Waste water treatment monitoring method and system based on fuzzy neural network

A technology of fuzzy neural network and wastewater treatment system, which is applied in the general control system, control/regulation system, adaptive control, etc. It can solve the problems of low prediction accuracy, high inspection accuracy, and long network training time to improve stability , precise control, and the effect of reducing the amount of chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

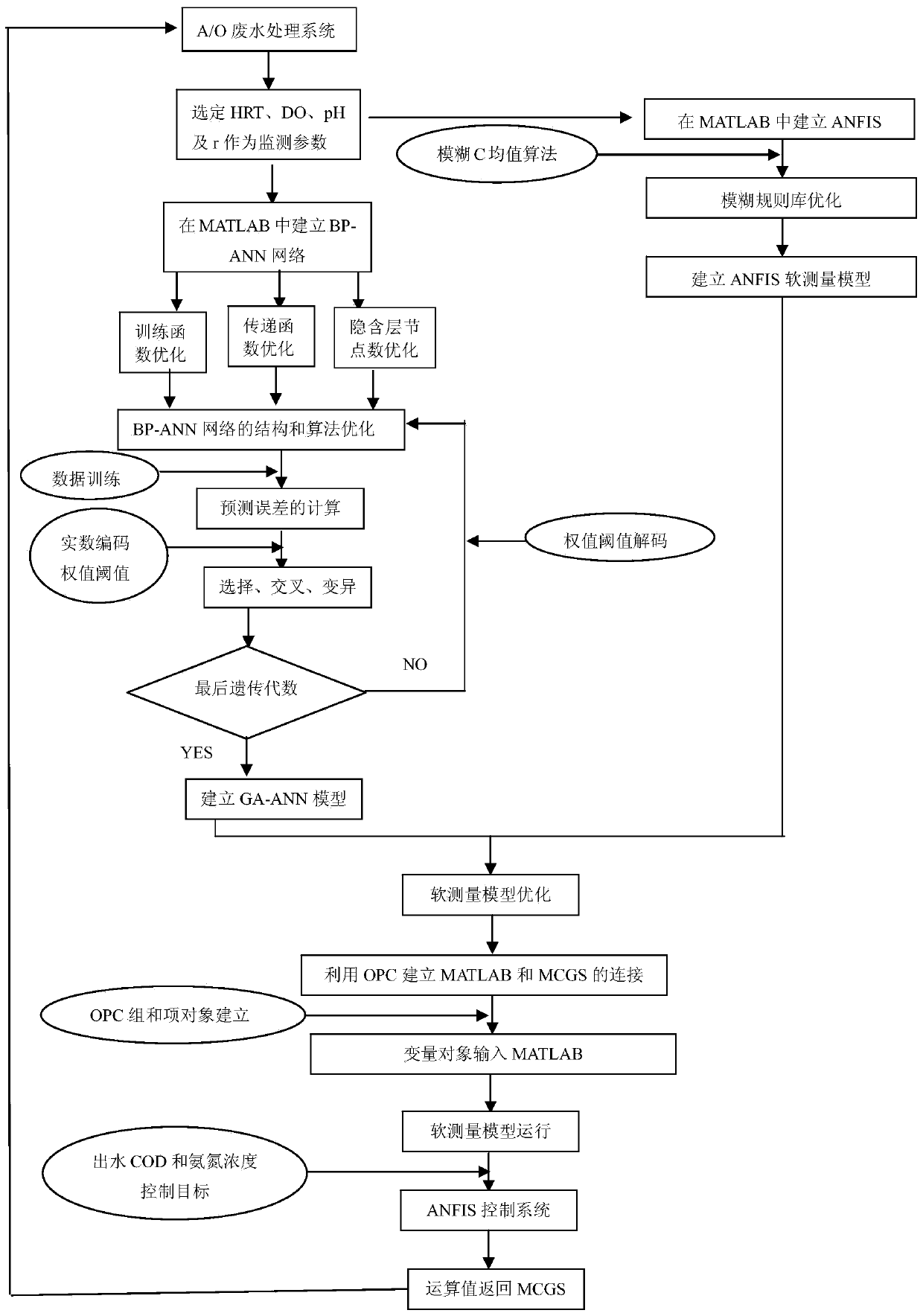

[0023] Such as figure 1 As shown, the wastewater treatment monitoring method and system based on fuzzy neural network of the present invention include:

[0024] (1) Analyze the process characteristics of the A / O biological nitrogen and phosphorus removal technology, select and install the necessary hardware equipment, design the PLC control program and carry out the engineering configuration of the industrial control software MCGS, and build an embedded automatic control system for papermaking wastewater treatment ;

[0025] (2) According to the biological characteristics of the A / O wastewater treatment system and combined with the structure and algorithm of the neural network, construct the optimal neural network soft sensor model: select the hydraulic retention time (HRT) of the A / O wastewater treatment system that can be monitored online, The relationship between the four parameters of water pH value (pH), dissolved oxygen in aerobic pool (DO) and mixed liquid reflux ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com