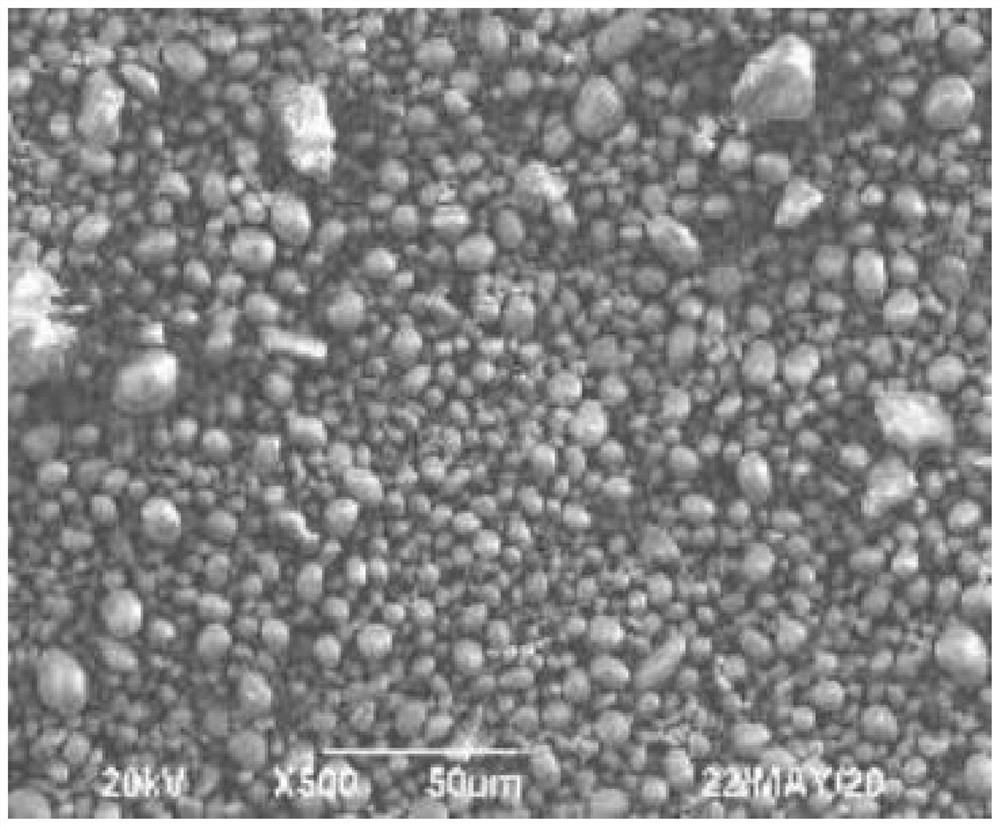

Preparation method of manganese precursor of positive electrode material of lithium manganate ion battery

PendingCN111994960AHigh purityControllable particle size distributionSecondary cellsPositive electrodesPtru catalystElectrical battery

The invention relates to the technical field of batteries, and discloses a preparation method of a manganese precursor of a positive electrode material of a lithium manganate ion battery. The preparation method of the manganese precursor comprises the following specific preparation steps: S1, ball-milling and activating metal manganese into manganese powder for later use; S2, adding manganese powder into a reaction kettle in multiple batches, adding five reagents including a catalyst A, a catalyst B, a catalyst C, a catalyst D and a catalyst E in proportion, introducing air for reaction, controlling the pH value in the reaction process, regulating and controlling the granularity of a precursor, stopping feeding when the target granularity is reached, and stopping reaction when the temperature is reduced to 40 DEG C or below; and S3, synthesizing the manganese precursor, washing the manganese precursor with water, carrying out filter pressing, centrifuging, drying, mixing in batches, sieving, removing iron, and packaging to obtain the product. Compared with a product synthesized by a traditional process, the manganese precursor prepared by the method is high in purity, controllablein particle size distribution, easy to calcine in a subsequent sintering process and excellent in performance, and the rate capability and the safety performance of the material can be improved on thebasis of improving the battery capacity.

Owner:湖南双富新材料科技有限公司

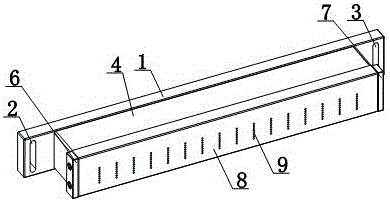

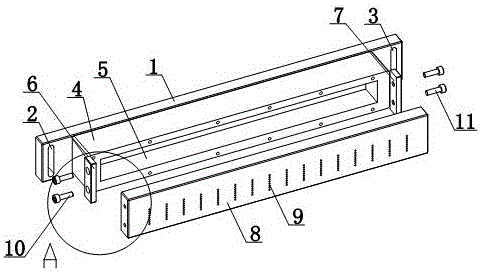

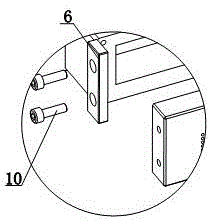

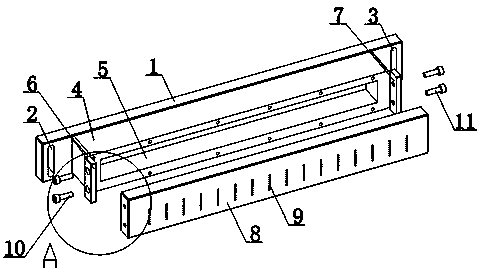

Mounting frame for spur rack calcination

InactiveCN106871648AEasy to calcineConvenient socketCharge supportsCharge treatment typeFixed frameEngineering

