Automatic cleaning device and method for precast mold of CRTSI type double-block sleeper

A cleaning device and double-block technology are applied in the field of automatic cleaning devices for prefabricated moulds of CRTS I double-block sleepers, which can solve the problems of difficulty in ensuring the cleaning quality, harm to workers' bodies, and high labor intensity, so as to avoid bodily injury. , The effect of reducing labor intensity and improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

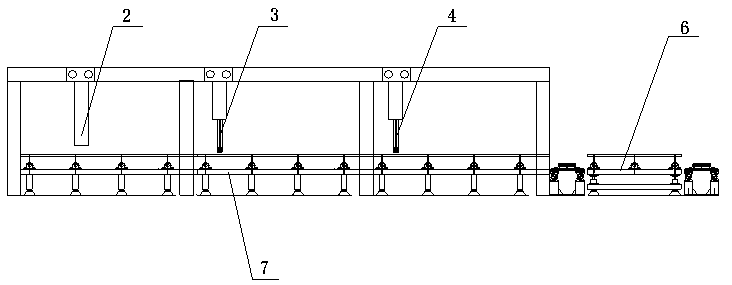

[0027] Such as figure 2 As shown, a prefabricated mold automatic cleaning device for CRTSⅠ type double-block sleepers, including a roller conveying device 7, a drying station 2, a primary cleaning station 3, a secondary cleaning station 4 and a cleaning and inspection station 6, The drying device 2, the primary cleaning station 3, the secondary cleaning station 4 and the cleaning inspection station 6 are arranged in sequence, the drying device 2, the primary cleaning station 3, the secondary cleaning station 4 and the cleaning inspection station Below the position 6 is provided with a roller conveying device 7 .

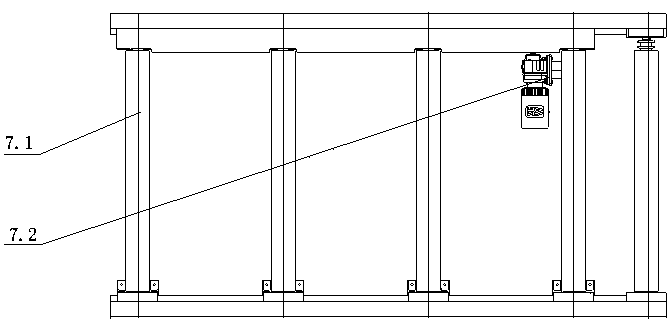

[0028] Such as image 3 , 4 As shown, the roller conveying device 7 includes a roller 7.1 arranged on the column I7.4, the roller 7.1 is driven by a reduction motor 7.2, and railings 7.3 are arranged on both sides of the roller 7.1.

[0029] Such as Figure 5 , 6 As shown, the drying station 2 includes a column II 2.2, a sensor 2.3, a resistance wire 2.4, a hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com