Deep N diffusion for trench IGBT

A deep diffusion and trench technology, applied in the field of IGBTs, can solve problems such as reducing on-resistance, and achieve the effects of reducing conversion loss, increasing irradiation dose, and reducing forward voltage drop.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

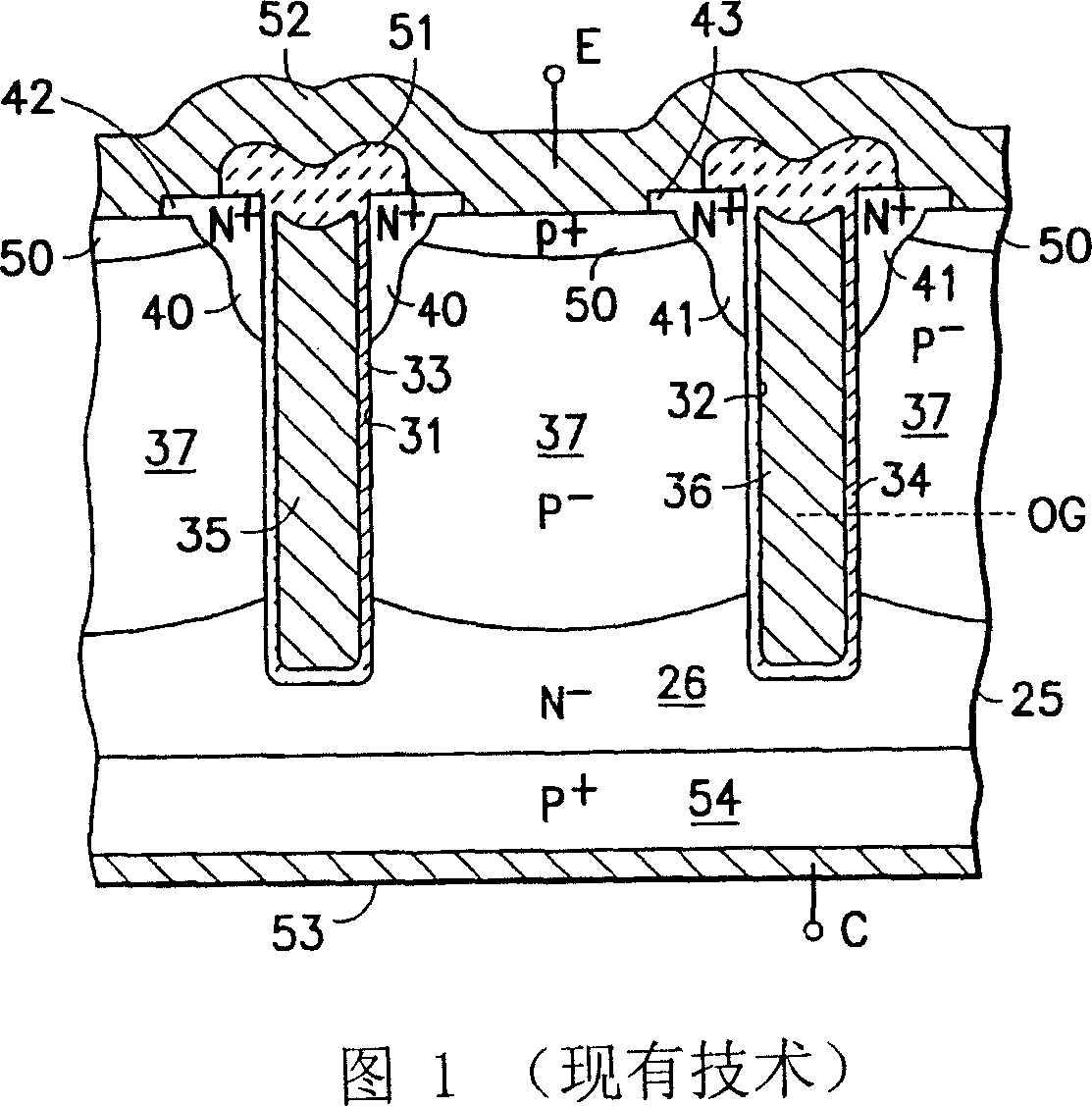

[0020] Referring first to Figure 1, a pair of adjacent units of the prior art structure of patent 6,683,331 are shown in cross-section.

[0021] Fabrication details of the device of FIG. 1 are disclosed in patent 6,683,331, including materials used and process details such as wafer thickness reduction and lifetime limit formation used and collector backside implant 54, among others.

[0022] The structure of Figure 1 is formed in a common starting wafer 25 of floating region material. However, epitaxial wafers may also be used. Wafer 25 has an N-body receiving adjacent deep trenches 31 and 32 lined with thin (eg 1000 A) silicon dioxide gate insulating layers 33 and 34, respectively, and filled with interconnect (not are shown and have external gate terminals G, schematically shown) conductive polysilicon gates 35 and 36 . Trenches 31 and 32 may be about 1.5 microns wide, spaced about 5-10 microns apart and may have a depth of 4-9 microns, and preferably about 6.5 microns. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com