Patents

Literature

79results about How to "Realize intelligent automation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Robot-based intelligent warehouse management method and device and storage medium

ActiveCN109264275ARealize intelligent automationFully automatedCo-operative working arrangementsStorage devicesStorage garageAutomation

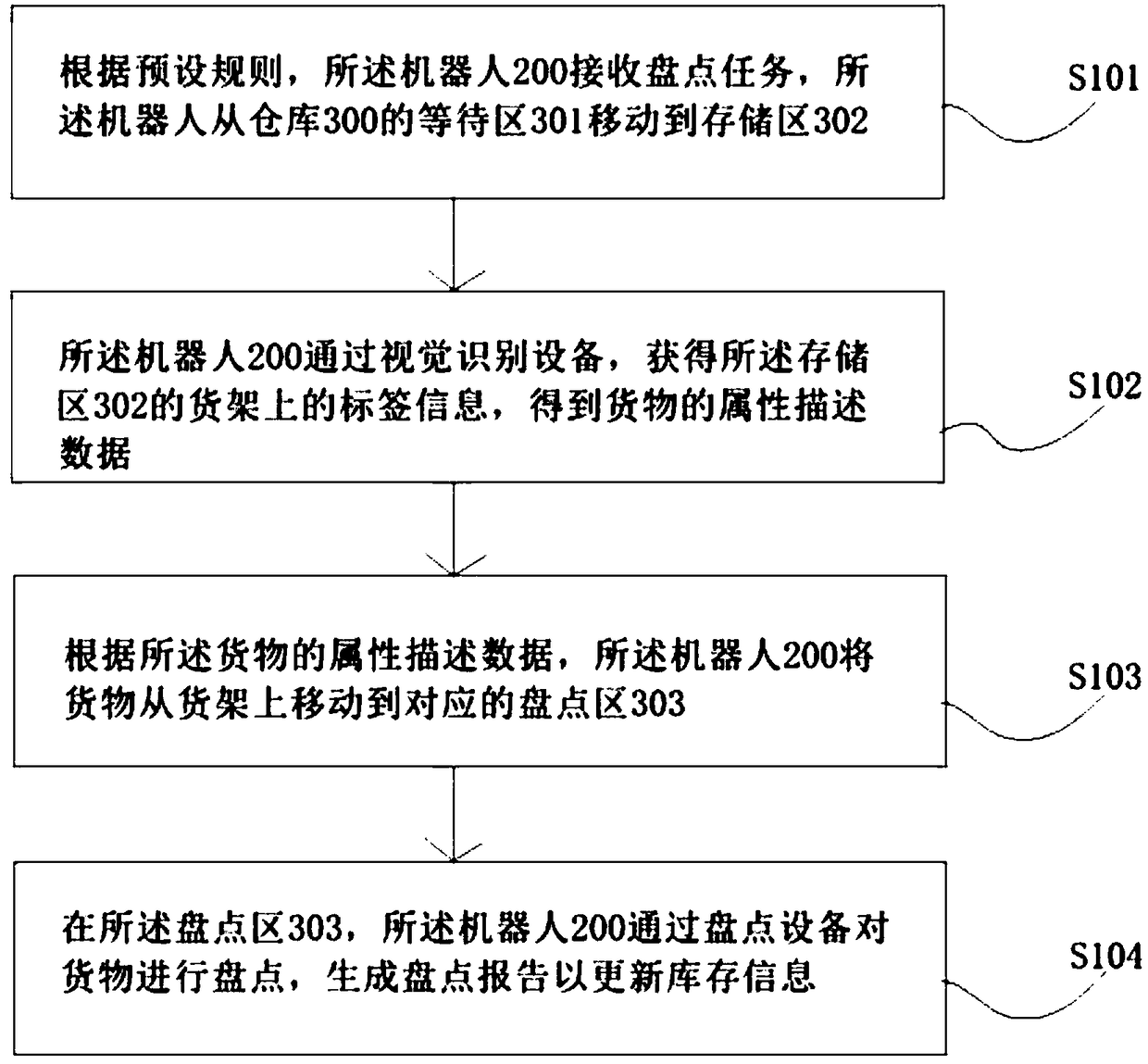

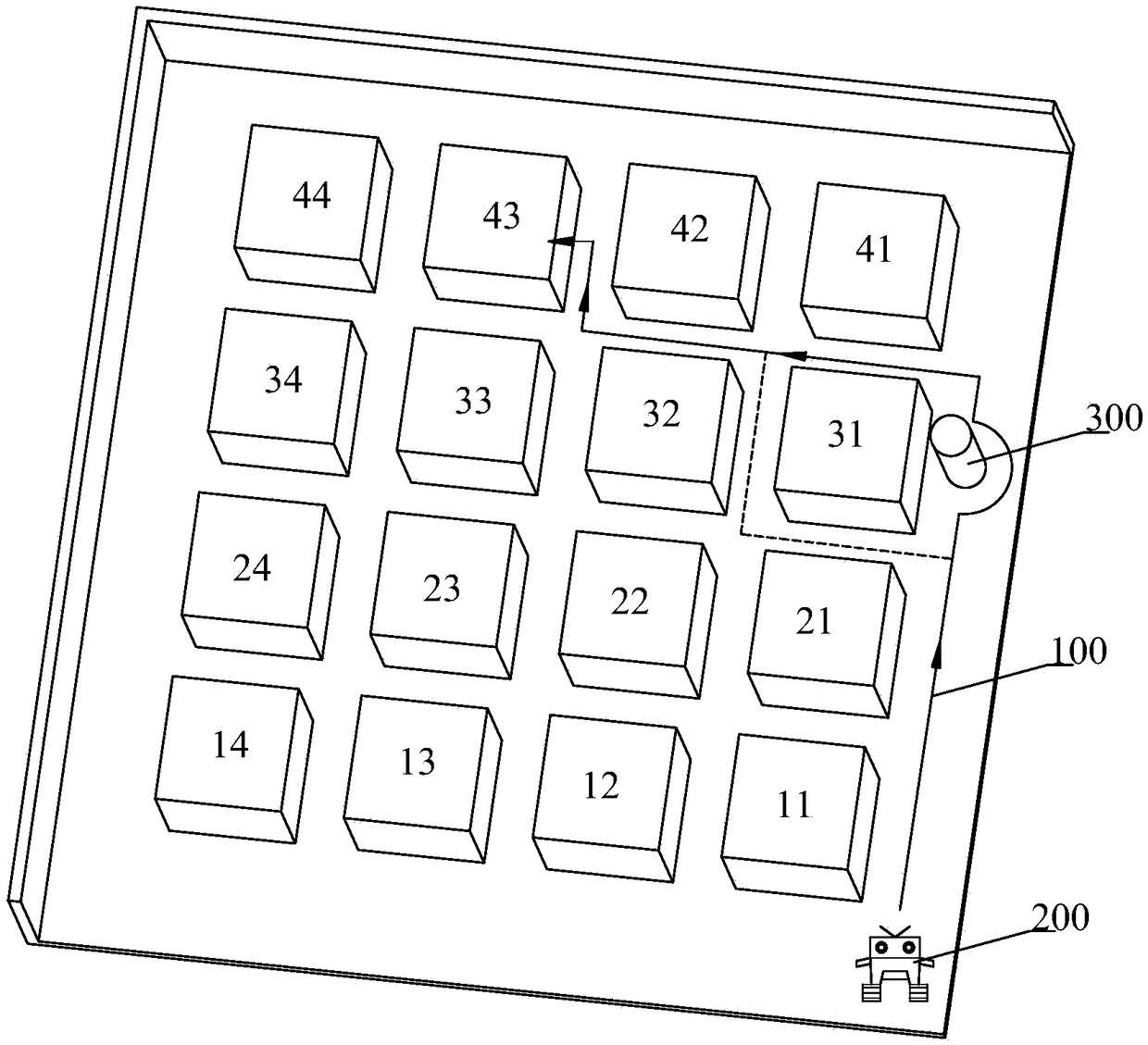

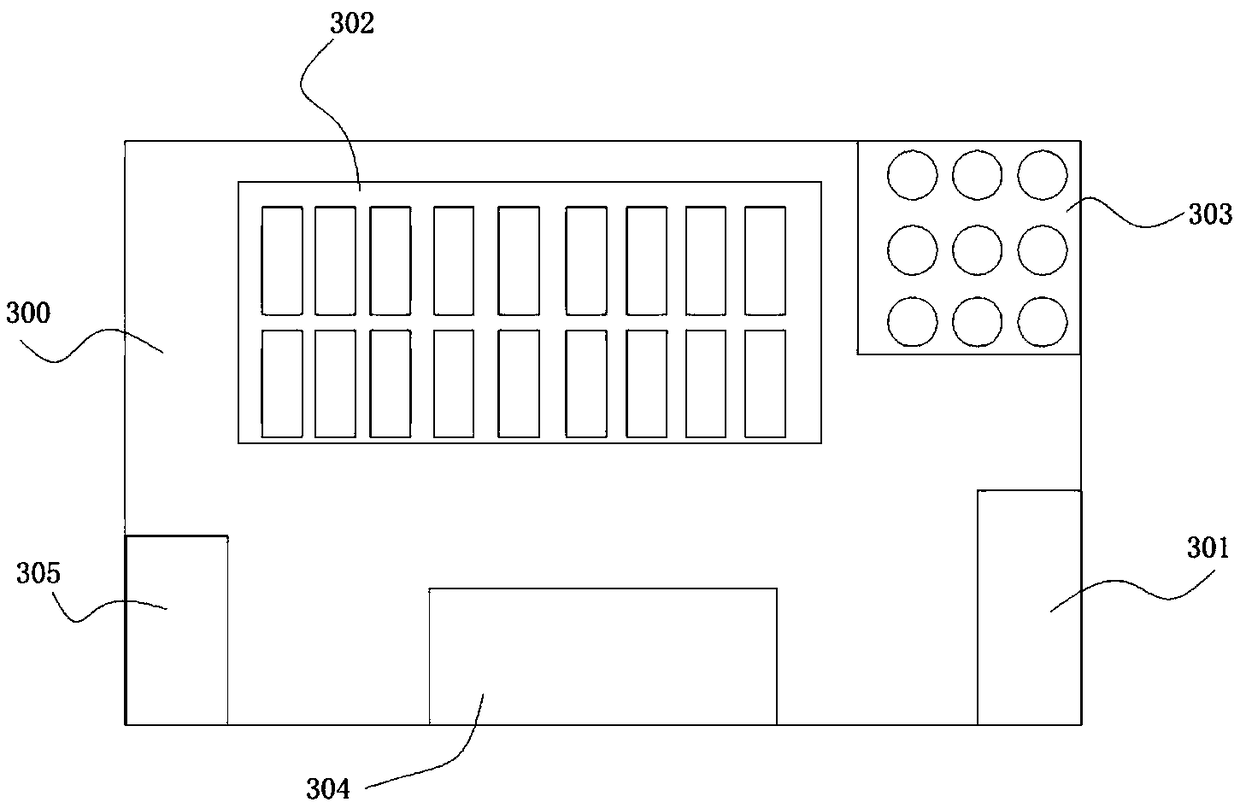

The invention discloses a robot-based intelligent warehouse management method and device and a computer readable storage medium, wherein the robot-based intelligent warehouse management method comprises the following steps: a robot receives an inventory task through a preset rule, the robot moves from a waiting area to storage area of a warehouse, the robot obtains label information on a shelf ofthe storage area through a visual recognition device, and obtains attribute description data of goods, the robot moves the goods from the shelf to a corresponding inventory area according to the attribute description data of the goods, and in the inventory area, the robot makes an inventory of the goods through an inventory device to generate inventory reports to update inventory information, so that the full automation of warehouse management is achieved, and the warehouse can intelligently check the goods in time, replenish the goods and store the goods in the warehouse, clear out abnormal goods in time, expired goods are cleared out in time and intelligent automation of the warehouse is achieved.

