Patents

Literature

64 results about "OLE for Process Control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Open Platform Communications (OPC) is a series of standards and specifications for industrial telecommunication. An industrial automation task force developed the original standard in 1996 under the name OLE for Process Control (Object Linking and Embedding for process control). OPC specifies the communication of real-time plant data between control devices from different manufacturers.

Remote monitoring system of sewage disposal process and implementation method thereof

InactiveCN102681497ASave human resourcesReduce operating costsTotal factory controlProgramme total factory controlOLE for Process ControlWeb service

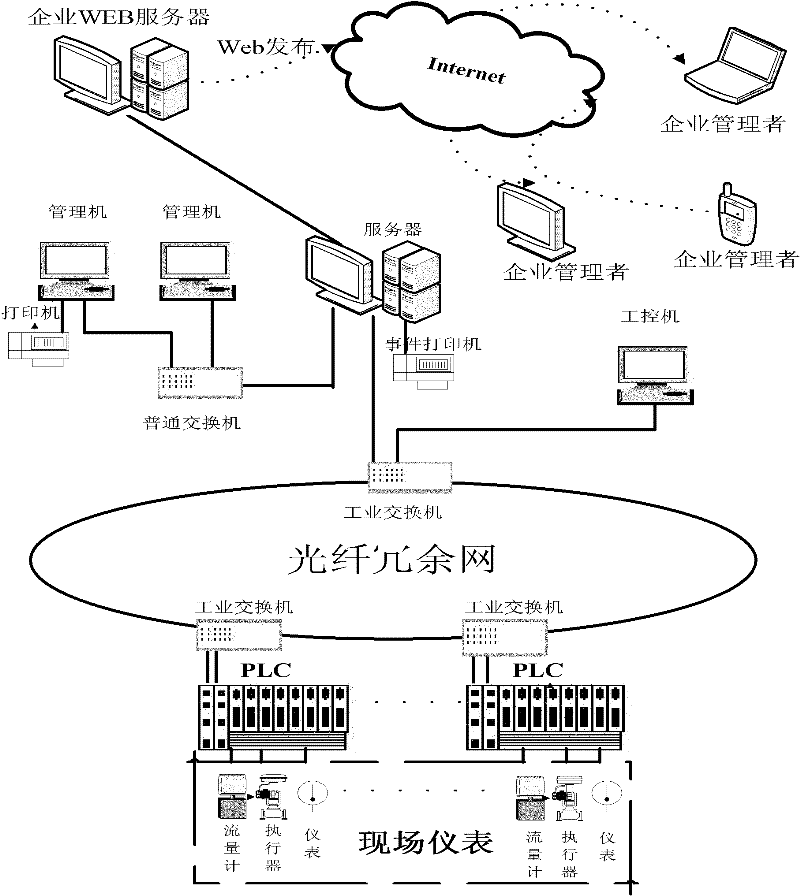

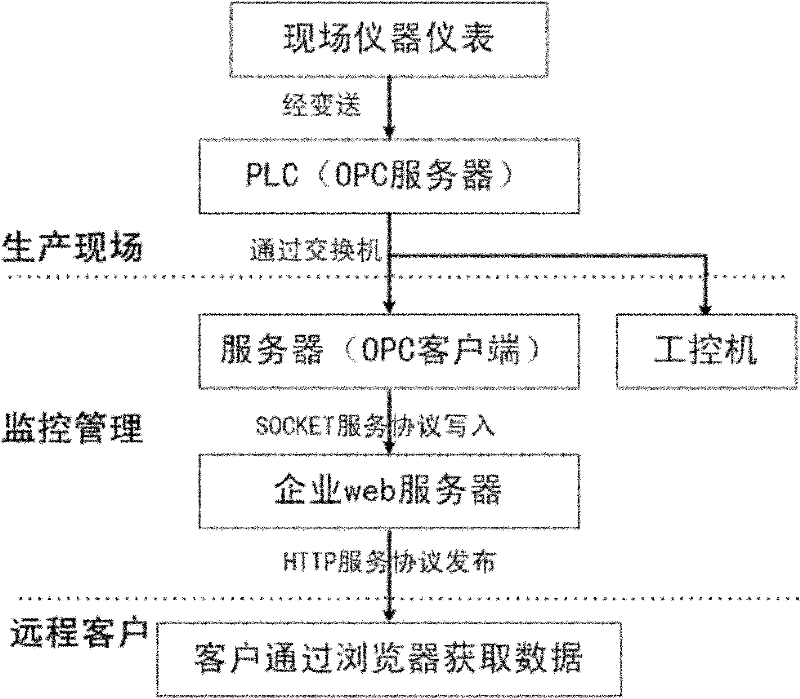

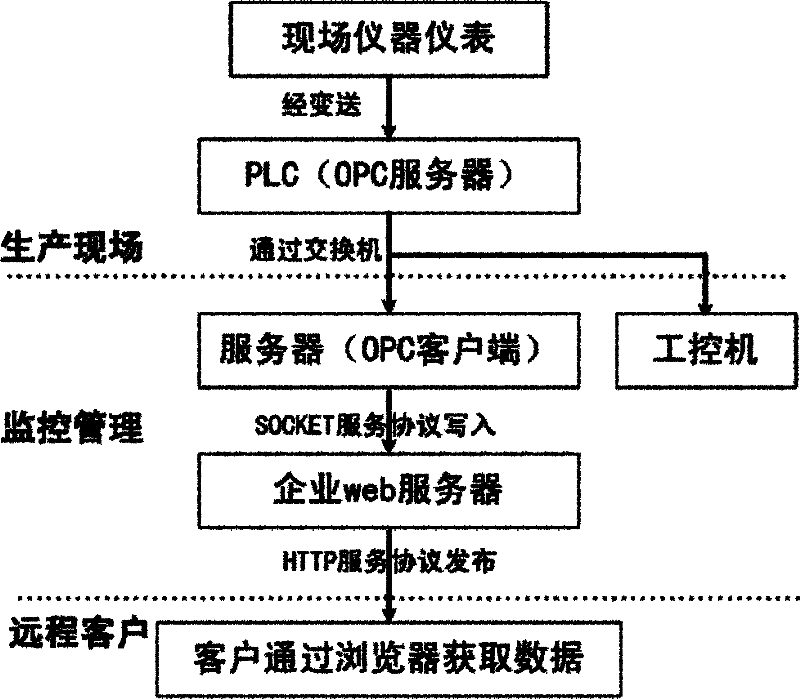

The invention relates to a remote monitoring system of a sewage disposal process and an implementation method thereof. The method comprises the steps: collecting real-time monitoring data and writing into a database of an enterprise WEB server database; issuing the real-time data by the enterprise WEB server through a standard http protocol; mapping the data into Internet server, directly obtaining the data from a browser when a customer browses the Web server, wherein the monitoring system comprises a field apparatus and a management device; transmitting the collected field data to a PLC (programmable logic controller) to control an execution component by a field instrument in the field apparatus; simultaneously carrying out data interaction on an industrial personal computer and a server by the PLC via an industrial switch; carrying out communication connection with the server through the switch by the industrial control computer in the management device; and issuing the data to the enterprise WEB server by the server as an OPC (OLE for process control) client. According to the remote monitoring system disclosed by the invention, an operator can achieve constantly grasping of production and operation in everywhere and the mode that a set of technical service personnel is configured for each sewage treatment plant in the past is avoided, so that manpower resource is greatly saved and the operation cost is reduced.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI +2

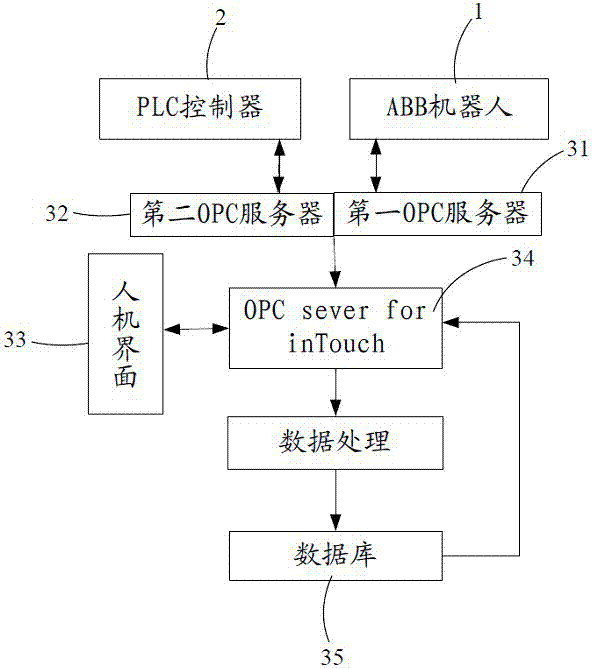

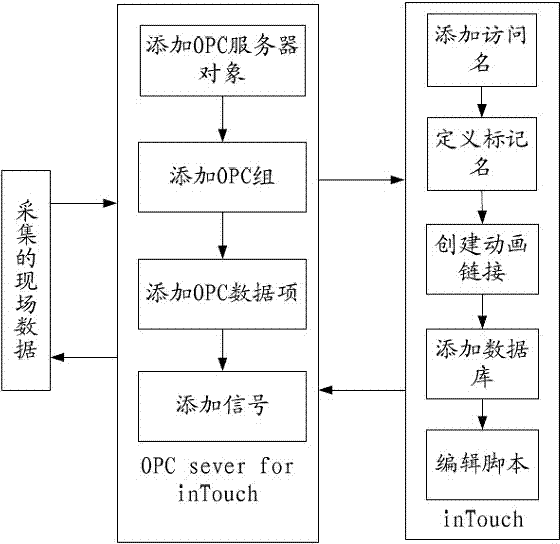

Robot control system

InactiveCN103240740AConvenient and quick diagnosisEasy maintenanceProgramme-controlled manipulatorHuman–machine interfaceOLE for Process Control

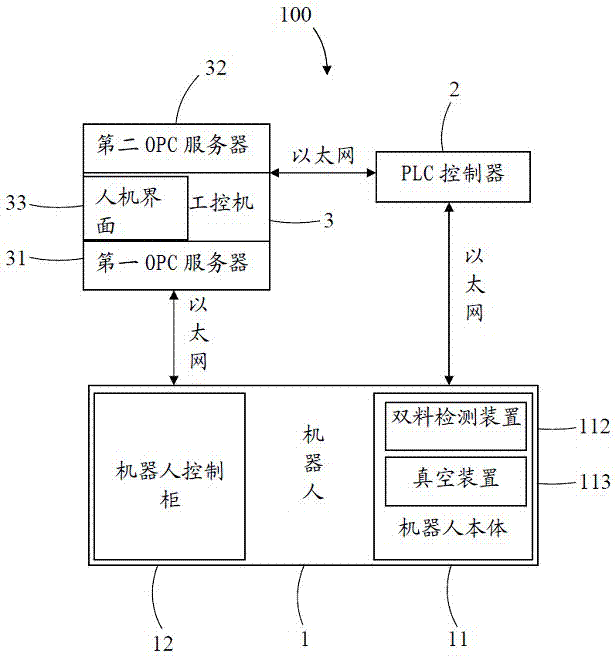

The invention provides a robot control system which comprises a robot, a programmable logic controller (PLC) and an industrial personal computer provided with configuration software. The PLC is in communication connection with the robot through the Ethernet and inputs control instructions into the robot to enable the robot to conduct corresponding operations. The industrial personal computer is respectively in communication connection with the robot and the PLC through the Ethernet and performs information interaction with the robot and the PLC respectively based on the OLE for process control (OPC) protocol, and the industrial personal computer is further provided with a first OPC server, a second OPC server, a man-machine interface and a connection plug-in connector, wherein the first OPC server and the second OPC server are respectively in information interaction with the robot and the PLC, the man-machine interface is built by adopting the configuration software, and the plug-in connector connects the configuration software, the first OPC server and the second OPC server.

Owner:JIANGSU BEIREN ROBOT SYST CO LTD +1

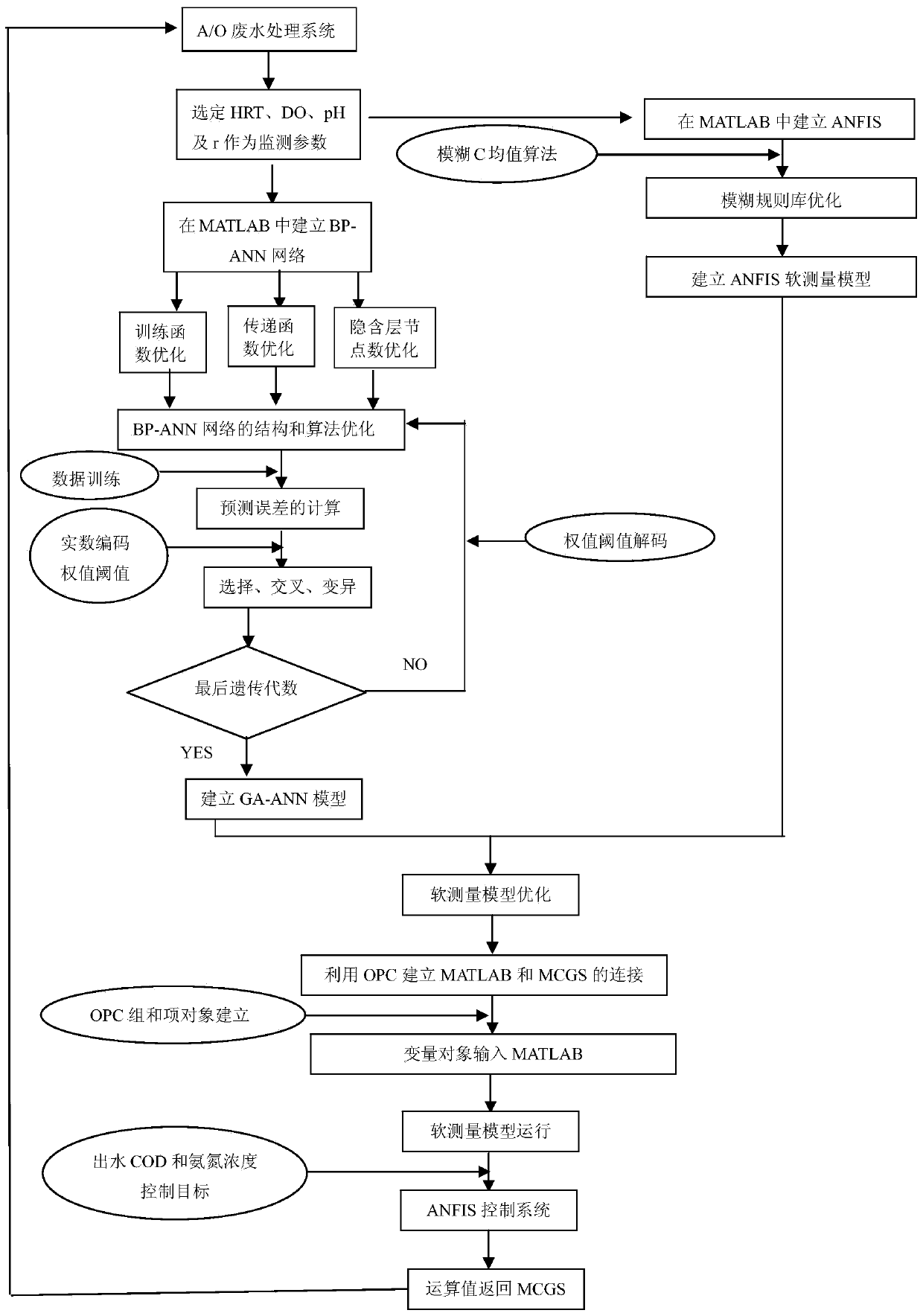

Waste water treatment monitoring method and system based on fuzzy neural network

InactiveCN103744293AImprove performanceImprove stabilityAdaptive controlChemical oxygen demandWater discharge

The invention provides a waste water treatment monitoring method based on a fuzzy neural network. According to the method, global search optimization is performed on the weight value and the threshold value of the neural network by applying a neural network structure algorithm and a real number encoding-based genetic algorithm on the basis of inspecting the influences of parameters such as the HRT (Hydraulic Retention Time) of an A / O (Anaerobic / Oxic) waste water treatment system, the DO (Dissolved Oxygen) in an aerobic pond and the reflux ratio r of mixed liquid on the COD (Chemical Oxygen Demand) and ammonia nitrogen of effluent water, so that an optimal BP-ANN (Back-Propagation Artificial Neural Network) soft measurement model and a GA-ANN (Genetic Algorithm-Artificial Neural Network) soft measurement model are built respectively. An intelligent dissolved oxygen optimization control system scheme based on the soft measurement models is built on the basis, data communication between the MATLAB (Matrix Laboratory) and MCGS (Microwave Command Guidance System) is realized in combination with an OPC (OLE for Process Control) technology, and an intelligent dissolved oxygen optimal control system is applied to dissolved oxygen optimal control in a paper-making waste water A / O technical treating process, so that energy saving and consumption reduction in paper-making waste water A / O treating engineering is realized. By adopting the waste water treatment monitoring method, the stability of the water quality of waste water discharged in the paper making industry can be increased greatly, accurate control is realized, and the chemical drug dosage and power consumption in a waste water treatment process are reduced.

