Process for extracting active Al(OH)3 product by utilizing aluminum ash or aluminum-rich waste residue

A technology of aluminum waste residue and activity, which is applied in the field of industrial waste residue extraction of aluminum hydroxide products, can solve the problems that aluminum ash cannot be effectively treated, the filter press cannot be filtered, and the environmental protection facilities are blocked, and achieves white color, reduced consumption, and environmental conditions. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

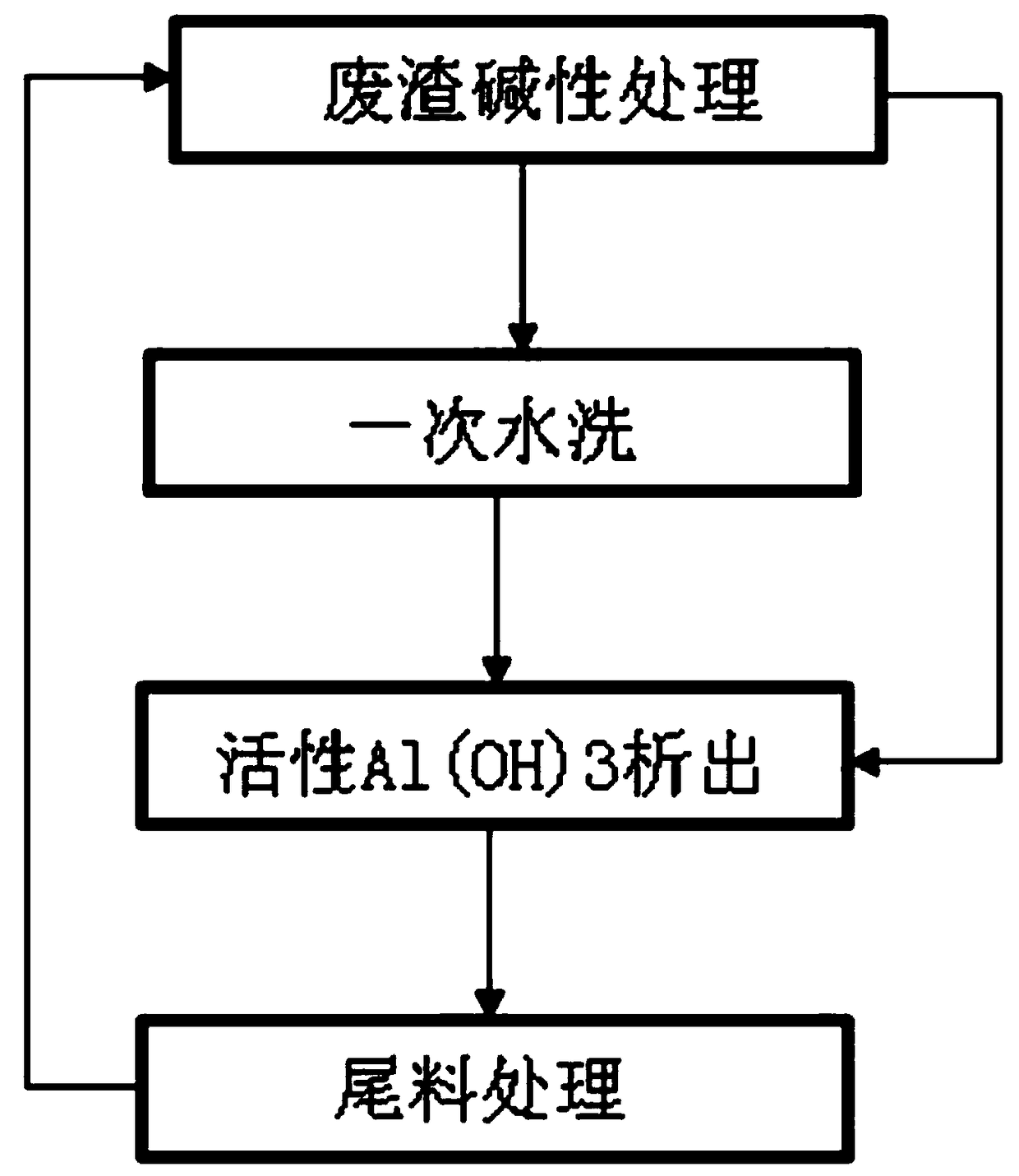

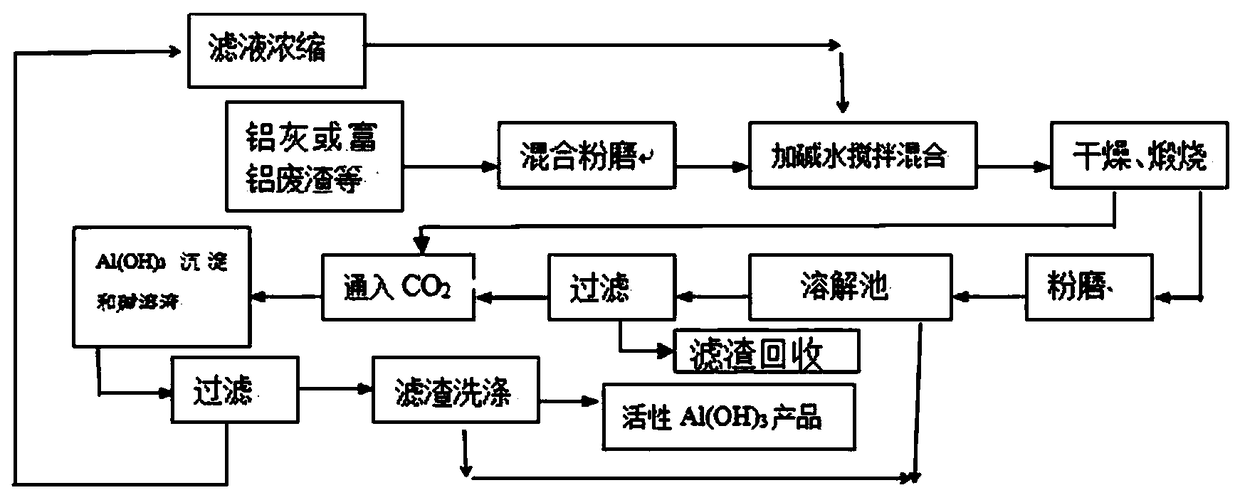

[0030] Such as figure 1 and 2 As shown, a method of extracting active Al(OH) by using aluminum ash or aluminum-rich waste slag 3 Product process, including the following steps:

[0031] S1, Alkaline treatment of waste slag, mixing aluminum ash with a particle size of not more than 80 mesh and 50% sodium carbonate alkaline water at normal temperature and pressure and allowing to stir evenly, and the mixing time is 10 minutes to obtain basic aluminum Ash mixture, and then dry the alkaline aluminum ash mixture at a constant temperature of 90°C until the water content is 3%, then raise the temperature to 700°C at a constant speed within 5 minutes, and calcinate at a constant temperature of 700°C for 20 minutes, wherein the calcination process CO produced in 2 The tail gas is purified and recovered for later use, and the calcined solid mixture is crushed by crushing equipment when it is naturally cooled to 200°C to obtain an alkaline powder mixture with a particle size not great...

Embodiment 2

[0039] Such as figure 1 and 2 As shown, a method of extracting active Al(OH) by using aluminum ash or aluminum-rich waste slag 3 Product process, including the following steps:

