SK85 carbon tool steel

A technology of carbon tool steel and processing technology, which is applied in the field of strip steel production and processing, and can solve problems such as broken, poor coarse-grained structure, and unfavorable production of fine blanking parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

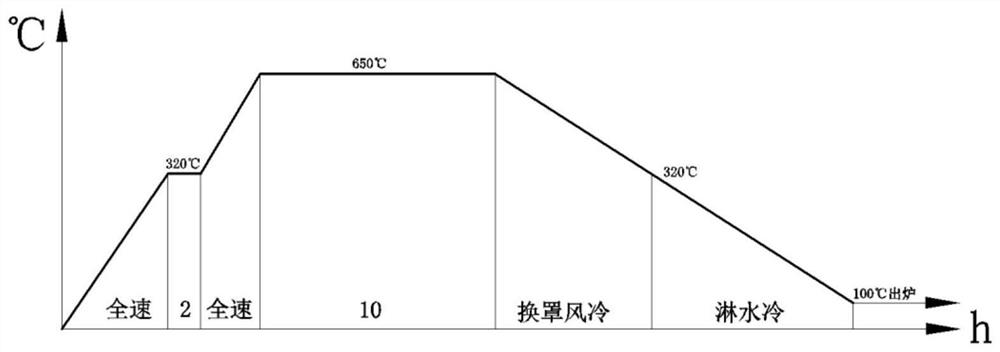

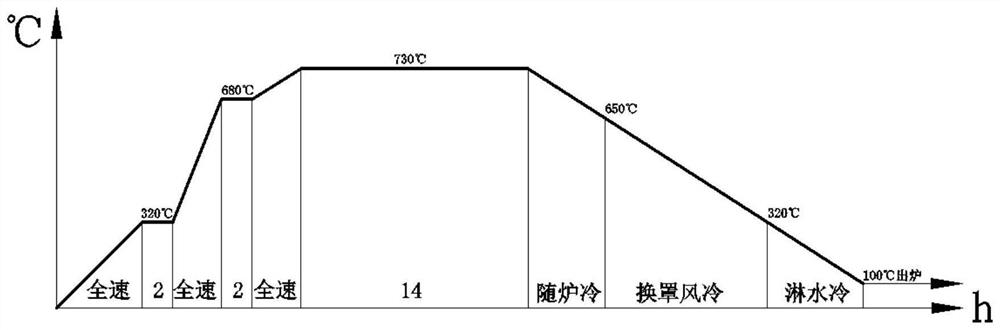

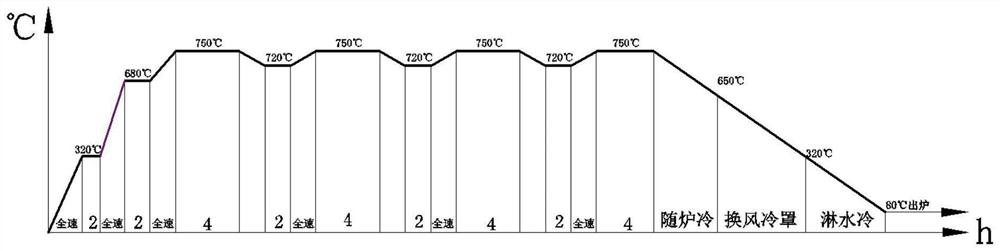

[0034] A kind of processing technology of SK85 carbon tool steel, comprises the steps:

[0035]Step 1, prepare raw materials, select spring steel hot-rolled coils with the brand name of SK85, wherein the chemical composition of SK85 hot-rolled coils (refer to JIS G3311-2004) requires: C: 0.80 to 0.90, Si:≦0.35, Mn:≦0.50, P:≦0.030, S:≦0.030, Cr:≦0.30, Ni≦0.25, Cu≦0.25; the mechanical properties requirements of SK85 hot-rolled coils are: tensile strength:≦1050MPa; SK85 The metallographic requirements of hot-rolled coils are: ferrite + pearlite structure, decarburized layer, when the thickness is > 5mm, decarburization is allowed ≦ 1% t, where t is the thickness of the hot-rolled steel plate, when the thickness is ≦ 5m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com