A kind of gel preparation method of gel forming zirconia ceramic plunger rod

A technology of zirconia ceramics and plunger rods, which is applied in the gel preparation field of gel-forming zirconia ceramic plunger rods, which can solve the problem of unfavorable connections between ceramic plunger rods and water injection pumps, the colloid structure is easily destroyed, and the injection rate can be reduced. Problems such as water pump production efficiency can be achieved to reduce cracking and structural shedding, which is conducive to molding and calcination, and is not easy to accumulate dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

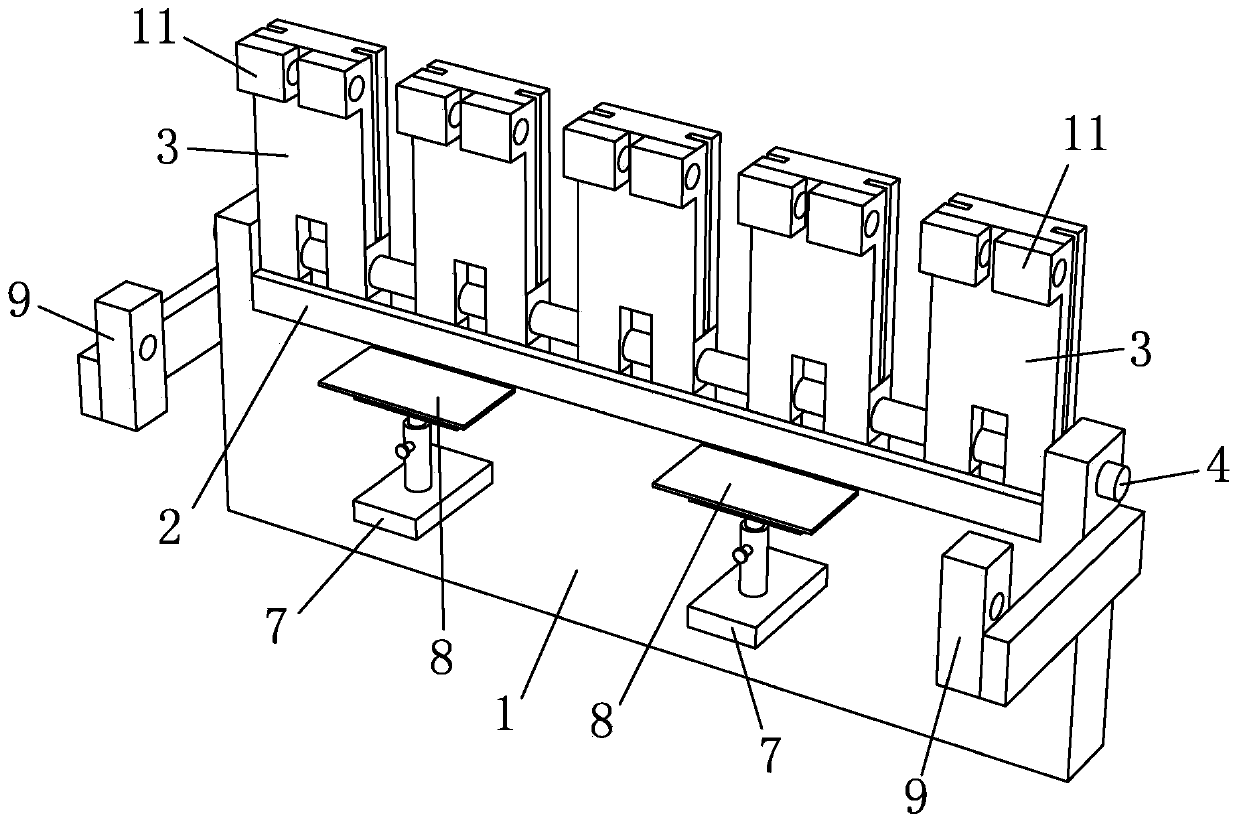

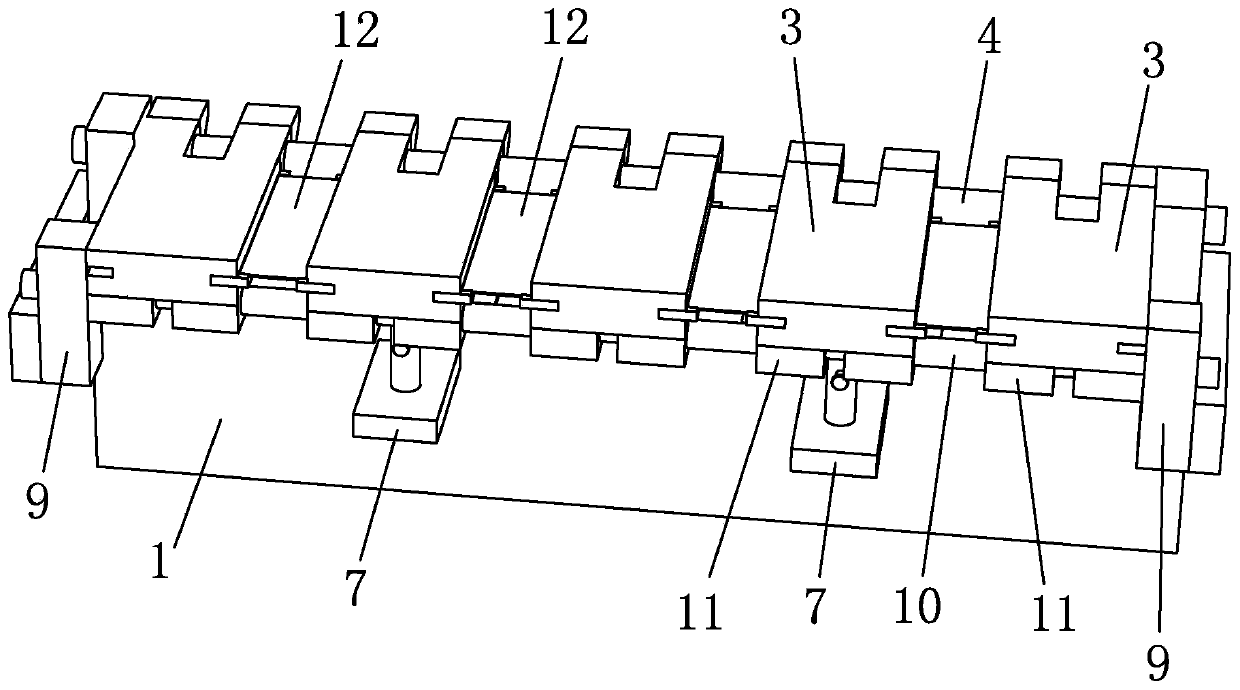

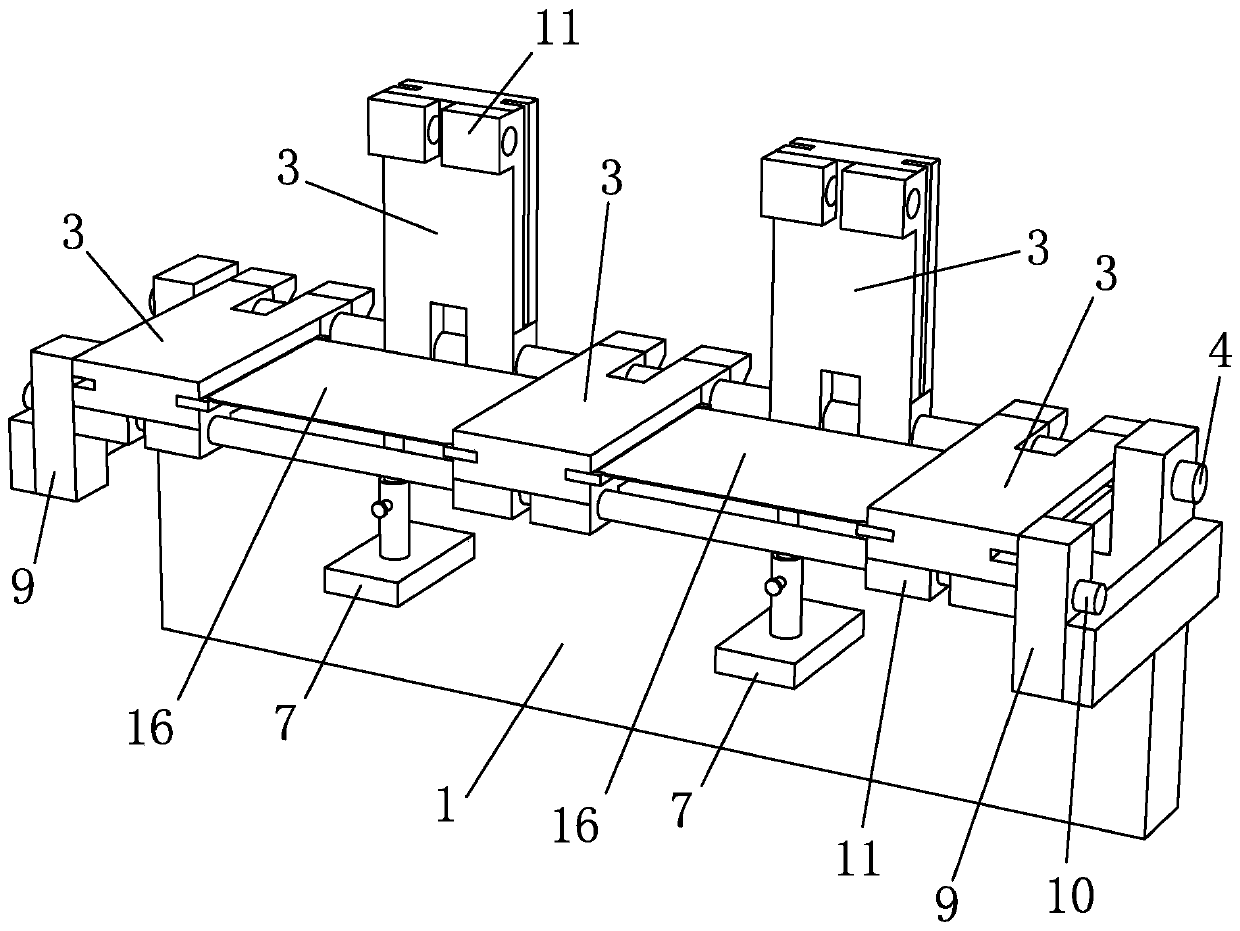

[0032] Such as Figure 1 to Figure 7 Shown, be the gel preparation method of a kind of gel forming zirconia ceramic plunger rod of the present invention, comprise the steps:

[0033] (a) Hydroxide-forming sol: first adjust the pH of the aqueous solution, then boil the zirconium salt solution at 120°C for 20-30 hours, and precipitate to obtain Zr(OH) 4 Colloid, then Zr(OH) 4 Colloids are aged.

[0034] (b) Gel preparation: first weld the baffle 2 at the notch of the gel shell 1, and set the slope of the baffle 2 inside the notch. Put swing arm 3 at the notch place again, penetrate rotating rod 4 at the notch place simultaneously, swing arm 3 is arranged on the rotating rod 4 one by one. Then swing arm 3 is adjusted and fixed one by one from left to right, swing arm 3 is rotated on turning bar 4, swing arm 3 keeps vertical state, and the briquetting block 15 of swing arm 3 bottom is against the slope of baffle plate 2. Then buckle the buckle 6 into the draw-in groove 5 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com