Method for detecting appearance of module lens

A technology of appearance inspection and lens, which is applied in the direction of measuring devices, optical testing for flaws/defects, and material analysis through optical means. It can solve problems such as low efficiency, low precision, and large influence of human factors, so as to meet production needs and be accurate. The effect of high precision and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

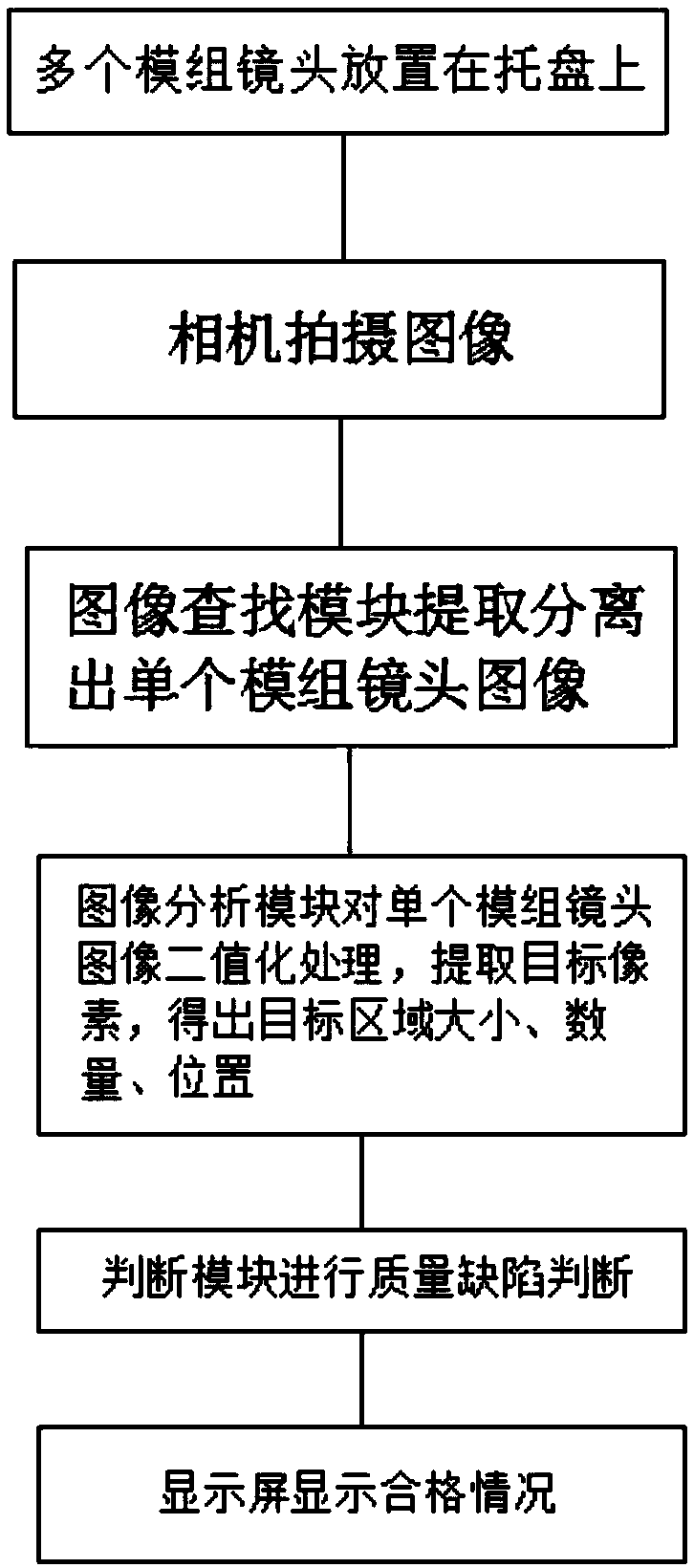

[0014] Attached below figure 1 , the specific embodiment of the present invention is described further:

[0015] A method for detecting the appearance of a module lens, comprising the following steps:

[0016] ① Place multiple module lenses equidistantly on the tray;

[0017] ② The camera shoots multiple module lens images, and the captured images are transmitted to the image search module of the computer. The image search module extracts and separates a single module lens image from the captured images. The image search module extracts and separates a single module through the ROI system Lens image, ROI system is the region of interest. The image to be processed outlines the area to be processed in the form of a box, circle, ellipse, irregular polygon, etc., which is called the region of interest. It can be viewed from the entire lens of multiple modules. A single module lens image is separated from the image, and the single module lens image is transmitted to the image ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com