Device for conveying plate-shaped elements

A conveyor and conveying surface technology, which is applied to conveyor objects, machine tools suitable for grinding workpiece edges, conveyors, etc., to achieve the effect of shortened modification time and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

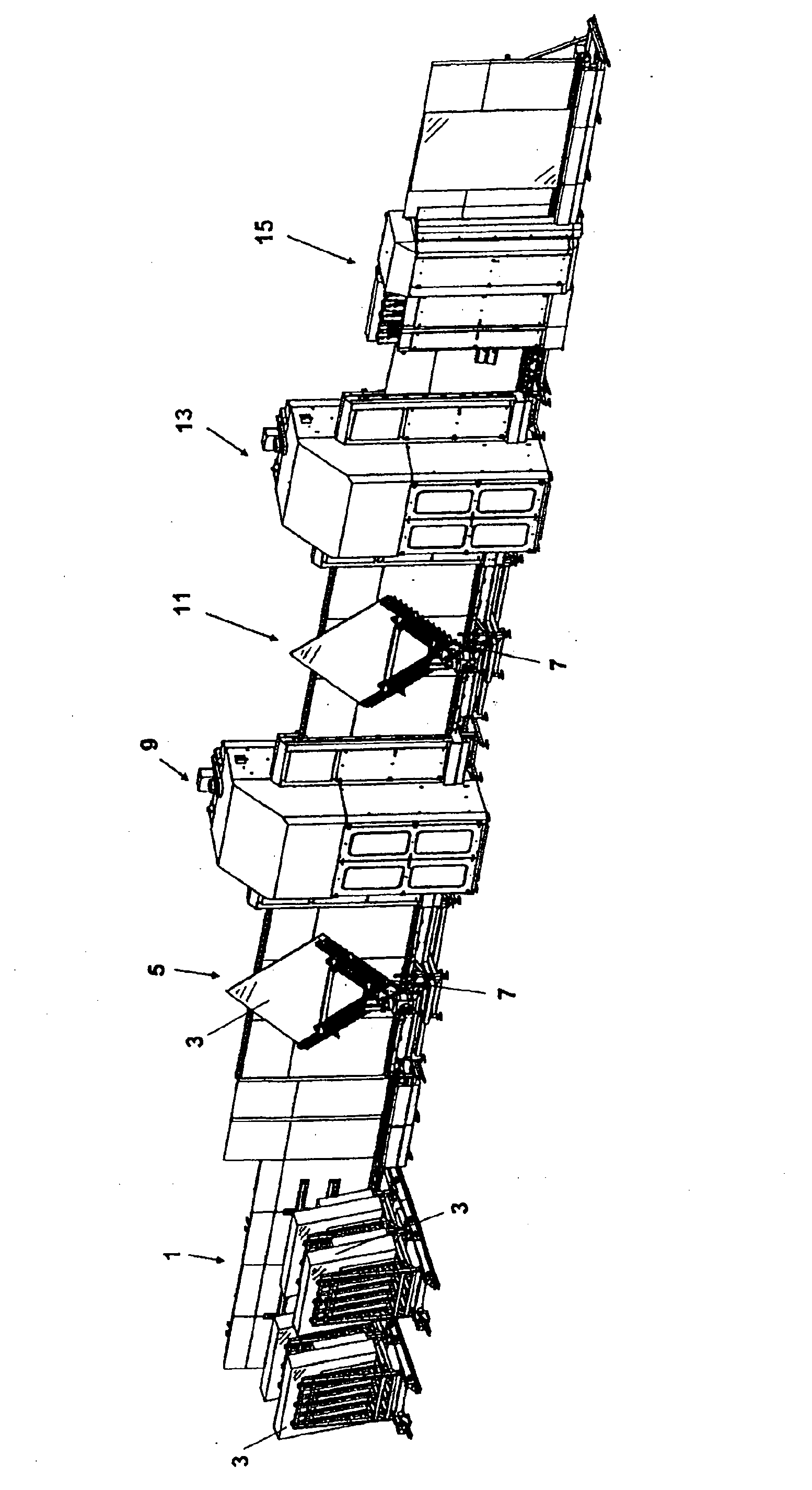

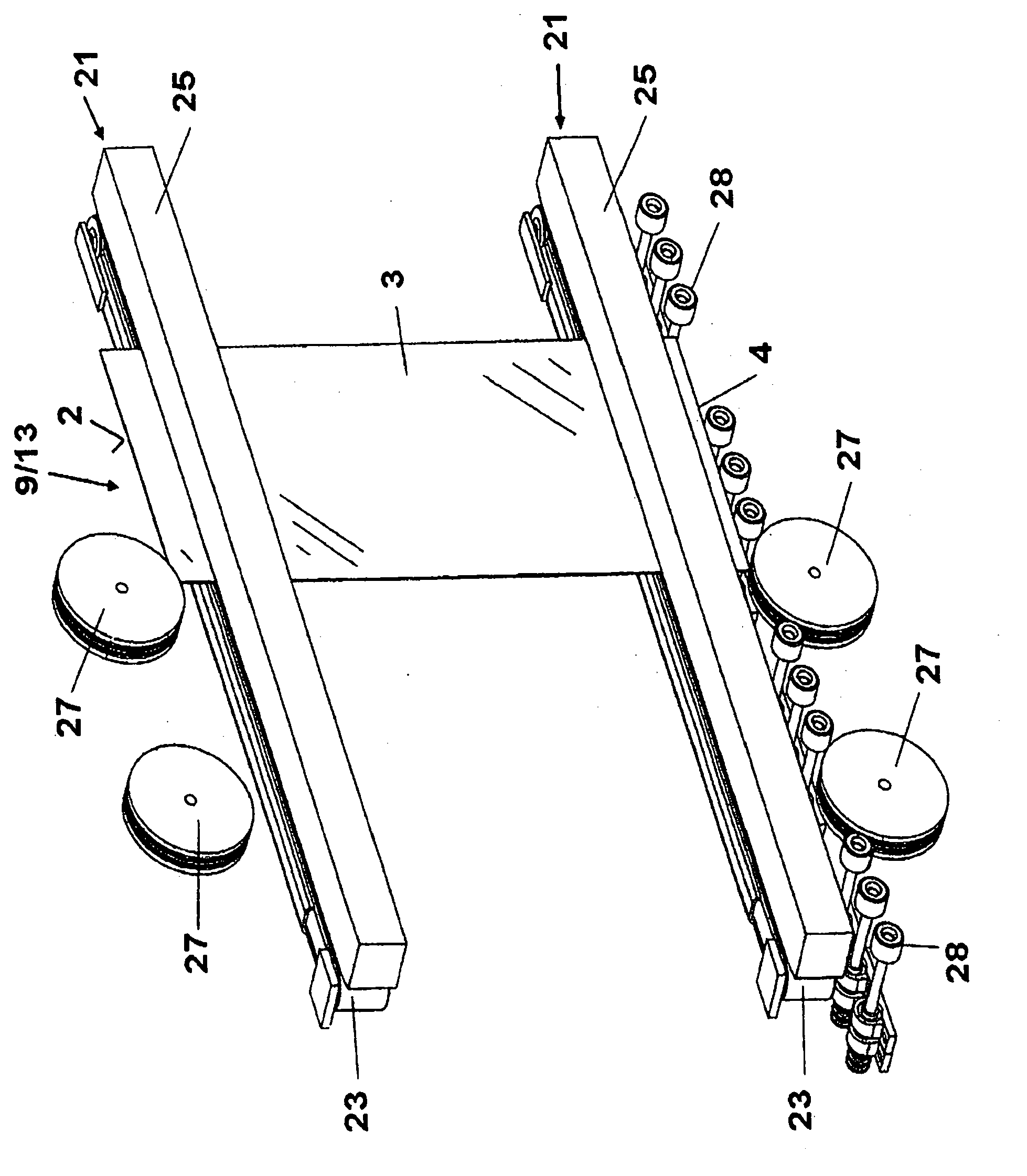

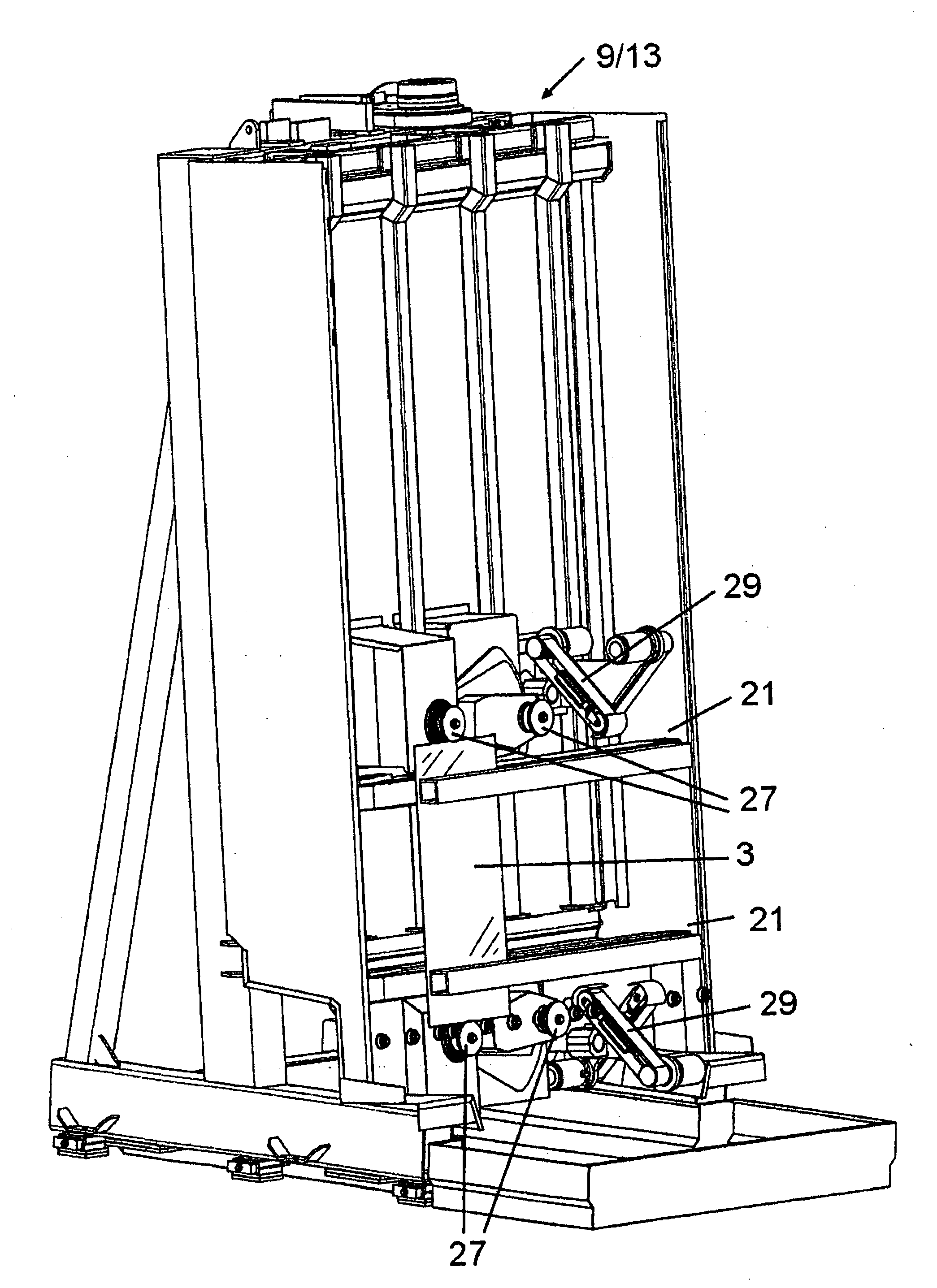

[0029] figure 1 The shown plant for producing glass panes with ground / cut edges comprises a loading station 1 on which glass panes 3 from a glass cutting plant or a warehouse are fed to the plant . Behind the loading station 1 there is a first turning station 5 with a first turning device 7 which orients the glass sheet 3 fed to the device so that its longer edge is vertical upright. At the subsequently provided first grinding station 9 , the upper and lower horizontal edges of the glass pane 3 are processed during passage, in particular ground and / or trimmed.

[0030] After the first grinding station 9, a second turning station 11 with a second turning device 7 is provided, which turns the glass pane 3 by 90° so that the glass pane 3 which has not yet been processed (longer) of) are oriented horizontally. A second grinding station 13 is arranged next to the second turning station 11 , in which the now horizontally oriented, (longer) upper part of the glass pane 3 is proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com