Preparation method of manganese precursor of positive electrode material of lithium manganate ion battery

A manganese precursor, ion battery technology, used in battery electrodes, manganate/permanganate, positive electrodes, etc., can solve the problem of difficulty in finding manganese precursors, and achieve controllable particle size distribution, high purity, The effect of efficient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

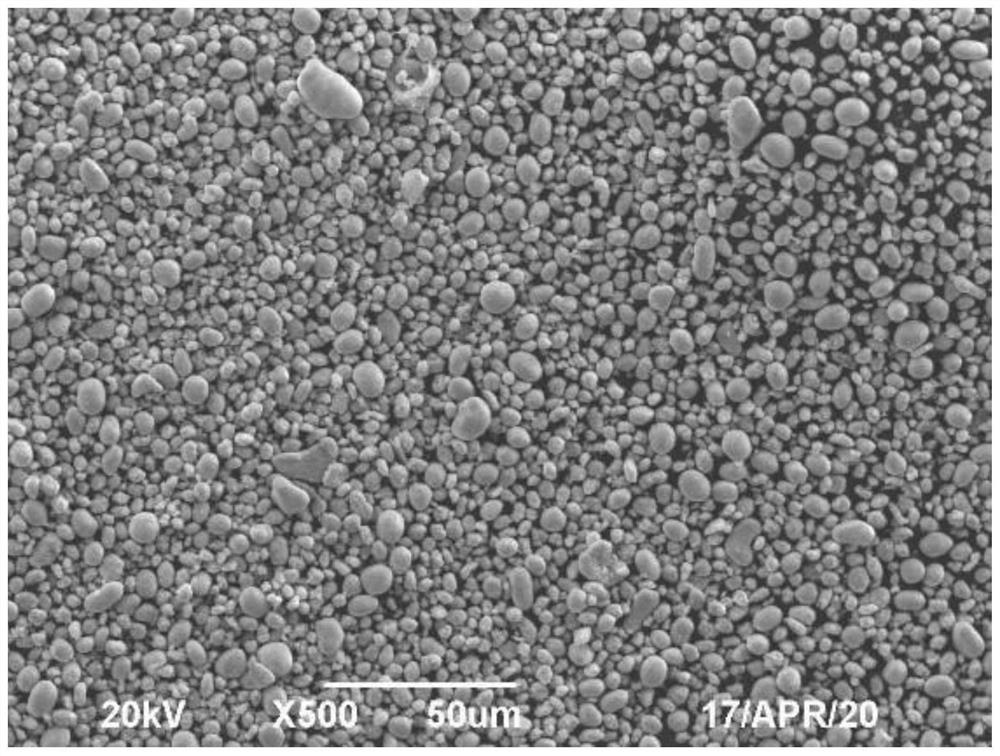

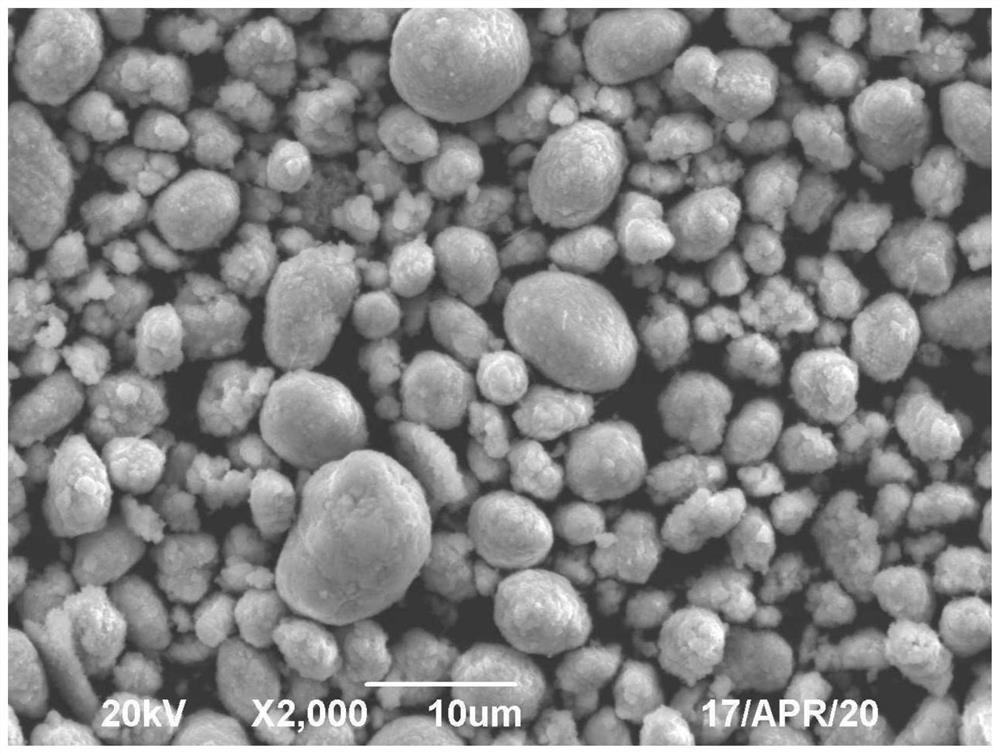

[0020] S1 After ball milling and activating metal manganese flakes for 2 hours, manganese slurry is prepared for use, and the particle size D50 of manganese powder is controlled within the range of 30-150 microns;

