Magnesium alloy micro-arc oxidation treatment device

A technology of micro-arc oxidation and processing equipment, which is applied in the direction of anodic oxidation, electrolytic coating, surface reaction electrolytic coating, etc. It can solve the problem of inability to ensure the orderly placement of steel pipes, the trouble of discharging and retrieving materials, and the inability to unload steel pipes, etc. problems, to avoid feeding difficulties, increase feeding efficiency, and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

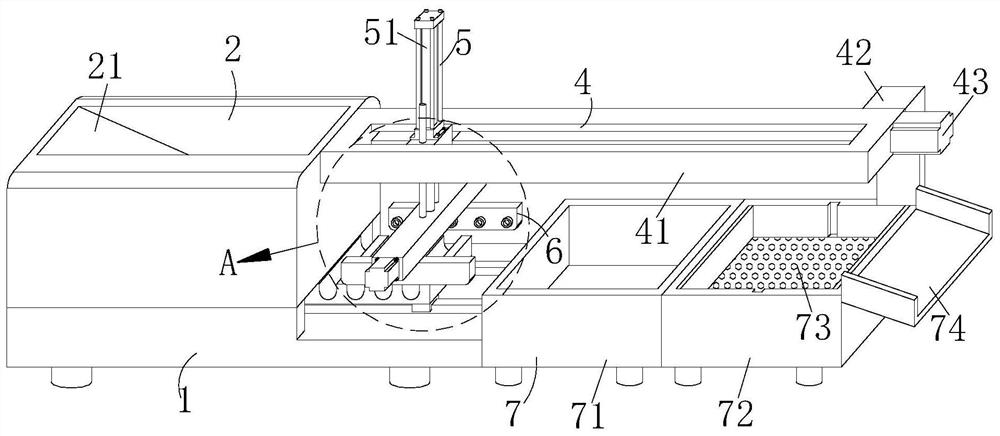

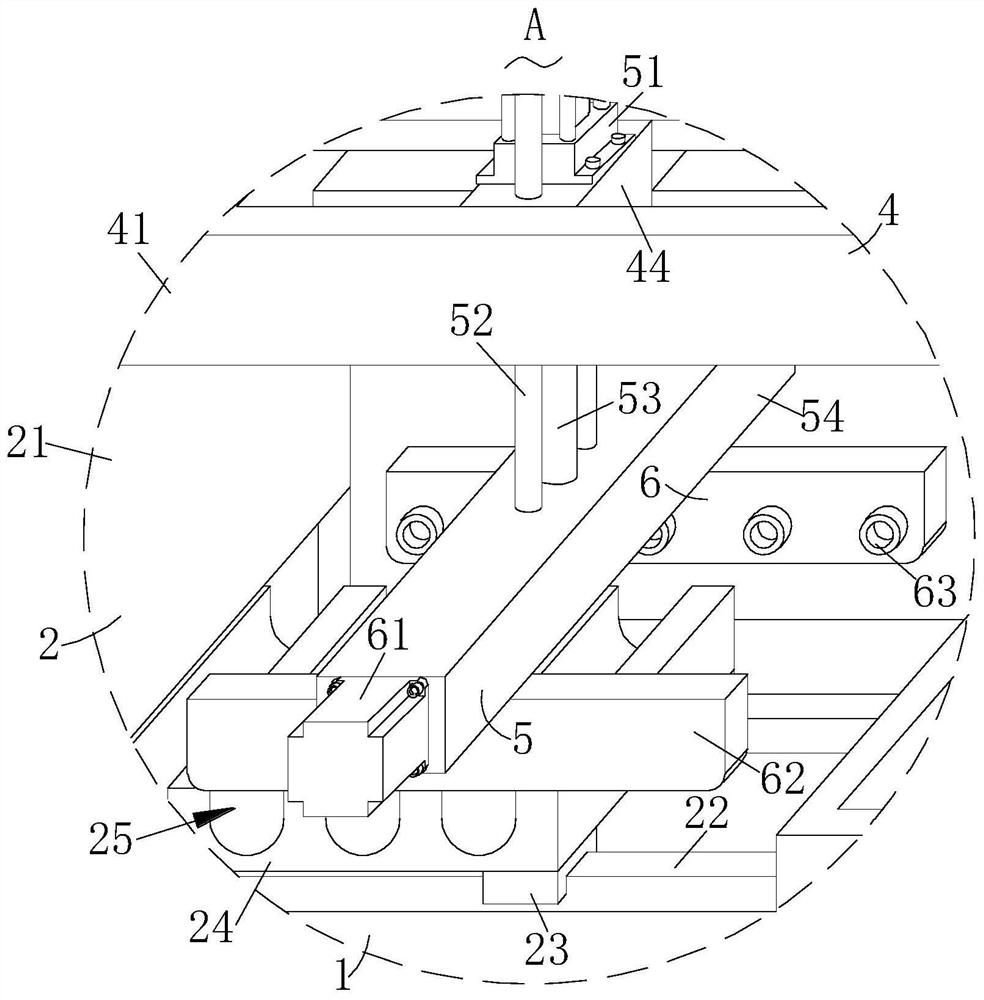

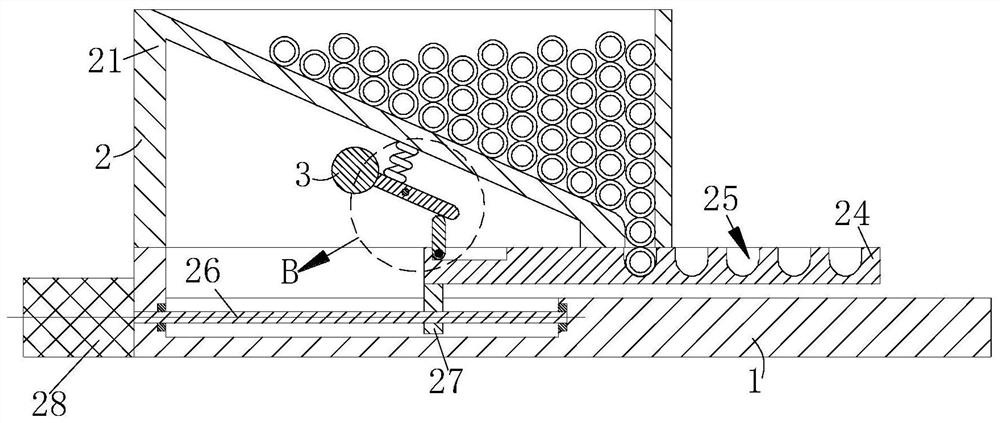

[0026] Such as Figure 1-Figure 7 As shown, a magnesium alloy micro-arc oxidation treatment device according to the present invention includes a base 1, a feeding structure 2, a vibrating structure 3, a moving structure 4, a retrieving structure 5, a clamping structure 6 and a processing structure 7, for The top of the base 1, which supports and installs other parts, is installed with the feeding structure 2 capable of automatic blanking, automatic sorting and automatic feeding of the steel pipes to be processed. The vibration structure 3 driven by the feeding structure 2 is used to vibrate and unload the components inside the feeding structure 2; installing at one end of the feeding structure 2 can facilitate the automatic transportation of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com