A double chamber kiln with low power consumption

A double-chamber kiln, low power consumption technology, applied in the field of industrial lime kiln, can solve the problems of high airflow resistance of materials, inability to use fuel, and high power consumption of products, achieve large process size, low fan pressure, and overcome material resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

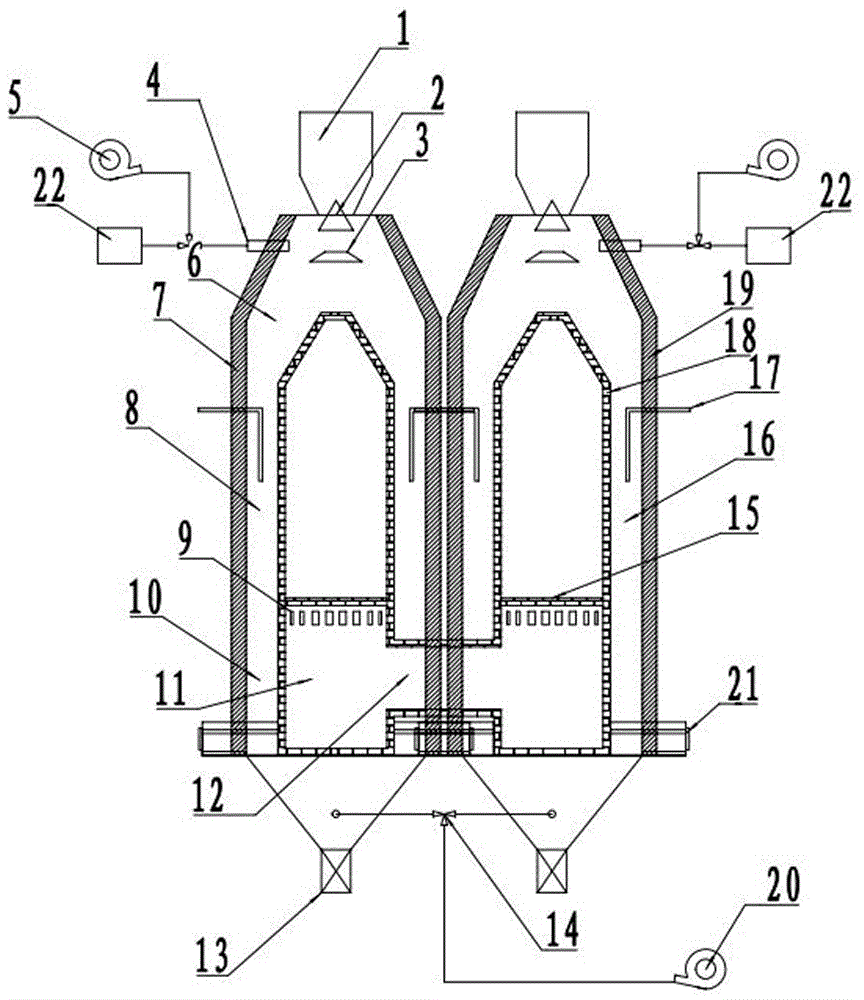

[0011] as attached figure 1 As shown, a low power consumption double-chamber kiln 16 is composed of an inner cylinder 18 and an outer cylinder 19 composed of a lime kiln body, the inner cylinder 18 and the outer cylinder 19 form an annular kiln chamber 16, and the annular kiln chamber 16 includes a feeding Device 1, distributor 2, combustion-supporting air 4, preheating zone 6, calcination zone 8, fuel injection port 17, inner tube flue gas port 9, inner tube partition 15, inner tube flue gas chamber 11, inner tube flue gas connection The channel 12 and the discharge device, the feeding device 1 is at the uppermost end of the annular kiln chamber 16, the distributor 3 is at the lower part of the feeding device 1, connected by the kiln mouth sealing device 2, the combustion-supporting air 4 enters from the upper part of the outer cylinder, and the preheating belt 6 , the calcination zone 8, and the cooling zone 10 are sequentially arranged in the annular kiln chamber 16 from to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com