Owner:ZHEJIANG YONGTAI PAPER IND GROUP +1

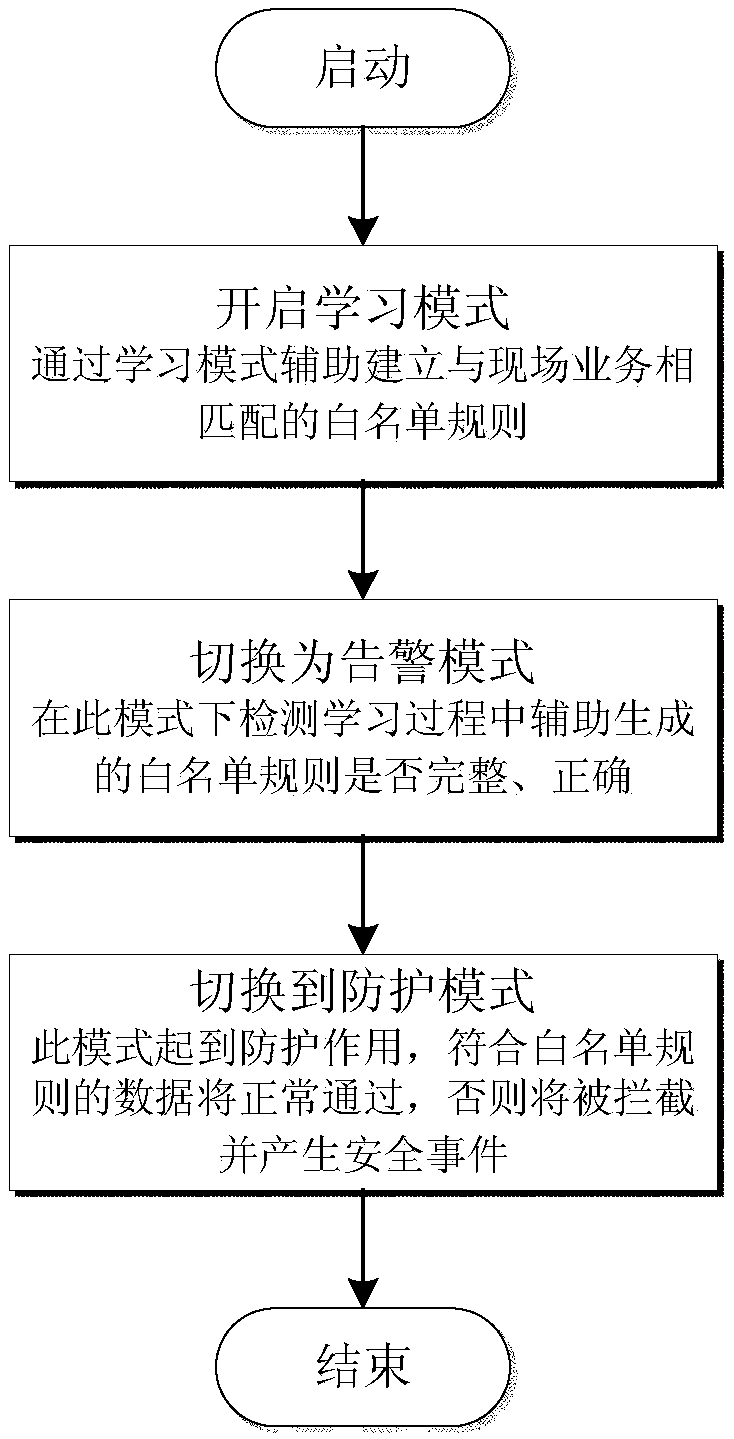

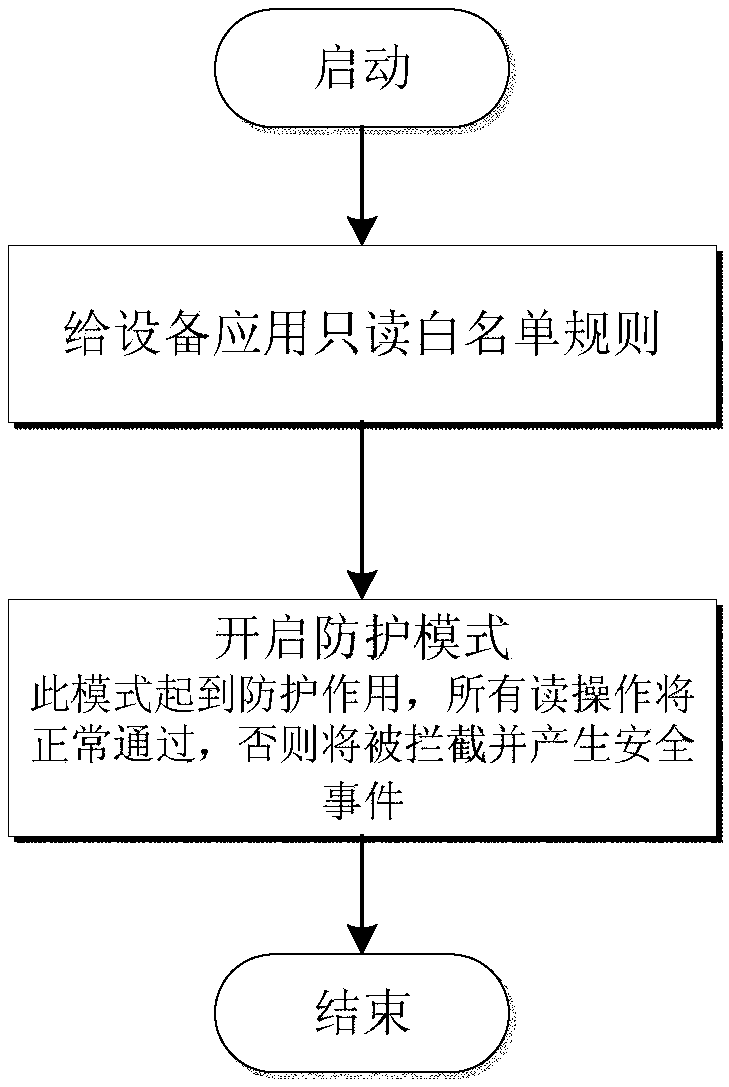

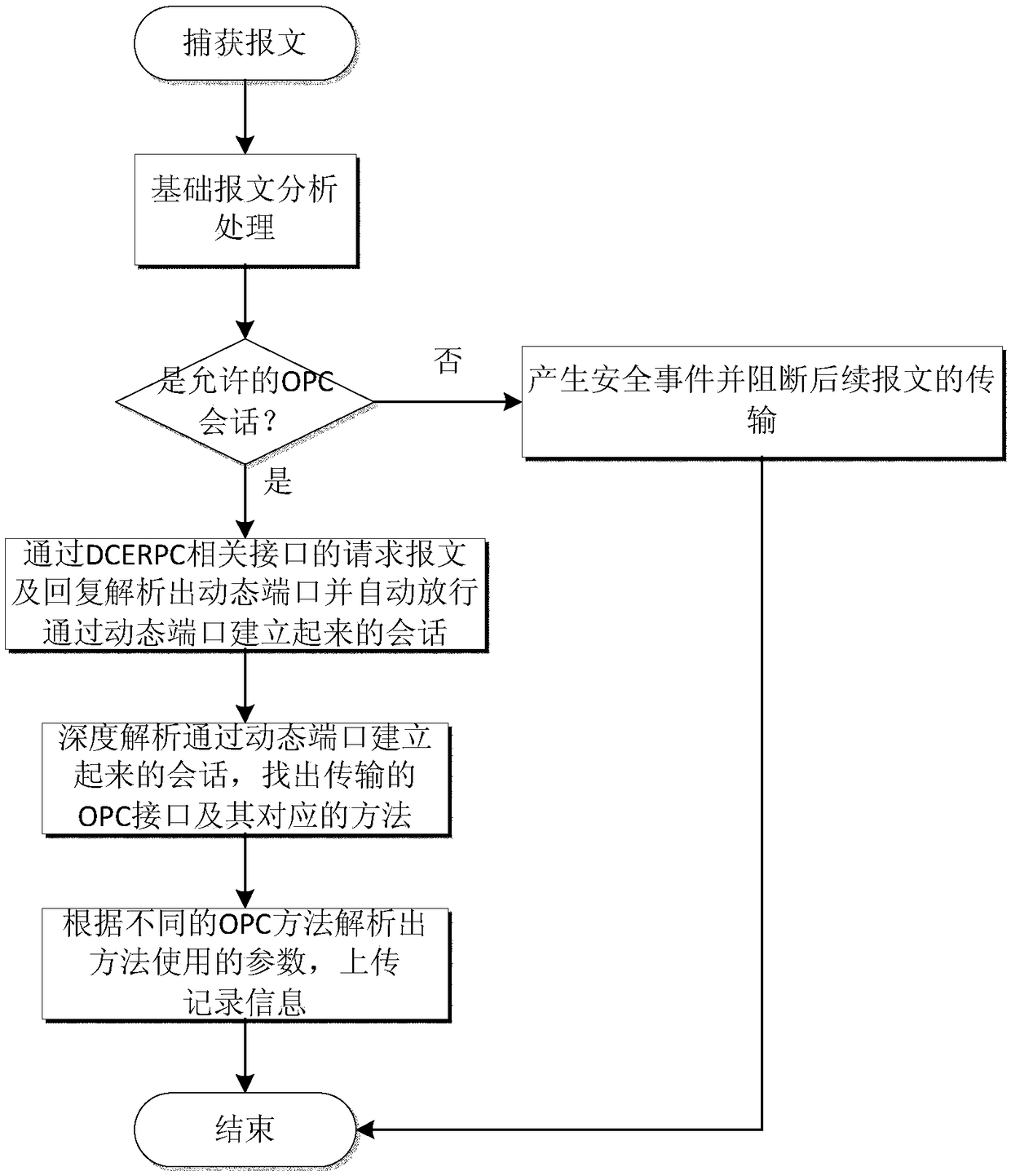

OPC protocol safety protection method for intelligently learning and presetting read-only whitelist rule

ActiveCN108848067AMonitoring Protection TransmissionGuaranteed correctnessData switching networksOLE for Process ControlOperation mode

The invention discloses an OLE for process control (OPC) protocol safety protection method for intelligently learning and presetting a read-only whitelist rule. The method comprises the following steps: step one, a network messagecapture; step two, basic message analytic processing; step three, protocol deep analysis and processing; step four, service processing; step five, whitelist rule generation; step six, read-only whitelist rule setting; step seven, monitoring protection equipment operation in an alarm mode; step eight, changing of the monitoring protection equipment to an operation mode; step nine, transmission of the data of the OPC protocol; and step ten, receiving and learning the message record information uploaded by the monitoring protection equipment. The method disclosed bythe invention has the advantages that the OPC protocol based on the TCP protocol can be identified, and the OPC protocol based on the UDP protocol can be monitored, protected and transmitted; an industrial field only having the collection action directly uses the preset read-only rule and the complex learning process is saved.

Owner:北京威努特技术有限公司

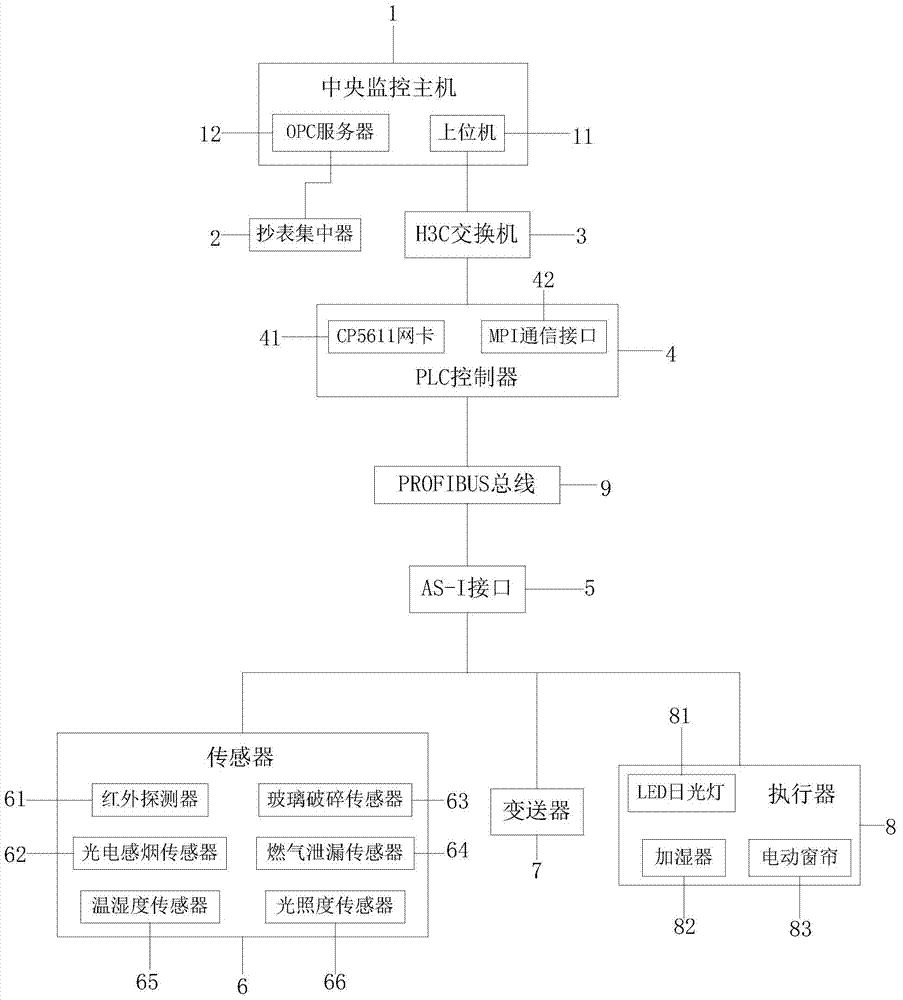

Intelligent home system

InactiveCN103676912AImprove securityRapid ResponseTotal factory controlProgramme total factory controlControl layerOLE for Process Control

The invention relates to the technical field of intelligent home, particularly relates to an intelligent home system. According to the technical scheme, the intelligent home system comprises a management layer, a control layer and a site device layer which are connected sequentially; the management layer comprises a central monitoring host; the control layer comprises a site controller; the site device layer comprises a sensor, a transmitter and an actuator; the central monitoring host adopts a web-based remote control platform; the central monitoring host comprises an OPC (Ole For Process Control) server and an upper machine. The intelligent home system has the advantages of enabling indoor environment to be correspondingly adjusted automatically to enable the indoor environment to be comfort according to change of external environment factors and meanwhile guaranteeing high safety of people, fortune and goods; being rapid in reaction to disasters and emergencies; achieving information exchange with the exterior in real time due to an improved network communication system.

Owner:GUIYANG POWER SUPPLY BUREAU OF GUIZHOU POWER GRID CO LTD

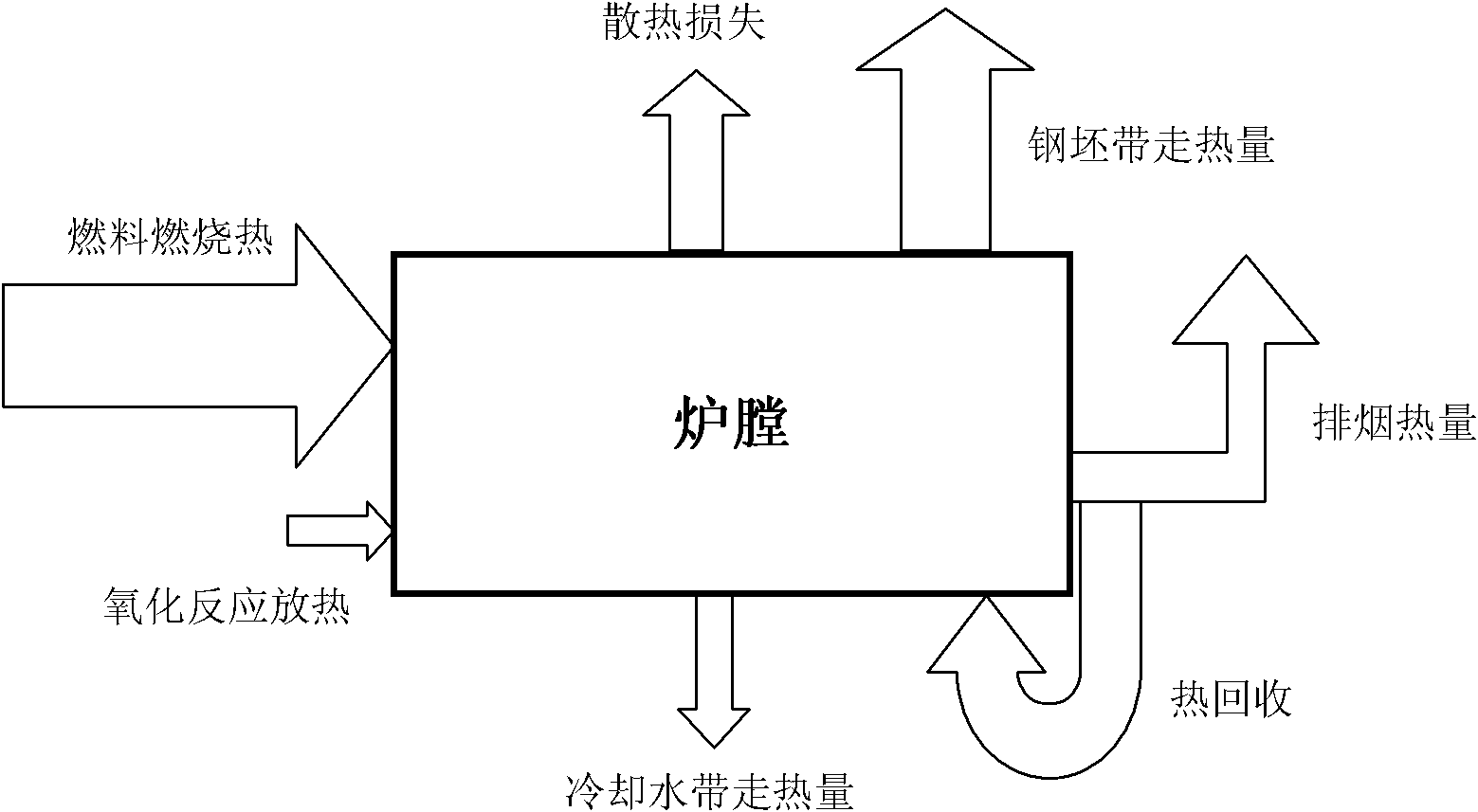

On-line heat balance testing diagnostic system for heating furnace

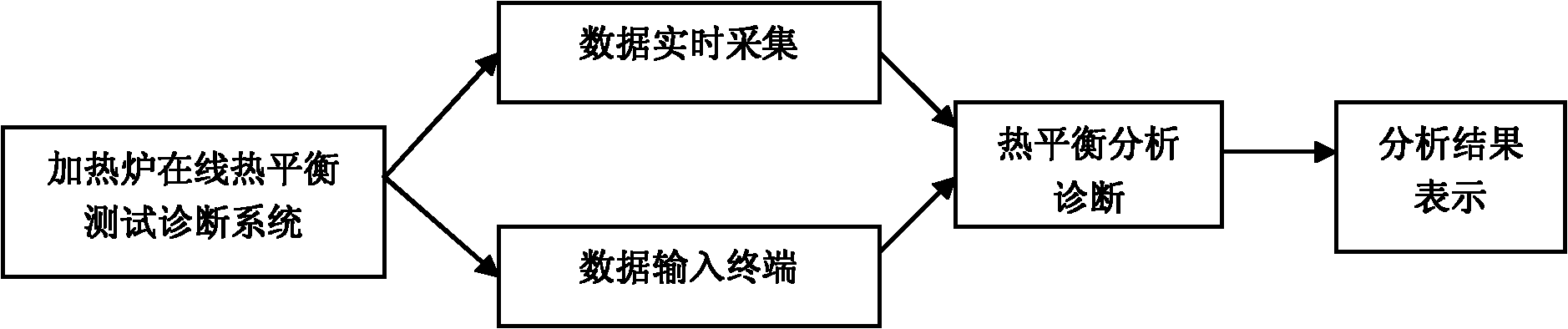

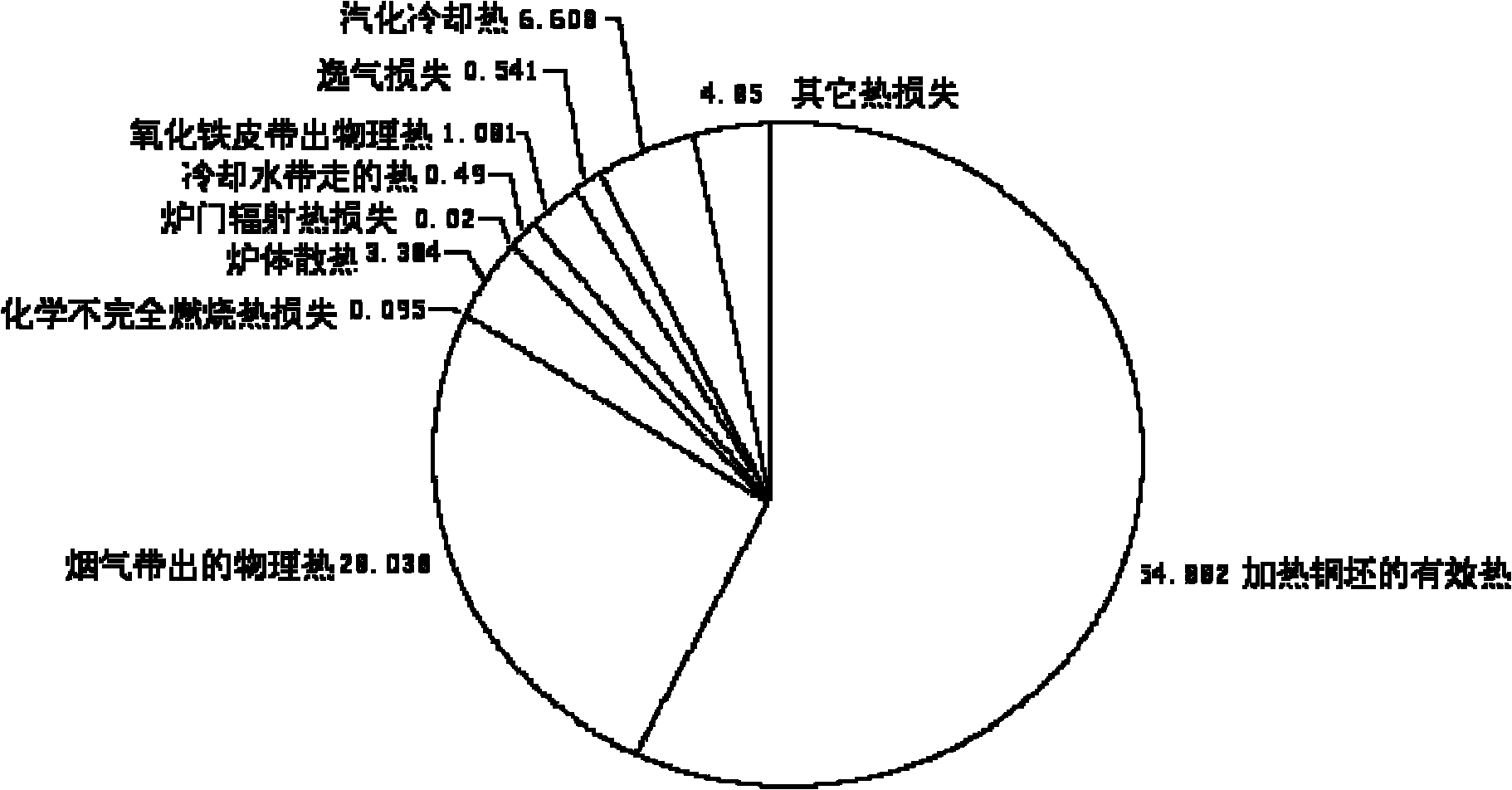

The invention relates to the field of estimation and diagnosis on the running state of a heating furnace, in particular relating to a system suitable for testing and diagnosing the on-line heat balance of a heating furnace. The system comprises a data processing module and a heat balance analysis module, wherein the data processing module is used for acquiring data in real time, namely, acquiring furnace temperature data on each section of the heating furnace, air-gas flow data on each section, evaporative cooling water volume, water pressure, water temperature data, steam output, temperature and pressure data from a basic automatic control system by utilizing an OPC (OLE for process control) technique; a human-computer interface terminal is used for inputting other related data required by the heat balance test for the heating furnace; and the heat balance analysis module is used for calculating the output data from the data processing module based on the heat engineering theory and the law of the conservation of energy, thereby generating an intuitive data table and graph and supplying a diagnosis result and a reasonable adjusting direction for the efficient running of the heating furnace.

Owner:WISDRI WUHAN WIS IND FURNACE

Filter stick forming process quality analyzing and tracing system

ActiveCN105760555AAvoid quality anomaliesReduce complexityRelational databasesCo-operative working arrangementsProcess qualityOLE for Process Control

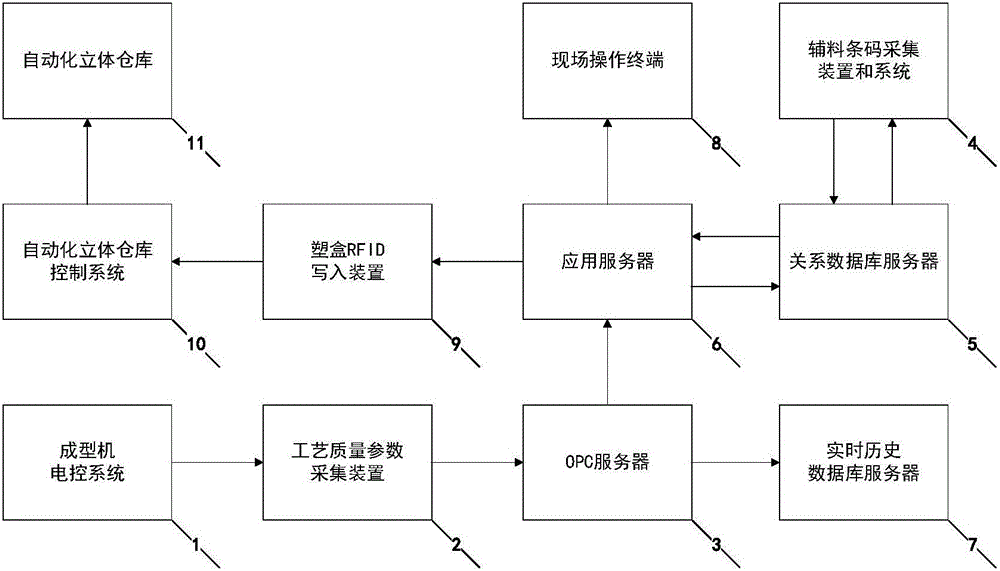

The invention relates to a filter stick forming process quality analyzing and tracing system. The system consists of a forming machine electric control system, a process quality parameter acquisition device, an OPC (OLE for Process Control) server, an auxiliary material bar code acquisition device and system, a relationship database server, an application server, a real-time history database server, a field operation terminal, a plastic box RFID (Radio Frequency Identification Devices) writing device, an automation three-dimensional warehouse control system, an automation three-dimensional warehouse and PROFINET industrial Ethernet. According to the filter stick forming process quality analyzing and tracing system, process quality parameters in an equipment production process are acquired in real time through the process quality parameter acquisition device, and real-time monitoring and feedback of the change situations, adjustment situations and abnormal situations of the process quality parameters in a filter bar production process are realized according to a process quality standard of filter bars through an analysis model based on big data and a full-sample statistics technology. Recurrence of quality anomalies is avoided; a delivery command is sent to the automation three-dimensional warehouse control system specific to quality anomalies found through analysis, so that the manual tracing complexity is lowered greatly.