Owner:SHENZHEN DORABOT ROBOTICS CO LTD

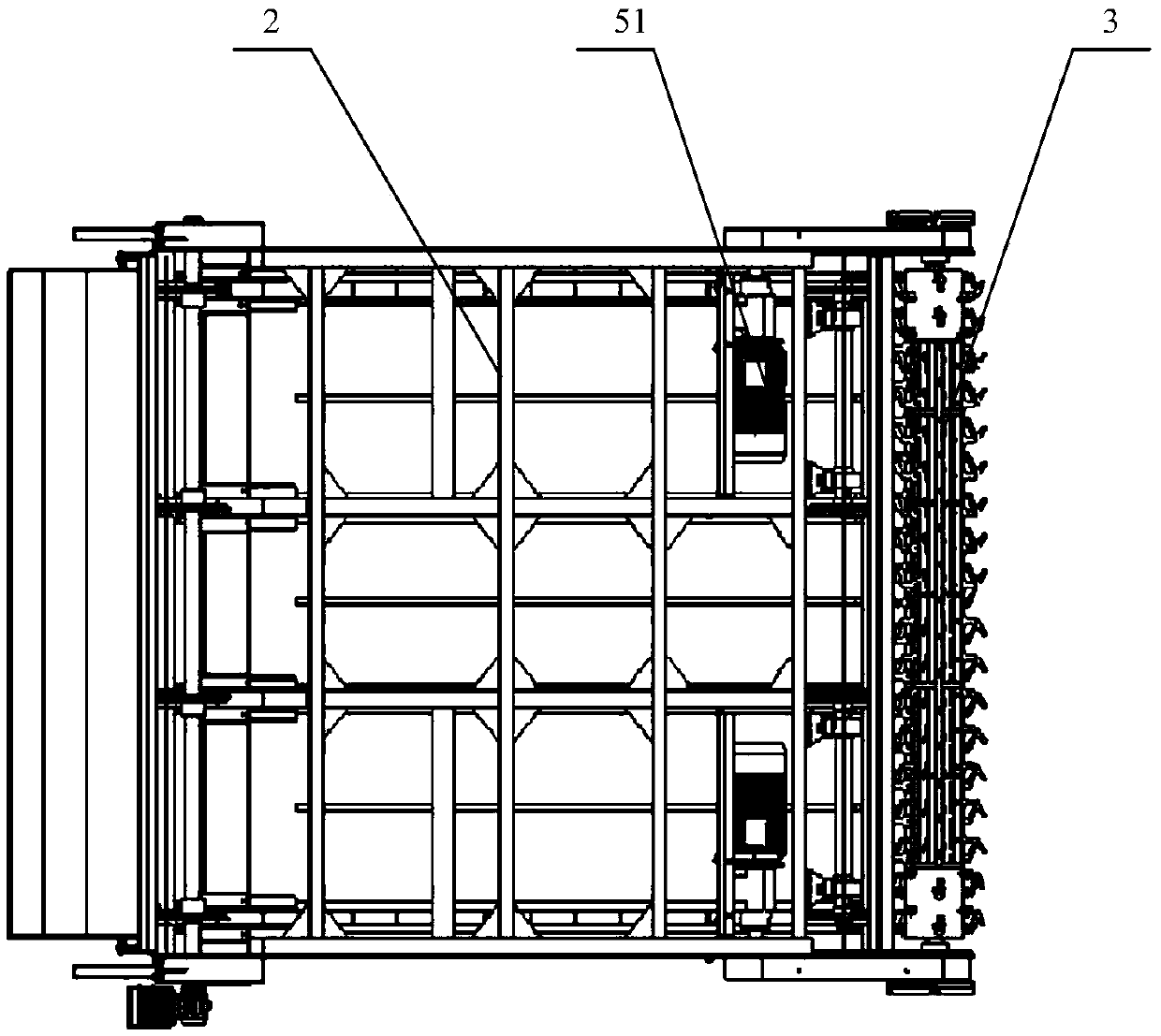

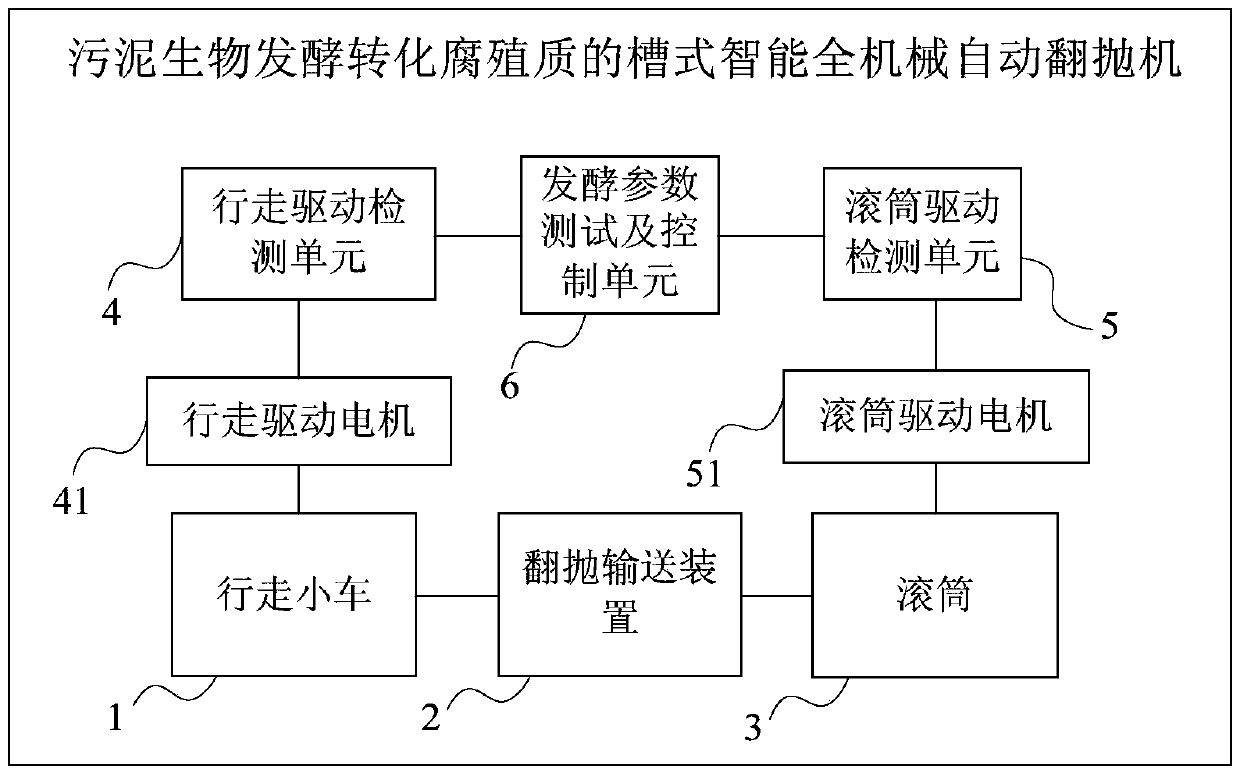

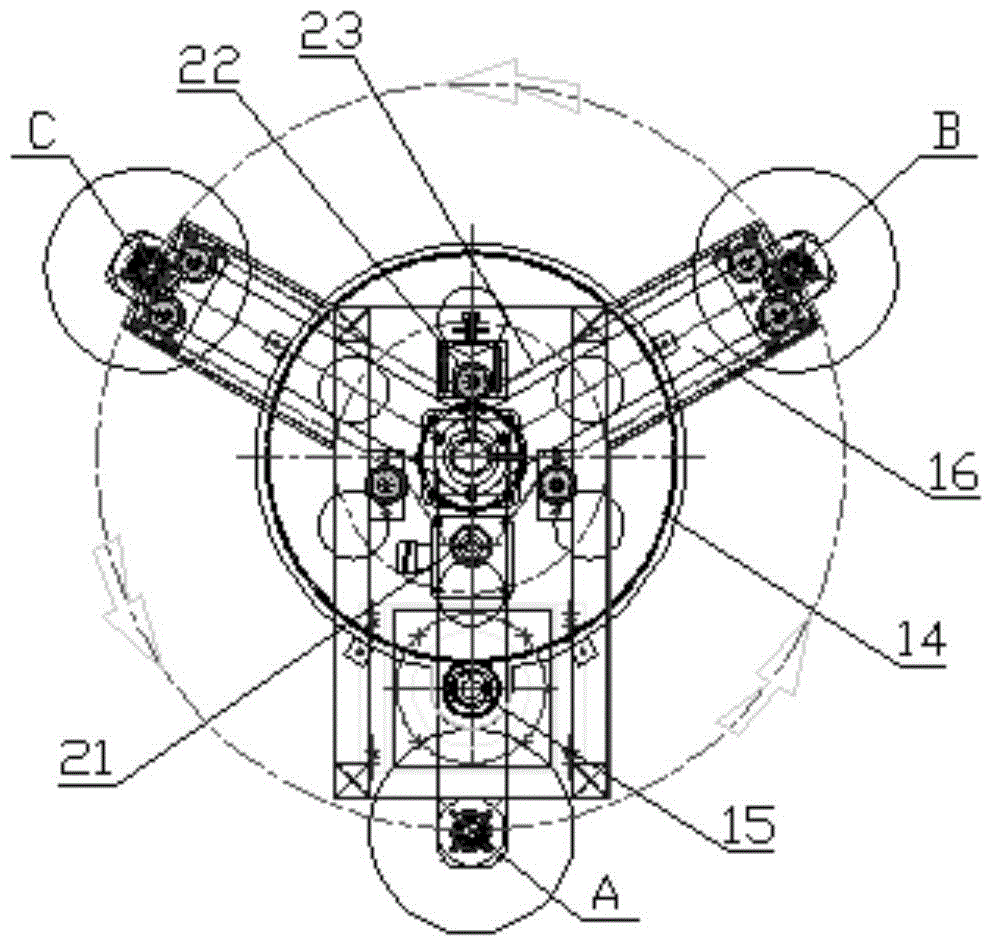

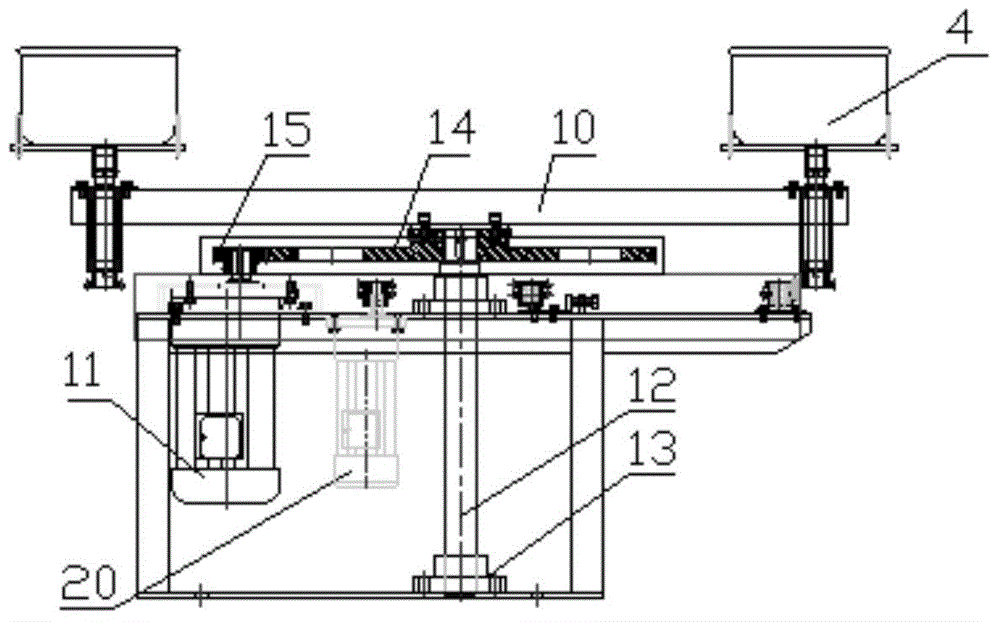

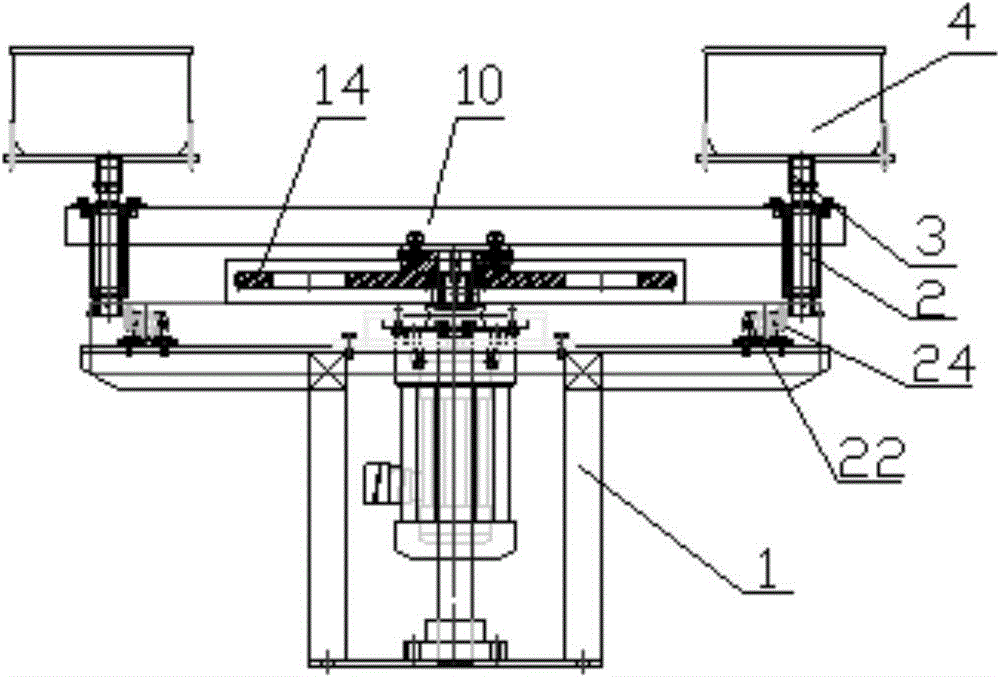

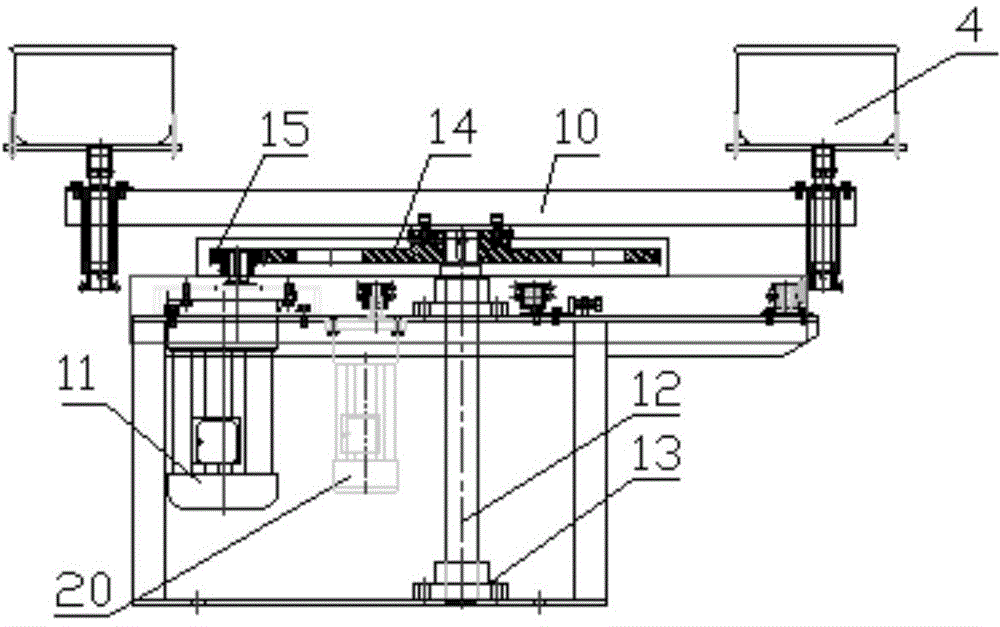

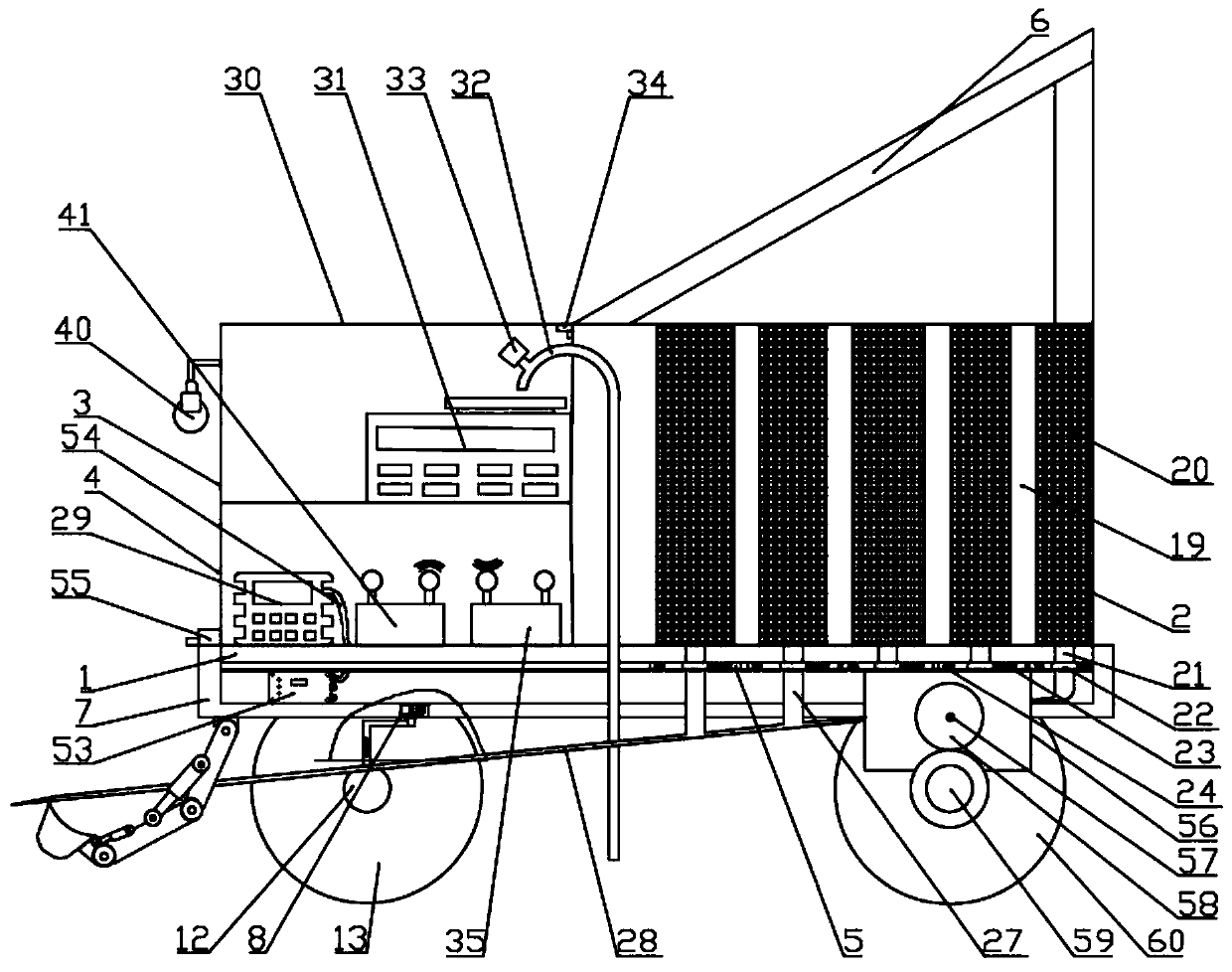

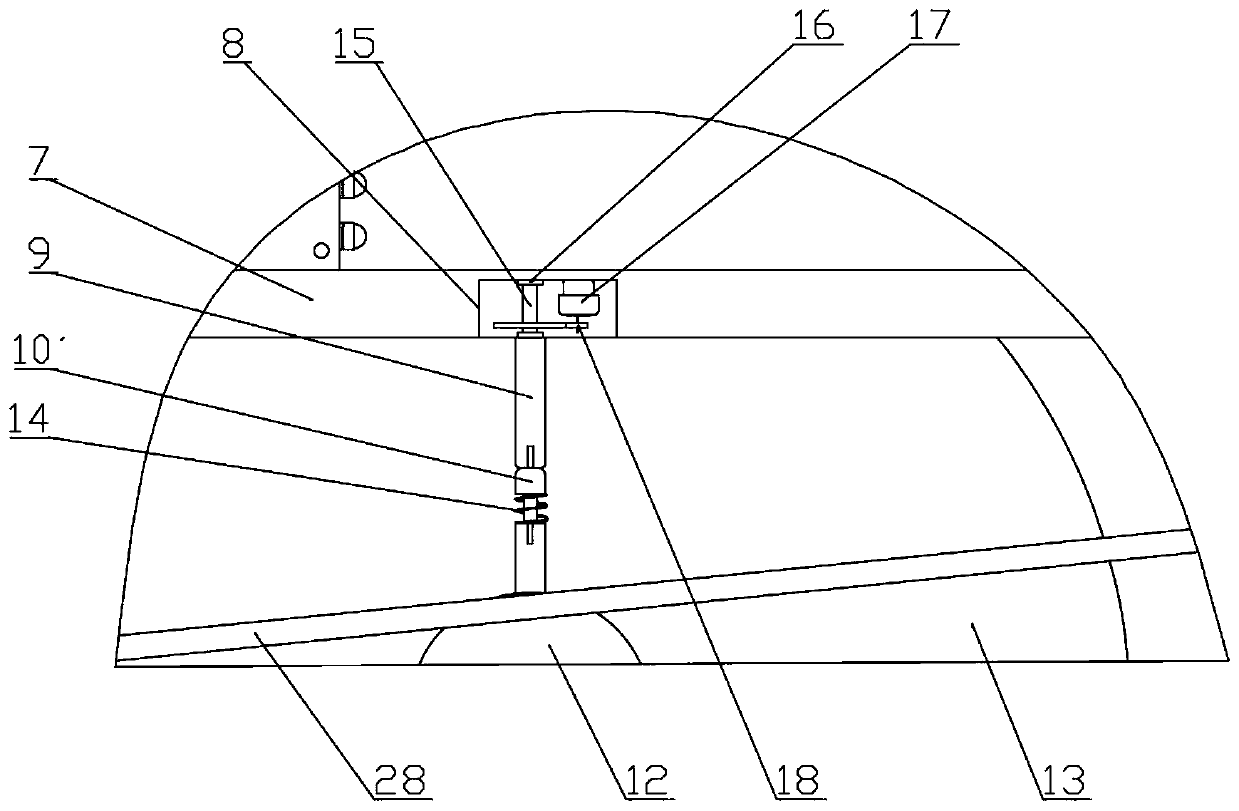

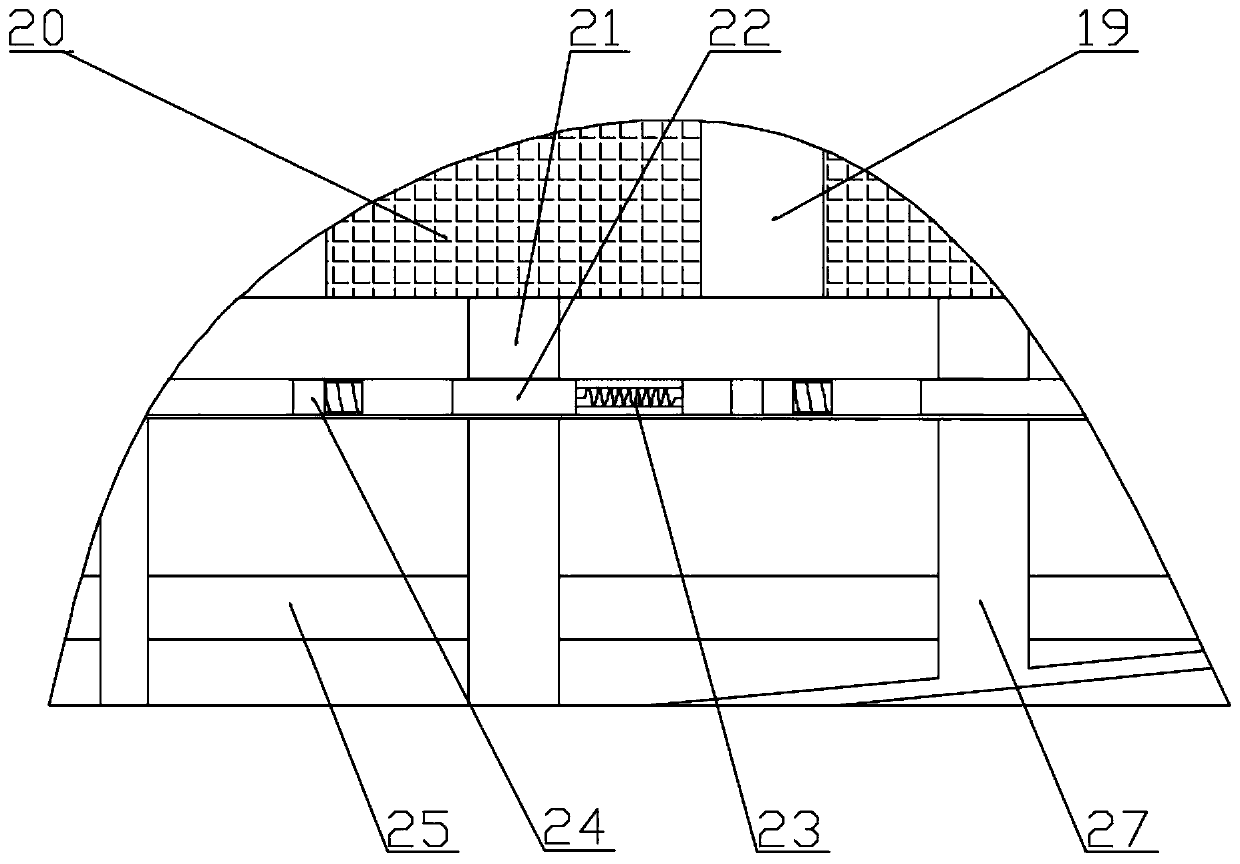

Fully-mechanical intelligent and automatic trough type compost turner with capacity of capacity of converting sludge into humus through biological fermentation

ActiveCN105503287ARealize intelligent automationReduce human inputBio-organic fraction processingClimate change adaptationElectricitySludge

The invention provides a fully-mechanical intelligent and automatic trough type compost turner with capacity of converting sludge into humus through biological fermentation. The fully-mechanical intelligent and automatic trough type compost turner with capacity of converting the sludge into the humus through biological fermentation comprises a travel trolley, a roller, a turned material conveying device, a travel drive detection unit, a roller drive detection unit and a fermentation parameter test and control unit, wherein the roller drive detection unit comprises a roller drive motor, an output end of the roller drive motor is connected with a roller shaft of the roller through a roller reducer, and the roller drive motor is used for driving the roller to rotate so as to turn materials in a fermentation trough; the fermentation parameter test and control unit is electrically connected with the travel drive detection unit and the roller drive detection unit and used for controlling output of a travel drive motor and the roller drive motor according to material resistance of the roller. The fully-mechanical intelligent and automatic trough type compost turner can realize automatic turning operation.

Owner:NANTONG ZHONGKE CHUNYUAN ENVIRONMENTAL PROTECTION EQUIP MFG CO LTD

Automatic hardware spraying process

InactiveCN104084360AReduced conversion timeRealize intelligent automationLiquid surface applicatorsSpraying apparatusElectric machineryDrive motor

The invention discloses an automatic hardware spraying process. The process includes that a revolution driving motor is started after a worker puts hardware on at a workstation A; when a to-be-sprayed product rotates to a workstation B along with a turntable, an autorotation driving motor is started after an electric eye sensor receives a signal; rotating shafts on the workstation B and a workstation C drive the product to rotate, and spraying guns are started to spray the product; the spraying guns are stopped after spraying is completed, the autorotation driving motor is stopped, and the revolution driving motor is started to enter a next working procedure. By the automatic hardware spraying process, production cost is lowered, and production efficiency is improved.

Owner:CHANGXING HUARUI MACHINERY EQUIP

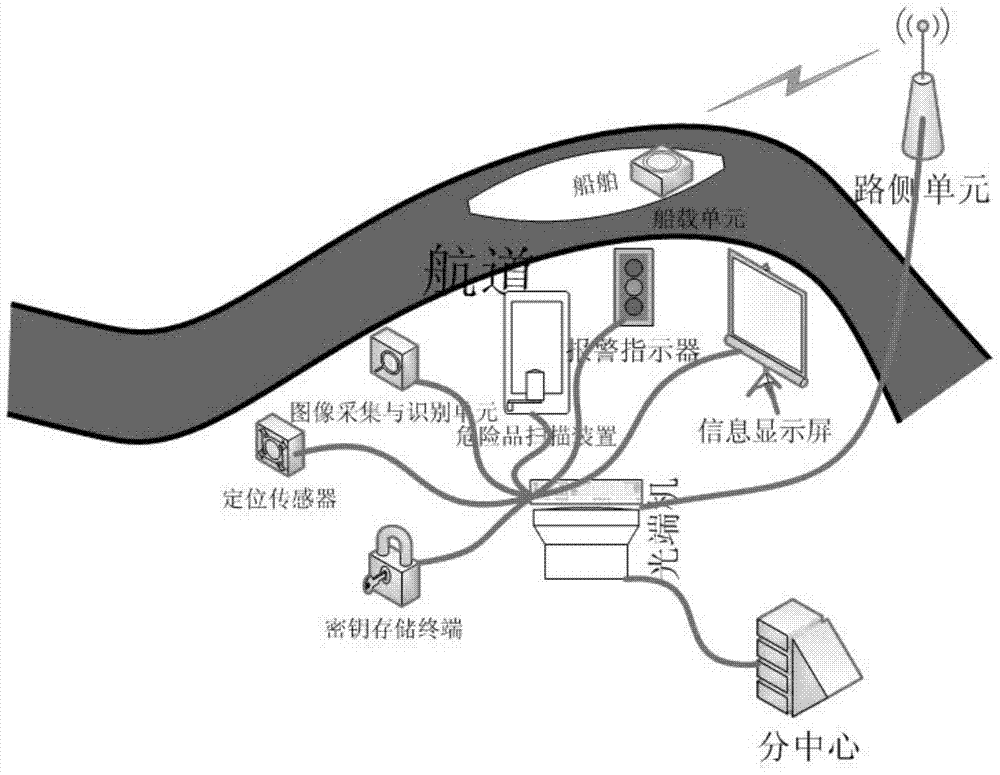

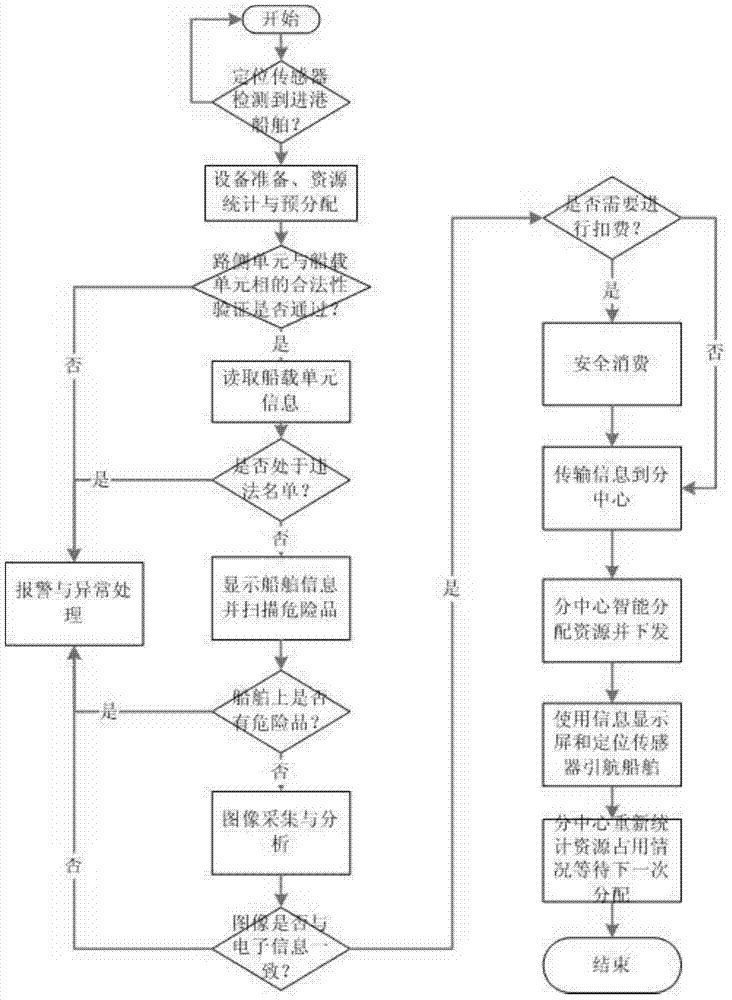

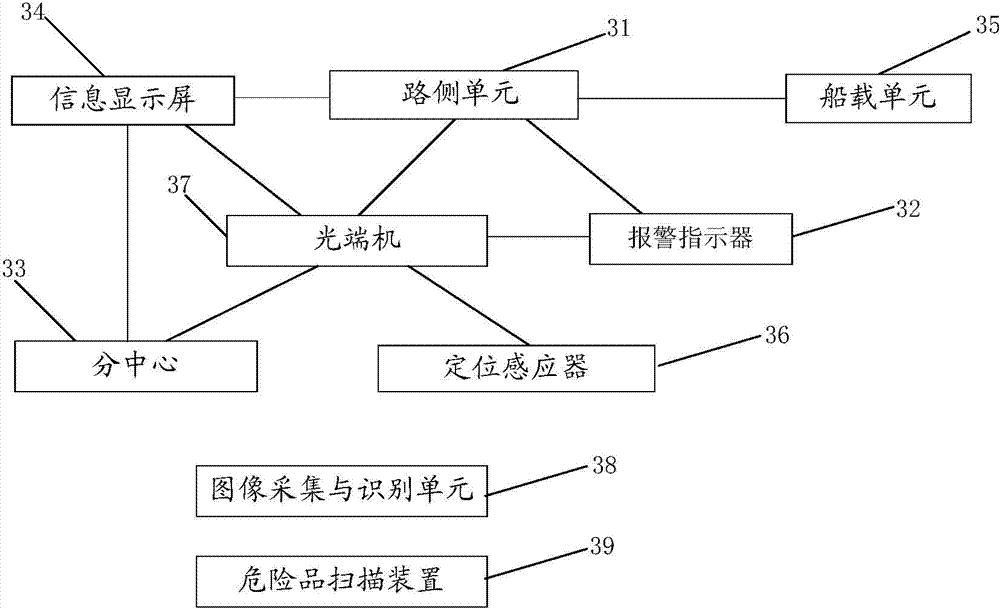

Intelligent port vessel management method and system

ActiveCN104517175AImprove operational efficiencyImprove resource utilizationResourcesLogisticsTransceiverOperational costs

An embodiment of the invention provides an intelligent port vessel management method and system. The method includes establishing an intelligent port vessel management system comprising a road side unit, an onboard unit, an optical transceiver, a positioning inductor, an information display screen and a branch center, and as the vessels enter the channel of the port, the positioning inductor induces the fact that the vessels enter the port; the positioning inductor sends a notification message that the vessels enter the port to the optical transceiver, and after receives the notification message, the optical transceiver notifies the road side unit and the onboard unit to perform two-way valid verification; after the two-way valid verification is passed, the branch center distributes port resources for the vessels. According to the arrangement, the DSRC (dedicated short range communication) technique and the intelligent management system are adopted to achieve the intelligent and automatic port vessel management, port running efficiency and port resource utilization rate are improved, running cost of the port is lowered, operation safety of the port is enhanced, the port resources are reasonably planned and the like.

Owner:AEROSPACE INFORMATION

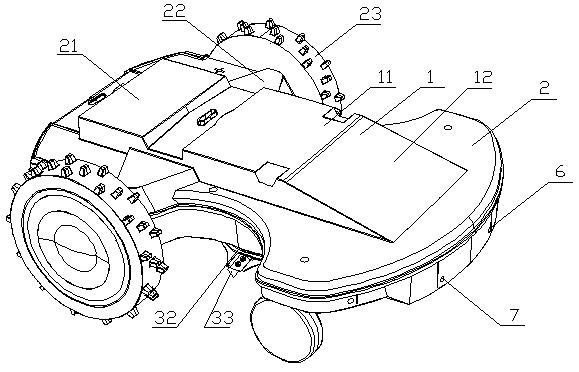

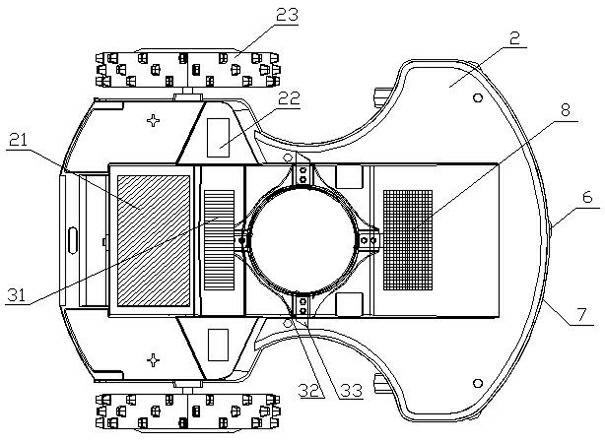

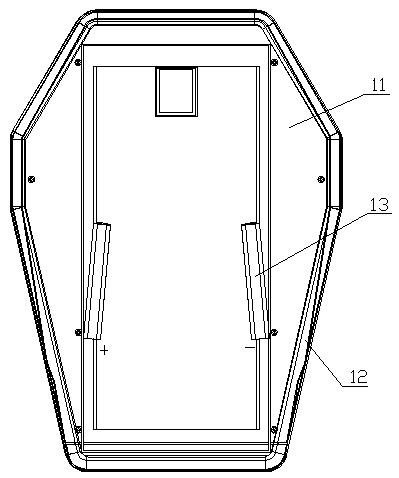

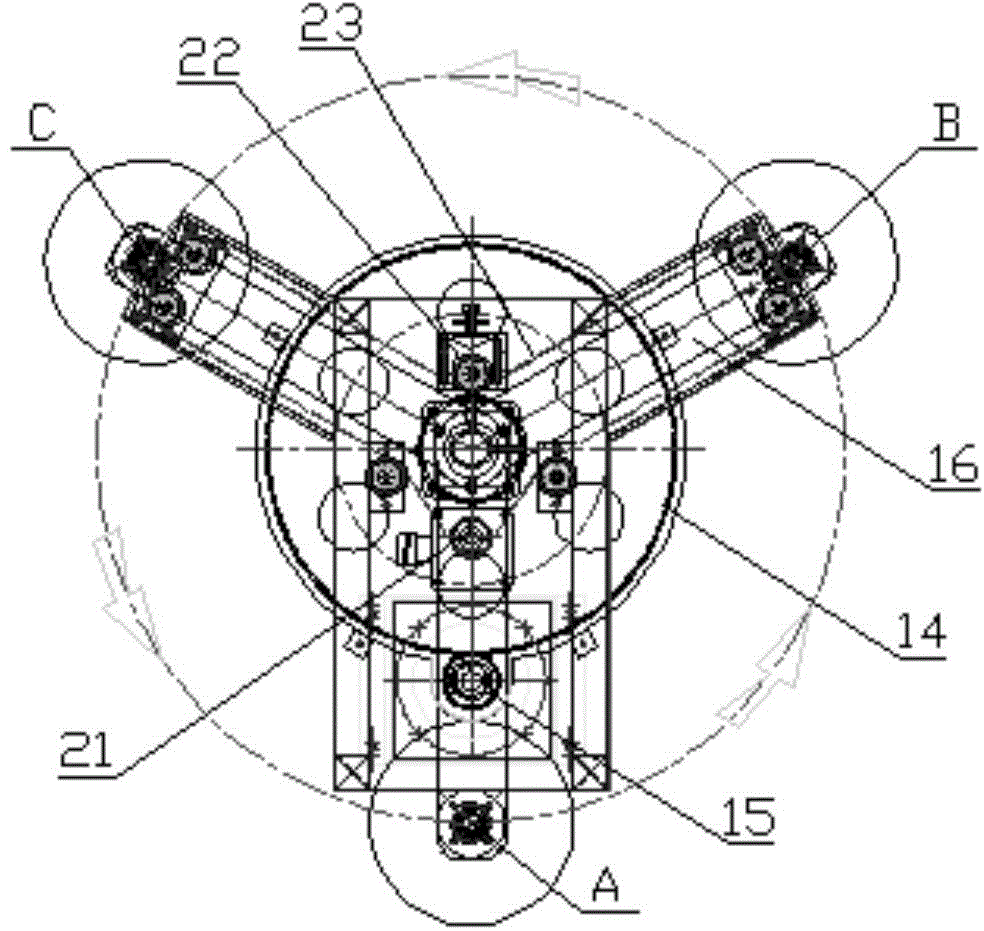

Solar intelligent mowing robot

InactiveCN102177785ALighter and smaller sizeSmall sizeMowersRenewable energy machinesControl systemSolar battery

The invention discloses a solar intelligent mowing robot, relating to the field of the application of robots. The solar intelligent mowing robot comprises a solar mechanism, a robot car body, as well as a mowing mechanism, a sensing device and a control system which are arranged in the robot car body, wherein the robot car body is provided with a car body upper cover; the solar mechanism comprises a solar panel, a solar battery array panel arranged on the solar panel, and a T-shaped bar arranged below the solar battery array panel; the top of the car body upper cover is provided with a metallic support; the metallic support is provided with a sliding chute; and the T-shaped bar is connected with the sliding chute in a matching way. In the invention, the mowing robot is supplied with power by solar energy, the intelligent automation of lawn care is realized, the working efficiency is improved, and the consumption of resources and the pollution of waste to environment are reduced.

