Detection defect removal intelligent control system and control method for yarns of circular weft knitting machine

An intelligent control system and technology of circular weft knitting machine, applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve the problems of affecting efficiency, low production efficiency, high production cost, etc., and achieve convenient use and simple structure. , to eliminate the effect of artificial operation uncertainty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

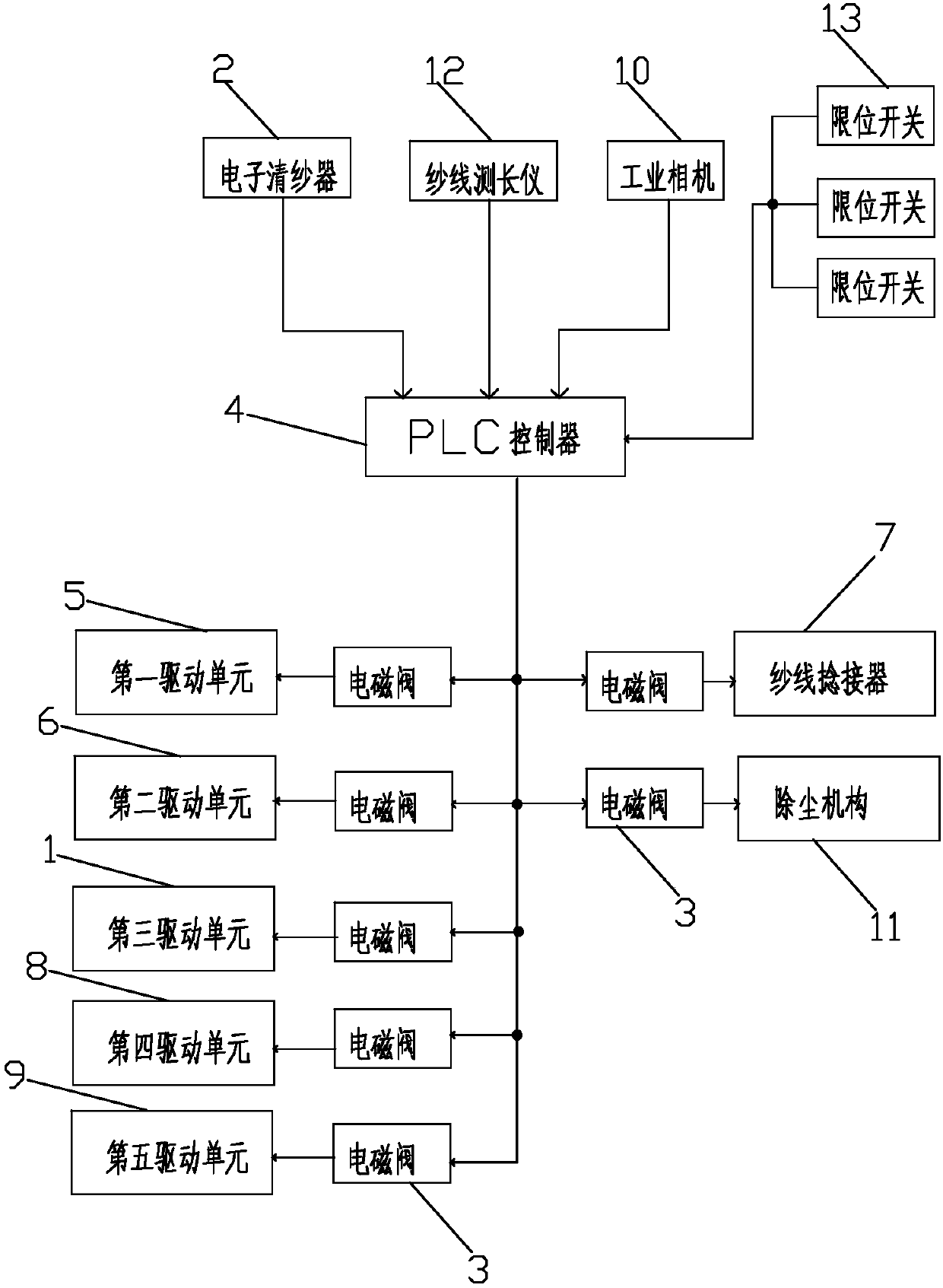

[0017] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

[0018] In the present invention, the electronic yarn clearer, the yarn splicer and the yarn changing mechanism all belong to the existing mechanisms, wherein the electronic yarn clearer can adopt the electronic yarn clearer of the QUANTUM3 model produced by the Swiss USTER company, and the electronic yarn clearer can detect The yarn supplied by the knitting circular weft machine has defects such as yarn slubs, fine knots, wrong counts, and chain-like yarn defects. Other detectors for detecting yarn defects can also be used, and the yarn splicer has disclosed similar technologies in China Patent No.: 200920061279.9; 200580030344.6; The storage of the yarn storage mechanism continues to provide the same function as the machine operation, so this structure is not specifically described in the embodiments.

[0019] refer to figure 1, the preferred yarn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com