Method for machining hot rolled steel strips

A technology for hot-rolled strip and hot-rolled coil, applied in metal processing equipment, heat treatment furnace, metal rolling, etc. The effect of improving the pass rate, improving labor productivity and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

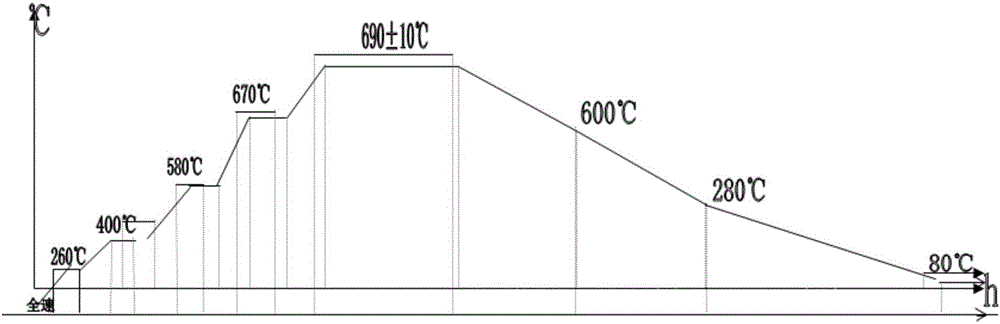

[0030] Embodiment one: if figure 1 Shown, a kind of method for processing hot-rolled steel strip, comprises the steps:

[0031] Step 1, preparing raw materials, selecting a hot-rolled coil plate whose brand name is BJS15C;

[0032] Step 2, the first slitting and slitting, transfer the hot-rolled coil prepared in step 1 to the first large slitting production line through the crane device for the first slitting and slitting, in order to facilitate subsequent processing, When the hot-rolled coil is slitting, a margin of about 0.5mm is reserved in the width direction. The allowable deviation of the thickness of the hot-rolled coil should comply with the regulations of GB / T709. 40μm; the thickness is 3mm to 8.0mm, the convexity is less than or equal to 60μm, the thickness is greater than 8.0mm, the convexity is less than or equal to 100μm, the surface of the hot-rolled coil must not have bubbles, cracks, scars, warping, cracking and inclusions, hot-rolled Coils must not be delami...

Embodiment 2

[0039] Embodiment two: if figure 1 Shown, a kind of method for processing hot-rolled steel strip, comprises the steps:

[0040] Step 1, preparing raw materials, selecting a hot-rolled coil plate whose brand name is BJS15C;

[0041] Step 2, the first slitting and slitting, transfer the hot-rolled coil prepared in step 1 to the first large slitting production line through the crane device for the first slitting and slitting, in order to facilitate subsequent processing, When the hot-rolled coil is slitting, a margin of about 0.5mm is reserved in the width direction. The allowable deviation of the thickness of the hot-rolled coil should comply with the regulations of GB / T709. 40μm; the thickness is 3mm to 8.0mm, the convexity is less than or equal to 60μm, the thickness is greater than 8.0mm, the convexity is less than or equal to 100μm, the surface of the hot-rolled coil must not have bubbles, cracks, scars, warping, cracking and inclusions, hot-rolled Coils must not be delami...

Embodiment 3

[0048] Embodiment three: as figure 1 Shown, a kind of method for processing hot-rolled steel strip, comprises the steps:

[0049] Step 1, preparing raw materials, selecting a hot-rolled coil plate whose brand name is BJS15C;

[0050] Step 2, the first slitting and slitting, transfer the hot-rolled coil prepared in step 1 to the first large slitting production line through the crane device for the first slitting and slitting, in order to facilitate subsequent processing, When the hot-rolled coil is slitting, a margin of about 0.5mm is reserved in the width direction. The allowable deviation of the thickness of the hot-rolled coil should comply with the regulations of GB / T709. 40μm; the thickness is 3mm to 8.0mm, the convexity is less than or equal to 60μm, the thickness is greater than 8.0mm, the convexity is less than or equal to 100μm, the surface of the hot-rolled coil must not have bubbles, cracks, scars, warping, cracking and inclusions, hot-rolled Coils must not be dela...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Convexity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com