[0040] S1, Alkaline treatment of waste slag, mixing aluminum-rich waste slag with a particle size of no more than 80 meshes and 90% sodium carbonate alkaline water at normal temperature and pressure, and allowed to stir evenly, and the stirring and mixing time was 60 minutes to obtain alkaline Aluminum-rich waste slag mixture, and then dry the alkaline aluminum-rich waste slag mixture at a constant temperature of 150°C until the water content is 1%, and then raise the temperature to 1200°C at a uniform rate within 10 minutes, and calcinate at a constant temperature of 1200°C for 120 minutes, wherein CO produced during calcination 2 The tail gas is purified and recovered for later use, and the calcined solid mixture is pulverized by a crushing equipment when it is naturally cooled to 100°C to obtain...

Embodiment 3

[0048] Such as figure 1 and 2 As shown, a method of extracting active Al(OH) by using aluminum ash or aluminum-rich waste slag 3 Product process, including the following steps:

[0049] S1, Alkaline treatment of waste slag, mixing aluminum ash and aluminum-rich waste slag with a particle size of no more than 80 mesh in any proportion and sodium carbonate alkaline water with a concentration of 80% at normal temperature and pressure and allowed to stir evenly, and The stirring and mixing time is 20 minutes to obtain the alkaline aluminum-containing waste residue mixture, and then the aluminum-containing waste residue mixture is dried at a constant temperature of 120°C until the water content is 0, and then the temperature is raised to 1000°C at a uniform speed within 5 minutes, and then heated at 1000°C Calcined for 60 minutes in a constant temperature environment, the CO produced during the calcination process 2 The tail gas is purified and recovered for later use, and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com