Composite reinforced construction rubber pipe

A composite reinforcement, rubber hose technology, applied in the direction of hoses, pipes, rubber layered products, etc., can solve the problems of affecting the service life, hurting people, poor bonding, etc., to improve safety reserves, improve compressive strength, and prolong use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The composite reinforced construction rubber hose of the present invention will be described in detail below in conjunction with the examples.

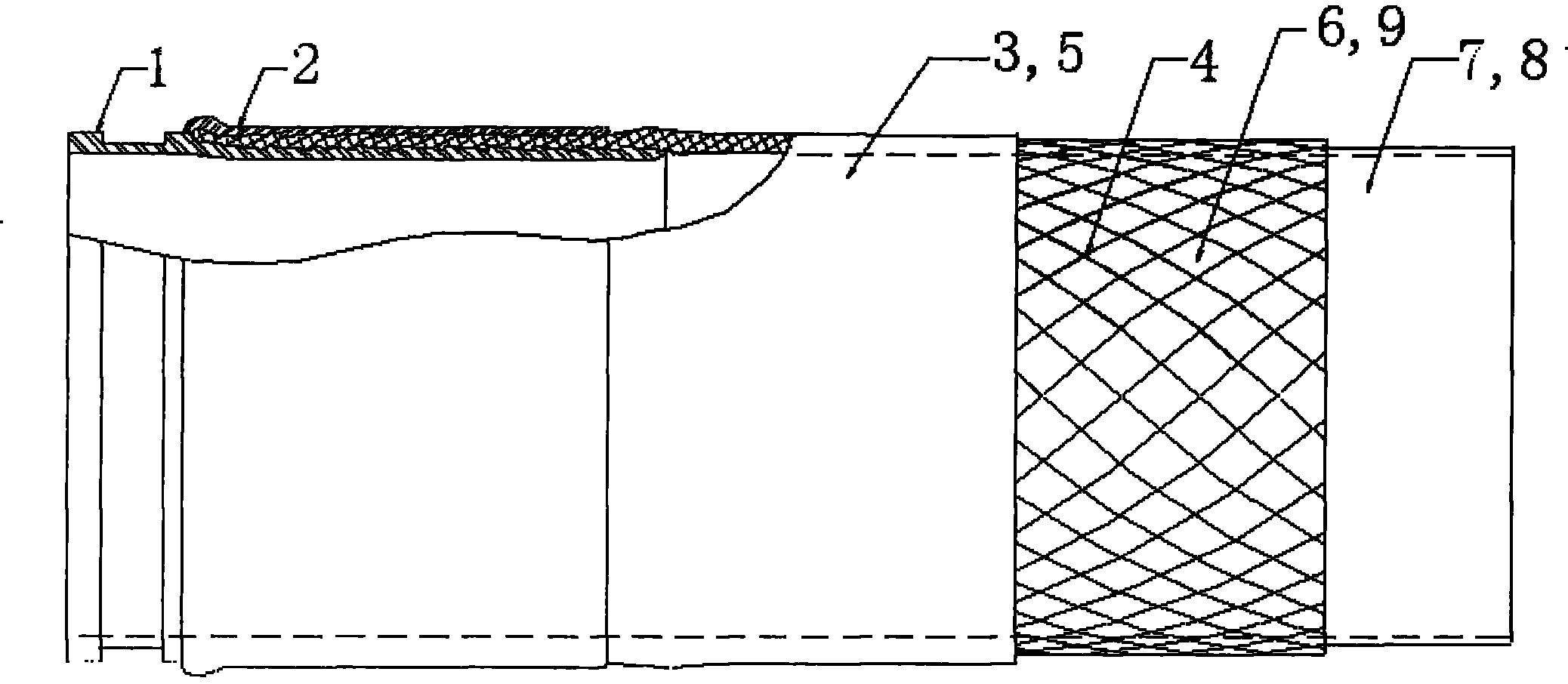

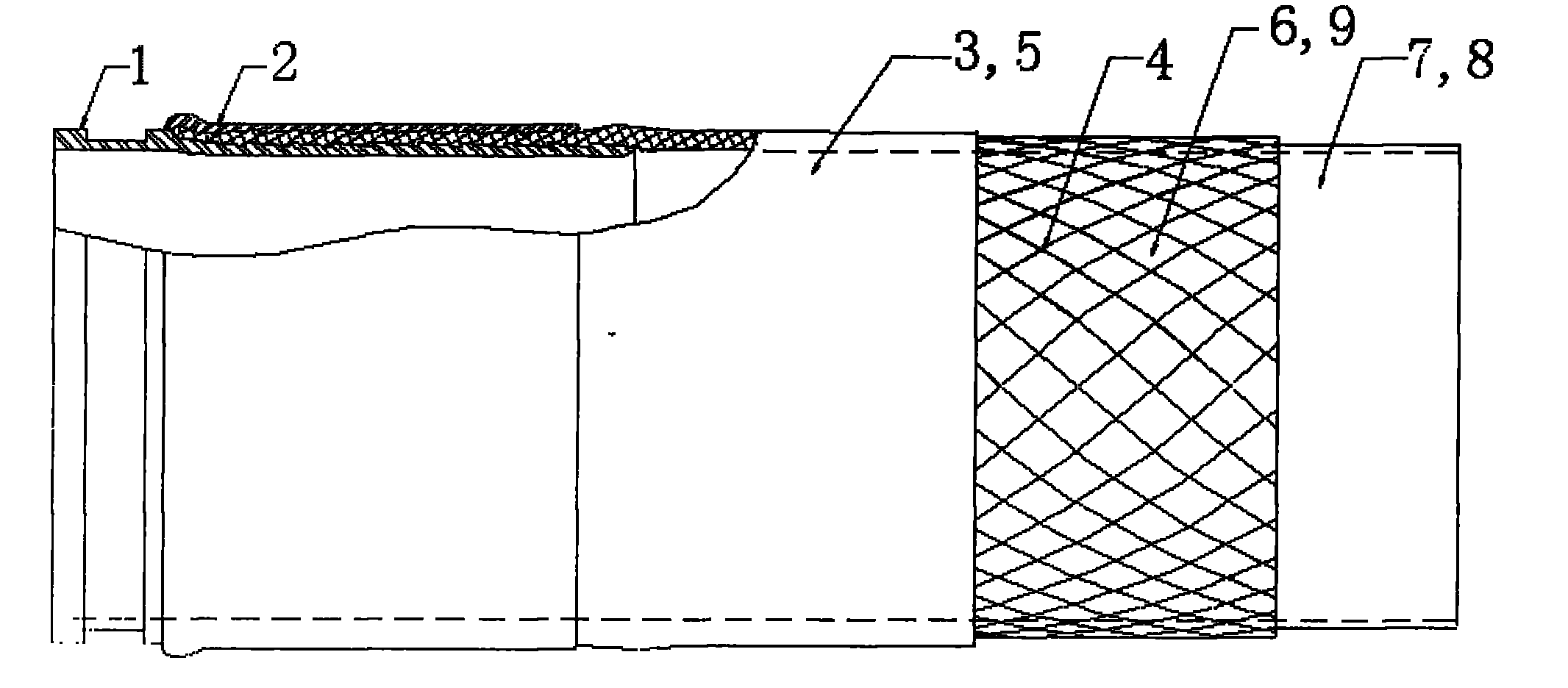

[0032] Fig. 1 is a schematic structural diagram of the composite reinforced construction rubber hose of the present invention.

[0033] The composite reinforced construction rubber hose of the present invention includes a pipe body 3 and a joint.

[0034] The pipe body 3 is a multi-layer composite pipe. The rubber at different parts of the pipe body 3 is divided into an outer rubber layer 5, a middle rubber layer 6 and an inner rubber layer 7 according to different functional requirements, and different formula designs and rubber mixing processes are adopted respectively. , to adapt to different functional requirements, thereby improving the anti-aging and wear resistance of the pipe body, inhibiting its low-temperature brittleness, and strengthening the bonding between the functional layers.

[0035] The middle rubber layer 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com