On-line heat balance testing diagnostic system for heating furnace

A diagnostic system and heat balance technology, applied in calorimeters, measuring devices, measuring heat, etc., can solve problems such as high cost and inability to comprehensively reflect the long-term control and operation level of heating furnaces, and achieve fast response speed, easy promotion, and easy operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment:

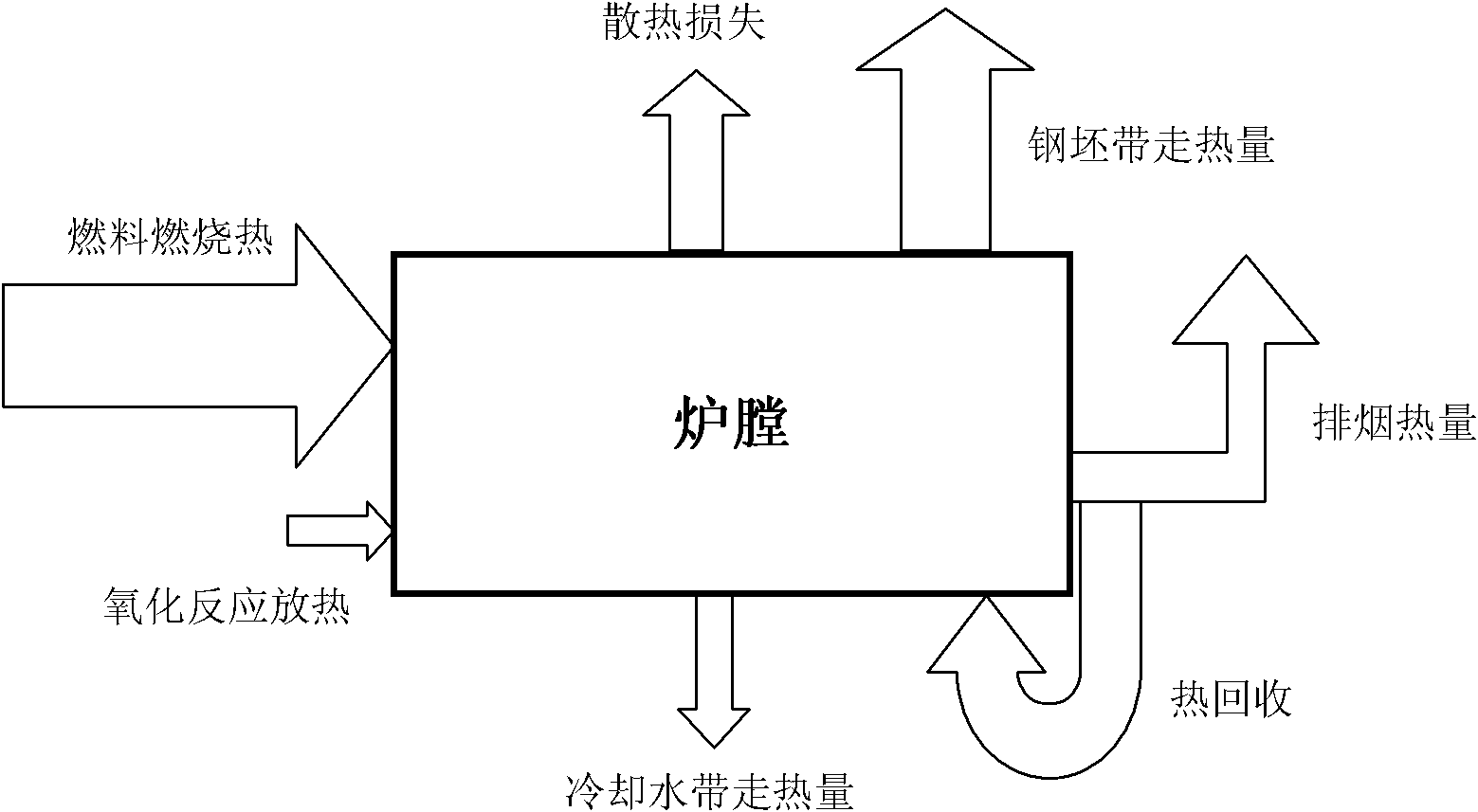

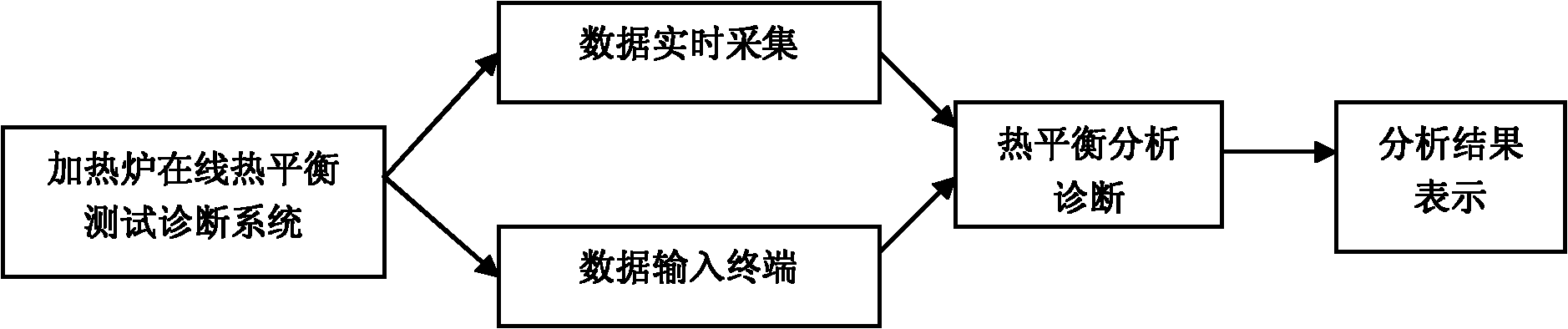

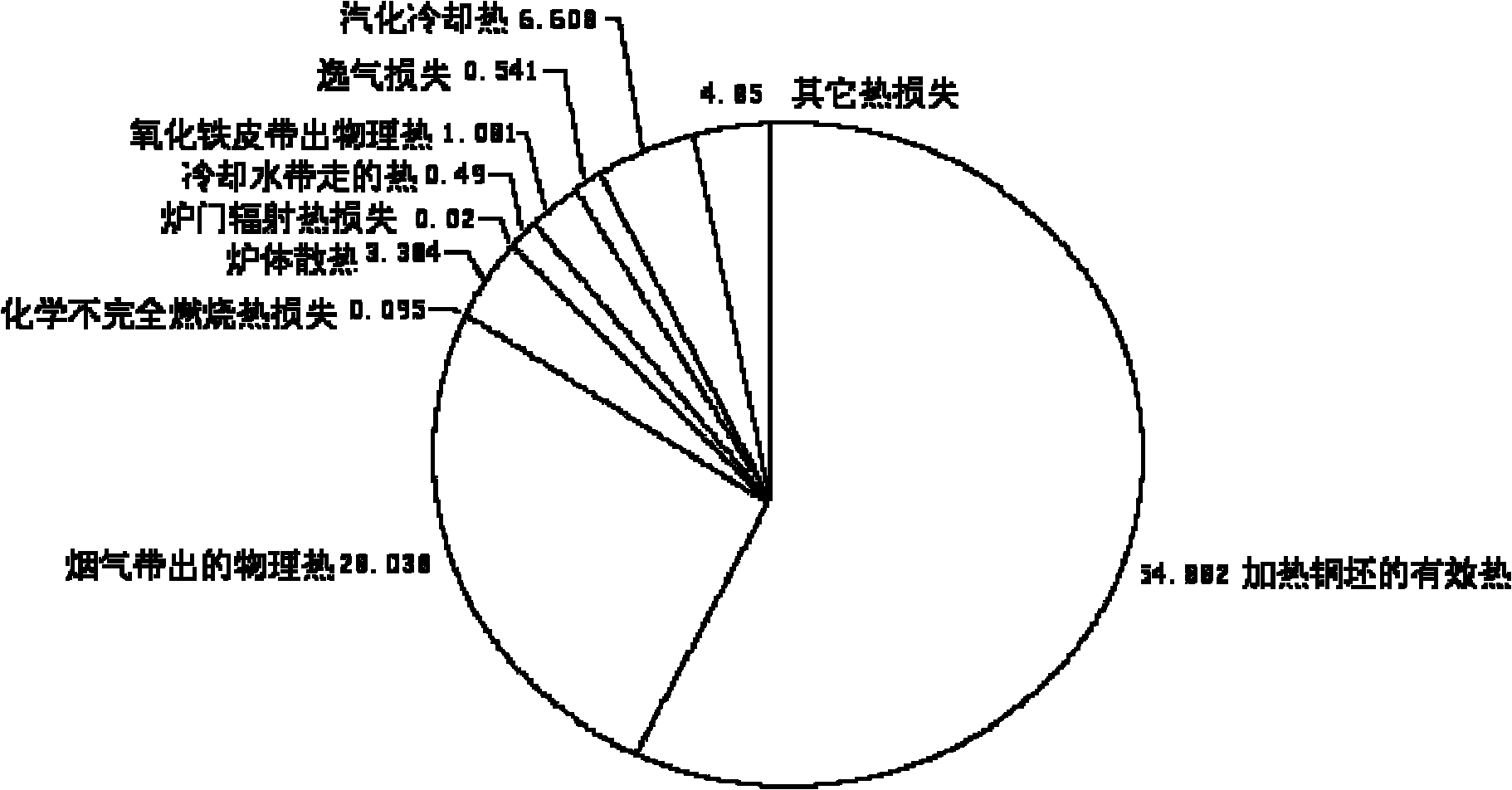

[0029] The heat balance test of the heating furnace should be more important in iron and steel enterprises. It can understand the production and operation status of the heating furnace, understand the fuel combustion status of the heating furnace, understand the heat income and thermal expenditure of the heating furnace, and understand the heating furnace The effective utilization efficiency of heat energy and the recovery and utilization level of residual energy, through the detailed analysis and research of the test and calculation results, combined with the specific conditions of the heating furnace's thermal operation, furnace structure and production management, etc., the actual working conditions of the heating furnace Make a scientific evaluation, summarize the advanced energy-saving experience of the heating furnace and find out the shortcom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com