Preparation method of calcined portland cement clinker using oil-based drilling cuttings

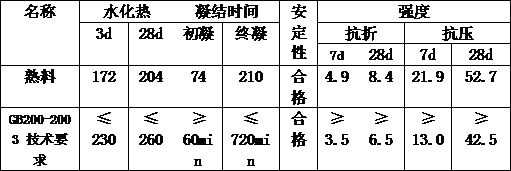

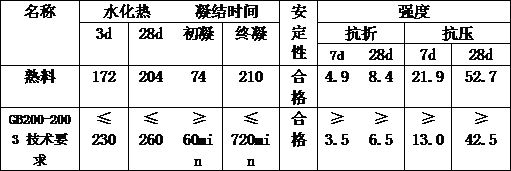

A technology of portland cement and drilling cuttings, applied in cement production, etc., to achieve the effects of enhanced burnability, low heat of hydration, and huge social effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] As a preferred embodiment of the present invention, this embodiment discloses:

[0030] A method for preparing calcined Portland cement clinker using oil-based drilling cuttings, comprising the following steps:

[0031]Step A, the pretreatment of diesel-based drilling cuttings, the diesel-based drilling cuttings are subjected to centrifugal deoiling and dehydration, so that the content of diesel-based drilling cuttings is reduced to below 5%, and the water content is reduced to below 5%; Oil and dehydrated diesel-based drilling cuttings are crushed so that the particle size of diesel-based drilling cuttings is less than 10mm; the crushed diesel-based drilling cuttings and water-absorbing agent are mixed according to the ratio of 100:10, and the mixture is formed after mixing silicon material;

[0032] Step B, preparation of low heat of hydration Portland cement clinker:

[0033] A, raw material preparation, prepare raw material according to 55 parts of limestone, 5 pa...

Embodiment 2

[0037] As another preferred embodiment of the present invention, this embodiment discloses:

[0038] A method for preparing calcined Portland cement clinker using oil-based drilling cuttings, comprising the following steps:

[0039] Step A, the pretreatment of diesel-based drilling cuttings, the diesel-based drilling cuttings are subjected to centrifugal deoiling and dehydration, so that the content of diesel-based drilling cuttings is reduced to below 5%, and the water content is reduced to below 5%; Oil and dehydrated diesel-based drilling cuttings are crushed so that the particle size of diesel-based drilling cuttings is less than 10mm; the crushed diesel-based drilling cuttings and water-absorbing agent are mixed according to the ratio of 100:8, and the mixture is formed after mixing silicon material;

[0040] Step B, preparation of low heat of hydration Portland cement clinker:

[0041] A, raw material preparation, prepare raw material according to 60 parts of limestone...

Embodiment 3

[0045] As another preferred embodiment of the present invention, this embodiment discloses:

[0046] A method for preparing calcined Portland cement clinker using oil-based drilling cuttings, comprising the following steps:

[0047] Step A, the pretreatment of diesel-based drilling cuttings, the diesel-based drilling cuttings are subjected to centrifugal deoiling and dehydration, so that the content of diesel-based drilling cuttings is reduced to below 5%, and the water content is reduced to below 5%; Oil and dehydrated diesel-based drilling cuttings are crushed so that the particle size of diesel-based drilling cuttings is less than 10mm; the crushed diesel-based drilling cuttings and water-absorbing agent are mixed according to the ratio of 100:6, and the mixture is formed after mixing silicon material;

[0048] Step B, preparation of low heat of hydration Portland cement clinker:

[0049] A, raw material preparation, prepare raw material according to 65 parts of limestone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com