Owner:CHINA TOBACCO ZHEJIANG IND

Access control methods, device and equipment based on OPC (OLE for Process Control) protocol and memory medium

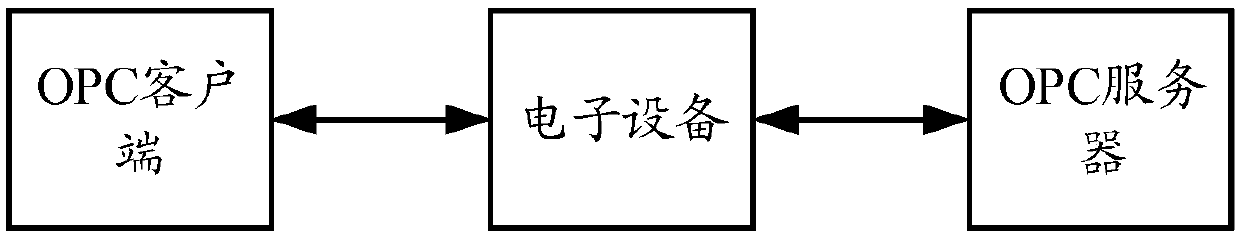

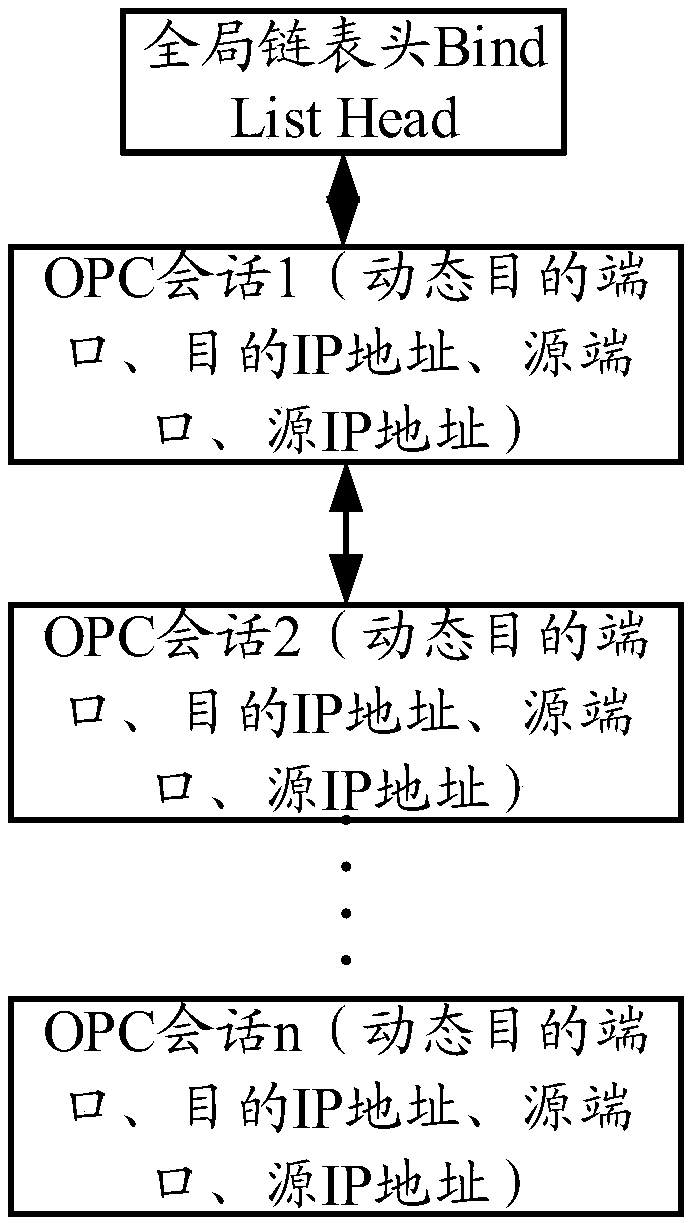

ActiveCN109639701AImplement access controlImprove security assuranceTransmissionOLE for Process ControlOperand

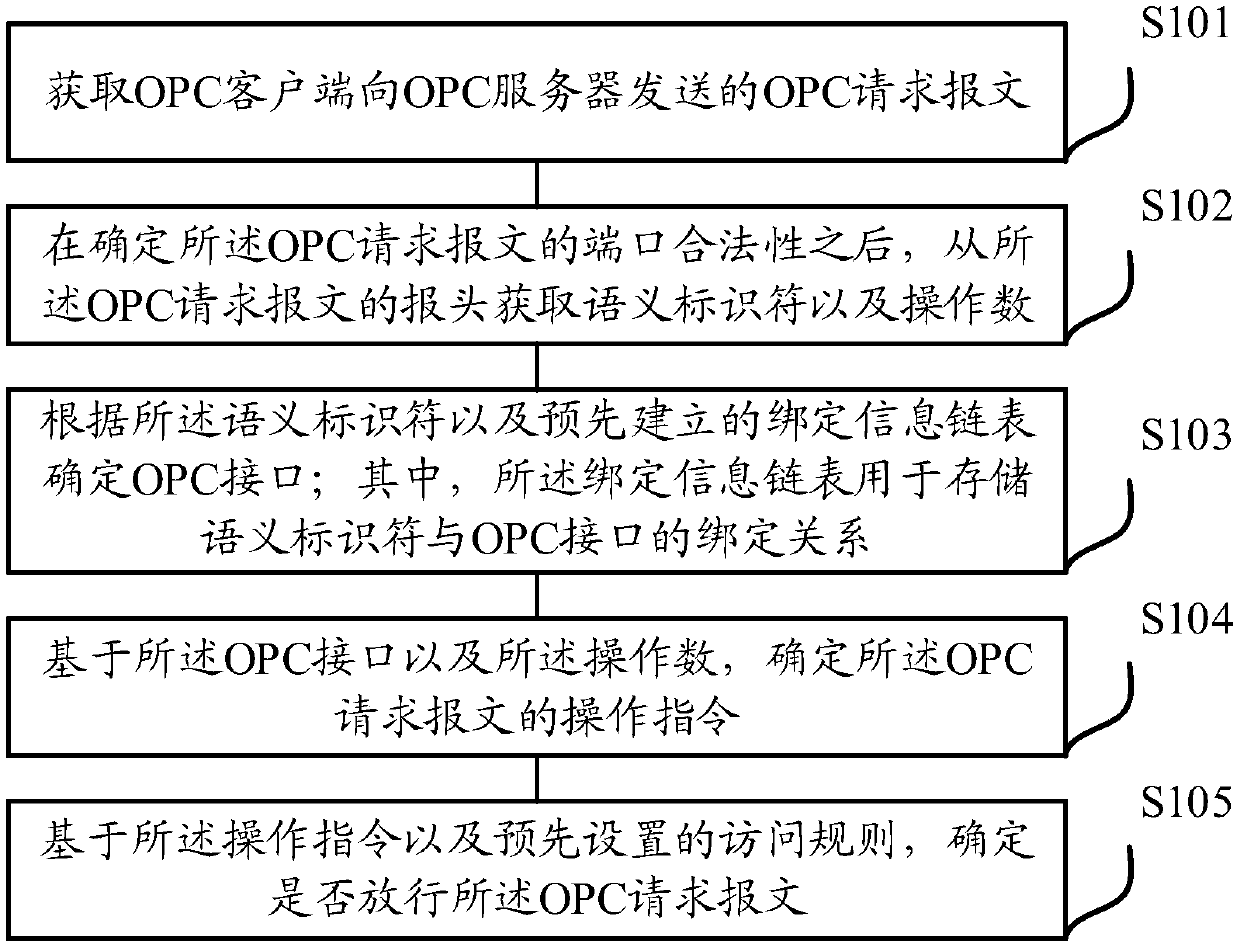

The invention provides access control methods, device and equipment based on an OPC (OLE for Process Control) protocol and a memory medium. A method comprises the steps of obtaining an OPC request message sent by an OPC client to an OPC server; obtaining a semantic identifier and operand from a message header of the OPC request message after port legality of the OPC request message is determined;determining an OPC interface according to the semantic identifier and a pre-established binding information linked list, wherein the binding information linked list is used for storing a binding relationship between the semantic identifier and the OPC interfaces; determining an operation instruction of the OPC request message based on the OPC interface and the operand; and determining whether to permit the OPC request message or not based on the operation instruction and a preset access rule. An instruction level of access control over the OPC message is realized, and relatively high securityassurance for an OPC communication process is provided.

Owner:HANGZHOU DPTECH TECH

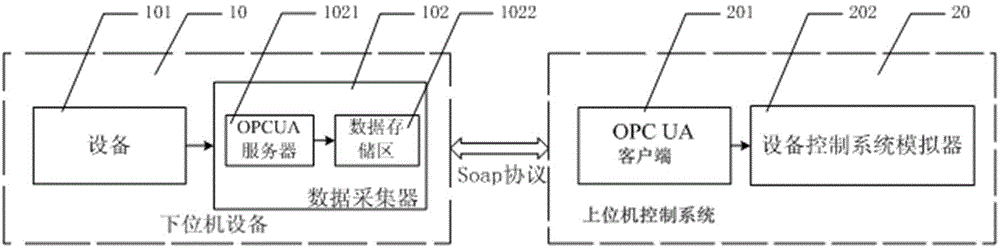

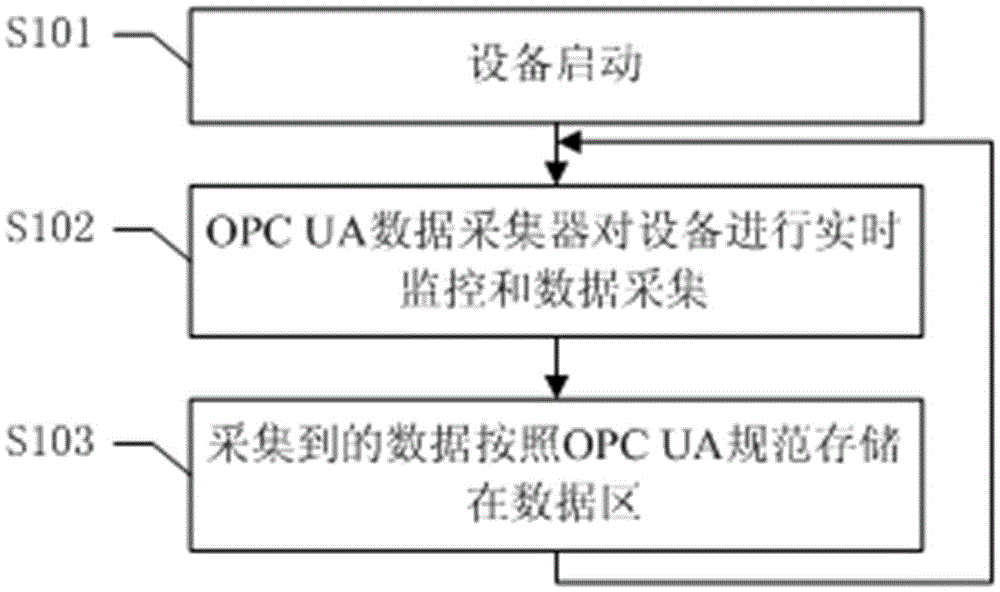

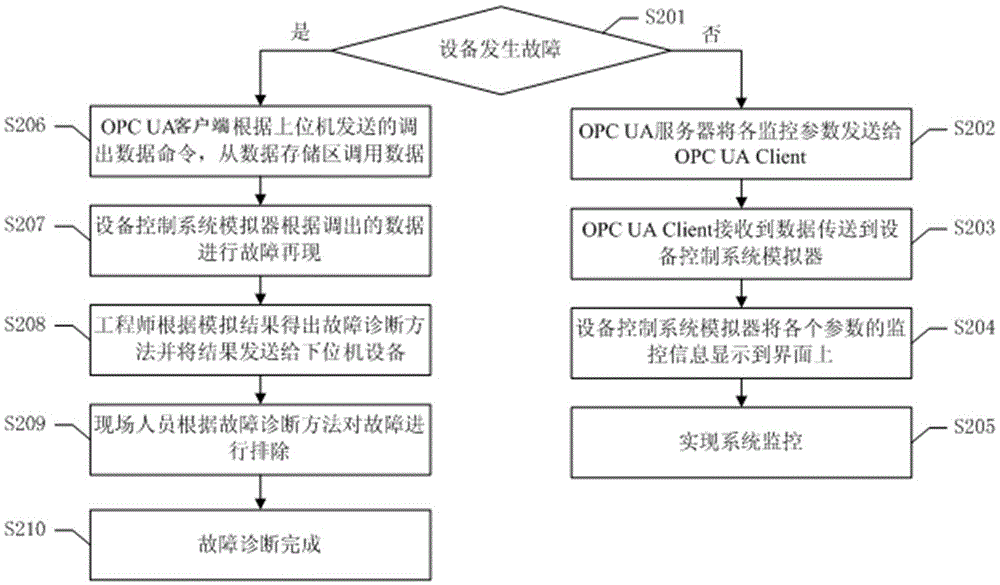

Remote monitoring system based on OPC UA (OLE for Process Control Unified Architecture) and fault removal method

InactiveCN105527910AImprove confidentialityImprove securityProgramme controlComputer controlOLE for Process ControlDiagnosis methods

The invention discloses a remote monitoring system based on an OPC UA (OLE for Process Control Unified Architecture) and a fault removal method. A traditional data acquisition and monitoring system is improved, and a data acquisition device based on an OPC UA, an OPC UA client and an equipment control system online simulator are added, so that a technician can immediately perform remote online fault reproduction after a fault occurs, and analyzes the fault to obtain a fault diagnosis method. The OPC UA client directly transmits the fault diagnosis method to the site, and people on site can diagnose the equipment fault according to the fault diagnosis method, so that the fault diagnosis time is greatly shortened and the efficiency is improved.

Owner:HANGZHOU ZHENPENG TECH CO LTD

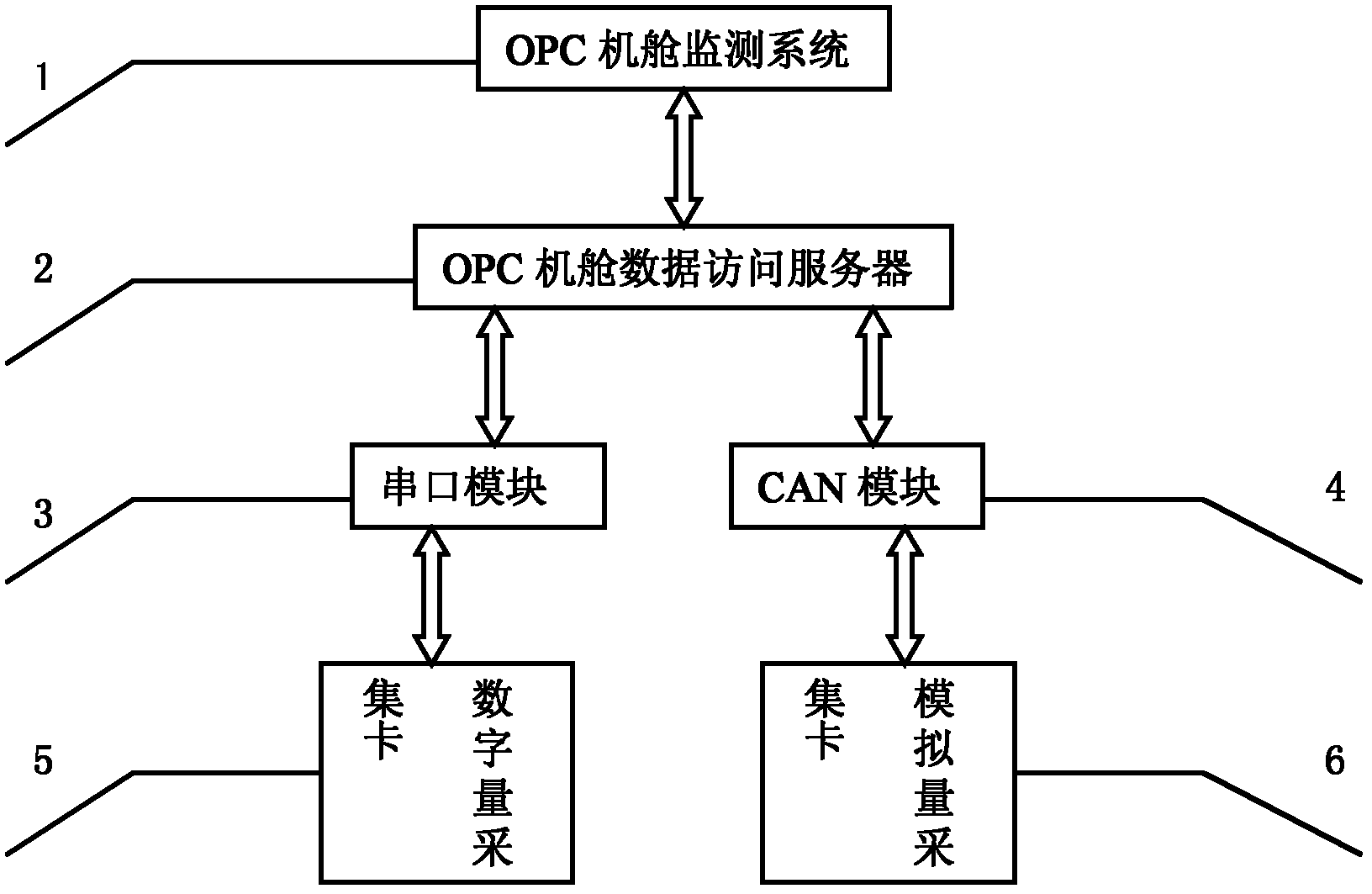

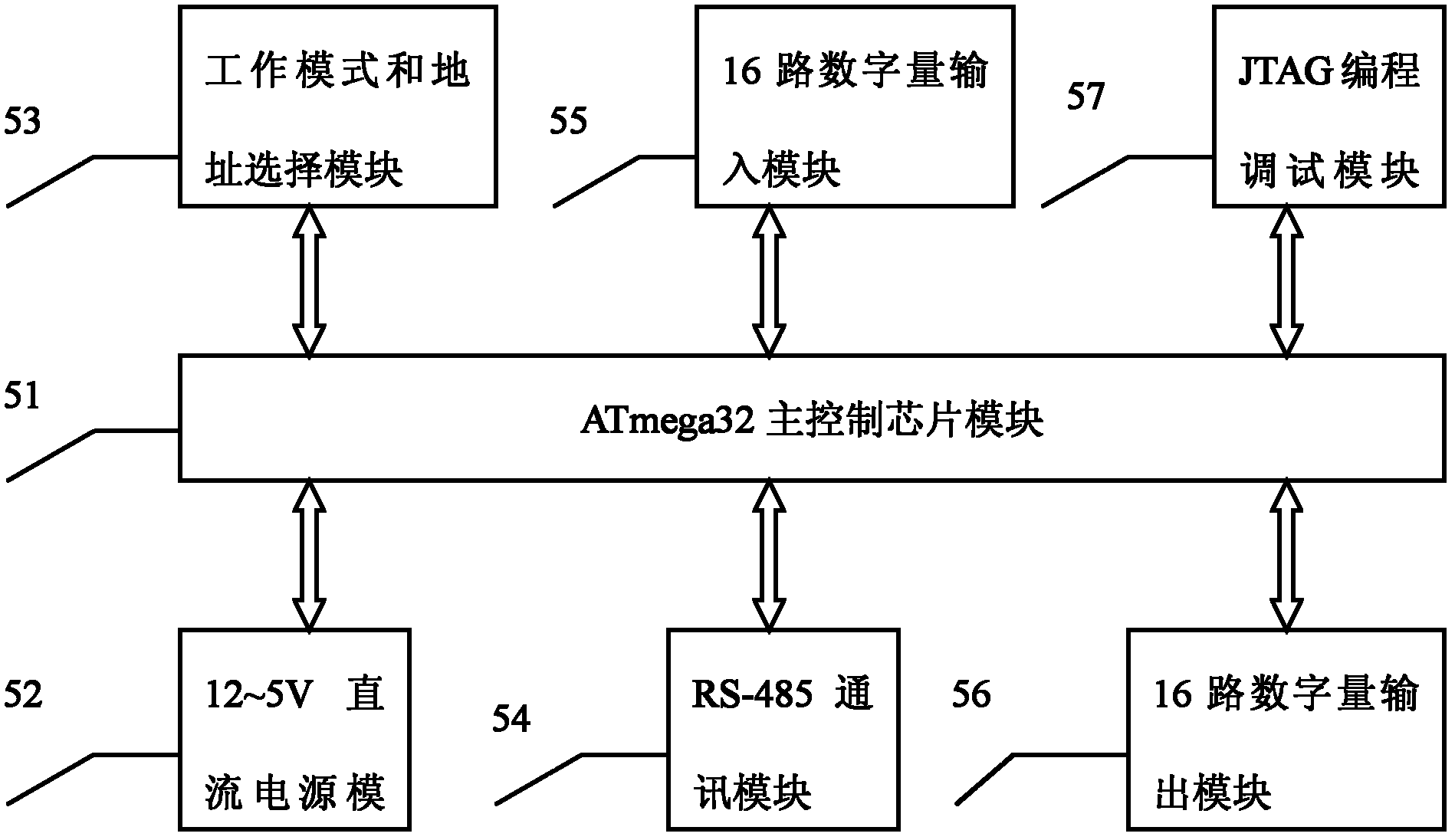

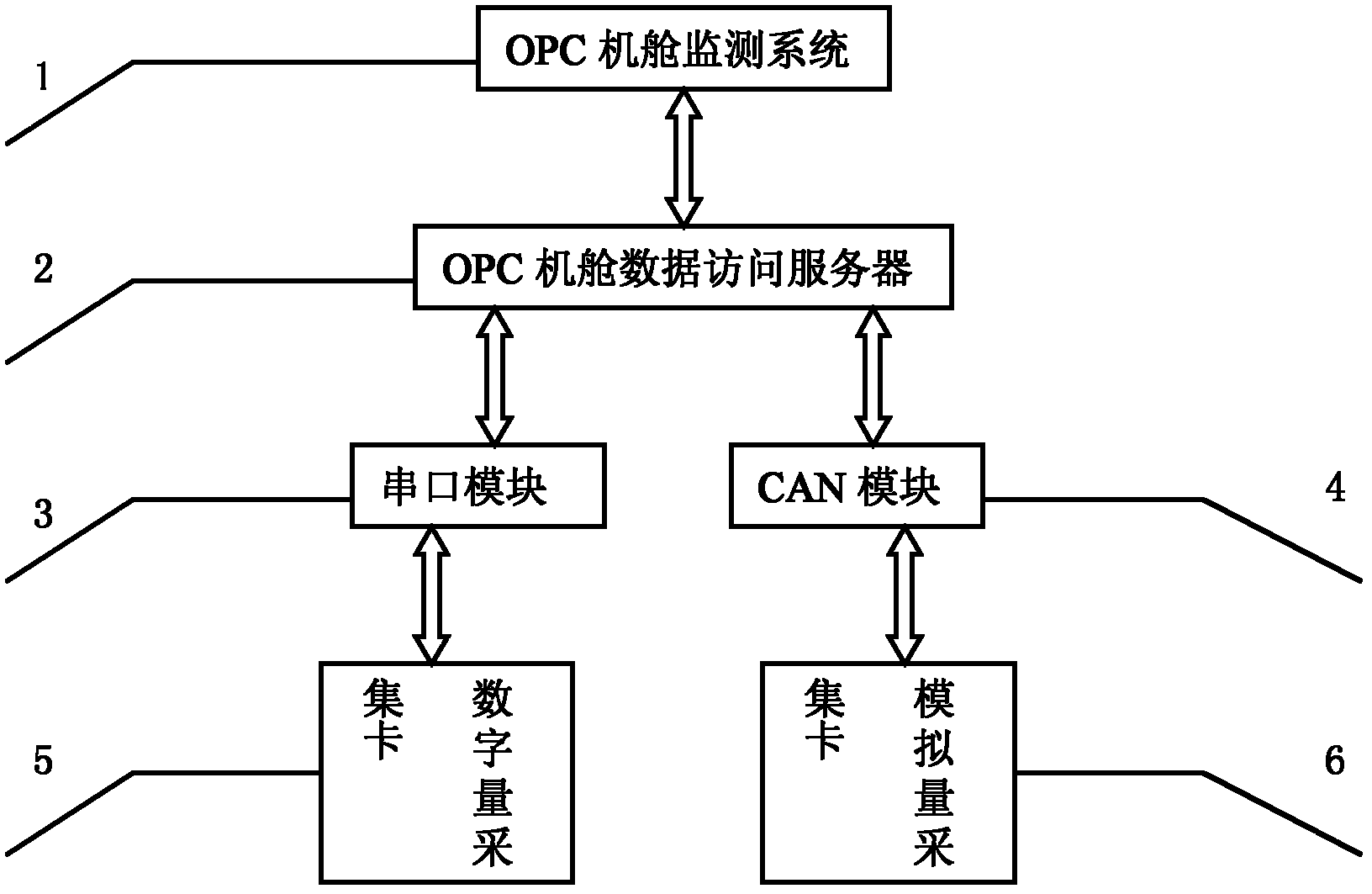

Marine engine room data acquisition and monitoring system based on OLE for process control (OPC) technology

InactiveCN102520655AReduce development costsSolve the problem of repeated developmentProgramme controlComputer controlOLE for Process ControlSoftware system

The invention discloses a marine engine room data acquisition and monitoring system based on an OLE for process control (OPC) technology. The system comprises: an OPC engine room monitoring system, an OPC engine room data access server, a serial port module, a CAN module, a digital quantity acquisition card module and an analog quantity acquisition card module. The OPC engine room monitoring system and the OPC engine room data access server use an OPC port technology standard to carry out mutual communication. The digital quantity acquisition card module and the analog quantity acquisition card module are intelligent acquisition cards. The OPC engine room monitoring system follows the technical standard of the OPC standard. The digital quantity acquisition card module used in the invention sets a working module and an address through a 8 bit dial switch so that acquisition point resources of an acquisition card can be used maximumly. According to the invention, because the technical standard of the OPC standard is used to design and develop a marine engine room state monitoring software system, a communication driving program of hardware equipment in the software system can not be developed repeatedly.