Owner:ZHEJIANG UNIV

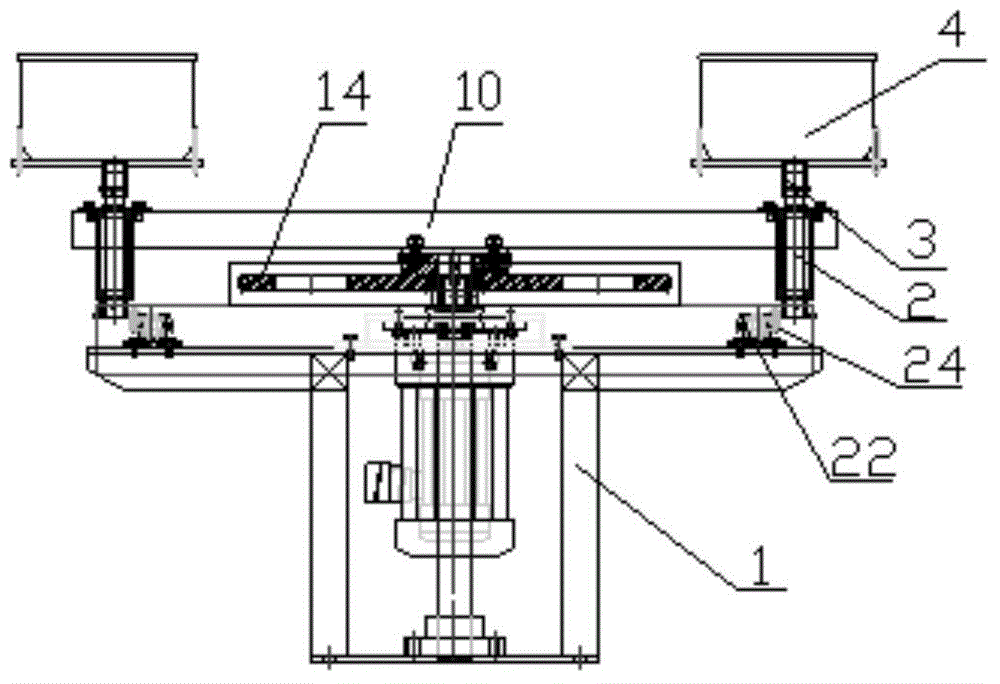

Automatic turntable for hardware spraying

InactiveCN104085651AReduced conversion timeRealize intelligent automationRotary conveyorsDrive motorEngineering

The invention discloses an automatic turntable for hardware spraying. The automatic turntable comprises a turntable frame. A turntable body is arranged upon the turntable frame. Positioning bearings are arranged on the upper portion and bottom portion of the turntable frame. A central shaft is arranged in the positioning bearings. A revolution gear which is arranged in the center of the turntable body is used for driving the same to rotate and fixed to the upper end of the central shaft. A revolution drive motor which is arranged on the turntable frame drives the revolution gear to rotate. A station A, a station B and a station C are circumferentially and uniformly formed on the turntable. Vertical rotary shafts are arranged on the stations. Product fixtures are arranged at the upper ends of the rotary shafts, and rotation chain wheels are arranged at the lower ends of the rotary shafts. A rotation drive motor which is mounted on the turntable drives the rotation chain wheels on the stations to rotate through a chain. By the automatic turntable, production cost is remarkably reduced, and production efficiency is improved.

Owner:CHANGXING HUARUI MACHINERY EQUIP

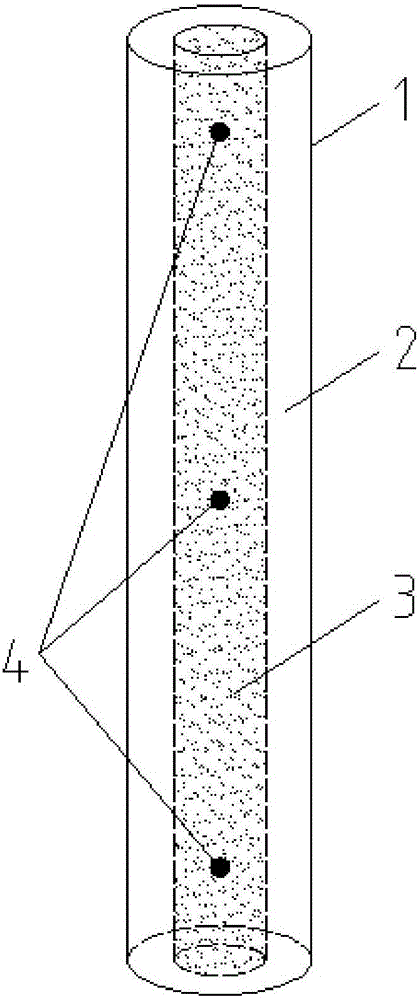

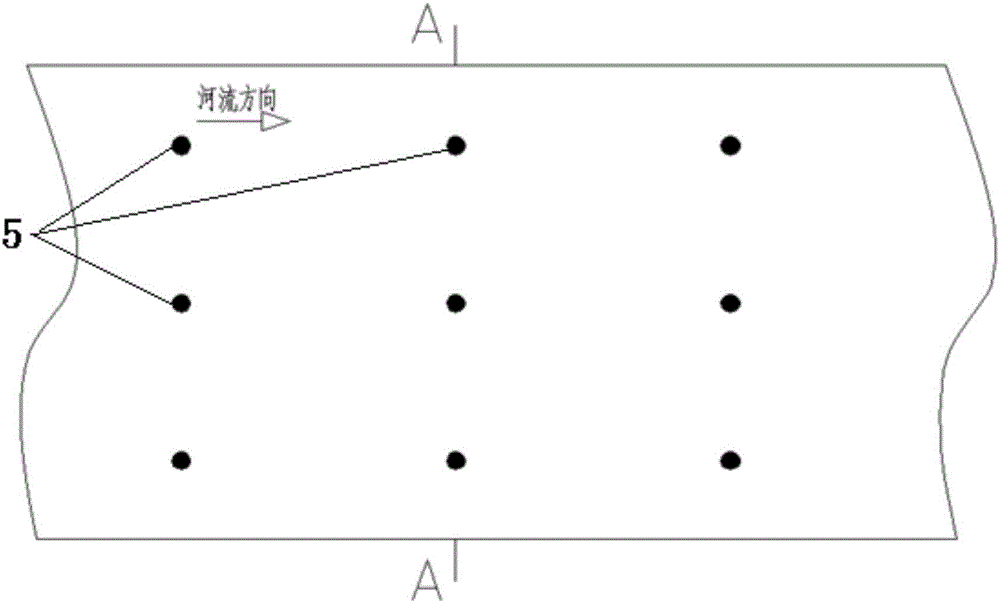

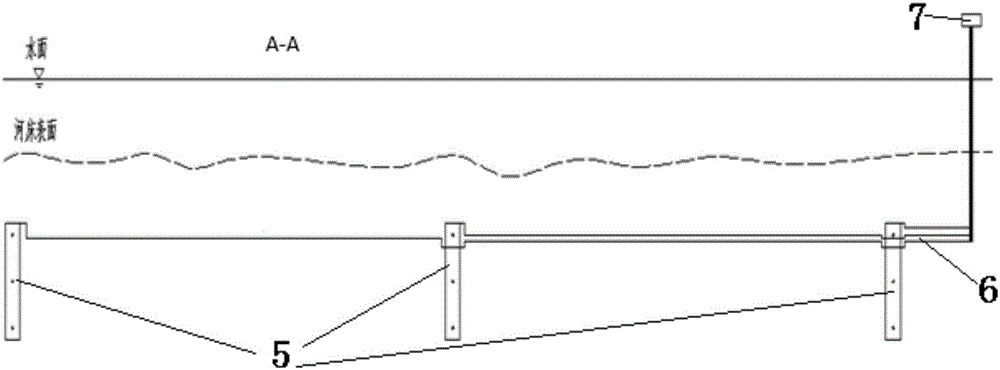

Intelligent river dredging guidance system

InactiveCN105113453ARealize intelligent automationEvaluation of dredging effectMeasurement devicesStream regulationGuidance systemRiver routing

The invention discloses an intelligent river dredging guidance system which can automatically acquire the river sediment deposit depth and the surface-ground water vertical underflow exchange rate to guide the river dredging operation and track and evaluate the river ecological characteristics. The intelligent river dredging guidance system is characterized in that lots of signal output terminals are in grid arrangement at a river sediment layer and are connected with an offshore signal receiving terminal through cable lines, corresponding programs are written according to temperature signals output by each signal output terminal and corresponding hydrothermal parameters to calculate the corresponding river deposit depth and vertical underflow exchange rate. The intelligent river dredging guidance system is wholly intelligent and automatic, can describe the river deposit conditions and the underflow exchange rate of surface water and ground water all the time to guide the river dredging operation, and not only breaks through the limitation of dredging according to experience at present, but also incorporates the underflow exchange concept of surface water and ground water into river ecological management, thereby being a precedent of river ecological management.

Owner:HOHAI UNIV

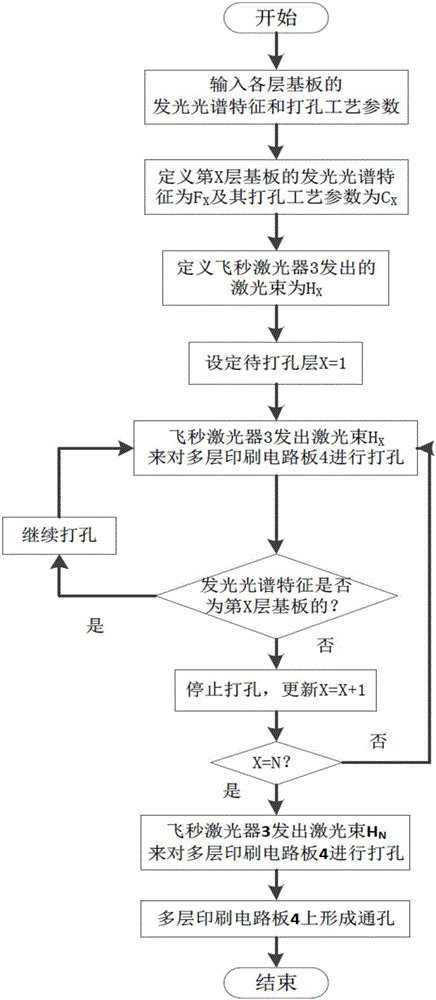

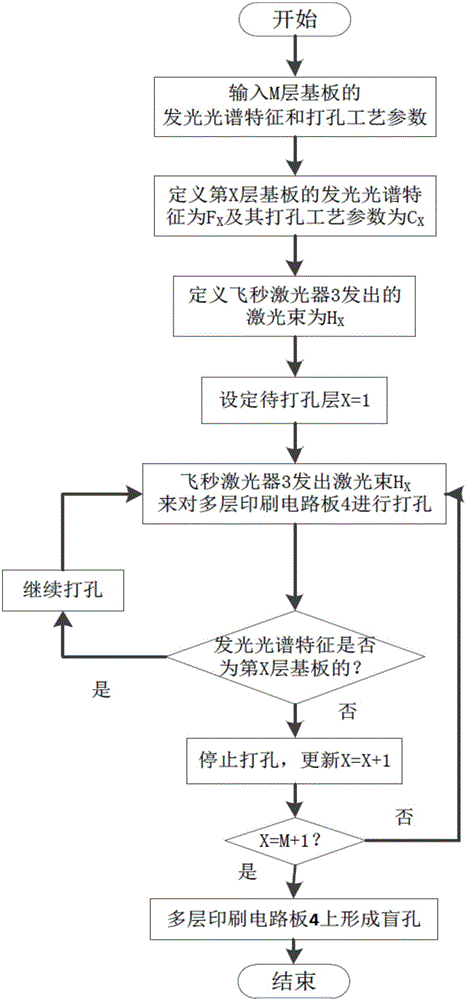

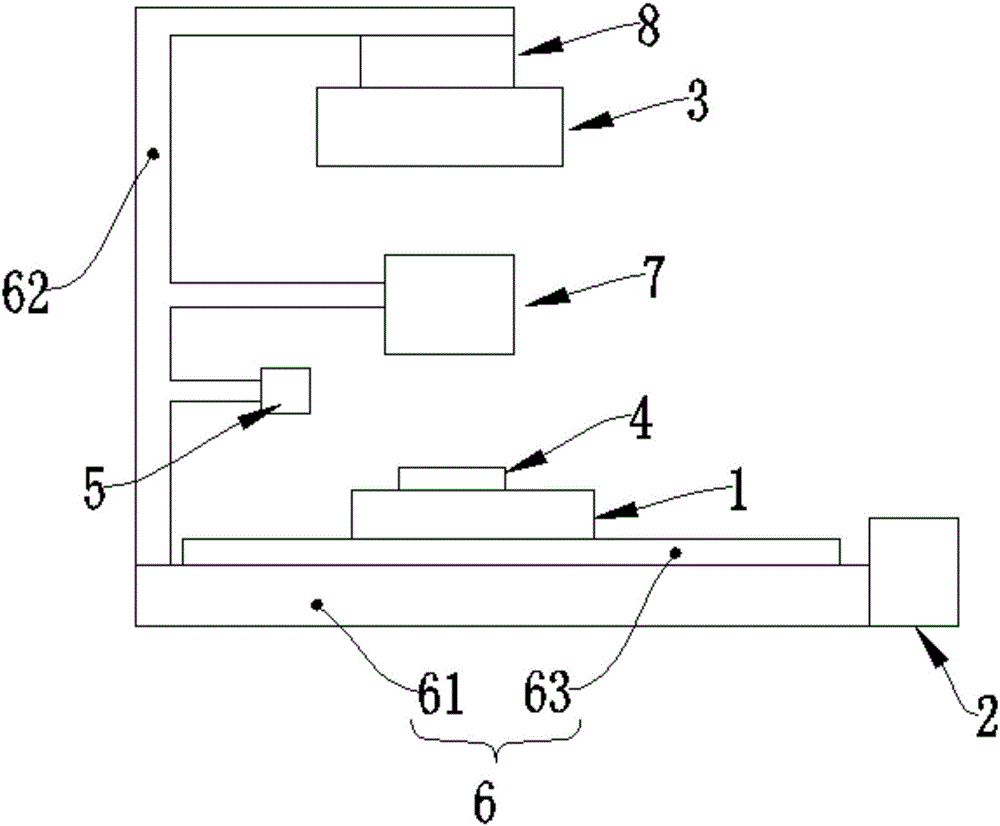

Laser punching method of multilayer printed circuit board and system using same

ActiveCN106695136AIncreased flexibility of useSwitch accuratelyPrinted circuitsMetal working apparatusPicosecond laserPunching

The invention discloses a laser punching method of a multilayer printed circuit board and a system using the same. The method comprises a process of punching a through hole in the multi-layer printed circuit board: (A1) the multilayer printed circuit board is placed on a punching worktable, a position to be punched of the multilayer printed circuit board is aligned to a femtosecond / picosecond laser, and the multi-layer printed circuit board is provided with N layers of substrates with different materials from top to bottom in the thickness direction; and the femtosecond / picosecond laser can output N laser beams with different wave lengths in a switching manner for correspondingly etching the N layers of substrates with different materials. The laser punching method of the multilayer printed circuit board comprises the process of punching the through hole in the multilayer printed circuit board and a process of punching a blind hole in the multilayer printed circuit board, realizes intelligent punching of the multilayer printed circuit board, intelligently identifies the punching layer number, automatically, quickly and accurately switches the femtosecond laser punching process parameters, is smooth in cross section of the machined through hole, and improves the punching quality and precision.

Owner:GUANGDONG UNIV OF TECH

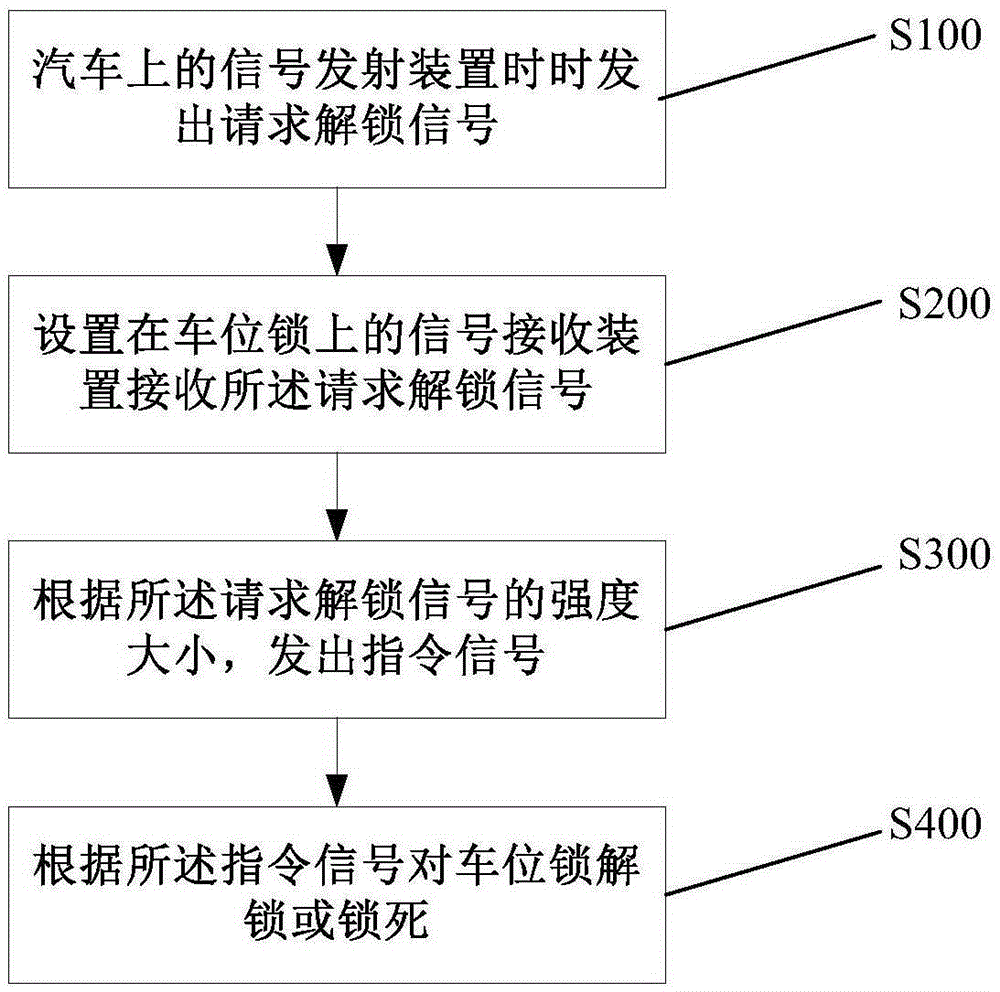

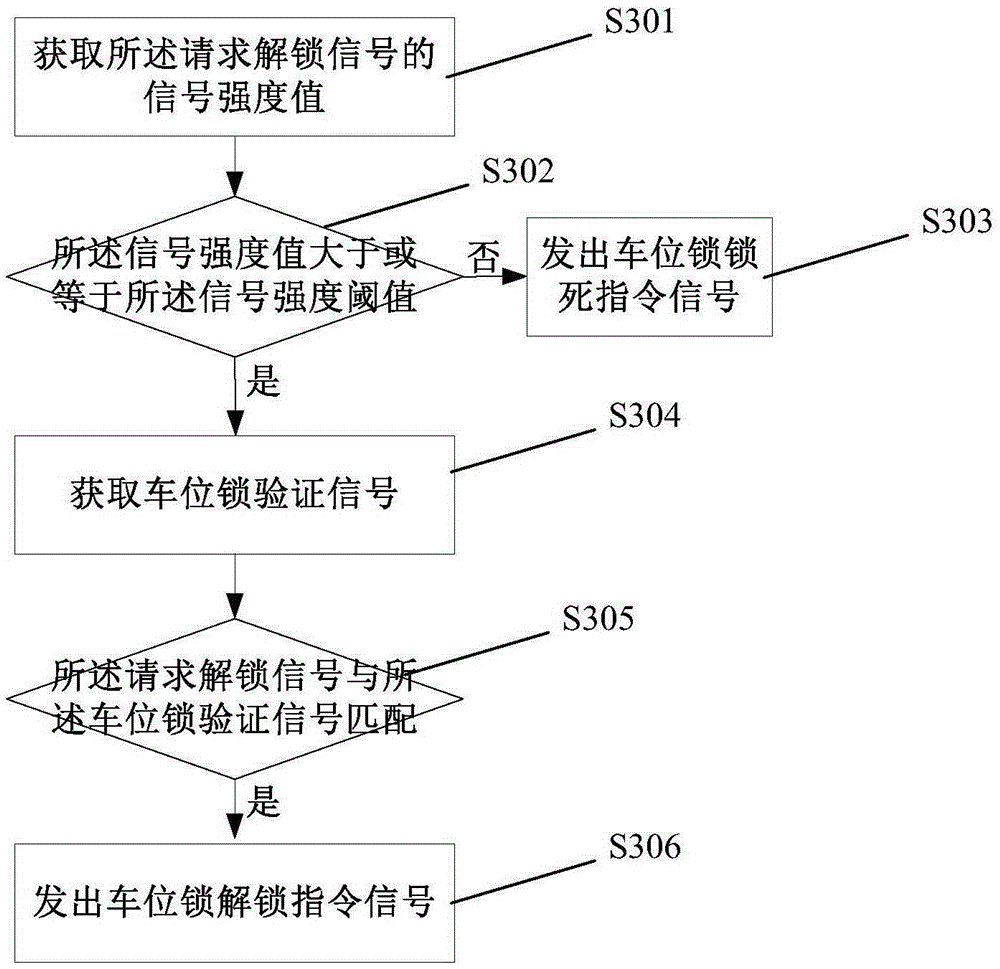

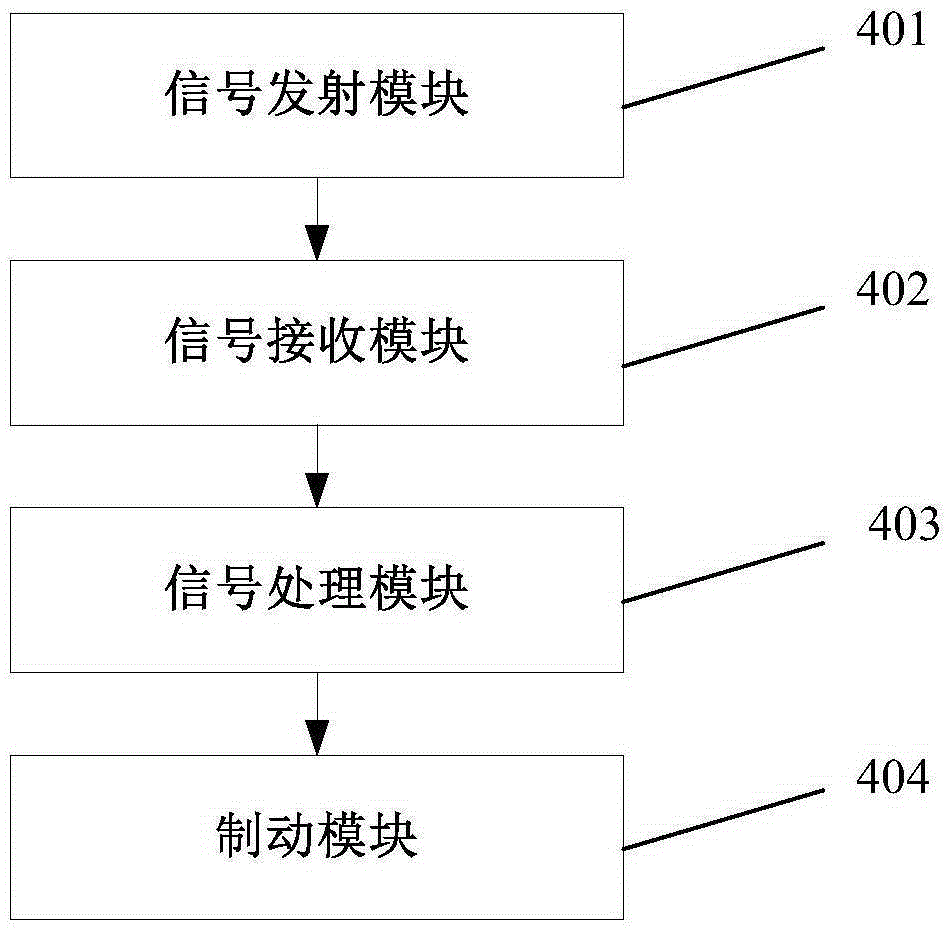

Method and system for intelligently controlling parking space locks

InactiveCN105257052ARealize intelligent automationProtected from being occupiedParkingsParking spaceReal-time computing

An embodiment of the invention discloses a method and system for intelligently controlling parking space locks. The method includes allowing signal emission devices on automobiles to constantly emit unlocking requesting signals; enabling signal receiving devices on the parking space locks to receive the unlocking requesting signals; emitting instruction signals according to the intensity of the unlocking requesting signals; unlocking or locking the parking space locks according to the instruction signals. The intensity of unlocking requesting signals which are emitted by the signal emission devices and are received by the signal receiving devices on parking spaces is increased along with decrease of the distances from the automobiles to the parking spaces, electric motors can drive rotation devices to unlock the parking space locks when the intensity of the unlocking requesting signals reaches a signal intensity threshold value, and the automobiles can run into the parking spaces. The intensity of the unlocking requesting signals which are received by the signal receiving devices on the parking space locks is decreased after the automobiles run away from the parking spaces, and the electric motors can drive the rotation devices to lock the parking space locks when the intensity of the unlocking requesting signals is lower than the signal intensity threshold value. The method and the system have the advantage that the parking space locks can be intelligently automated and can be more conveniently and quickly used.

