Robot control system

A control system and robot technology, applied in the direction of program control of manipulators, manipulators, manufacturing tools, etc., can solve problems such as unsatisfactory direct communication, achieve great practical value, facilitate diagnosis and maintenance, and improve control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings. However, these embodiments do not limit the present invention, and the structural, method, or functional changes made by those skilled in the art based on these embodiments are all included in the protection scope of the present invention.

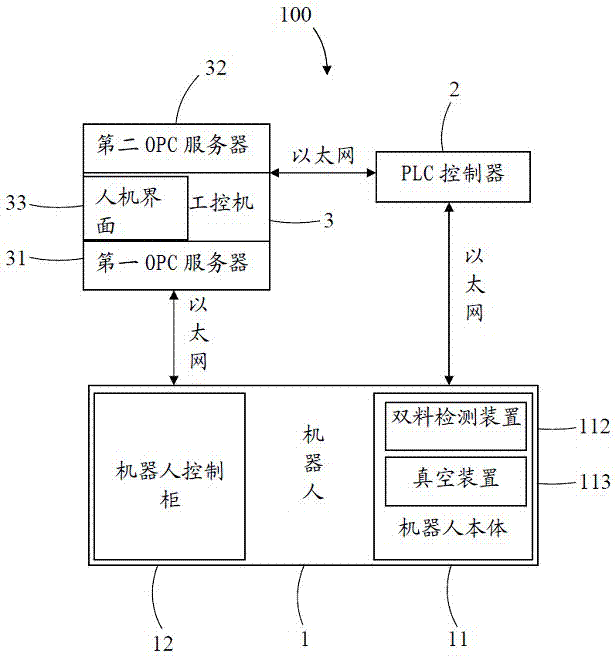

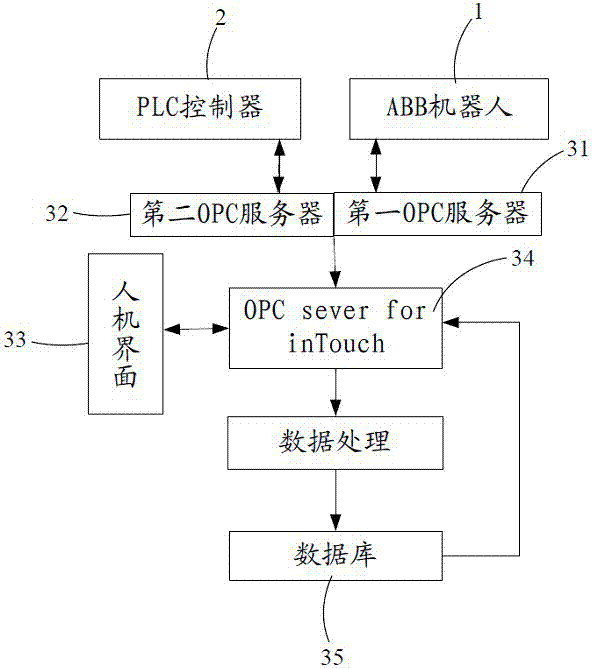

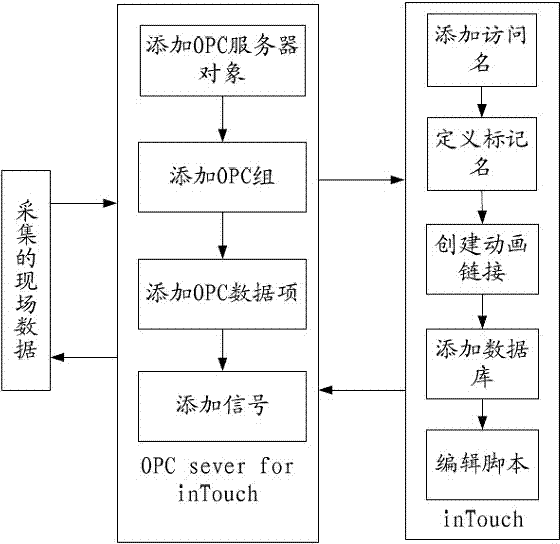

[0019] Please refer to figure 1 Shown is a preferred embodiment of the robot control system 100 of the present invention. The robot control system 100 of the present invention includes a robot 1, a PLC controller 2 that inputs control instructions to the robot 1 for the robot 1 to perform corresponding operations, and an industrial computer 3 provided with configuration software. The robot 1, the PLC controller 2 and the industrial computer 3 communicate with each other through Ethernet.

[0020] Combine figure 1 As shown, the robot 1 of the present invention is an ABB feeding robot, which includes a robot body 11 and a rob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com