Automatic turntable for hardware spraying

An automatic turntable and hardware technology, applied in rotary conveyors, conveyors, transportation and packaging, etc., can solve problems such as increasing equipment and labor costs, reducing production efficiency, saving time for workpiece conversion and improving production efficiency. , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

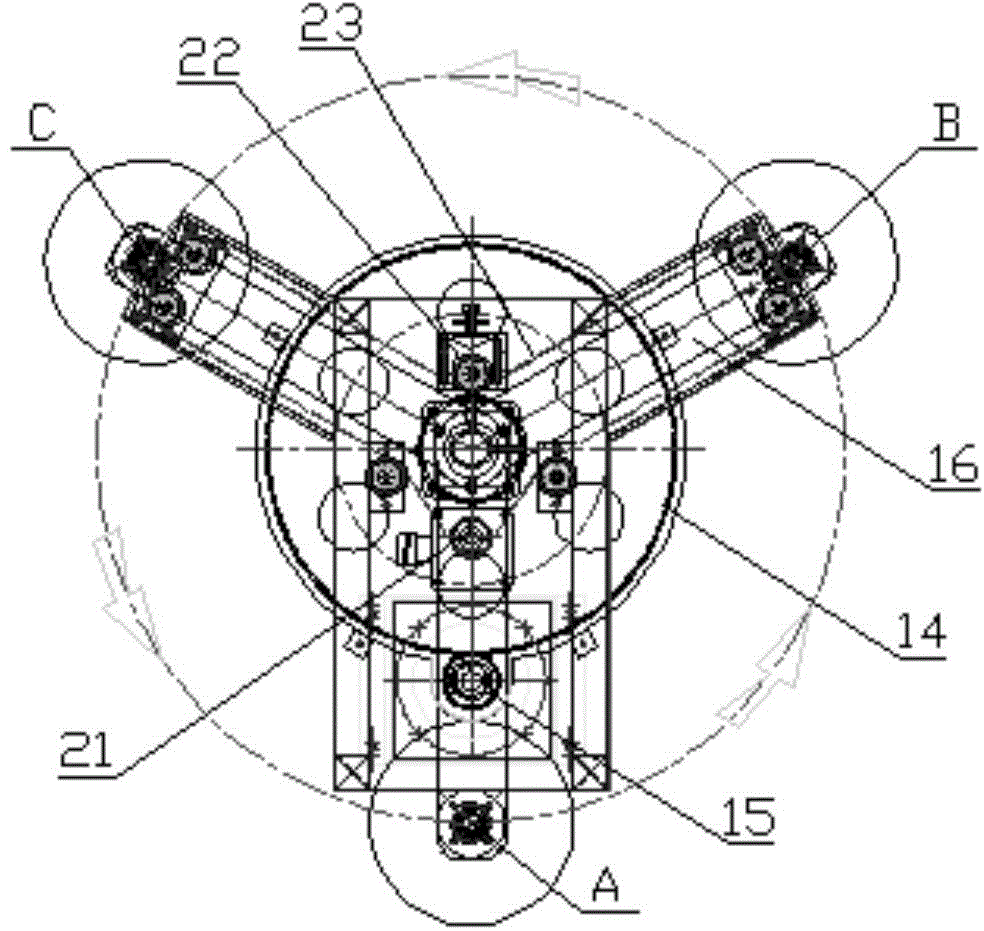

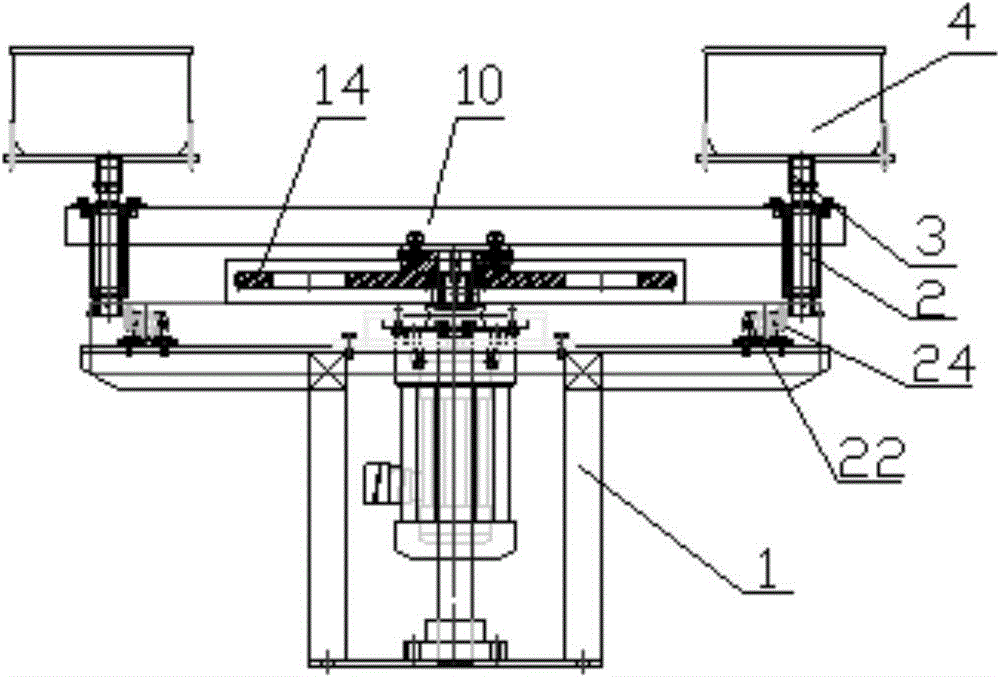

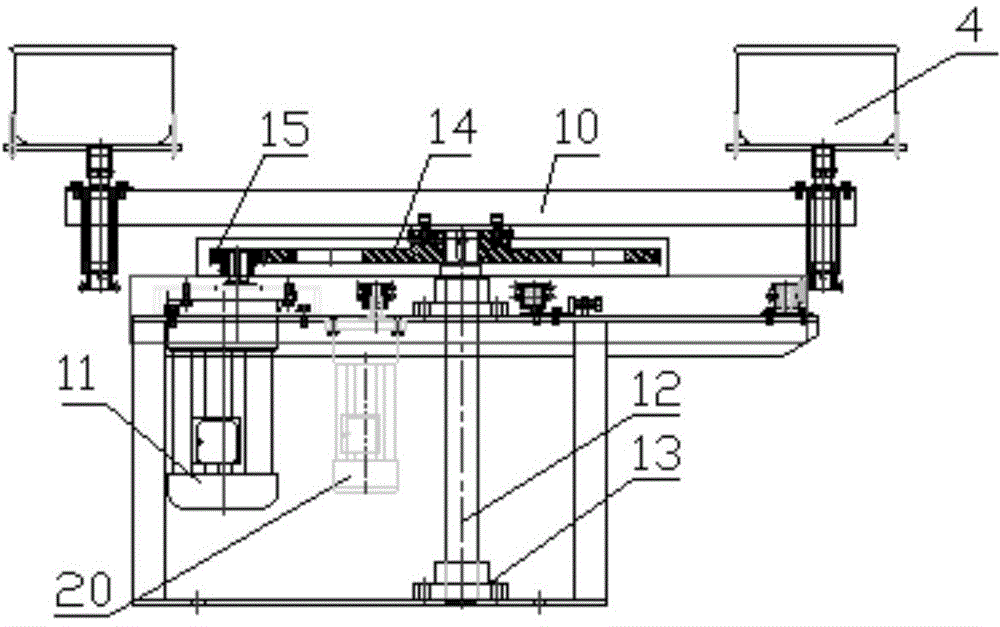

[0015] Such as Figure 1 to Figure 3 As shown, an automatic turntable for hardware spraying includes a turntable support 1, a turntable 10 is arranged above the turntable support, positioning bearings 13 are provided on the upper and bottom of the turntable support, and a central shaft 12 is installed in the positioning bearing In the center of the turntable, there is a revolving gear 14 that drives the turntable to rotate, and the upper end of the revolving gear is fixed to the center shaft. A revolving drive motor 11 is provided on the turntable support, and the revolving drive motor drives the drive through a driving gear 15. The revolving gear 14 rotates, and the turntable is evenly arranged with three stations A, B, and C along the circumferential direction. The A station is the upper and lower parts station, the B station is the product primer spraying station, and the C station is the product topcoat Spraying stations, each station is provided with a vertical rotating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com