A preparation process of high-grade cement based on modified fluorine gypsum

A high-grade cement and preparation technology, which is applied in the field of cement production, can solve the problems of uneven raw material composition, high power consumption, and low heat consumption, and achieve the effect of improving energy and time utilization and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

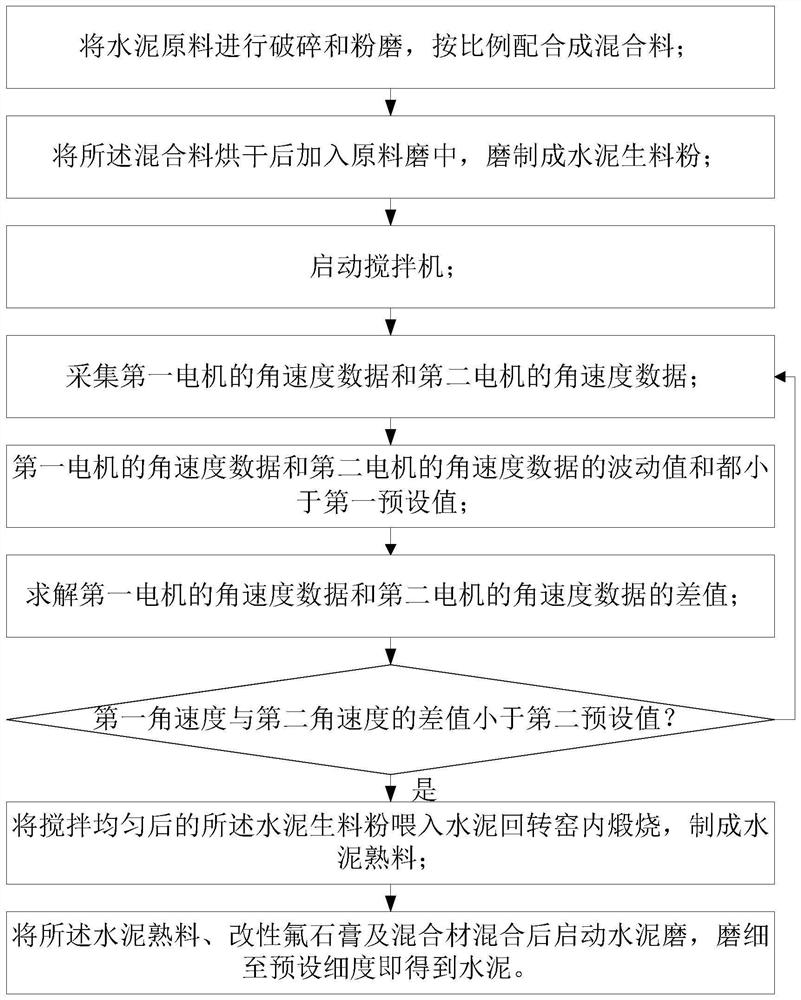

[0022] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

[0023] like figure 1 , figure 2 As shown, in the present invention, a high-grade cement preparation process based on modified fluorogypsum is provided, comprising:

[0024] Step S1, crushing and pulverizing the cement raw materials, and mixing into a mixture in proportion;

[0025] Step S2, adding the mixture into the raw material mill after drying, and starting the raw material mill to grind the mixture into cement raw meal powder;

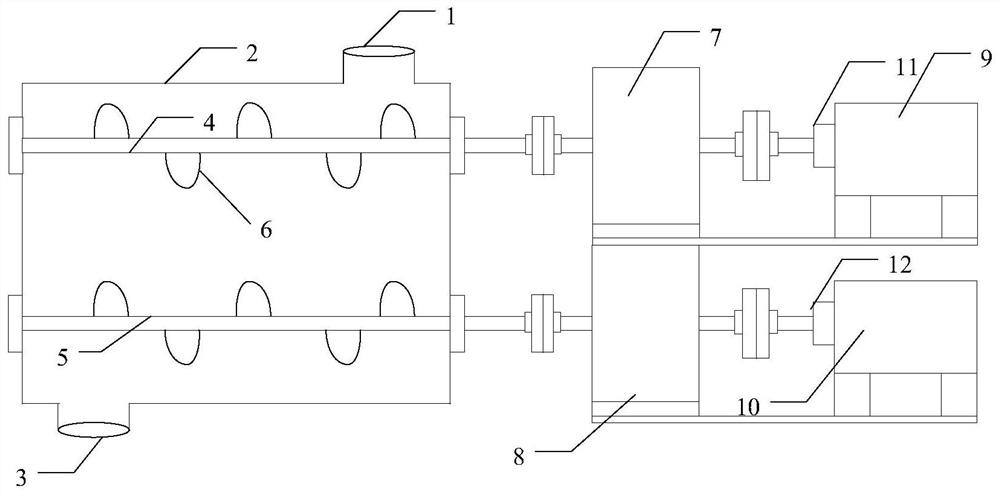

[0026] Step S3, pour the cement raw meal powder into a mixer for mixing; the mixer includes: a feed port 1, a tank body 2, a discharge port 3, a first screw shaft 4, a second screw shaft 5, and a paddle. 6. The first reducer 7, the second reducer 8, the first motor 9, the second motor 10, the first photoelectric encoder 11 and the second photoelectric encoder 12, the feeding port 1 is arranged in the tank body 2. Just abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com