Method for producing high titanium type acid pellet vanadium titanium by chain grate - rotary kiln

A vanadium-titanium oxide ball and rotary kiln technology, which is applied in the production process of oxide pellets, can solve problems such as unfavorable use of blast furnaces, difficulties in meeting the requirements for drying and preheating of grate machines, and affecting production smoothness and product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

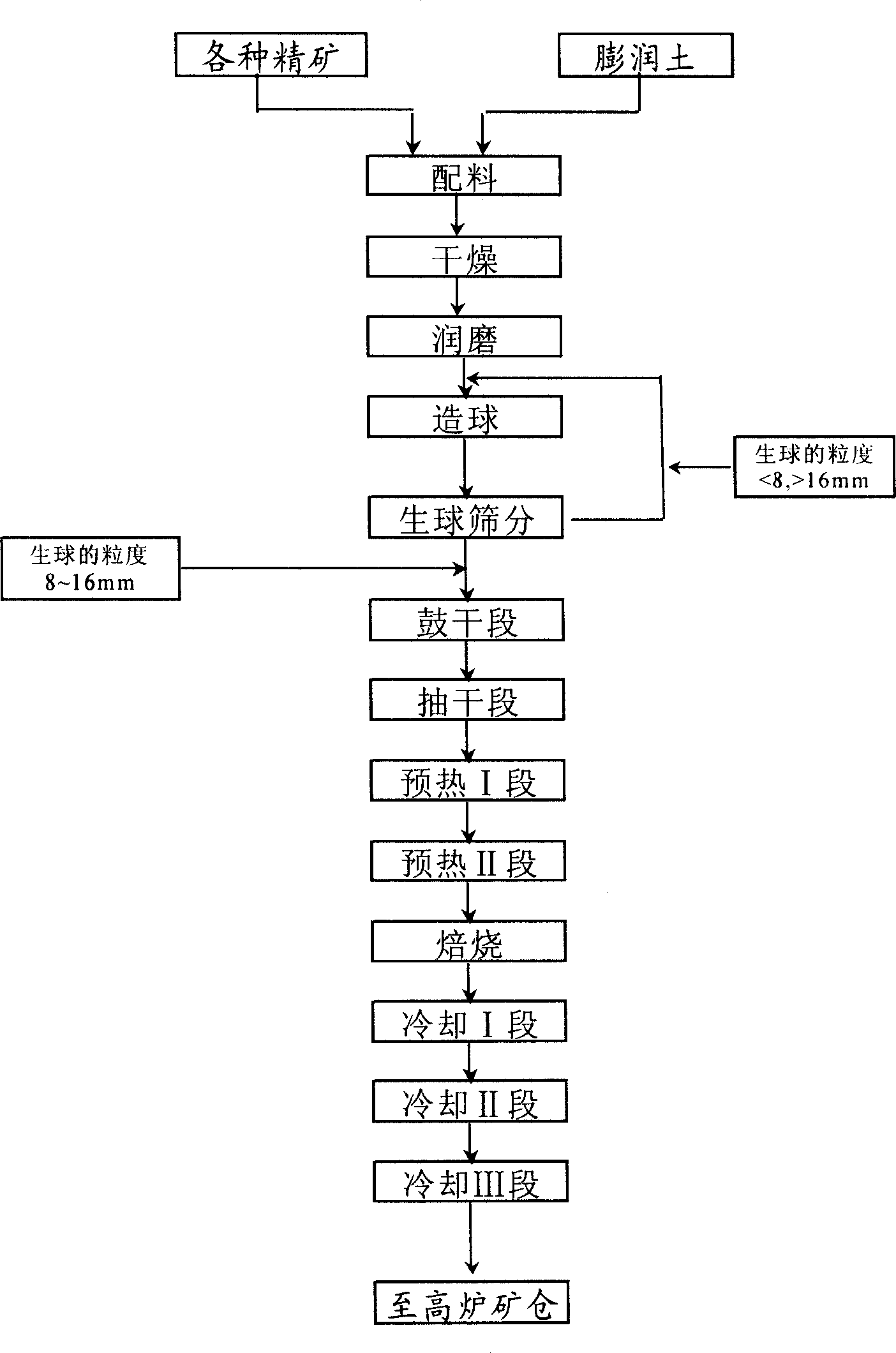

Image

Examples

Embodiment Construction

[0008] Examples are given below, and the present invention is further described in conjunction with the examples.

[0009] If a 1.2 million tons / year chain grate-rotary kiln is used to produce high-titanium vanadium-titanium oxide pellets, the physical and chemical indicators of the vanadium-titanium magnetite concentrate and the ordinary magnetite concentrate are first tested, and then the tested vanadium-titanium magnetite concentrate is Ore (the main components are, TFe: 56.5%; TiO 2 : 10.4%; V 2 o 5 : 0.63%; S: 0.29%; P: 0.01%) and ordinary magnetite concentrate (mainly composed of TFe: 60.5%; S: 0.13%; P: 0.05%) are respectively grabbed into the mine bin by a crane, and adjusted The size and speed of the gate valve of the disc feeder control the feeding amount of the magnetite concentrate. The ratio is vanadium-titanium magnetite concentrate: ordinary magnetite concentrate = 7:3, and the amount of bentonite is based on vanadium-titanium magnetite concentrate and ordinar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com