Owner:DALIAN MARITIME UNIVERSITY

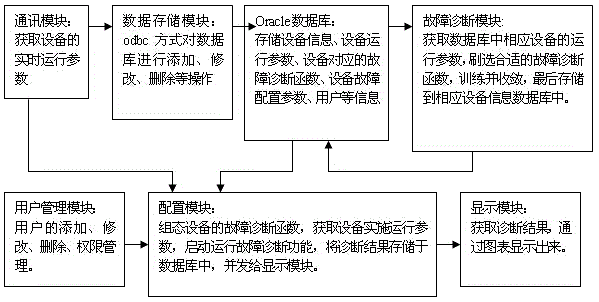

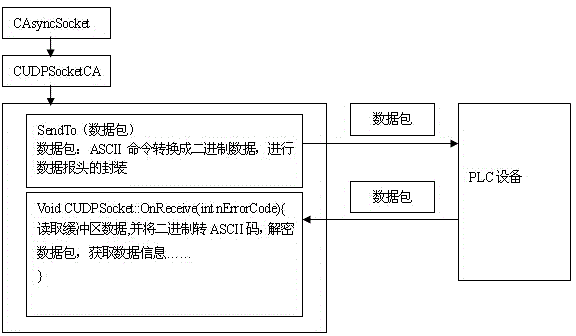

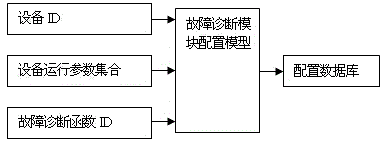

Fault diagnosis system of oil delivery process

InactiveCN104808650AImplement fault diagnosisRealize remote browsingFault responseElectric testing/monitoringOLE for Process ControlOperational system

The invention discloses a fault diagnosis system of an oil delivery process, and relates to a computer diagnosis system. The system comprises a server for operating installing. Net, wherein a PC (Personal Computer) machine is configured; a hard disk meets an operation system and a Windows xp 32 bit operation system; the system is characterized by comprising a communication module, a data storage module, a fault diagnosis module, a configuration module, a user management module, an operation module and a display module. Field data is acquired, and enterprise level opc (OLE for Process Control) service is established, so real-time data communication with opc is realized by using C++ language, the real-time data of the equipment is acquired, the data is stored in a cloud server, fault diagnosis of the oil delivery equipment is realized in real time with a data training fault detection model by using the cloud server, and remote browsing of equipment information, data management, management of equipment and management of a measuring point are realized through a web technology; finally a fault of the equipment is transmitted to a related responsible person by using a short message technology to remind overhauling equipment.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

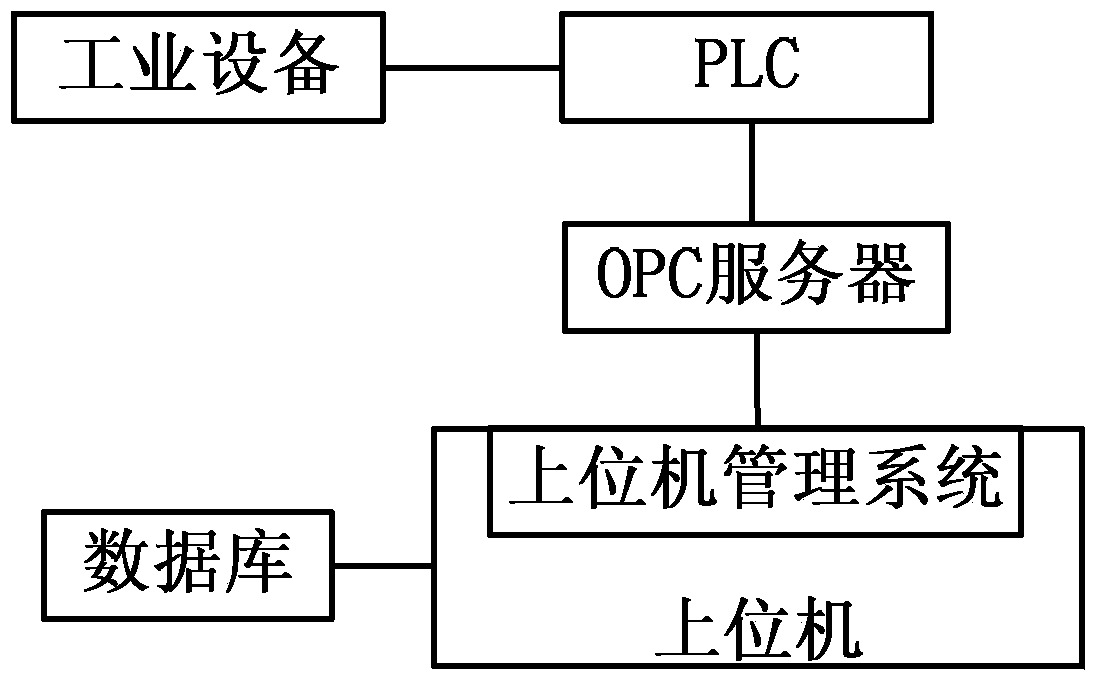

Data-warehouse-based industrial control upper computer management system and data processing method

InactiveCN103425085AQuick analysisImprove interactivityProgramme control in sequence/logic controllersOLE for Process ControlData warehouse

The invention discloses a data-warehouse-based industrial control upper computer management system which comprises a PLC (programmable logic controller) module for data acquisition, an OPC (OLE for process control) module communicated with the PLC, a display module for displaying PLC real-time monitoring data, a database for storing PLC measurement data and an analyzing module. The analyzing module is used for building a data warehouse, for data inquiry and digging, by using collected data and according to user's requirements. The data warehouse is built by using the data collected by the PLC, the analyzing tool OLAP is used to analyze the collected data such as temperature and air pressure to obtain valuable data, and accordingly enterprise production capability and equipment operation condition analyzing capability are improved. The data-warehouse-based industrial control upper computer management system in good in interactivity and high in data analyzing capability.

Owner:SUZHOU CHIEN SHIUNG INST OF TECH

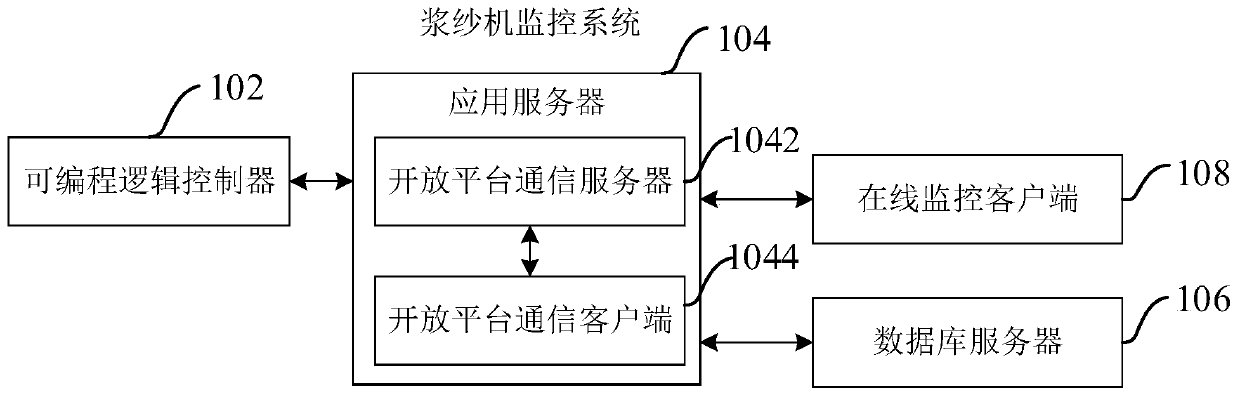

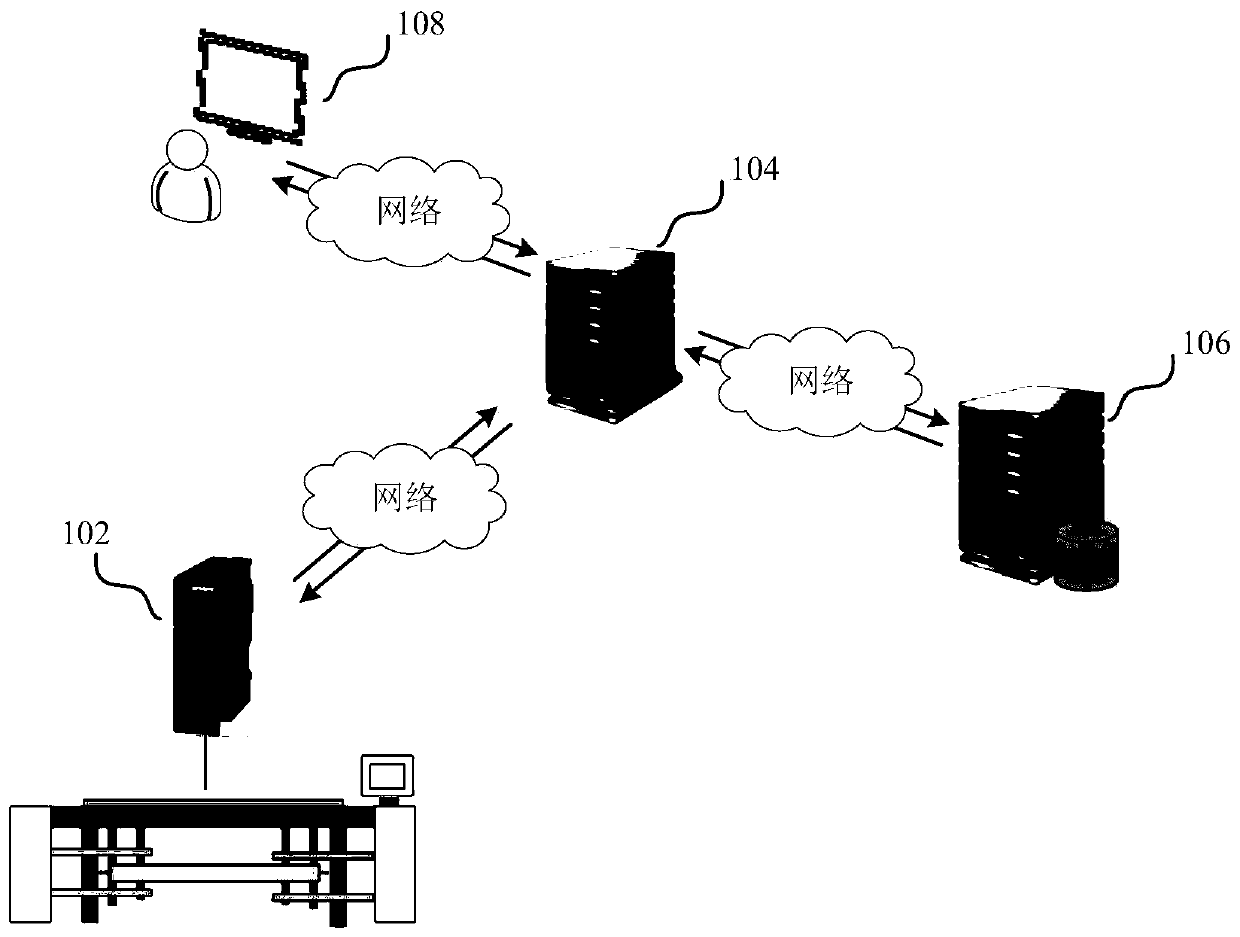

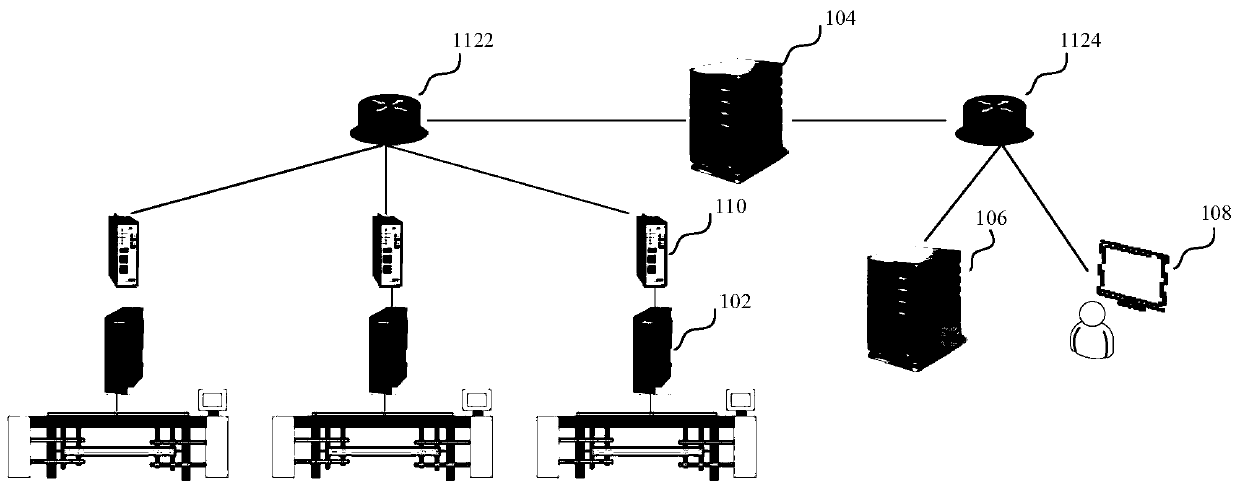

Sizing machine monitoring system and method, computer equipment and storage medium

PendingCN111400384AControllable sizing processIncrease productivityDatabase management systemsProgramme control in sequence/logic controllersOLE for Process ControlEmbedded system

The invention relates to a sizing machine monitoring system and method, computer equipment and a storage medium. The system comprises a programmable logic controller, an application server, an open platform communication server, an open platform communication client, a database server and an online monitoring client, wherein the programmable logic controller is used for collecting running state data of the sizing machine in the production process; the application server is used for deploying programs and interface services of the sizing machine monitoring system; the open platform communication server is used for communicating with the programmable logic controller and acquiring running state data from the programmable logic controller; the open platform communication client is used for processing the running state data and storing the running state data into a database. By adopting the system, the running state and the production progress of the sizing machine can be monitored on line, a traditional method for manually monitoring the sizing production process is replaced, and the production efficiency is greatly improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

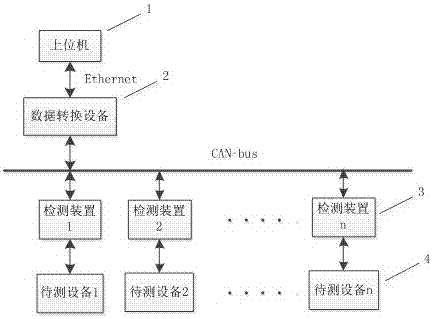

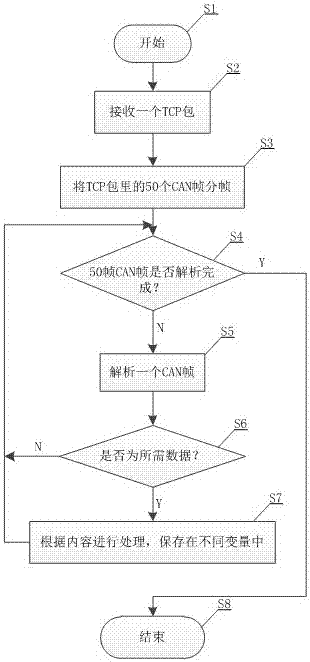

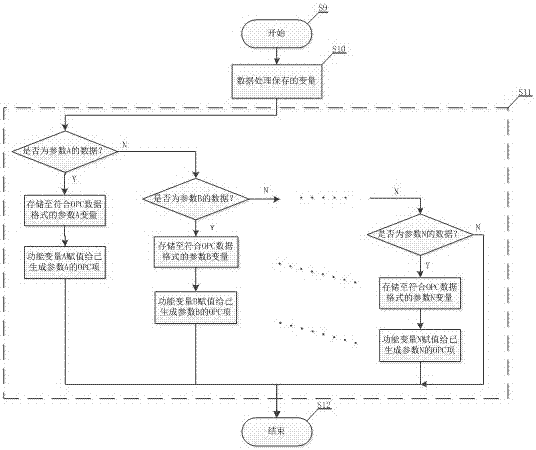

Data acquisition monitoring system and acquisition monitoring method based on CAN bus and OPC (OLE for process control) technology

PendingCN107018028ARealize transmissionRealize data collectionData switching networksOLE for Process ControlData acquisition

The invention discloses a data acquisition monitoring system and acquisition monitoring method based on a CAN bus and an OPC (OLE for process control) technology. The system comprises an upper computer and data conversion equipment connected with the upper computer by a network cable; the data conversion equipment is connected with a plurality of detection devices by CAN communication wires; and the detection devices are connected with corresponding to-be-detected equipment. The method comprises the following steps of: (I) data processing of frames received by the upper computer; (II) data conversion of the frames received by the upper computer; (III) debugging on the detection devices; and (IV) operation of the detection devices. The invention provides the field data acquisition monitoring system suitable for industrial application, so that transmission of instructions and data between acquisition monitoring software and the detection devices is implemented, equipment parameters which need to be monitored are acquired by utilizing the detection devices and data (detection results) is shared with other clients in an OPC mode.

