Bolt model automatic detection device and control method

A technology of automatic detection device and control method, applied in sorting and other directions, can solve the problems of product scrapping cost loss, unstable detection effect, backward detection technology, etc., to reduce after-sales service costs, strong visual capture effect, and visual capture effect. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

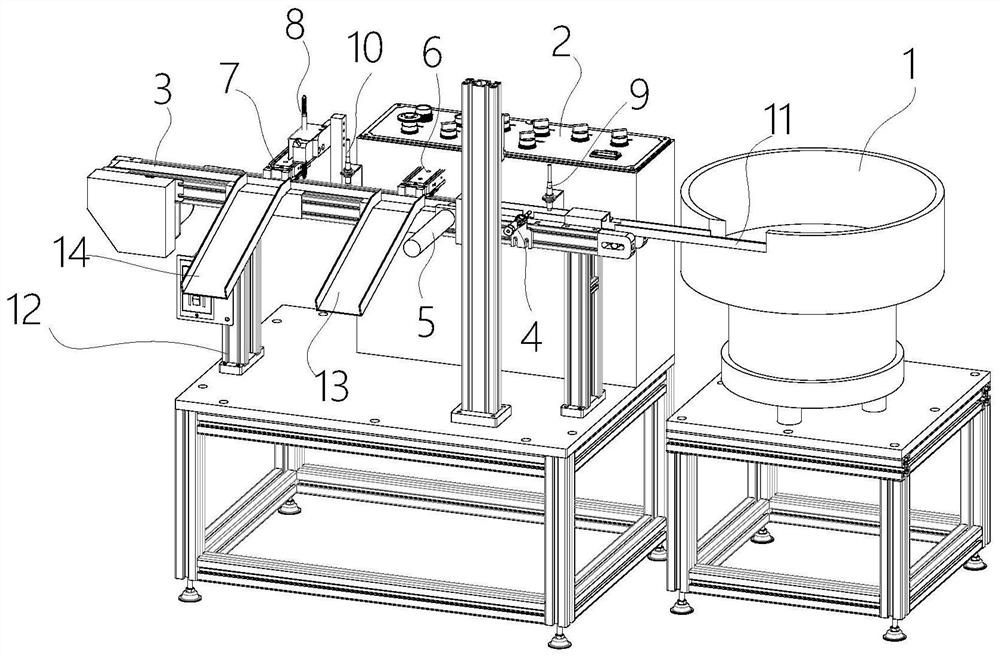

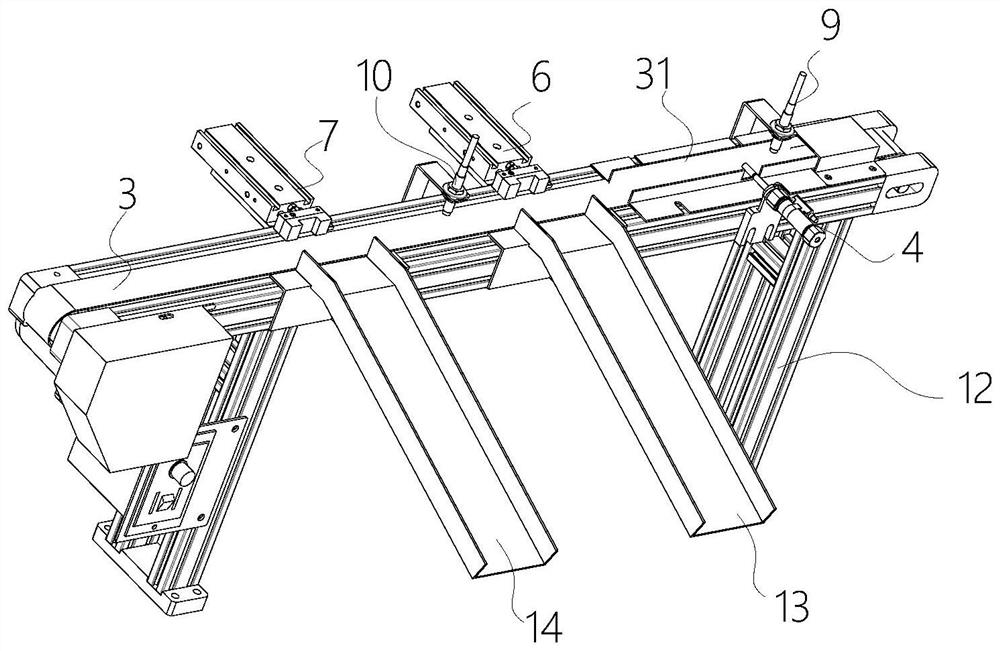

[0045] In view of the current use of the original manual detection method to distinguish bolts of different specifications, the detection technology is backward, the detection effect is unstable and prone to misuse and mixed use, which directly leads to the problem that the parts cannot be assembled and the cost of product scrapping is lost. This embodiment proposes An automatic detection device for bolt type, such as Figure 1-Figure 3As shown, including: bolt transmission device, visual inspection system and bolt pushing mechanism.

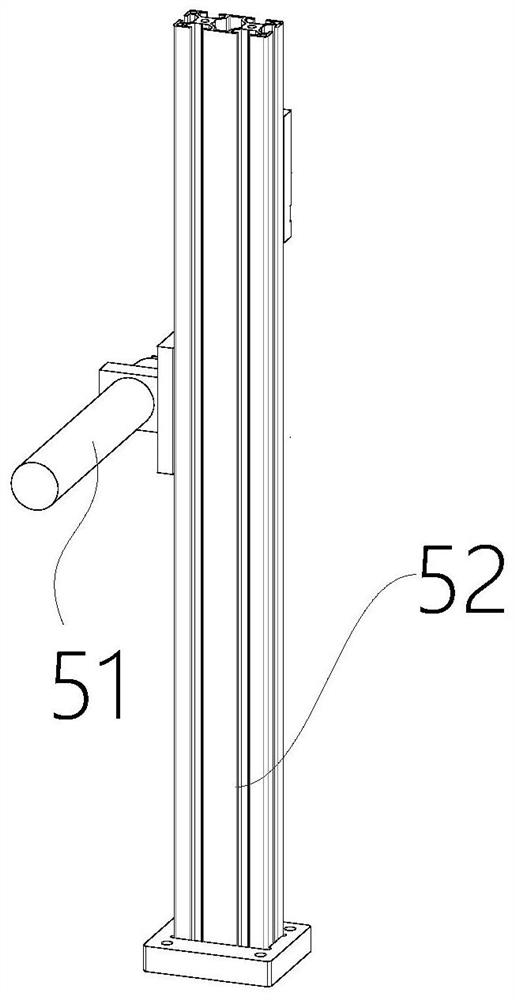

[0046] The bolt transmission device sequentially transports the bolts through the belt line 3 ; specifically, the bolt transmission device includes a support frame 12 on which the belt line 3 is arranged. Preferably, the bolt transmission device further includes a vibrating plate 1 , and the vibrating plate 1 arranges the bolts in an orderly orientation through vibration before outputting them. The output end of the vibration plate 1 is provide...

Embodiment 2

[0062] This embodiment discloses the control method of the bolt type automatic detection device of the embodiment. The control method includes: when the visual detection device collects the image information of the bolts conveyed by the belt line, and distinguishes the qualified products from the non-qualified bolts according to the image information , the control bolt pushing mechanism pushes qualified products and / or non-qualified products out of the belt line.

[0063] Further optionally when the pushing mechanism includes a first pushing cylinder, the control method includes:

[0064] When the bolts are conveyed sequentially on the belt line, the visual inspection system is controlled to collect the image information of the bolts conveyed by the belt line, and the qualified and non-qualified bolts are distinguished according to the image information;

[0065] Control the first push cylinder to push qualified or non-qualified products out of the conveyor.

[0066] Further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com