Owner:张伟

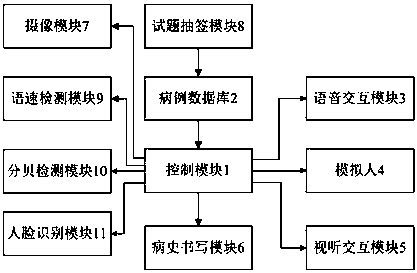

A standardized patient simulation system based on artificial intelligence for humanistic assessment

InactiveCN109147529ARealize intelligent automationEducational modelsElectrical appliancesPatient simulationTest question

The invention relates to a standardized patient simulation system based on artificial intelligence, which can realize humanistic examination, comprising: a control module; a voice interaction module which is connected with the control module and interacts with the examinees according to the test questions to simulate the interrogation scene; a simulated human, which connected with the control module, simulates the physical signs of the patient according to the examination questions, and is used for the physical examination of the examinee; an audio-visual interaction module, which is connectedwith the control module, according to the test questions to simulate the movement of the patient and the sound of various signs; and a humanistic assessment module which is connected with the controlmodule and collects the voice information and expression information of the examinees during the assessment, and sends the information to the control module to evaluate the interrogative attitude ofthe examinees. The invention can identify and understand the questioning of the examinee and feedback according to the data and information recorded in the case database. It can simulate the movementof virtual patient and the sound of every physical sign. It can replace the existing teaching mode of using real person as standardized patient; And according to the voice and expression of the realization of the intelligent humanities assessment.

Owner:SHANGHAI GEMMA MEDICAL SCI & TECH CO LTD

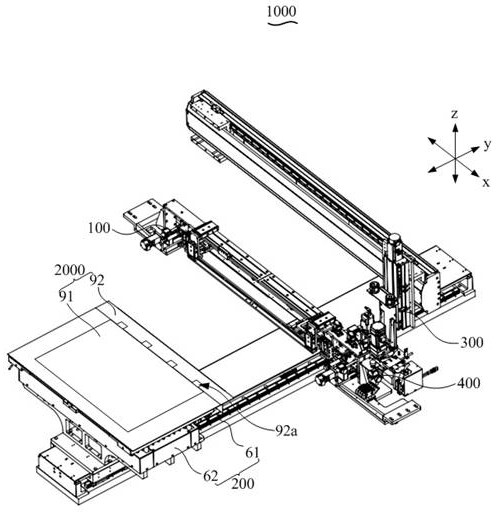

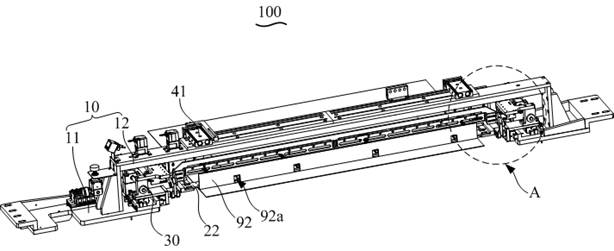

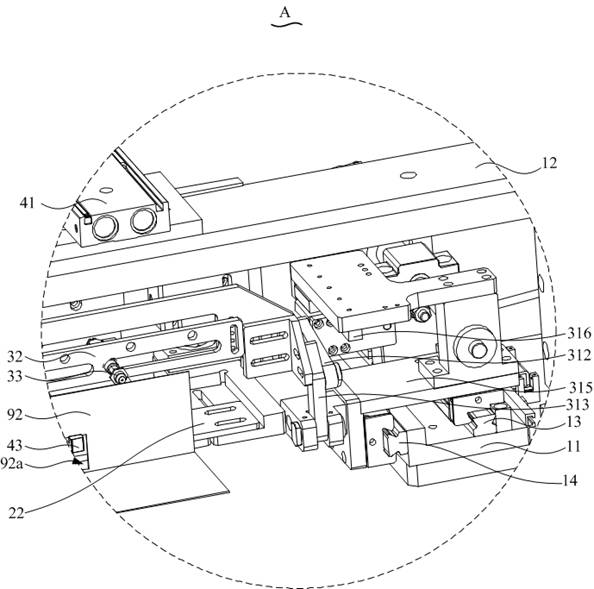

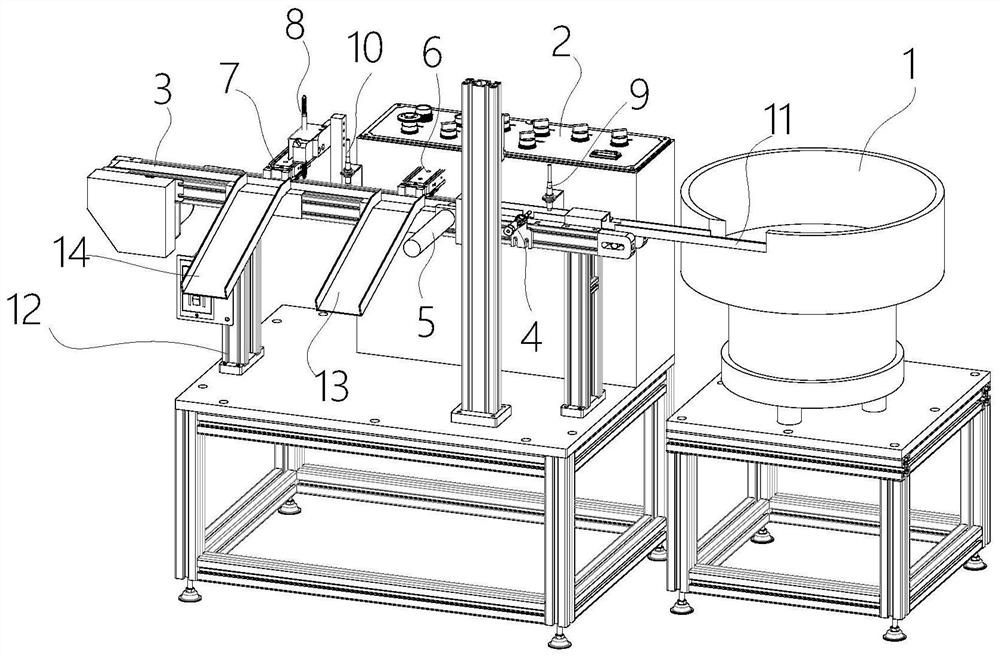

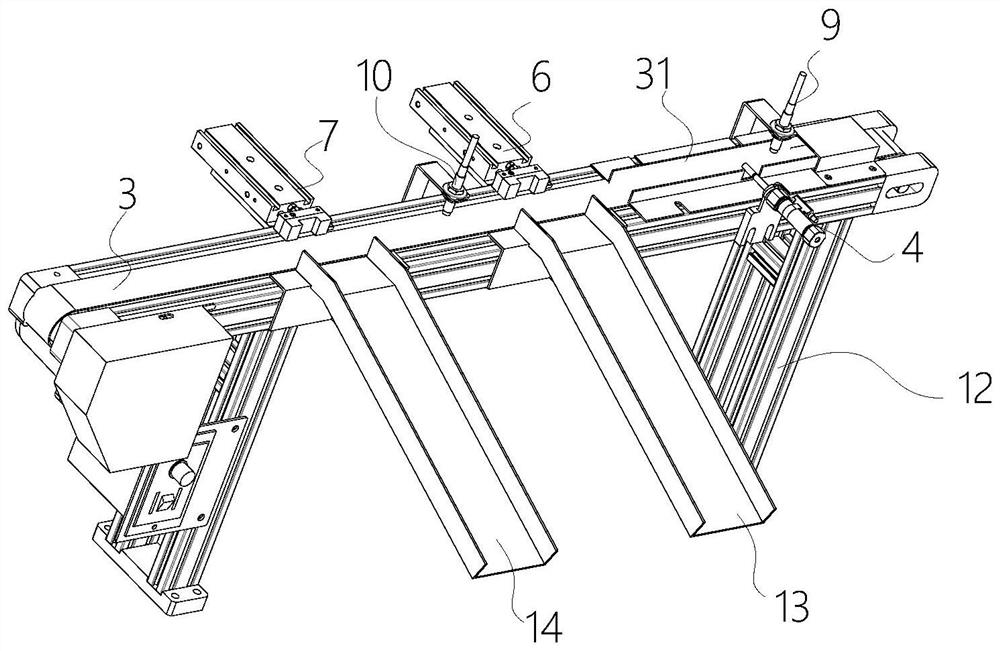

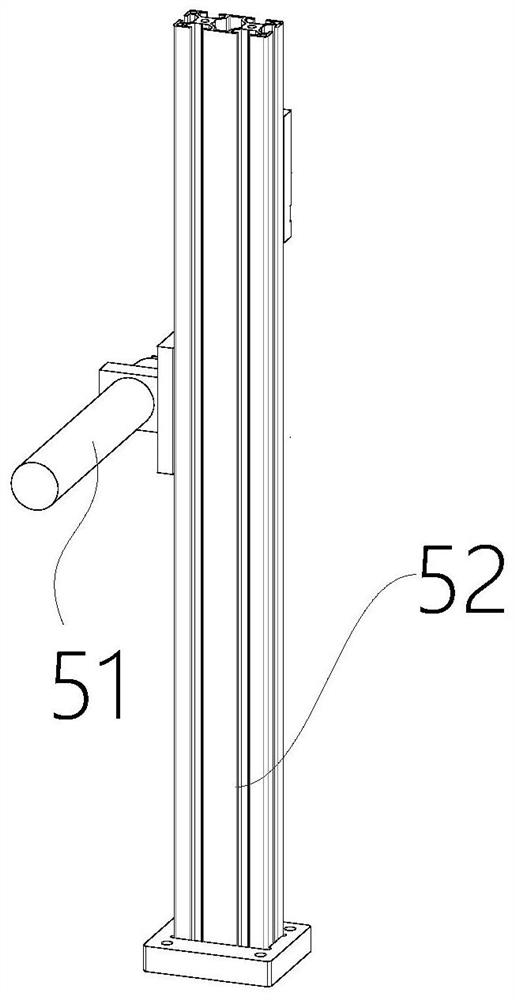

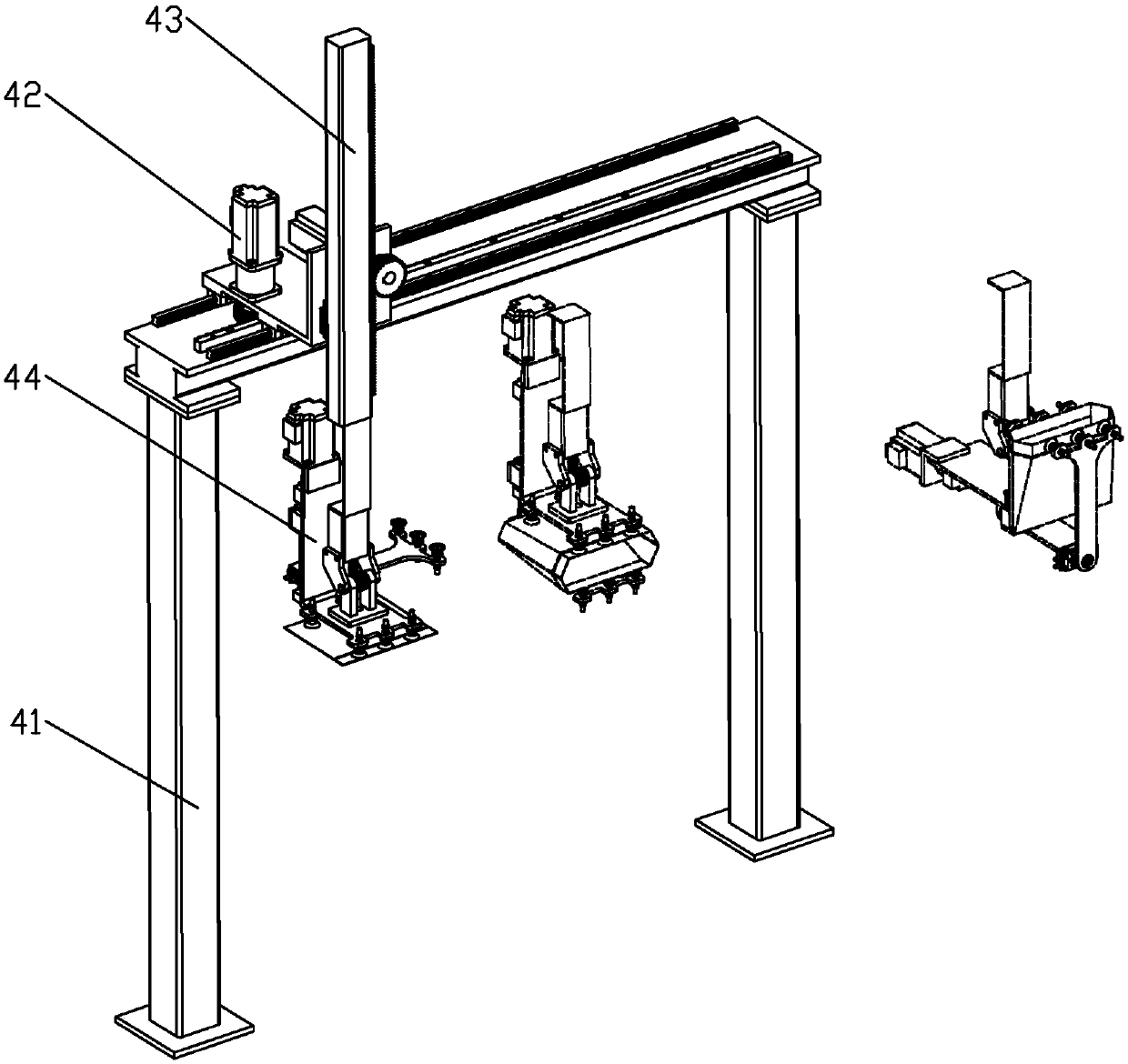

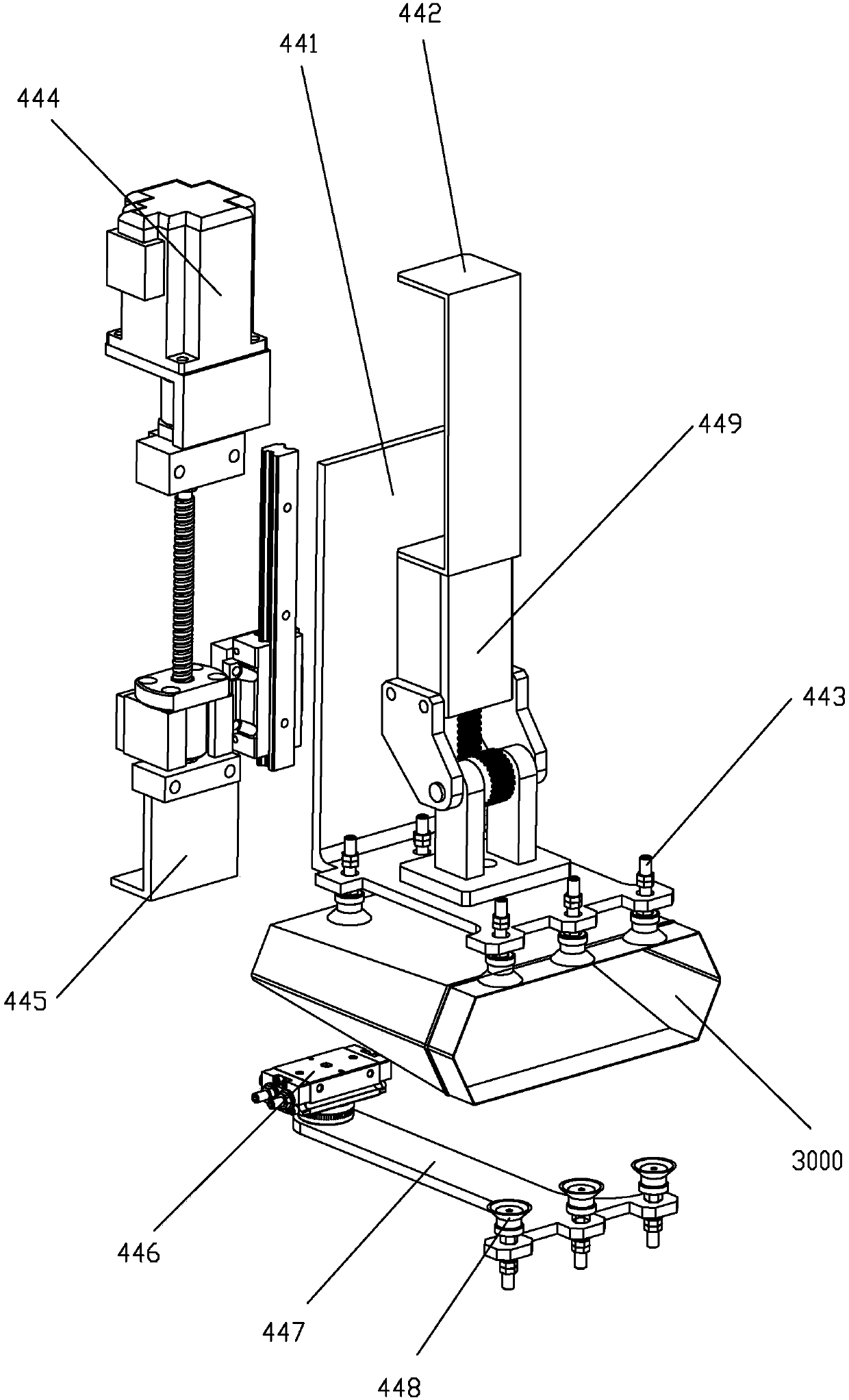

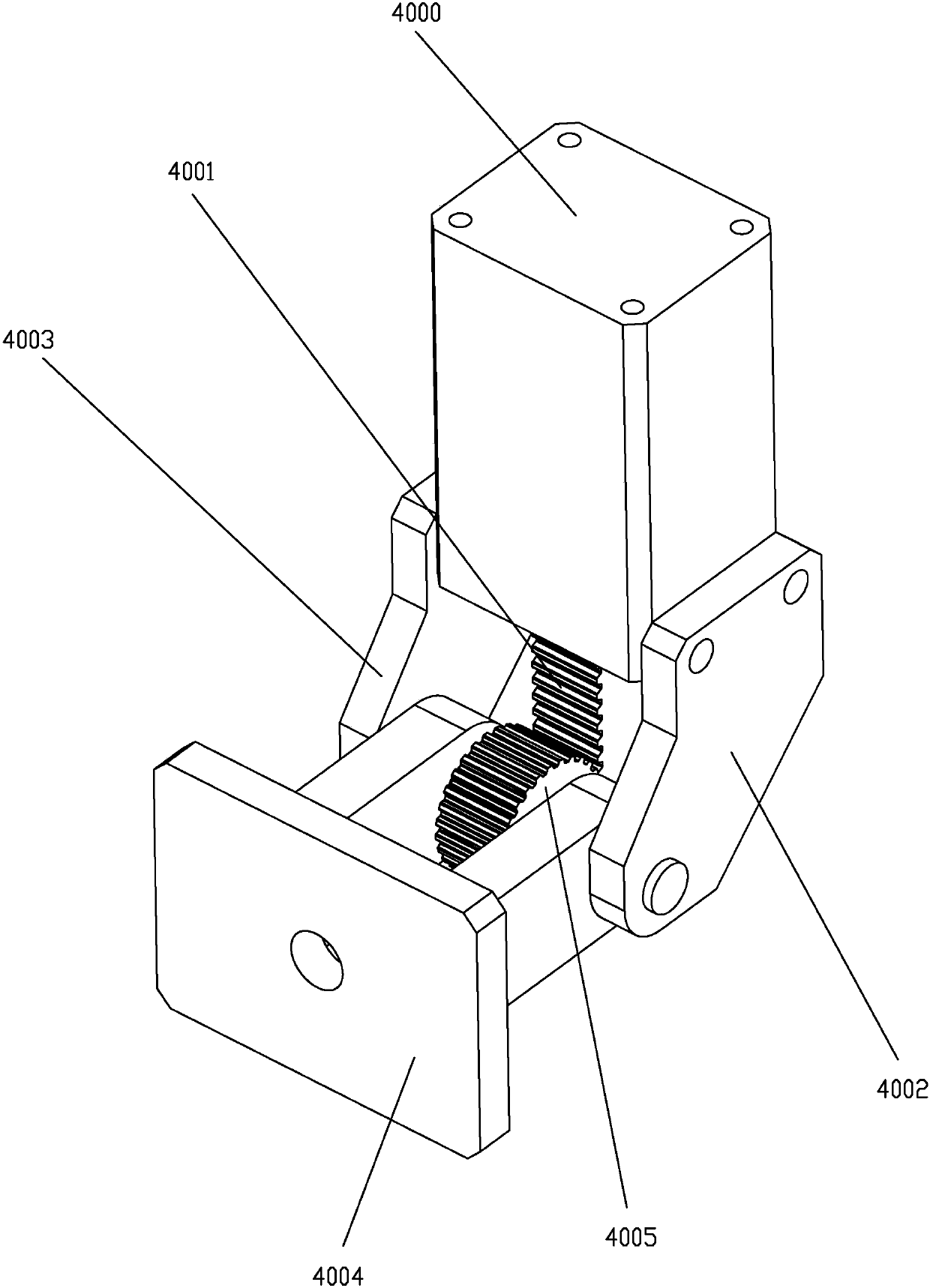

Cloud-based PCB folding device

ActiveCN114401587AImprove folding efficiencyHigh precisionPCB positioning during processingStructural engineeringMechanical engineering

The invention discloses a cloud-based PCB turnover device, the cloud-based PCB turnover device comprises a turnover mechanism, a controller and a cloud server, the controller is electrically connected with the turnover mechanism and is in signal connection with the cloud server, and the cloud server is used for monitoring the controller and controlling the turnover mechanism to turn over the turnover mechanism. The folding mechanism comprises a mounting frame, a positioning assembly, a pressing assembly, an adjusting adsorption assembly and a bending assembly, and a folding station used for placing a to-be-folded product is formed on the mounting frame; the positioning assembly is used for shooting and positioning a to-be-folded product; the downward pressing assembly is connected with the mounting frame and can move towards or away from the folding station so as to press the back plate; the adjusting adsorption assembly can drive the PCB to move so that an included angle can be formed between the hole diameter direction of the inserting hole and the placing plane of the product to be turned over. And the bending assembly can pass through the jack to abut against the board surface of the PCB and drive the PCB to be folded towards the direction of the back board. The PCB folding equipment based on the cloud end provided by the invention is high in folding precision.

