Curing agent and method for reducing leaching toxicity of manganese element in cement

A technology of curing agent and element, applied in cement production, etc., can solve the problems of less research on cement leaching toxicity, achieve the effects of reducing leaching toxicity, promoting the calcination process, and increasing the liquid phase amount

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

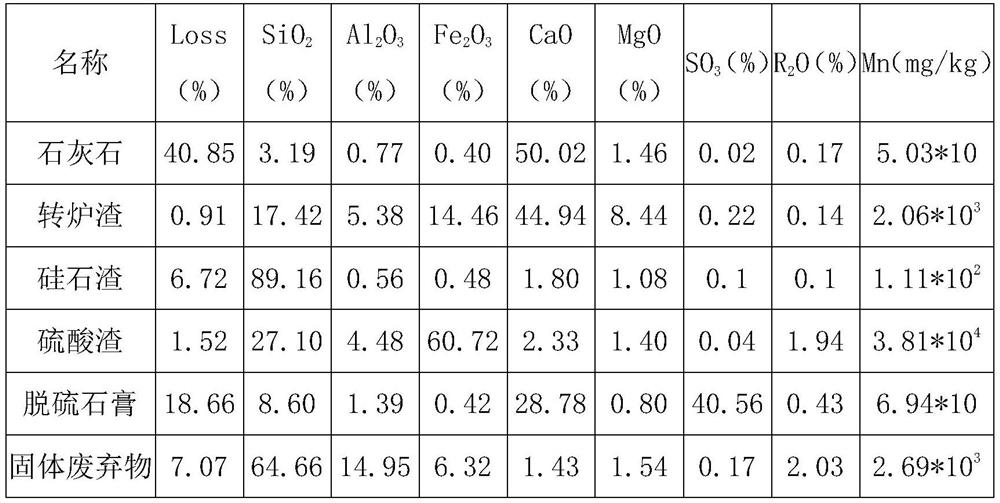

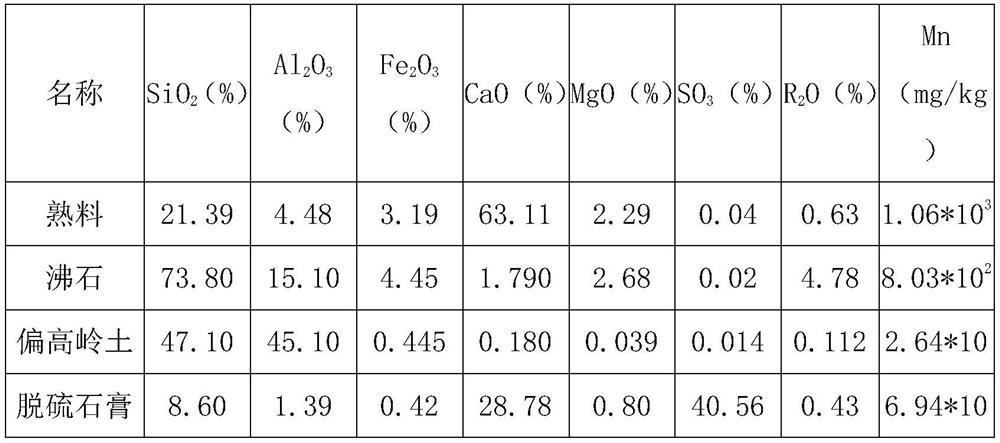

Image

Examples

Embodiment 1

[0043] 1) Implementation plan batching scheme: converter slag 2.9%, silica stone slag 2.0%, sulfuric acid slag 1.7%, solid waste 9.8%, limestone 83.5%, curing agent I (desulfurization gypsum+NaF) 0.1%, all materials are mixed, in Calcined at 1400°C to obtain the required clinker. The mass ratio of desulfurized gypsum and NaF in curing agent Ⅰ is 96:4, in which desulfurized gypsum controls its SO 3 The content is 43%;

[0044] 2) The prepared clinker is mixed with mixed slag (burned coal gangue: volcanic ash 3:1), limestone powder, desulfurized gypsum and curing agent II (zeolite + metakaolin) to prepare cement. The mass fraction of zeolite in curing agent II is 66%, and the mass fraction of metakaolin is 34%.

[0045] Batching scheme is as follows table 4:

[0046] Table 4

[0047]

[0048] The test results are shown in Table 5 below.

[0049] table 5

[0050]

Embodiment 2

[0060] 1) Implementation plan batching scheme: converter slag 2.9%, silica stone slag 2.0%, sulfuric acid slag 1.7%, solid waste 9.8%, limestone 83.1%, curing agent I (desulfurization gypsum+NaF) 0.5%, all materials are mixed, in Calcined at 1400°C to obtain the required clinker. The mass ratio of desulfurized gypsum and NaF in curing agent Ⅰ is 96:4, in which desulfurized gypsum controls its SO 3 The content is 43%.

[0061] 2) The prepared clinker is mixed with mixed slag (burned coal gangue: volcanic ash 3:1), limestone powder, desulfurized gypsum and curing agent II (zeolite + metakaolin) to prepare cement. The mass fraction of zeolite in curing agent II is 66%, and the mass fraction of metakaolin is 34%.

[0062] Batching scheme is as follows table 7:

[0063] Table 7

[0064]

[0065]

[0066] The test results are shown in Table 8 below.

[0067] Table 8

[0068]

[0069] It can be seen from Table 8 above that:

[0070] 1) Compared with the 0.1% desulfuri...

Embodiment 3

[0074] 1) Implementation plan batching scheme: converter slag 2.9%, silica stone slag 2.0%, sulfuric acid slag 1.7%, solid waste 9.8%, limestone 82.6%, curing agent I (desulfurization gypsum+NaF) 1.0%, mix all materials, Calcined at 1400°C to obtain the required clinker. The mass ratio of desulfurized gypsum and NaF in curing agent Ⅰ is 96:4, in which desulfurized gypsum controls its SO 3 The content is 43%.

[0075] 2) The prepared clinker is mixed with mixed slag (burned coal gangue: volcanic ash 3:1), limestone powder, desulfurized gypsum and curing agent II (zeolite + metakaolin) to prepare cement. The mass fraction of zeolite in curing agent II is 66%, and the mass fraction of metakaolin is 34%.

[0076] Batching scheme is as follows table 9:

[0077] Table 9

[0078]

[0079] The test results are shown in Table 10.

[0080] Table 10

[0081]

[0082] It can be seen from the above table:

[0083] 1) Compared with 0.1% and 0.5% desulfurized gypsum+NaF in Examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com