Shell inserting device for full-automatic wire harness double-end shell inserting machine

A fully automatic, wire harness technology, applied in the assembly/disassembly of contact parts, etc., can solve the problems of poor continuity between terminal push-out and feeding, inconvenient terminal replacement, unfavorable device operating speed, etc., to achieve high production efficiency, improve efficiency, Strong overall continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

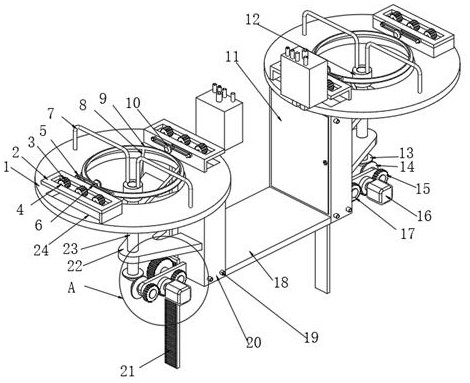

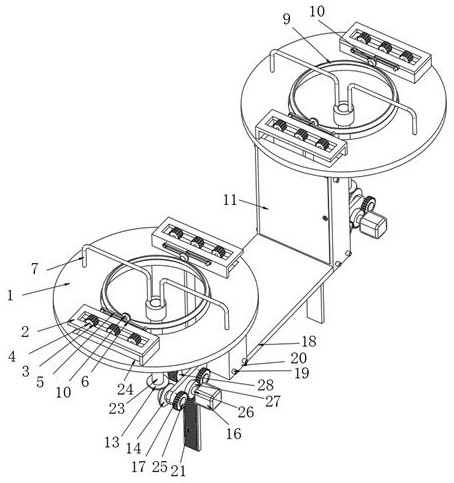

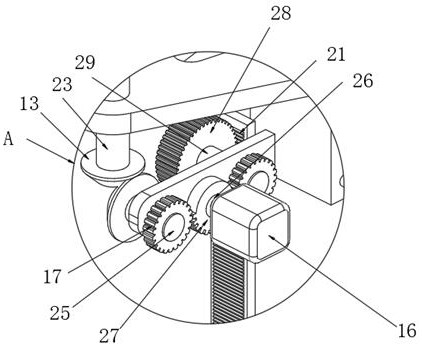

[0039] Such as Figure 1-5 As shown in and 7-10, a case insertion device for a fully automatic wire harness double-head case insertion machine includes a turntable 1, and notches 24 are symmetrically opened on both sides of the top of the turntable 1, and are used to insert the terminals to be used in the case. Move upward through the notch 24 to the limit plate 2 fixedly connected to the top of the turntable 1 at the notch 24. An opening is provided on the outside of the limit plate 2, and can be removed through the opening after the terminal insertion is completed.

[0040] Further, the material cylinder 20 arranged at the notch 24 at the bottom of the turntable 1 is used to store the terminals, and a pressing plate 31 is slidably connected inside the material cylinder 20, and the pressing plate 31 can drive the terminals loaded inside the material cylinder 20 to move upwards, so that the terminals Move to the inside of the limit plate 2, a chute 30 is opened on one side of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com