An air-conditioning chassis sheet metal part and its welding method

An air-conditioning chassis and welding method technology, applied to welding equipment, arc welding equipment, metal processing equipment, etc., to achieve the effects of optimizing operating conditions, increasing production efficiency, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention is further described in conjunction with the following examples.

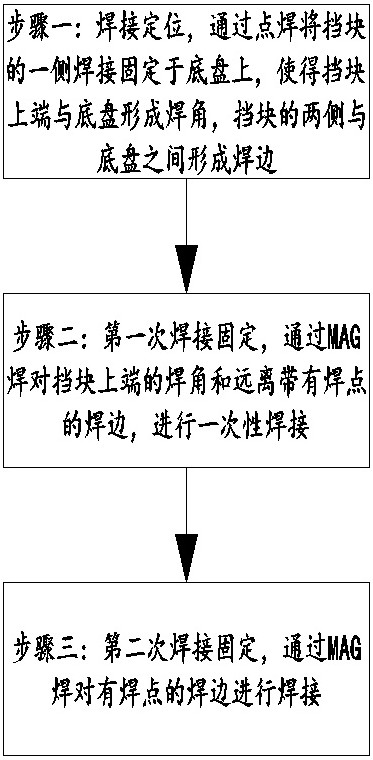

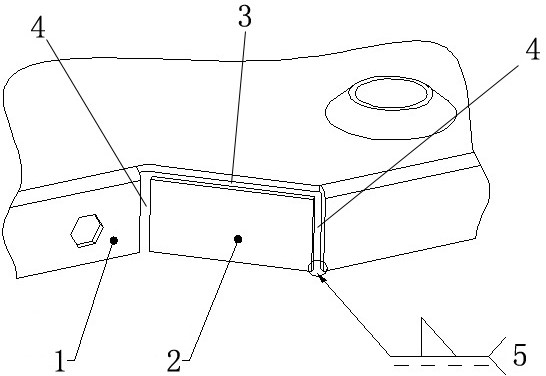

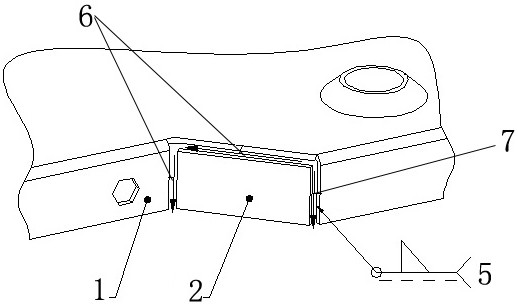

[0030] Such as Figure 1-3 As shown, the present embodiment provides a welding method for air-conditioning chassis sheet metal parts, including the following steps:

[0031] (1) Welding positioning: One side of the block 1 is welded and fixed on the chassis 2 by spot welding, so that the upper end of the block 1 and the chassis 2 form a positioning welding angle 3, and a weld is formed between both sides of the block 1 and the chassis 2. side 4;

[0032] (2) The first welding fixation: through MAG welding, the positioning welding angle 3 on the upper end of the stopper 1 and the welding edge 4 away from the welding spot 5 are carried out at one time according to the fixing path 6 of the first welding; not only can the The coherent operation of the welding path, that is, one-step completion of the operation, optimizes the time for welding preparation and shutdown waiting, and at th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com