Owner:SHENZHEN YUANSHUO AUTOMATION TECH

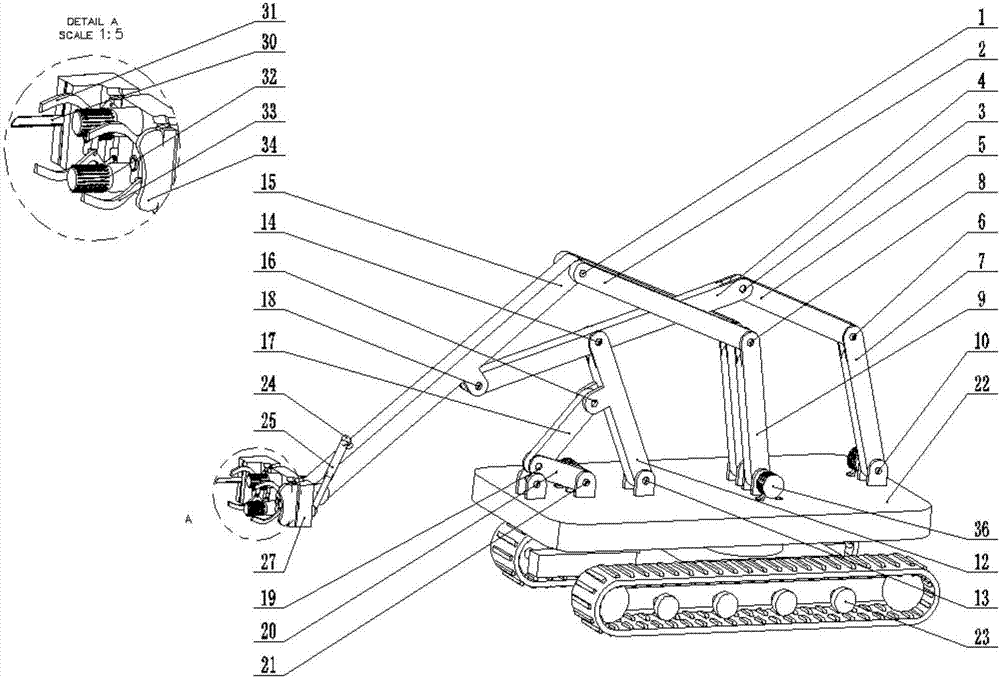

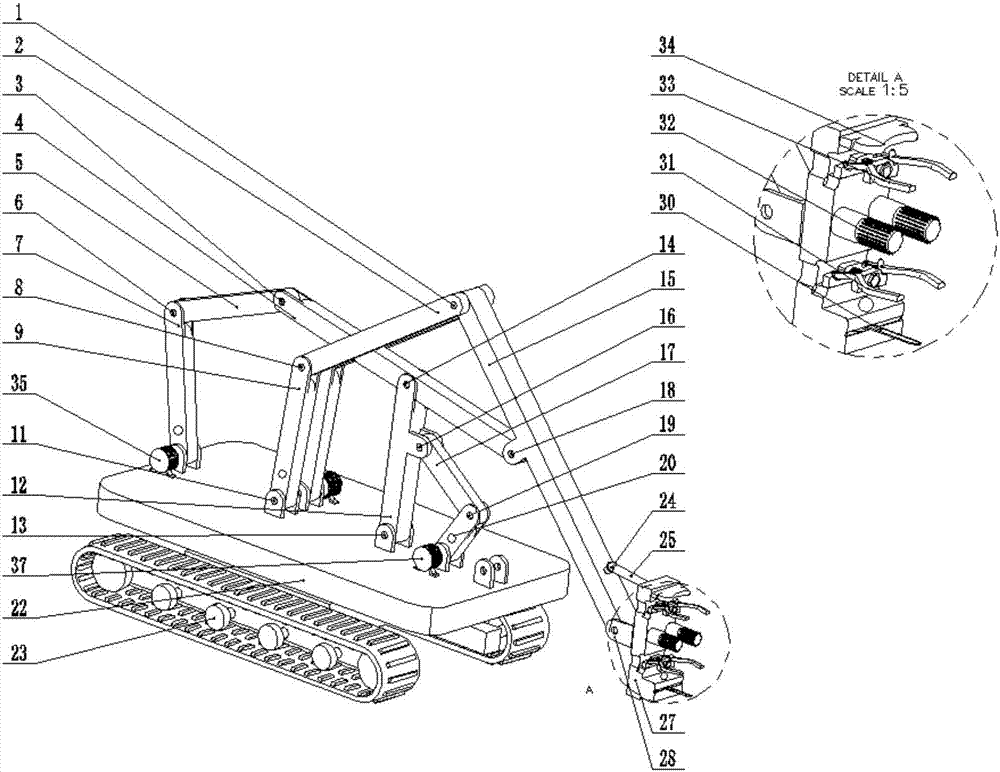

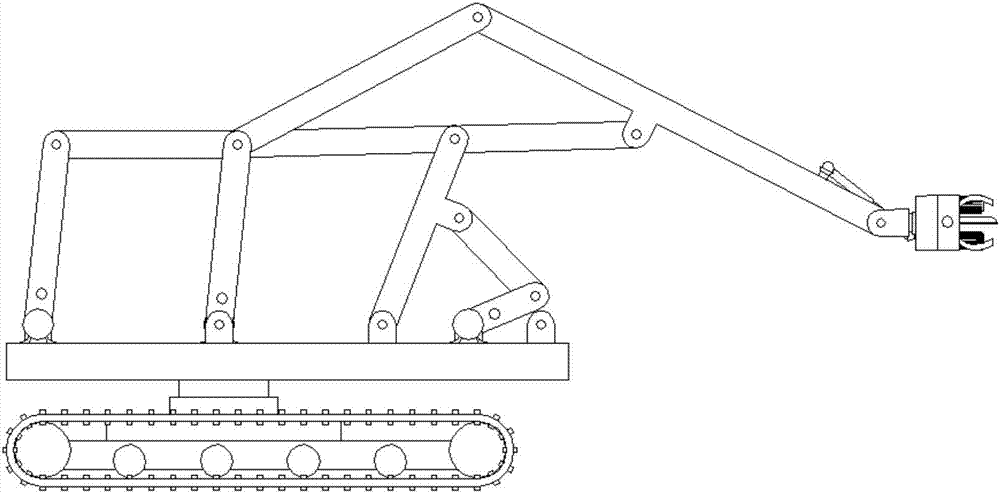

Automatic large-space two-structure-state metamorphic tree pruning and lumbering robot

InactiveCN106965149AAchieve acquisitionRealize processingProgramme-controlled manipulatorCuttersHydraulic cylinderDrive motor

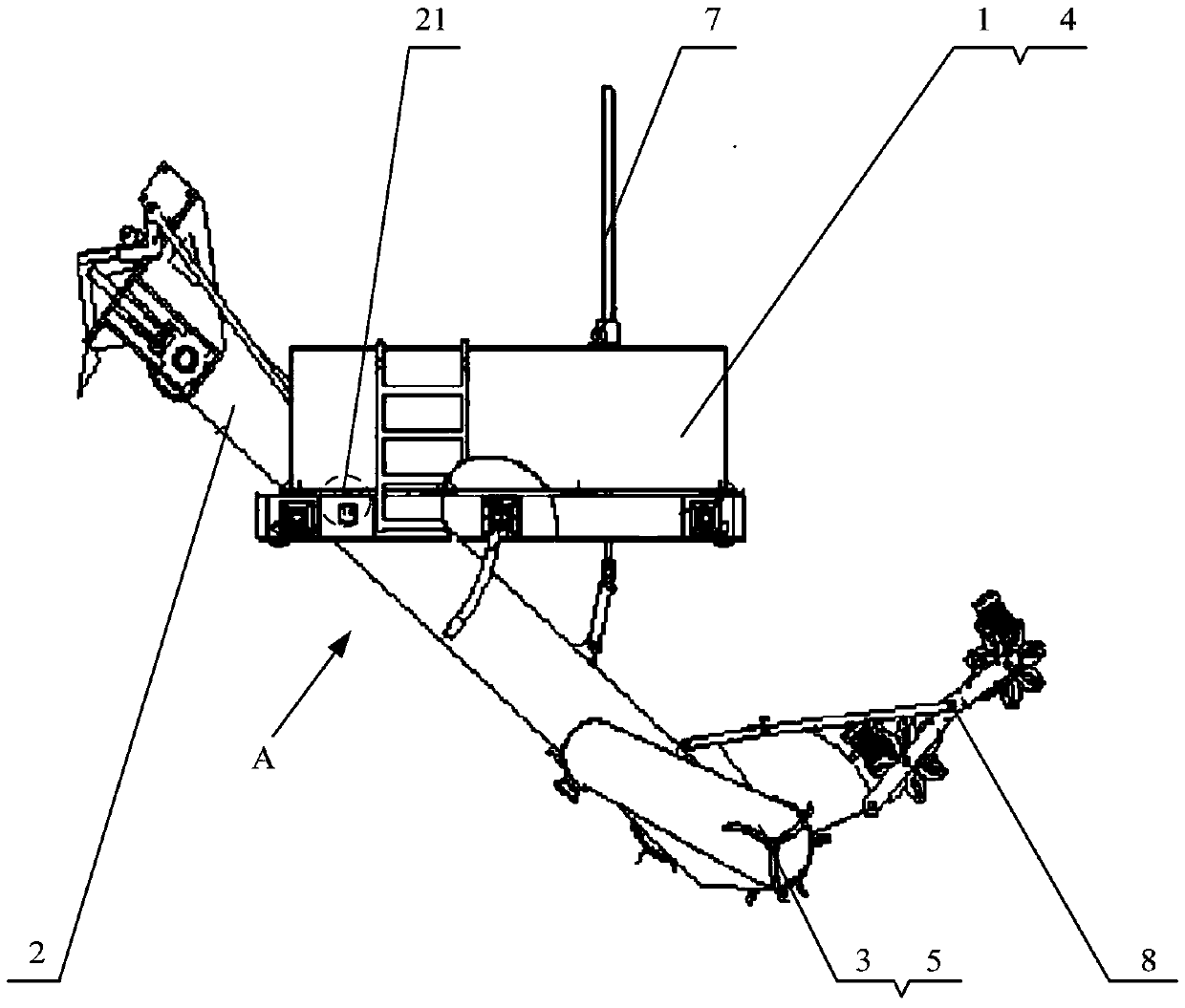

The invention discloses an automatic large-space two-structure-state metamorphic tree pruning and lumbering robot. The robot comprises sensors, a driving motor, a travelling device, a machine frame, a link mechanism, a hinge, a hydraulic cylinder, a hooke joint and a lumbering combination mechanism. The sensors are composed of three angular displacement sensors, one range sensor and one displacement sensor and are arranged at different positions of an actuating arm and the lumbering combination mechanism, so that automatic information acquiring, processing, storage and output are implemented, and digital and intelligent automation operation with the functions of tree pruning, trimming, lumbering and fixed-size timber cutting is realized. The automatic large-space two-structure-state metamorphic tree pruning and lumbering robot has the outstanding advantages of being automatic, intelligent, large in working space, high in dynamic stability, low in manufacturing cost and diversified in function.

Owner:GUANGXI UNIV

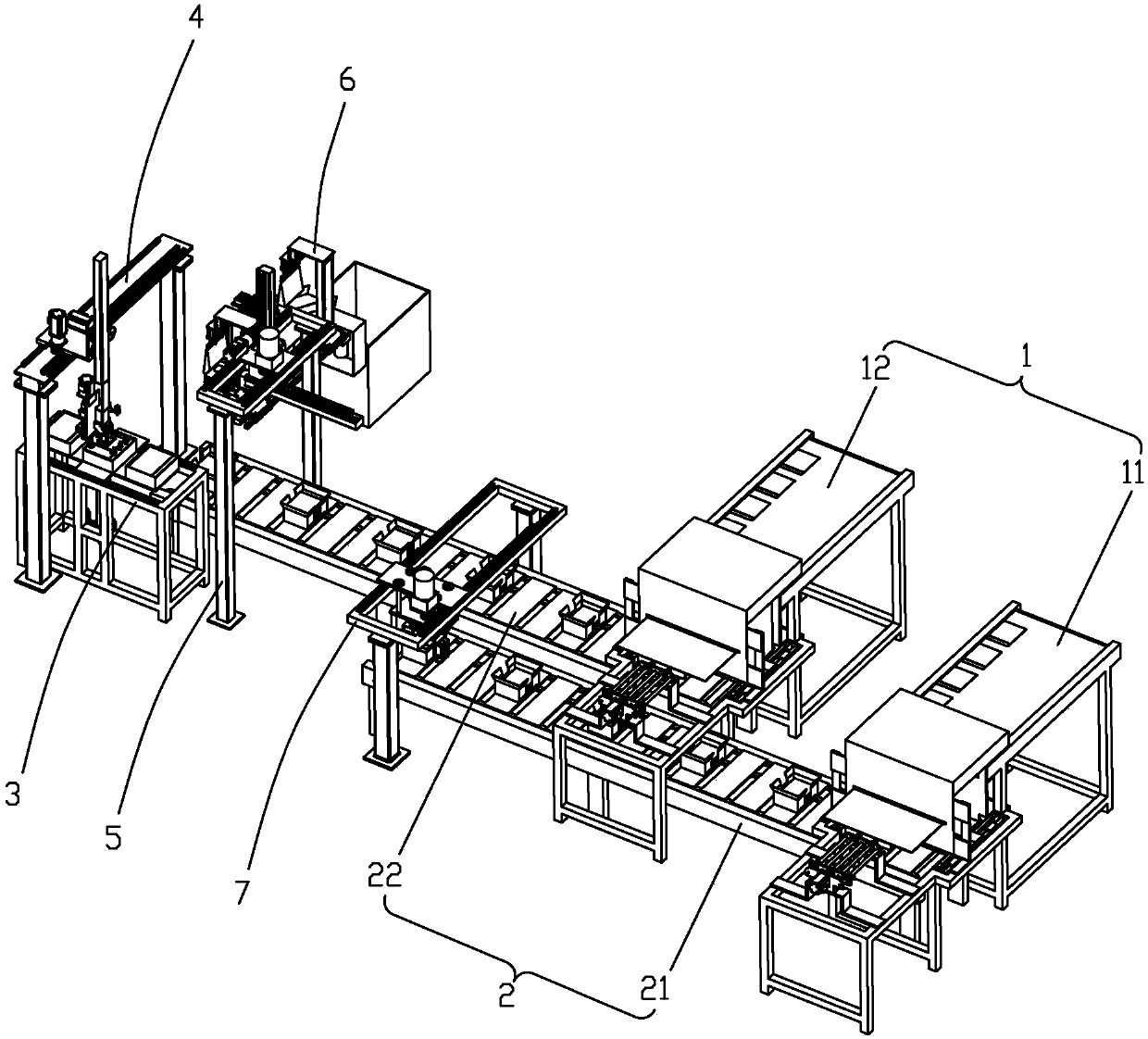

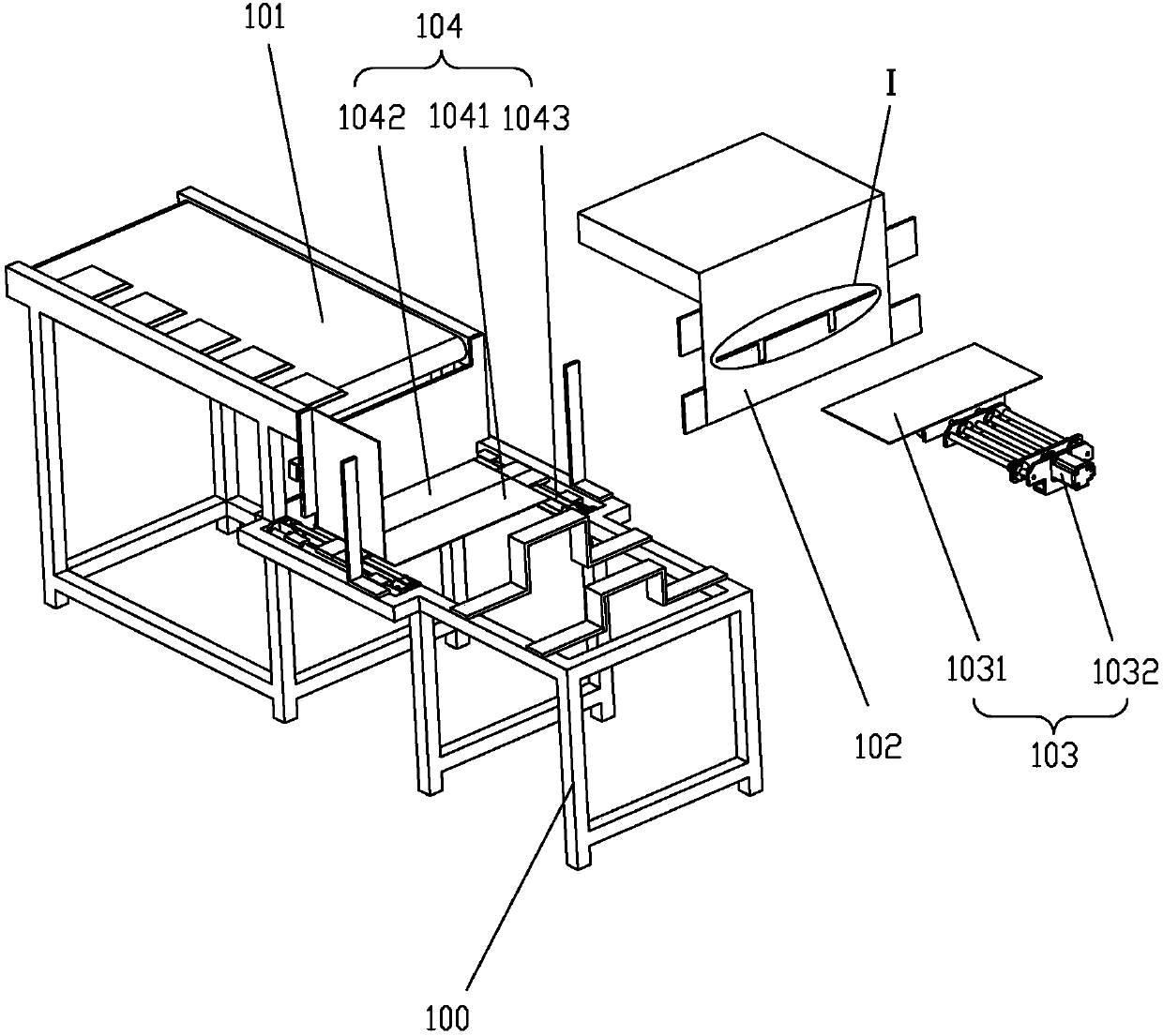

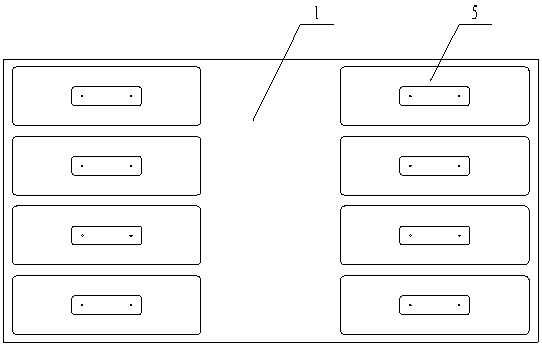

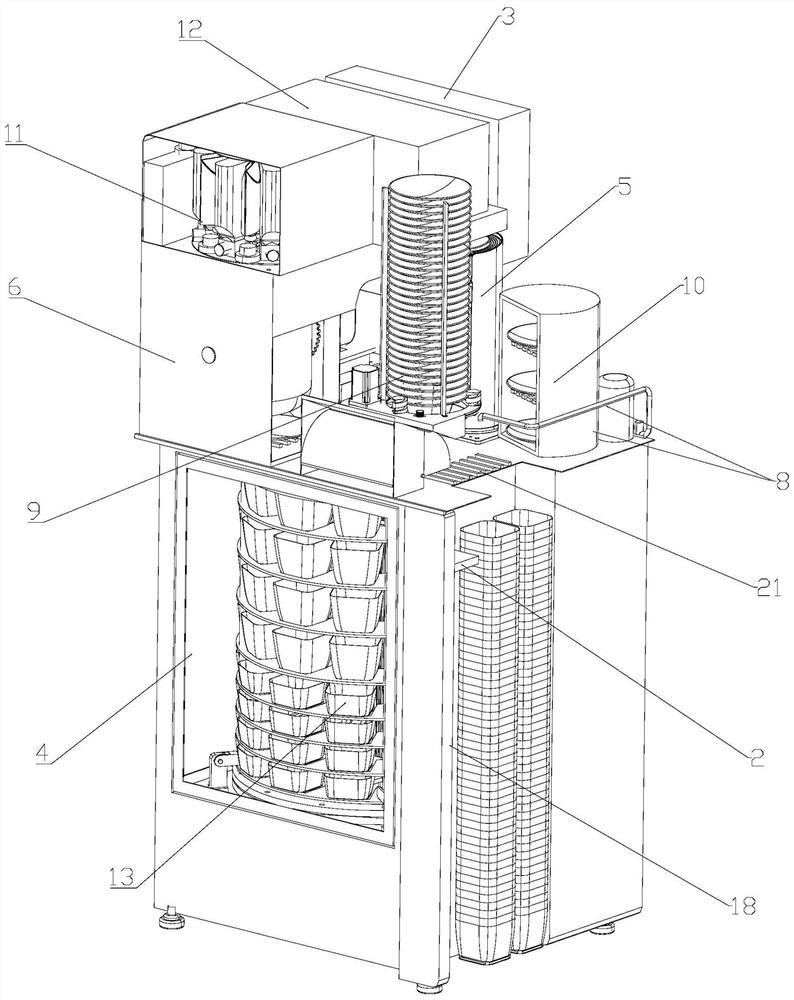

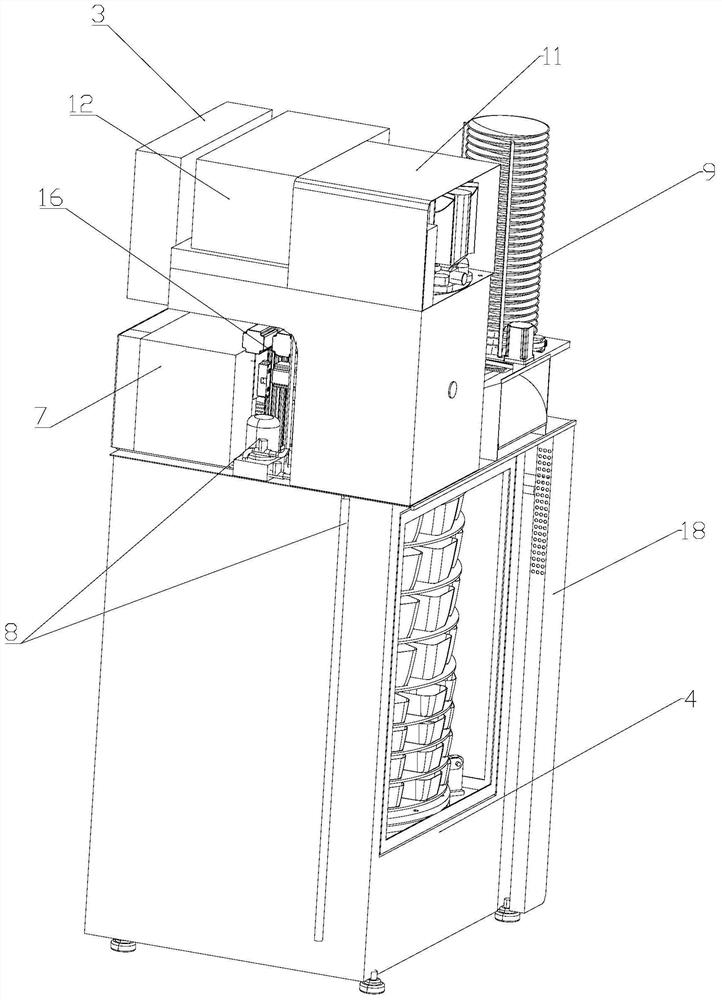

Automatic split charging packaging production line for packaging bags

ActiveCN107804536AShorten the timeReduce manufacturing costWrapper twisting/gatheringIndividual articlesProduction lineEngineering

The invention discloses an automatic split charging packaging production line for packaging bags. The production line comprises a packaging bag stack dividing device, a packaging bag conveying devicearranged on the lower side of the packaging bag stack dividing device, a main bag carrying and putting device arranged on the left front side of the packaging bag conveying device, a main bag grabbingand opening dismantling device arranged on the upper left side of the main bag carrying and putting device in a crossing manner, a packaging bag taking, putting and containing device on the upper left side of the packaging bag conveying device in a crossing manner, and a main bag packaging and unloading device arranged between the main bag grabbing and opening dismantling device and the packagingbag taking, putting and containing device and located on the rear left side of the packaging bag conveying device. According to the production line, the production line has the prominent advantages that automatic packaging bag arranging, conveying, clamping and packaging are integrated, intelligent and automatic packaging bag split charging is achieved, labor intensity is greatly reduced, production efficiency is improved to the great extent, the problems that due to the manual factor, the randomness is large, and bagging is in disorder are solved, normalized and standard production is facilitated, and production cost and management cost are greatly reduced.

Owner:中山市器美机器人科技有限公司

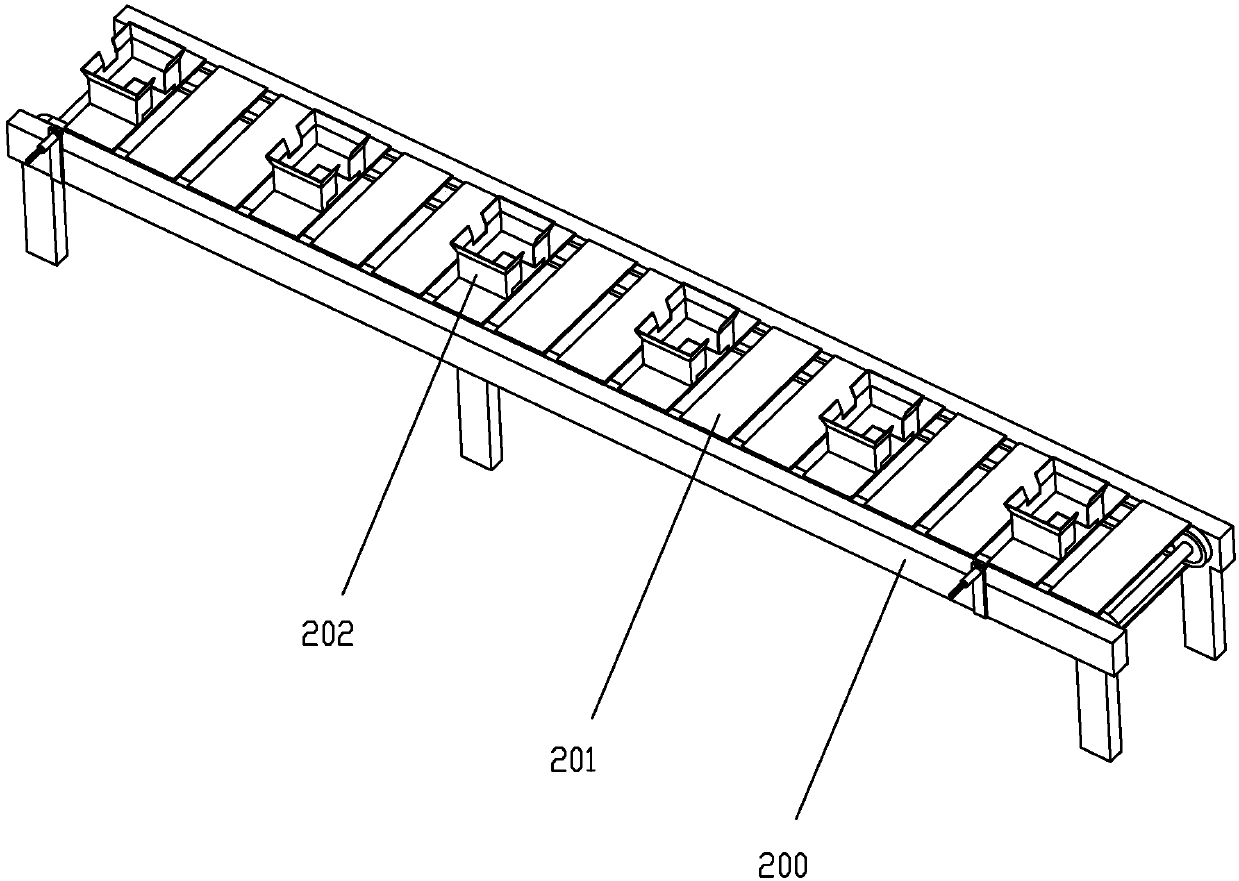

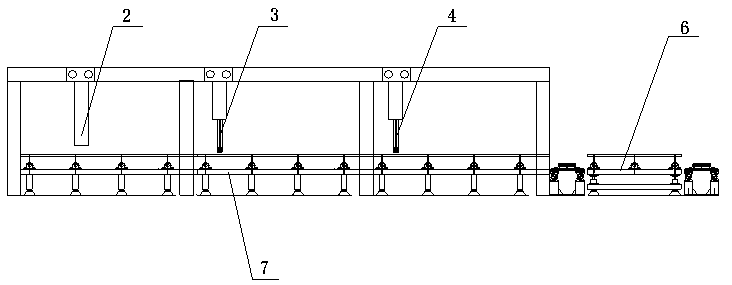

Automatic cleaning device and method for precast mold of CRTSI type double-block sleeper

PendingCN108772942AAutomate cleaningAvoid bodily harmDrying gas arrangementsAuxillary shaping apparatusProduction lineEngineering

The invention belongs to the technical field of sleeper prefabricating of a high-speed railway double-block type ballastless track, and particularly relates to an automatic cleaning device and methodfor a precast mold of a CRTSI type double-block sleeper. The automatic cleaning device comprises a roller conveying device, a drying station, a primary cleaning station, a secondary cleaning station and a cleaning inspection station, wherein the drying device, the primary cleaning station, the secondary cleaning station and the cleaning inspection station are sequentially arranged, and the rollerconveying device is arranged below the drying device, the primary cleaning station, the secondary cleaning station and the cleaning inspection station. Through the automatic cleaning method for the sleeper mold in the production and manufacture processes of the high-speed railway CRTSI type double-block sleeper, automatic cleaning of the sleeper mold in a production line can be realized, the intelligent and automatic mold cleaning is realized, the body injury of workers is avoided, the labor intensity of the workers is reduced, and the construction efficiency is greatly improved.