Owner:RES INST OF PHYSICAL & CHEM ENG OF NUCLEAR IND

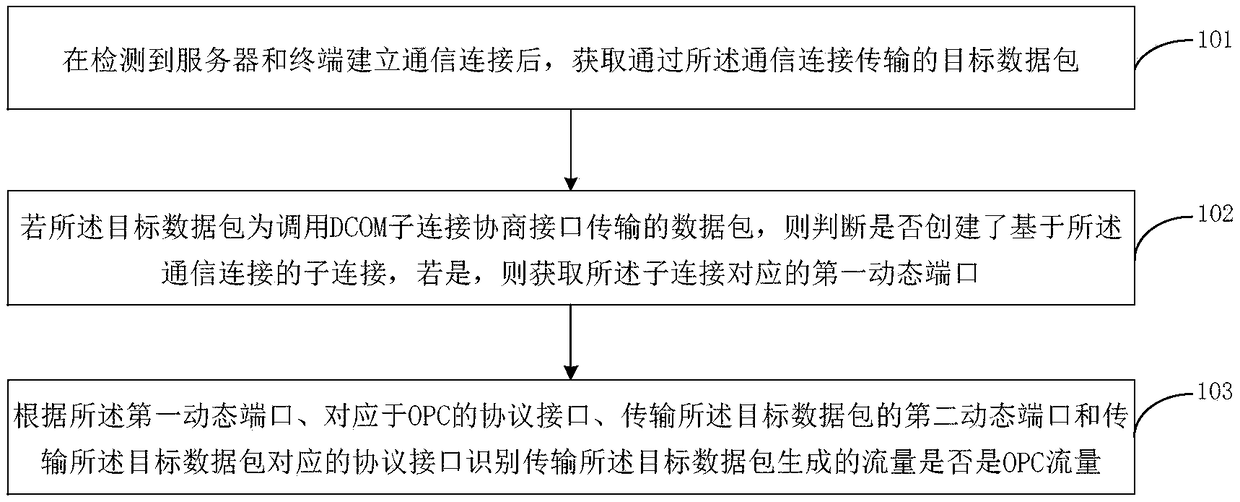

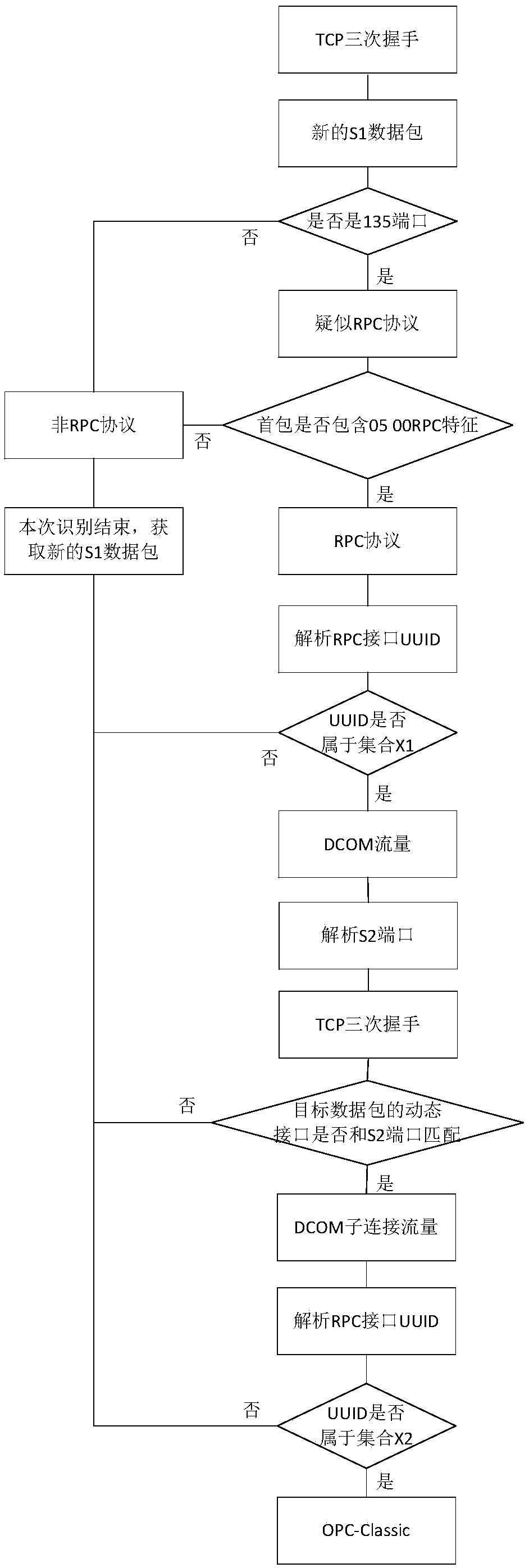

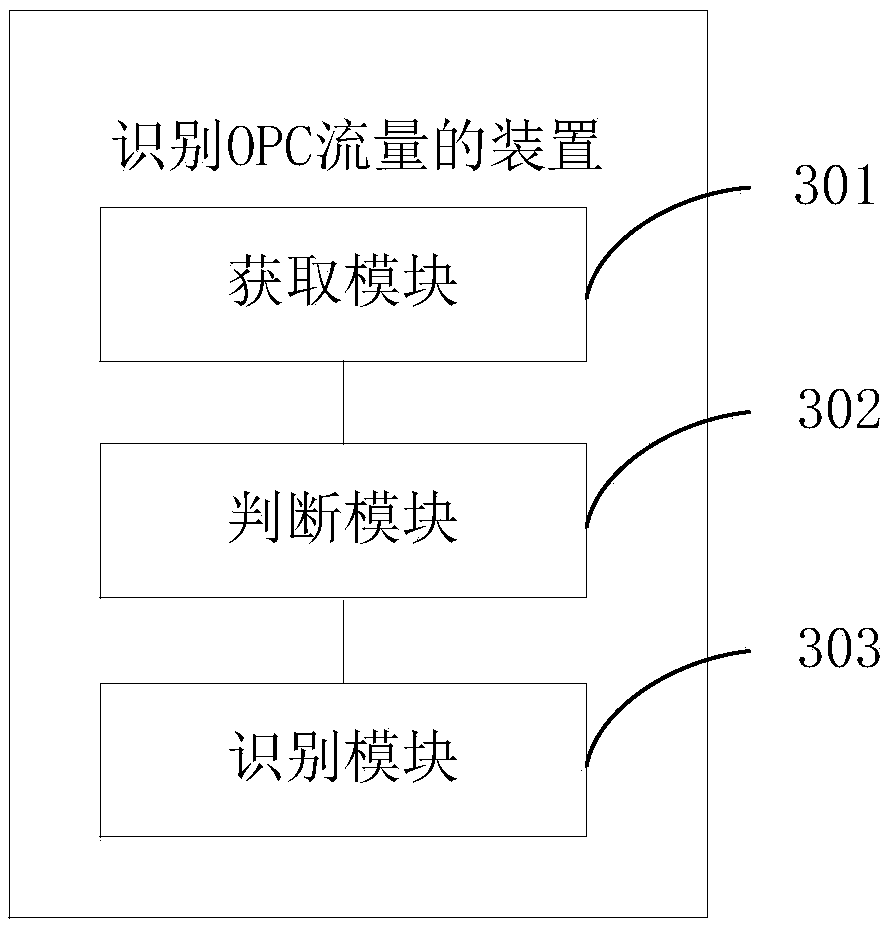

Method and device of identifying OPC (OLE for Process Control) traffic

ActiveCN109474540AEliminate potential safety hazardsData switching networksTraffic capacityOLE for Process Control

The embodiment of the invention discloses a method and a device of identifying OPC traffic. According to the method, a transmitted target data packet is acquired after a server and a terminal establish a communication connection, if it is judged that the target data packet is transmitted by calling a DCOM sub-connection negotiation interface, a dynamic interface and a protocol interface of transmission of the target data packet are detected after it is detected that a sub-connection is created on the basis of the communication connection, and if the dynamic interface transmitting the target data packet is a dynamic interface of the sub-connection and the protocol interface is also a protocol interface belonging to OPC, it is determined that traffic generated by the target data packet is the OPC traffic. According to the method, the characteristics of OPC communication service are fully considered, the dynamic interface created in a communication process and the protocol interface usedin the communication process are combined for judging whether the traffic generated by the transmitted data packet belongs to OPC traffic, precise identification on the OPC traffic is realized, security hidden-troubles existing in data transmission are eliminated, and a guarantee is also provided for accurate counting of the OPC traffic.

Owner:BEIJING QIANXIN TECH

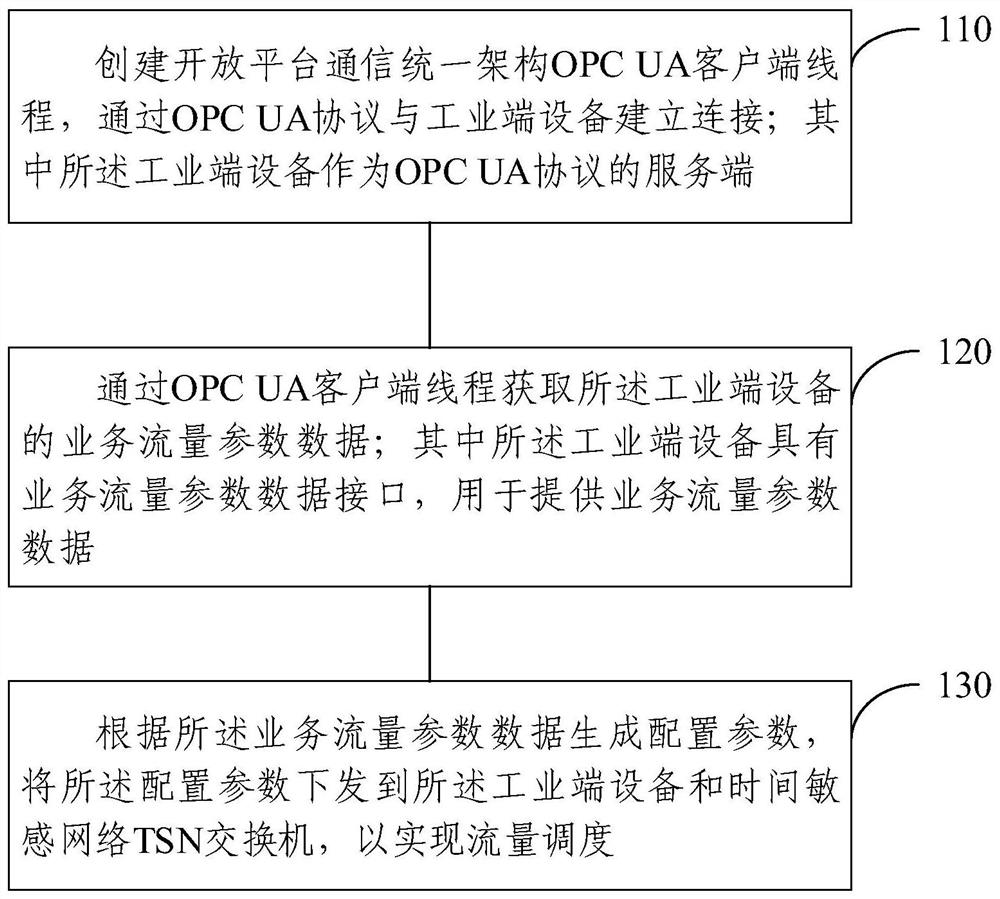

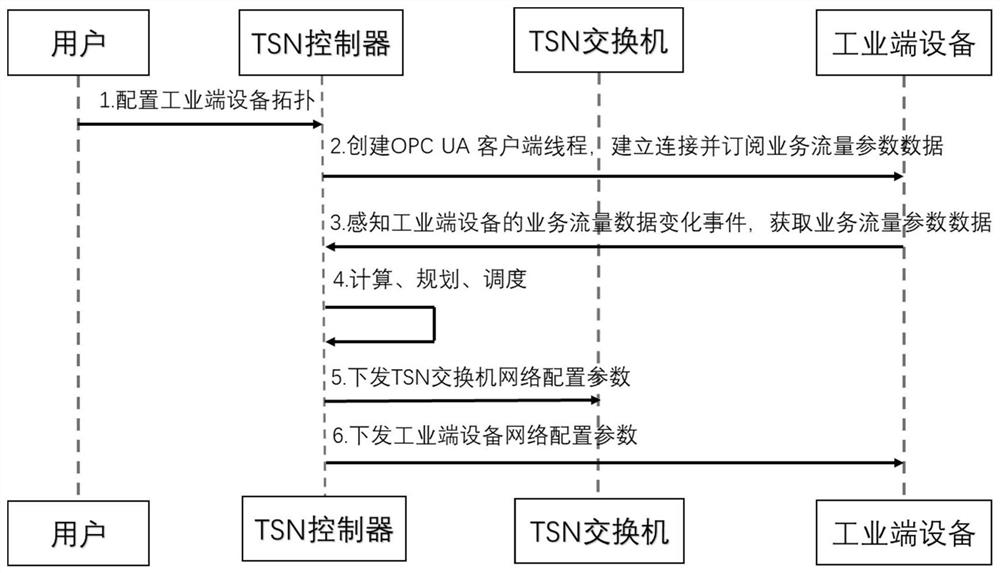

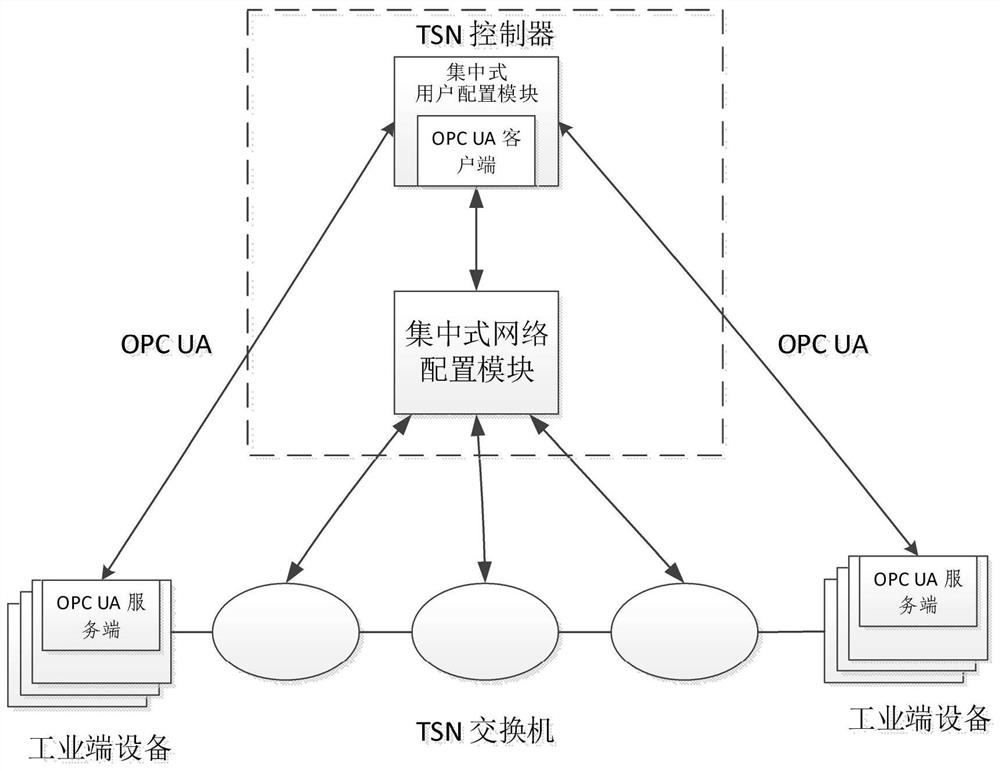

Method, time-sensitive network controller and system for receiving and managing industrial end equipment

PendingCN114189444ARealize dynamic acquisitionImplement schedulingTransmissionService flowService model

Owner:PURPLE MOUNTAIN LAB

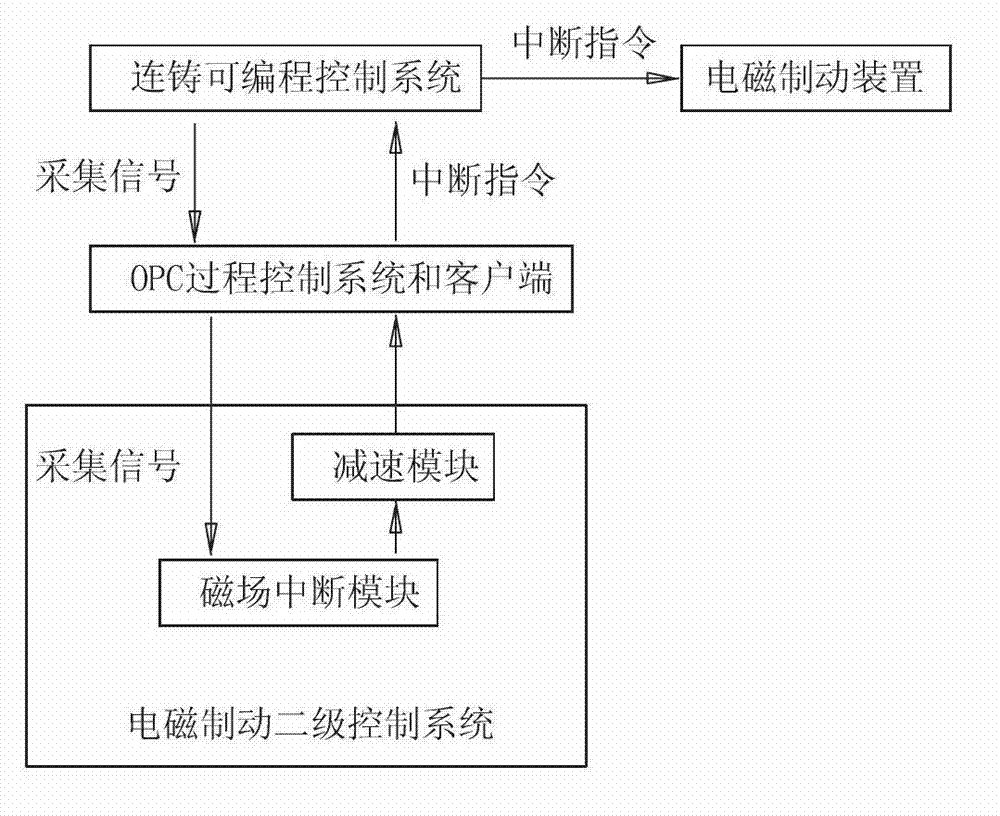

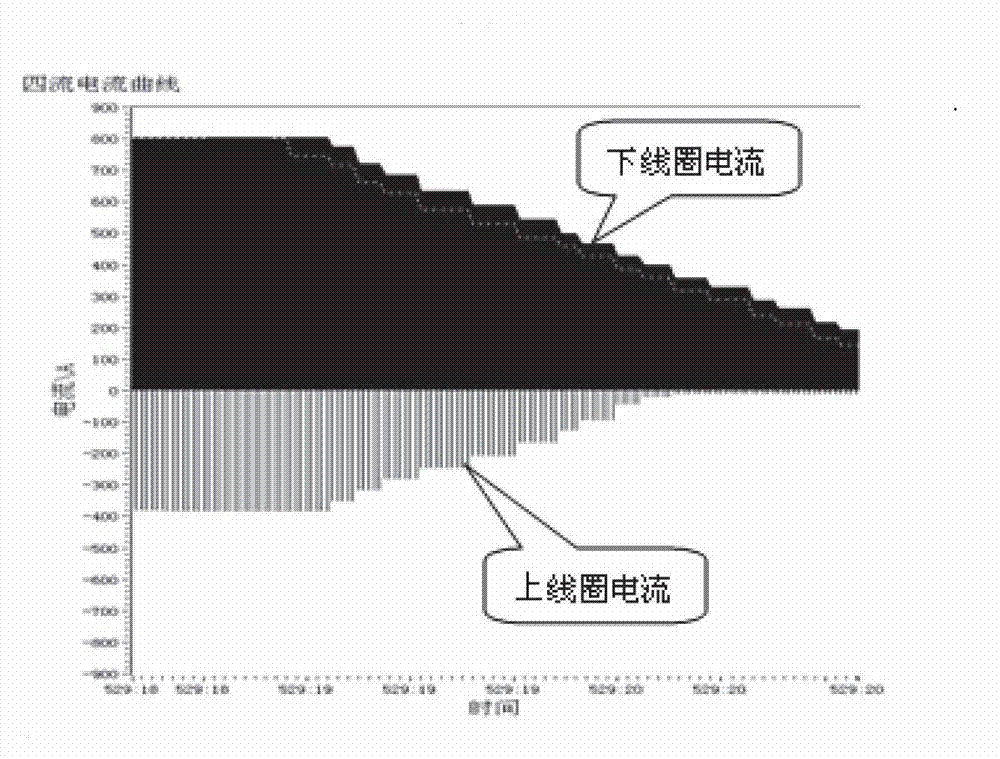

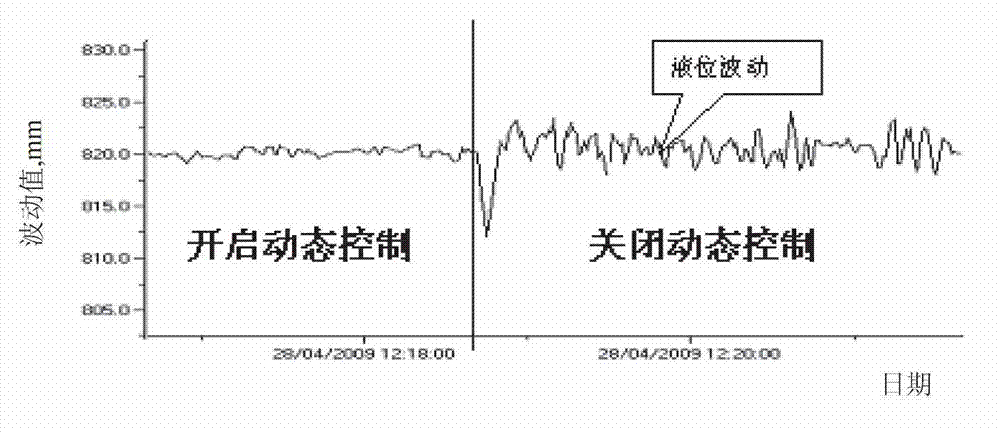

Dynamic control method for electromagnetic braking device of crystallizer

ActiveCN102921916AEasy to operateReasonable current deceleration waveformOLE for Process ControlInertia force

The invention belongs to the technical field of ferrous metallurgy continuous casting, and particularly relates to a dynamic control method for an electromagnetic braking device of a crystallizer. The method is on the basis of a continuous casting programmable control system, an OPC (Ole for Process Control) process control system and a client. The method is characterized in that an electromagnetic braking second-level interrupting control system is arranged and communicated with the continuous casting programmable control system through the OPC process control system; the electromagnetic braking second-level interrupting control system comprises a magnetic field interrupting module and a decelerating module; and once the electromagnetic braking device is stopped, the decelerating module is used for controlling the electromagnetic braking current according to a sine basis wave function. Compared with the prior art, the dynamic control method has the beneficial effects that 1) the stability of the electromagnetic braking device in running is higher; 2) the electromagnetic braking device can be automatically stopped once abnormal conditions occur, so that the accident can be prevented from spreading caused by inaccurate artificial judgment or failing to close in time; and 3) the most reasonable gradient of the current in an interval in which the inertia force and the lorentz force are balanced is ensured, so that the time for stopping is reduced, and the smooth transition among the declining curves is ensured.