The invention discloses a mounting frame for calcining a straight rack, comprising a mounting seat and a mounting mechanism, a plurality of mounting grooves are arranged on the mounting seat, the mounting mechanism includes a push plate and a fixing mechanism, the fixing mechanism includes a fixing cylinder, and the The front part is provided with a connecting shaft, the push plate is set on the mounting seat, the lower part of the push plate is provided with a bump, the bump is set at the position of the installation groove, the rear part of the push plate is provided with a fixing rod, and the fixing rod is connected with the connecting shaft; The plate is provided with a fixing piece, the fixing piece includes a fixing pin, one end of the fixing pin is provided with a lock ring, and the other end of the fixing pin is provided with a lock cap; a fixing frame is arranged between the mounting seat and the fixing mechanism, and the upper part of the fixing frame is provided with The convex piece is arranged between the fixing cylinder and the connecting shaft; the fixing pin is connected with the fixing frame, and the locking cap is arranged on the inner side wall of the fixing frame. In the present invention, the spur gear rack to be processed is placed at the position of the installation groove on the mounting seat, and the spur gear rack can be placed in the calcining furnace, so that the spur gear rack can be calcined conveniently.

Owner:于法周

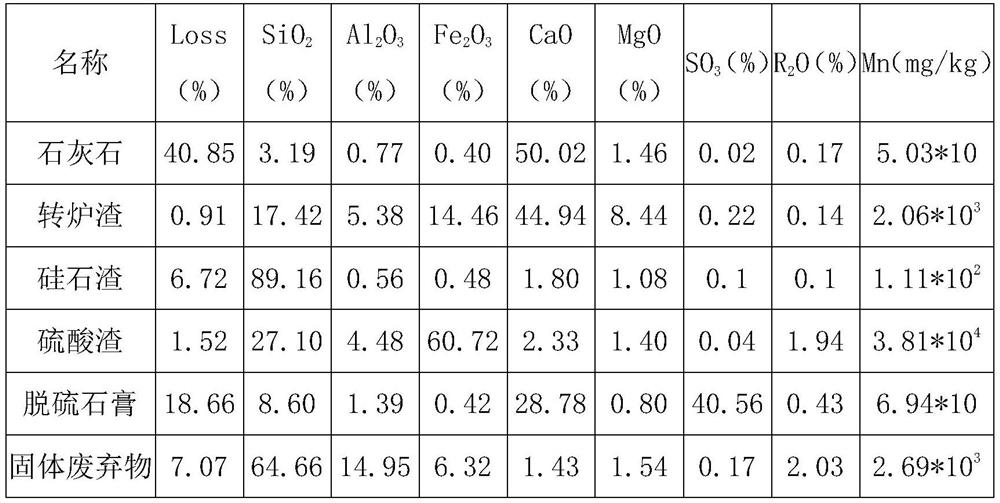

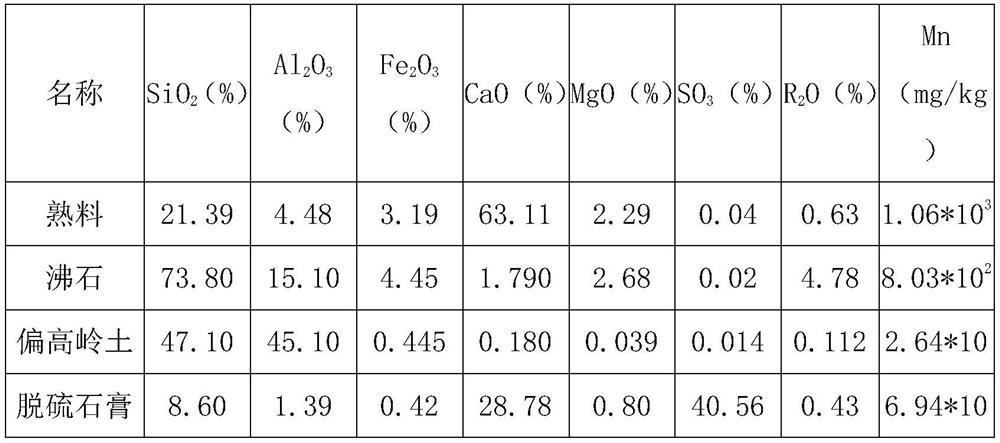

Curing agent and method for reducing leaching toxicity of manganese element in cement

The invention relates to a curing agent and a method for reducing leaching toxicity of a manganese element in cement. The method is characterized in that the leaching toxicity of the manganese element in the cement is reduced by adding the curing agent in clinker calcination and cement grinding processes; the curing agent I added in the clinker calcining process is mainly composed of flue gas desulfurization gypsum and NaF, the mass ratio of the flue gas desulfurization gypsum to the NaF is (96-98): (2-4), and the SO3 content of the flue gas desulfurization gypsum is controlled to be 40%-45%; the curing agent II added in the cement grinding process is mainly composed of zeolite and metakaolin, the zeolite accounts for 65%-67% by mass, and the metakaolin accounts for 33%-35% by mass. According to the invention, effective utilization of solid wastes with relatively high heavy metal content is realized, the leaching toxicity of the heavy metal manganese element in the cement product is reduced, and the reduction amplitude can reach more than 70% through comprehensive consideration.

Owner:GEZHOUBA SONGZI CEMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com