Owner:CHINA RAILWAY NO 3 GRP CO LTD +2

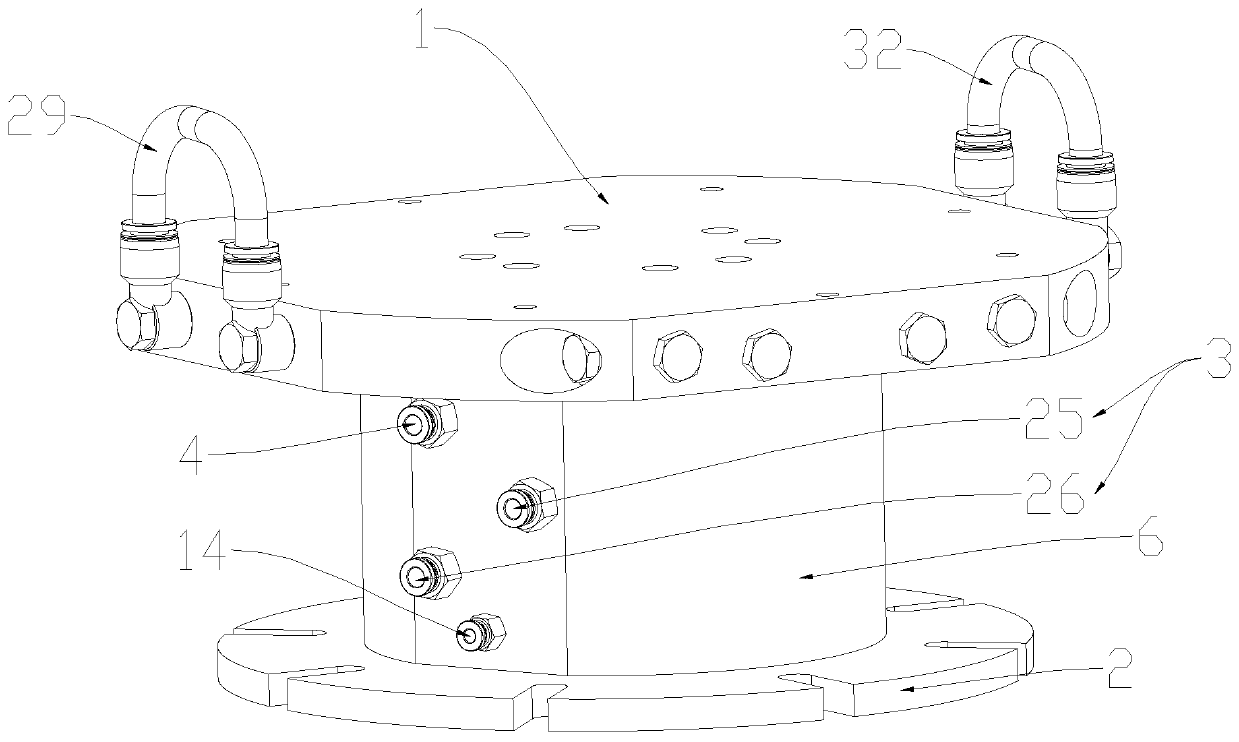

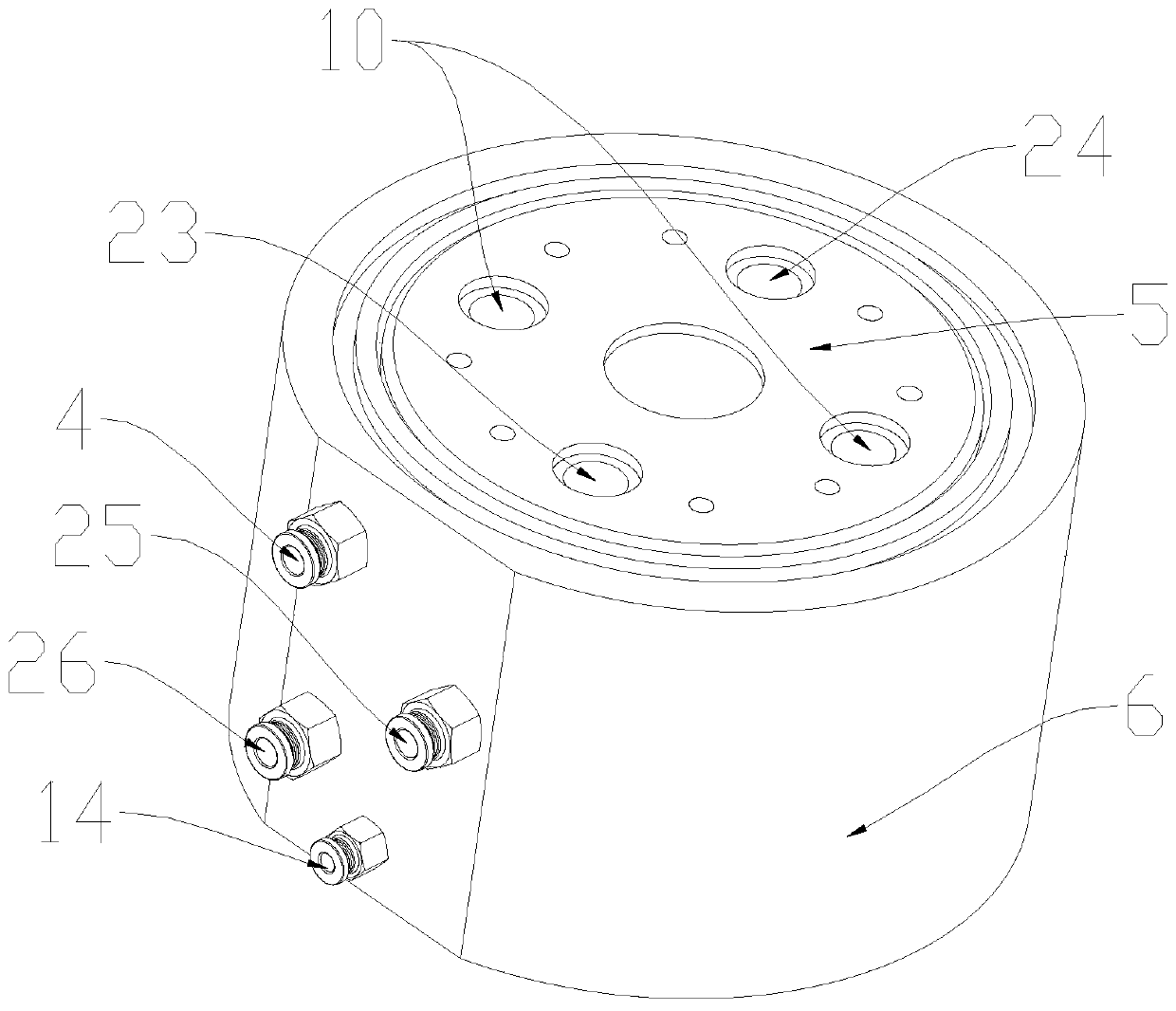

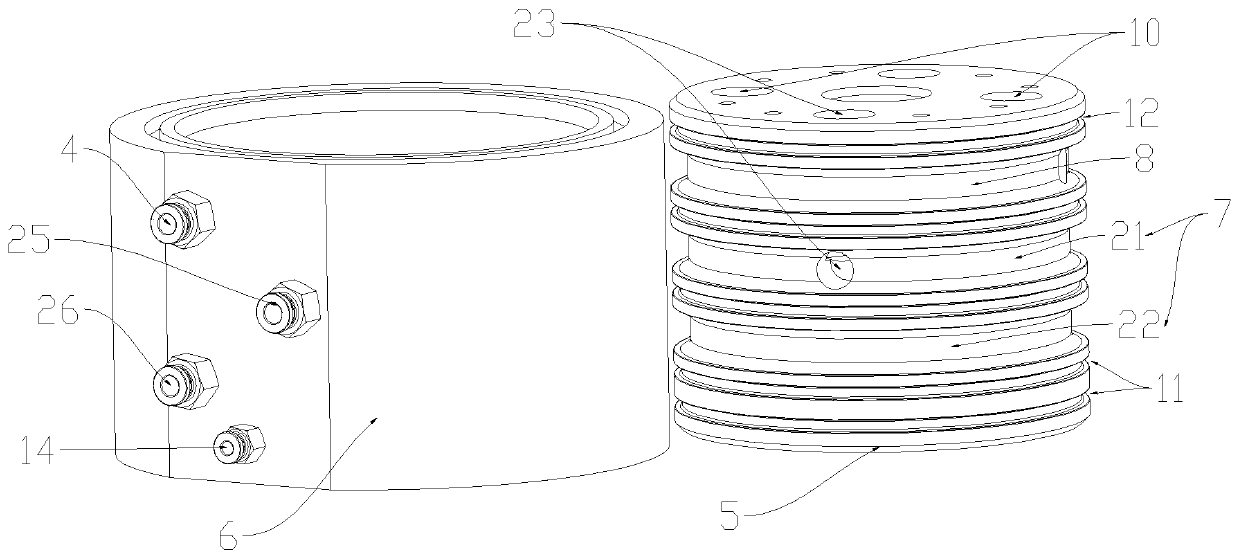

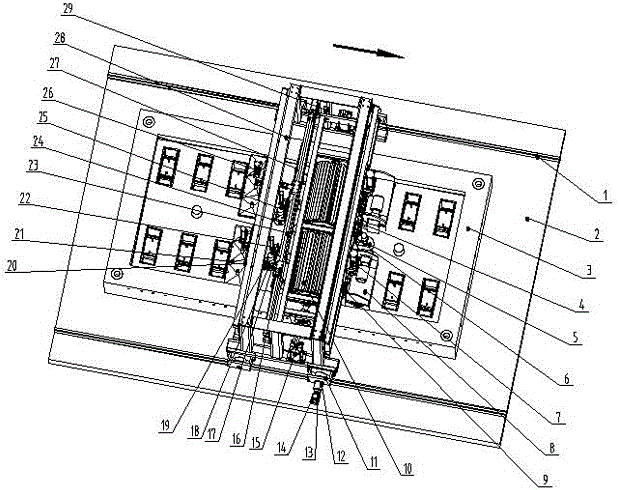

Additional material rotating worktable with circular cooling function

PendingCN111112610AReduce the temperatureGuaranteed process performanceAdditive manufacturing apparatusIncreasing energy efficiencyCooling fluidWorkbench

Owner:佛山宇仁智能科技有限公司

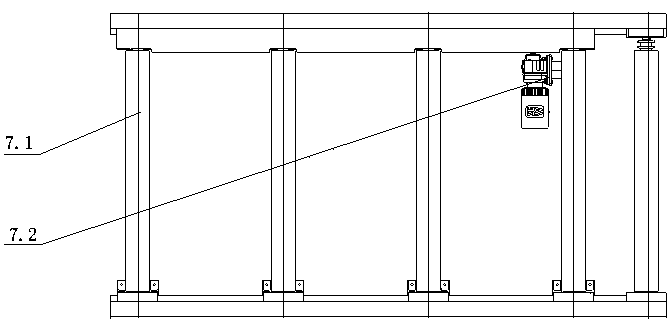

Intelligent cleaning robot suitable for high-speed railway ballastless track plate molds

ActiveCN106393404ARealize intelligent automationImprove work efficiencyCeramic shaping apparatusLight railAutomation

The invention provides an intelligent cleaning robot suitable for high-speed railway ballastless track plate molds. The intelligent cleaning robot comprises an I-shaped steel light rail arranged on the ground of a working area; a frame body is arranged above the light rail; rail wheel modules are respectively arranged at two ends of the frame body, and are connected with a speed reducer through couplings A; the speed reducer is connected with a travel servo motor; the frame body is provided with a cleaning system and a dust removing system; and the cleaning system includes a disc-shaped brush assembly, a special-shaped brush roller assembly, a large brush roller and a columnar brush assembly. The intelligent cleaning robot can realize unmanned cleaning work of molds in a production line, realizes intelligent automation, and greatly improves the working efficiency.

Owner:CHINA RAILWAY NO 9 GRP +1

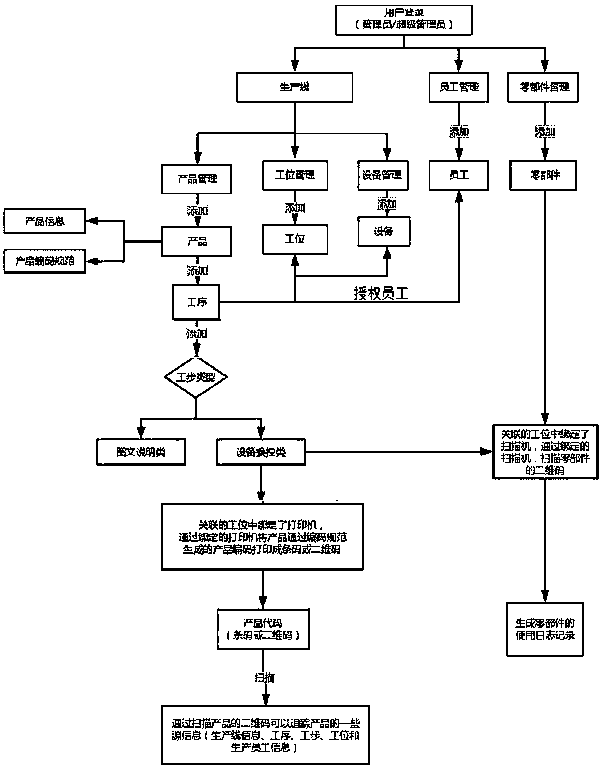

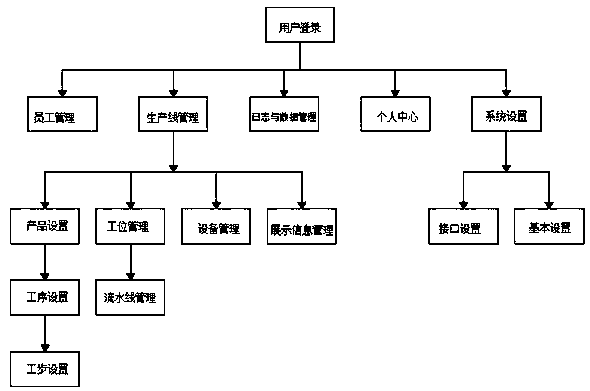

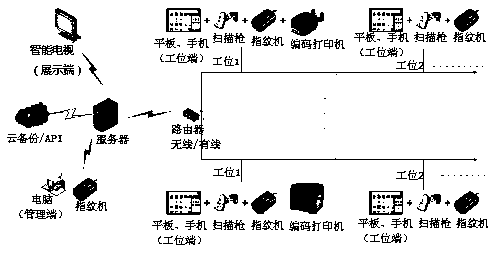

Production line management system

InactiveCN109615196ARealize joint real-time online managementRealize intelligent managementOffice automationResourcesProduction lineTime management

The invention discloses a production line management system, which comprises a management end, the management end comprises a production line management module, and the production line management module comprises a product setting unit, a process setting unit and a work step setting unit; the product setting unit is used for adding and deleting products, modifying product information and setting product coding rules; the procedure setting unit is used for associating procedures with stations, setting procedure pictures and instructions, exporting procedure information, confirming a procedure completion mode and creating, editing and deleting procedures; and the work step setting unit is used for setting work step pictures and instructions, setting equipment control actions, setting associated parts and creating, editing and deleting work steps. Management of finished products, semi-finished products or assembly bodies on the production line is achieved, management of the products, theprocedures and the working steps is achieved, joint real-time online management of the production line is achieved, intelligent management of the production line is achieved, the production efficiencyis effectively improved, and good practicability is achieved.

Owner:成都好空气科技发展有限公司

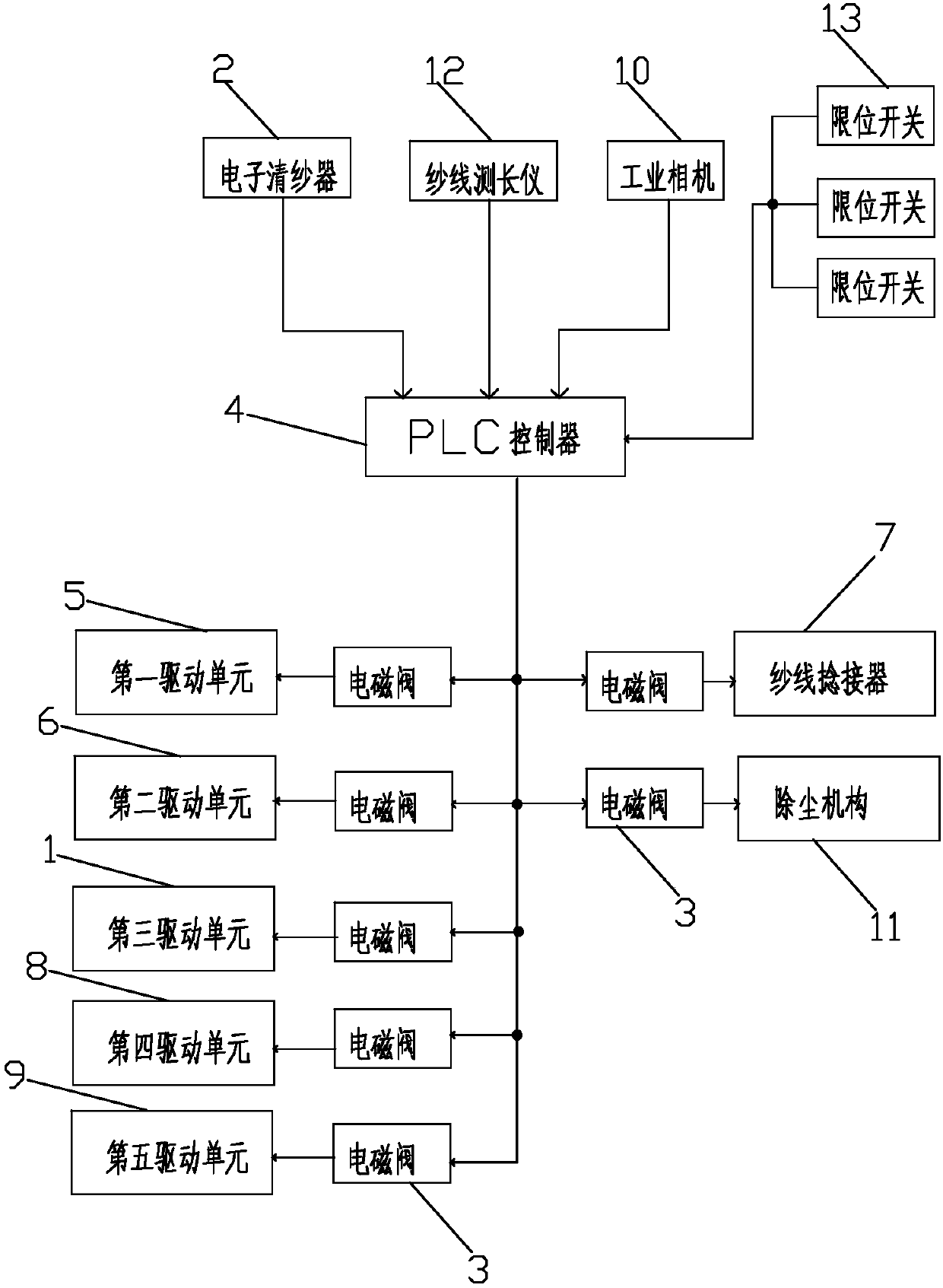

Detection defect removal intelligent control system and control method for yarns of circular weft knitting machine

ActiveCN107829204ASimple structureEasy to useWeft knittingIntelligent control systemProgrammable logic controller

The invention relates to the field of textile machinery, and provides an intelligent detection defect removal device for yarns of a circular weft knitting machine. The intelligent detection defect removal device comprises a rotary worktable, a creel, an electronic yarn clearer for detecting defects of the yarns, a plurality of electromagnetic valves, a PLC (programmable logic controller), a firsttravel mechanism, a second travel mechanism, a yarn splicer, a clamping mechanism, a rotary yarn pulling mechanism, a support, an industrial camera and a dust removal mechanism. The rotary yarn pulling mechanism is arranged on the support, the upper-section yarns at defect positions, which are used as fixed points, of the clamped yarns can be rotationally downwardly pulled by the rotary yarn pulling mechanism, the upper-section yarns and the lower-section yarns at defect positions of the yarns can cross one another by the aid of the rotary yarn pulling mechanism to form crosses, the yarn splicer can slide on the support in the horizontal direction via the second travel mechanism, a yarn splicing opening of the yarn splicer directly faces the crossed yarns which form the crosses, and the yarns can be shorn and spliced by the yarn splicing opening. The intelligent detection defect removal device has the advantage that the problems of incapability of effectively processing yarns with defects detected by existing circular weft knitting machines, time and labor wastage during manual splicing, low production efficiency and influence on the quality of textile fabrics due to factors such as the constant availability of yarn defects and manual connectors can be effectively solved by the aid of the intelligent detection defect removal device.

Owner:泉州威廉针织科技研究院股份有限公司

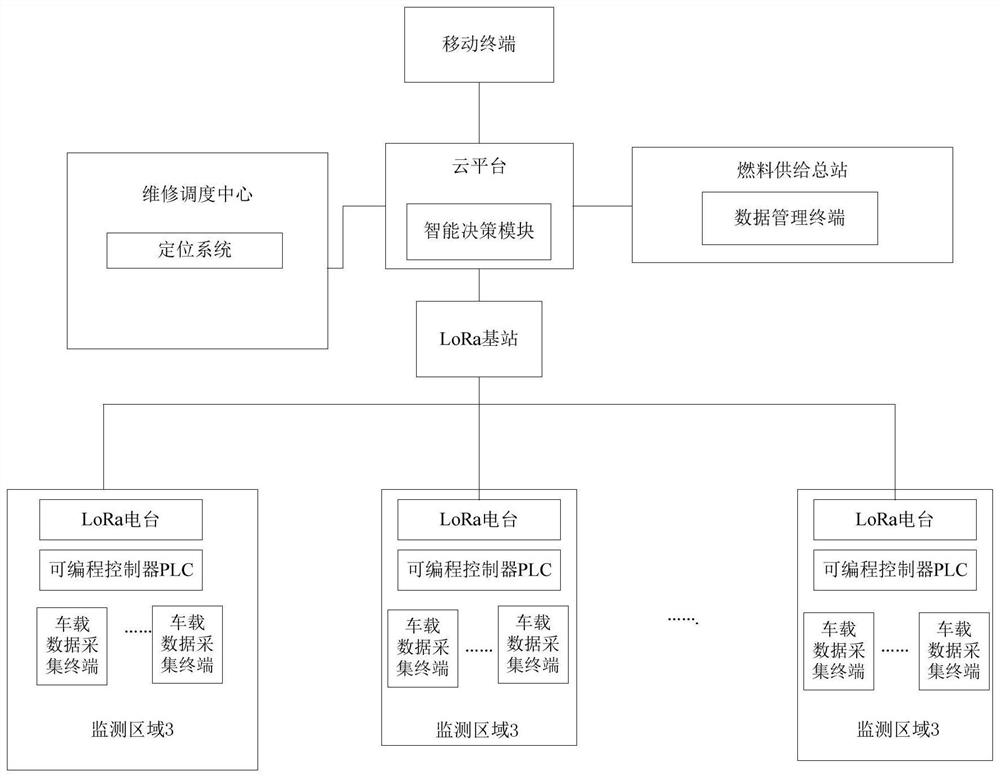

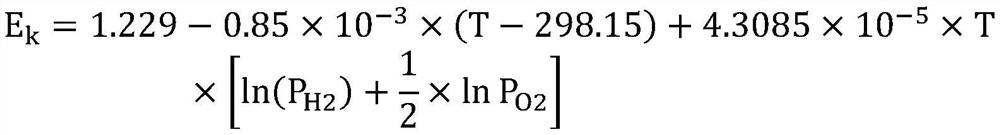

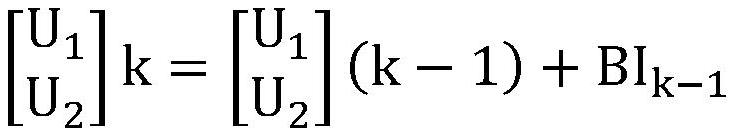

Fuel cell forklift comprehensive management monitoring system based on intelligent Internet of Things

PendingCN114019891AAchieve intelligent automation and precisionReduce labor inputLifting devicesProgramme control in sequence/logic controllersIn vehicleForklift truck

The invention relates to a fuel cell forklift comprehensive management monitoring system based on the intelligent Internet of Things. The system comprises a vehicle-mounted data acquisition terminal, collecting real-time state information of the fuel cell forklift and transmitting the real-time state information to the cloud platform; an intelligent decision-making module of the cloud platform, estimating the fuel usage amount of each monitoring area according to the collection result of the vehicle-mounted data collection terminal, generating a fuel supply scheme and sending the fuel supply scheme to a data management terminal of a fuel supply master station, the intelligent decision-making module further evaluating the health condition of a battery of the forklift according to the collection result, and early warning is conducted when it is detected that the battery is abnormal, and generating and sending a fault maintenance scheme to the maintenance scheduling center; and a maintenance dispatching center, determining the position of the fault vehicle and dispatching maintenance personnel to go to the field for maintenance. The system can remotely manage the use conditions of the fuel cell forklifts in a plurality of monitoring areas in a centralized manner, so that the labor investment is reduced, and the management efficiency and level are improved.