Owner:ANGANG STEEL CO LTD

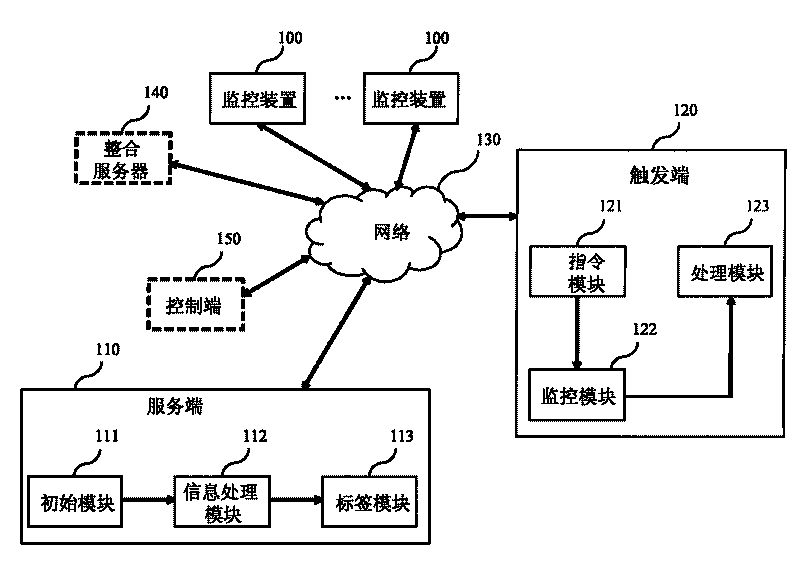

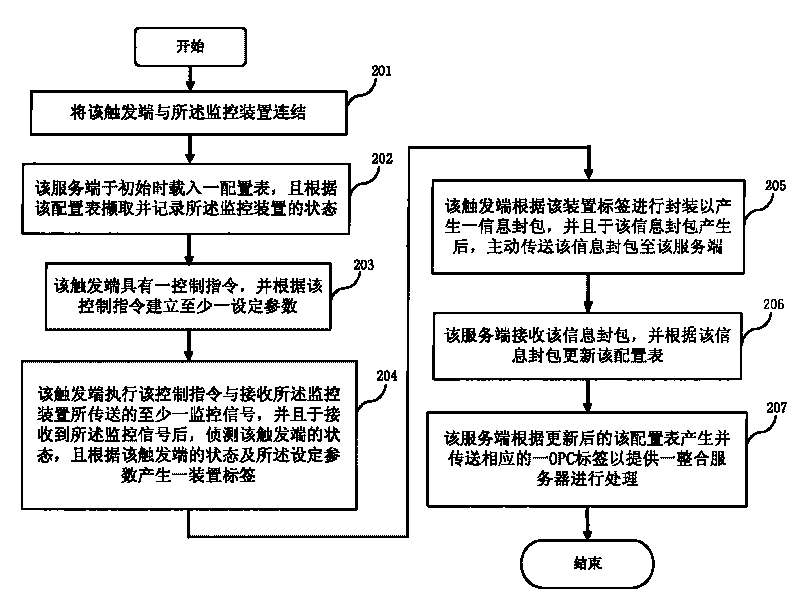

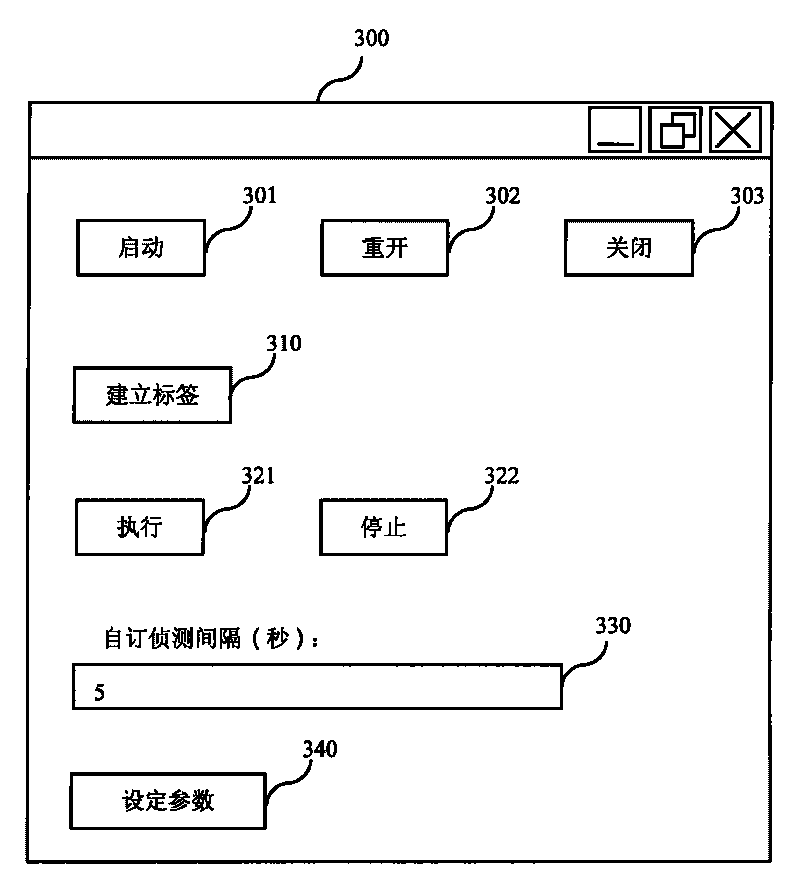

Active monitoring system and method thereof

ActiveCN101738958AImprove monitoring efficiencyIncrease profitProgramme controlComputer controlOLE for Process ControlActive monitoring

An active monitoring system and a method thereof are used for solving the problem that real-time monitoring cannot be effectively performed and bandwidth is occupied. A trigger end detects a monitoring device to generate a device tag, and the device tag is encapsulated and actively transmitted to a service end through a network, so that the service end automatically produces an industrial communication standard interface (namely, OLE for Process Control, OPC) tag for an integration server to fulfill the aim of improving the monitoring efficiency and the bandwidth utilization ratio.

Owner:MOXA INC

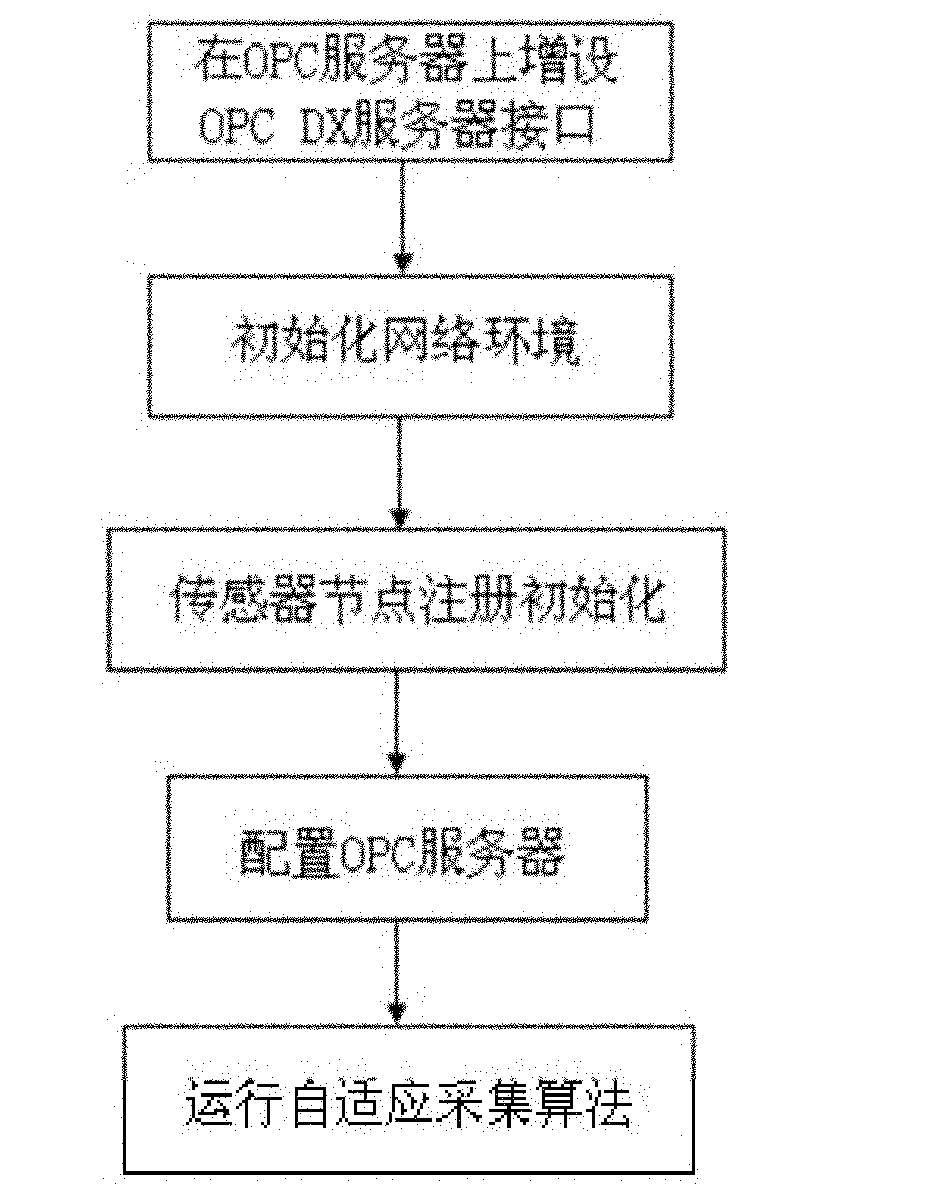

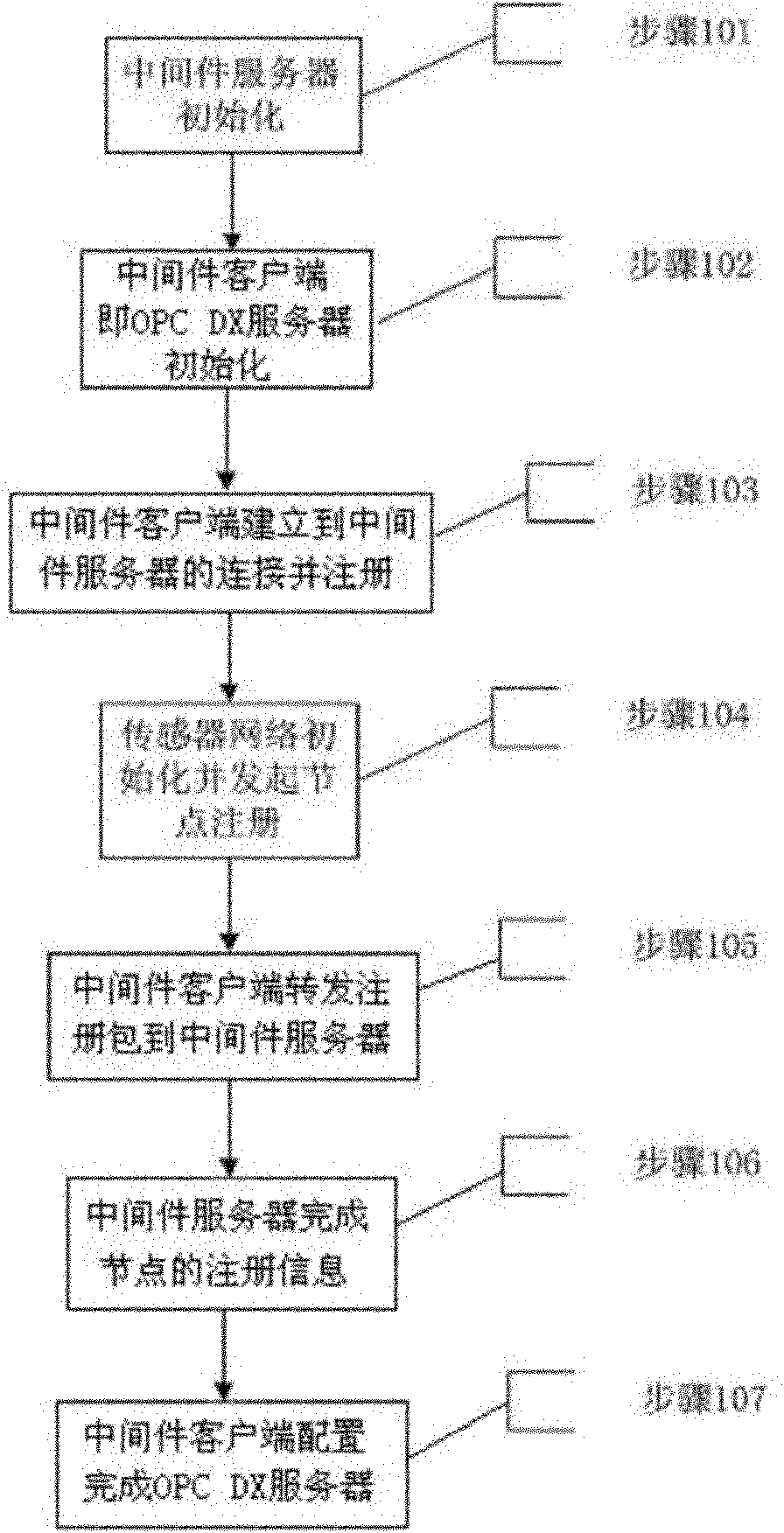

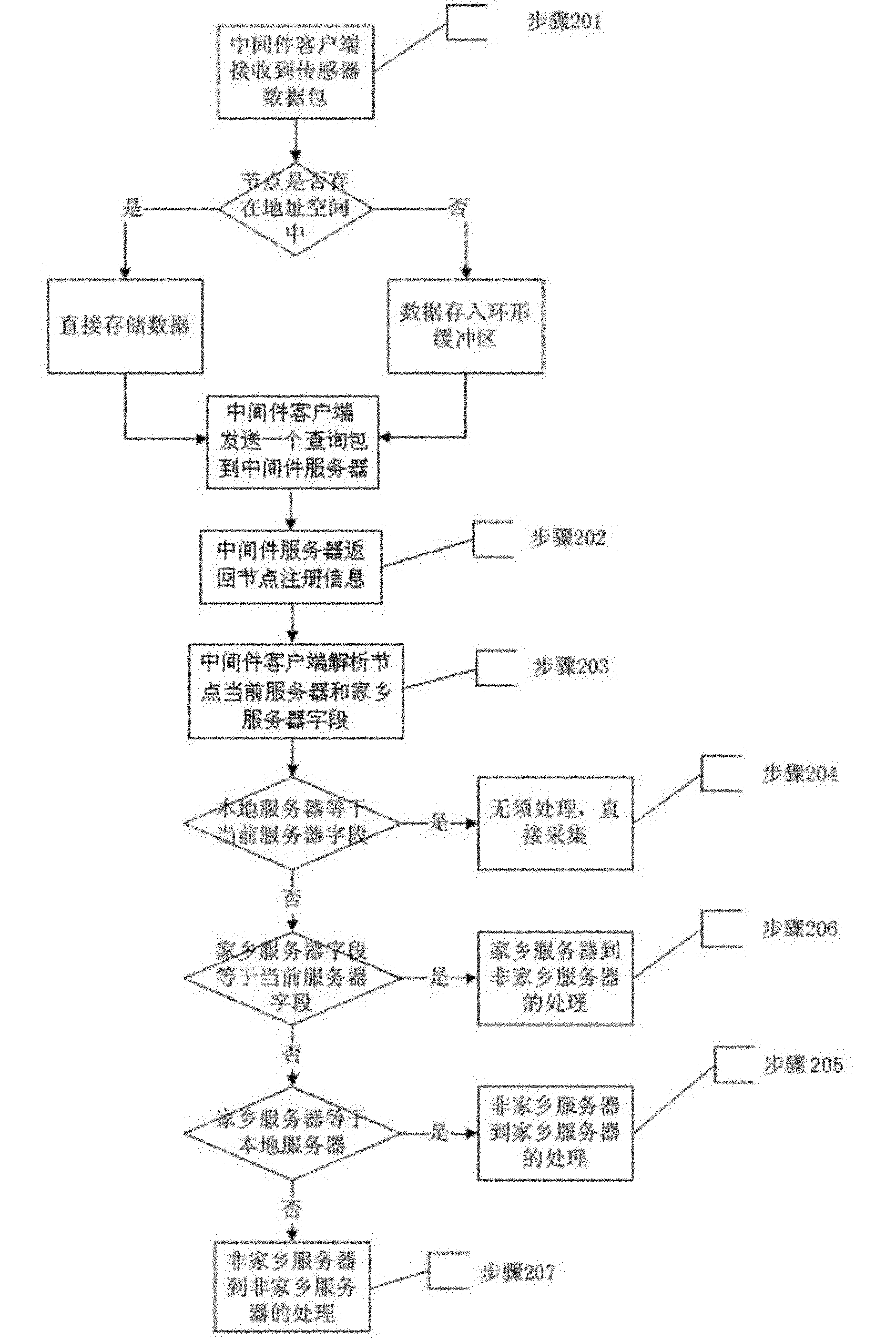

Solution of node data resource modification under topology reconfiguration of WSN (Wireless Sensor Network)

InactiveCN102082803AReal-time transmissionMinor changesNetwork topologiesData switching networksData connectionOLE for Process Control

The invention discloses a solution of node data resource modification under topology reconfiguration of a WSN (Wireless Sensor Network), belonging to the field of real-time data collection of WSNs. A solution for collecting data to a real-time database seamlessly in real time is designed during network topology reconfiguration by adopting a DX (Data Exchange) rule in the industrial standard OPC (OLE for Process Control). The solution concretely comprises the following steps of: finishing node registering and collector configuring at the stage of system initiation; and carrying out a self-adaptive collection algorithm so as to achieve the aim of seamlessly acquiring in real time. The invention can mainly realize that data connection is established between two OPC servers through the DX, thus data can be transmitted to the corresponding OPC server in real time to finish the collection of a real-time database system after the topology reconfiguration is sent.

Owner:HUAZHONG UNIV OF SCI & TECH

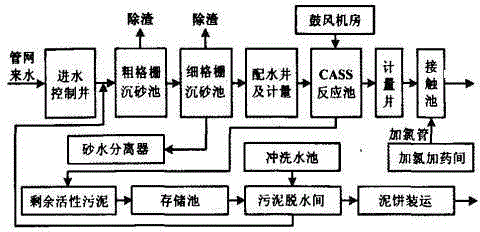

Municipal sewage treatment system adopting OPC (OLE for Process Control) monitoring

InactiveCN104418467AReduce speedGuaranteed speedWater treatment parameter controlTreatment with anaerobic digestion processesSocial benefitsOLE for Process Control

The invention relates to a municipal sewage treatment system adopting OPC (OLE for Process Control) monitoring. The municipal sewage treatment system comprises a first-stage sewage treatment device and a second-stage sewage treatment device as well as a sensor group, an OPC server and an OPC client, wherein the sensor group is connected with the first-stage sewage treatment device and the second-stage sewage treatment device, the OPC server is connected with the sensor group and the OPC client is connected with the OPC server. By the municipal sewage treatment system adopting OPC monitoring, the cost of the system is reduced, good compatibility and stability of a communication network are ensured and the seamless integration of devices from different manufacturers is achieved; and meanwhile, the communication rapidity is ensured, the treatment system provides convenience for further improvement on the production process, the production and maintenance costs are decreased, the labor intensities of production and maintenance workers are decreased and the treatment system has good economic and social benefits.

Owner:冉骏

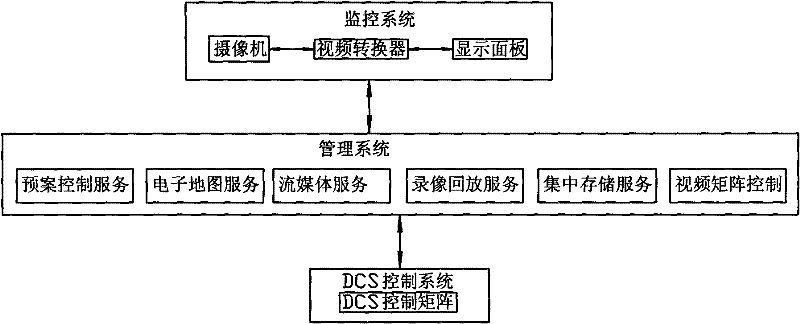

Automatic alarm interlocking control device

InactiveCN102681499AReliable detectionEasy to manageProgramme total factory controlOLE for Process ControlDistributed control system

The invention relates to an automatic alarm interlocking control device for detecting security in the workshop production and realizing the control. The automatic alarm interlocking control device comprises a monitoring system, a management system and a distributed control system (DCS), wherein the monitoring system is connected to the DCS through the management system, an OLE for process control (OPC) standard is adopted for interlocking interfaces among the systems. The interlocking interface of each system adopts the OPC standard, when the DCS detects the abnormality such as high voltage and high temperature, the real-time video image on the spot is automatically displayed; and in addition, an image of a corresponding station can be looked up in real time by clicking a DCS process flow interface, and the automatic alarm interlocking control device has advantages of reliability in detection and convenience in management.

