Dynamic control method for electromagnetic braking device of crystallizer

An electromagnetic braking and dynamic control technology, applied in the field of iron and steel metallurgy continuous casting, can solve the problems of too late to turn off the power supply, unable to automatically turn on, accident expansion, etc., to achieve stable operation effect, improve the degree of intelligence and stability, shorten the stop effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

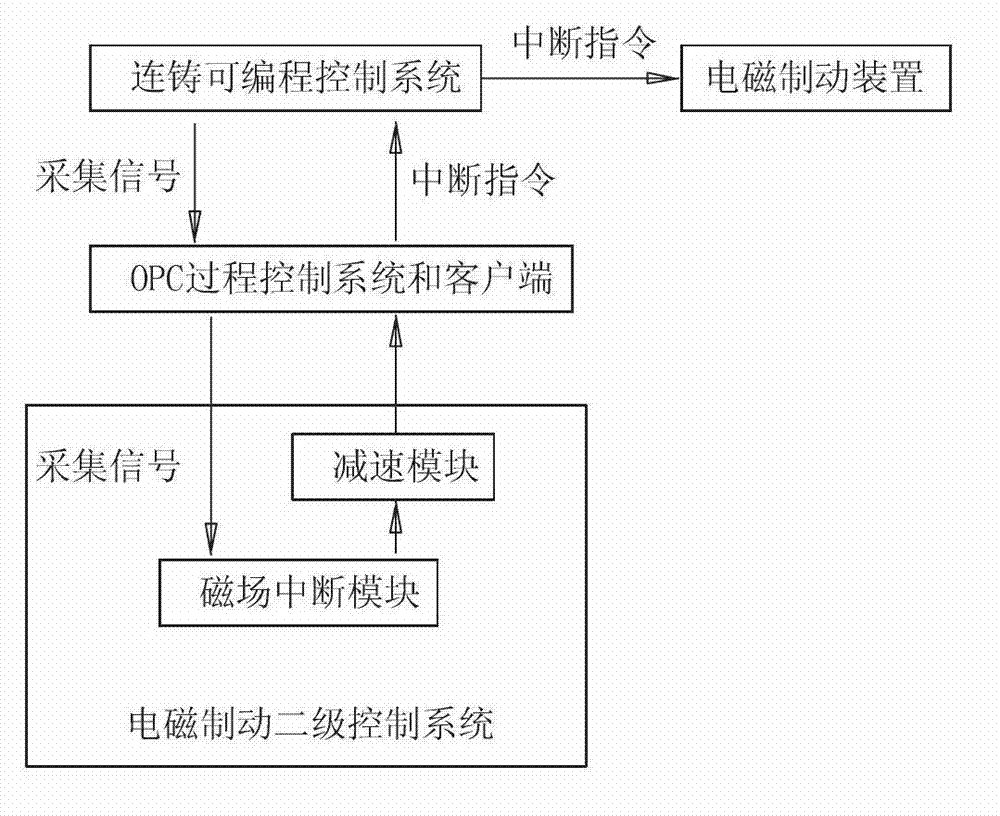

[0027] See figure 1 , which is a schematic block diagram of the control structure of the embodiment of the dynamic control method of the electromagnetic braking device of the crystallizer according to the present invention. By means of the continuous casting programmable control system, the OPC process control system and the client, the electromagnetic braking secondary interrupt control system is set through The OPC process control system communicates with the continuous casting programmable control system. The electromagnetic brake secondary interruption control system includes a magnetic field interruption module and a deceleration module. The specific control steps are as follows:

[0028] 1) The OPC process control system and the client collect fault signals in real time, and transmit the collected fault signals to the electromagnetic brake s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com