Owner:天津新氢动力科技有限公司

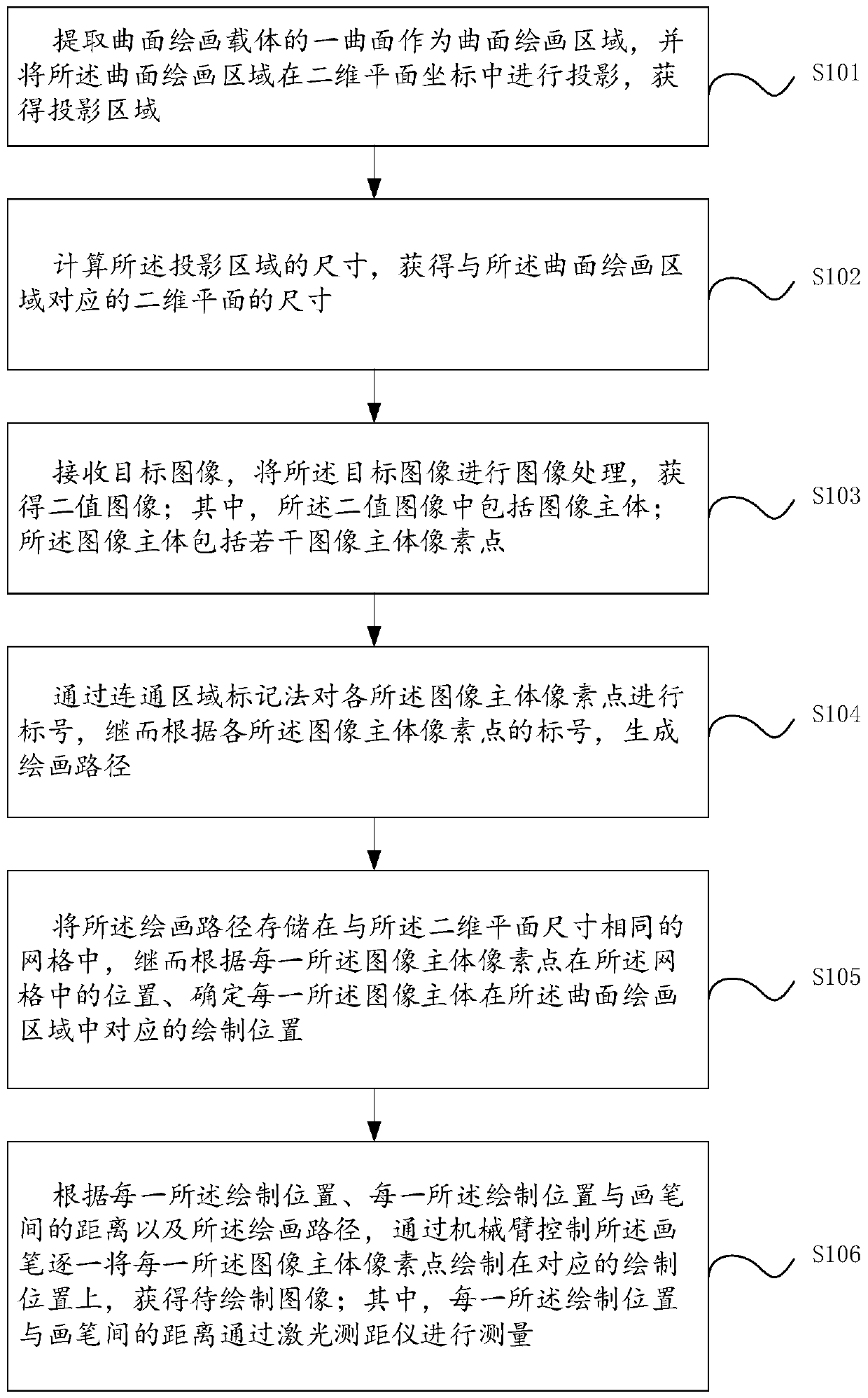

Drawing method, device and system based on curved surface drawing carrier

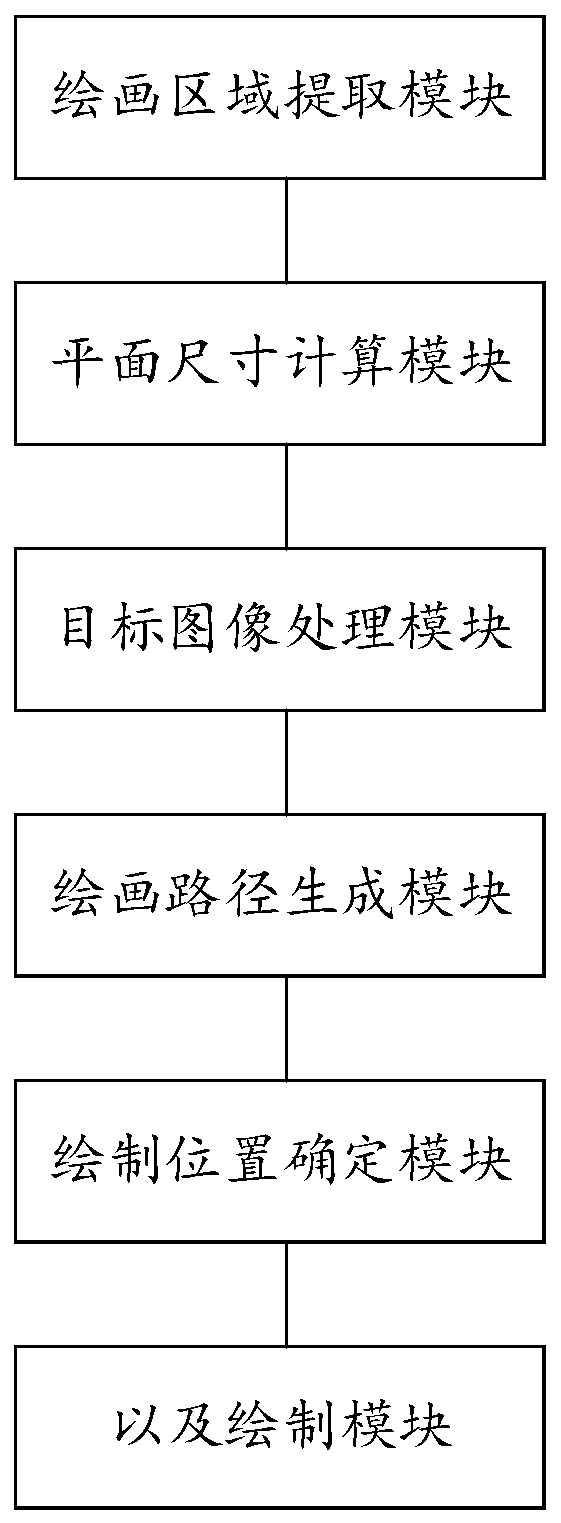

InactiveCN110587599ARealize automatic paintingRealize intelligent automationProgramme-controlled manipulatorImage analysisImaging processingComputer graphics (images)

The invention discloses a drawing method, device and system based on a curved surface drawing carrier. The method comprises the steps that a curved surface drawing area is extracted from the curved surface drawing carrier, the curved surface drawing area is projected in a two-dimensional plane coordinate to obtain a projection area, and the size of the projection area is calculated to obtain the size of a two-dimensional plane; a target image is received, and the target image is subjected to image processing to obtain a binary image; pixel points of each image main body in the binary image arenumbered through a connected area marking method, and a drawing path is generated; the drawing path is stored in a grid with the same size as the two-dimensional plane, and then the drawing positionof each image main body is determined according to the positions of the pixel points of each image main body in the grid; and according to each drawing position, the distance between each drawing position and a drawing pen and the drawing path, the pixel points of each image main body are drawn one by one on the corresponding drawing positions. According to the method, device and system, automaticdrawing on the curved surface drawing carrier can be realized, and the labor cost is saved.

Owner:GUANGDONG INTELL VISION TECH CO LTD

Bolt model automatic detection device and control method

PendingCN111871836AAvoid quality anomaliesRealize intelligent automationSortingStructural engineeringVisual perception

The invention discloses a bolt model automatic detection device and a control method. The bolt model automatic detection device comprises a bolt conveying device, a visual detection system and a boltpushing mechanism; the bolt conveying device sequentially conveys bolts through a belt line; the visual detection system is used for collecting image information of the bolts conveyed by the belt lineand distinguishing qualified products from unqualified products of the bolts according to the image information; the bolt pushing mechanism is used for pushing the qualified products and / or the unqualified products of the bolts conveyed by the belt line out of the belt line; and when a result of distinguishing the bolts on the belt line by the visual detection system is that the bolts are the qualified products or the unqualified products, a pushing instruction is sent to the bolt pushing mechanism, and the qualified products and / or the unqualified products are pushed out of the belt line bythe bolt pushing mechanism. The bolt model automatic detection device can automatically detect bolt models, and improves the bolt detection efficiency and the bolt detection accuracy.

Owner:GREE ELECTRICAL APPLIANCE WUHU +1

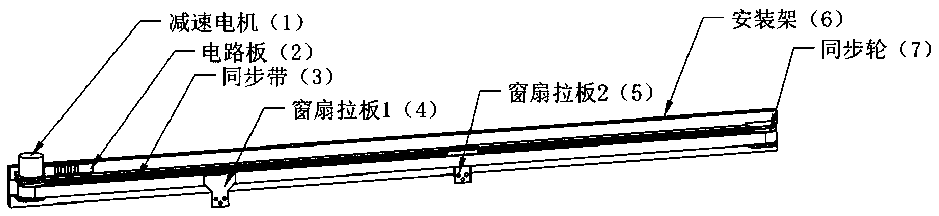

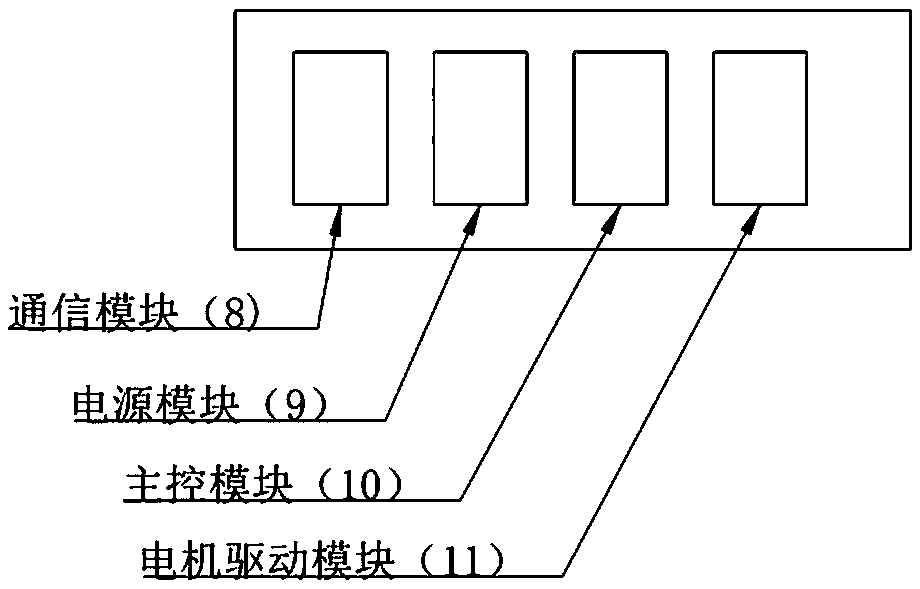

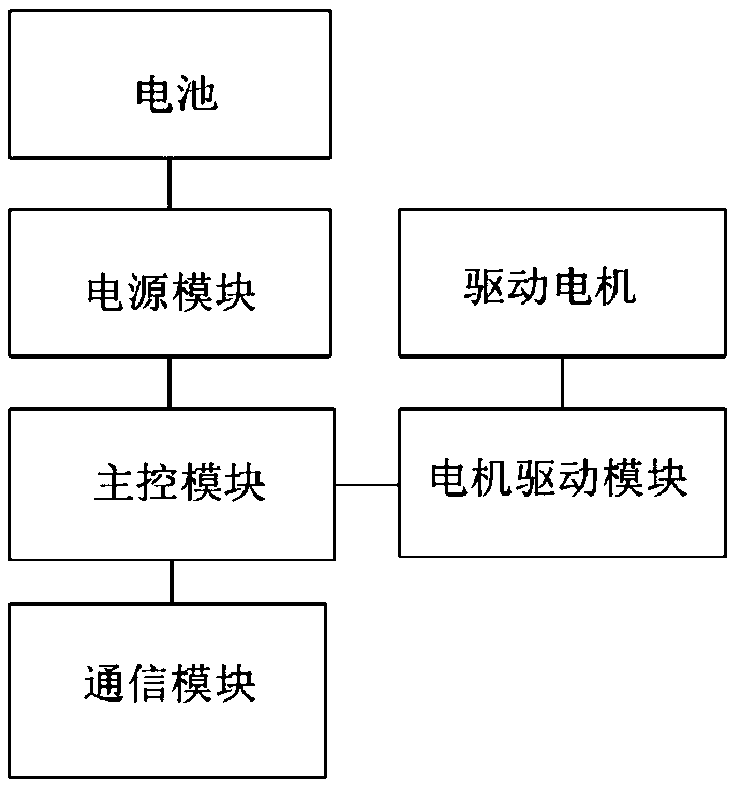

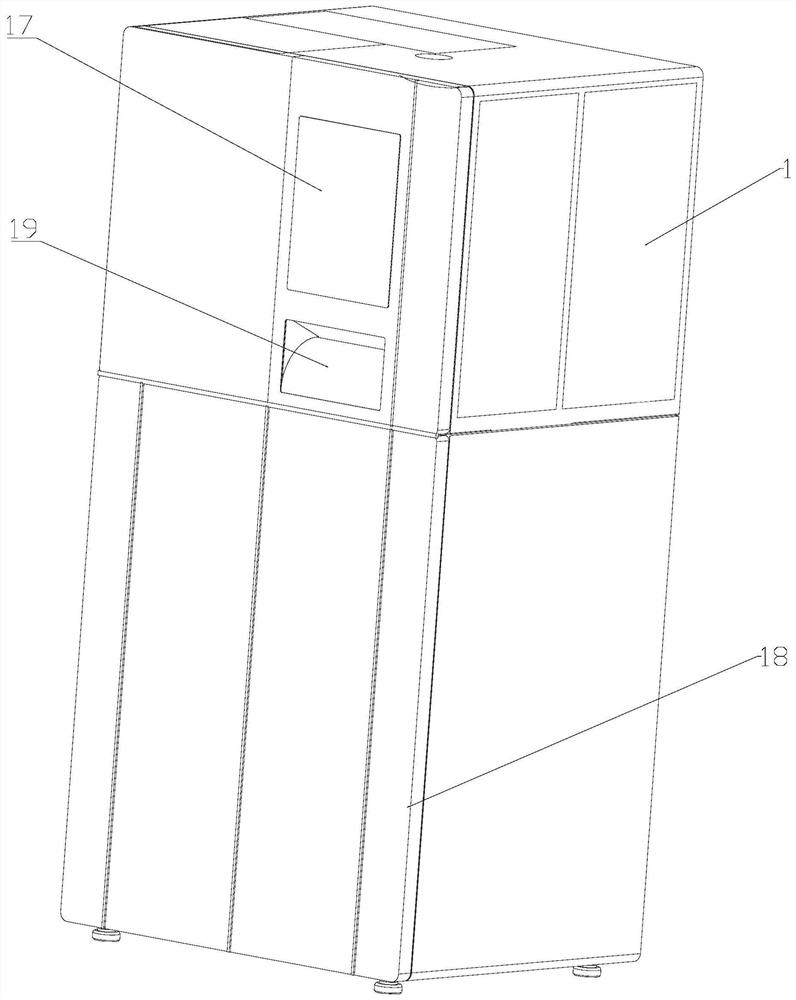

Fixed rail sliding type novel Internet of things automatic door and window opening and closing device

PendingCN111425104AEven strengthReasonable speedPower-operated mechanismElectric machineryLoudspeaker

The invention belongs to the technical field of Internet of things home furnishing, and particularly relates to a fixed rail sliding type novel Internet of things automatic door and window opening andclosing device. The device comprises a gear motor, a circuit board, a synchronous belt, a door and window sash pull plate 1, a door and window sash pull plate 2, a mounting frame and a synchronous wheel, wherein the circuit board comprises a communication module, a power supply module, a main control module and a motor driving module; the circuit board comprises a camera, a main control module, apower supply module, a camera driving module, a communication module, a lithium battery, a loudspeaker and a voice alarm driving module; and the camera is installed at the upper end of a fixed door and window frame, the mounting frame of which is fixedly connected to the outer side of a sliding groove, making contact with a rail groove, of a rail door and window. The automatic door and window opening and closing device designed by the invention is mainly applied to fixed rail sliding type doors and windows in families and various indoor buildings and fixed rail sliding type cabinets, drawersand other scenes in the buildings, intelligent automation, remote and voice control of various articles in the Internet of things era are realized, a large amount of time and energy are saved, and theeffects of convenience, rapidness and high efficiency are achieved.

Owner:智慧式有限公司

Smart kitchen and scheduling method thereof

PendingCN112493830AImprove efficiencyEasy to useDomestic cooling apparatusLighting and heating apparatusCool storageFood material

A smart kitchen comprises a cabinet body, a weighing assembly and an electrical system, a refrigerating box body is arranged on the lower portion in the cabinet body, and a mechanical arm, an automatic cooker, a micro steaming and baking machine, a water system, a plate separating mechanism and a heat preservation box are arranged above the refrigerating box body. An automatic seasoning adding mechanism and a range hood are arranged above the automatic cooker. The smart kitchen can realize full-automatic operation of food material cold storage, steaming, boiling, stir-frying and stewing operation of food, seasoning adding, water adding, pot cover opening and closing, food material adding into a pot, dish discharging, heat preservation, pot brushing and material conveying and transferring,does not need manual operation, and can realize full-automatic intelligent operation; the smart kitchen is simple and compact in structure, high in space utilization rate, few and light in moving parts and low in equipment cost; energy consumption is low, the fault probability is low, and later maintenance cost is low.

Owner:昀厨智能制造工程(烟台)有限公司

Intelligent automatic fertilizer applicator

InactiveCN109729798AReduce wasteMeet the best soil requirementsFertiliser distributersFertilising methodsRemote controlEngineering

The invention discloses an intelligent automatic fertilizer applicator which comprises a base, wherein a chemical fertilizer storage box, a square box, a control box, a small bulge and a solar panel are arranged on the base; a steering mechanism is arranged on the lower surface of the base; a chemical fertilizer storage and usage mechanism is arranged inside the chemical fertilizer storage box; asoil constituent detection mechanism, an automatic driving device and a remote control device are arranged inside the square box; the steering mechanism comprises a support frame, a groove, an L-shaped supporting rod I, an L-shaped supporting rod II, a beam, a gear shaft, a bearing I, a stepping motor and a gear; a monitoring mechanism is arranged on the square box; the chemical fertilizer storageand usage mechanism comprises a chemical fertilizer placement box, a baffle, a chemical fertilizer storage box, a through hole I, a circular iron cover, a spring, an electromagnet, a plank, a throughhole II, an iron pipe I and an iron pipe II; and the soil constituent detection mechanism comprises a control box, a controller, a detection box, a soil constituent analyzer, a U-shaped pipe, a fan and an infrared sensor I. The intelligent automatic fertilizer applicator disclosed by the invention has the beneficial effects of simple structure and high practicality.

Owner:河北东石科技有限公司

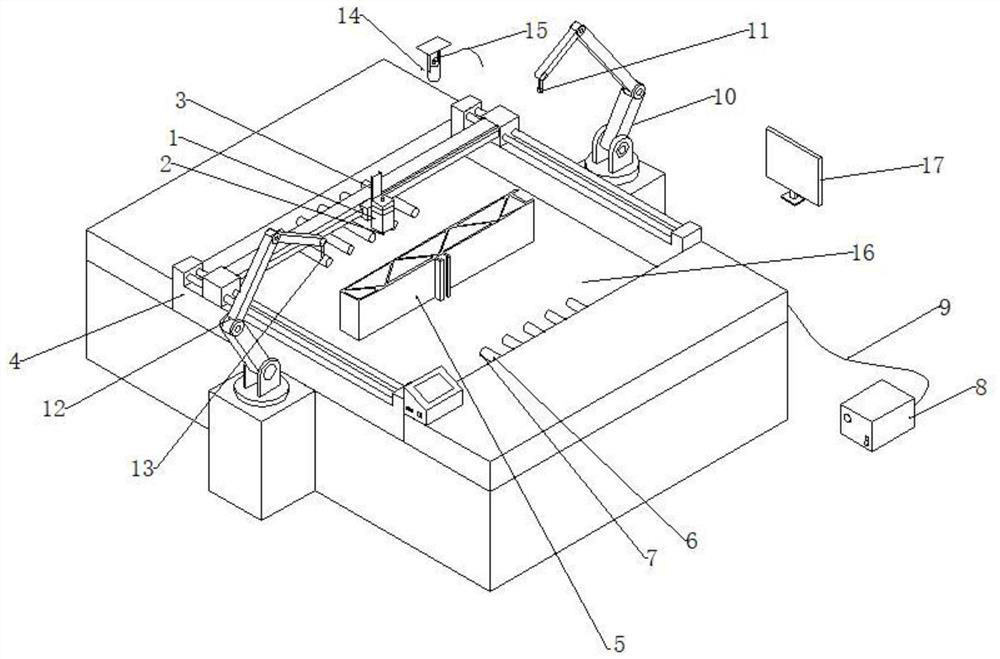

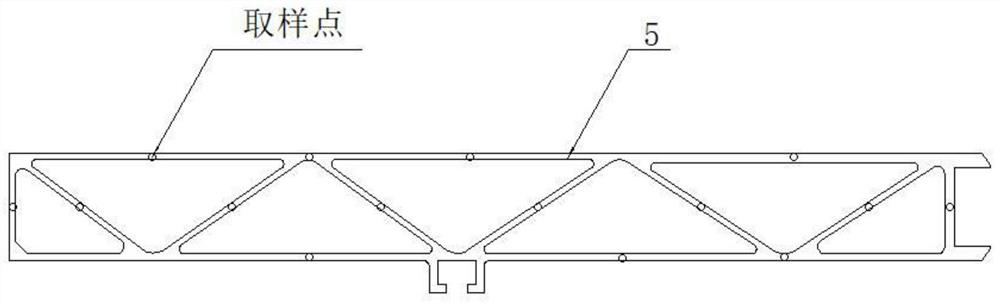

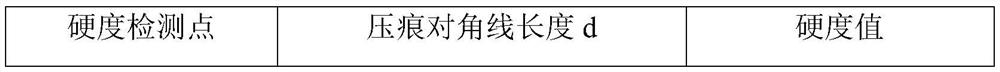

Online automatic detection system and method for hardness of aluminum alloy profile

PendingCN112945777ACalculation method is simpleEasy to measurePreparing sample for investigationOptically investigating flaws/contaminationControl systemData acquisition

The invention belongs to the technical field of aluminum alloy profile production detection equipment. The invention discloses an online automatic detection system for hardness of the aluminum alloy profile. The system comprises a workbench used for placing the aluminum alloy profile, a detection unit arranged above the workbench and used for detecting the hardness, a visual unit used for obtaining image data of the aluminum alloy profile, and a control system used for processing the data and outputting a control instruction, wherein the control system is connected with the detection unit and the vision unit. The automatic detection method comprises steps of sample fixing, data acquisition, coordinate operation, automatic grinding, hardness detection, hardness value calculation and automatic marking. The control system controls the vision unit, the polishing unit, the detection unit and the marking unit to automatically detect hardness of the aluminum alloy profile, manual intervention is not needed in the process, hardness detection efficiency is improved, a guarantee is provided for large-batch detection work, and intelligent automation of hardness detection is achieved.

Owner:CHINA ZHONGWANG

Automatic fetching and opening device for packaging bag main bag and automatic packaging production line

PendingCN107856912AEasy to put inExquisite structurePackagingProcess engineeringManufacturing engineering

The invention discloses an automatic fetching and opening device for a packaging bag main bag and an automatic packaging production line. The automatic fetching and opening device for the packaging bag main bag comprises a stretching-over connection support, a front-back drive mechanism, an up-down drive mechanism and a grabbing and opening mechanical arm. According to the automatic fetching and opening device for the packaging bag main bag, through the grabbing and opening mechanical arm, the main bag capable of containing packaging bags can be automatically, easily and rapidly grabbed and opened, and then the packaging bags are conveniently placed in the main bag; and in this way, the labor intensity is lowered, the subpackage time of the packaging bags is saved, so that the production efficiency can be improved to the greatest extent, and the production cost of an production enterprise is lowered. The automatic packaging production line has the outstanding feature of integrating automatic discharging of the packaging bags, conveyance of the packaging bags, clamping of the packaging bags and sealing of the packaging bags. The problems that due to manual factors, the randomness ishigh, and packaging is disorderly are solved, so that normalized and standard production is facilitated, and therefore the production cost and the management cost can be greatly reduced.

