Industrial byproduct gypsum calcining machine

An industrial by-product gypsum and calcination technology, applied in the field of gypsum production, can solve problems such as dead ends, brittle gypsum, and uneven distribution, and achieve the effects of improving quality, increasing space, and shortening time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

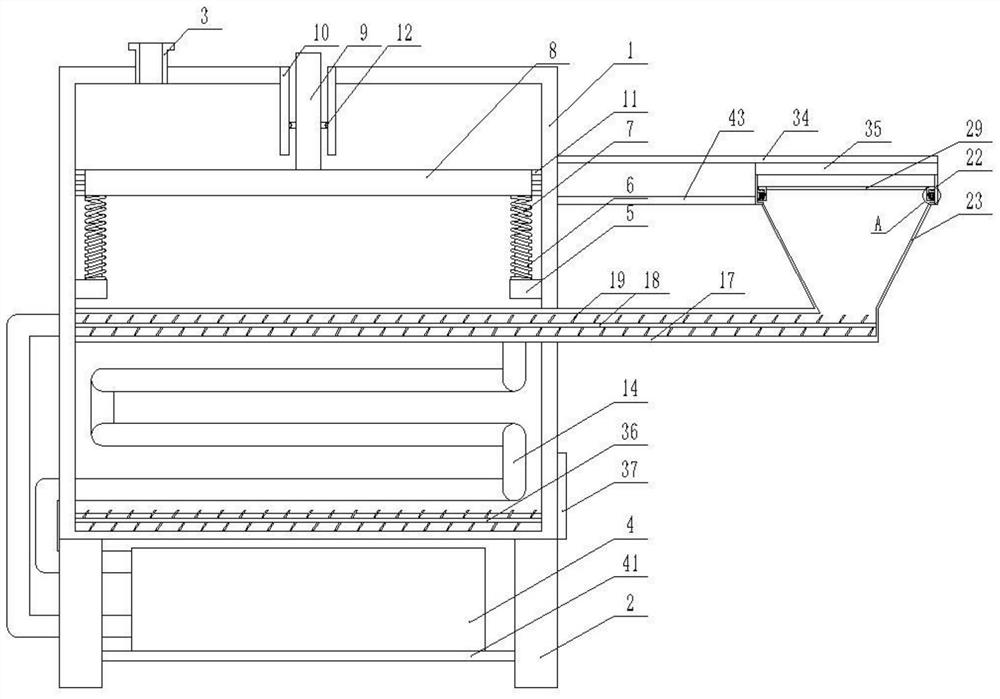

[0052] An industrial by-product gypsum calciner, mainly CaSO 4 -2H 2 O is calcined to form CaSO 4 -0.5H 2 O, the calciner of the present application includes a body shell 1, a plurality of columns 2 are fixedly welded at the lower end of the body shell 1, the body shell 1 is supported by the columns 2, and a support frame 41 is installed between the columns 2, and the support frame 41 can be formed by Several square steel pipes and angle steels arranged vertically and horizontally are welded on the column 2, and devices such as the steam generator 4 and the air pump are fixed on the support frame 41, or the large steam generator 4 and the air pump are fixed on the support frame 41 through the ground. The scheme of fixing steam generator 4 and air pump is suitable for small-scale calciners, while medium-sized and large-scale calciners are suitable for fixedly installing steam generator 4 and air pumps on the ground.

[0053] Preferably, a weighing module 44 is fixedly instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com