Owner:JIANGSU CHANGQING AGROCHEMICAL CO LTD

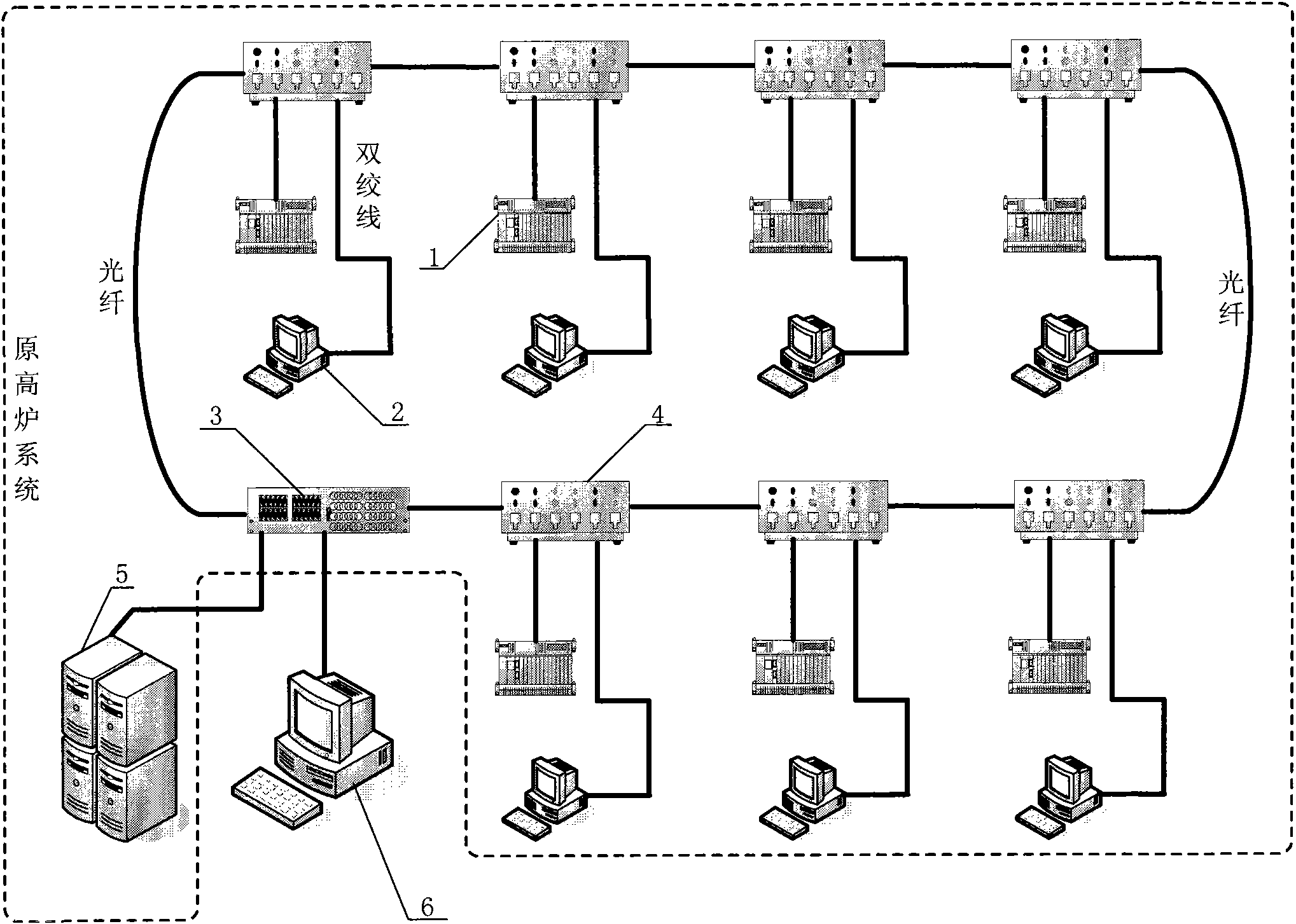

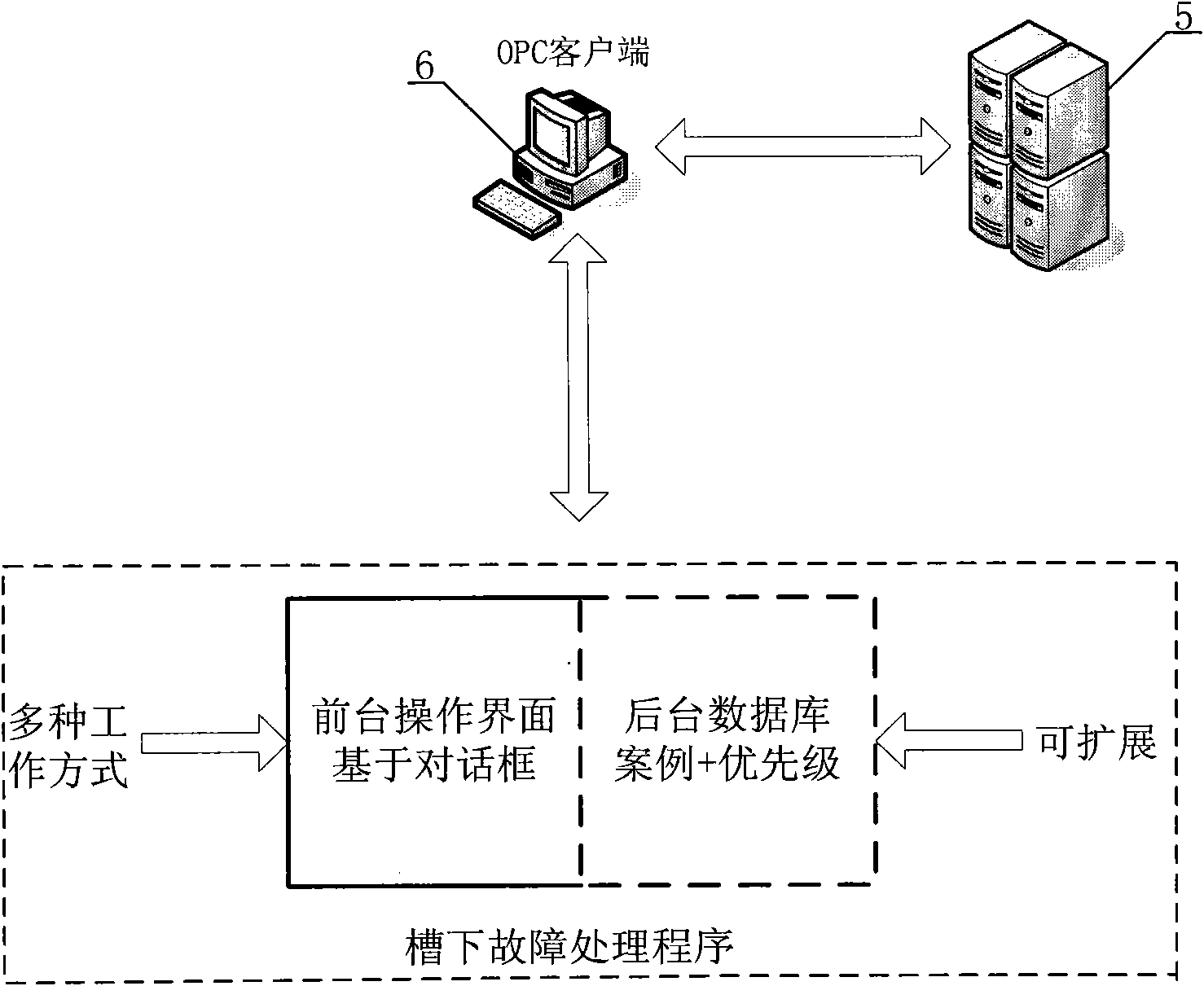

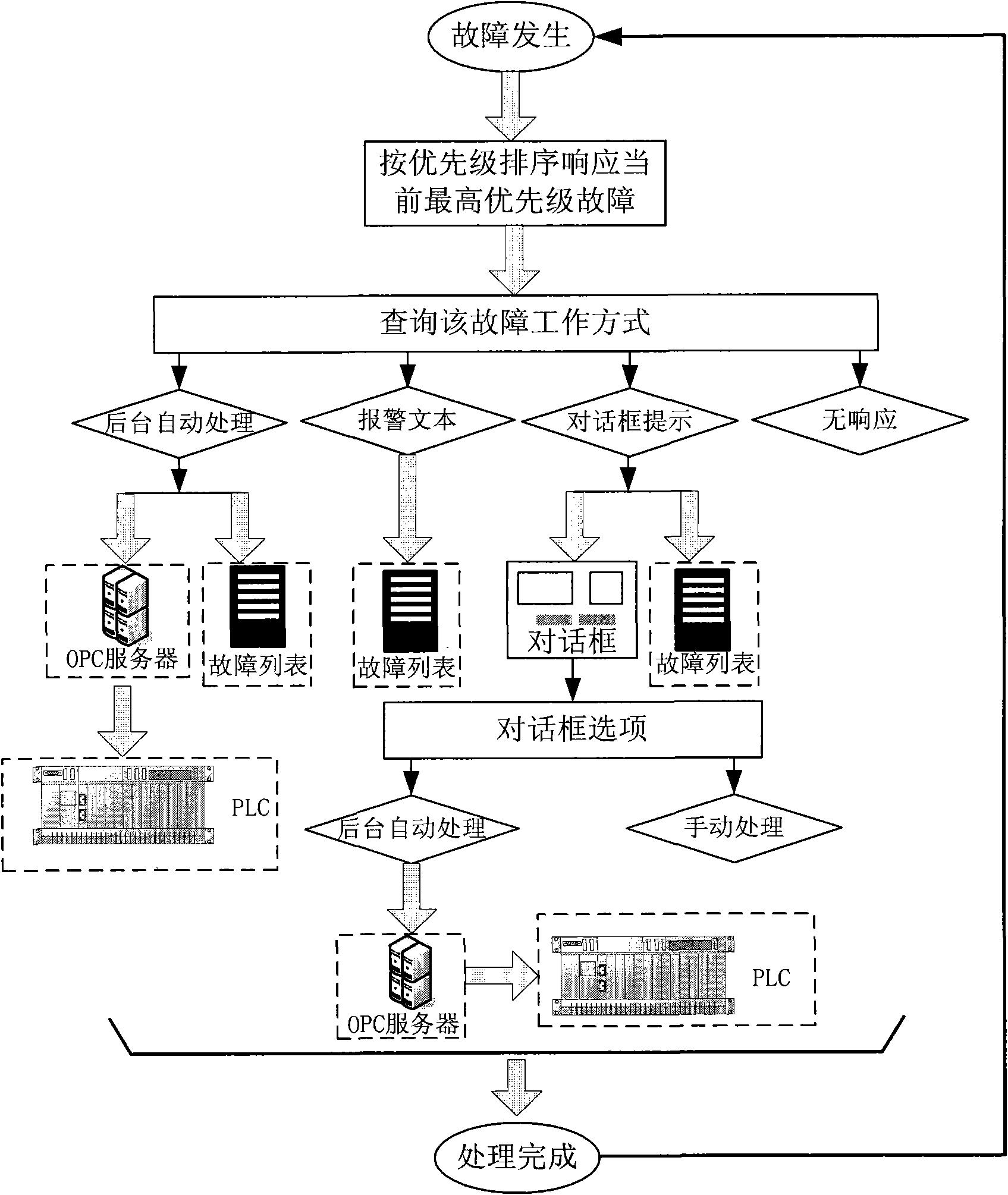

Method for diagnosing and processing faults below blast furnace groove

InactiveCN101892335ALess investmentSmall footprintBlast furnace componentsBlast furnace detailsOLE for Process ControlMode selection

The invention provides a method for diagnosing and processing faults below a blast furnace groove. The method is realized by a fault diagnosis and processing program installed on a fault response PC. The fault diagnosis and processing program comprises an OPC (OLE for Process Control) client, a background database, a fault processing program and an operating interface, wherein the OPC client and an OPC server interact data for synchronizing and updating PLC (Programmable Logic Controller) real-time data; the background database is communicated with the fault processing program and provides a fault case and a processing method therefor; the fault processing program analyzes the collected data to determine the fault content and provides the processing method in combination with the background database; and the operating interface provides a fault list, a working mode selection and a dialog box. In the invention, only one fault response PC machine is necessarily added based on the original control system of the blast furnace, the invention has less equipment investment and favorable use effect and small occupation space.

Owner:WISDRI ENG & RES INC LTD

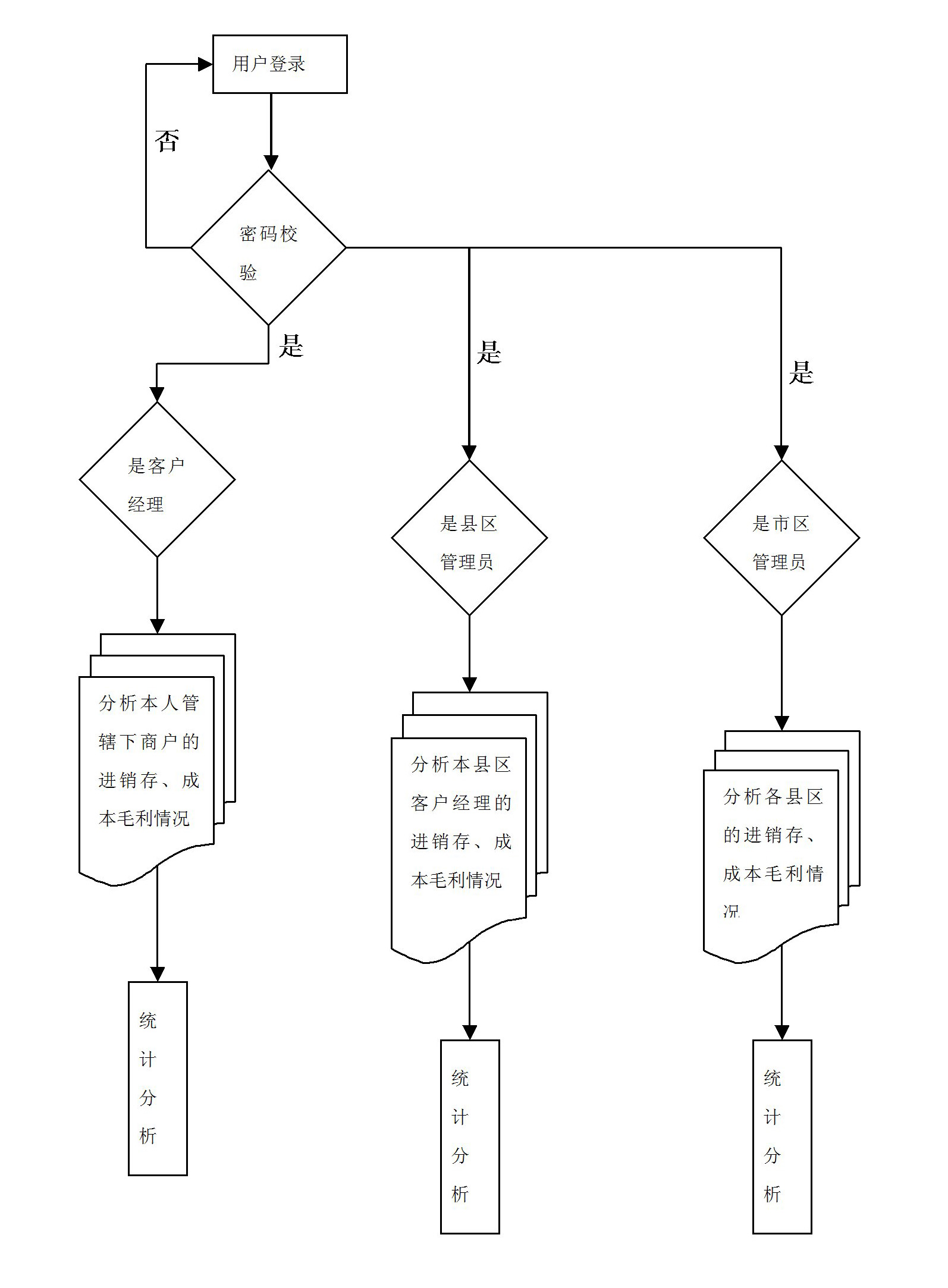

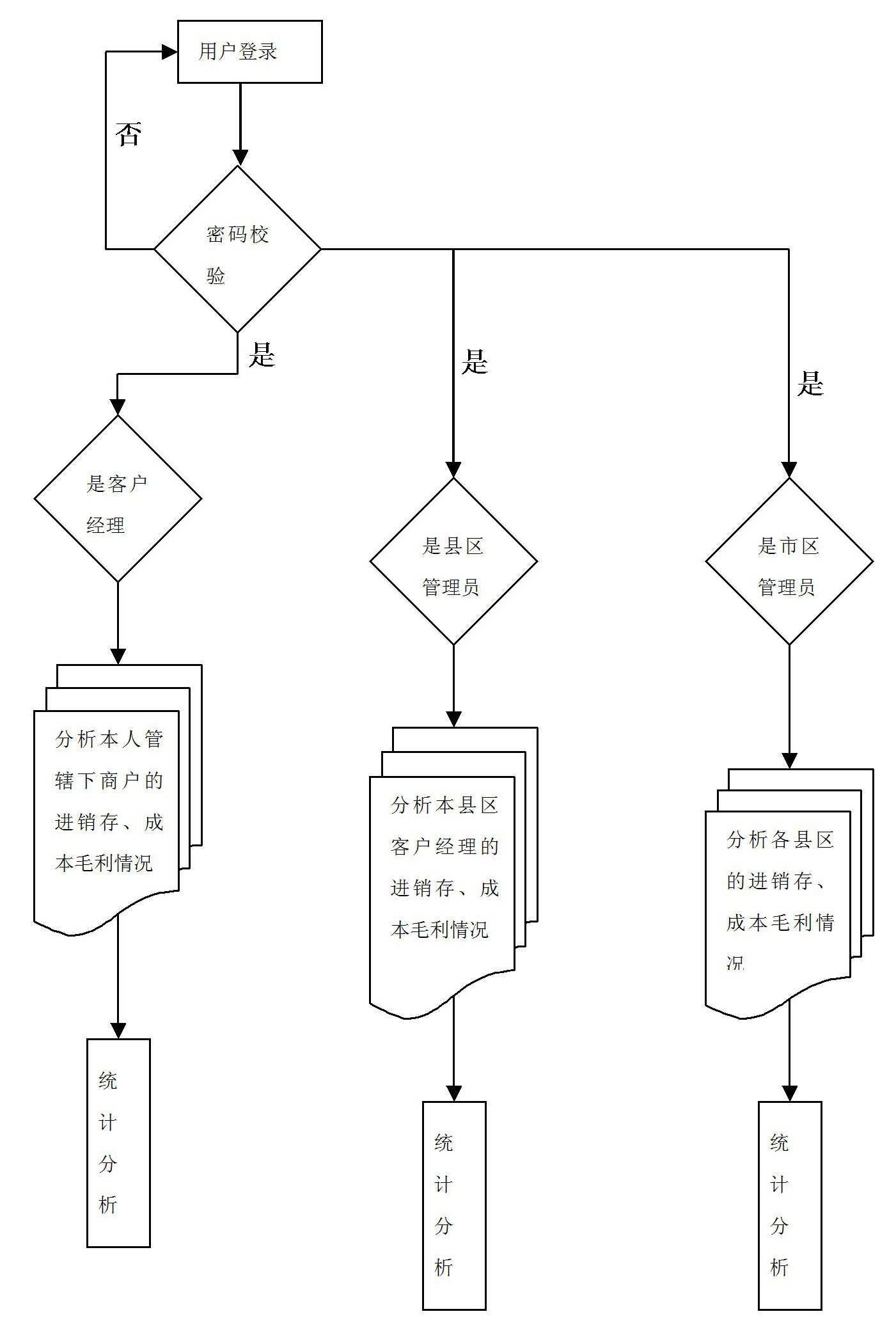

Financing analysis system in operation of commercial tenants

InactiveCN101976421AMaximization of legitimate interestsBig cigarette incomeFinanceMarketingData warehouseOLE for Process Control

The invention relates to a data analysis method, in particular to a financing analysis system in operation of commercial tenants. The financing analysis system utilizes an OLE for process control (OPC) operation interface technology to carry out acquisition and information management on data in an internal data warehouse, and the system consists of two parts, namely an OPC server and an OPC customer manager side; the OPC server collects data information of sale of the commercial tenants, utilizes the data warehouse and an on-line analysis technology (OLAP) to analyze mined data and masters the operation condition of the commercial tenants for tobacco; an OPC customer manager communicates with an OPC object by the OPC server, accesses data sources, and then transmits the data sources to the OPC customer manager side by an OPC interface; and the OPC customer manager side receives data information by the standard OPC interface, and accesses the server and a background database connected with the server by the browser. The analysis system is mainly used for managing the operation conditions of the unit commercial tenant, and leads the customer manager to provide service for the commercial tenants, thus providing basis for adjusting sale strategies by companies.

Owner:河南省烟草公司鹤壁市公司

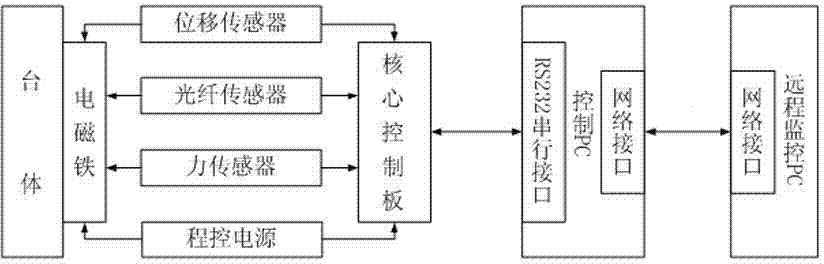

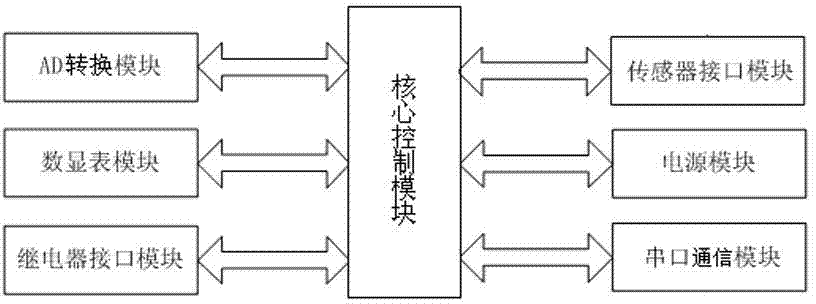

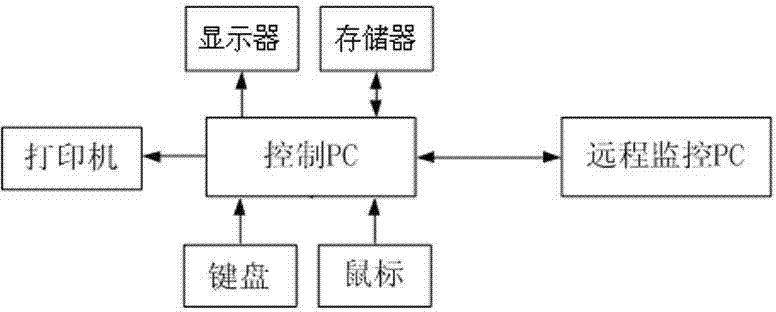

OPC (OLE for process control) based electromagnet performance test system

InactiveCN104501871AImplement automated testingImprove test efficiencyElectrical testingOLE for Process ControlEngineering

The invention discloses an OPC (OLE for process control) based electromagnet performance test system. The system comprises a data acquisition unit, a program control power source, a core control board, a control PC (personal computer) and a remote monitoring PC. The output end of the data acquisition unit is connected with the core control board; the program control power source is connected with an electromagnet and the core control board; the core control board is connected with the control PC through a serial bus. The control PC is connected with the remote monitoring PC through a network interface via the OPC function. The data acquisition unit acquires pressure and displacement signals of the electromagnet in real time; the program control power source acquires voltage and current signals and transmit them to the core control board; the core control board processes the acquired data and transmits it to the control PC; the control PC displays, stores and prints test results according to the data input by the core control board; thus, automatic testing of electromagnet performance is achieved, and test efficiency and test precision are greatly improved.