Owner:中山市器美机器人科技有限公司

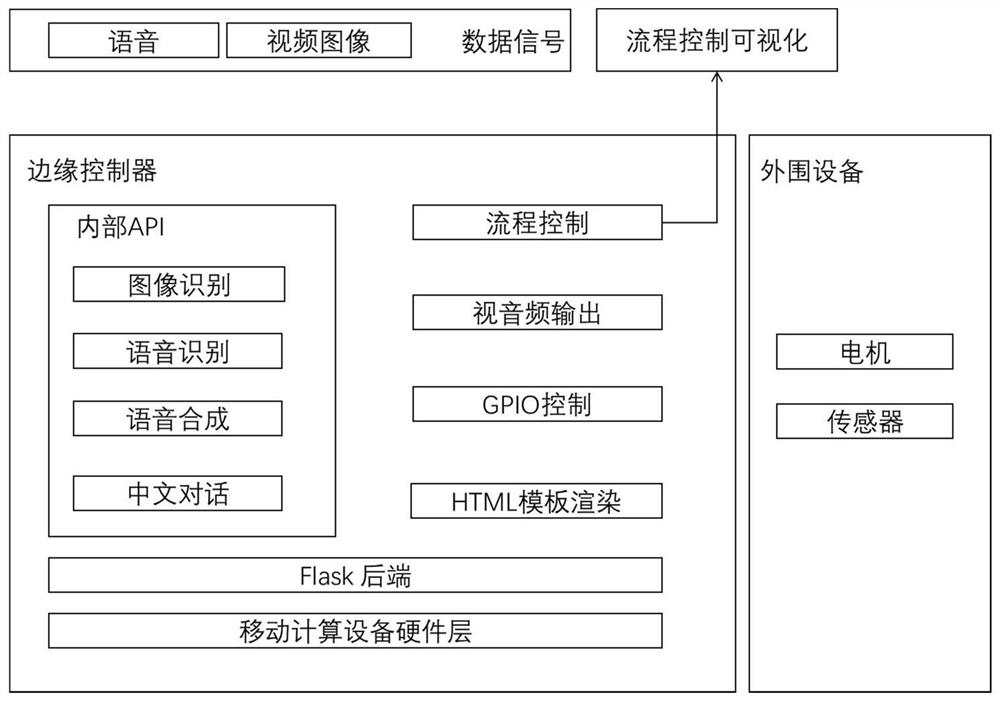

Intelligent man-machine interaction innumerable network control module

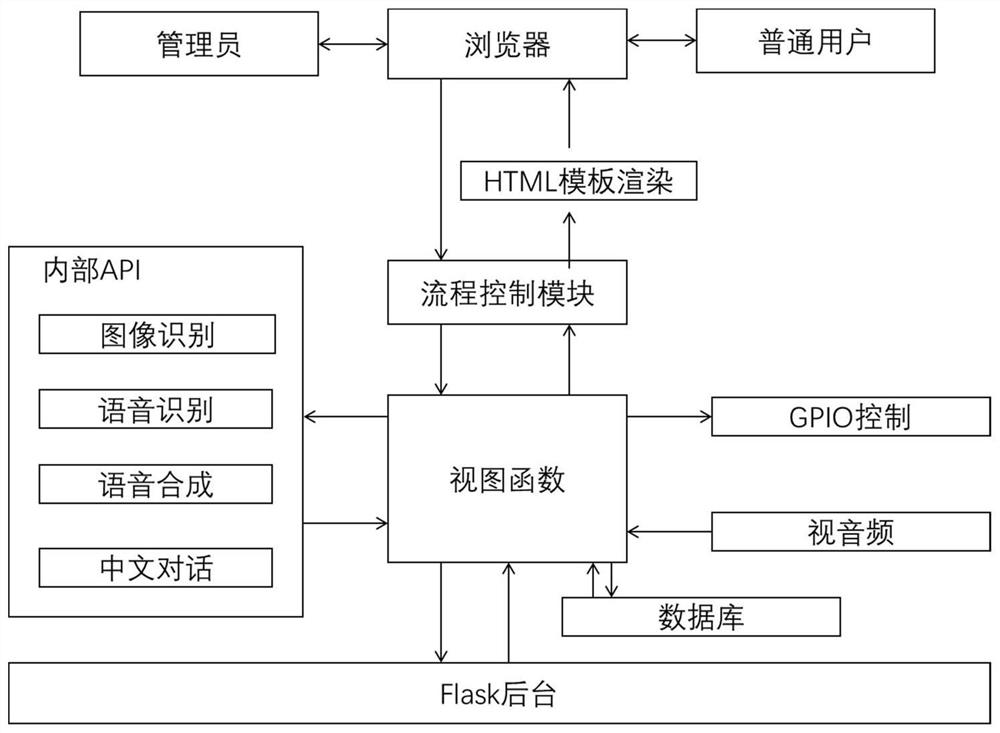

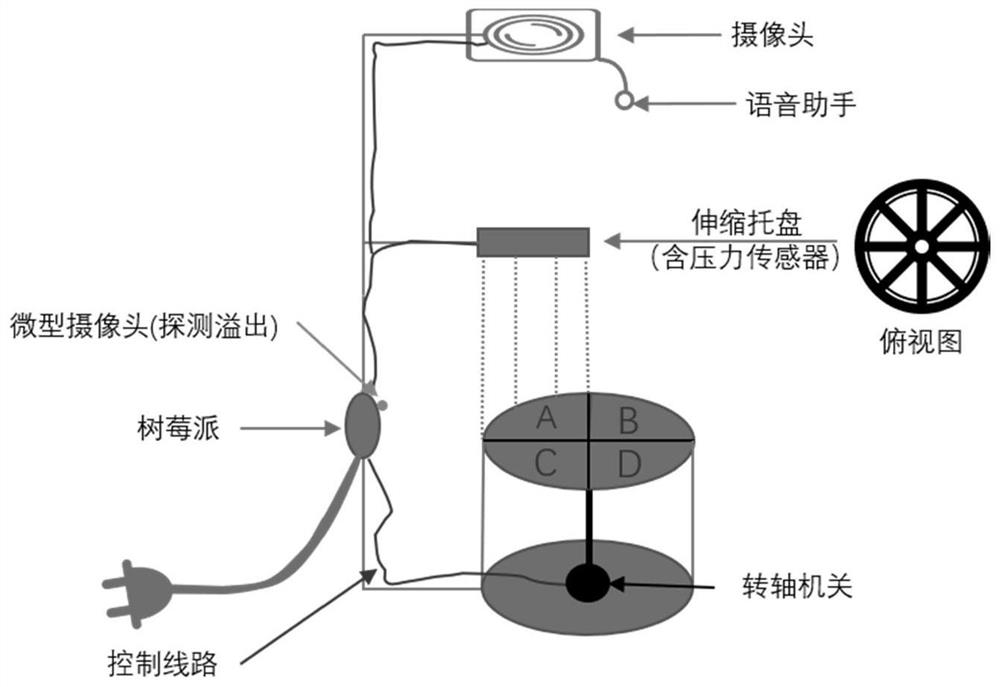

ActiveCN111722770AFast for Rapid DeploymentRealize the whole life cycleDatabase management systemsSpeech analysisFull life cycleNetwork control

The invention discloses an intelligent man-machine interaction infinite network control module which comprises a mobile computing equipment hardware layer, a Flask rear end, an internal API, a processcontrol module, a video and audio output module, a GPIO control module, an HTML template rendering module and peripheral equipment. During use, peripheral equipment is connected to the GPIO control module and the video and audio output module; the equipment is connected to a network, an administrator user is connected with the same local area network through an external computer to enter a configuration interface of the device, the operation process of Internet of Things control is visually completed by dragging a corresponding module, the configuration process is simple and rapid, intelligent automation is achieved, and the processing complexity of Internet of Things device access is reduced; the full life cycle of the Internet of Things data from generation to recovery is realized, quick access of household Internet of Things equipment is facilitated, the summary efficiency of different Internet of Things data can be improved, and the environmental protection benefit is obvious.

Owner:ENG UNIV OF THE CHINESE PEOPLES ARMED POLICE FORCE

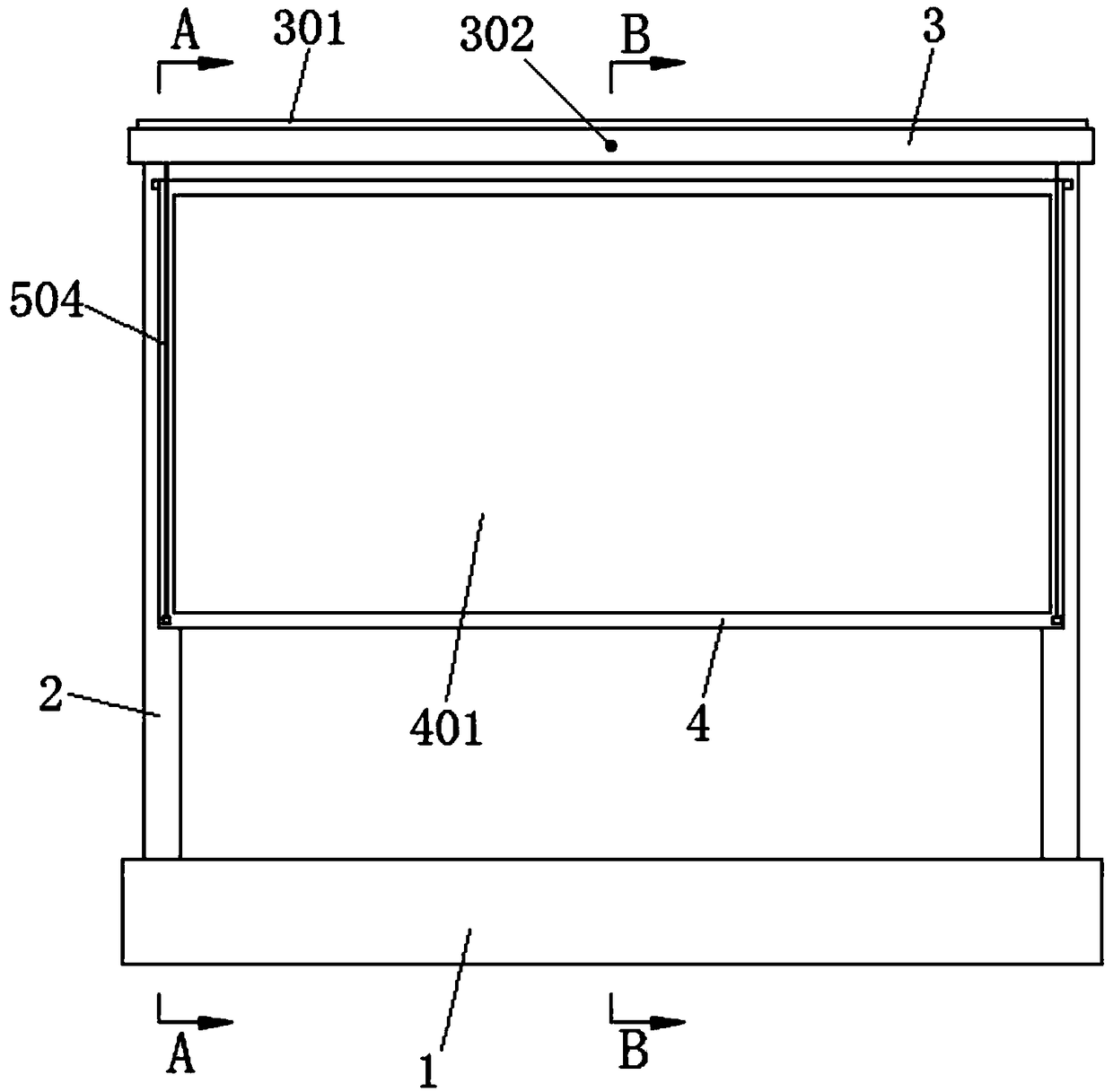

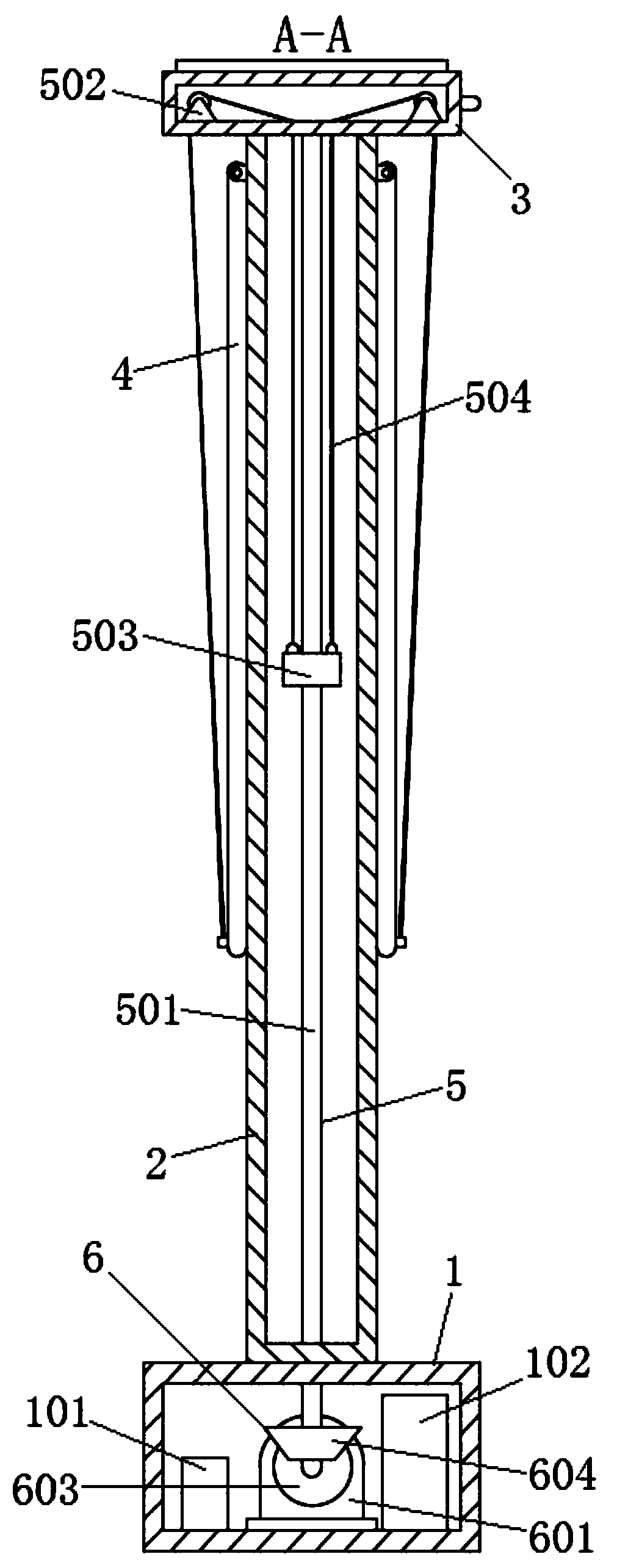

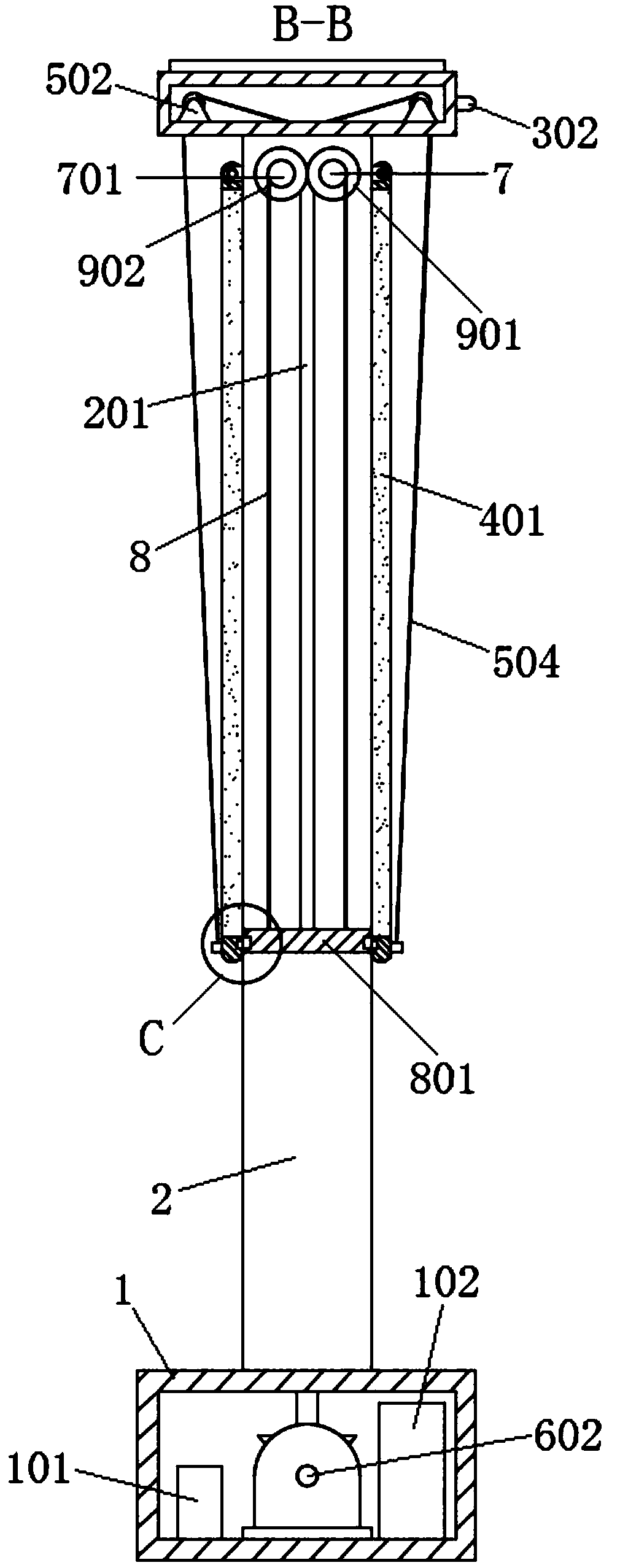

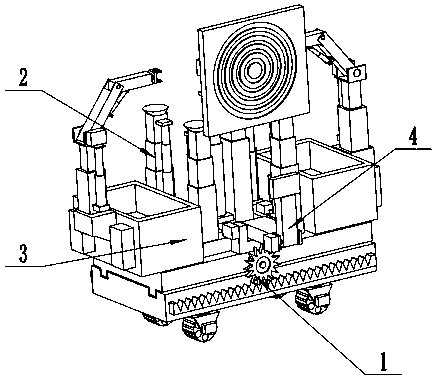

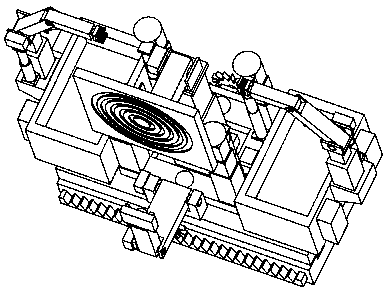

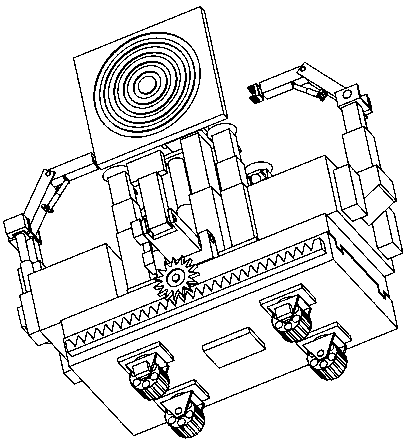

Adjustable rain-sheltering advertising sign device

The invention discloses an adjustable rain-sheltering advertising sign device, and relates to the technical field of advertising sign equipment. The adjustable rain-sheltering advertising sign devicecomprises a base; supporting columns are arranged on the two sides of the top face of the base; the top ends of the two supporting columns are connected through a top box; frames are arranged betweenthe two supporting columns; the top ends of the two frames are connected to the supporting columns through a core shaft; power transmission mechanisms for controlling the frames to rotate are arrangedinside the supporting columns; power mechanisms for controlling the power transmission mechanisms to move are arranged inside the base; a first reel and a second reel are arranged at the lower portion of the top box side by side; one end of the first reel is rotationally connected with the side face of the supporting column through a rotating mechanism, and the other end of the first reel is rotationally connected on the side face of the other supporting column; the two ends of the second reel are rotationally connected on the side faces of the supporting columns; advertising curtains are wound around the peripheral side face of the first reel and the peripheral side face of the second reel respectively. According to the adjustable rain-sheltering advertising sign device, the frames are driven by the power mechanisms and the power transmission mechanisms to open and close, the popularization value is effectively improved, and the adjustable rain-sheltering advertising sign device is suitable for popularization.

Owner:芜湖等莱智能科技有限公司

Intelligent military moving target

InactiveCN109612339ARealize intelligent automationReasonable structureMovable targetsTarget detectorsTarget surfaceHydraulic cylinder

The invention discloses an intelligent military moving target. The intelligent military moving target comprises a traveling part, a target frame part, a grabbing part and an image transmission part, and is characterized in that the lower end surface of a square frame of the target frame part is fixedly connected with the upper end surface of an upper sliding plate of the traveling part; the lowerend surface of a target surface storage box of the grasping part is fixedly connected with the upper end surface of the upper sliding plate of the traveling part; a traveling controller of the traveling part is used for controlling a first motor to drive traveling wheels so as to drive equipment to arrive at a designated position; a second motor, a gear, a first telescopic rod and a first hydraulic cylinder work coordinately, so that height adjustment and left-right movement of the target surface can be carried out; when the target surface needs to be replaced, a second telescopic rod and a second hydraulic cylinder work coordinately to pull up the target surface; and a third telescopic rod, a third hydraulic cylinder, a first grabbing arm, a fourth hydraulic cylinder and a second grabbingarm of the grabbing part work coordinately to control a grabber to put the grabbed target surface into the target surface storage box and then grab the new target surface for replacement from the target surface storage box on the other side.

Owner:丁风海

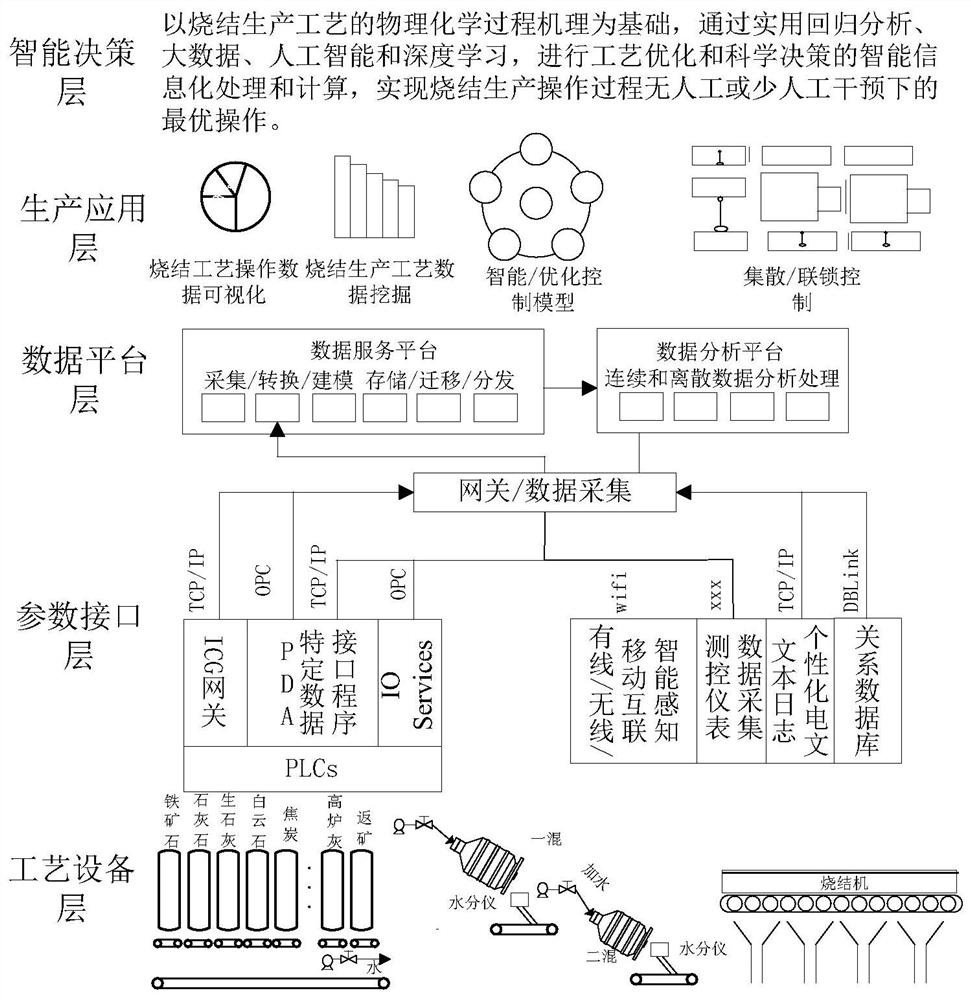

Intelligent management/control/maintenance cloud platform architecture for sintering production process flow

The invention relates to the technical field of intelligent informatization of sintering production, in particular to an intelligent management / control / maintenance cloud platform architecture for a sintering production process flow, which can realize big data sharing and redundancy under an information security condition, improve information analysis and operation maintenance efficiency and guide and optimize process operation and production management in real time. The architecture includes a process equipment layer, a parameter interface layer, a data platform layer, a production application layer and an intelligent decision-making layer. The process equipment layer comprises production equipment and an information acquisition device; the parameter interface layer comprises an industrial gateway and a switch, and realizes data access and management functions; the data platform layer comprises a data preprocessing and data storage sub-layer, a data modeling sub-layer and a service sub-layer; the production application layer comprises intelligent analysis, prediction and model sintering industry intelligent control and application software and environment; the intelligent decision-making layer carries out intelligent informatization processing of process optimization and scientific decision making, and intelligent optimal operation in the sintering production operation process is achieved.

Owner:东北大学秦皇岛分校

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com