[0021] The reaction temperature of S2 is controlled at 60°C, the synthesis method is batch type, the feed rate of manganese source is controlled at 100kg / h, and 10kg of reagent A, 1L of reagent B, 150ml of reagent C, 150ml of reagent D, and reagent E are added with a metal molar ratio of 0.005 Sulfate, through the air or oxygen for oxidation precipitation reaction, air or oxygen 60m 3 / h, control the PH value to realize the regulation of the particle size of the precursor, the PH control range is between 7-8, stop feeding when it reaches 6 microns, and stop the reaction when the temperature drops below 40°C;

[0022] After the S3 manganese precursor is synthesized, the corresponding impurities are removed by pressure filtration or centrifugal washing, and then drie...

Embodiment 2

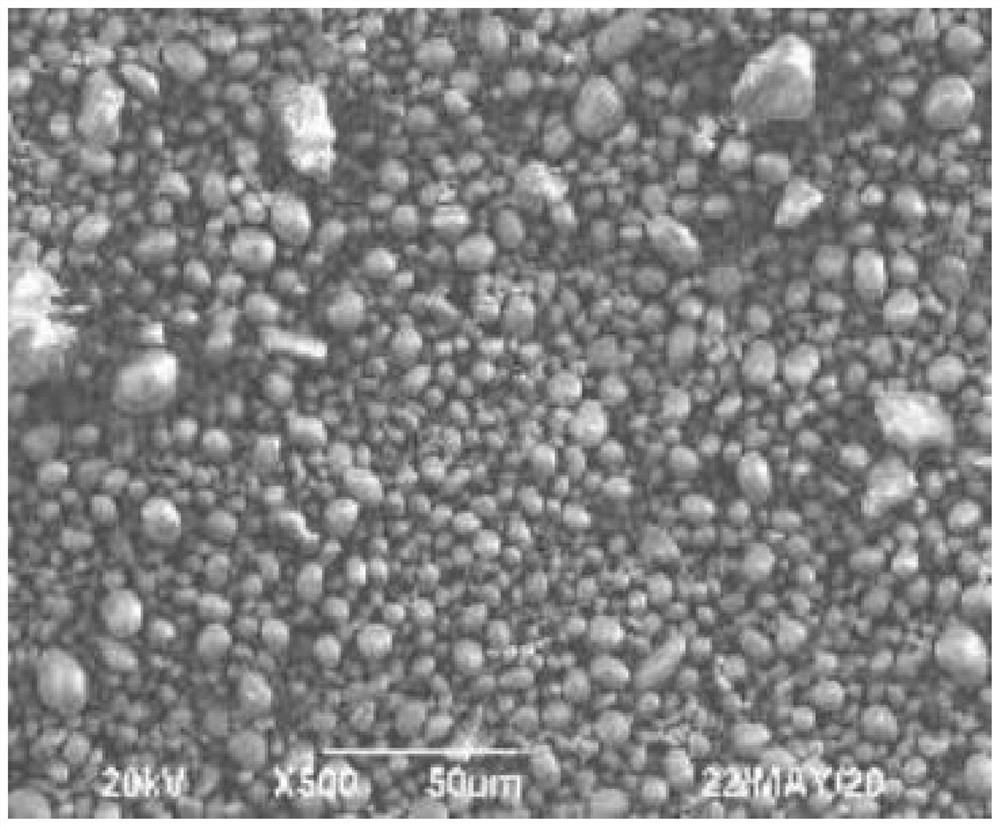

[0024] S1 After activating the manganese flakes by ball milling for 1 hour, make manganese slurry for later use, and the particle size of the manganese powder is controlled at 60-150 microns;

[0025] The S2 reaction temperature is controlled at 65°C, the synthesis method is batch type, the manganese source feed rate is controlled above 150kg / h, and 15kg of A reagent, 1.5L of B reagent, 150ml of C reagent, and 150ml of D reagent are added, and the E reagent is a metal mole. Sulphate with a ratio of 0.01, the oxidation precipitation reaction is carried out by feeding air, and the air volume is 80m 3 / h, the pH control range is between 10-11, stop feeding when the product reaches 10 microns, and stop the reaction when the temperature drops below 40°C;

[0026] After the S3 manganese precursor is synthesized, the corresponding impurities are removed by pressure filtration or centrifugal washing, and then dried and sieved to remove iron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com