Owner:XIANGTAN UNIV

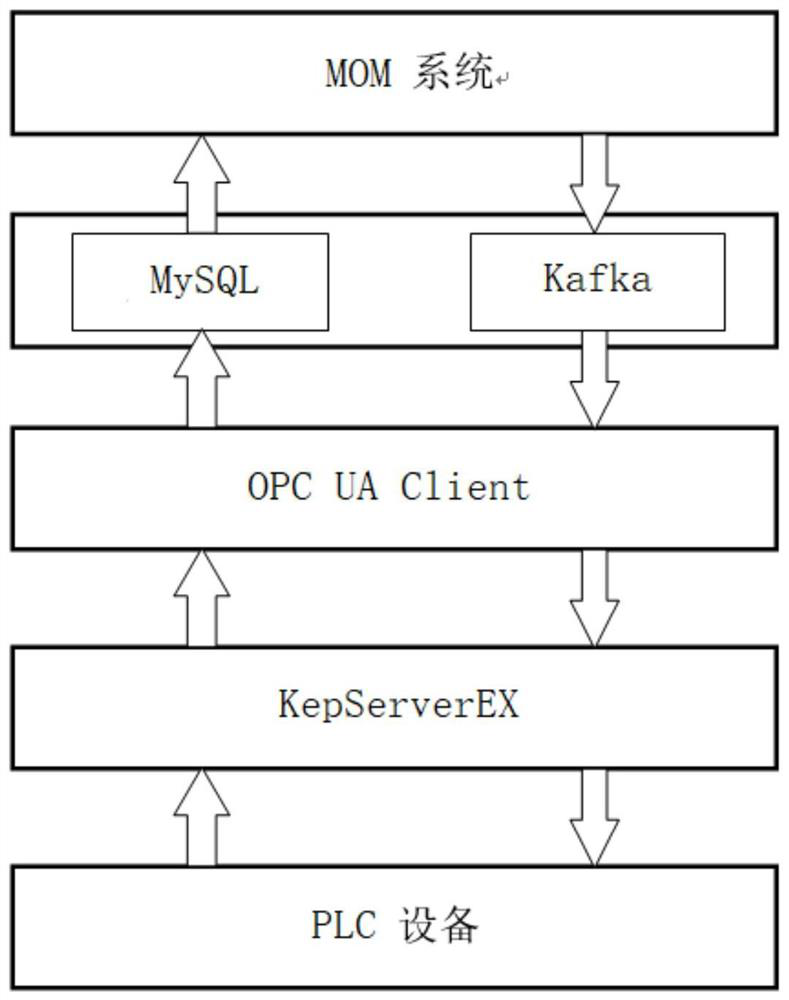

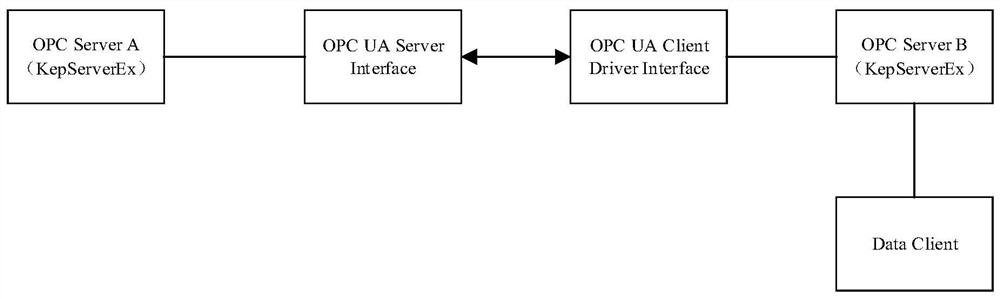

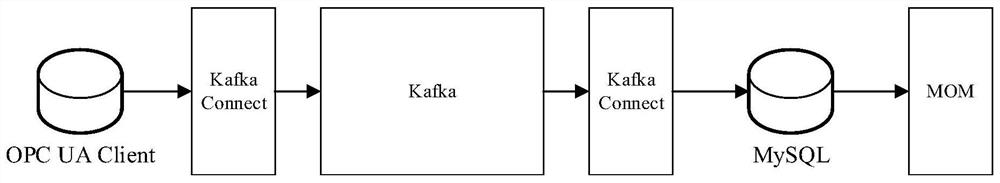

MOM system automation equipment data interaction integration platform and method based on OPC UA protocol

PendingCN112764944ARealize data interactionImplement integrated managementInterprogram communicationData switching networksOLE for Process ControlPrivate network

Owner:HARBIN YULONG AUTOMATION

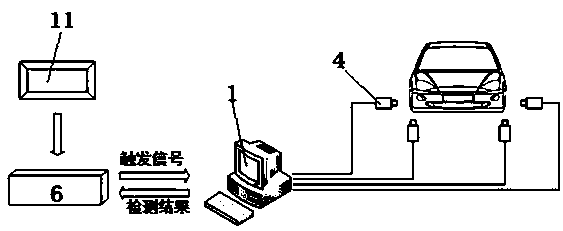

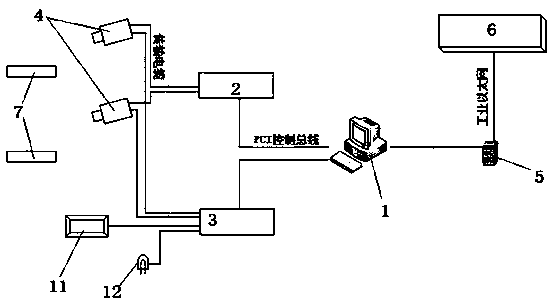

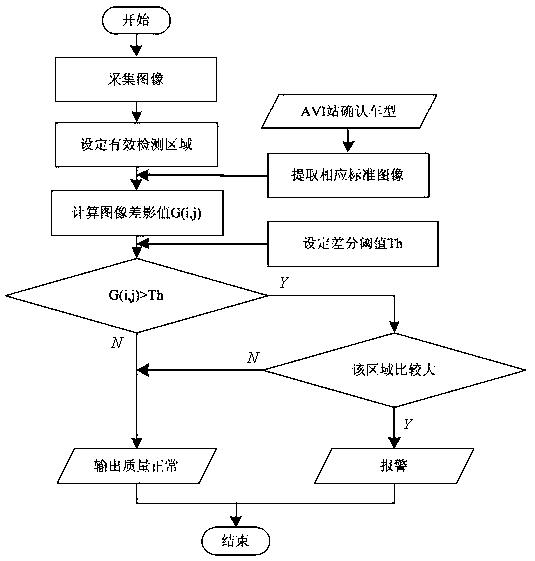

Vehicle painting rocker panel glue visual inspection system and method

InactiveCN109991237AImprove accuracyReduce labor costsMaterial analysis by optical meansOLE for Process ControlProgrammable logic controller

The invention discloses a vehicle painting rocker panel glue visual inspection system and method. The vehicle painting rocker panel glue visual inspection system comprises an industrial control computer (1), an image processor module (2), a high-speed input / output (I / O) module (3), a camera module (4), an OLE for process control (OPC) server module (5) and a programmable logic controller (PLC) (6); the OPC server module is connected with the PLC and the industrial control computer, the industrial control computer is connected with the camera module through the high-speed I / O module, the cameramodule comprises a plurality of industrial cameras arranged on a vehicle production assembly line, and the industrial cameras are symmetrically arranged on two sides of a vehicle; and the image processor module is connected with the camera module and controls the camera module to collect rocker panel painting images, and the image processor module is connected with the industrial control computer. According to the vehicle painting rocker panel glue visual inspection system and method, the quality of vehicle rocker panel glue can be automatically detected through a visual system technology, automatic detection and alarming of the gluing quality problems of the edge consistency of the painting rocker panel glue of the bottom of the vehicle, the surface defect, glue breaking at a rocker panel and the like can be realized, the precision is greatly improved, and the labor cost is reduced.

Owner:SAIC MAXUS AUTOMOTIVE CO LTD

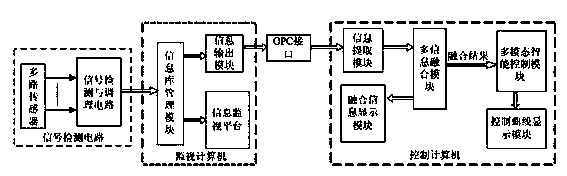

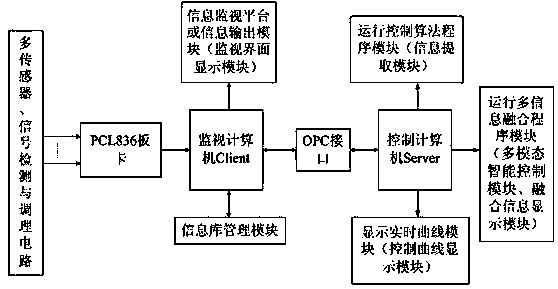

Device and method for multi-information detection and fusion based on OPC (OLE for Process Control) technology

InactiveCN103365284AFlexible structureOvercome deficienciesTotal factory controlProgramme total factory controlOLE for Process ControlMeasurement precision

The invention discloses a device and a method for multi-information detection and fusion based on OPC (OLE for Process Control) technology. The device comprises a signal detection circuit, a monitoring computer and a control computer, which are sequentially connected together, as well as an OPC interface connected between the monitoring computer and the control computer and used for realizing communication. The device and the method for multi-information detection and fusion based on OPC technology can overcome the problem in the prior art that single information has shortcomings, and is likely to cause the defects of inaccuracy in measurement, low measurement precision, error accumulation and poor safety, and so on; multi-information fusion remedies the defects of single information so as to realize the advantages of being accurate to measure, being unlikely to cause error accumulation, and improving measurement precision and safety.

Owner:LANZHOU JIAOTONG UNIV

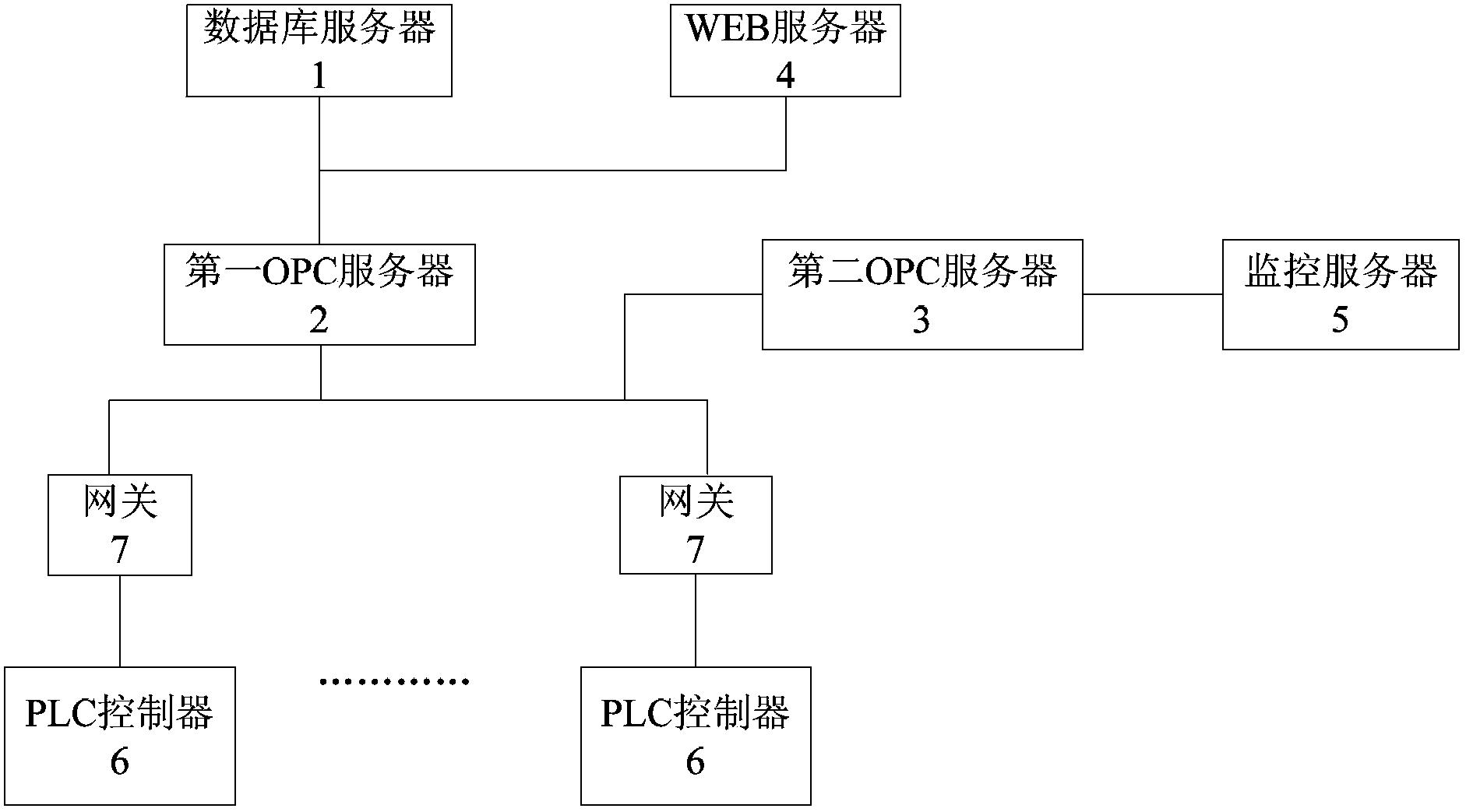

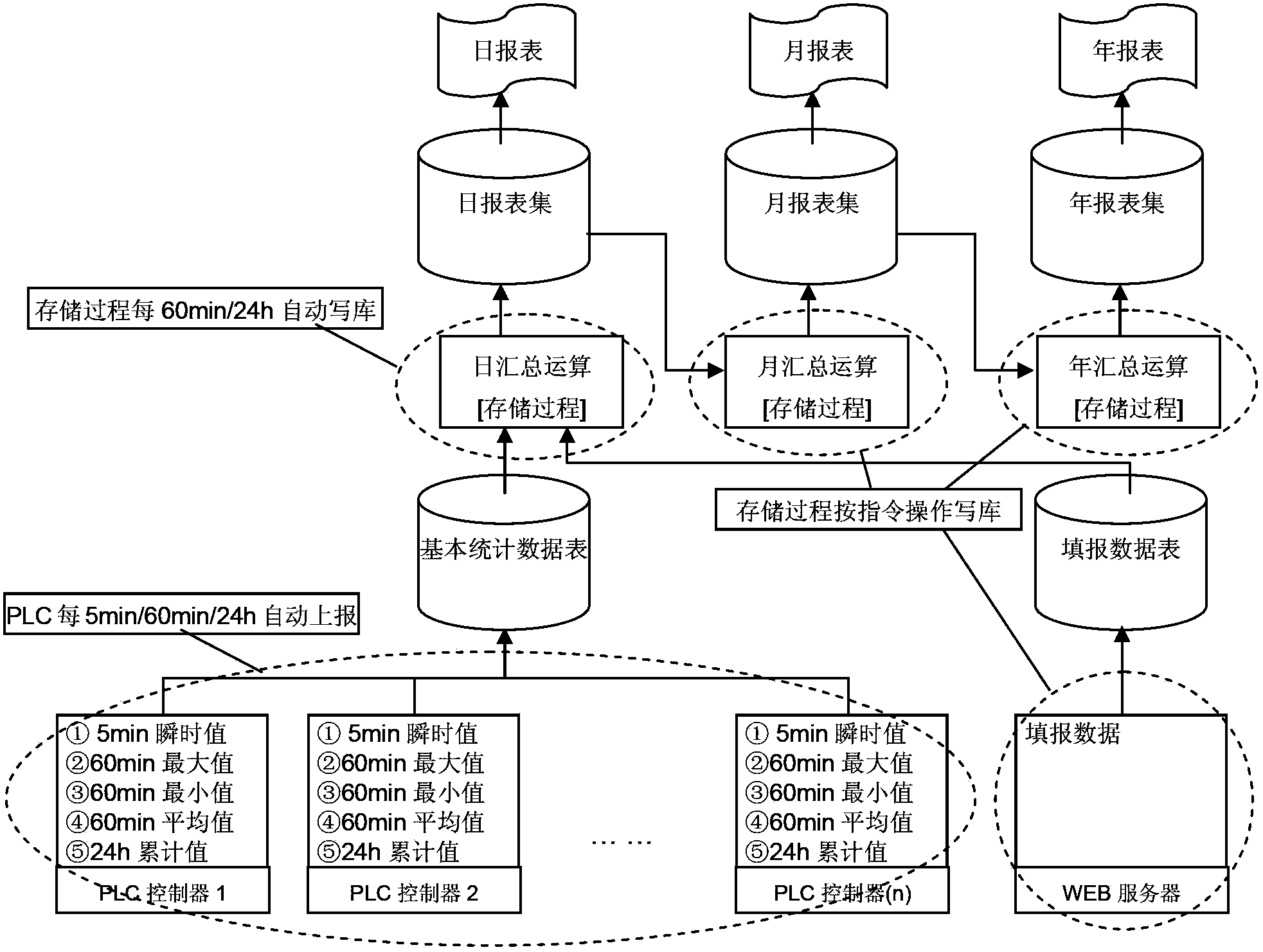

Distributed data statistical processing system and application thereof

ActiveCN103455488AWorkload balanceRaise attentionSpecial data processing applicationsOLE for Process ControlProgrammable logic controller

The invention relates to a distributed data statistical processing system and application thereof. The distributed data statistical processing system comprises a database server, a first OLE for process control (OPC) server, a second OPC server, a WEB server, programmable logic controllers (PLCs) and a monitoring server. The database server is respectively connected with the first OPC server and the WEB server, the first OPC server and the second OPC server are both connected with the PLCs, and the second OPC server is connected with the monitoring server. The application of the distributed data statistical processing system particularly comprises steps that the PLCs automatically store basic statistical data into the database server and transmit the basic statistical data to the monitoring server through the second OPC server; the WEB server stores reported data into the database server in real time; the database server sequentially establishes daily statement, monthly statement and annual statement according to a basic statistical data table and a reported data table at regular intervals. Compared with the prior art, the distributed data statistical processing system and the application of the distributed data statistical processing system have the advantages of balancing data processing masks, improving data statistical processing efficiency and the like.

Owner:SHANGHAI YUANDONG SCI & TECH

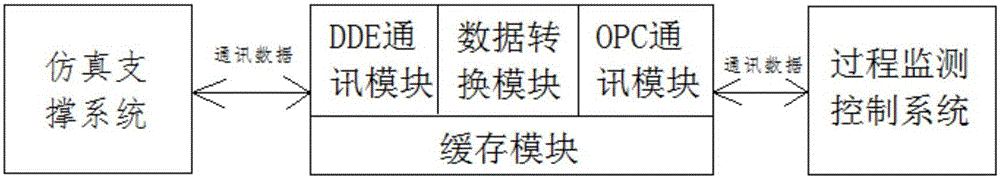

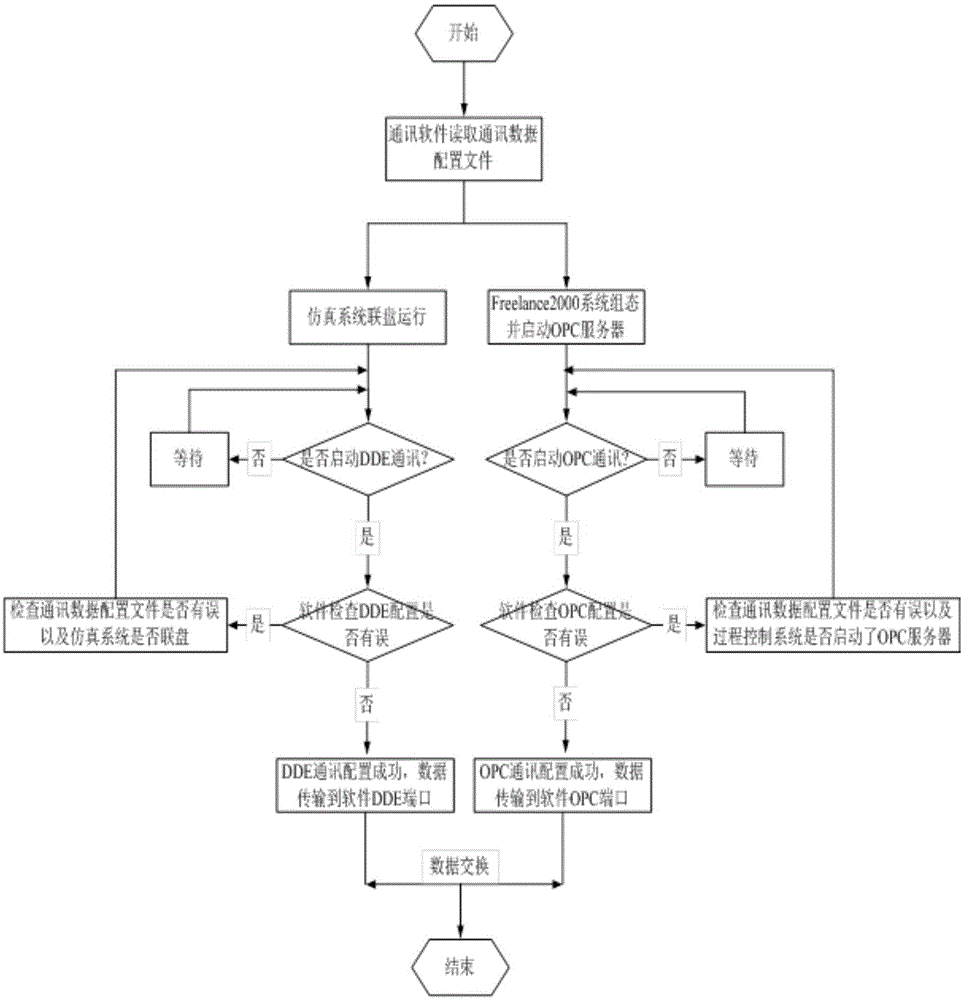

Real-time data communication system and method applied between process monitoring control system and emulation support system

ActiveCN105138390ARealize real-time data communicationAchieve integrationSoftware simulation/interpretation/emulationOLE for Process ControlDynamic Data Exchange

The present invention discloses a real-time data communication system applied between a process monitoring control system and an emulation support system. The real-time data communication system comprises an OPC (OLE for Process Control) communication module in communication with the process monitoring control system, a DDE ((Dynamic Data Exchange) communication module in communication with the emulation support system, and a data conversion module used for performing mutual conversion on data in the OPC communication module and the DDE communication module. The present invention further discloses a real-time data communication method applied between the process monitoring control system and the emulation support system. The method comprises the steps of communication data reception, data conversion, communication data transmission and the like. The real-time data communication system and method has beneficial effects of implementing fusion of two different data exchange mechanisms of OPC and DDE and implementing real-time communication of large data volume.

Owner:NAVAL UNIV OF ENG PLA

Freshly squeezed oil production control method

InactiveCN102929153AImprove product qualityImplement queryComputer controlOLE for Process ControlVegetable oil

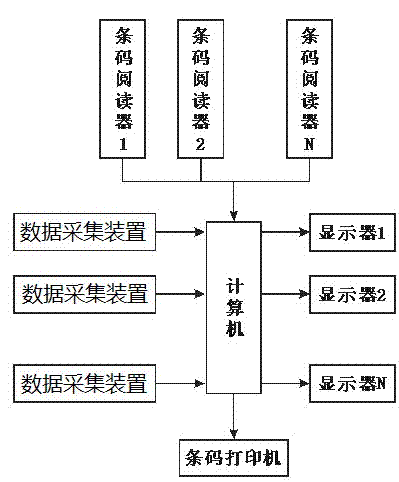

The invention discloses a freshly squeezed oil production control method, which comprises a freshly squeezed oil production control system, wherein the freshly squeezed oil production control system comprises a plurality of data acquisition units, a plurality of readers, a plurality of displays and a printer; the readers, the data acquisition units, the displays and the printer are connected with a computer in an oil press; the computer communicates with an OLE for process control (OPC) server; the data acquisition units communicate with a manufacturing execution system (MES) website server; and the data acquisition units are in one-to-one connection with a current adjusting device, a timer, a motor, a steam boiler, a steam valve and a hydraulic pump of the oil press. By the freshly squeezed oil production control method, the information of the vegetable oil production process can be automatically recorded, important production raw materials in the vegetable oil production process are inquired, and the vegetable oil product quality is greatly improved.

Owner:雷学军

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com