Rotor outer diameter detection device

A technology for detecting device and rotor outer diameter, applied in measuring devices, instruments, etc., can solve the problems of uneven force on the motor rotor, poor reliability, low measurement accuracy, etc., to prevent product quality abnormalities and reduce measurement errors. , the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

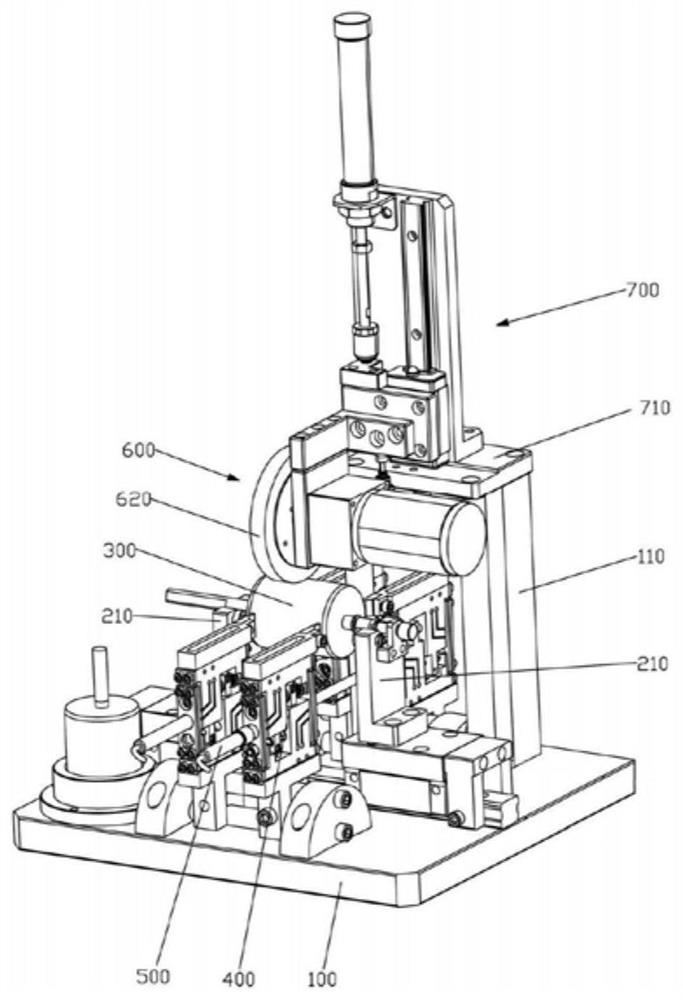

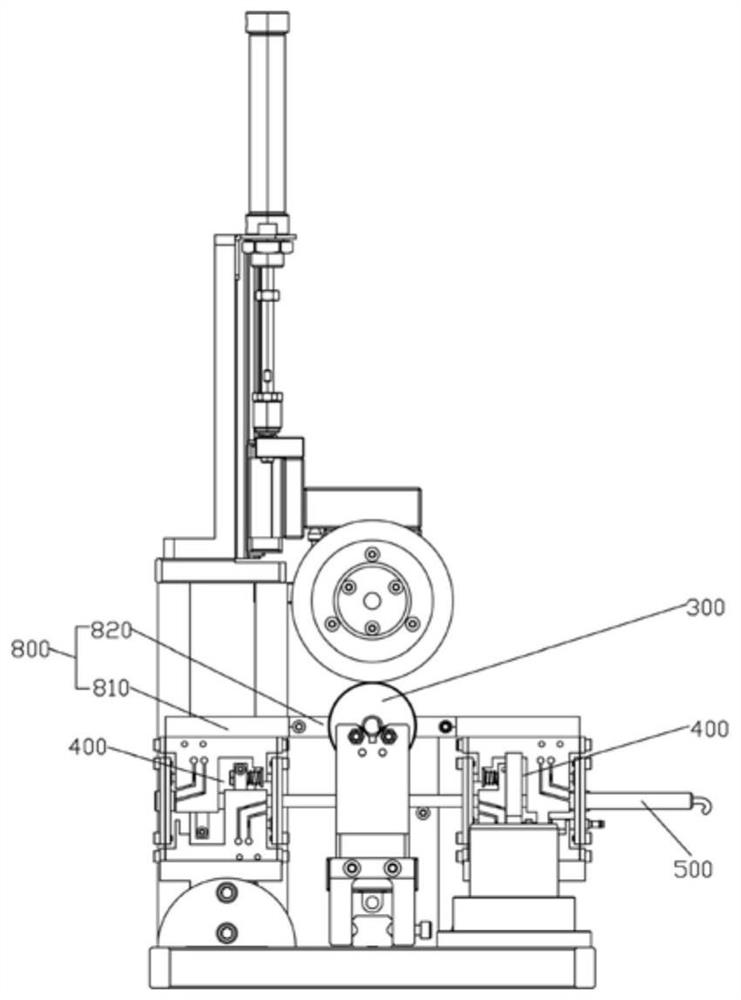

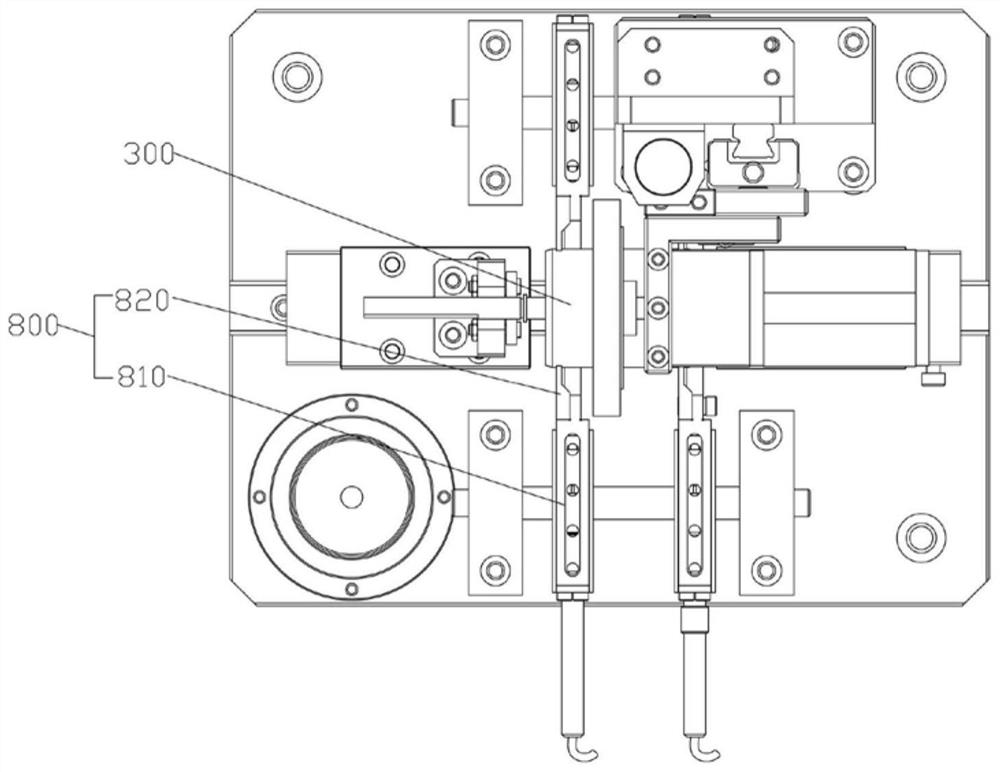

[0038] Such as figure 1 and figure 2 As shown, the rotor outer diameter detection device proposed in the embodiment of the present invention includes a base 100, a support mechanism, at least one pair of spring-type measuring mechanisms and a sensor 500. In this embodiment, the rotor outer diameter detection device has two pairs of spring-type Measuring mechanism 400 .

[0039] The support mechanism is installed on the base 100, and the rotor 300 is rotatably installed on the support mechanism. Every pair of spring-type measuring mechanism 400 is fixed on the base 100, and two spring-type measuring mechanisms 400 in each pair of spring-type measuring mechanism are arranged radially symmetrically with the rotor 300, and two springs in every pair of spring-type measuring mechanism The spring-type measuring mechanism 400 is in contact with the outer surface of the rotor 300, and the rotation of the rotor 300 drives the spring-type measuring mechanism 400 to generate a stretchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com