A steel ball charging device

A technology of charging device and steel ball, applied in quenching device, furnace, heat treatment equipment and other directions, can solve the problems of high labor intensity and waste of quenching liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

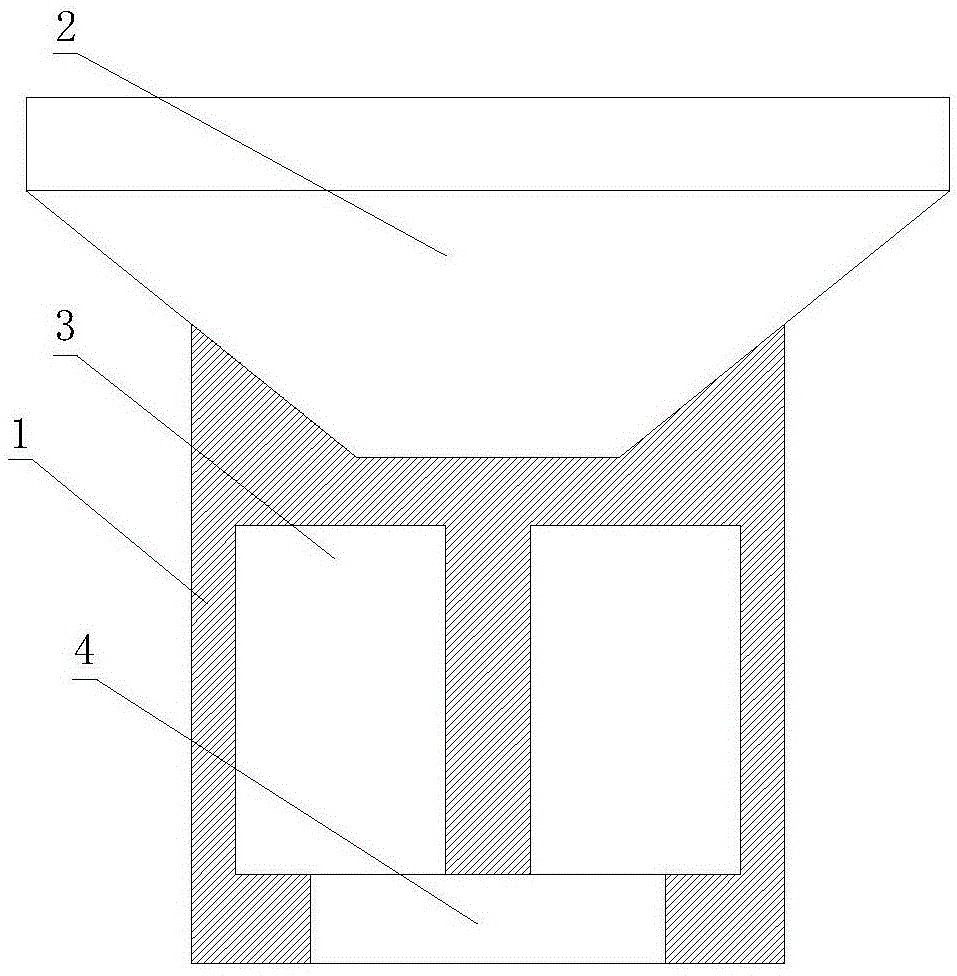

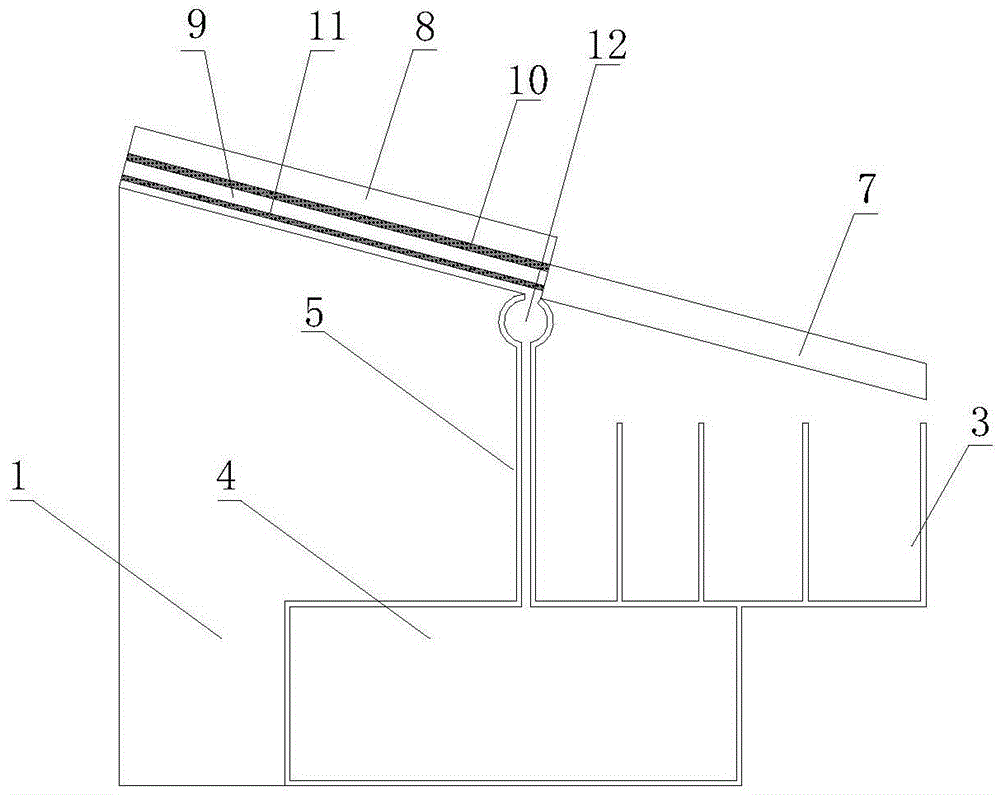

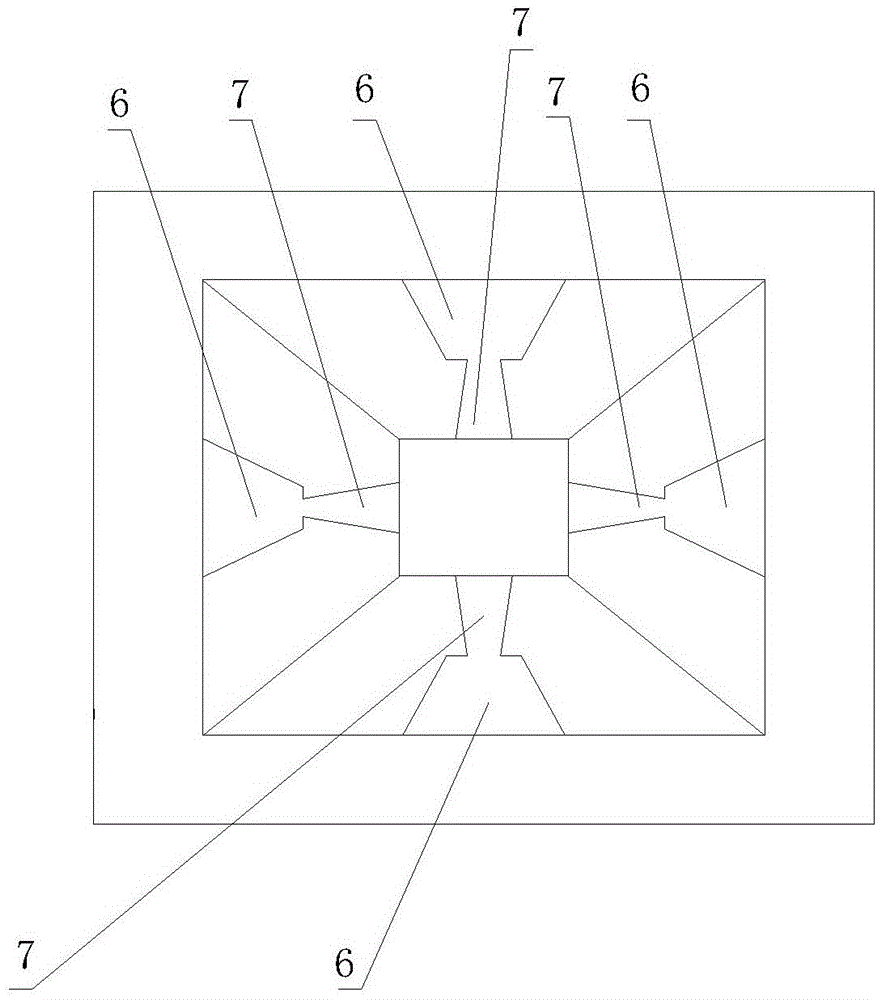

[0012] Such as Figure 1-3 as shown, figure 1 It is a structural schematic diagram of a steel ball charging device proposed by the present invention; figure 2 for figure 1 Partial sectional view of image 3 for figure 1 Schematic diagram of the local top view structure.

[0013] refer to Figure 1-3 , a steel ball charging device proposed by the present invention includes a bracket 1, a screening box 2 and a collection box 3, the screening box 2 and the collection box 3 are all installed on the bracket 1, and the screening box 2 is located above the collection box 3 The screening box 2 is funnel-shaped, and the surrounding walls of the screening box 2 are provided with multiple slideways, and the slideways extend from the screening box 2 upper end to the screening box 2 lower ends, and the distances between adjacent slideways are all equal, and the slideways It is formed by connecting the upper liquid collection channel 6 and the lower channel channel 7, wherein the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com